Page 1

00-02-0172 page 1 of 2

Description

The L100, L100W series are general purpose level Swichgage instruments

designed for small engines and pumps. They connect to the crankcase

through a 1/4 NPT pipe nipple and/or 1/2 NPT fittings.

The L120, L127 and L128 series Lube Level Swichgage instruments are

designed for specific engines and mount directly to the machined surface on

the crankcase.

■

L120 Series fits engines previously manufactured by Witte Engine Works,

Lufkin Industries and now manufactured by Arrow Speciality Company.

■

L127 Series fits Fairbanks-Morse ZC series engines, Bell Manufacturing,

and similar engines.

■

L128 Series fits Arrow Speciality engines and the Climax/Continental

Emsco series.

Specifications

Float Actuated Oil Level Swichgage®instrument

Installation Instructions

Models L100, L100W, L120, L127, and L128

00-02-0172

Revised 03-07

Section 15

Read the following information before installing. A visual inspection of this product for damage during shipping is recommended

before mounting. These installation instructions are intended for all L100, L120, L127, and L128 Series models.

GENERAL INFORMATION

L100

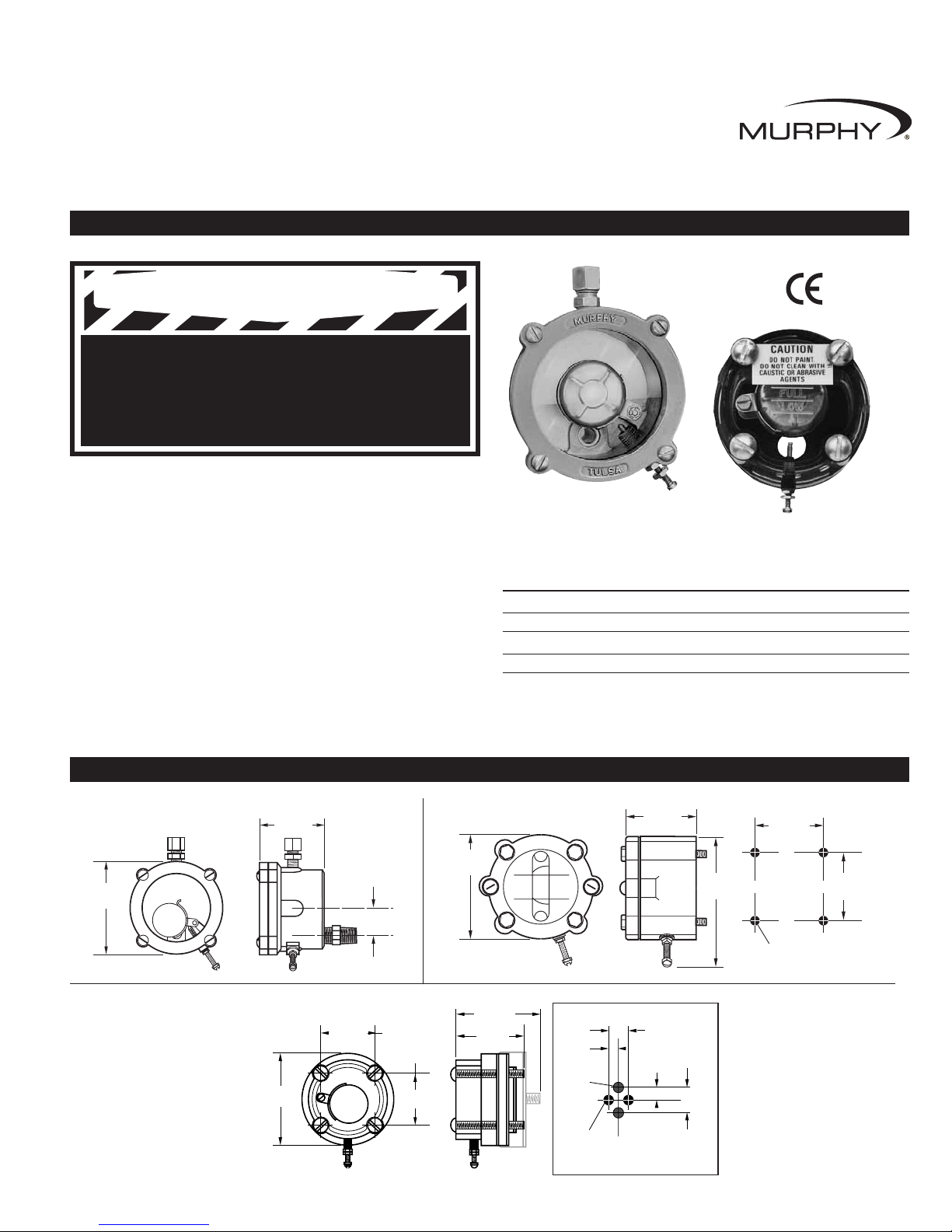

DIMENSIONS

L120

2-1/8 in.

(54 mm)

4-5/16 in.

(110 mm)

3-3/8 in.

(86 mm)

2-7/32 in.

(56 mm)

Mounting Holes 4 places,

5/16 in. (8 mm) diameter

2-7/32 in.

(56 mm)

L127 and L128

L100 and L100W

2-3/4 in.

(70 mm)

2 in.

* *

(51 mm)

2-1/2 in.*

(64 mm)

2-15/64 in.

(57 mm)

Mounting

**

holes 4 places

5/16 in. (8 mm)

diameter

2-15/64 in.

(57 mm)

** Applies to L127 only

* Applies to L128 only

47/64 in.

(19 mm)

3/8 in.

(10 mm)

17/32 in.

(13 mm)

1-17/32 in.

(39 mm)

Mounting

holes 2 places

5/16 in. (8 mm)

Oil inlet

holes

L128 Mounting Dimensions

C

L

27/32 in.

(21 mm)

3-1/8 in.

(79 mm)

2-1/8 in.

(54 mm)

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔✔

Disconnect all electrical power to the machine.

✔✔

Make sure the machine cannot operate during installation.

✔✔

Follow all safety warnings of the machine manufacturer.

✔✔

Read and follow all installation instructions.

Contact

Rating Case Float Gasket

L100/L100W 2A 30 V Aluminum Brass Neo-Cork

L120 2A 30 V Aluminum Brass Buna-N

L127 2A 30 V Nylon Brass Buna-N

L128 2A 30 V Nylon Brass Neo-Cork

L127/L128

†

† Products covered by this literature comply with EMC Council directive 89/336/EEC

regarding electromagnetic compatibility except as noted.

WARNING

Page 2

00-02-0172 page 2 of 2

Warranty

A limited warranty on materials and workmanship is given with this FW Murphy product.

A copy of the warranty may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

INSTALLATION

TYPICAL WIRING DIAGRAM

The oil level Swichgage instrument can be connected to a Murphy magnetic

switch or magneto. Switch contact rating is 2 A @ 30 VAC/DC resistive,

circuit closes to ground.

Models L100, L100W

1. Install the pipe fittings into the crankcase drain or other fitting in the bottom

of the crankcase. Use Teflon tape or non-hardening thread sealant. A tee

should be installed so that it can be used as the crankcase drain. Be sure to

install a pipe plug in the open side of the tee.

2. For crankcases vented to atmosphere, install the l/4 in. (6 mm) tube fitting

and cane in the top of the L100/L100W. For non-atmospheric crankcases,

install the tube fitting and connect 1/4 in. (6 mm) copper tubing to a suitable fitting in the crankcase cavity above the normal operating and splash

level of the lubricant. Note that the tube must remain open at all times and

that it can be closed by oil splash. This will cause improper operation of

the lube level Swichgage instrument.

Models L120, L127

and L128

1. All mounting surfaces must be

clean of oil, grease, and dirt.

2. Be sure the mounting plate to

engine crankcase gasket is properly aligned with the bolt hole

and mounting plate hole patterns.

3. FOR THE L127, be sure that the

float grounding strap extends into

the crankcase cavity and fits tight against the crankcase.

4. Tighten mounting screws in a crisscross pattern. Do not overtighten the screws

as this may cause case or mounting plate distortion resulting in oil leakage.

All Models

1. Fill the crankcase with oil to the engine manufacturer’s specified

LOWEST level.

2. IMPORTANT: Adjust the low level contact screw so that the circuit

“makes” (check continuity with an Ohm meter). Contact is NOT factory set.

3. Fill the crankcase to “full” level and observe that the float has risen and no

longer “makes” with the low level contact. If the Swichgage instrument

also has a high level contact the float should NOT “make” with the high

level contact with normal oil level. Set the high level contact at an appropriate setting for a crankcase overfill condition.

4. Attach appropriate wiring to the engine shutdown or alarm system. Consult

appropriate Murphy or engine manufacturer’s wiring instructions. Typical

wiring is shown below.

5. Start the engine and verify that the oil level remains in a “safe” running

level and that there are no oil leaks. Allow the engine to warm up and

check that mounting screws are tight. CAUTION: Do not over tighten.

6. To check switch operation, open crankcase drain to allow oil level to drop until

the low level contact “makes” and shuts down the engine. Refill crankcase.

WARNING:

Disconnect all electrical power from the

equipment and disable the equipment so it cannot start

during the installation period.

CAUTION:

Perform the wiring operation with the power

source off. Observe all contact and voltage ratings.

CAUTIONS:

Do NOT paint L127 or L128.

Do NOT clean L127 or L128 with caustic or abrasive

solutions or compounds. Do NOT clean L127 or L128

with solvents. Clean ONLY with soap and water.

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819

Rosenberg, Texas 77471 USA

Phone: +1 281 633 4500 Fax: +1 281 633 4588

E-mail: sales@fwmurphy.com

FRANK W. MURPHY, LTD

Church Rd Laverstock

Salisbury SP1 1QZ UK

Phone: +44 172 241 0055 Fax: +44 172 241 0088

E-mail: sales@fwmurphy.co.uk

Web site: www.fwmurphy.co.uk

COMPUTRONIC CONTROLS, LTD

41 - 43 Railway Terrace Nechells

Birmingham B7 5NG UK

Phone: +44 121 327 8500 Fax: +44 121 327 8501

E-mail: info@computroniccontrols.com

Web site: www.computroniccontrols.com

FW MURPHY INSTRUMENTS (HANGZHOU) CO. LTD

77 23rd Street

Hangzhou Economic & Technological Development Area

Hangzhou, Zhejiang 310018 China

Phone: +86 571 8788 6060 Fax: +86 571 8684 8878

FW MURPHY

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100 Fax: +1 918 317 4266

E-mail: sales@fwmurphy.com

INDUSTRIAL PANEL DIVISION

Fax: +1 918 317 4124

E-mail: ipdsales@fwmurphy.com

MURPHY POWER IGNITION

Web site: www.murphy-pi.com

www.fwmurphy.com

Printed in U.S.A.

L127 Mounting Screws

1/4-20 x 2 in. (51 mm)

4 Places

Engine

Block

Oil Port

Float

Ground

Strap

Machined

Surface

Float

Magneto

OR

Murphy Magnetic Switch

Loading...

Loading...