Page 1

DF-94063N page 1 of 4

Installation and Operation of the

DF Series Hydrostatic Head Level Switches

DF-94063N

Revised 09-03

Section 15

(00-02-0170)

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended before mounting. It is your responsibility to have a qualified person install this unit and make sure it conforms to NEC

and local codes.

GENERAL INFORMATION

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

*

**

CAUTION:

Certain dangers to human safety and to equipment may occur if some equipment is stopped without

pre-warning. It is recommended that monitored functions

be limited to alarm only or to alarm before shutdown.

Description

The DF series are diaphragm operated “hydrostatic head pressure”

level switches. A pressure sensitive diaphragm operates a snap-switch

that can be wired directly to electric pilot circuits to control pumps at

predetermined levels. Typical application is to start and stop electric

driven pump(s) to maintain tank levels. It is also applicable to engine

driven pumps.

The Nitrile sensing diaphragm is impervious to most liquids and is

sensitive enough to control levels with 1/4 in. (6 mm) repeatability.

See model descriptions for limits of switch trip point adjustability.

Materials include aluminum body, nylon bottom plate and a special

alloy leaf snap-switch as standard.

This simple level switch is highly reliable and can be worked into most

new or existing system without major modification or special tools.

DF755 and DF757 are suitable for atmospheric tanks in a non-hazardous location.

The SPDT snap-switch for the DF755 is preset for a 4 in. (102 mm)

differential in liquid level, operating at approx. 6 inches (152 mm) rising, and resetting at approx. 2 inches (51 mm) falling level.

The DF757 trip point is adjustable over a 108 inches (2743 mm) differential.

Specifications

Snap-switch Ratings

SPDT (standard–all models)

• 5 A @ 125, 250, or 480 VAC

• 1/2 A @ 125 VDC, 1/4 A @ 250 VDC

Case/Lid: Aluminum (standard); all non-explosion proof models.

Bottom Plate: Glass-filled nylon.

Process Connection: 1 NPT (standard)

Maximum Pressure Rating: 25 psi (172 kPa) [1.72 Bar].

Conduit Connection (electrical): 1/2 NPT.

Warranty

A limited warranty on materials and workmanship is given with this FW

Murphy product. A copy of the warranty may be viewed or printed by going

to www.fwmurphy.com/support/warranty.htm

WARNING

Page 2

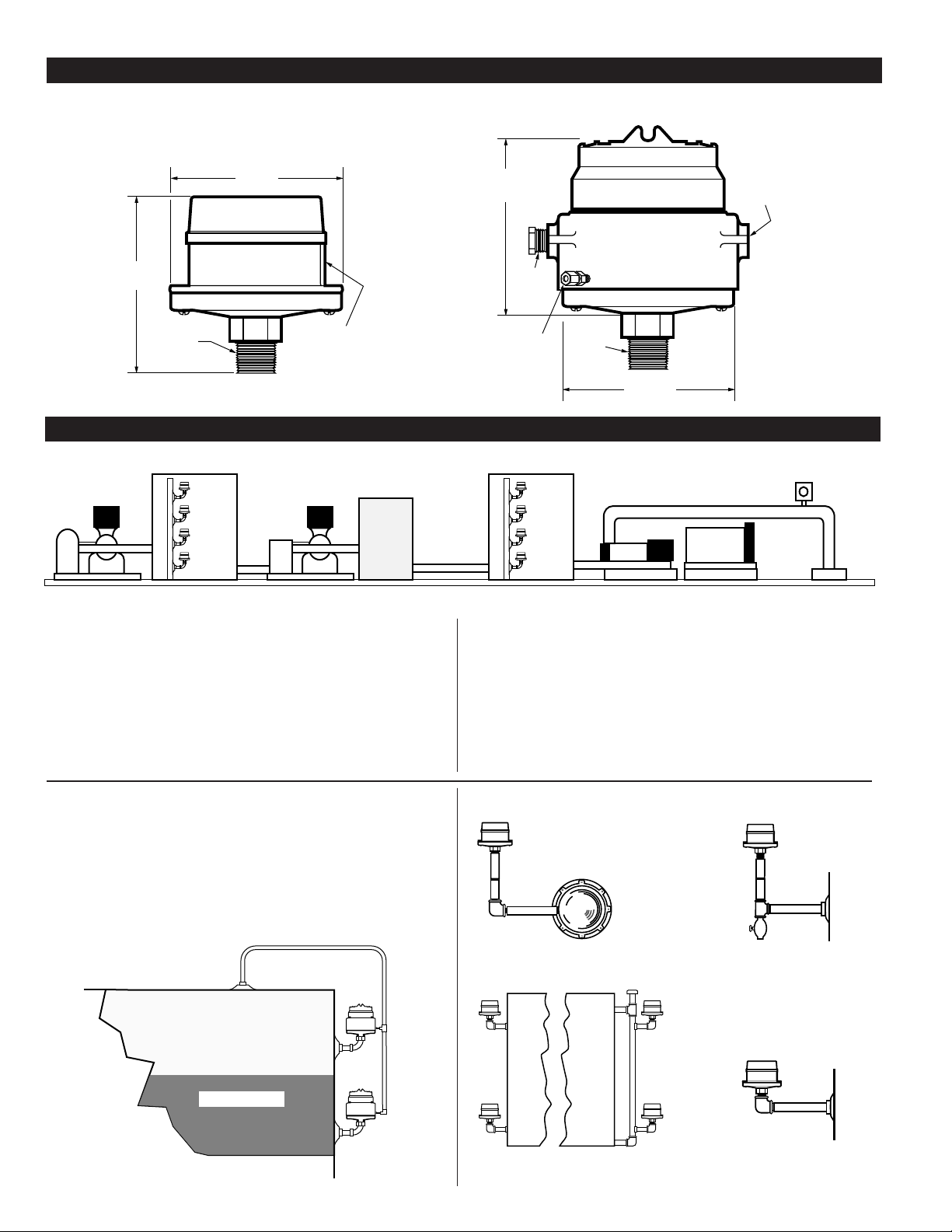

TYPICAL APPLICATIONS

DIMENSIONS

Typical Water Flood Control System

The diagram above displays eight DF Series switches installed on a

Raw Water tank and a Clear Water tank. When raw water rises to

predetermined level, DF#1 stops the supply pump. As tank level

falls below the predetermined level, DF#2 starts the supply pump. If

the tank level continues to fall, DF#3 initiates shutdown of the supply pump. DF#4 stops transfer pump before raw water tank is completely pumped out.

When clear water reaches the predetermined level, DF#5 stops the

transfer pump. As tank level falls to predetermined low level, DF#6

starts the transfer pump. If the tank level continues to fall due to the

failure of the filters section, DF#7 initiates shutdown of the transfer

pump. (DF755 located at this level will also operate backwash

equipment). DF#8 stops injection pump before tank pumps completely out.

An OPL Series pressure SWICHGAGE

®

stops injection pump when

pressure reaches predetermined high or low pressure.

Tank with Low Pressure

Gas Blanket (DF755EX)

The DF755EX (below) is shown installed on a crude oil tank where

a low pressure gas blanket is used to prevent evaporation loss. It is

mounted directly to the side of the tank or on riser pipe 4 to 7 in.

(102 to 178 mm) below level to be controlled. Pump automatically

stops or starts when liquid reaches predetermined high or low level.

Typical Tank Mounting Methods (DF755)

Tank Wall Mounting With

Drain Cock

Bull Plug Installation

Directly

On Tank

Riser Pipe

Method

Tank Wall Mounting

DF755 and DF757

DF755EX

1 NPT

(standard)

6-5/32 in.

(156 mm)

5-1/2 in.

(140 mm)

1/2 NPT

For Electrical

Connection

7-21/32 in.

(194 mm)

5-5/8 in.

(143 mm)

1 NPT

(standard)

1/2 NPT

Plug

1/2 NPT

For Electrical

Connection

1/4 in. (6 mm)

Tube Fitting

(DF756 only)

DF-94063N page 2 of 4

Raw Water Tank Clear Water Tank

Supply

Pump

DF#1

DF#2

DF#3

DF#4

Transfer

Pump

Filter

DF#5

DF#6

DF#7

DF#8

Injection Pump

OPL Series

SWICHGAGE

®

Fuel Tank

Gas Blanket

Gas Liquid

Page 3

DF-94063N page 3 of 4

The MAC1 Volume Air Cell when attached to the DF755 can monitor

water levels on a sump. Activate alarms or start a pump directly. The

MAC1 Volume Air Cell is non-corrosive and provides 1/4-20 stainless

steel mounting studs.

The MACT1 Tubing Kit provides 4 ft. (1.2 m) flexible, non-corrosive

1/4 in. (6 mm) tubing (cut to fit). The kit includes necessary fittings to

attach tubing.

Both the MAC1 air cell and MACT1 tubing kit are available from

Murphy.

Volume Cell Operation

As liquid rises around the volume cell, it compresses air inside the cell

and forces it up in the sensor line. As air pressure increases due to the

water level continuing to rise, sufficient pressure will be applied to activate the internal snap-switch, which in turn starts the pump. As the liquid level is pumped down, pressure decreases and the above procedure

is reversed. The pump is stopped and held in a standby condition. An

air purge may be required in the sensor line. Consult factory.

Choosing a Volume Cell

The volume cell should be constructed of material which will be unaffected by the liquid being measured. For proper “pressure-to-level”

ratio, the minimum dimensions of the volume cell should be 6 in. (152

mm) inside diameter and 3 in. (76 mm) inside depth. The sensor line

can be of any diameter or material either flexible, or solid, as long as it

is of sufficient length to reach from the volume cell to the desired loca-

tion for the DF755. All fittings and connections should be air-tight to

avoid loss of “charge”. Tube lengths longer than 4 ft. (1.2 m) should

have provision for periodic air purging.

Installation of the Volume Cell

Install the volume cell according to the level you wish the pump to start

and stop. Secured the volume cell with a substantial bracket which will

not allow the cell to be “floated”

or tilted when the water level

rises. The DF755 should be

installed well above the highest

water level and in a position

that will allow access for

adjustment or repair.

NOTE: Periodically operate pump

manually until water level reaches a

point approximately 1/2 in. (13 mm)

below bottom of the volume cell. This

will automatically re-charge the unit

and compensate for normal

absorption of air into water.

Small electric air pumps are

available to automatically

charge system at all times.

USING THE DF755 WITH MAC1 VOLUME CELL ACCESSORY

AIR

Sensor Line

(MACT1 Tube Kit)

DF755

Volume Cell

(MAC1)

A

B

C

Hydrostatic Head

Pressure

Vent (DF755EX)

or Tube Fitting

(DF756)

B

C

A

Hydrostatic Head

Pressure

As the liquid level rises, hydrostatic head pressure is applied to the

diaphragm

A. The diaphragm is forced upward forcing the actuator arm B

to activate the snap-switch C.

Models DF755 and DF755EX are factory set and operate at approximately

2 in. (51 mm) and 6 in. (152 mm) rising above the level at which the

diaphragm is mounted. The switch resets back to normal condition at

approx. 2 inches (51 mm) falling level. The trip point(s) for Model DF757

are adjustable between 2 in. (51 mm) and 110 in. (2794 mm) for high and

low (make/break) operation by knobs,

D.

For sealed tanks, model DF755EX can be fitted with a tube fitting to balance the top of the diaphragm chamber to a tank gas blanket (see Typical

Applications). The DF755EX is supplied with an atmospheric vent fitting.

Setpoint Adjustment (DF757)

1. Locate threaded adjustment shaft and adjustment

knobs (see drawing above).

2. To increase low level setpoint, rotate lower

knob counterclockwise.

NOTE: If adjustment shaft turns

when rotating adjustment knobs,

grasp the adjustment shaft with a

pair of needle nose pliers–then

rotate knob.

DF755

DF755EX

DF757

BASIC OPERATION

Adjustment

Shaft

C

B

D

A

Hydrostatic Head

Pressure

Page 4

DF-94063N page 4 of 4

TYPICAL WIRING

SERVICE PARTS

Starts at Low Level, Stops at High

Start motor when predetermined low level is reached and stop when high

level is reached. Keeps tank level within selected limits. Motor starter

equipped with H.O.A.

Starts at High Level, Stops at Low

Start motor when predetermined high level is reached and stop when low level

is reached. Motor starter equipped with H.O.A.

Single Magneto Shutdown

Wiring of magneto to N.O. switch terminal will shut down engine at predetermined high level, shown below. Wire to N.C. terminal to shutdown on

low level.

Dual Magneto Shutdown

Shutdown dual magneto engines using Murphy MS2120 Magnetic Switch.

Diagram below shows hookup for low level shutdown. Wiring changes and

mounting locations are necessary for high level shutdowns.

DF755

Description Part Number

Cover (aluminum) 15050081

Case (aluminum) 15050082

Cover Screws (3), #6–32 x 5/16 round head 80040607

SPDT snap-switch and movement assembly/repair kit (5 amp) 15000122

Screws (3) for switch assembly to case, #6–32 x 1/4 round head 80040605

Diaphragm repair kit 15000123

Bottom Plate (1 NPT connection) 15050083

Bracket and movement repair kit 15000313

SPDT snap-switch and insulator repair kit (5 amp) 15000121

DF755EX

Cover (aluminum) 15050154

Case (aluminum) 15050155

Gasket 15050305

SPDT snap-switch and movement assembly/repair kit (5 amp) 15000118

Screws (2) for switch assembly to case, #6–32 x 1/4 round head 80040605

Actuator assembly/repair kit 15000119

Diaphragm repair kit 15000123

Bottom Plate (1 NPT connection) 15050083

Screw (1), #8–32 x 1/4 round head 80040814

Terminal cup washer 00000827

Plug 1/8 plastic pipe hex (DF755EX) 86060203

Connector, 1/4 tube x 1/8 pipe male (DF756) 85030402

Plug 1/2 NPT hex (brass) 86060801

SPDT snap-switch and insulator repair kit (5 amp) 15000117

DF757

Cover (aluminum) 15050081

Case (aluminum) 15050594

Cover Screw (3), #6–32 x 5/16 round head 80040607

SPDT snap-switch and bracket assembly/repair kit (5 amp) 15000174

Screws (2) for switch bracket and assembly to case (#6–32 x 1/4 round head) 80040605

Spring and piston assembly/repair kit 15000190

Diaphragm repair kit 15000123

Bottom Plate (1 NPT connection) 15050083

SPDT snap-switch and insulator repair kit (5 amp) 15000230

MAGNETO

N.O.

C

N.C.

CONTROL SYSTEMS & SERVICES DIVISION

P.O. Box 1819; Rosenberg, Texas 77471; USA

+1 281 633 4500 fax +1 281 633 4588

e-mail sales@fwmurphy.com

MURPHY DE MEXICO, S.A. DE C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

+52 444 8206264 fax +52 444 8206336

Villahermosa Office +52 993 3162117

e-mail ventas@murphymex.com.mx

www.murphymex.com.mx

FRANK W. MURPHY, LTD.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

+44 1722 410055 fax +44 1722 410088

e-mail sales@fwmurphy.co.uk

www.fwmurphy.co.uk

MURPHY SWITCH OF CALIFORNIA

41343 12th Street West

Palmdale, California 93551-1442; USA

+1 661 272 4700 fax +1 661 947 7570

e-mail sales@murphyswitch.com

www.murphyswitch.com

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MACQUARRIE CORPORATION

1620 Hume Highway

Campbellfield, Vic 3061; Australia

+61 3 9358 5555 fax +61 3 9358 5558

e-mail murphy@macquarrie.com.au

FW Murphy

P.O. Box 470248

Tulsa, Oklahoma 74147 USA

+1 918 317 4100

fax +1 918 317 4266

e-mail sales@fwmurphy.com

www.fwmurphy.com

R

E

G

I

S

T

E

R

E

D

USA–ISO 9001:2000 FM 28221

UK–ISO 9001:2000 FM 29422

Printed in U.S.A.

C

C

HIGH

N.O.

N.C.

N.O.

N.C.

LOW

DF755

#1

DF755

#2

MOTOR

MOTOR

Magneto

Magneto

Model MS2120

6 2 3

1 4

Jumper #2 & #5

HIGH

N.O.

N.C.

N.O.

N.C.

LOW

DF755

#1

DF755

#2

N.O.

C

N.C.

C

C

5

Loading...

Loading...