Murphy Engine and Generator Controls Keystart 9620, Keystart 9620 Installation Instructions Manual

Page 1

W

6

2

00-02-0657

Keystart 9

0 series

rev ision A, 22

nd

September 2008

catalogue section 40 & 75

Engine & Generator Controls

Installation Instructions

Please read th e f ollow ing informatio n before i nstalling. A visual inspection of this product for damage dur ing

shipping is recommended before installation. It is your responsibility to ensure that qualified mechanical and el ec trical

technicians install this product. If i n doubt, please contac t your local Murphy representat ive.

GENERAL INFORMATION

Product specifications

power supply:

ARNING

BEFORE BEGINNING INSTALLATION OF TH IS PRODUCT

Disconnect all electrical power to the machine

Make sure the m a chi n e cann ot operate during installatio n

Follow all safety warnings of the mach ine manufacturer

Read and follow all installation instruction s

General

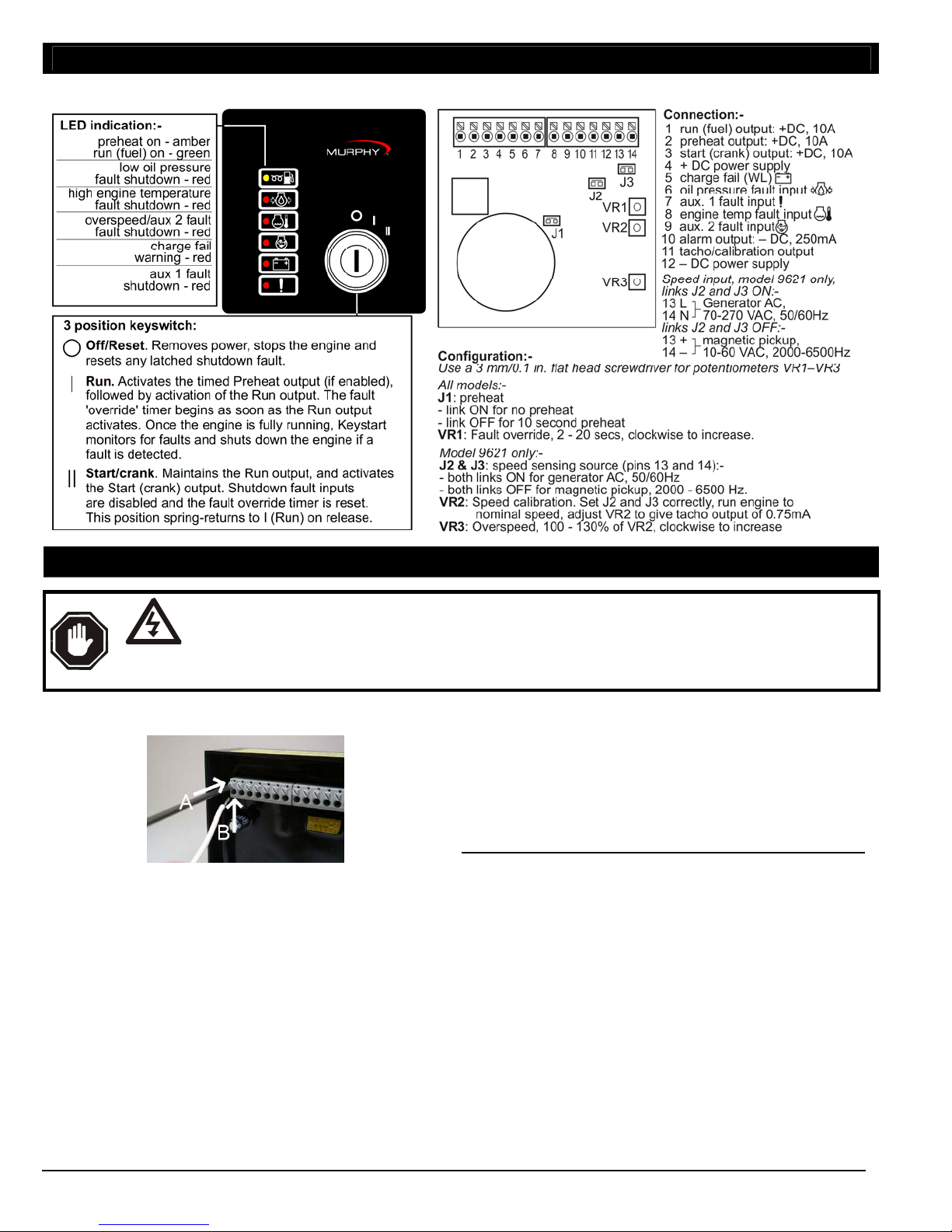

The Keystart 9620 series provides manual start/stop and automatic

fault shutdown protection for generators, pumps and other enginedriven applicat ions.

Keyst art features a 3 way keyswitch for operator control of th e engine,

with 6 LEDs for indication of status and faults - see ‘front view’ diagram

for details. Electrical connection an d configurat ion option s are at the rear

- see ‘Rear view, connection and settings’ diagram.

For each Keystart ordered, the following is supplied:

• 1 x Keystart module, fitted with 2 x panel mounting clips

• 2 x keys

• these instructions

Panel installation

Keystart is designed for front-of-panel mounting in a DIN standard

92 x 92 mm (3.6 x 3.6 in.) c ut-out. Allow 75mm (3.0 in. ) behind the

panel for the case depth, keyswitch and cable connection.

Secure the case to the panel with the two ratcheted mounting clips:

1. 2. 3.

Remove the plastic

mounting clips from

the Keystart case:

release each clip ’s

ratchet mechanism by

pulling outwards (A),

then slide the clip

back and off the

case (B).

At the front of the

panel, insert the

Keystart (without

clips ) into th e panel

cut-out (C).

At the rear of the panel,

refit the two mounting

clips into the slots on

the Keystart case (D).

Slide each clip forward

until the arms ( E) are

secured behind the

panel face. Ratchet

mechani sm (F ) prevents

the clip from moving

backwards.

operating voltage:

steady state

brown out / cranking

current consumption < 100mA

inputs:

fault switch inputs: close to negative DC during fault

–ve input defined as: –1V to +1V w.r.t. – ve DC supply

speed sensing input:

generator AC (J2+J3 on)

mag. pickup (J2+J3 off)

outputs:

run, preheat positive D C, switched NO relay contact,

start (crank) positive DC via keyswitch contacts,

alarm negative DC (open collector

calibration/tacho to suit 0 – 1 mA, 75 Ohm meter

output = 0.75mA at rated engine speed

adjustable settings:

preheat timer 0 or 10 secs (link J1),

fault ov erride timer 2 to 20 secs (VR1),

overspeed trip level 100 to 130 % (VR3) of

general:

overall dimensions (w x h x d) 96 x 96 x 95 mm / 3.8 x 3.8 x 3.7 in.

panel cut-out size DIN 92 x 92 mm / 3.6 x 3.6 in.

weight approx . 300 g / 0.7 lb

operating temperature –35°C to +55°C / –31°F to 131°F

70 – 270 VAC rms,

<50 to >60 Hz. nominal

10 – 60 VAC peak,

<2000 to >6500 Hz. nominal

(all ratings non-reactive)

10 A max. @ 24VDC

10 A max. @ 24V DC

NPN transistor), 250mA max.

nominal speed calibration (VR2),

default = 110% (of 50 or 60 Hz)

Model options

7 – 30 VDC

5 VDC

(model 9621 only)

default = 0 secs

default = 10 secs

Page 2

GENERAL INFORMATION (cont.)

Front view and operation

Rear view, connections and settings

ELECTRICAL CONNECTION

WARNING: DANG ER OF INJURY OR DEATH. Ke ystart 9621 cont r ol lers allow connection

of high voltage AC cir cui t s . Bef or e connect i on, disconnection or handl ing of these units,

DANGER !

HIGH VOL TS

Electrical connection to 0.5 to 1.5 mm² / 16 – 20 AWG panel wiring is

by spring-clamp terminal s at the rear.

•

pre-strip 8 to 10 mm / 0.3 to 0.4 in. of ins ulation from each wire.

• Ab ove each terminal i s a square push-button with a diagonal slot.

Insert a flat-head screwdriver into the slot (A), then push down to

(towards the front of the Keystart ) to open the ter minal cl amp.

• insert the wire into the terminal (B), checking that the insulation is

clear of the cl amp. Release the screwdri ver/spring clamp pressure

and check that the wire is secure.

General connecti on r ecommendat i ons

Murphy make several recommendations for the electrical connection

of engine and generator controllers.

• minimise controller output load current (i.e. wear/tear and potential

damage) by using slave relays between the controller outputs and

high power end-devices such as fuel and starter solenoids.

• Suppress (at source) electrical interference from panel relay and

engine solenoid coils, using flywheel diode or proprietary snubber

networ ks as appropriate.

Murphy - Keystart 9620 series installation instructions 00-02-0657 revision A 22nd September 2008 p2/4

ensure that all AC and DC power suppli es ar e i sol ated. Connection to or disconnection from

live wiring may also cause damage to t he Keystart’s internal components.

• use separate routing for AC and DC wiring harnesses.

• use separate wiring for a) connection of battery charger to battery,

and b) connection of battery to panel DC supply. Separate wiring will

reduce high frequency battery charger output noise on the panel DC

power supply.

Terminal f unct ions

Pin Function

Run (fuel) output

1

Preheat output

2

These r elay outputs provide control for a the engine’s

preheater and (energised to run) fuel / ignition circuits.

When configuration link J3 is on (the default setting),

the Preheat output (terminal 2) does not oper ate. If link

J3 is removed, terminal 2 gives a positive DC output for

10 seconds, and the preheat LED lights, beginning from

when the key is switched to the I (RUN) position.

After any preheat time has expired, the Run output (pin 1)

gives a positive DC output (operating engine fuel) and the

green ‘run’ LED lights. The Run output and LED remain

active until the operator swi tches the key to O (STOP) or

until the Keystart initiates an automatic fault shutdown.

Both Run and Preheat outputs are rated 10 Amp max.

@ 24VDC. Murphy recommend the connection of slave

relays with suppress ed coils between these outputs and fuel

solenoid coil and engine preheaters - see ‘typical connection’

diagram below.

Page 3

ELECTRICAL CONNECTION (cont.)

Terminal f unct ions (cont.)

Pin Function

3 Start (crank) output

Pin 3 gives a positive DC, 16 Amp rated output when the key

is switched to position II (start/crank). To prolong keyswitch

contact life, connect a slave relay (with suppressed coil)

between pin 3 and the engine starter solenoid coil - see

‘typical connection’ diagram below.

4

Power Supply, Positive DC

12

Power Supply, Negative DC

The Keystart operates with an y smoot h DC / battery voltage in

the range 7 – 30V. Supply brown-out protection is fitted as

standard. Connect a 5 Amp anti-surge fus e in the positive DC

line (pin 4) .

5 Charge fail

The charge fail LED lights, but there is no shutdown or alarm,

when pin 5 is connected to battery negative. When using a

ch arge alternator, connect pin 5 to the al ternat or w arning l amp

(WL) terminal. (Note: pin 5 supp lies the alternator excitation

current).

6

Low Oil Pressure (LOP) fault input

7

Auxiliary 1 fault input

8

High Engine Temperature (HET) fault input

9

Auxiliary 2 fault input

Use remote switch/relay contacts that connect these inputs

to battery negative during fault conditions. The Keystart

shuts down the engine, lights the appropriate fault LED,

and activates the alarm output. Note: activation of pin 9

(Aux 2 input) causes engine shutdown and illumination of

the overspeed LE D.

For all the above inputs, shutdown is inhibited during engine

cranking and until the end of the fault ‘override’ time (adjustable

2 – 20 secs us ing potentiometer VR1, clockwise to increase).

To reset a shutdown fault condition, turn the key to O (Off) or

remove the DC power supply.

10 Alarm output

Pin 10 is a semiconductor-based (open collector NPN t ransistor)

output that gives a negative DC output immediately after a fault

shutdown. Output rating is 250mA max.: the output typically

dr ives an audible/visi ble alarm circuit, usi ng a slave relay with

suppressed coil - s ee ‘typical connection’ opposite.

11

Tachometer (speed calibration) output

This output is designed to work with a 0 - 1 mA DC ammeter,

either a) during set-up to aid speed calibration, or b) in normal

operation to indicate engine speed or generator Hz.

For calibration, connect meter positive to pin 11 and meter

negative to battery negative, e.g. at terminal 12. See ‘speed

sensing and calibration’ below for setup procedure.

For indication of engine RPM or generator Hz, the 0 – 1mA

meter requires a custom scale: when correctly calibrated

using VR2, Keystart gives 0 mA at 0 RPM /Hz. and 0.75mA

(3/4 scale) at normal running RPM/Hz.

Pin Function

With links J2 & J3 ON:

Generator AC Live

13

Generator AC Neutral

14

When configuration links J2 and J3 are fitted (the default factory

setting), terminals 13 and 14 are configured for overspeed

sensing using a high voltage, generator AC 50/60Hz. signal.

The input accepts generator AC voltages between 70 and

270 VAC rms. A 1 Am p anti-surge fuse should be connected

in series with AC live (pin 13). See ‘speed sensing’ below for

correct calibration of this input using potentiometers VR2 and

VR3.

To configure these terminals to magnetic pickup engine

speed sensing, see section below.

With links J2 & J3 OFF:

Magnetic pickup signal input

13

Magnetic pickup return

14

When configuration links J2 and J3 are removed, terminals 13

and 14 are configured for speed sensing by a magnetic pickup

and flywheel/gearwheel c ombination.

Connect the magnetic pickup to the input using two-core and

scr een cable. To mi nimise electrical interference on t he speed

signal, connect the cable screen t o earth at one end only.

Magnetic pickup signal requirements are 10 – 60 VAC peak,

with frequency between 2000 and 6500 Hz. when the engine is

running at nominal speed. See ‘speed sensing’ below for correct

calibration of this input using potentiometers VR2 and VR3.

To configure these terminals for generator AC frequency

sen sing, see section above.

Typical connection

DANGER !

HIGH VOLTS

Murphy - Keystart 9620 series installation instructions 00-02-0657 revision A 22nd September 2008 p3/4

Page 4

SPEED SENSING AND CALIBRATION

Keystart model 9621 includes a speed sensing input and automatic

shutdown protection for engine overspeed faults. Before use, model

9621’s speed input must be correctly configured (us ing circuit-board

links J2 and J3) and calibrated (using potentiometers VR2 and VR3).

Selection of speed signal source: links J2 and J3

Links J2 and J3 allow configuration of the speed sensing input

(terminals 13 and 14) for either generator AC (the factory default

setting) or magnetic pickup signals. Use small pliers to add or

remove the links as required:

J2 and J3

Terminal 13 and 14 configuration

links

ON Generator AC, 70 - 270 VAC rms, 50 or 60 Hz nominal.

OFF Magnetic pickup, 10 – 60 VAC peak, 2000 to 6500 Hz

nominal.

Speed calibration

Speed cal ibration is a two stage proces s:

1) Nominal speed calibration: potentiometer VR2

The factory default setting is for generator AC speed sensing, with

standard models for 50 or 60Hz nominal calibration. To recalibrate

for other systems:

• Select the speed sensing method (generator AC or magnet ic

pickup) using links J2 and J3 as detailed above.

• Turn VR2 fully clock wise (sets calibration for m aximum n omin al

frequency).

• Connect a 0 – 1mA, 75 Ohm meter between pin 11 and battery

negative, as detailed in ‘electric al connection’ above.

• Start and run the engine to nominal (normal running) speed.

• Tu rn VR2 anti-clockwise (decreasing th e cali bration frequ ency)

until the ammeter rises to read 0.75mA.

Maintenance and Warranty

The Keystart series contains no user-servic eable parts. Maintenance

is therefore limited to the following preventative checks:

• Check th at all electr ical connections are secure.

• Check that the Keystart is securely clamped in the front of

panel aperture, and kept free f rom ingress of water or build

up of excessive dust/dirt. The front face label and casing may

be wiped with a clean, damp cloth. Do not use cleaning solvents.

Each Keystart is supplied with a two year warranty on materials

and workmanship. In the event of a fault or technical query, please

contact your Murphy representative for technical support.

2) Overspeed setting: potentiometer VR3

VR3 allow s adjustment of t he overspeed tri p point, between

approximately 100 and 130% of the nominal AC or magnetic pickup

frequency (as set us ing VR2). The VR3 factory default setting is

110% (of either 50 or 60Hz). To adjust the overspeed trip level:

• Turn VR3 fully clockwise (to maximum, approx. 130% of nominal)

• Start and run the engine. Increase engine speed to the required

oversp eed/over-frequency tri p level.

• Tu rn VR3 slowly anti -clockwis e (decreasing the ov erspeed trip

level) until the Keystart shuts down the engine and indicates

‘overspeed’.

Where the engine speed cannot be22 September 2008 adjusted,

or if the speed signal cannot be simulated (e.g. with an adjustable

signal generator), an approximate overspeed setting must be made

(e.g. potentiometer mid-span = approximately 115% of VR2 nominal).

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

FW MURPHY

P.O.Box 470248, Tulsa, Oklahoma 74147 USA

+1 918 317 4100 Fax: +1 918 317 4266

E-mail: sales@fwmurphy.com

INDUSTRIAL PANEL DIVISION

Fax: +1 918 317 4124

E-mail: ipdsales@fwmurphy.com

MURPHY POWER IGNITION

Website: www.murphy-pi.com

CONTROL SYSTEMS AND SERVICES DIVISION

P.O.Box 1819, Rosenberg, Texas 77471 USA

Phone: +1 281 633 4500 Fax: +1 281 633 4588

E-mail: sales@fwmurphy.com

Murphy - Keystart 9620 series installation instructions 00-02-0657 revision A 22nd September 2008 p4/4

MURPHY, the Murphy logo, are registered and/or common law trademarks of Murphy Industries, Inc. This document, including

textual matter and illustrations, is copyright protected by Frank W Murphy Ltd., with all rights reserved. © 2008 Frank W Murphy Ltd.

FRANK W. MURPHY LTD.

Church Rd, Laverstock,

Salisbury, SP1 1QZ, Unite d Kingdom

Tel: +44 1722 410055

Fax: +44 1722 410088

E-mail: sales@fwmurphy.co.uk

Web: www.fwmurphy.co.uk

COMPUTRONIC CONTROLS

41 – 43 Railway Terrace, Nechells,

Birmingham, B7 5NG, United Kingdom

Tel: +44 121 327 8500

Fax: +44 121 327 8501

E-mail: sales@computroniccontrols.com

Web: www.compu troniccontrols.com

FW MURPHY INTERNATIONAL TRADING (SHANGHAI) CO. LTD.

Suite 1704, Tower B, City Center of Shanghai; 100 Zunyi Road,

Shanghai, 200051 China

Phone: +86 21 6237 2082 Fax: +86 21 6237 2083

E-mail: mhong@fwmurphy.com

FW MURPHY INSTRUMENTS (HANGZHOU) CO. LTD.

rd

Street, Hangzhou Economic & Technological Development Area

77 23

Hangzhou, Zhejiang 310018 China

Phone: +86 571 8788 6060 Fax: +86 571 8684 8878

Loading...

Loading...