Page 1

HD-96044N page 1 of 4

Installation and Operation Instructions for

Dual Set Point Speed Switch

HD9063 Series

HD-96044N

Revised 03-01

Section 20

(00-02-0179)

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended

before mounting. It is your responsibility to have a qualified person install this unit and make sure it conforms to NEC and local codes.

GENERAL INFORMATION

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

Description

The HD9063 Series is a unitized two set point speed switch with

SPDT relay outputs. HD9063 is a PC-board configuration with

standoffs for mounting in a control panel or cabinet.

Models are available for crank disconnect/overspeed and for

underspeed/overspeed applications. Trip points can be field

adjusted on all models. LED’s next to the set point potentiometers

indicate that the trip point has been reached and the relay(s) have

operated. An overspeed test circuit is built-in; it will actuate the

output relay at a point below actual overspeed set point.

The HD9063 can disconnect the starter on automatic start engine

applications and shutdown the engine if an overspeed situation

occurs. Re-engagement of the starter is inhibited until RPM

returns virtually to zero.

HD9063-USOS models allow operation of control circuits

according to the speed of the driver or as a pre-alarm.

Two separate adjustable speed switches are included on one

common board.

Specifications

Power Supply:

Voltage: 8-30 VDC

Maximum Current: 150 mA

Frequency Signal:

Voltage, Magnetic Pickup Signal Models

•

Minimum: 0.35 Vrms

•

Maximum: 60 Vrms

Maximum Current, Magnetic Pickup Signal Models: 4.8 µA.

Adjustment Range, Magnetic Pickup Signal Models

•

HD9063 Model

Crank Disconnect: 250-6,000 Hz

Overspeed: 1,100-10,000 Hz

•

HD9063-USOS Model

Underspeed: 200-5,800 Hz

Overspeed: 1,100-10,000 Hz

Reset Differential, Magnetic Pickup Signal Models

•

HD9063 Model

Crank Disconnect: Dropout 160 Hz ± 5%

Overspeed: 200 Hz Differential

•

HD9063-USOS Model

Underspeed: +5% of Set point Differential

Overspeed: 155 Hz ± 10% Differential

Output: Relay Contact, SPDT, Resistive Load: (2) 5 A, 30 VDC

Adjustment: (2) 270°–turn potentiometer

Temperature Range: 14 to 158°F (-10 to 70°C)

WARNING

Page 2

HD-96044N page 2 of 4

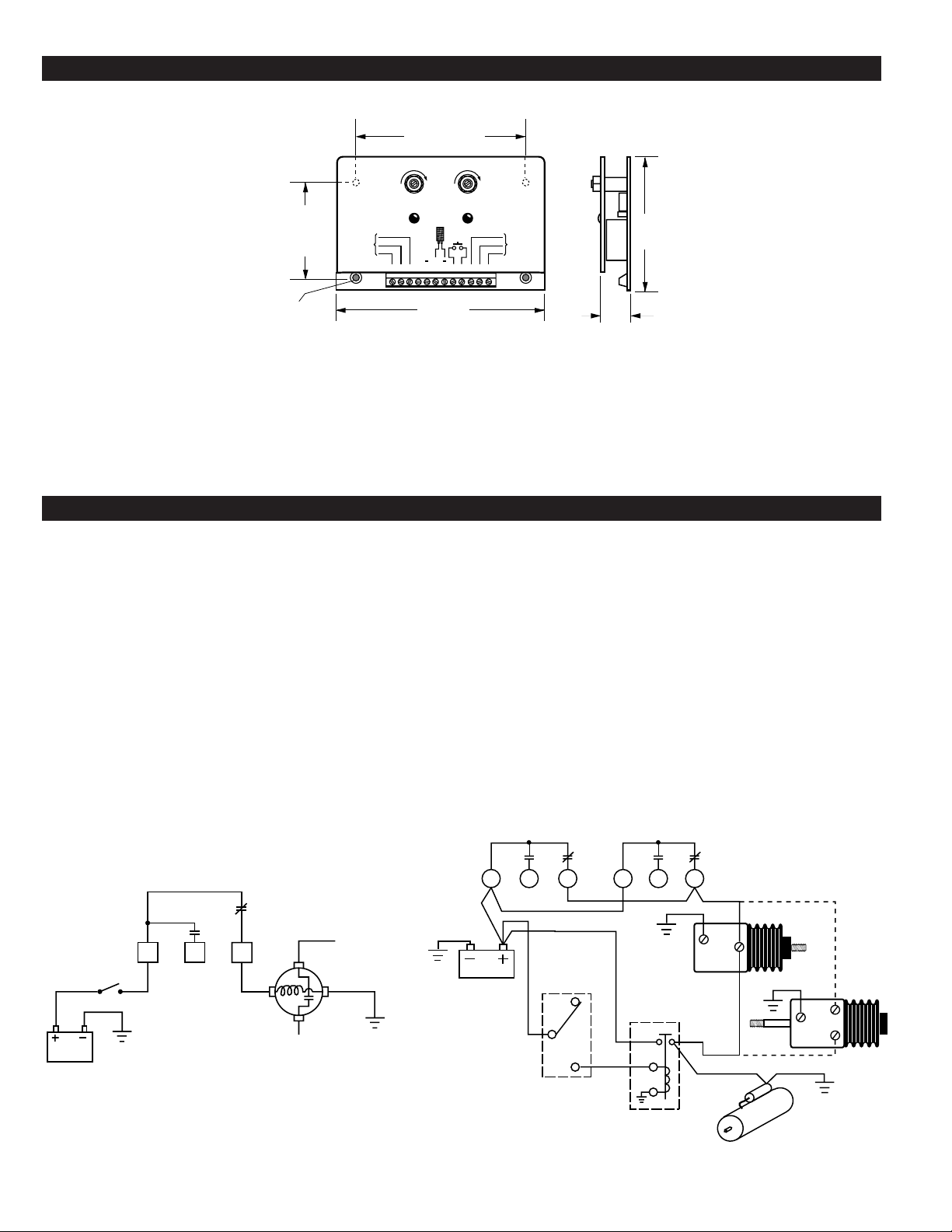

Crank Disconnect Relay

An understanding of the crank disconnect function for your particular system is critical to speed switch installation. It is also

important to consider the 5 A current limitation of K1 relay contacts. Figure 1 illustrates the use of a low-current pilot relay to

operate the high-current starter solenoid. In operation, battery

voltage is supplied through the normally closed contacts of the

speed switch crank disconnect relay K1. When the engine starts,

K1 energizes and its normally closed contacts open. This action

de-energizes the pilot relay and inhibits the starter from operating

until the engine nearly stops. The normally open contacts may be

used if a contact closure is required to disable the cranking function for your system.

Overspeed and Underspeed Relay

NOTE: Underspeed relay available on HD9063-USOS only.

The overspeed and underspeed functions of the speed switch may

be used in various systems to effect engine shutdown or actuate an

alarm in the event of engine overspeed or underspeed. Figure 2

illustrates the overspeed/underspeed function being used to control

a fuel rack solenoid. In this application, battery voltage is available

to the solenoid through normally open contacts of the relay (K2

overspeed) (K1 underspeed). If the engine speed exceeds the nor-

mal overspeed or underspeed set point, relay K1 or K2 energizes

and this voltage energizes the solenoid, shutting down the engine.

Similarly, the normally closed contacts may be used if engine shutdown is to be initiated by removal of battery voltage.

HD9063 and HD9063-USOS

1

Overspeed Relay K2

Contact opens on overspeed or

underspeed and drops out solenoid.

OPTIONAL

Energize

NO

Off

Start

NO NC

2 31

Underspeed Relay K1

NO NC

2 3

Battery

Starter

Switch

Starter Contactor

Relay

Starter

Energize

Hold

MOUNTING DIMENSIONS

Figure 1

Figure 2

Mounting

1. Drill four 3/16 in. (5 mm) diameter mounting holes (refer to

mounting hole dimensions above).

2. Align the plastic standoffs on the HD9063 with the 4 mounting

holes and push gently until standoffs snap into place.

CAUTION: Pushing too hard could damage board.

Mounting

1. Drill four 1/4 in. (6 mm) diameter mounting holes (refer to mount-

ing hole dimensions above).

2. Secure with four 10-32 screws.

RELAY FUNCTIONS

4 in. (102 mm)

Mounting Holes

2-1/4 in.

(57 mm)

Mounting

Holes

INTERNAL

CRANK

DISCONNECT

RELAY

CONTACTS

E

A

R

C

N

I

CRANK

DISCONNECT

NC

NO

EXT.

C

POWER

(+) (+)( ) ( )

123456789101112

S

E

OVERSPEED

EXT.

MAG.

PICKUP

EXT.

TEST

E

A

R

S

C

E

N

I

NC

NO

C

INTERNAL

OVERSPEED

RELAY

CONTACTS

2-3/4 in.

(70 mm)

Mounting

Standoffs

4 Places

4-1/2 in.

(114 mm)

3/4 in.

(19 mm)

Crank

Enable

Battery

Crank

Disconnect Relay

K1

321

Starter Solenoid

Battery

Starter

Pilot Relay

To

Page 3

HD-96044N page 3 of 4

CAUTION: PERFORM THE WIRING OPERATION WITH THE POWER SOURCE “OFF”

MAGNETIC PICKUP INSTALLATION

A magnetic pickup is an AC generator. It is normally installed

into the flywheel housing of an internal combustion engine, so

that the starter ring gear acts upon it to generate a voltage pulse

each time a gear tooth passes the end of the sensor.

Magnetic Pickup Installation (see Figure 5)

Drill and tap a hole in the flywheel housing (See Specifications

Chart below for model and thread size). IMPORTANT: Drilling

too deep may damage ring gear teeth. Blow chips with air hose

when drilling and tapping hole.

Gap Adjustment

Insert magnetic pickup and turn until it stops at the face of the gear.

Back-off the gear by turning the pickup counterclockwise

1/4, 1/2, or 3/4 turn (Figure 4)

.

See Gap Chart (above, right) to determine gap

distance based on the turn. Check gap clearance by rotating the gear completely around.

NOTE: Magnetic pickup gap should be

adjusted so that the minimum voltage required

is attained at the engine’s lowest RPM. The

voltage will increase as the speed increases.

If erratic readings occur, remove magnetic

pickup and check the magnetic tip for metal chips.

Murphy Magnetic Pickup Specifications Chart

Pickup Total Threaded Thread

Model Length Length Size

MP3298* 3 in. (76 mm) 3 in. (76 mm) 5/8-18 UNF

MP7906

†

3 in. (76 mm) 3 in. (76 mm) 3/4-16 UNF

MP7905

††

4-1/2 in. (114 mm) 4-1/2 in. (114 mm) 3/4-16 UNF

*

Replaces 20-01-0080 and MP100. Lead wire hookup (12 in. [305 mm]).

†

Replaces 20-01-0081. Lead wire hookup (12 in. [305 mm]).

††

Replaces 20-01-0082. Lead wire hookup (12 in. [305 mm]).

Gap Chart

1. Connect terminal 5 on the HD9063 to engine ground and

connect terminal 4 to battery positive (see Figure 3).

2. Connect the magnetic pickup cable conductors to terminals

6 and 7.

3. If cable is shielded, connect shield to engine chassis ground.

4. If desired, connect a normally open test push button switch

between terminals 8 and 9.

5. Connect crank disconnect circuit to crank disconnect termi-

nals 1 thru 3 as discussed in Crank Disconnect Relay

Function, page 2. On HD9063-USOS models connect the

overspeed circuits 1 thru 3 as discussed in Overspeed Relay

and Underspeed Relay Function, page 2.

6. Connect the overspeed circuits to overspeed terminals 10 thru

12 as discussed in Overspeed Relay and Underspeed Relay

Function, page 2.

WIRING

123456789101112

(+) (+)( ) ( )

K1 K2

12

Common Common

Normally Open Normally Open

Normally Closed Normally Closed

Test

Pushbutton

DC Positive

DC Negative

(Engine Ground)

From Magnetic Pickup

To Engine

Crank Control

Circuit

or

to Shutdown

Circuits

(HD9063-USOS)

To

Shutdown

Circuits

THREAD

SIZE

5/8-18 UNF

3/4-16 UNF

1/4

1/2

3/4 1

GAP

.013 in. .028 in. .035 in. .055 in.

(0.33 mm) (0.71 mm) (0.88 mm) (1.39 mm)

.015 in. .030 in. .045 in. .062 in.

(0.38 mm) (0.76 mm) (1.14 mm) (1.57 mm)

TURN

1/4

1/2 3/4

AC

Meter

After adjusting,

set locknut.

Drill and tap casing

(see thread sizes in

Specifications).

Casing

Gear (must be made

of magnetic material).

NOTE: Clean gear casing

and magnetic sensor

of metal chips or filings.

Gap

(see Gap Chart)

Always use a two-conductor shielded cable. Ground the

shield to a metal frame ground at the engine end only.

Never run these wires

next to spark plug wires

or in wire loom with other

wires carrying inductive

loads or alternating current.

Figure 3

Figure 4

Figure 5

Page 4

HD-96044N page 4 of 4

ADJUSTING THE SPEED SWITCH

Adjustment of the Dual Set point Speed Switch is performed

when the system is otherwise operational in all respects.

See Figure 6 for location of Crank Disconnect, Underspeed and

Overspeed potentiometers.

Crank Disconnect Set Point Adjustment

1. If engine serves as a backup for an electric pump or other

motor driven device, turn off the associated electric motor.

2. Reset any associated switches.

3. Ground engine ignition system or shut off fuel to engine to dis-

able engine from starting.

4. Loosen locknut on Crank Disconnect set point potentiometer

and turn potentiometer fully clockwise.

5. Operate electrical switch(es) as appropriate so that engine will

begin to crank.

6. While engine is cranking, slowly turn Crank Disconnect Set

point potentiometer counterclockwise until Crank Disconnect

LED lights (Figure 6). Engine should stop cranking.

7. Now turn the potentiometer clockwise 1/16 turn.

8. Enable engine and allow it to start, verifying that starter disengages.

If starter motor stays engaged too long, lower set point slightly

by turning potentiometer counterclockwise in increments of no

more than 1/16 turn. Re-test after each adjustment by starting

engine, and continue adjustment until starter disconnects as

soon as engine starts.

If starter motor does not stay engaged long enough, raise set

point slightly by turning potentiometer clockwise in increments

of 1/16 turn. Re-test after each adjustment.

9. Tighten locknut on Crank Disconnect set point potentiometer.

NOTE: A starter protection feature prevents starter from being

engaged until engine almost completely stops after running.

Overspeed and Underspeed

Set Point Adjustment

OVERSPEED

1. Loosen locknut on Overspeed set point potentiometer and turn

potentiometer fully clockwise.

2. Start engine and run at highest normal operating RPM.

3. Slowly turn Overspeed adjustment potentiometer counter-

clockwise until overspeed switch trips or engine shuts down.

The LED light should flash.

4. Turn potentiometer approximately 2° clockwise, then

tighten locknut.

5. Reset switches as applicable and restart engine.

NOTE: An overspeed test switch connected as shown in Figure 3

provides a means for decreasing set point for test purposes.

6. If a test push button is installed, press push button and verify

that overspeed LED (Figure 6) flashes and engine shuts down

or switch trips.

UNDERSPEED

NOTE: Underspeed is available on HD9063-USOS models only.

1. Loosen locknut on Underspeed set point potentiometer and turn

potentiometer fully counterclockwise.

2. Start engine and run at lowest normal operating RPM.

3. Slowly turn Underspeed adjustment potentiometer clockwise

until underspeed switch trips or engine shuts down. The LED

light should flash.

4. Turn potentiometer approximately 2° counterclockwise, then

tighten locknut.

5. Reset switches as applicable and restart engine.

NOTE: An overspeed test switch connected as shown in Figure 3

provides a means for decreasing set point for test purposes.

6. If overspeed test push button is installed, press push button and

verify that overspeed LED (Figure 6) flashes and engine shuts

down or switch trips.

Figure 6

Warranty

A limited warranty on materials and workmanship is given with this FW

Murphy product. A copy of the warranty may be viewed or printed by

going to www.fwmurphy.com/support/warranty.htm

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

+1 281 633 4500 fax +1 281 633 4588

e-mail sales@fwmurphy.com

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mail ventas@murphymex.com.mx

www.murphymex.com.mx

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

www.fwmurphy.co.uk

MURPHY SWITCH OF CALIFORNIA

41343 12th Street West

Palmdale, California 93551-1442; USA

+1 661 272 4700 fax +1 661 947 7570

e-mail sales@murphyswitch.com

www.murphyswitch.com

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MACQUARRIE CORPORATION

1620 Hume Highway

Campbellfield, Vic 3061; Australia

+61 3 9358 5555 fax +61 3 9358 5558

e-mail murphy@macquarrie.com.au

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100

fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

R

E

G

I

S

T

E

R

E

D

USA–ISO 9001:2000 FM 28221

UK–ISO 9001:2000 FM 29422

Printed in U.S.A.

Crank Disconnect

Potentiometer

Crank

Disconnect

or

Underspeed

LED

Underspeed Potentiometer

or

(HD9063-USOS)

E

A

R

S

C

E

N

I

EXT.

MAG.

NC

NO

C

PICKUP

EXT.

POWER

(+) (+)( ) ( )

123456789101112

EXT.

TEST

Overspeed Potentiometer

E

A

R

S

C

E

N

I

NC

NO

C

Overspeed

LED

Loading...

Loading...