Murphy iGUARD Installation And Operation Manual

Phase-out / Discontinued Product

Check Availability

iGUARD

Digital Generator Set Controller

Installation and Operations Manual

00-02-0522

04-06-11

Section 75

Phase-out / Discontinued Product

Check Availability

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our

specifications and designs at any time. The latest version of this manual can be found at www.fwmurphy.com.

Please read the following information before installing.

BEFORE BEGINNING INSTALLATION OF THIS MURPHY

PRODUCT:

Disconnect all electrical power to the machine.

Make sure the machine cannot operate during installation.

Follow all safety warnings of the machine manufacturer.

Read and follow all installation instructions.

Please contact FW MURPHY immediately if you have any

questions.

Phase-out / Discontinued Product

Check Availability

T able of Conte nt s

Introduction ............................................................................................................................. 1

Product Description ...................................................................................................... 1

User Interface and Navigation ...................................................................................... 1

iGUARD Operating Instructions ............................................................................................ 3

Operating Sequence .................................................................................................... 3

Programming the iGUARD from the Keypad ................................................................ 5

Settings and Definitions ......................................................................................................... 8

Operating Parameters .................................................................................................. 8

Communication Parameters ....................................................................................... 12

Miscellaneous Parameters ......................................................................................... 13

Engine Parameters .................................................................................................... 16

Generator Parameters ............................................................................................... 18

Digital Inputs and/or Relay Outputs ............................................................................ 21

Analog Inputs ........................................................................................................................ 30

Manufacturers Specifics ...................................................................................................... 36

iGUARD Typical Installation and Mounting ....................................................................... 38

iGUARD Electrical Installation ............................................................................................. 41

Electrical Hook up ...................................................................................................... 41

Energy Monitoring Board (EMB) ................................................................................ 45

Installing the Mimic/Annunciator DM/A .............................................................................. 50

DM/A Mimic/Annunciator Versions ............................................................................. 50

Specifications ........................................................................................................................ 58

Standard Components ............................................................................................... 58

iGUARD Options and Accessories ..................................................................................... 59

Phase-out / Discontinued Product

Check Availability

(THIS PAGE INTENTIONALLY LEFT BLANK)

Phase-out / Discontinued Product

Check Availability

Introduction

This document is designed to support a user in getting familiar with the iGUARD Digital

Generator Set Controller and how to navigate the interface, modify the settings and install and

operate the controller. Before attempting to set up the controller, be sure to read and

understand this manual in its entirety.

Product Description

Description

The iGUARD controller is a high performance, state of the art, digital generator set controller.

This robust controller features high-speed microprocessors, and high accuracy AC

measurements. The iGUARD is a menu driven system, organized by "stacks", with "substacks" where required. User connections are made via the plug in connectors on the rear of

the controller. The iGUARD controller has a textured finish; UV stabilized polycarbonate

injection molded housing, and is sealed with an “o” ring to help protect the iGUARD from the

environment. There is a back cover protecting the Energy monitoring Board (EMB) to prevent

contact with circuit board components and potentially harmful AC voltage wiring.

User Interface and Navigation

The keypad on the iGUARD is a capacitive touch sensing system. There are no mechanical

switches to wear or stick, and the technology has been time proven in many applications. It

operates in extreme temperatures, with gloves, through ice, snow, mud, grease, etc., and it

allows complete sealing of the front of the iGUARD. It does operate slightly differently than a

membrane keypad, in that there is no tactile feedback. The ‘key is pressed’ feedback is

provided by momentarily beeping the audible alarm. The keys on the keypad do the following

functions:

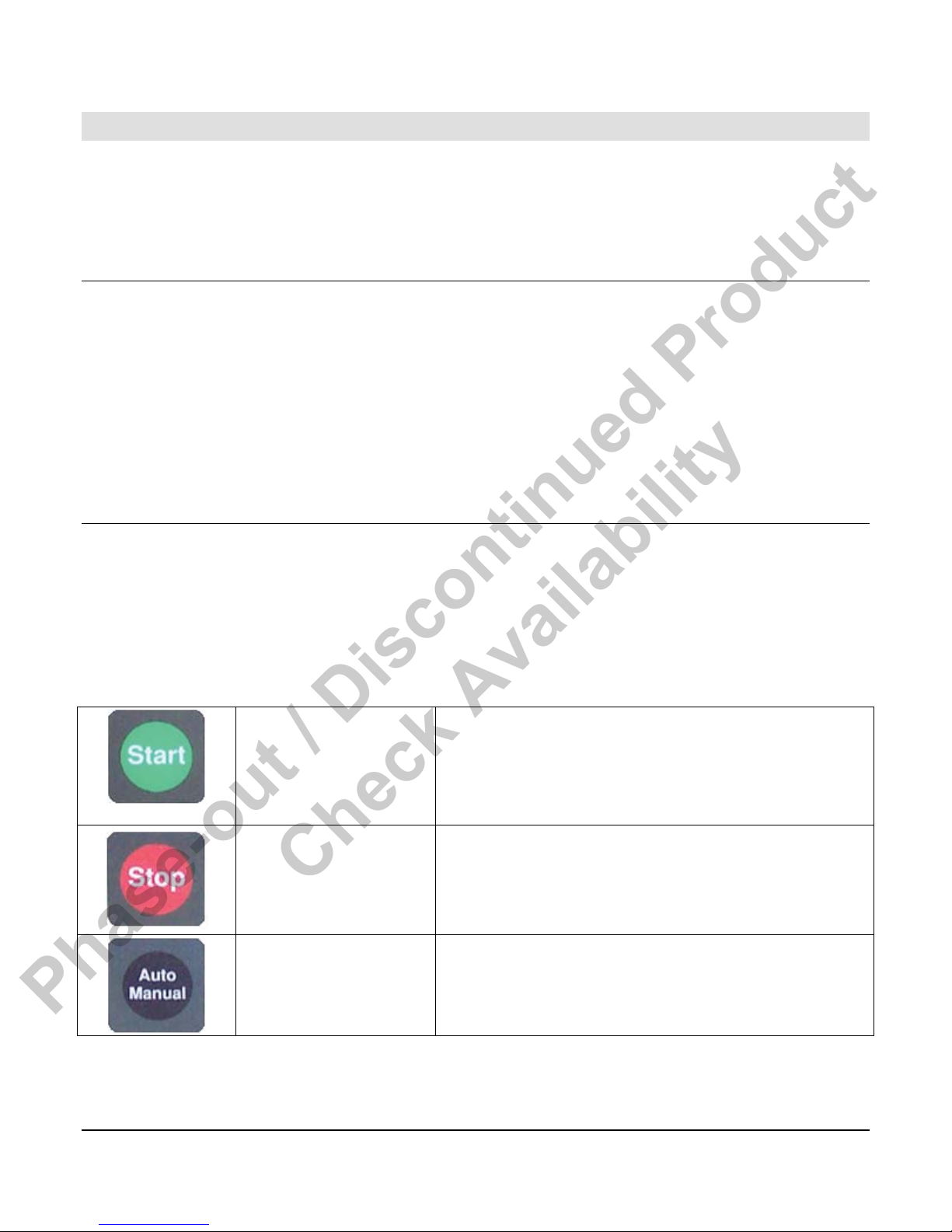

START

STOP

Auto/Manual

In Manual mode pressing the start pad will cause

the engine to start. In automatic mode the screen

will display an error message that system must be

in manual mode to start with the start button.

In automatic or manual mode pressing the stop pad

will stop the set. The system is forced into a

manual mode, and will not autostart until returned

to automatic mode.

Selects manual (sometimes-called local) operation

or automatic mode (system monitors a digital input

for a start signal).

Section 75 00-02-0522

04-06-11 - 1 -

Phase-out / Discontinued Product

Check Availability

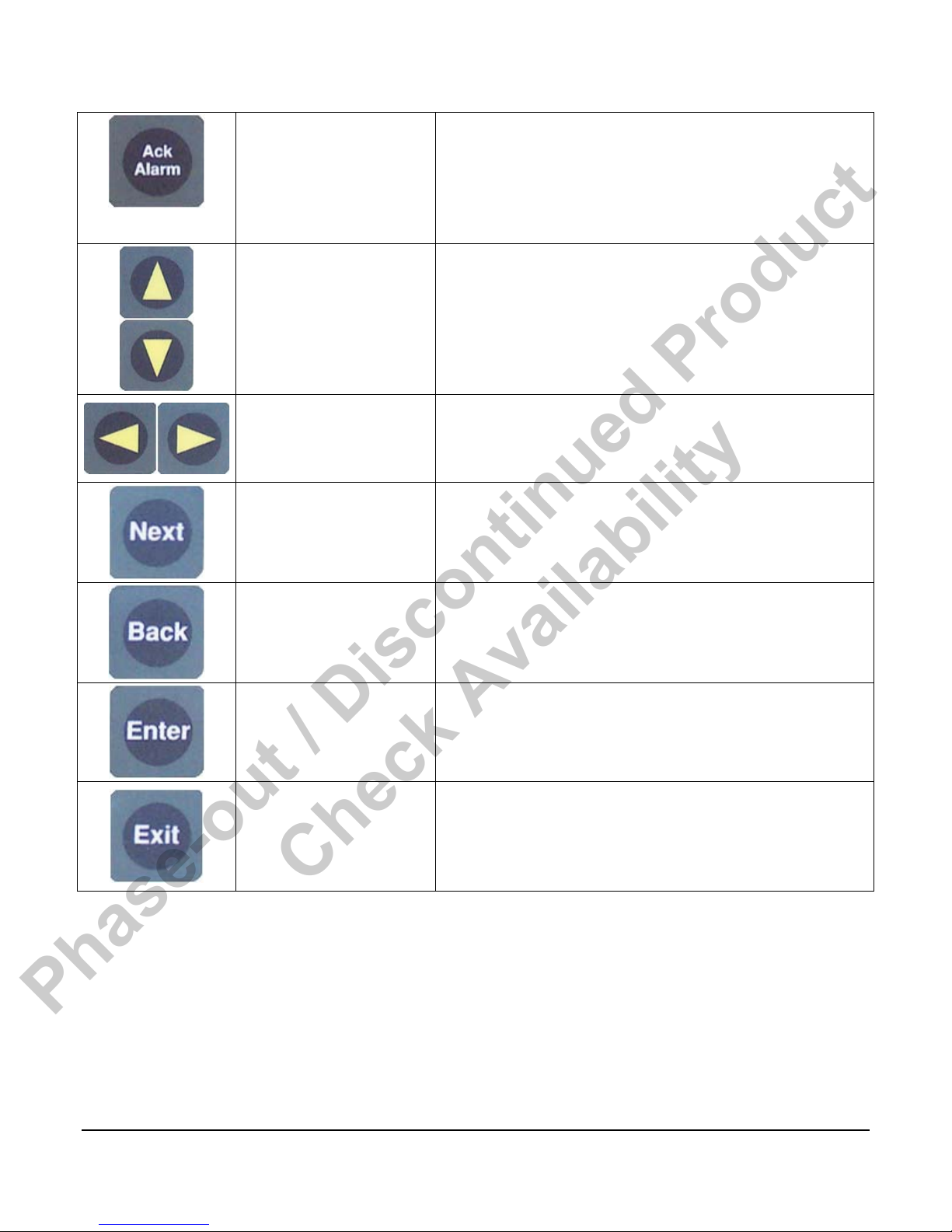

Acknowledge/Alarm

Up / Down Arrows

Left / Right Arrows

Next

Back

For warnings that do not cause a shutdown,

pressing this pad will clear the alarms active at that

moment. If the conditions subsequently clear and

re-occur or if additional warnings occur, the

common alarm output will come back on.

In program mode scrolls the menu selections and

also scrolls through the choices for a given

parameter.

In normal operation steps forward/backward

through the screens available in the active

submenu

In normal operation steps forward through the main

menu selection

In normal operation steps backward through the

main menu selections.

Enter

Exit

In program mode, pressing Enter will allow a

variable to be changed, and then pressing Enter

again will accept the displayed /new value.

In normal operation returns the system to the main

(default) screen. In program mode cancels any

changes made unless the "Enter" pad has already

been pressed.

Section 75 00-02-0522

04-06-11 - 2 -

Phase-out / Discontinued Product

Check Availability

iGUARD Operating Instructions

Operating Sequence

The iGUARD controller, while reprogrammable, follows a standard operating sequence. This

operating sequence is basically a set of machine states that happen in a pre-determined order.

Machine states can be set to zero if not needed, or adjusted to fit the application. For the basic

operating sequence, see the iGUARD Sequence Appendix in the Installing the

Mimic/Annunciator DM/A section, this document. The iGUARD operating sequence includes

the following modes:

Ready to Start Mode

Prestart Delay Mode

Prelube Mode

Preheat

Cranking / Crank Rest Mode

Crank Disconnect / Engine

Running Mode

Warmup Mode

Automatic start mode ready for a contact closure to initiate an

automatic start and run sequence.

A timer used to prevent nuisance starts, or to warn nearby

personnel that automatic equipment is about to start (set to 0

to bypass).

In larger generators there may be a requirement for

automatic lubrication prior to cranking (set to 0 to bypass).

Timer set to provide the correct amount of precrank operation

of the air intake heaters used to facilitate starting in cold

conditions. (Set to 0 to bypass).

Engine is attempting to start and will go through the number

of selected starting attempts.

Engine speed is greater than the crank disconnect.

Timer to allow system to run unloaded for selected time (set

to 0 to bypass).

At Load Mode

Power Good Mode

Cooldown Mode

Section 75 00-02-0522

04-06-11 - 3 -

Generator is running at load.

This mode is to prevent nuisance start/stops. The controller

continues running but monitors the remote start contact while

in this mode. The power good timer must expire before the

system can proceed to cooldown. Any further call to run

resets the power good mode timer to its preset value.

Generator runs unloaded for a preset time.

Phase-out / Discontinued Product

Check Availability

Energized to Stop

Stopped Mode

Postlube Mode

The Energized to Stop timer is ON and the Energized to Stop

output is active.

Generator has come to a complete stop.

In larger generators there may be a requirement for

automatic lubrication after a normal start/run/stop cycle

before the engine can be restarted (set to 0 to bypass). After

postlube, the system returns to Ready to start. Additionally

there are two fault shutdown modes:

Shutdown / Lockout with Cooldown Mode - In

the case of some faults the controller will open the

"at load’ contact and then go through a normal

cooldown and stop sequence, but will not allow an

automatic restart without a system reset.

Immediate Shutdown/Lockout (no Cooldown)

Mode - Because of the severity of most faults, the

controller will cause an immediate

Shutdown/Lockout without a cooldown period, and

will not allow an automatic restart without a system

reset.

Shutdown / Lockout with

Cooldown Mode

Immediate

Shutdown/Lockout (no

Cooldown) Mode

In the case of some faults the controller will open the "at

load’ contact and then go through a normal cooldown and

stop sequence, but will not allow an automatic restart without

a system reset

Because of the severity of most faults, the controller will

cause an immediate Shutdown/Lockout without a cooldown

period, and will not allow an automatic restart without a

system reset.

Section 75 00-02-0522

04-06-11 - 4 -

Phase-out / Discontinued Product

Check Availability

Programming the iGUARD from the Keypad

The iGUARD controller can be programmed in two separate ways. Most setup can be done

from the front panel. There are some parameters, such as changing passwords that require

the use of the iGCON software tool. The iGUARD programming menus can be accessed at

any time by pressing the left and right arrows at the same time. This will bring up the password

menu:

The factory defaults (and what they allow access to) for the various levels of password are:

Access Security - Allows input of 4-character security code.

PASØ - No operational Access. It allows viewing of the data screens but

parameters cannot be edited.

PAS1 - Operational Access. It allows Manual Start and Stop but parameters

cannot be edited.

PAS2 - Parameter View Access. Allows for viewing of all parameters and

editing of the following parameter settings:

Change Language

Key Sensitivity Level

Back Light On/Off

Ack Maintenance Timers

Enable Beeper

Select Pressure Units

Select Temperature Units

Modify Date

Edit Clock Start and Stop Timers

PAS3 - Parameter Edit Access. Allows for viewing and parameter editing

but does not allow calibration of AC.

PAS4 - Calibration Access. Allows calibration of the AC parameters.

PAS5 - kW Limit Edit and Config Select Access. Allows editing of kW limits

and various communication addresses.

Section 75 00-02-0522

04-06-11 - 5 -

Phase-out / Discontinued Product

Check Availability

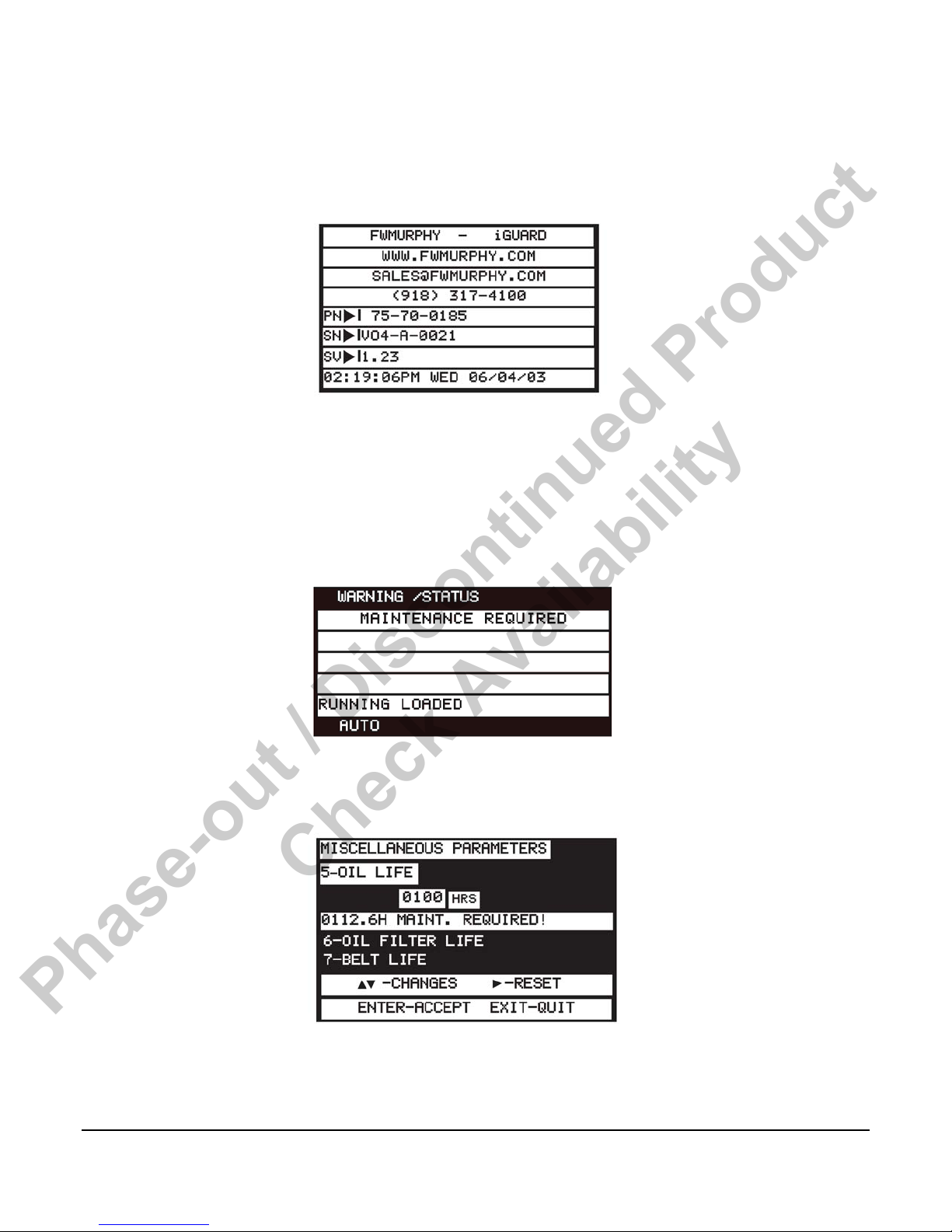

What to do if you lose your Password

Press NEXT until you see the screen with a graphic display of the Murphy logo. Press NEXT

once to go to the system information screen.

Write down the serial number, the current date, and time showing on the real time clock

display, and contact us (918) 317-4100, ask for technical support). We will provide a temporary

password that will allow you to access the system to recover the passwords.

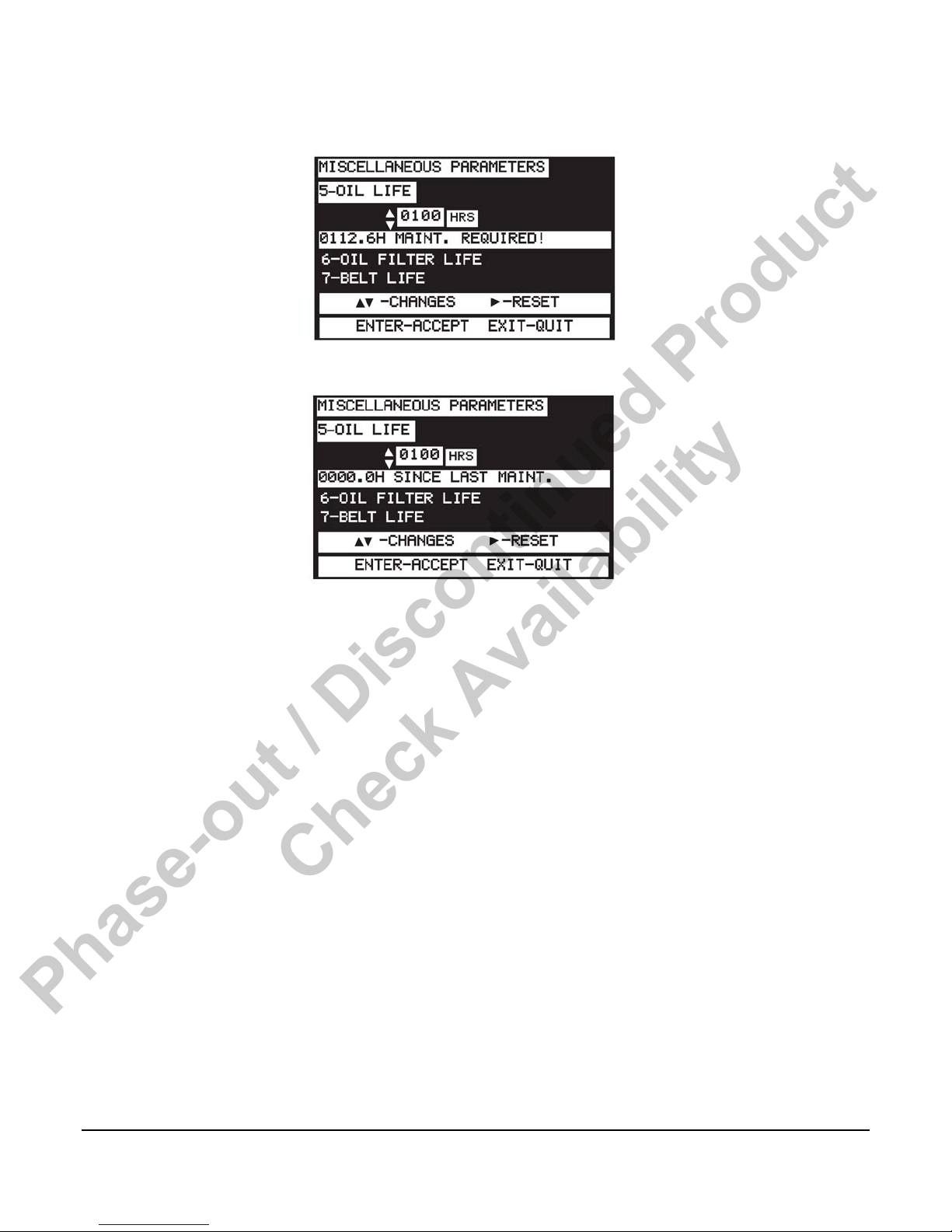

Acknowledging Maintenance Timers

Status/ Warning Screen - You may see this warning/status message:

This is information that one or more of your maintenance reminder timers has expired. To

acknowledge the warning and reset the timer, enter the programming mode, and go to the

Miscellaneous Parameters screen.

Section 75 00-02-0522

04-06-11 - 6 -

Phase-out / Discontinued Product

Check Availability

Press Enter and the screen should change to this display with the number quantity flashing:

Press the right arrow to reset and the display should change to:

Each timer can be acknowledged as it expires, or whenever the maintenance is done, if it

precedes the timer reaching 0.

Displaying Data

Use the Auto scroll function.

To turn the Auto scroll function ON, press the ENTER and NEXT keys at the same time. There

are three Auto scrolling speeds temporarily displayed on the top line each time ENTER and

NEXT keys are pressed (4 seconds, 8 seconds, 12 seconds). To select a different speed,

simultaneously press the ENTER and NEXT keys again to go to the next speed section. To

turn off the Auto scroll function press the EXIT and NEXT keys at the same time. If the

iGUARD is left on a non-scroll screen (like the Warnings/status screen) it will display only the

Warning/status screen.

When Programming

Touching the left arrow takes you immediately to the “TOP” of the program selection list.

The right arrow takes you immediately to the “BOTTOM” of the selection list.

Section 75 00-02-0522

04-06-11 - 7 -

Phase-out / Discontinued Product

Check Availability

Settings and Definitions

Operating Parameters

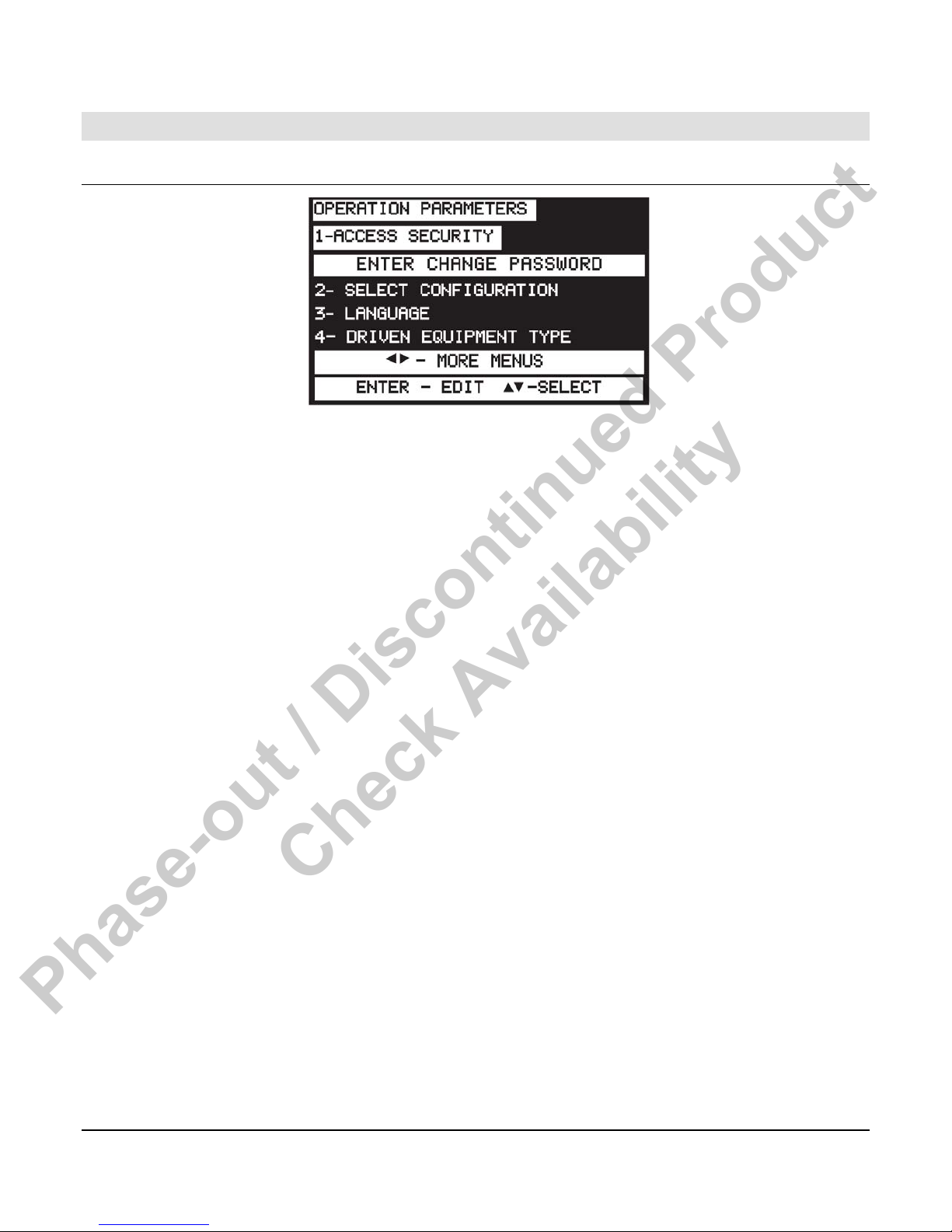

To bring up the iGUARD Programming Screen, press the Left and Right arrow keys

simultaneously. After gaining access to this screen, you can use the Left, Right, Up and Down

keys to navigate from column to column and to adjust the values or change characters

displayed. Press Enter when password is correct.

The security level is shown on the bottom of the display. Press Exit to bring up the Parameters

screen.

1. Access Security - Allows input of 4-character security code.

Level - No operational Access. It allows viewing of the data screens but

parameters cannot be viewed or edited.

Level 1 - Operational Access. It allows Manual Start and Stop but

parameters cannot be viewed or edited.

Level 2 - Parameter View Access. Allows for viewing of all parameters and

editing of the following parameter settings:

Change Language

Key Sensitivity Level

Back Light On/Off

Ack Maintenance Timers

Enable Beeper

Select Pressure Units

Select Temperature Units

Select Temperature Units

Date Display Format

Modify Date

Edit Clock Start and Stop Timers

Section 75 00-02-0522

04-06-11 - 8 -

Phase-out / Discontinued Product

Check Availability

Level 3 - Parameter Edit Access. Allows for viewing and parameter editing

but does not allow calibration of AC.

Level 4 - Calibration Access. Allows calibration of AC parameters.

Level 5 - kW Limit Edit and Config Select Access. Allows editing of kW

limits and various communication addresses.

2. Language - Allows selection of language used to display text.

a. English (Default)

b. Spanish

c. etc. (future expansion)

3. Driven Equipment Type - Allows selection of type of equipment that is driven by the

engine.

a. None (engine only, ignores all AC parameters)

b. AC Alternator (Genset) (Default)

4. Key Sensitivity Level - Determines how sensitive the touch pad keys are for your

application.

a. Low*

b. Normal (Default)

c. High

5. Default Screen - When the system is running this selects the screen that will show.

Event History

Warnings / Status

Engine / Gen Status

Meters

Nominal Meter

Splash Screen

Information

NOTE: * Newer versions of the controller/software will not have a “LOW”

sensitive selection.

6. Lamp Test - Tests LCD.

7. LCD Backlight - Turns the iGUARD display backlight off, unless an error condition

activates the common visual alarm.

a. Disabled

b. Enabled (Default)

8. Guard Beeper - Keypress indication and/or audible warning buzzer.

Section 75 00-02-0522

04-06-11 - 9 -

Phase-out / Discontinued Product

Check Availability

a. Disabled

b. Enabled - Beeps with each keypress, sounds for errors. (Default).

9. Pressure Units - User selection of display units.

a. PSI (Default)

b. kPa

c. bar

10. Temperature Units - User selection of display units.

a. Fahrenheit (Default)

b. Celsius

11. Date Display - Format Selectable.

a. American Style (Default)

b. European Style

12. Event Types to record.

a. All events (Default)

b. Shutdown events only

13. Clear Event History - Erases all stored history events.

14. Standby Mode Timer - When the timer expires, the system goes into a lower power

standby mode. After it times out the LCD screen changes to a text message, the blue LCD

backlight is turned off, and the Energy Monitoring board is de-powered. Any keypress or a

remote call to run wakes the unit up. Value can be set between 30 seconds and 59 minutes 30

seconds or can be set to OFF.

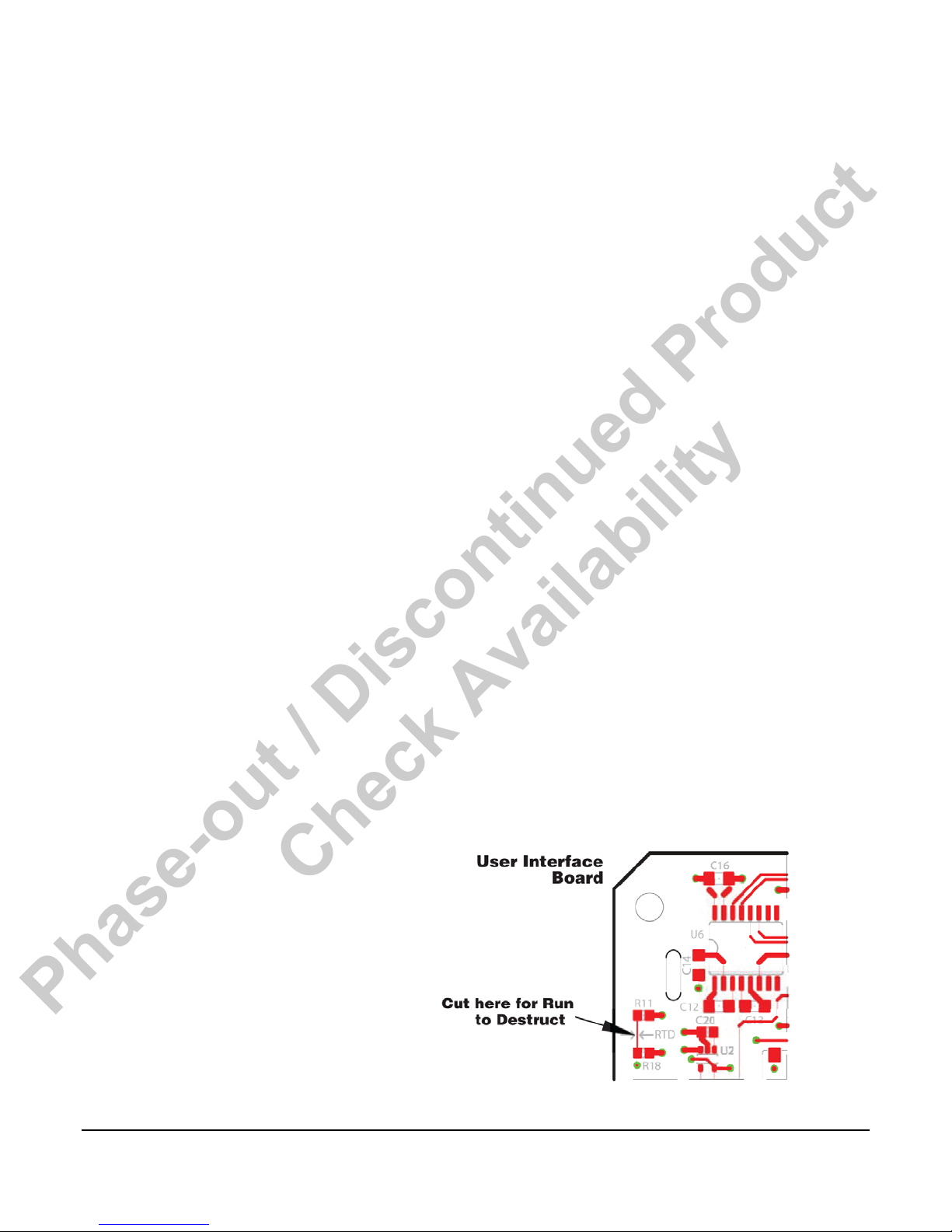

15. Run to Destruct - When run to destruct is enabled, the system will only sound alarms for

errors, instead of shutting down. Since this could lead to the destruction of the equipment or

the load, there is both a menu selection and a jumper that must be physically cut (see

schematic diagram), making this a deliberate choice.

a. Disabled (Default)

b. Enabled

16. Edit Time and Date - Allows user to adjust

Section 75 00-02-0522

04-06-11 - 10 -

Phase-out / Discontinued Product

Check Availability

time and date of iGUARD.

17. Input - Output Test - Shows the status of the analog inputs, digital inputs, and relay

outputs.

a. The analog input screen shows any change in the inputs. For example

if the resistance value of a resistive sender changes, the counts will

change.

i. Analog channel number

ii. Name/setup label

iii. Actual value

b. The digital input screen shows the status of the digital inputs.

i. Digital Input Number

ii. Name/setup label

iii. Made/open

c. Relay output status allows the forcing of any relay out. The screen

shows:

i. Relay output number

ii. Name/setup label

iii. State

NOTE: Analog values, digital input, and relay status may be read on these

screens at any time. The relays may only be forced in “Manual Mode”

while not running.

18. Reset Configuration - Allows user to force a complete reset to a known state and clears

all programming and customization.

19. Operation Mode

a. Manual, Auto, NFPA - If not in Auto, you’ll get Not-In-Auto alarm.

b. Manual, Auto No Warning - It disables the Not-In-Auto alarm.

c. Manual Mode Only - Can only be started from the front keypad.

20. Duplicate Senders - Allows ‘one only’ or more than one sender for engine pressures

and temperatures.

21. Repeater #1 (set to Mimic as Default)

a. Set as Mimic Allows control capabilities without programming.

b. Set as Annunciator Allows viewing without control.

Section 75 00-02-0522

04-06-11 - 11 -

Phase-out / Discontinued Product

Check Availability

22. Repeater #2 (set to Mimic as Default)

a. Set as Mimic Allows control capabilities without programming.

b. Set as Annunciator Allows viewing without control.

23. Winter/Summer Setpoint

a. Set Below Setpoint - If temperature is below setpoint, during start up,

automatic pre-heating begins.

b. Set Above Setpoint – If temperature is above setpoint, during start up,

pre-heating is bypassed.

Communication Parameters

1. J2 Protocol type - Selects the function that the selectable comm. port (on J2) will perform

a. RS-232 iGUARD config

b. RS-485 Modbus server

2. Modbus Server (SLAVE)” address - Sets the address of the Modbus server (247 is

default)

3. RS-485 Server (SLAVE) bit frame - Sets the number of start, data & stop bits for serial

communications via RS-485 Modbus

a. 10 bits N-8-1

b. 11 bits N-8-2

4. Server (SLAVE) Baud Rate - sets the number of start, data & stop bits for serial

communications via RS-485 Modbus

a. 9600

b. 19200

c. 38400 (Default)

5. RS-485 Client (MASTER)” bit frame - sets the number of start, data & stop bits for serial

communications via RS-485 Modbus

a. 10 bits N-8-1

b. 11 bits N-8-2

6. Client (MASTER)” Baud Rate – communication speed on the RS-485 Client (Master) port

a. 9600

b. 19200

c. 38400 (Default)

NOTE: Be aware that when using the iGUARD to drive PowerView analog

gages or the Remote I/O board, those devices only operate at 38400

baud.

Section 75 00-02-0522

04-06-11 - 12 -

Phase-out / Discontinued Product

Check Availability

7. Modem Connection - Sets the com port for RS-232 based modem communications

a. Enabled

b. Disabled (Default)

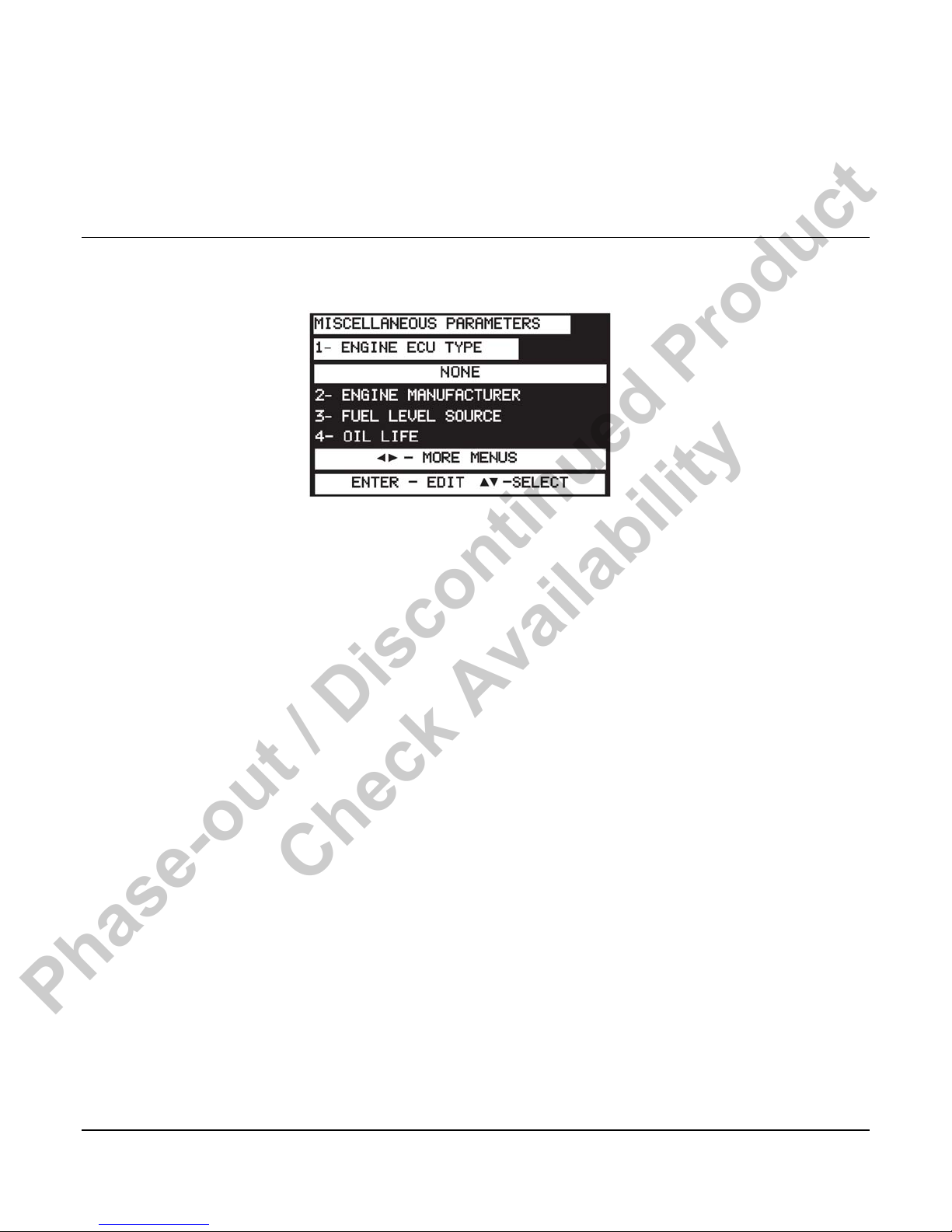

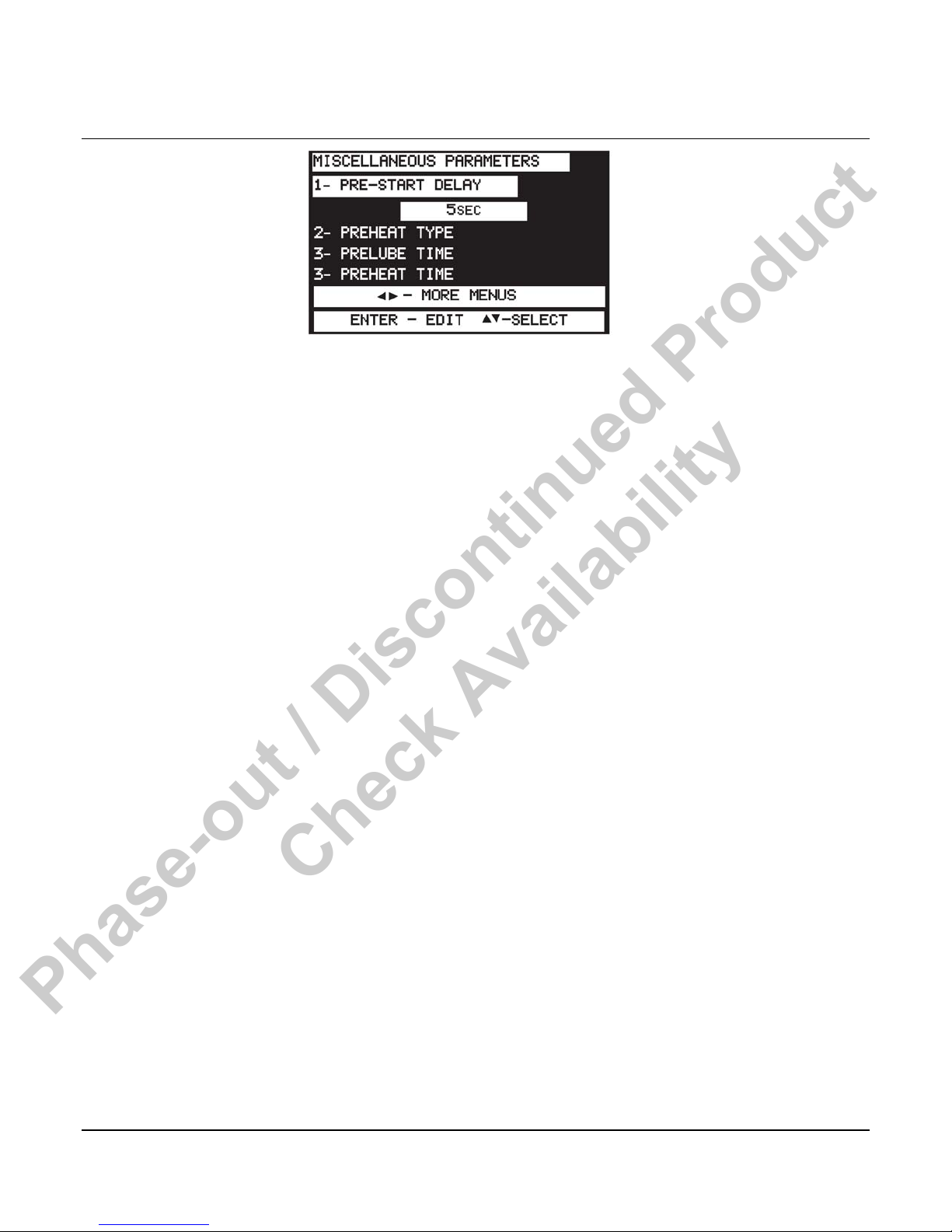

Miscellaneous Parameters

Review the materials supplied with the engine/ECU by the manufacturer to become familiar

with the specifics of your engine.

1. Engine ECU Type - Selects which ECU communications interface will be used to provide

engine parameters.

a. None (mechanically governed/controlled engine) (Default)

b. J1939

Section 75 00-02-0522

04-06-11 - 13 -

Phase-out / Discontinued Product

Check Availability

2. Crank Cut Type - Selects the primary crank and the secondary crank cuts. The options are

as follows:

Primary Secondary

J1939 MPU

J1939 AC Freq

J1939 Digit input

J1939 None

MPU J1939

MPU AC Freq

MPU Digit input

MPU None

AC Freq J1939

AC Freq MPU

AC Freq Digit input

AC Freq None

3. ECU Address Claim

a. None Required

b. Single ECU

c. Multiple ECU’s

4. Engine Manufacturer - Selects engine manufacturer.

Manufacturer Manufacturer

a

b

Section 75 00-02-0522

04-06-11 - 14 -

Caterpillar

Cummins

i

j

Isuzu

Kubota

Phase-out / Discontinued Product

Check Availability

c

d

e

f

g

h

NOTE: Caterpillar, Cummins, Deere, Detroit, Deutz, Ford, GM, Hatz, Isuzu,

Kubota, Lister-Petter, Mercedes, Perkins, Volvo are registered trademarks of

their respective corporations

5. J1939 Crankcut Count - Is the number of consecutive measurements of the RPM above

the Crankcut RPM, required to achieve crank disconnect.

6. Fuel Level Source - Select level source.

Deere

Detroit

Deutz

Ford

GM

Hatz

k

l

m

n

o

Lister-Petter

Mercedes

Perkins

Volvo

Other (Default)

a. None (Default)

b. J1939

c. Analog Input

7. Oil Life - Sets service interval timer for end user maintenance reminder. (Default 100

hours)

8. Oil Filter Life - Sets service interval timer for end user maintenance reminder. (Default 100

hours)

9. Belt Life - Sets service interval timer for end user maintenance reminder. (Default 100

hours)

10. Battery Life - Sets service interval timer for end user maintenance reminder. (Default 100

hours)

11. Fuel Filter Life - Sets service interval timer for end user maintenance reminder. (Default

100 hours)

12. Air Filter Life - Sets service interval timer for end user maintenance reminder. (Default

100 hours)

13. Overhaul Life - Sets service interval timer for end user maintenance reminder. (Default

1000 x 10 hours)

Section 75 00-02-0522

04-06-11 - 15 -

Phase-out / Discontinued Product

Check Availability

Engine Parameters

1. Pre-Autostart Delay - When system is in automatic mode, sets how long unit waits after a

remote run signal is active before proceeding with automatic start sequence. (Default 5

seconds, set to zero to bypass.)

2. Pre-Heat Type - Determines how long the preheat output is active.

a. None - No preheat. (Default)

b. Pre-Crank - For strictly the preheat timer length.

c. Crank Through - Preheat for the preheat timer + crank time.

d. Bypass Timer - Preheat + crank + start up lockout bypass.

e. Warm-Up - Preheat + crank + start up lockout bypass + warm-

up.

3. Pre-Lube Time - Amount of time a prelube output stays on prior to allowing a start. (Default

ø sec.)

4. Pre-Heat Timer - Amount of time that an engine is preheated prior to cranking. (Default ø

sec.)

5. Purge Crank Time - In gaseous-fueled engine applications, a purge crank is used to

prevent gas build up and vent any accumulated gaseous fuel from the system so that it will

start with a known condition. The engine cranks for a pre-settable time with the fuel output deenergized. (Default ø sec.)

6. Crank Time - In an automatic crank cycle the longest time that the engine cranking motor

can be energized. (Default is 15 sec.)

7. Crank Rest Time - In an automatic crank cycle, the time that the engine cranking motor is

off between crank attempts. (Default 15 sec.)

8. Start Attempts - The maximum number of times that the engine cranking motor is

energized without a successful engine start. (Default 3 cycles)

9. Startup Bypass Time - Temporarily disables the low engine oil pressure, high engine

temperature and various other shutdown faults until the engine can come to a running

condition. (Default 15 sec.)

Section 75 00-02-0522

04-06-11 - 16 -

Loading...

Loading...