Page 1

00-02-0251

02-27-08

Section 70

EG21 and EGS21 Series Electric Gage and Swichgage® Installation

for Pressure, Temperature, Fuel Level, Voltmeter and Ammeter

IMPORTANT NOTICE FOR ALL EG21 ELECTRIC GAGES AND EGS21 ELECTRIC

SWICHGAGES FOR 24VDC AND 32VDC APPLICATIONS

A change in the dial illumination circuit has made it necessary to change the external wiring harness.

If you use the incorrect wiring harness, irreparable damage will occur to the gage mechanism.

The table below lists correct wire harness assemblies for units by manufacturing date. For date code

R1 (January 1996) or earlier (Q12, Q11, etc.) the wire harness can be identified by P/N and by

BLACK shrink tubing on the YELLOW wire. For date code R1 (February 1996) and later (R3, R4,

etc.) the wire harness can be identified by P/N and by RED shrink tubing on the YELLOW wire.

Date Code R1 or Earlier Date Code R2 or Later

05004546

05004547

05004548

05004549

05004550

05004551

05004552

If dial illumination is NOT required, either wire harness can be used on any date code, if the YELLOW

wire is NOT connected.

05006166

05006167

05006168

05006169

05006170

05006171

05006172

Wire/Connector Assembly

NOTE:

EG21 Series gage and EGS21 Series Swichgage movement and illumination

require 12VDC to function. For 24 or 32 volt systems, voltage converters are built into the

electrical wire/connector assembly

and supplied with instrument.

Listed below are replacement part numbers for all wire/connector assemblies. Voltage converter included for 24

and 32 volt. Specify part number when ordering.

12 VDC 24 VDC 32 VDC

EG21P / T / F 05004506 05006166 (05004546)* 05006167 (05004547)*

EGS21P / T / F 05004507 05006168 (05004548)* 05006169 (05004549)*

EG21AM 05004505 05006170 (05004550)* 05006171 (05004551)*

EGS21AM 05004504 05006172 (05004552)*

EG21VM 05004508 05004508

EGS21VM 05004504 05004504

* For gages with date code R1 (January 1996) or earlier (Q12, Q11, etc.,) specify part number shown in parenthesis.

⎯

⎯

⎯

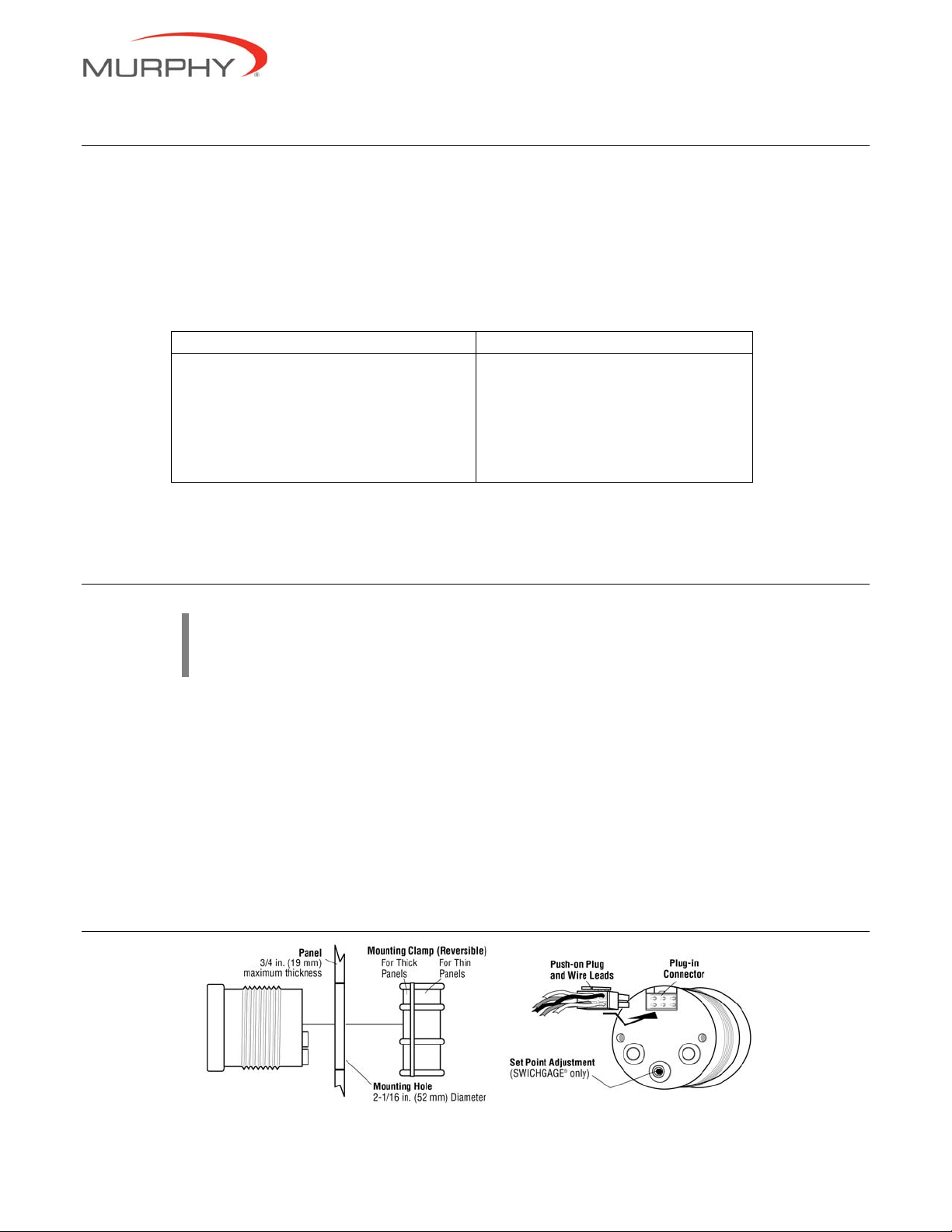

Gage Installation

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MURPHY, the Murphy logo, and Swichgage

matter and illustrations, is copyright protected by Murphy Industries, Inc., with all rights reserved. (c) 2008 Murphy Industries, Inc.

®

are registered and/or common law trademarks of Murphy Industries, Inc. This document, including textual

Page 2

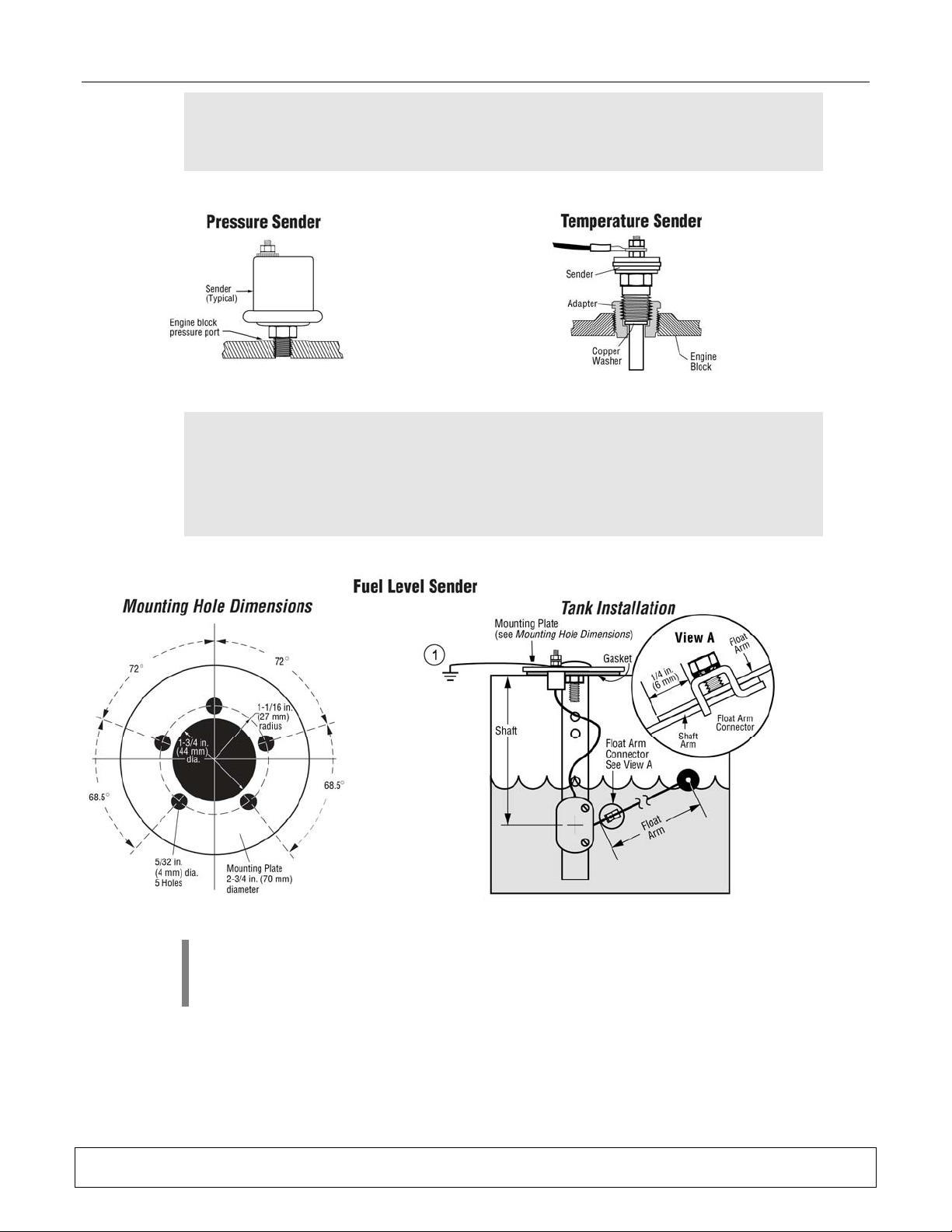

Sender Installation

CAUTION: Do not use sender body to tighten.

If sealant tape or pipe dope is used on the pressure sender, be sure

that the tape or dope does not plug the sender’s orifice.

Page 2 of 4.

CAUTION: Extreme caution must be used in handling or working on

or around the fuel tank. It must be worked on only in a WELL

VENTILATED area. Keep all flame and hot materials away from it.

Do not smoke while working on or around the tank. Avoid sliding or

dragging the tank, or other actions which may cause a spark.

NOTE:

another wire must be added from one of the sender mounting bolts to the battery ground

(negative post). See 1 in the ‘Tank Installation’ illustration above.

Warranty

may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

- A limited warranty on materials and workmanship is given with this FW Murphy product. A copy of the warranty

When installing the fuel sender in a non-metallic tank using a single wire sender,

Page 3

Basic Wiring

WARNING: Disconnect battery negative cable before wiring o r

service.

Sender Wiring

Page 3 of 4.

*Yellow wire is optional for gage illumination

and does not need to be connected for gage

to operate.

Swichgage Wiring

WARNING: DISCONNECT BATTERY NEGATIVE CABLE BEFORE

WIRING OR SERVICE.

CAUTION: Connecting full Battery potential to the brown wire can

damage the Swichgage. Shutdown circuit is rated for 300 mA

continuous, 900 mA inrush. Circuit rounds out at set point.

Warranty

may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

- A limited warranty on materials and workmanship is given with this FW Murphy product. A copy of the warranty

Page 4

Page 4 of 4.

CAUTION: Devices containing solid state components can be

damaged or caused to malfunction when used in systems which

incorporate inductive loads (e.g. relays, so le noid s, etc .) that can

generate voltage spikes.

To reduce the potential for this type of damage, instal l a flyback or

clamping diode across all inductive load s (see wir ing diagra m

below).

Use Murphy diode package 65-00-0343 or equiva lent . A typica l

diode is 1N4005 which is readily available from commercial

sources. Failures of this type are not covered by our Limited

Warranty.

Warranty

may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm

- A limited warranty on materials and workmanship is given with this FW Murphy product. A copy of the warranty

Loading...

Loading...