Page 1

DT-8605N

®

®

Gasket

123456 789101112

OPEN

0

1

2

3

6

9

4

5

7

8

0

1

2

3

6

9

4

5

7

8

0

1

2

3

6

9

4

5

7

8

Calibration Rocker

Switches

Overspeed

Switches**

Wiring

Terminals

**Applies to overspeed models only.

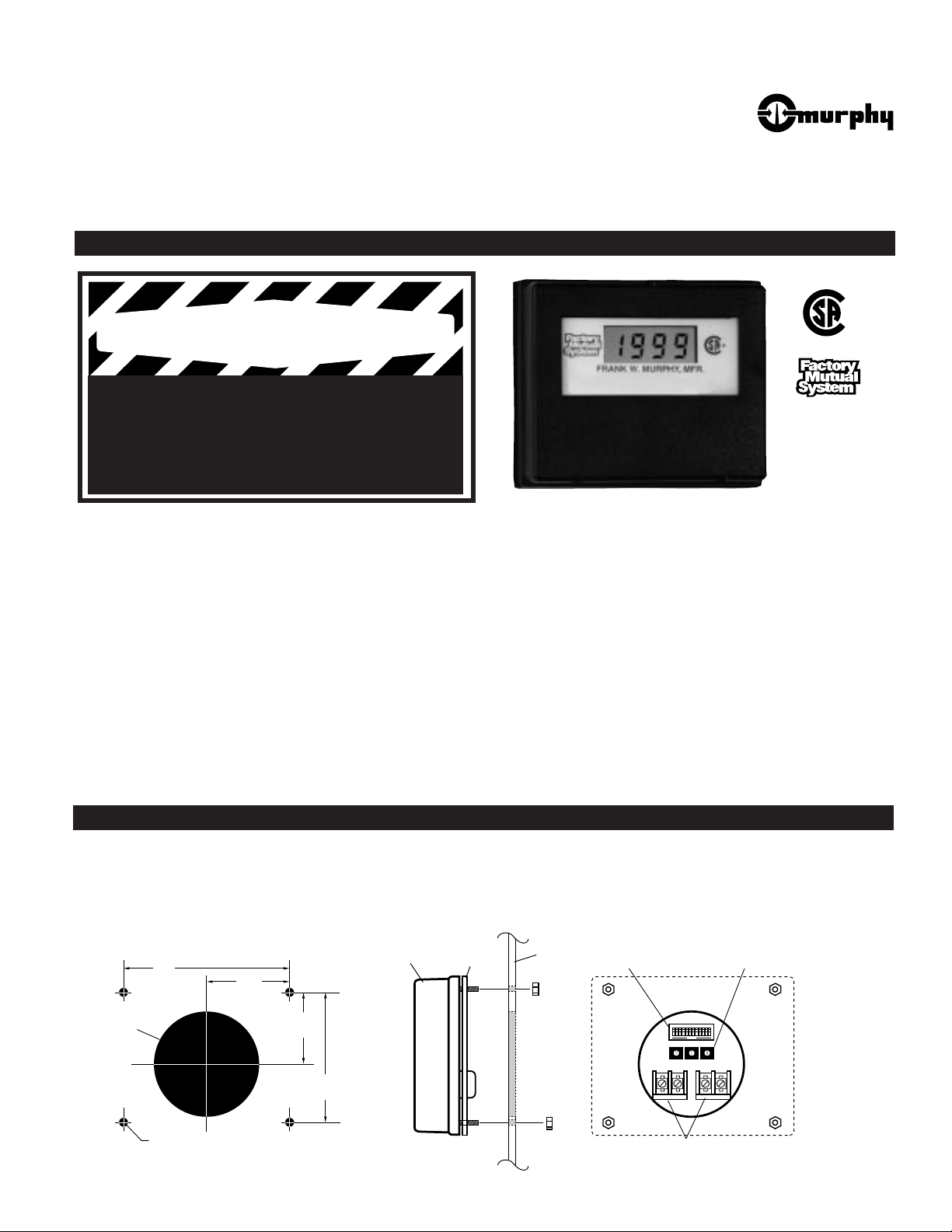

4 in.

(102 mm)

2 in.

(51 mm)

3-1/2 in.

(89 mm)

2 in.

(51 mm)

3/16 in (5 mm)

diameter, 4 places

3-1/8 in.

(79 mm)

diameter

Tachometer

Panel

Revised 07-97

SELECTRONIC®Digital Tachometer/TACHSWICH™

Section 20

(00-02-0180)

Installation Instructions

DT9800 Series

Please read the following information before installing. A visual inspection of this product for damage during shipping is

recommended before mounting. It is your responsibility to have a qualified person install this unit and make sure installation

conforms to NEC and local codes.

GENERAL INFORMATION

*

WARNING

*

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

Class I,

Division 2,

Group D

Description

The Digital SELECTRONIC®DT9800 series features a tachometer-only and

tachometer with built-in overspeed switch. These tachometers are highly

accurate and dependable due to digital solid-state electronics and a quartz

crystal time base. The surface-mount enclosure makes it easy to install.

Tachometer power and RPM data are supplied by a magnetic pickup or

capacitor discharge (CD) ignition–depending on model chosen. The RPM

data is converted and displayed on a four digit, easy-to-read liquid crystal

display (LCD). The LCD displays up to 9999 RPM.

The DT9803 and DT9804 are tachometer-only models. The DT9803 is

powered by a magnetic pickup. The DT9804 is powered by a CD ignition.

The TACHSWICH™ models, DT9805 and DT9806, combine a digital

tachometer and overspeed switch. The DT9805 is powered by a magnetic

pickup and the DT9806 is powered by a CD ignition.

MOUNTING

1. Before installing, b

calibration rocker switches and overspeed switches from the back of

the panel.

2. Drill mounting holes according to the dimensions below.

Mounting Hole Dimensions

e sure there will be enough clearance to access the

Specifications

Input Signal Source

DT9803: 18 to 112 volts peak to peak or 3.5 to 40 Vrms.

DT9805: 18 to 112 volts peak to peak or 7 to 40 Vrms.

DT9804 and DT9806: 90 to 400 VDC, CD ignition.

Temperature Range: -4 to 158°F (-20 to 70°C).

Accuracy: ±1 RPM.

Frequency Range:

DT9803 and DT9805: 1 to 15 KHz.

DT9804 and DT9806: 3 to 666 Hz.

Overspeed Switch Rating (DT9805 and DT9806 only):

SCR output. 5 A @ 400 VDC.

*

Class I, Div. 2, Group D Hazardous Locations. Models DT9803 and DT9805 magnetic pickup powered

18 to 112 Vpp input. Models DT9804 and DT9806 used with CD ignition. Contact Murphy for details.

The equipment must be installed in a suitable enclosure accepted by local authorities.

3. Be sure the gasket is in place on the back of the tachometer before

installing. Insert the tachometer from the front of the panel aligning the

mounting studs with the appropriate holes. Secure the tachometer using the

four 6/32 nuts, but do not overtighten the nuts as case damage could occur.

Back View

1

Page 2

1 G2 3

SW

ALT 2

ALT 1

GRD

Pressure Overspeed Level

123

12345678

45

To Negative Ground

CD Ignition

Adapter

Package

Emergency

Stop Switch

Frame

Ground

Connected to

Corresponding Numbers

On Terminal Block Below

307-PH-CD

TATTLETALE

®

Connect to

Good Engine

Ground

2 Conductor

Shielded Cable

Belden or

Equivalent

To Magnetic Pickup

NEG

POS

MPU OS

Back of

DT9805

SWICHGAGE

®

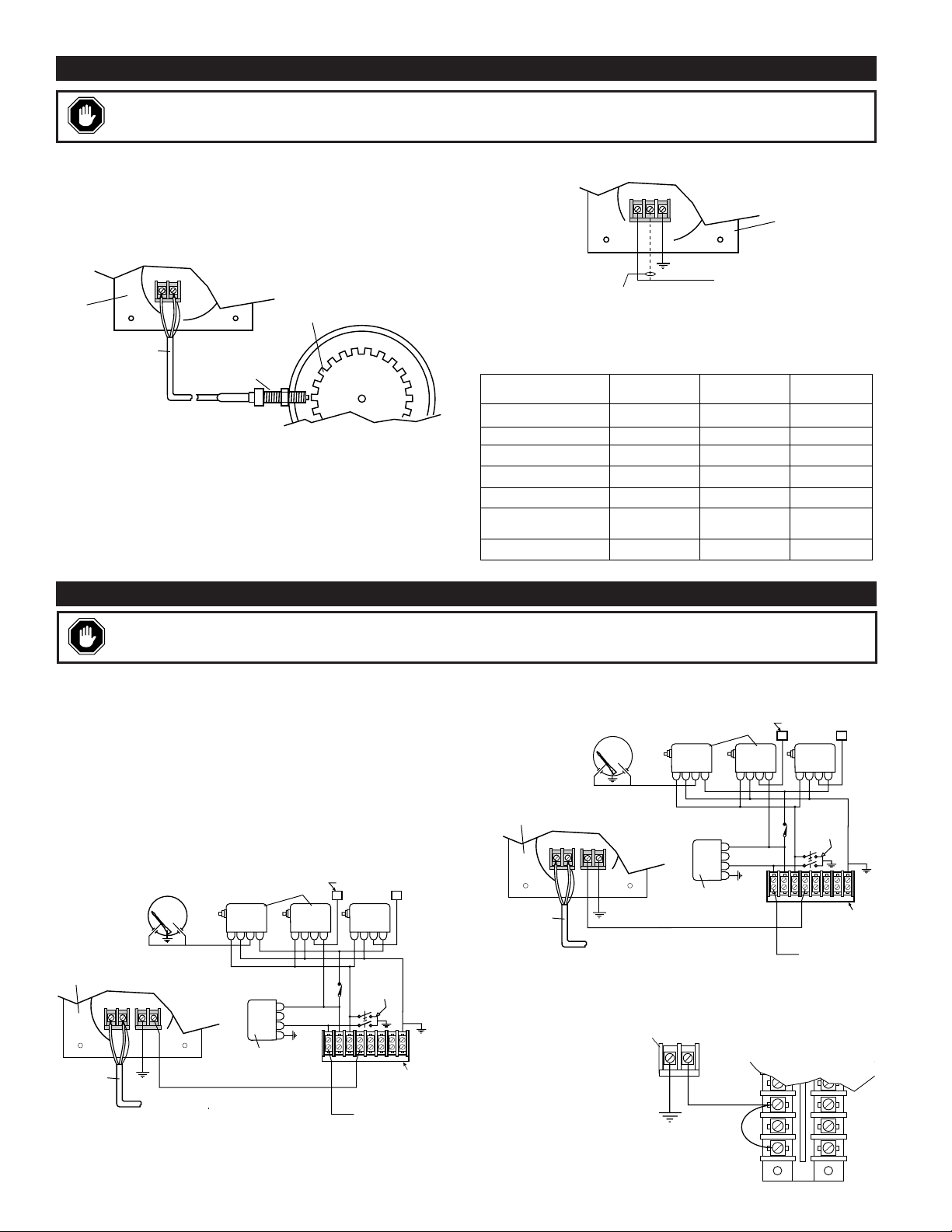

DT9803 AND DT9804 TYPICAL WIRING

1 G2 3

SW

ALT 2

ALT 1

GRD

Pressure Overspeed Level

123

12345678

45

To Positive Ground

CD Ignition

Adapter

Package

Emergency

Stop Switch

Frame

Ground

Connected to

Corresponding Numbers

On Terminal Block Below

307-PH-CD

TATTLETALE

®

Connect to

Good Engine

Ground

2 Conductor

Shielded Cable

Belden or

Equivalent

To Magnetic Pickup

POS

MPU OS

NEG

Back of

DT9805

SWICHGAGE

®

Magnetic Pickup

2 Conductor

Shielded Cable

Belden or

Equivalent

Back of

DT9803

Flywheel

MPU

Optional Connection for

150-400 V Ignitions

Negative Ground Ignition

90-150

NEG

150-400

Back of

DT9804

Ignition

MFG & Series

Ground

Polarity

Peak Output

Voltage

Use Figure

Altronic I, III, & V Negative 120 6

Altronic II Positive 350 7

Bendix S-1800, BLAR Negative 250 6

Bendix Side-winder Positive 300 7

Fairbanks Morse SCSA Positive 180 7

Fairbanks Morse

3000 & 9000

Negative 225 6

American Bosch Magtronic

Negative 165 6

WARNING

:

PERFORM THE WIRING INSTALLATION WITH THE POWER SOURCE OFF. DO NOT

ROUTE TACHOMETER LEADS WITH PRIMARY IGNITION WIRING.

DT9803

Connect the magnetic pickup cable conductors to the MPU terminal as

shown in Figure 1. Use a two conductor shielded cable between the

DT9803 and the magnetic pickup.

Figure 1:

DT9803 typical wiring

Table 1:

DT9804

Before wiring the DT9804, determine the output voltage and ground

polarity of the ignition. Table 1 lists the Peak Output Voltage and

Ground Polarity of some common ignitions.

Connect the DT9804 tachometer to the CD ignition. Figure 2 shows a

typical wiring diagram for negative ground ignition system.

Figure 2:

Output Voltage & Polarity of Common CD Ignitions

DT9804 typical wiring for negative ground ignition

DT9805 AND DT9806 TYPICAL WIRING

WARNING

:

PERFORM THE WIRING INSTALLATION WITH THE POWER SOURCE OFF.

DO NOT ROUTE TACHOMETER LEADS WITH PRIMARY IGNITION WIRING.

DT9805

1. Connect the magnetic pickup as shown in Figure 3 .

2. Connect the overspeed switch wiring as shown Figures 3 and 4.

Observe the polarity of the overspeed switch. The positive terminal

must be connected to the positive side of the circuit as shown.

3. If connecting to a Murphy LCDT annunciator refer to Figure 5. See

General Catalog for more information on the LCDT.

Figure 3:

2

DT9805 typical wiring for negative ground ignition

Figure 4:

Figure 5:

DT9805 and DT9806

DT9805 typical wiring for positive ground ignition

Overspeed

Switch Terminals

on DT9805 or DT9806

negative ground

connection to Murphy

LCDT (for positive ground

ignitions, reverse the

negative and positive wires

on the tachometer so that

the positive terminal is grounded.)

NEG

POS

46

50

Murphy LCDT

Annunciator

Terminal Block

Page 3

DT9806

1234 5 6789101112

OPEN

Pushed

“ON”

(closed)

Side View

Number of

Cylinders

Calibration Switch Code

123456 891011127

ONON

12

ON ON

22

ONON

24

ONON

42

ONON

44

ON

52

ON

54

ON

62

ON

64

ONON

82

ON ON

84

ONON

10 4

ON

12 4

ONON

16 4

ON ON

ONONON

ONONON

Number of

Cycles

ON

32

Before wiring the DT9806, determine the output voltage and ground

polarity of the ignition. Table 1 lists the Peak Output Voltage and Ground

Polarity of some common ignitions.

Figure 6 displays wiring to a negative ground ignition and Figure 7 for

positive ground units. If the ignition output voltage is 90-150 volts,

If connecting to a Murphy LCDT annunciator refer to Figure 5. See

General Catalog for more information on the LCDT.

NOTE: When installing the DT9806 in a Murphy panel, always connect

the DT9806 to the ignition/input side of the power adapter. If the DT9806

input is connected to the output of the adapter, its display will read zero

RPM, since the adapter filters out the ignition pulses.

connect the ignition lead to the 90-150 input terminal on the DT9806; if it

is 150-400 volts, then connect the lead to the 150-400 terminal.

Figure 6:

1. Locate the calibration switches on back of the unit (see page 1).

2. If calibrating the DT9804 and DT9806 advance to step 3. If calibrating

3. To set the calibration code on the DT9804 and DT9806, refer to Table 3.

NOTE: if the ignition system has two energy storage capacitors, count only

Table 2:

Number

of Gear

Teeth

250 2-3-5-6-7-8

249 1-2-3-5-6-7-8

248 4-5-6-7-8

247 1-4-5-6-7-8

246 2-4-5-6-7-8

245 1-2-4-5-6-7-8

244 3-4-5-6-7-8

243 1-3-4-5-6-7-8

242 2-3-4-5-6-7-8

241 1-2-3-4-5-6-7-8

240 9

239 1-9

238 2-9

237 1-2-9

236 3-9

235 1-3-9

234 1-2-3-9

233 4-9

232 1-4-9

231 2-4-9

230 1-2-4-9

229 3-4-9

228 1-3-4-9

227 1-2-3-4-9

226 5-9

DT9806 typical wiring for negative ground ignition

Figure 7:

CALIBRATING THE DT9800 SERIES TO YOUR ENGINE

150 2-4-5-8-9

149 3-4-5-8-9

148 1-2-3-4-5-8-9

the DT9803 and DT9805, find the number of teeth for your gear in

Table 2. Close the series of calibration switches listed next to the

number of gear teeth.

Calibration

Switches

DO NOT USE A PENCIL TO PUSH SWITCHES

Find the line that matches your engine's cylinders and cycles and set the

DT9804/DT9806 according to the switches marked “ON”.

half the actual number of engine cylinders for the calibration code.

DT9803 and DT9805 Calibration Chart

Close Switch

Number(s)

Number

Close Switch

of Gear

Number(s)

Teeth

225 1-5-9

224 2-5-9

223 3-5-9

222 1-3-5-9

221 2-3-5-9

220 2-3-5-9

219 1-4-5-9

218 2-4-5-9

217 1-2-4-5-9

216 3-4-5-9

215 2-3-4-5-9

214 1-2-3-4-5-9

213 6-9

212 2-6-9

211 1-2-6-9

210 1-3-6-9

209 2-3-6-9

208 1-2-3-6-9

207 1-4-6-9

206 2-4-6-9

205 3-4-6-9

204 1-3-4-6-9

203 1-2-3-4-6-9

202 5-6-9

201 2-5-6-9

Number

Close Switch

of Gear

Number(s)

Teeth

200 1-2-5-6-9

199 1-3-5-6-9

198 2-3-5-6-9

197 4-5-6-9

196 1-4-5-6-9

195 1-2-4-5-6-9

194 1-3-4-5-6-9

193 2-3-4-5-6-9

192 7-9

191 2-7-9

190 1-2-7-9

189 1-3-7-9

188 1-2-3-7-9

187 1-4-7-9

186 2-4-7-9

185 3-4-7-9

184 2-3-4-7-9

183 5-7-9

182 2-5-7-9

181 1-2-5-7-9

180 1-3-5-7-9

179 1-2-3-5-7-9

178 1-4-5-7-9

177 1-2-4-5-7-9

176 1-3-4-5-7-9

Number

Close Switch

of Gear

Number(s)

Teeth

175 1-2-3-4-5-7-9

174 1-6-7-9

173 1-2-6-7-9

172 1-3-6-7-9

171 1-2-3-6-7-9

170 1-4-6-7-9

169 3-4-6-7-9

168 2-3-4-6-7-9

167 5-6-7-9

166 2-5-6-7-9

165 3-5-6-7-9

164 1-2-3-5-6-7-9

163 1-4-5-6-7-9

162 1-2-4-5-6-7-9

161 2-3-4-5-6-7-9

160 8-9

159 2-8-9

158 1-3-8-9

157 1-2-3-8-9

156 2-4-8-9

155 3-4-8-9

154 1-2-3-4-8-9

153 1-5-8-9

152 3-5-8-9

151 1-2-3-5-8-9

147 2-6-8-9

146 1-3-6-8-9

145 4-6-8-9

144 1-2-4-6-8-9

143 2-3-4-6-8-9

142 1-5-6-8-9

141 3-5-6-8-9

140 1-2-3-5-6-8-9

139 2-4-5-6-8-9

138 1-3-4-5-6-8-9

137 7-8-9

136 3-7-8-9

135 1-2-3-7-8-9

134 1-2-4-7-8-9

133 2-3-4-7-8-9

132 1-5-7-8-9

131 1-3-5-7-8-9

130 1-4-5-7-8-9

129 3-4-5-7-8-9

128 6-7-8-9

127 3-6-7-8-9

126 4-6-7-8-9

125 3-4-6-7-8-9

124 1-2-3-4-6-7-8-9

123 3-5-6-7-8-9

122 4-5-6-7-8-9

121 3-4-5-6-7-8-9

Table 3:

Consult Murphy for Cylinder and Cycle combinations not listed on this table

DT9806 typical wiring for positive ground ignition

120 10

119 3-10

118 1-4-10

117 1-3-4-10

116 1-5-10

115 2-3-5-10

114 1-2-4-5-10

113 6-10

112 1-3-6-10

111 2-4-6-10

110 1-2-3-4-6-10

109 3-5-6-10

108 1-4-5-6-10

107 2-3-4-5-6-10

106 3-7-10

105 1-4-7-10

104 1-2-3-4-7-10

103 1-3-5-7-10

102 2-4-5-7-10

101 6-7-10

100 2-3-6-7-10

99 1-3-4-6-7-10

98 1-2-5-6-7-10

97 4-5-6-7-10

96 8-10

95 1-2-3-8-10

94 2-3-4-8-10

93 1-3-5-8-10

92 3-4-5-8-10

91 1-2-6-8-10

90 1-2-4-6-8-10

89 2-5-6-8-10

88 2-4-5-6-8-10

87 2-7-8-10

86 2-4-7-8-10

85 1-2-5-7-8-10

84 1-2-4-5-7-8-10

83 3-6-7-8-10

82 3-4-6-7-8-10

81 1-2-3-5-6-7-8-10

80 9-10

79 2-4-9-10

78 3-5-9-10

77 2-3-4-5-9-10

76 4-6-9-10

75 1-2-5-6-9-10

74 2-3-4-5-6-9-10

73 2-4-7-9-10

72 1-3-5-7-9-10

71 1-6-7-9-10

70 2-3-4-6-7-9-10

69 2-4-5-6-7-9-10

68 4-8-9-10

67 1-3-5-8-9-10

66 1-2-6-8-9-10

65 1-5-6-8-9-10

64 7-8-9-10

63 1-2-3-4-7-8-9-10

62 1-2-3-4-5-7-8-9-10

61 1-2-3-4-6-7-8-9-10

60 11

59 1-5-11

58 1-2-6-11

57 2-3-5-6-11

56 1-4-7-11

55 1-3-4-5-7-11

54 2-5-6-7-11

53 1-2-3-8-11

52 2-3-4-5-8-11

51 1-3-5-6-8-11

50 1-3-4-7-8-11

49 2-3-6-7-8-11

48 9-11

47 1-2-4-5-9-11

46 4-5-6-9-11

45 1-3-5-7-9-11

44 3-5-6-7-9-11

43 1-3-5-8-9-11

42 1-2-3-5-6-8-9-11

41 1-2-4-5-7-8-9-11

40 10-11

39 1-2-3-6-10-11

38 1-5-7-10-11

37 1-3-4-5-6-7-10-11

36 1-2-4-6-8-10-11

35 1-2-4-5-7-8-10-11

34 1-2-3-4-9-10-11

33 2-3-7-9-10-11

32 8-9-10-11

Calibration Code for DT9804 and DT9806

3

Page 4

0

1

2

3

6

9

4

5

7

8

0

1

2

3

6

9

4

5

7

8

0

1

2

3

6

9

4

5

7

8

X 1000 X 100 X 10

0

1

2

3

6

9

4

5

7

8

0

1

2

3

6

9

4

5

7

8

0

1

2

3

6

9

4

5

7

8

SETTING OVERSPEED SET POINTS: DT9805 AND DT9806

®

FRANK W.

MFR.

The overspeed set point switches are available on the DT9805 and

DT9806 only. The overspeed set point can be set within ± 5 RPM, over a

range of 0010 to 9990 RPM. Setting of the overspeed set points is made by

properly adjusting of three rotary switches. Each switch can be adjusted in

increments of ten. To set the switches perform the following:

1. Locate the three rotary switches on the back of the unit (Figure 8).

2. Insert a small blade screwdriver inside the arrow slot. Turn the

screwdriver until the arrow pointer is facing the number you choose.

EXAMPLE: You want the overspeed to trip at 1850 RPM (Figure 8):

(1) Rotate the X-1000-arrow to the (1),

(2) Rotate the X-100-arrow to the (8),

(3) Rotate the X-10-arrow to the five (5).

DT9804 AND DT9806 TROUBLESHOOTING

Figure 8:

Overspeed switch

set at 1850 RPM

If the DT9804 or DT9806 tachometer reading is incorrect or erratic follow

the steps below in order until the devices read properly.

1. Check for proper voltage for your ignition system (90-150).

2. Check all grounds, be sure they are good and tight.

3. Separate ignition wires from primary coil wires.

4. Check switches for correct settings according to the number of engine

cylinders. Where the ignition system has two storage capacitors, the

7. The common ground for the capacitor discharge ignition system coils

must be grounded to the engine block, preferably as close to each coil

as possible.

8. If the Murphy adaptor package is used make sure the tach is connected

to the input (ALT 1, ALT 2) not the output.

9. Calibration Check: Hook 110 VAC 60 Hz hot to the input 90-150 and

the neutral to the negative input. These readings are ±1 RPM.

tachometer must be set for half the number of engine cylinders.

DO NOT USE A PENCIL TO PUSH SWITCHES

.

5. Check reading on 110 VAC 60 Hz with all switches open or on 0. The

display should read all 0's. Also refer to the calibration chart in step 9.

6. The shutdown lead must be separated at least 12 in. (305 mm) from the

high-tension spark plug leads. The best practice is to run the shutdown

lead from the junction box to the panel in a separate conduit.

Warranty

A two-year limited warranty on materials and workmanship is given with this

Murphy product. Details are available on request and are packed with each unit.

Dip Switches On Reading

2, 4, 5 60

1, 5, 9 639

3, 6, 10 1284

2, 8, 11 2704

1, 7, 12 4951

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

■ Frank W. Murphy Manufacturer

P.O. Box 470248; Tulsa, Oklahoma 74147; USA

Since 1939

tel. (918) 627-3550 fax (918) 664-6146

e-mail fwmurphy@ionet.net

■ Frank W. Murphy Southern Division

P.O. Box 1819; Rosenberg, Texas 77471; USA

tel. (281) 342-0297 fax (281) 341-6006

e-mail murphysd@intertex.net

Printed in U.S.A.

4

■ Frank W. Murphy, Ltd.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

tel. +44 1722 410055 fax +44 1722 410088 tlx 477088

e-mail sales@fwmurphy.co.uk

■ Frank W. Murphy Pte., Ltd.

26 Siglap Drive; Republic of Singapore 456153

tel. +65 241-3166 fax +65 241-8382

e-mail fwmsales@fwmurphy.com.sg

■ Murphek Pty., Ltd.

1620 Hume Highway; Campbellfield, Vic 3061; Australia

tel. +61 3 9358-5555 fax +61 3 9358-5558

■ Murphy de México, S.A. de C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

tel. +52-48-206264 fax +52-48-206336

e-mail murmexsl@sanluis.podernet.com.mx

■ Murphy Switch of California

P.O. Box 900788; Palmdale, California 93590; USA

tel. (805) 272-4700 fax (805) 947-7570

e-mail sales@murphyswitch.com

■ Frank W. Murphy France

tel. +33 1 30 762626 fax +33 1 30 763989

056499

Loading...

Loading...