Page 1

EMS PRO

Engine Monitoring System Controller

Installation and Operations Manual

00-02-0716

2013-06-03

Section 40

Page 2

systems.

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our

specifications and designs at any time.

ENOVATION CONTROLS has made efforts to ensure the reliability of the EMS PRO

and to recommend safe use practices in system applications. Please note that in any

application, operation and controller failures can occur. These failures might result in

full control outputs or other outputs that might cause damage to or unsafe conditions

in the equipment or process connected to the EMS PRO.

Good engineering practices, electrical codes, and insurance regulations require that

you use independent external protective devices to prevent potentially dangerous or

unsafe conditions. Assume that the EMS PRO can fail with outputs full ON, outputs

full OFF or that other unexpected conditions can occur.

Please read the following information before installing.

BEFORE BEGINNING INSTALLATION OF THIS MURPHY

PRODUCT:

• This installation information is intended for all EMS PRO Series models. A visual

inspection of this product before installation for any damage during shipping is

recommended.

• Disconnect all electrical power to the machine. Failure to disconnect all electrical

power connections before welding can result in damage to the panel and/or its

components.

• It is your responsibility to have a qualified technician install the unit and make sure

installation confirms with local codes.

• Observe all Warnings and Cautions in each section of these instructions.

• The EMS PRO is designed for use in industrial environments. There might be

potential difficulties in ensuring electromagnetic compatibility in other

environments due to conducted as well as radiated disturbances.

• Please contact ENOVATION CONTROLS immediately if you have any questions.

IMPORTANT! False or improper use and operation of electronic

products could be dangerous. It is required that point-of-operation

guarding devices be installed and maintained. All such devices must

meet OSHA and ANSI Machine safety standards. The manufacturer shall

not accept any responsibility for installation, application or safety of

Page 3

Table of Contents

Introduction ................................................................................................................................. 1

Product Description ......................................................................................................1

User Interface and Navigation ......................................................................................2

Quick Set Up ............................................................................................................................... 6

Setting the Time/Date Clock .........................................................................................7

Setting for Mechanical Engines ....................................................................................7

Start/Stop Settings .......................................................................................................8

System Throttling Types ..............................................................................................9

Transducer Types ...................................................................................................... 10

Tier 4 Emissions ......................................................................................................... 11

Unit System – Metric or English ................................................................................. 12

Operational Directions ............................................................................................................ 12

AUTO Start/Stop Sequence ....................................................................................... 12

Start Sequence .......................................................................................................... 13

Stop Sequence ........................................................................................................... 15

Manual Start/Stop Sequence ..................................................................................... 16

Special Features ........................................................................................................ 18

Menus ........................................................................................................................ 19

Inputs and Outputs ..................................................................................................... 31

General Information ................................................................................................................. 33

LCD CONTRAST ADJUSTMENT ON STARTUP ...................................................... 33

General Wiring Precautions ....................................................................................... 33

Communications ........................................................................................................ 34

ENTRY CODE SUPPLEMENT ................................................................................................. 38

LOADING PROGRAM ............................................................................................... 38

Installation ................................................................................................................................. 39

EMS PRO Mounting and Dimensions ........................................................................ 39

Specifications ........................................................................................................................... 40

Page 4

NOTES

Page 5

Introduction

This document is designed to support a user in getting familiar with the EMS PRO and how to navigate

the interface, modify the settings and install and operate the controller. The Quick Set Up guide assists

with establishing the different functions in the EMS PRO System Controller. Before attempting to set

up the controller, be sure to read and understand this manual in its entirety.

Product Description

The EMS PRO is a flexible, all-in-one customizable unit that meets the needs of engine-driven pumping

equipment applications. The EMS PRO is a dedicated microprocessor-based, single-engine controller.

It offers field-adjustable operating parameters that can be changed without the need for a laptop

computer. It is able to support both mechanical and J1939 electronic engines.

The EMS PRO has a selectable auto start/stop with many auto throttling options. The auto start/stop

options (Single Contact, Floats, Momentary, and Transducer) are available at the touch of a button. In

addition, there are many performance-enhancing features, all of which are available via a back-lit

operator interface that’s easy to learn and use. The display is readable day or night.

The EMS PRO is designed for use with a SCADA system, offering Modbus® RTU protocol on either the

RS232 or RS485 port. See the Modbus portion of this manual for details.

NOTE: Harness kit 40000536 is available to “bring out” the (2) wire RS485 to the

bottom of the enclosure. The RS232 is accessed via a DB9 connector located on

the display/CPU board. Customer modification to the enclosure is required to use

either port.

Section 40 00-02-0716

2013-06-03 - 1 -

Page 6

User Interface and Navigation

This section defines how to navigate through the EMS PRO user interface. It will assist the user in

understanding the screens and keys used to modify settings and how each works.

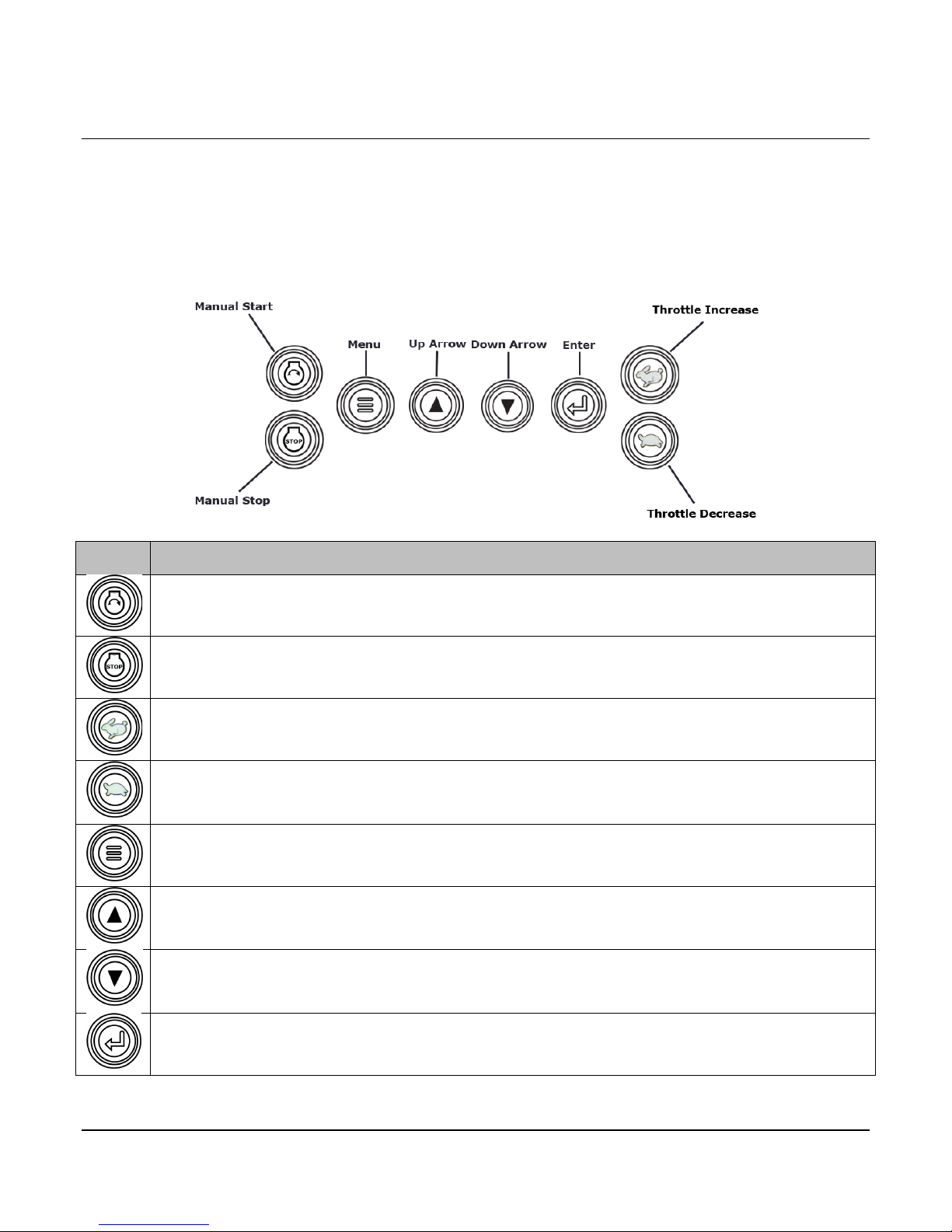

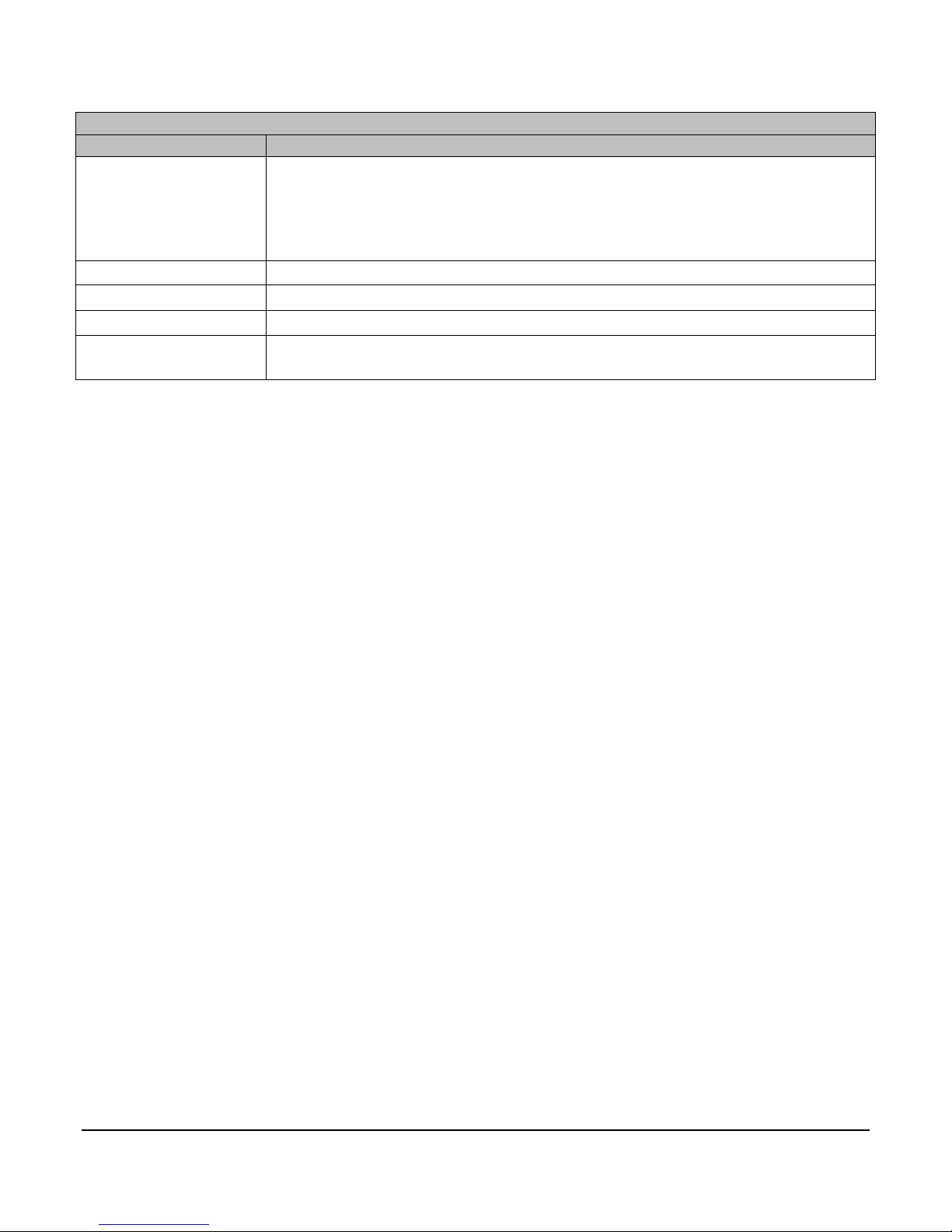

Membrane Keypad

The membrane keypad is made up of eight buttons. All of the functions for the EMS PRO can be set

using these eight buttons.

ICON Description

“START” = In the “MAN” (manual) mode this will initiate a start sequence. Can be used for

local auto start if “Local Pushbutton” is selected in start/stop type, S35.

“STOP” = In the “MAN” (manual) mode this will initiate a stop sequence. Can be used for

local auto stop if “Local Pushbutton” is selected in start/stop type, S35.

“THROTTLE INCREASE” = In the “MAN” (manual) mode this will increase engine speed.

“THROTTLE DECREASE” = In the “MAN” (manual) mode this will decrease engine speed.

“MENU” = Toggles between the front display and the password window and allows user to

exit menus.

“UP” arrow = Scrolling on the front display, scrolling through and increasing values in the “S”

& “P” numbers.

“DOWN” arrow = Scrolling on the front display, scrolling through and decreasing values in the

“S” & “P” numbers.

“ENTER” = Getting into the “S” or “P” numbers group after the correct entry code is entered,

getting into an actual “S” or “P” number selected to make changes.

Section 40 00-02-0716

2013-06-03 - 2 -

Page 7

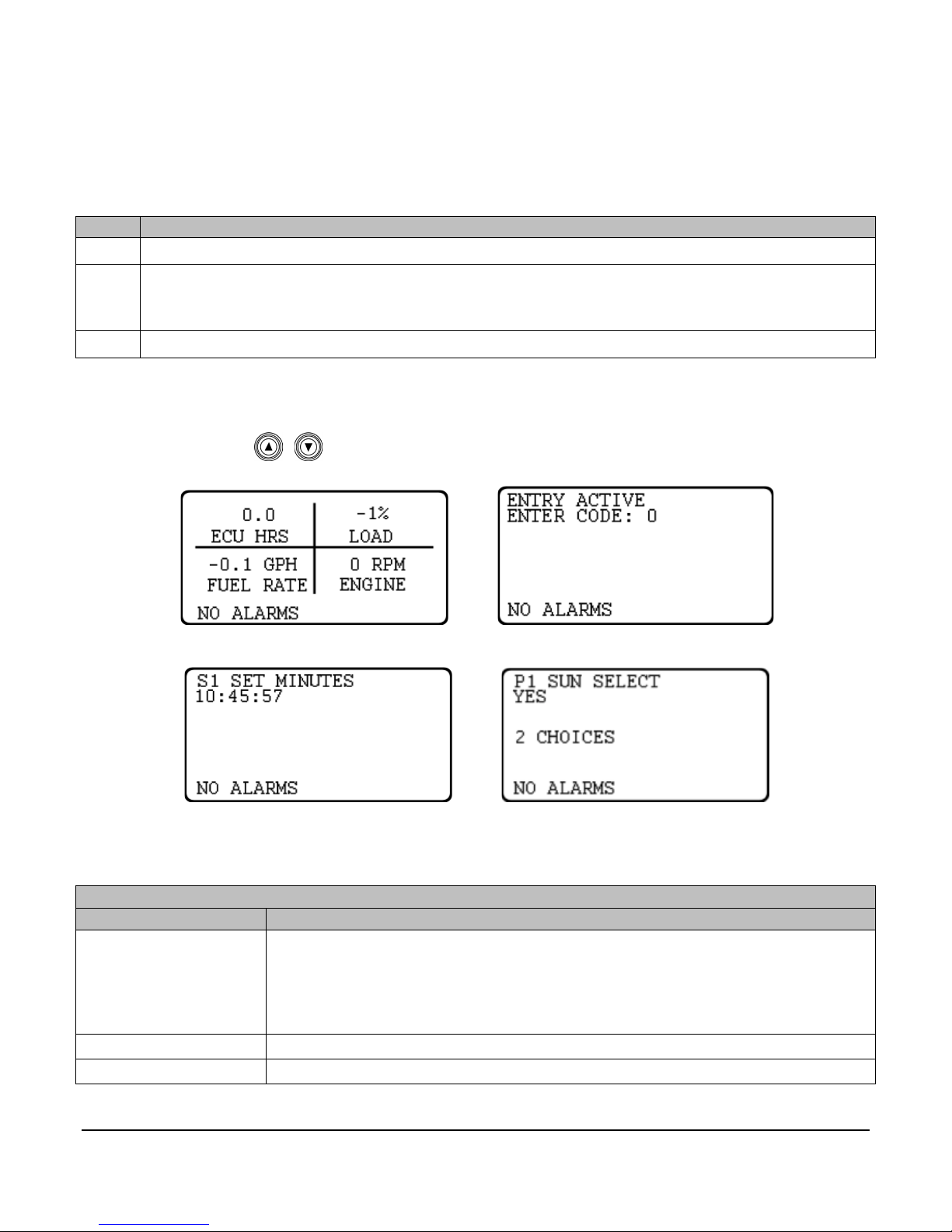

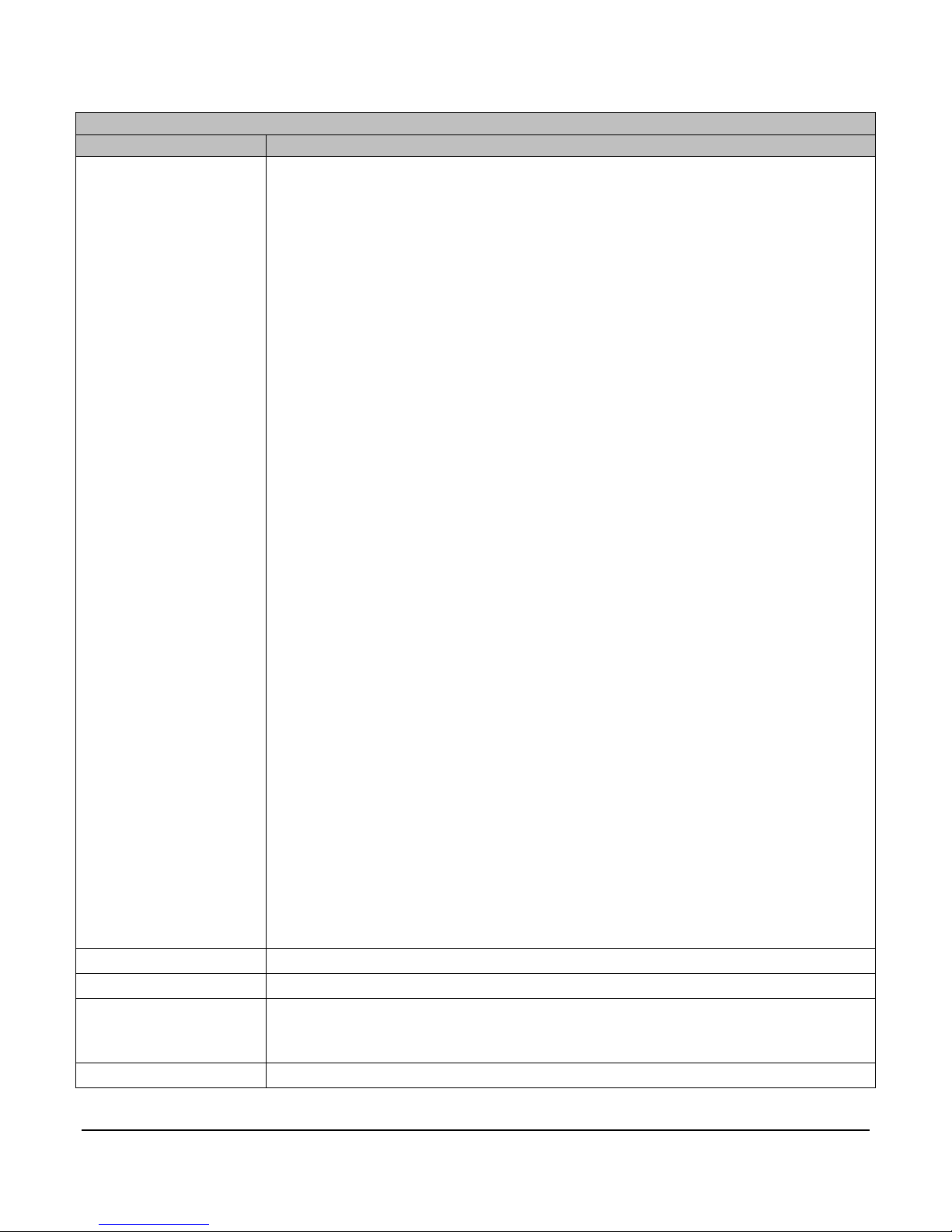

Input

Description

AUTO

Functions described in the “Auto Start/Stop Sequence” of this document.

OFF

Disconnects control power to prevent the engine from starting or continuing to run through the

control panel. The OFF position provides an immediate shutdown whenever the key switch is

placed in this position while the engine is running in either the automatic or manual modes.

MAN

Functions as described in the “MAN Start/Stop Sequence” in this document.

Screens Displayed

Screen Name

Description

FW MURPHY or

This is the last line of the text page when pressing the down arrow key from

BUILD xxxxxx

Refer to the program and build number when requesting technical assistance.

PROGRAM 50333178

Refer to the program and build number when requesting technical assistance.

Key Switch

The controller accepts inputs from a 3 position key switch. The 3 positions are “AUTO”, “OFF” and

“MAN”:

Screens Displayed

During normal operation, the controller allows you to scroll through a number of informative front screen

displays by using the membrane keys. Below are several example screens.

Example Four-Up Screen Entry Code Screen

Example S-Number Screen Example P-Number Screen

The screens displayed by the EMS PRO are listed and described below:

MURPHY or

ENOVATION

CONTROLS

the default screen.

Section 40 00-02-0716

2013-06-03 - 3 -

Page 8

Screens Displayed

Screen Name

Description

SELECTOR XXXX

There are three positions displayed on this line: AUTO and MAN. When a start

START”, “CLOCK START”, “SCADA START”

DAY OF THE WEEK

This line shows the present day of the week.

DD MMM YYYY

This line displays the present date.

HH:MM:SS

This line shows the present time.

STATE:

XXXXXXXXXX

The following are the different states the controller will execute during the auto

sequence:

signal is active, the display will change to show the start option being used in

place of Auto or MAN: “SINGLE CONTACT START”, “FLOAT START”,

“MOMENTARY START”, “PRESSURE START”, “LEVEL START”, “TEMP

Section 40 00-02-0716

2013-06-03 - 4 -

Page 9

Screens Displayed

Screen Name

Description

STATE:

This text line displays any of the following states the controller will execute

OFF position and then back to AUTO or MAN.

FUEL XXX%

This displays the current fuel level as sensed from a sender.

SYS BAT XX.X VDC

This displays the current engine battery voltage.

SYS HRS or ECU HRS

This displays the current total engine run time. The prompt and data shown in

SELECT”. S39 will not appear when S38 is set to “MECHANICAL”.

LEAD SPD XXXX RPM

This displays the internally generated lead/command speed.

during the auto sequence:

• PANEL READY occurs when the key switch is in the AUTO position and

no shutdowns have occurred. The controller is waiting for an auto start

condition to occur.

• START DELAY occurs when a start signal is active and the start delay is

timing. The start signal must remain active throughout this delay before

the auto start sequence can continue.

• PRESTART occurs after the start delay expires. During this state, the

prestart output is turned ON. This output remains on until the engine

actually starts.

• WAIT FOR ECU occurs after the Prestart delay expires, if “ECU” is

selected in the engine type. During this state, the unit allows the ECU to

initialize prior to cranking. A “J1939 COMM FAIL” will occur if the PRO is

not receiving CAN data when this delay expires.

• CRANK ON occurs when cycle cranking begins. During this state, the

crank output is turned ON.

• CRANK OFF occurs when cycle cranking begins. During this state, the

crank output is turned OFF.

• RECRANK DELAY occurs if the engine speed drops below the “crank

stop” set point before the “shutdown lockout delay” expires. Cycle

cranking continues when this delay expires.

• WARMUP occurs after the engine starts. During this state, the engine is

throttled to the warm-up RPM until this delay expires.

• AT LOAD occurs after the Warm-up delay expires. The low discharge

pressure shutdown is armed when this delay expires.

• FILL MODE occurs after the Warm-up delay expires. During this state,

the engine is throttled to minimum rpm and held there until this delay

expires.

• STOP DELAY occurs when a stop signal is active and the stop delay is

timing. The stop signal must remain active throughout this delay before

the auto stop sequence can continue.

• COOLDOWN occurs after the Stop Delay has expired. During this state,

the engine is throttled to the cooldown rpm.

• SHUTDOWN occurs if a shutdown condition is detected. Reasons for

shutdown include low oil pressure, high engine temperature, overspeed,

etc. During this state, the engine is signaled to shutdown and all start

signals are ignored until the state is reset by moving the key switch to the

XXXX.X

this display is dependent on S38 ”ENGINE TYPE” and S39 ”ECU HOUR

Section 40 00-02-0716

2013-06-03 - 5 -

Page 10

Screens Displayed

Screen Name

Description

ENG XXXX RPM

This displays the current engine RPM sensed from either a magnetic pickup

or as broadcasted from the ECU.

OIL PR XXX PSI

This displays the current engine oil pressure as sensed from an electric

gauge sender, or as broadcasted from the ECU.

ENG TEMP XXX °F

This displays the current engine jacket water temperature as sensed from an

electric gauge sender, or as broadcasted from the ECU.

DISCH PR XXX PSI

(IF SELECTED)

This displays the current discharge pressure as sensed from a transducer.

LEVEL XX.X

(IF SELECTED)

This displays the current system level as sensed from a transducer.

AMB TEMP XXX °F

(IF SELECTED)

This displays the current ambient temperature as sensed from a Murphy

Model 12 transducer.

LOCAL THROT

This is only show if Local Throttle is selected in S36.

SOOT LEVEL

This shows the soot level percentage. There are also 3 alarms associated

“REGEN NEEDED HIGH”.

UREA LEVEL

This shows the urea level percentage as broadcasted over CAN SPN 1761.

FIRST FOUR-UP

(DEFAULT SCREEN)

The first four-up screen should display Engine Oil Pressure, Engine Coolant

powering up the controller.

SECOND FOUR-UP

The second four-up screen should display Run Hours, Fuel Consumption,

icons by temporarily writing over ECU run hours, LOAD%, and FUEL RATE.

SHUTDOWN SCREEN

This screen shows the last five shutdowns that have occurred. This screen can

(IF SELECTED)

(IF SELECTED)

(IF SELECTED)

SCREEN

ECU ONLY SCREEN

Quick Set Up

with this Status sent from the ECU. The Alarms will be displayed on the

Alarm line as “REGEN NEEDED LOW”, “REGEN NEEDED MEDIUM”, or

Temp, Battery Voltage, & Engine RPM. This is the default screen when

Engine Load %, & Engine RPM. This screen can be viewed by pressing the

arrow up key from the default screen. This screen will also display (3) Tier 4

be accessed by pressing the arrow up key past the four-up screen(s).

This section is to help in setting portions of the program in which cover the primary uses of this

controller. The steps below will only cover how to change certain portions of the program to better suit

your application. There are other parameters to be setup in the menus before the unit is placed in

service.

NOTE: This section is used as a reference guide and this entire document

should be completely read and understood before ever placing the controller into

service.

Section 40 00-02-0716

2013-06-03 - 6 -

Page 11

Setting the Time/Date Clock

Setting up the clock is critical to many of the other functions of the EMS PRO. Use the following steps

to set the EMS PRO Clock. The clock includes the time (displayed in 24hr format), the date and the day

of the week.

1. Access the S numbers menu by pressing [Menu].

2. Use the [Up Arrow] and [Down Arrow] to scroll to the correct Entry Code (See Entry Code

Supplement for Entry Codes).

3. When the correct Entry Code is displayed, press [Enter] to access the S numbers menu.

NOTE: If the incorrect code is entered, “PASSWORD FAILURE” will appear on

the display. Press [Enter] and try again.

NOTE: (S1 - S6) are the S-Numbers used to set the clock. See the S number

section of this manual for details.

4. Press [Up Arrow] and [Down Arrow] to scroll through the S-Numbers.

5. Press [Enter] when displaying the correct S number to highlight the current setting.

6. Use the [Up Arrow] and [Down Arrow] to enter the correct setting in the S number.

7. Press [Enter] to un-highlight the value and to move to another S number.

8. Repeat steps 4 through 7 for each clock and date setting.

9. When setup is complete, exit the S Menu by pressing [Menu].

NOTE: The user must be out of the S or P number (un-highlighted) to exit the

menu.

NOTE: Accessing the S or P numbers to change any set point is done in the

same manner as above.

10. Verify the clock is set to the current time, date and day of the week.

Setting for Mechanical Engines

The EMS PRO Controller factory defaults are set to run on an ECU equipped engine. In order to set

the controller to work on a mechanical engine, follow the steps below:

1. Access the S numbers menu by pressing [Menu].

2. Use the [Up Arrow] and [Down Arrow] to scroll to the correct Entry Code (See Entry Code

Supplement for Entry Codes).

3. When the correct Entry Code is displayed, press [Enter] to access the S numbers menu.

NOTE: If the incorrect code is entered, “PASSWORD FAILURE” will appear on

the display. Press [Enter] and try again.

Section 40 00-02-0716

2013-06-03 - 7 -

Page 12

NOTE: (S7, 38 & 40) are the S-Numbers used to set the controller for a

mechanical engine. See the S number section of this manual for details.

4. Press the [Up Arrow] and [Down Arrow] until (S38) ENGINE TYPE is displayed, press [Enter]

to highlight the current setting.

5. Press the [Up Arrow] and [Down Arrow] until MECHANICAL is displayed, press [Enter] to un-

highlight the new setting.

6. Press the [Up Arrow] and [Down Arrow] until (S40) ENG THR TYPE is displayed, press

[Enter] to highlight the current setting.

7. Press the [Up Arrow] and [Down Arrow] until MECHANICAL is highlighted then press [Enter]

to un-highlight the new setting.

8. Press the [Up Arrow] and [Down Arrow] until (S7) SPEED CALIB is displayed, press [Enter]

to highlight the current setting.

9. Press the [Up Arrow] and [Down Arrow] to enter the number of teeth on the engine’s flywheel

ring gear and press [Enter] to un-highlight the new setting.

10. Exit the S Menu by pressing [Menu].

NOTE: For mechanical engine throttling, see the PCBA SHUNTS section of this

manual for details.

Start/Stop Settings

There are five start/stop types in S35: SINGLE CONTACT, FLOATS, MOMENTARY, TRANSDUCER,

LOCAL PB (GREEN AND RED PUSHBUTTONS).

Single Contact Start/Stop:

The Single Contact Start/Stop is when a remote contact closes and remains closed for auto start, and

re-opens for auto stop.

(2) Float Start/Stop:

The (2) Float Start/Stop is when both float contacts are closed for auto start, and both float contacts are

open for auto stop.

Momentary Start/Stop:

The Momentary Start/Stop is when a contact closes momentarily for auto start, and a second contact

closes momentarily for auto stop.

Transducer Start/Stop:

A transducer is used for auto throttling. There are set points, allowing the operator to enter the

appropriate values.

Local Pushbutton Start/Stop:

The Local Pushbutton Start/Stop is when the local panel mounted green and red pushbuttons are used

for auto start/stop.

Section 40 00-02-0716

2013-06-03 - 8 -

Page 13

Use the following steps to select the correct start/stop:

1. Access the S numbers menu by pressing [Menu].

2. Use the [Up Arrow] and [Down Arrow] to scroll to the correct Entry Code (See Entry Code

Supplement for Entry Codes).

3. When the correct Entry Code is displayed, press [Enter] to access the S numbers menu.

NOTE: If the incorrect code is entered, “PASSWORD FAILURE” will appear on

the display. Press [Enter] and try again.

NOTE: S35 is the S-Number used for the start/stop type. See the S number

section of this manual for details.

4. Press the [Up Arrow] and [Down Arrow] until (S35) START/STOP SELECT is displayed,

press [Enter] to highlight the current setting.

5. Press the [Up Arrow] and [Down Arrow] until the desired selection is displayed, press

[Enter] to un-highlight the new setting.

6. Exit the S Menu by pressing [Menu].

System Throttling Types

There are (3) throttling types in S37: MAX. RPM, TRANSDUCER, LOCAL THROTTLE.

Max. RPM:

The Engine is throttled to the max. rpm set point.

Transducer:

A transducer is used for auto throttling. There are set points, allowing the operator to enter the

appropriate values.

Local Throttle:

An external 0-5 vdc potentiometer is used for auto throttling. There are set points, allowing the operator

to enter the appropriate values.

Use the following steps to select the correct transducer type:

1. Access the S numbers menu by pressing [Menu].

2. Use the [Up Arrow] and [Down Arrow] to scroll to the correct Entry Code (See Entry Code

Supplement for Entry Codes).

3. When the correct Entry Code is displayed, press [Enter] to access the S numbers menu.

NOTE: If the incorrect code is entered, “PASSWORD FAILURE” will appear on

the display. Press [Enter] and try again.

Section 40 00-02-0716

2013-06-03 - 9 -

Page 14

NOTE: S36 is the S-Number used for the transducer type. See the S number

section of this manual for details.

4. Press the [Up Arrow] and [Down Arrow] until (S36) SYSTEM THROTTLE TYPE is

displayed, press [Enter] to highlight the current setting.

5. Press the [Up Arrow] and [Down Arrow] until the desired selection is displayed, press

[Enter] to un-highlight the new setting.

6. Exit the S Menu by pressing [Menu].

Transducer Types

There are (10) transducer types in S37: NONE -- PRESSURE CONTROL -- LEVEL CONTROL -TEMPERATURE CONTROL -- PRESSURE CONTROL / LEVEL DISPLAY -- LEVEL CONTROL /

PRESSURE DISPLAY -- PRESSURE DISPLAY -- LEVEL DISPLAY --PRESSURE CONTROL / FLOW

STOP -- PRESSURE CONTROL / FLOW STOP & THROTTLE. Below are the step-by-step instructions

to set up these options.

None:

There is no transducer wired to the controller.

Pressure Control:

Pressure start/stop and throttling.

Level Control:

Level start/stop and throttling.

Temperature Control:

Temperature start/stop. Throttling to the maximum rpm set point will occur.

Pressure Control / Level Display:

Pressure start/stop, throttling, and level displayed with high and low alarms.

Level Control / Pressure Display:

Level start/stop, throttling, and pressure displayed with high and low shutdowns.

Pressure Display:

Pressure is displayed with high and low shutdowns.

Level Display:

Level is displayed with high and low alarm.

Pressure Control / Flow Stop:

Pressure start, throttling, and flow stop.

Pressure Control / Flow Stop & Throttle:

Pressure start, flow stop, and flow throttling.

Section 40 00-02-0716

2013-06-03 - 10 -

Page 15

Use the following steps to select the correct transducer type:

1. Access the S numbers menu by pressing [Menu].

2. Use the [Up Arrow] and [Down Arrow] to scroll to the correct Entry Code (See Entry

Code Supplement for Entry Codes).

3. When the correct Entry Code is displayed, press [Enter] to access the S numbers menu.

NOTE: If the incorrect code is entered, “PASSWORD FAILURE” will appear on

the display. Press [Enter] and try again.

NOTE: S37 is the S-Number used for the transducer type. See the S number

section of this manual for details.

4. Press the [Up Arrow] and [Down Arrow] until (S37) XDUCER TYPE is displayed, press

[Enter] to highlight the current setting.

5. Press the [Up Arrow] and [Down Arrow] until the desired selection is displayed, press

[Enter] to un-highlight the new setting.

6. Exit the S Menu by pressing [Menu].

Tier 4 Emissions

The Tier 4 Emissions set up allows users of the EMS PRO to use it on an Interim Tier 4 engine. The

controller displays the SOOT level when the engine has been de-rated and/or when regeneration

(regen) is required to return to normal service on the front display.

NOTE: Please read and understand S84 (Request DPF Regen) found in the Snumber table.

• If the regen is selected, the ECU will perform a regen automatically.

• If a regen is requested, the controller will command the ECU to perform a

regen. This feature will only occur if ECU conditions allow.

• If Inhibit Regen is selected, no regen occurs.

To use the controller on a Tier 4 engine, follow the steps below:

1. Access the S Menu by pressing [Menu]

2. Press the [Up Arrow] and [Down Arrow] to scroll to the correct Entry Code (See Entry Code

Supplement for Entry Codes).

3. Press the [Up Arrow] and [Down Arrow] until (S82) TIER RATING is displayed in the menu

and press [Enter].

4. Press the [Up Arrow] and [Down Arrow] until TIER 4 is highlighted and press [Enter].

5. Press the [Up Arrow] and [Down Arrow] until (S83) TIER4 STATE and press [Enter].button.

The default value is set to AUTO. If you want the engine state to be in INHIBIT DPF REGEN

use the [Up Arrow] and [Down Arrow] to highlight the text and press [Enter].

6. To set the Diesel Particulate Filter (DPF) Regeneration follow the steps below:

NOTE: If all conditions for a regen to occur are not met, this request could be

ignored by the ECU.

a. Access the S Menu by pressing [Menu]

b. Press the [Up Arrow] and [Down Arrow] to scroll to the correct Entry Code (See Entry

Code Supplement for Entry Codes).

Section 40 00-02-0716

2013-06-03 - 11 -

Page 16

c. Press the [Up Arrow] and [Down Arrow] until (S84) AUTO DPF REGEN is displayed in

the menu and press [Enter].

d. Press the [Up Arrow] until YES is highlighted and press [Enter].

NOTE: S84 is only available if S83”TIER 4 RATING” is set to 4, S38

“ENGINE TYPE” is set to ECU, the engine RPM is above S23 “CRANK

STOP RPM”, and the ECU output (Output 1) is on.

NOTE: Once the regen has started, this menu must continue to be

displayed until the regen is complete and NO is displayed on the menu.

e. Press [Menu] to exit the S Menu.

7. The following TIER 4 alarms will appear on the alarm line. Icons are displayed on the ECU 4 up

temporarily replacing ECU running hours, Load% and Fuel rate:

a. REGEN NEEDED LOW. (Status message based on Particulate Filter spn 3701)

b. REGEN NEEDED MEDIUM. (Status message based on Particulate Filter spn 3701)

c. REGEN NEEDED HIGH. (Status message based on Particulate Filter spn 3701)

d. REGEN NEEDED (Status message based on Particulate Filter spn 3697 with steady

and flashing ICON).

e. EXHAUST HIGH TEMP. (Based on spn 3698 with steady ICON).

f. REGEN INHIBIT (Status message based on spn 3703 with Steady ICON).

Unit System – Metric or English

This setting allows the user to change the default units from English units (PSI and °F) to Metric units

(KPA & °C). Use the following steps to change the units:

1. Access the S Menu by pressing [Menu]

2. Press the [Up Arrow] and [Down Arrow] to scroll to the correct Entry Code (See Entry Code

Supplement for Entry Codes).

3. Press the [Up Arrow] and [Down Arrow] until (S81) UNIT SYSTEM is displayed in the menu

and press [Enter].

4. Press the [Up Arrow] and [Down Arrow] until METRIC is highlighted and press [Enter].

5. Press [Menu] to exit the S Menu.

Operational Directions

AUTO Start/Stop Sequence

The following choices are available in the “start/stop type” S Number:

• Single Contact: A remote contact closes to start and re-opens to stop.

• Floats (2 contacts): Both contacts close for start and both contacts re-open for stop.

• Momentary (2 contacts): One contact momentarily closes for start; one contact momentarily

closes for stop.

Section 40 00-02-0716

2013-06-03 - 12 -

Page 17

• Transducer: Starting and stopping is controlled by S Number set points. System pressure,

level, and temperature are available in the “transducer type” S Number.

NOTE: SCADA START. If the engine is not already running, an auto start can be

accomplished through the Modbus start/stop register. This feature does not

function if the engine is already running from one of the above conditions. If the

engine is running, and the actual start condition is not present, an auto stop will

occur if the start/stop register is “toggled” to “1” then back to “0”.

Start Sequence

• When the AUTO - OFF- MAN key switch is in the “AUTO" position (with no failures present), the

SELECTOR text line displays “AUTO” and the text line STATE displays “PANEL READY”.

NOTE: When the key is turned to the AUTO position, and ECU is selected for

engine type, the ECU enable output will turn ON for a period of 30 minutes prior

to the engine starting. After this 30 minute period of inactivity, the output will

become inactive. This delay will not prevent an auto start sequence from

occurring. The following shutdown/alarm circuits are armed:

1. LOW FUEL ALARM Self-clearing alarm if set point is above 0%.

• When a start condition occurs, the controller initiates an auto start sequence. The SELECTOR: text

line will display start type while the STATE: text line will display “START DELAY”:

The start condition must remain active throughout the start delay, or the delay will reset to

zero.

• When the “START DELAY” expires, the following will occur:

The STATE: text line will display “PRESTART DELAY”.

The “prestart delay” begins timing.

The prestart output turns ON.

• When the “PRESTART DELAY” expires, the following will occur:

The following shutdown circuits are armed:

- LOW COOLANT LEVEL.

- HIGH / LOW OIL LEVEL.

- HIGH DISCHARGE PRESSURE.

- OVERSPEED.

- OVERCRANK.

- PUMP LOW OIL LEVEL.

- PUMP HIGH OIL TEMPERATURE.

- PUMP HIGH HOUSING TEMPERATURE. (N.C. opens for fault)

- XDUCER OOR (OUT OF RANGE) HIGH (Only if float backup not selected)

- XDUCER OOR (OUT OF RANGE) LOW (Only if float backup not selected)

- HIGH SYSTEM LEVEL (Self-clearing alarm or shutdown)

- LO SYSTEM LEVEL (Self-clearing alarm or shutdown)

- Auxiliary 1 (configurable)

- Auxiliary 2 (configurable)

- Auxiliary 3 (configurable)

The ECU output is turned on.

Section 40 00-02-0716

2013-06-03 - 13 -

Page 18

NOTE: WAIT FOR ECU is displayed if ECU is selected in engine type.

This is a fixed 10 second delay to allow the ECU to warm up prior to cranking.

• When the “WAIT FOR ECU” delay expires, the following will occur:

The STATE: text line will display “CRANK ON/OFF”.

NOTE: A NO SPEED SIGNAL shutdown will occur (when enabled) if the

controller does not read a frequency within 3 seconds after cranking begins.

The Alt excite output is turned ON.

The crank output is turned ON and cycle cranking begins at this point for all engine types.

NOTE: CYCLE CRANKING. If the engine does not start on the first crank, the

controller will de-energize the starter output for the rest cycle.

NOTE: OVERCRANK. If the engine fails to start after the number of cranking

attempts is exceeded, OVERCRANK will be indicated on the display. The auto

start sequence will be stopped, requiring manual reset of the controller. The

controller is reset by moving the panel key switch to the "OFF" position.

• When the engine speed rises above the crank stop set point, the following will occur:

The STATE: text line will display “WARMUP”.

The “warm-up delay” begins timing.

The crank output is turned OFF.

The prestart output is turned OFF.

The internal hourmeter begins recording engine run hours.

The engine is throttled to the “WARMUP RPM” set point.

NOTE: If “mechanical” is selected as the engine type, the AT03069 throttle

actuator will throttle the engine. If “electronic” is selected, the ECU throttling is

determined by what is selected in the in the “ECU THROTTLE TYPE”.

The “shutdown lockout” delay begins timing. When this delay expires, the following

shutdown/alarms are armed:

- LOW OIL PRESSURE.

- HIGH ENGINE TEMPERATURE.

- LOSS OF SPEED.

- ALT FAIL/LOW BAT. Self-clearing alarm.

NOTE: If the engine speed drops below the “crank stop” set point before the

“shutdown lockout” delay expires, the “re-crank” delay begins timing. When this

delay expires, cycle cranking will resume.

Section 40 00-02-0716

2013-06-03 - 14 -

Page 19

NOTE: If the engine speed drops below the “crank stop” set point after the

“shutdown lockout” delay expires, the engine will be shutdown on LOSS OF

SPEED.

NOTE: If “electronic” is selected for” engine type”, the ECU will control and arm

the shutdowns. The exceptions are any shutdowns external to the ECU, in which

case the controller will arm and shutdown as necessary.

• When the “warm-up delay” expires, the following will occur:

The clutch output is turned ON when the engine speed reaches the “clutch engage” RPM

set point.

The STATE: Text line will display “FILL MODE”.

The “fill mode” delay begins timing, and the engine is throttled to and remains at the

“minimum RPM” set point.

The “at load” delay begins timing.

• When the “fill mode” delay expires the following will occur:

The engine is released to auto throttle determined by what is selected in the “system throttle

type”.

The STATE: text line will display “AT LOAD”.

• When the “at load” delay expires the following will occur:

The LOW DISCHARGE PRESSURE shutdown is armed (if selected).

Stop Sequence

• When a stop condition occurs, the controller will initiate an auto stop sequence.

The STATE: text line will display “STOP DELAY”.

The stop condition must remain active throughout the stop delay, or the delay will reset to

zero.

• When the “stop delay” expires, the following will occur:

The SELECTOR: text line will display “AUTO” and the STATE: text line will display

“COOLDOWN”.

The engine is throttled to the cooldown RPM set point.

The clutch output is turned OFF when the engine speed drops to the “clutch disengage”

RPM set point.

The “low discharge pressure” shutdown is ignored.

• When the “cooldown delay” expires, the following will occur:

The SELECTOR: text line will display “AUTO” and the STATE: text line will display “PANEL

READY”.

The Fuel Output/ECU enable is turned OFF.

The Alt excite output is turned OFF.

The internal hour meter stops recording engine run hours.

All shutdowns are ignored.

Section 40 00-02-0716

2013-06-03 - 15 -

Page 20

Controller will “Go to Sleep” after 30 minutes of inactivity once engine has shutdown to

conserve battery life. The controller will awake once any key is pressed or input is enabled.

(This is Standby Mode)

The controller is now waiting and ready for another start sequence to occur.

Manual Start/Stop Sequence

There is only one start option in the manual mode.

Start Sequence

• When the user places the AUTO - OFF- MAN key switch in the “MAN" position, with no failures

present, the SELECTOR: text line will display “MAN”. The text line STATE: will display “PANEL

READY”.

• When the key is turned to the MAN position and ECU is selected for engine type, the ECU enable

output turns ON for a period of 30 minutes prior to the engine starting. After this 30 minute period of

inactivity, the output becomes inactive. This has no affect on the start sequence if Mechanical is

selected as the engine type.

A. The following shutdown/alarm circuits are armed:

1. LOW FUEL ALARM Self-clearing alarm if set point is above 0%.

• To achieve a start condition, press the green start key. This will initiate the “prestart delay” after the

start key is pressed, the following will occur:

The STATE: text line will display “PRESTART DELAY”.

The “prestart delay” begins timing.

The prestart output turns ON.

• When the “PRESTART DELAY” expires, the following will occur:

The following shutdown circuits are armed:

- LOW COOLANT LEVEL.

- HIGH / LOW OIL LEVEL.

- HIGH DISCHARGE PRESSURE.

- OVERSPEED.

- OVERCRANK.

- PUMP LOW OIL LEVEL.

- PUMP HIGH OIL TEMPERATURE.

- PUMP HIGH HOUSING TEMPERATURE. (N.C. opens for fault)

- XDUCER OOR (OUT OF RANGE) HIGH (Only if float backup not selected)

- XDUCER OOR (OUT OF RANGE) LOW (Only if float backup not selected)

- HIGH SYSTEM LEVEL (Self-clearing alarm or shutdown)

- LO SYSTEM LEVEL (Self-clearing alarm or shutdown)

- Auxiliary 1 (configurable)

- Auxiliary 2 (configurable)

- Auxiliary 3 (configurable)

The ECU output is turned on.

Section 40 00-02-0716

2013-06-03 - 16 -

Page 21

NOTE: WAIT FOR ECU is displayed if ECU is selected in engine type.

This is a fixed 10 second delay to allow the ECU to warm up prior to cranking.

• When the “WAIT FOR ECU” delay expires, the following will occur:

The STATE: text line will display “CRANK ON/OFF”.

NOTE: A NO SPEED SIGNAL shutdown will occur (when enabled) if the

controller does not read a frequency within 3 seconds after cranking begins.

The Alt excite output is turned ON.

The crank output is turned ON and cycle cranking begins at this point for all engine types.

NOTE: CYCLE CRANKING. If the engine does not start on the first crank, the

controller will de-energize the starter output for the rest cycle.

NOTE: OVERCRANK. If the engine fails to start after the number of cranking

attempts is exceeded, OVERCRANK will be indicated on the display. The auto

start sequence will be stopped, requiring manual reset of the controller. The

controller is reset by moving the panel key switch to the "OFF" position.

• When the engine speed rises above the crank stop set point, the following will occur:

The STATE: text line will display “AT LOAD”.

The “shutdown lockout” delay begins timing. When this delay expires, the following

shutdowns/alarms are armed:

- LOW OIL PRESSURE.

- HIGH ENGINE TEMPERATURE.

- LOSS OF SPEED.

- ALT FAIL / LOW BAT. Self-clearing alarm.

The “at load” delay begins timing. When this delay expires, the following shutdowns/alarms

are armed:

- LOW DISCHARGE PRESSURE.

Throttling is done using the panel mounted hare and tortoise buttons.

Stop Sequence

• When the red stop key is pressed, the following will occur:

The SELECTOR: text line will display “MAN” and the STATE: text line will display

“COOLDOWN”.

The engine is throttled to a cooldown RPM set point by the operator.

Section 40 00-02-0716

2013-06-03 - 17 -

Page 22

NOTE: If the user does not manually throttle down the engine, it will not idle

down in COOLDOWN before the engine is shut down.

The clutch output is turned OFF when the engine speed drops to the “clutch disengage”

RPM set point.

The “low discharge pressure” shutdown is ignored.

• When the “cooldown delay” expires, the following will occur:

The SELECTOR: text line will display “AUTO” and the STATE: text line will display “PANEL

READY”.

The fuel/ECU enable is turned OFF.

The Alt excite output is turned OFF.

The internal hourmeter stops recording engine run hours.

All shutdowns are ignored.

Controller will “Go to Sleep” after 30 minutes of inactivity once engine has shutdown to

conserve battery life. The controller will awake once any key is pressed or input is enabled.

(This is Standby Mode)

The controller is now waiting and ready for another start sequence to occur.

Special Features

Shutdown History

The Controller stores the last ten (10) shutdowns that have occurred due to system malfunctions. This

record can be found in the P-numbers with the date and time stamp of the shutdown. The Shutdown

history screen will also display the last 5 shutdowns.

Float Backup

• If the level transducer fails high or low, a shutdown will occur.

• If the float backup feature is enabled, a shutdown will not occur and the controller will start and stop

on floats.

• If the engine is already running, it will remain running until a float stop occurs. During backup float

operation, the engine is throttled to the maximum rpm set point.

NOTE: This feature remains in effect until the controller is reset, even if the transducer

comes back into range. The start/stop and throttle types will have to be set back to

TRANSDUCER to resume normal operation.

Clock Start

Regardless of the start/stop type selected, the controller will also start by selecting days and start / run

times in the P numbers. If the engine is already running from another condition, and the clock time

occurs, the clock start time is ignored.

Overspeed Shutdown

If an overspeed shutdown occurs, output 9 turns ON for 15 seconds to actuate the air damper.

Section 40 00-02-0716

2013-06-03 - 18 -

Page 23

S-Number

Description

S0

Manual ‘EXIT’ from the S-number setup mode. Press “menu to exit”

S1

Set Time Minutes. To adjust the minutes portion of the Real Time Clock.

S2

Set Time Hours. To adjust the hours portion of the Real Time Clock.

S3

Set Date Day. To adjust the day portion of the date display.

S4

Set Date Month. To adjust the month.

S5

Set Date Year. To adjust the year.

S6

Set Day of Week. Adjusts day of week Sunday through Saturday. Day advances with

date.

S7

SPEED CALIB: This setting is used to calibrate the speed signal so that the controller

nown RPM and then change the number until the top line

set to 120.

S8

OVERSPEED: This setting allows you to enter the highest speed the engine can run

before damage is caused. If the controller senses that the engine has exceeded this

speed, it will signal the engine to shutdown. Factory set to 2000.

S9

LOCKOUT DELAY: This delay is used to ignore conditions such as low oil pressure

Auxiliary I/O

The three auxiliary inputs control the three auxiliary outputs (1 to 1, 2 to 2, and 3 to 3). These are

configurable in the S numbers.

Standby Mode

Standby Mode will occur when the engine is not running and the controller has not seen any activity for

30 minutes. The standby mode will turn OFF the LCD backlight and heater while in this mode. Any

activity will take the controller out of standby mode into active or ready state (e.g. Start switch becomes

active or operator presses a key on the membrane).

Menus

S-Number Description and Listing

The S-numbers are used for customizing the controller to your specific application. Included in the Snumbers are the adjustable variables for the system. These S-Numbers must be set before trying to

use the controller. Following is a list of available S-Numbers and a short description of the function of

each. See Secret Code Supplement for the entry code number.

will display engine RPM. Simply enter the number of Pulses per revolution the magnetic

pickup or alternator supplies to the controller. Another way to set this variable is to get

the engine running at a k

matches your known RPM. The resulting number is the pulses per revolution. Factory

when the engine first starts to allow the pressure time to reach its normal operating range

(adjustable from 1 to 60 seconds). Factory set to 30.

Section 40 00-02-0716

2013-06-03 - 19 -

Page 24

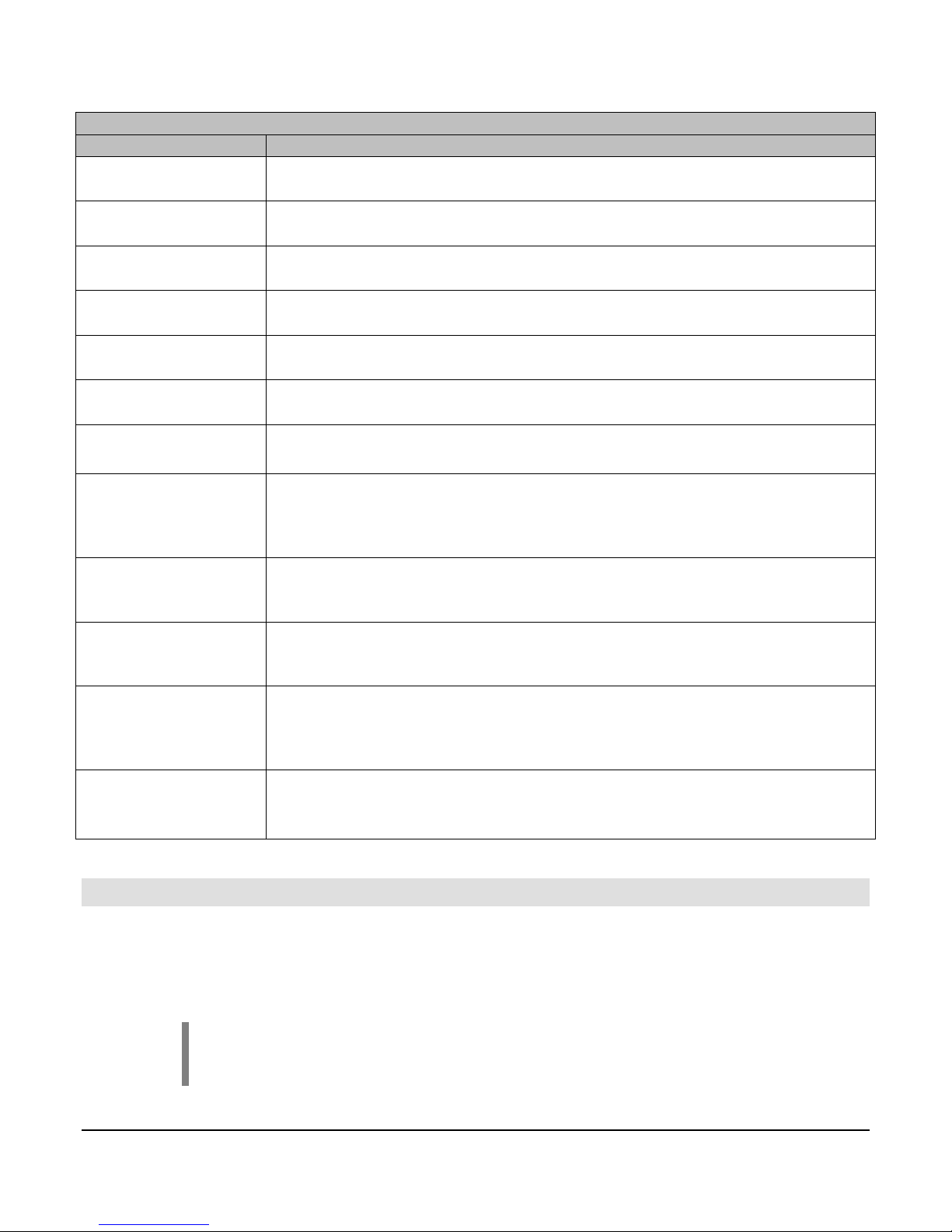

S-Number

Description

S10

LOP @ LOW SPD: The EMS PRO Controller gives you two oil pressure shutdown

point. The controller automatically changes the shutdown

Shutdown point.

S11

LOP @ HI SPD: This set point is the higher oil pressure shutdown point that is referred to

in LOP @ LOW SPD (S10) above. This is the point that you want the engine to

higher oil pressure, you can avert damage that could be caused by waiting to shut down

the engine at the lower set-point needed to accommodate an idle. Factory set to 30.

S12

LOP LO SPEED: Set this to your engine idle speed. If the engine is running at this

point selected in S10,

the controller will initiate an automatic shutdown. Factory set to 600.

S13

LOP HI SPEED: Set this to your engine maximum speed. If the engine is running at this

point selected in S11, the controller will

0

5

10

15

20

25

30

35

40

600 1200 1800 2400

point. As the engine speed increases, the controller automatically

S14

HI ENG TEMP: Adjust this setting to the engine jacket water temperature you do not

S15

LOW FUEL LEVEL ALARM: Enter in the fuel level that will cause a self-clearing alarm to

occur. This alarm is disabled when set to 0%.Factory set to 0%.

S16

LOW FUEL LEVEL SHUTDOWN: Enter in the fuel level that will cause a shutdown

alarm to occur. This shutdown is disabled when set to 0%.Factory set to 0%.

S17

ALT FAIL/LOW BAT: Enter in the alternator fail/low battery voltage alarm value that will

above this set point to clear. Factory set to 10.0 VDC.

S18

WARMUP DLY: You can adjust this variable to the number of seconds you want your

(adjustable from 1 to 9,999 seconds). Factory set to 180.

S19

COOLDOWN DLY: You can adjust this variable to the number of seconds you wish to

1 to 9,999 seconds). Factory set to 180.

points. For engines that develop very little oil pressure at an idle, you put a lower

shutdown setting in this set

point between the Low Speed Shutdown point and the High Speed

Factory set to 15.

shutdown during normal high speed engine operation. By shutting down the engine at a

speed, an idle for example, and the oil pressure reaches the set

speed, and the oil pressure reaches the setinitiate an automatic shutdown. Factory set to 1600.

The Graph above shows how the set point changes between your high speed set-point

and low speed set

raises the oil pressure shutdown set point along a straight line between the two set points

you entered.

want to exceed. If the controller senses a temperature higher than this set point, it will

initiate an automatic shutdown. Factory set to 220.

cause a self-clearing alarm to occur. When the alarm is active, it must increase 0.2 VDC

engine to warm-up before it engages the clutch and throttles up to an at load condition

Section 40 00-02-0716

2013-06-03 - 20 -

cool down your engine before it shuts OFF after a stop signal is received (adjustable from

Page 25

S-Number

Description

S20

CRANK TIME: Set this delay to the desired amount of time you want each engine

cranking attempt to last. Consult your engine manual for recommended cranking and

resting times (adjustable from 1 to 30 seconds). Factory set to 10.

S21

REST TIME: Set this delay to the desired amount of time you want each rest period

and cranking times (adjustable from 1 to 30 seconds). Factory set to 10

S22

RECRANK DELAY: This delay is used to adjust the amount of time the controller will

has expired (adjustable from 1 to 30 seconds). Factory set to 10.

S23

CRANK STOP RPM: This RPM set point is used to adjust where the controller releases

controller senses whether the engine is running or not. Factory set to 300.

S24

CRANK ATTEMPTS: Set the number of attempts you would like the controller to try an

reset. Factory set to 6.

S25

WARMUP RPM: This is the engine RPM the controller will throttle the engine to during

up speed.

S26

COOLDOWN RPM: This is the engine RPM the controller will throttle the engine to

S27

MIN ENG RPM: When throttling in the AT LOAD state, the engine will not throttle below

this set point. Factory set to 750.

S28

MAX ENG RPM: When throttling in the AT LOAD state, the engine will not throttle above

this set point. Factory set to 1600.

S29

RATE INC RPM: This set point is used to customize how fast or slow the controller will

throttling is achieved. (All engines) Factory set to 10.

S30

RATE DEC RPM: This set point is used to customize how fast or slow the controller will

throttling is achieved. (All engines) Factory set to 10.

S31

THR MIN PULS: This set point is used to further customize the way controller will throttle

the engine. Higher numbers will cause the throttling outputs to stay active for longer

periods of time when the system is throttling either up or down. If the engine is hunting

between cranking attempts to last. Consult your engine manual for recommended resting

wait for the engine to stop moving before attempting another crank if a false start occurs.

A false start is when the engine starts but then dies before the LOCKOUT DELAY (S9)

the starter during cranking. Set this to the RPM the engine attains just as it starts. This

way, the starter is not engaged unnecessarily after the engine starts. This is how the

engine start. If the engine fails to start after the number of attempts you have selected, it

will fail and display OVERCRANK on the front display. This shutdown requires a manual

warm-up in auto mode. Consult the engine manual for the optimum warmFactory set to 600.

during cooldown. Consult the engine manual for the optimum cooldown speed. Factory

set to 600.

increase the engine RPM while throttling. Experiment with this number until the proper

decrease the engine RPM while throttling. Experiment with this number until the proper

then lower the value. If the engine never reaches the set point then increase the value.

(Used with MECHANICAL engine throttle type S40). Factory set to 8400.

Section 40 00-02-0716

2013-06-03 - 21 -

Page 26

S-Number

Description

S32

THR FDBK DLY: This set point is used to adjust the amount of time the controller waits

to sample the change made by the previous throttle pulse. If the system pressure, for

takes a long time to change based on engine speed changes, this set point

reased. However, if the system pressure responds quickly then set the

S33

THR SENSITIVITY: This set point adjusts the throttle sensitivity when it closes in on the

Factory set to 700.

S34

SET ADJ DLY: This delay allows the controller to stop making adjustments to the engine

RPM for this delay. It allows for a settling time after making a speed adjustment

(adjustable from 1 to 999 seconds). (All engines) Factory set to 1.

S35

STRT/STP SEL: Enter the type of auto start/stop required: SINGLE CONTACT,

Factory set to SINGLE

S36

XDUCER TYPE: Enter the type of transducer being used. NONE, PRESSURE

CONTROL, LEVEL CONTROL, PRESSURE CONTROL/LEVEL DISPLAY, LEVEL

PRESSURE CONTROL/ FLOW STOP, PRESSURE CONTROL/FLOW STOP &

S37

SYS THR TYPE: Enter the type of system auto throttling required. MAXIMUM RPM,

TEMPERATURE CONTROL, the system throttle type will default to MAX RPM. Factory

S38

ENGINE TYPE: Enter ECU (electronic diesels), ECU/SENDER (electronic diesels that

S39

ECU HOUR SELECT: When set to “ECU-J1939” the hourmeter display will show data

, the hourmeter display will show the internal

example,

should be inc

variable to a smaller value. (Used with MECHANICAL engine throttle type S40) Factory

set to 2.

desired set point. Higher numbers cause it to make coarser signal adjustments when

approaching a set point than lower numbers. This set point is used to keep the controller

from overshooting and undershooting the set point. Lower the number if the controller is

hunting. Raise the value if the controller doesn’t achieve the desired set point. (Used

with MECHANICAL engine throttle type S40)

FLOATS, MOMENTARY, TRANSDUCER, LOCAL PB.

CONTACT.

When set to FLOATS:

• Empty: Wire one side of a N.O. low float to digital input 3. Wire one side of N.O. high float to

digital 4.

• Fill: Wire one side of N.C. low float to digital input 4. Wire one side of N.C. high float to digital

input 3. The opposite side of the contacts should be wired to common ground.

CONTROL/PRESSURE DISPLAY, PRESSURE DISPLAY, LEVEL DISPLAY,

THROTTLE. Factory set to NONE.

TRANSDUCER, or LOCAL THROTTLE. Note: If the XDUCER TYPE set point is set to

don’t broadcast oil pressure), MECHANICAL (non ecu engines). Factory set to ECU

from SPN247. If set to “SYSTEM”

hourmeter. Factory set to ECU-J1939. (Note: This display is only visible if “ENGINE

TYPE” (S38) is set to ECU. If S38 is set to MECHANICAL the hourmeter display will

default to the internal hourmeter.)

Section 40 00-02-0716

2013-06-03 - 22 -

Page 27

S-Number

Description

S40

ENG THR TYPE: Enter “MECHANICAL”, “J1939 (TSC1)” or “ANALOG” for the engine

throttle type. “MECHANICAL” uses digital outputs for throttling with both ECU and

.

(Note: When using

(JOHN DEERE ECU’S, IT IS

TSC1 FOR SPEED CONTROL)

S41

SENDER TYPES: This set point allows you to select between Murphy resistive sending

to MURPHY SENDER.

S42

START DLY: Set this delay on engine start to the number of seconds that the start signal

t be present before the controller accepts it and initiates an auto start sequence

(adjustable from 1 to 9,999 seconds). Factory set to 1.

S43

PRESTART DLY: The time the prestart output is turned ON prior to cranking the engine.

(adjustable from 1 to 9,999 seconds). Factory set to 1.

S44

STOP DLY: Set this delay on engine stop to the number of seconds that the stop signal

from 1 to 9,999 seconds). Factory set to 1.

S45

START PSI: When “pressure” is selected in the start / stop type, an auto start will occur

Factory set to 40.

S46

STOP PSI: When “pressure” is selected in the start / stop type, an auto stop will occur

0 to 1000 PSI)

Factory set to 60.

S47

MAINTAIN PSI: When “pressure” is selected in the throttle type, the engine will be

points to maintain this

pressure. (adjustable from -500 to 1000 PSI) Factory set to 50.

S48

DEADBAND PSI: When “pressure” is selected in the throttle type, no throttling will occur

while the pressure is in the deadband. This set point extends above and below the

S49

HI DISCH PSI: When “pressure” is selected in either the start / stop or throttle type, an

S50

LOW DISCH PSI: When “pressure” is selected in either the start / stop or throttle type, an

S51

AT LOAD DLY: This delay begins timing after the warm-up delay expires. The Low

9,999 seconds). Factory set to 180.

S52

FILL MODE DLY: This delay begins timing after the warm-up delay expires. The engine

9,999 seconds). Factory set to 0.

MECHANICAL engine types while “J1939” only works if “ECU” is selected in S38

ANALOG is reserved for future use. Factory Set to J1939.

MECHANICAL THR Type, refer to S29-S34 for setup.)

RECOMMENDED TO TURN OFF ALL OTHER THROTTLING OPTIONS WHEN USING

units or VDO resistive sending units for Pressure and Temperature senders. Factory set

mus

must be present before the controller accepts it and initiates a stop sequence (adjustable

when the discharge pressure drops to this set point. (adjustable from -500 to 5000 PSI)

when the discharge pressure rises to this set point. (adjustable from -50

throttled between the “minimum” and “maximum” rpm set

maintain set point. (adjustable from 0 to 50 PSI) Factory set to 2.

immediate shutdown will occur if the pressure rises to this set point. (adjustable from 500 to 1000 PSI) Factory set to 90.

immediate shutdown will occur if the pressure drops to this set point (adjustable from 500 to 1000 PSI) Factory set to 25.

Discharge Pressure shutdown is armed when this delay expires. (adjustable from 0 to

is held at the minimum RPM set point until this delay expires. (adjustable from -500 to

Section 40 00-02-0716

2013-06-03 - 23 -

Page 28

S-Number

Description

S53

PRESSURE MAX: Set this to the maximum value of the pressure transducer. For

PSI) Factory set to 100 PSI

S54

PRESSURE MIN: Set this to the minimum value of the pressure transducer. For

0 to 5000

S55

PSI XDUCER MAX CNT: With 5 VDC or 20mA. applied to the analog channel, make the

VDC, enter 1023 in this set point)

S56

PSI XDUCER MIN CNT: With 1 VDC or 4mA. applied to the analog channel, make the

VDC, enter 0 in this set point)

S57

START LEVEL: When “level” is selected in the start / stop type, an auto start will occur

to 15.0 FT.

S58

STOP LEVEL: When “level” is selected in the start / stop type, an auto stop will occur

to 5.0 FT.

S59

MAINTAIN LEVEL: When “level” is selected in the throttle type, the engine will be

throttled between the “minimum” and “maximum” rpm set points to maintain this level.

(adjustable from 0 to 100.0 FT) Factory set to 10.0 FT.

S60

DEADBAND LEVEL: When “level” is selected in the throttle type, no throttling will occur

set point. (adjustable from 0 to 100.0 FT) Factory set to 1.0 FT.

S61

LEVEL OFFSET: Enter in feet the distance from the bottom of the tank or sump to the

transducer. This value is added to the actual level reading. Factory set to 0.0

S62

LEVEL TYPE: Enter type of level control required. The choices are “Empty”, “Fill” or

S63

HIGH LEVEL: A self-clearing alarm will occur if the level reaches this setpoint. Factory

set to 20.0 FT.

S64

LOW LEVEL: A self-clearing alarm will occur if the level reaches this setpoint. Factory

set to 1.0 FT.

S65

LEVEL MAX: Set this to the maximum value of the level transducer. For example, if the

20 FT.

S66

LEVEL MIN: Set this to the minimum value of the level transducer. For example, if the

example, if the transducer range is 0-100 PSI, enter 100. (adjustable from -500 to 5000

example, if the transducer range is 0-100 PSI, enter 0. (adjustable from -50

PSI) Factory set to 0.

top line read the same value as the bottom line. Factory set to 904. (If transducer is 0-5

top line read the same value as the bottom line. Factory set to 181. (If transducer is 0-5

when the system level reaches this set point. (adjustable from 0 to 100.0 FT) Factory set

when the system level reaches this set point. (adjustable from 0 to 100.0 FT) Factory set

while the level is in the deadband. This set point extends above and below the maintain

“Proportional”. Empty starts on high and stops on low. Fill starts on low and stops on

high. S57 and S58 should be set accordingly. Proportional throttling is dedicated to

EMPTY. The engine is throttled to the maximum rpm setpoint if the level is at or above

the start level. As the level drops, the engine will be throttled down proportionally. When

the level drops to the stop setpoint, the engine will be at the minimum rpm setpoint, and

an auto stop will occur. Factory set to Empty.

NOTE: This setpoint does not apply to FLOATS.

transducer range is 0-10.0 FT, enter 10.0. (adjustable from 0 to 100 FT) Factory set to

transducer range is 0-10.0 FT, enter 0. (adjustable from 0 to 100 FT) Factory set to 0.

Section 40 00-02-0716

2013-06-03 - 24 -

Page 29

S-Number

Description

S67

LVL CNT MAX: With 5 VDC or 20mA applied to the analog channel, make the top line

enter 1023 in this set point)

S68

LVL CNT MIN: With 1 VDC or 4mA. Applied to the analog channel, make the top line

S69

LVL XDCR OOR HI: When “level” is selected in the start / stop or throttle type, and “No”

ble if the

S70

LVL XDCR OOR LO: When “level” is selected in the start / stop or throttle type, and “No”

ble if the

S71

START TEMP: When transducer is selected in the start/stop type and “temp control” is

S72

STOP TEMP: When transducer is selected in the start/stop type and “temp control” is

S73

ENBL FLT BCKP: (Enable Float Backup) The choices are “YES” or “NO”:

S74

ENBL PVA20-A: Enter Yes if this oil pressure gauge will be on the RS485 port. Factory

set to NO.

S75

ENBL PVA20-B: Enter Yes if this water temperature gauge will be on the RS485 port.

Factory set to NO.

S76

ENBL PVA20-C-12: Enter Yes if this voltmeter (12vdc) will be on the RS485 port.

Factory set to NO.

S77

ENBL PVA20-C-24: Enter Yes if this voltmeter (24vdc) will be on the RS485 port.

Factory set to NO.

S78

ENABLE PVA20-T: Enter Yes if this tachometer will be on the RS485 port. Factory set

to NO.

S79

CLTCH ENG RPM: When the engine speed reaches this set point after the warm-up

delay has expired, the clutch output is turned ON. Factory set to 600.

S80

CLTCH DIS-ENG RPM: When the engine speed reaches this set point during the

cooldown delay, the clutch output is turned OFF. Factory set to 600.

read the same value as the bottom line. Factory set to 904. (If transducer is 0-5 VDC,

read the same value as the bottom line. Factory set to 181. (If transducer is 0-5 VDC,

enter 0 in this set point)

is selected in the float backup enable, a shutdown will occur if the transducer’s raw count

reaches this set point. Factory set to 1000. This feature is not availa

transducer is 0-5 VDC.

is selected in the float backup enable, a shutdown will occur if the transducer’s raw count

reaches this set point. Factory set to 100. This feature is not availa

transducer is 0-5 VDC.

selected in transducer type, an auto start will occur when the system temperature falls to

this set point (adjustable from 0 to 115°F). Factory set to 34°F.

selected in transducer type, an auto stop will occur when the system temperature rises to

this set point (adjustable from 0 to 115°F). Factory set to 38°F.

• “YES” will cause the float switches to take control of the system if the transducer

fails on OOR high or low.

• “NO” causes a shutdown if the transducer fails on OOR high or low.

During float backup operation, the controller will remain on float operation until the

controller is manually reset. Factory set to No.

Section 40 00-02-0716

2013-06-03 - 25 -

Page 30

S-Number

Description

S81

UNIT SYSTEM: Enter either Metric or English for displayed values. Factory set to

S82

TIER RATING: Enter either Tier3 or Tier4 for electronic engines. Factory set to Tier3.

S83

TIER4 STATE: Select the Regen option that best suits the application. The options to

Factory set to INHIBIT DPF

S84

REQUEST DPF REGEN: Selecting YES will initiate a regen. After pushing the “yes”

. Allow the

S85

AUX 1 TYPE CONFIG: Enter N.C or N.O. for auxiliary switch 1. Factory set to N.O.

S86

AUX 2 TYPE CONFIG: Enter N.C or N.O. for auxiliary switch 2. Factory set to N.O.

S87

AUX 3 TYPE CONFIG: Enter N.C or N.O. for auxiliary switch 3. Factory set to N.O.

S88

AUX 1 DELAY: Auxiliary 1 switch must remain active throughout this delay for auxiliary 1

. The delay will reset if the input is removed before the delay expires.

S89

AUX 2 DELAY: The Auxiliary 2 switch must remain active throughout this delay for

expires. (Adjustable from 1 to 9,999 seconds) Factory set to 1.

S90

AUX 3 DELAY: The Auxiliary 3 switch must remain active throughout this delay for

S91

S80 FUEL METRIC CONFIG. Enter “Liter/hr.” or “Imperial Gallon/hr. Factory set to

Liter/hr.

S92

S80 OIL PSI METRIC CONFIG. Enter “KPA” or “BAR Factory set to KPA.

S93

STOP FLOW: When “flow” is selected in S37, an auto stop will occur when the flow

S94

MAINTAIN FLOW: When “flow” is selected in S37, the engine will be throttled between

English.

choose are AUTO DPF REGEN or INHIBIT DPF REGEN.

REGEN.

NOTE: This option only available if TIER RATING (S82) is set to

Tier4.

button, the display will go from “no” to “yes” when the regen is complete

controller to return to “no” before exiting the S number. The controller will remain at this S

number until the regen is complete. Factory set to NO.

NOTE: This display is only available if S82”TIER 4 RATING” is set

to 4, S38 “ENGINE TYPE” is set to ECU, the engine RPM is above

S23 “CRANK STOP RPM”, and the ECU output (Output 1) is on.

output to turn ON

(Adjustable from 1 to 9,999 seconds) Factory set to 1.

Auxiliary 2 output to turn ON. The delay will reset if the input is removed before the delay

Auxiliary 3 output to turn ON. The delay will reset if the input is removed before the delay

expires. (Adjustable from 1 to 999,999 seconds) Factory set to 1.

drops to this set point. (adjustable from -500 to 10,000 GPM) Factory set to 1000 GPM.

Section 40 00-02-0716

2013-06-03 - 26 -

the “minimum” and “maximum” rpm set points to maintain this flow. (adjustable from -500

to 10,000 GPM) Factory set to 5000 GPM.

Page 31

S-Number

Description

S95

DEADBAND FLOW: When “flow” is selected in S37, no throttling will occur while the

(adjustable from -500 to 10,000 GPM) Factory set to 500 GPM.

S96

FLOW BYPASS DLY: This delay begins timing when an auto start condition is

when this delay expires. (adjustable from 0 to 9,999 seconds). Factory set to 180.

S97

FLOW BUBBLE TIMER: This delay begins timing when a flow stop condition occurs,

to 9,999 seconds).

Factory set to 30.

S98

FLOW MAX: Set this to the maximum value of the flow transducer. For example, if the

00 to 10,000

GPM) Factory set to 10,000 GPM.

S99

FLOW MIN: Set this to the minimum value of the flow transducer. For example, if the

S100

FLOW CNT MAX: With 5 VDC or 20mA applied to the analog channel, make the top line

S101

FLOW CNT MIN: With 1 VDC or 4mA. Applied to the analog channel, make the top line

S102

AUXILIARY 1 INPUT CONFIG. Enter; “Aux 1”, “Flow Switch”, “Pivot Shutdown”,

S103

AUXILIARY 2 INPUT CONFIG. Enter “Aux. 2”, ”System Flow”, “Pivot Shutdown”,

S104

AUXILIARY 3 INPUT CONFIG. Enter; “Aux 3”, “Pivot Shutdown”, “Vibration”, “Low

P-Number

Description

P0

Manual 'EXIT' from the S-number setup mode. Press " 'MENU' TO EXIT"

P1

SUN SELECT: Set this to YES if you want to start your engine on SUNDAY. Set it to

NO if you want to lock out the start time on this day. Factory set to NO.

P2

MON SELECT: Set this to YES if you want to start your engine on MONDAY. Set it to

NO if you want to lock out the start time on this day. Factory set to NO.

P3

TUE SELECT: Set this to YES if you want to start your engine on TUESDAY. Set it to

NO if you want to lock out the start time on this day. Factory set to NO.

P4

WED SELECT: Set this to YES if you want to start your engine on WEDNESDAY. Set

it to NO if you want to lock out the start time on this day. Factory set to NO.

flow is in the deadband. This set point extends above and below the maintain set point.

accepted by the controller. The Flow stop S93, and the external flow switch are armed

either by S93 or the external flow switch. The condition must remain throughout this

delay on every occurrence or the delay resets. (adjustable from 0

transducer range is 0 to 10,000 GPM, enter 10,000. (adjustable from -5

transducer range is 0 to 10,000 GPM, enter 0. (adjustable from -500 to 10,000 GPM)

Factory set to 0.

read the same value as the bottom line. Factory set to 904. (If transducer is 0-5 VDC,

enter 1023 in this set point)

read the same value as the bottom line. Factory set to 181. (If transducer is 0-5 VDC,

enter 0 in this set point)

“Vibration”, “Low Suction”, “Fuel Leak”, “Aux 1 Shutdown”. Factory set to Aux. 1.

“Vibration”, “Low Suction”, “Fuel Leak”, “Aux. 2 Shutdown”. Factory set to Aux. 2.

Suction”, “Fuel Leak”, “Aux. 3 Shutdown”, “Request Regen”. Factory set to Aux. 3.

P-Number Description and Listing

The EMS PRO Controller has P-numbers in addition to the S-numbers previously configured. These

are accessed in the same manner but using a different access code. See the Secret Code Supplement

for this code number.

Section 40 00-02-0716

2013-06-03 - 27 -

Page 32

P-Number

Description

P5

THUR SELECT: Set this to YES if you want to start your engine on THURSDAY. Set it

to NO if you want to lock out the start time on this day. Factory set to NO.

P6

FRI SELECT: Set this to YES if you want to start your engine on FRIDAY. Set it to NO

if you want to lock out the start time on this day. Factory set to NO.

P7

SAT SELECT: Set this to YES if you want to start your engine on SATURDAY. Set it

to NO if you want to lock out the start time on this day. Factory set to NO.

P8

CLCK A RUN TM: This set-point lets you set in the amount of time you would like your

.

Factory set to 0.0.

P9

CLCK A HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

P10

CLCK A MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P11

CLCK B RUN TM: This set-point lets you set in the amount of time you would like your

Factory set to 0.0.

P12

CLCK B HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

P13

CLCK B MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P14

CLCK C RUN TM: This set-point lets you set in the amount of time you would like your

Factory set to 0.0.

P15

CLCK C HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

P16

CLCK C MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P17

CLCK D RUN TM: This set-point lets you set in the amount of time you would like your

Factory set to 0.0.

P18

CLCK D HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

P19

CLCK D MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P20

CLCK E RUN TM: This set-point lets you set in the amount of time you would like your

Factory set to 0.0.

P21

CLCK E HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

engine to run on your first start time. You have 12 available start times per day (A – L)

format. For example, if you want to start in the 3 o'clock in the afternoon hour, set it to

example, if you want to start at 8:30 in the morning, you would adjust this until it read

engine to run on your first start time. You have 12 available start times per day (A – L).

format. For example, if you want to start in the 3 o'clock in the afternoon hour, set it to

example, if you want to start at 8:30 in the morning, you would adjust this until it read

engine to run on your first start time. You have 12 available start times per day (A – L).

format. For example, if you want to start in the 3 o'clock in the afternoon hour, set it to

example, if you want to start at 8:30 in the morning, you would adjust this until it read

engine to run on your first start time. You have 12 available start times per day (A – L).

format. For example, if you want to start in the 3 o'clock in the afternoon hour, set it to

example, if you want to start at 8:30 in the morning, you would adjust this until it read

engine to run on your first start time. You have 12 available start times per day (A – L).

format. For example, if you want to start in the 3 o'clock in the afternoon hour, set it to

Section 40 00-02-0716

2013-06-03 - 28 -

Page 33

P-Number

Description

P22

CLCK E MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P23

CLCK F RUN TM: This set-point lets you set in the amount of time you would like your

Factory set to 0.0.

P24

CLCK F HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

P25

CLCK F MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P26

CLCK G RUN TM: This set-point lets you set in the amount of time you would like your

Factory set to 0.0.

P27

CLCK G HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

P28

CLCK G MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P29

CLCK H RUN TM: This set-point lets you set in the amount of time you would like your

Factory set to 0.0.

P30

CLCK H HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

P31

CLCK H MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P32

CLCK I RUN TM: This set-point lets you set in the amount of time you would like your

Factory set to 0.0.

P33

CLCK I HR: This set-point lets you set the clock hour you would like to start in 24hr

15. Factory set to 00.

P34

CLCK I MIN: This set-point lets you set the clock minute you would like to start. For

30 in the minute portion Factory set to 00.

P35