Page 1

CE-05171N page 1 of 44

CE-05171N

Effective 05-13-05

Section 50

(00-02-0590)

CENTURION

Configurable Controller

Installation and

Operations Manual

TTMM

TM

Page 2

CE-05171N page 2 of 44

WARNING!

FW MURPHY has made efforts to ensure the reliability of the

Centurion Controller and to recommend safe usage practices in

system applications. Please note that in any application, operation

and controller failures can occur. These failures may result in full

control outputs or other outputs which may cause damage to or

unsafe conditions in the equipment or process connected to the

Centurion Controller. Good engineering practices, electrical codes,

and insurance regulations require that you use independent external

protective devices to prevent potentially dangerous or unsafe conditions. Assume that the Centurion Controller can fail with outputs full

on, outputs full off, or that other unexpected conditions can occur.

Please read the following information before installing the Centurion

Controller. This installation information is intended for Centurion

Controller. A visual inspection of this product before installation for

any damage during shipping is recommended.

Disconnect all power and be sure machine is inoperative before

beginning installation.

Installation is to be done only by qualified technician.

Observe all Warnings and Cautions at each section in these instructions.

Device shall be wired in accordance with Class I, Division 2 wiring

methods.

This equipment is suitable for use in Class I, Division 2, Groups B,

C, and D hazardous Areas.

WARNING–Explosion Hazard–Substitution of components may

impair suitability for Class I, Division 2.

Please contact FW MURPHY immediately if you have any questions.

Warranty

A limited warranty on materials and workmanship

is given with this FW Murphy product.

A copy of the warranty may be viewed or printed by going to

www.fwmurphy.com/support/warranty.htm

1.0 Warning and Limited Warranty

MURPHY, the Murphy logo, Centurion and C3 are registered and/or common law trademarks of Murphy Industries, Inc.

This document, including textual matter and illustrations, is copyright protected by Murphy Industries, Inc., with all rights

reserved. (c) 2004 Murphy Industries, Inc.

Windows®. Modbus® and other third party product or trade names referenced herein are the property of their respective

owners and are used for identification purposes only.

Page 3

TTD-98055N page 3 of 44

Table of Contents

1.0 WARNING AND LIMITED WARRANTY..................................................................................2

2.0 OVERVIEW.........................................................................................................................................5

Basic Components and Key Features of the C3 Series.....................................................................................5

Optional Components....................................................................................................................................5

3.0 INPUT/OUTPUT TYPES................................................................................................................6

3.1 Input/Output Types and Specifications for the Centurion C3-1...................................................................6

3.1.1 Digital Inputs (DI)..........................................................................................................................6

3.1.2 Analog Inputs (AI) ........................................................................................................................7

3.1.3 Thermocouple Inputs (TC)...........................................................................................................7

3.1.4 Magnetic Pickup (MPU)...............................................................................................................8

3.1.5 Digital Outputs (DO).....................................................................................................................8

3.1.6 Types and Specifications for the Optional Analog Output on the Centurion C3-1 -A....................9

Analog Outputs (AO).............................................................................................................................9

3.2 Input/Output Types and Specifications for the Optional C3-2 Expansion Module to the Centurion C3-1.........9

3.2.1 Analog Inputs (AI)........................................................................................................................ 9

3.2.2 Thermocouple Inputs (TC)......................................................................................................... 10

3.2.3 Analog Outputs (AO)..................................................................................................................10

4.0 HAZARDOUS AREA OPERATION......................................................................................... 10

5.0 HARDWARE INSTALLATION AND WIRING..................................................................... 11

5.1 Mounting the Centurion Controller.........................................................................................................11

5.2 Mounting the Centurion C3-3 Display.....................................................................................................11

5.3 Power Supply Wiring.............................................................................................................................11

Power........................................................................................................................................................11

Centurion C3-1 I/O Module................................................................................................................... 11

Centurion C3-2 Optional Expansion Module...........................................................................................11

5.4 Wiring the Centurion C3-3 Display.........................................................................................................12

5.5 Wiring the Centurion C3-1/C3-2.........................................................................................................13/14

6.0 USING C3-3 DISPLAY TO VIEW AND CONFIGURE

THE CENTURION CONTROLLER SETTINGS.............................................................................15

6.1 Features.............................................................................................................................................. 15

6.1.1 Keypad Description and Navigation..........................................................................15/16/17/18

6.1.2 Display Context........................................................................................................................19

6.1.3 Numeric Entry..........................................................................................................................19

6.2 Operational Screens............................................................................................................................. 20

6.2.1 Default Operating Screen......................................................................................................... 20

6.2.2 F W Murphy Logo Screen........................................................................................................ 20

6.2.3 Corporate and Version Information Screen.............................................................................. 20

6.2.4 Shutdown History Screen........................................................................................................ 21

6.2.5 Event History Screen................................................................................................................21

6.2.4 Active Alarms Screen............................................................................................................... 21

6.2.5 Gage Display........................................................................................................................... 22

6.2.6 Line By Line ............................................................................................................................ 22

6.2.7 Custom PID Screen............................................................................................................22/23

6.3 Setup Screens and Menus.....................................................................................................................23

6.3.1 Password Screen.....................................................................................................................23

6.3.2 Digital Input..............................................................................................................................24

6.3.3 Digital Output...........................................................................................................................24

6.3.4 Analog Input........................................................................................................................24/25

6.3.5 Analog Output.....................................................................................................................25/26

Page 4

TTD-98055N page 4 of 44

6.3.6 Thermocouple Input................................................................................................................26

6.3.7 General Timer Setup...............................................................................................................27

6.3.8 Maintenance Timer Setup.......................................................................................................28

6.3.9 Set points Setup.....................................................................................................................29

6.3.10 Control Output Setup.......................................................................................................29/30

6.3.11 PID Setup.............................................................................................................................30

6.3.12 Initial RPM Setup.................................................................................................................. 31

6.3.13 Miscellaneous Setup.............................................................................................................31

6.3.14 Lube No Flow Set Up........................................................................................................... 32

6.3.15 Lube No Flow Status............................................................................................................ 32

6.3.16 Super User Menu............................................................................................................ 32/33

6.3.17 Configuration Download (Download Only Screen)................................................................. 33

6.3.18 Display Board Status.............................................................................................................33

6.3.19 Digital Input Status................................................................................................................ 34

6.3.20 Digital Output Status............................................................................................................. 34

6.3.21 Analog Input Status...............................................................................................................34

6.3.22 Analog Output Status.......................................................................................................34/35

6.3.23 Thermocouple Status............................................................................................................ 35

6.3.24 Communication Status.....................................................................................................35/36

6.3.25 PID Diagnostics.....................................................................................................................36

6.4 Additional Navigational Aids................................................................................................................ 37

6.4.1 Function Key........................................................................................................................... 37

6.4.2 Help Key................................................................................................................................. 37

7.0 COMMUNICATIONS...................................................................................................................37

7.1 Communication Ports.......................................................................................................................... 37

Port 1 (SERIAL)................................................................................................................................37

Port 2 (SERIAL)................................................................................................................................37

Port 2 (USB).....................................................................................................................................38

Port 3 (CAN).....................................................................................................................................38

7.2 Downloading Configurations and Firmware Updates............................................................................. 38

7.2.1 Boot Loader ...........................................................................................................................38

7.2.2 Downloading Configurations Via C3-3 Display........................................................................ 38

Special 35 Jump Code................................................................................................................... 38

7.2.3 Downloading Configurations Via MConfigPro Software...........................................................39

7.2.4 Pass Through.........................................................................................................................39

7.2.5 Downloading Firmware Updates to the C3-3 Display..............................................................39

Special 35 Jump Code....................................................................................................................39

Super User Menu............................................................................................................................39

7.2.6 Error Messages...................................................................................................................... 40

7.3 Modbus Protocol.................................................................................................................................41

7.4 Features of Transferring Data in Modbus.............................................................................................. 41

7.5 Modbus Register Address Listings........................................................................................................ 41

8.0 GLOSSARY.....................................................................................................................................42

9.0 APPENDICES

.................................................................................................................................43

9.1 Back Panel LED Description................................................................................................................. 43

9.2 Controller Accuracies, and Tolerances ............................................................................................... 43

9.3 Restrictions on Numeric Values in Gage and PID Monitor Screens.......................................................... 43

9.4 Set Up Sheet....................................................................................................................................... 43

9.0 How to Order................................................................................................................................ 44

Page 5

CE-05171N page 5 of 44

2.0 Overview

The Centurion configurable controller is a control and monitoring system expressly designed to meet the requirements of

three specific kinds of applications: Screw and Reciprocating Compressors, and Pumps. To that end, it is able to satisfy

the particular needs and inevitable variations that exist in real world applications because the Centurion controller is enormously flexible and configurable within fixed parameters. The Centurion controller is a system designed to monitor, control, protect, and optimize small to medium sized gas operated compressors and pumps in the field by monitoring set

points and digital, analog, and thermocouple input points and providing the logic to take corrective and/or proactive

steps to maintain proper operation. The Centurion controller also allows for controlled shut down and no-flow monitoring

as well as expanded and auto start up, and engine control capabilities, which are so critical to the systems the Centurion

controller is designed to protect.

The Centurion controller provides real-time data via communications ports to a connected display and/or supervisory

system. This advanced system offers multiple options for remote communications and operation including HMI's, PLC's,

PC’s, and SCADA systems. The industry standard Modbus protocol means greater support for a wide variety of communication equipment including radio and satellite communications systems.

The heart of the Centurion system is the Main Input/Output (I/O) Module, known as C3-1, which can be mounted on a

standard DIN rail. While it is designed to work with any Modbus (Master) compliant HMI (Human Machine Interface) or

with no operator interface at all, it is optimally configured and field-configurable through MConfigPro, powerful software

developed to configure the controller. Parameters can be modified through C3-3 Display, F W Murphy’s specially programmed controller display, in the field without special need for laptop or software.

Basic Components and Key Features of the C3TMSeries

The C3 Series consists of a Display Module, a Main I/O Module, and optional Expansion I/O Module. No special cables

are required. The Centurion system is designed for use within a weatherproof enclosure only.

■ Display Module (C3-3 Head): 128 x 64 LCD graphic display; (-40 to 85) °C

■ Main I/O Module (C3-1):

• 32 Digital Inputs (DI)

• 10 Digital Outputs (DO)

• Separate direct input for Analog and Thermocouple inputs:

– 12 AI on the Centurion C3-1

– 8 TC on the Centurion C3-1

• 1 Magnetic Pickup (MPU).

• C3-1-A: Same as C3-1, plus two (2) Analog Output (AO).

■ Expansion I/O Module (C3-2) as required: 8 AI, 8 TC, and 4 AO

Optional Components:

The C3-1 hardware may be configured with 2 analog outputs and it may be augmented through an Expansion Module

(C3-2) which provides analog outputs and additional analog and thermocouple inputs.

C3-1-A with Analog Outputs:

■ 2 Analog Outputs

C3-2 Expansion:

■ 8 Analog Inputs

■ 8 Thermocouple Inputs

■ 4 Analog Outputs

Page 6

CE-05171N page 6 of 44

3.0 Input/Output Types

3.1 Input/Output Types and Specifications for the Centurion C3-1

3.1.1 Digital Inputs (DI)

Number of Devices: 32

Device Types: Discrete Input, Normally Open (N/O) or Normally Closed (N/C),

active high/active low, non-incendive.

There is one screw terminal connector for each digital input.

Terminals 30 to 61 are DI terminals.

Green LEDs give visual indication of active input signal.

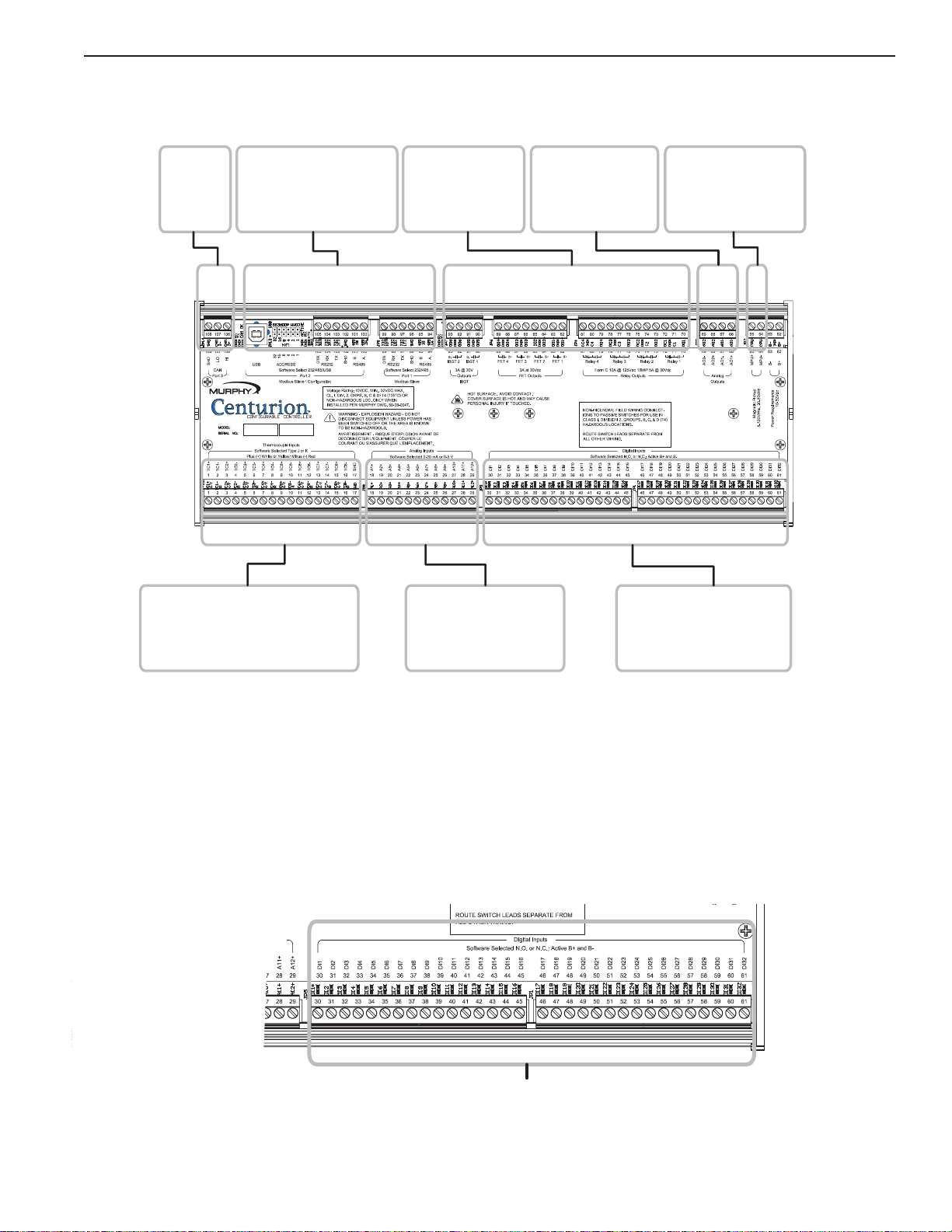

C3-1

CAN

J1939

Thermocouple Inputs

(TC) See 3.1.3

Communications

(RS4232, 485, USB)

Digital Outputs

(DO) See 3.1.5

Analog Inputs

(AI) See 3.1.2

Optional

Analog Outputs

(AO) See 3.1.6

Magnetic Pickup

(MPU) See 3.1.4

Digital Inputs

(DI) See 3.1.1

C3-1

Digital Inputs

Page 7

CE-05171N page 7 of 44

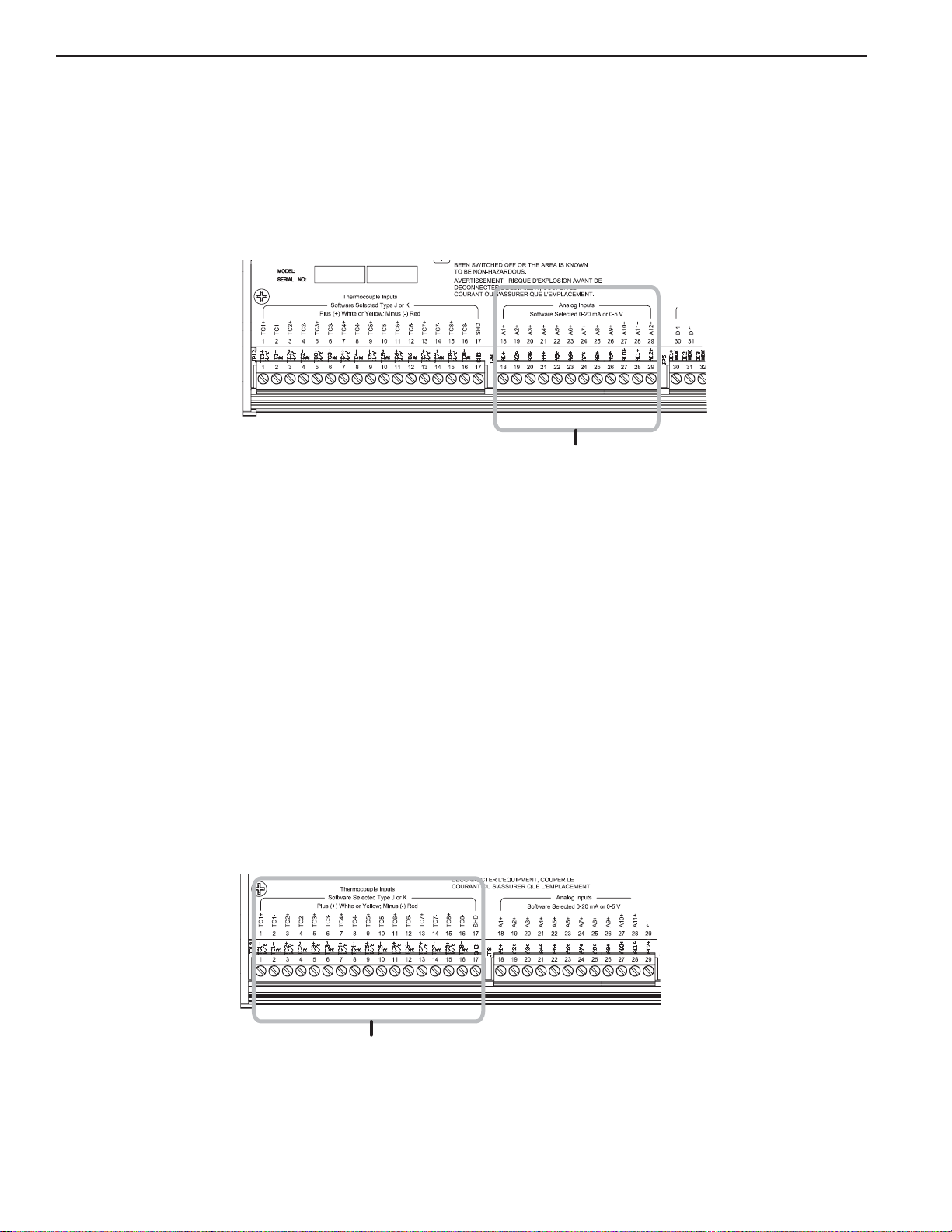

3.1.2 Analog Inputs (AI)

NNuummbbeerr ooff DDeevviicceess:: 1122

Device Types: Analog Input, (4 to 20) mA or (0 to 5) V, 10 bit hardware.

There is one screw terminal connector for each analog input.

Terminals 18 to 29 are AI terminals.

3.1.3 Thermocouple Inputs (TC)

NNuummbbeerr ooff DDeevviicceess:: 88

Device Types: Thermocouple Input, Type J or K, 12 bit hardware.

Open Thermocouple Detection: Drives terminal reading high (max of scale).

Automatic Cold Junction Compensation is built-in.

There are two screw terminal connectors for each thermocouple.

Terminals 1 to 16 are TC terminals where White or Yellow indicate positive inputs and Red indicates negative inputs.

An additional terminal connector is provided, identified as SHD, which isolates thermocouple shields. This connection, at terminal 17, is intended to be wired to an isolated bus bar for thermocouple shield wires. If grounded thermocouples are used, the shied terminal should not be connected.

C3-1

Analog Inputs

C3-1

Thermocouple Inputs

Page 8

CE-05171N page 8 of 44

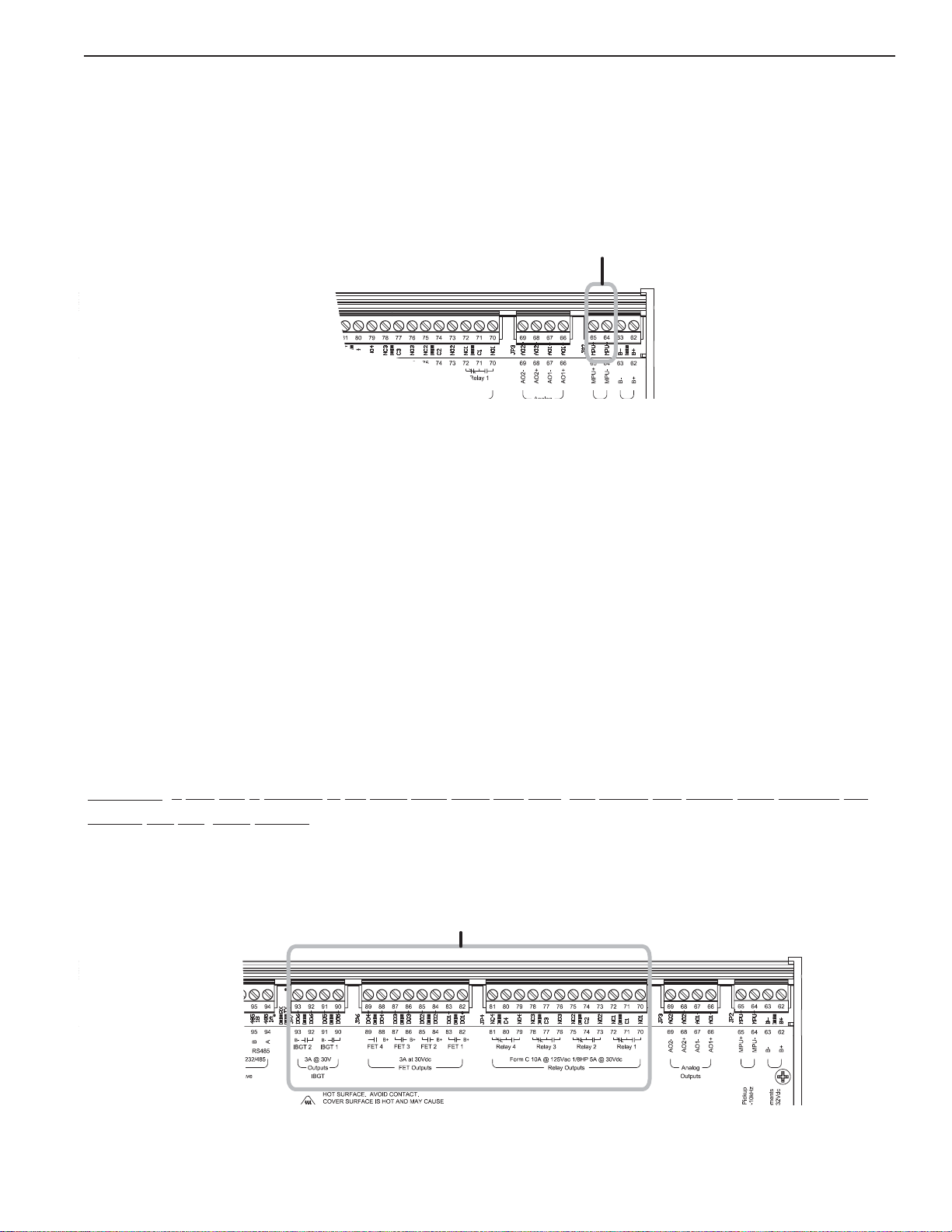

3.1.4 Magnetic Pickup (MPU)

NNuummbbeerr ooff DDeevviicceess:: 11

Device Types: Magnetic Pickup or MPU, (5 to 120) Vrms, (30 to 10k) Hz.

There are two screw terminal connectors for the Magnetic Pickup .

Terminals 64 and 65 are MPU terminals.

3.1.5 Digital Outputs (DO)

NNuummbbeerr ooff DDeevviicceess:: 1100

Device Types: Discrete Output, Normally Open (N/O) or Normally Closed (N/C)

● Four (4) relay outputs, form C, dry contacts

● Four (4) FETs (high speed)

● Two (2) IGBTs (high power)

There are three screw terminal connectors for each relay output and two screw terminal connectors for each

FET and IGBT output.

Terminals 70 to 81 are for the four relay terminals.

Terminals 82 to 89 are for the four FET terminals.

Terminals 90 to 93 are for the two IGBT terminals.

Green LEDs give a visual indication of active output signal.

Warning:

AA hheeaatt ssiinnkk iiss aattttaacchheedd ttoo tthhee ccoovveerr uussiinngg aaccoorrnn ssttyyllee nnuuttss.. TThhee ssuurrffaaccee aarreeaa aarroouunndd tthheessee ffaasstteenneerrss ccaann

bbeeccoommee vveerryy hhoott.. AAvvooiidd ccoonnttaacctt..

Magnetic Pickup

C3-1

Digital Outputs

C3-1

Page 9

TTD-98055N page 9 of 44

3.1.6 Types and Specifications for the Optional Analog Output on the Centurion C3-1 -A

Analog Outputs (AO)

NNuummbbeerr ooff DDeevviicceess:: 22

Device Types: Analog Output, (4 to 20) mA or (0-5)V, 16 bit hardware

There are two screw terminal connectors for each analog output.

The AO optional module is added to the C3-1 at the factory inside the DIN enclosure. While these terminals are

present on all models the feature may not be installed.

3.2 Input/Output Types and Specifications for the Optional C3-2 Expansion Module to the Centurion C3-1

3.2.1 Analog Inputs (AI)

NNuummbbeerr ooff DDeevviicceess:: 88

Device Types: Analog Input, (4 to 20) mA or (0 to 5) V, 12 bit hardware.

There is one screw terminal connector for each analog input.

Terminals 126 to 133 are AI terminals.

Optional Analog Outputs

C3-1-A

C3-2

Analog Inputs

Page 10

TTD-98055N page 10 of 44

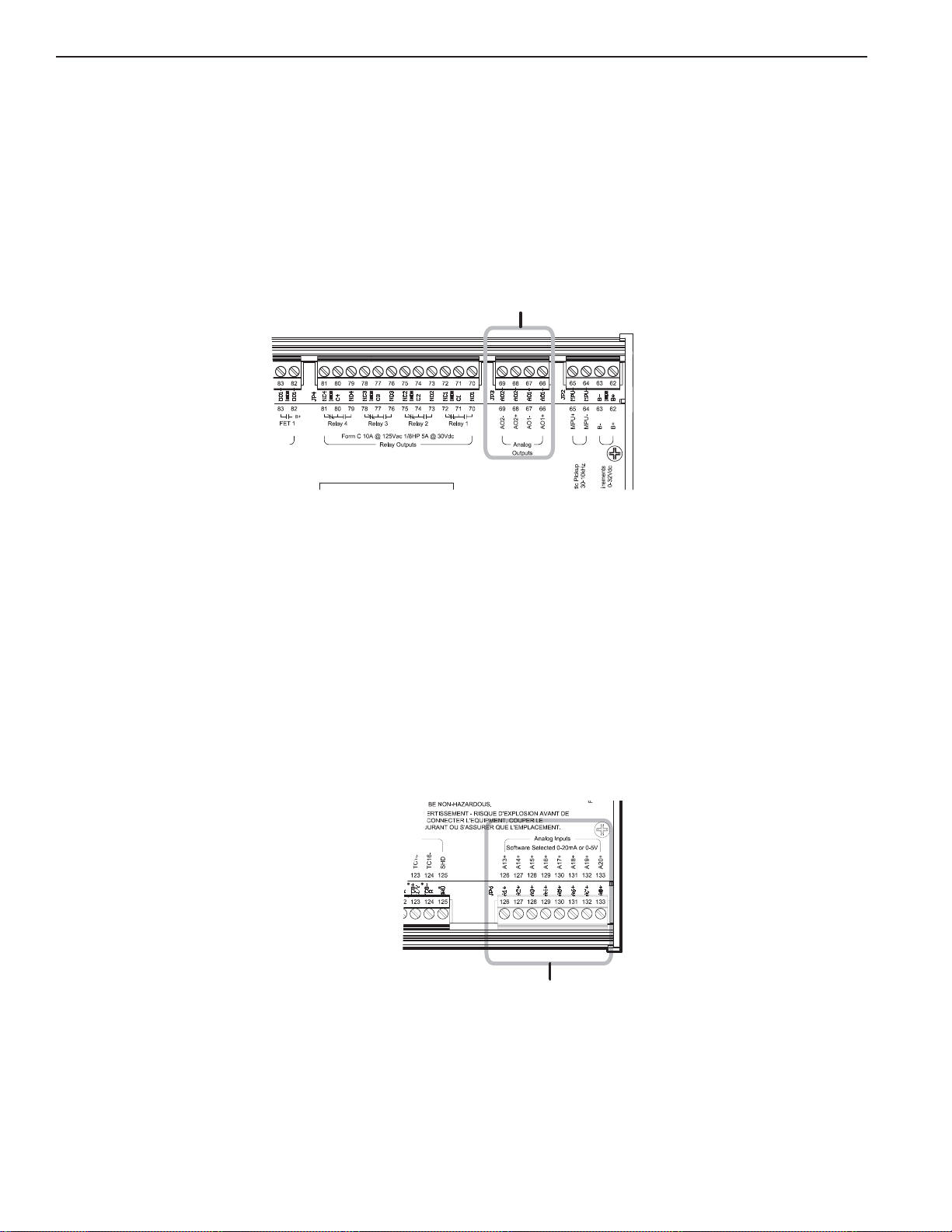

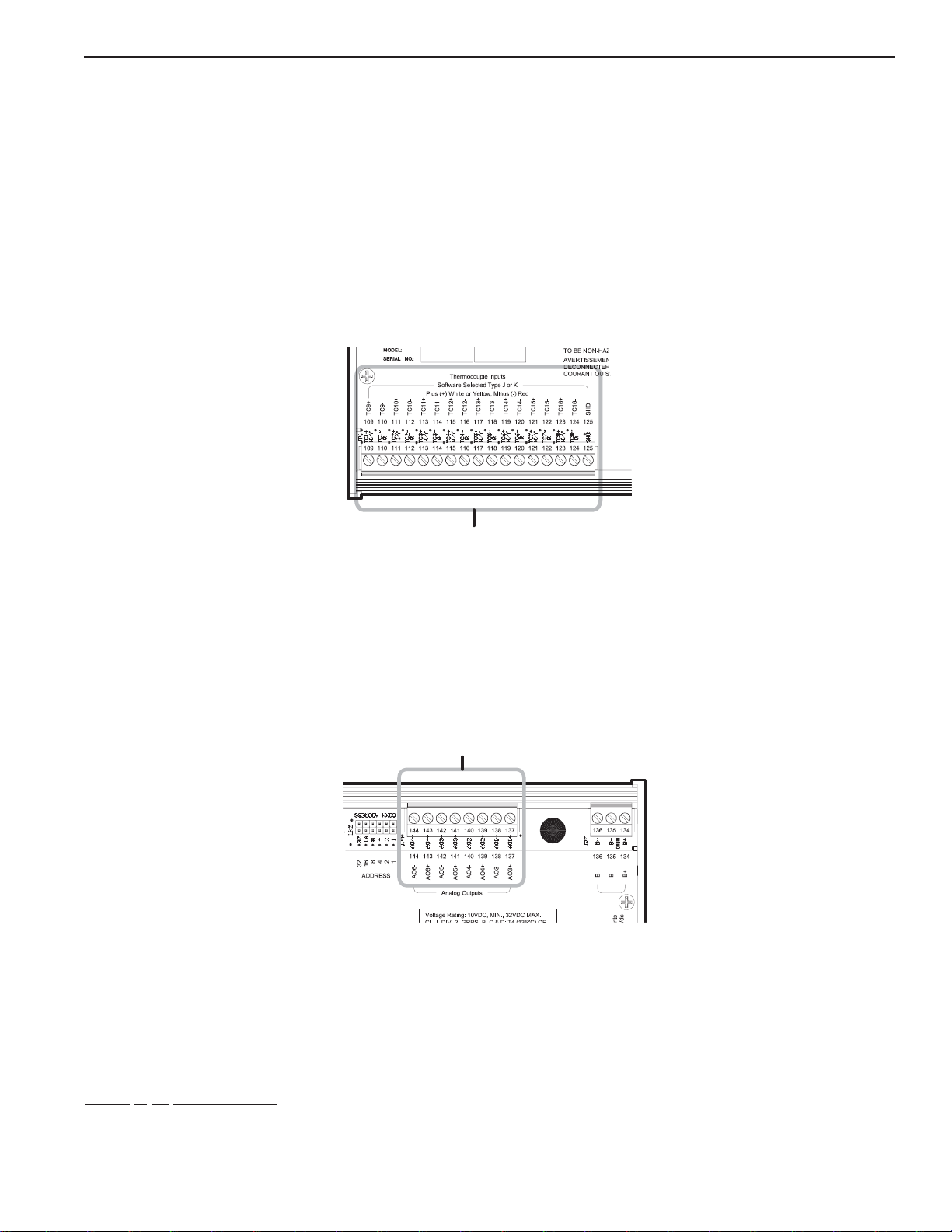

3.2.2 Thermocouple Inputs (TC)

NNuummbbeerr ooff DDeevviicceess:: 88

Device Types: Thermocouple Input, Type J or K, 12 bit hardware

Open Thermocouple Detection: Drives channel reading high (max of scale).

There are two screw terminal connectors for each thermocouple input.

Terminals 109 to 124 are TC channels where White or Yellow indicate positive inputs and Red indicates negative inputs.

An additional terminal connector is provided, identified as SHD, which isolates thermocouple shields. This connection, at terminal 125, is intended to be wired to an isolated bus bar for thermocouple shield wires. If grounded thermocouples are used, the shied terminal should not be connected.

3.2.3 Analog Outputs (AO)

NNuummbbeerr ooff DDeevviicceess:: 44

Device Types: Analog Output, (4 to 20) mA or (0-5) V, 16 bit hardware

There are two screw terminal connectors for each analog output.

Terminals 137 to 144 are AO terminals.

4.0 Hazardous Area Operation

The Centurion approvals for CSA, CLASS 1, DIVISION 2, Groups B, C and D are pending.

Warning:

EExxpplloossiioonn hhaazzaarrdd –– DDoo nnoott ddiissccoonnnneecctt tthhee eeqquuiippmmeenntt uunnlleessss tthhee ppoowweerr hhaass bbeeeenn sswwiittcchheedd ooffff,, oorr tthhee aarreeaa iiss

kknnoowwnn ttoo bbee nnoonn--hhaazzaarrddoouuss..

C3-2

Thermocouple Inputs

Analog Outputs

C3-2

Page 11

TTD-98055N page 11 of 44

5.0 Hardware Installation and Wiring

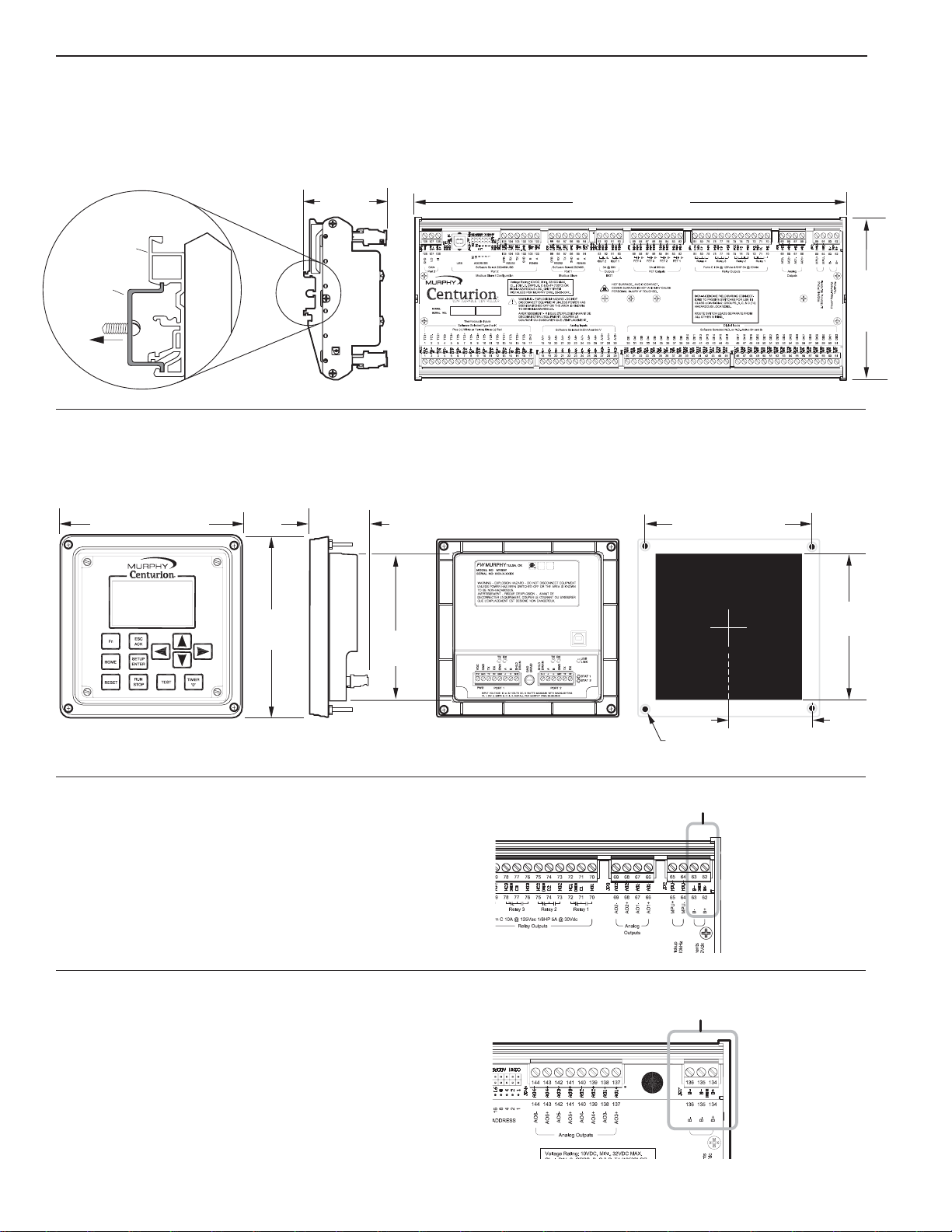

5.1 Mounting the Centurion Controller

The Centurion can be mounted vertically or horizontally on a standard DIN rail. Three clamp type feet along the bottom of

the controller attach to the DIN rail, however, rail stops are recommended to prevent sliding.

5.2 Mounting the Centurion C3-3 Display

The Centurion C3-3 Display can be mounted in the same hole cutout of other Murphy display modules. Four screws

attached the display bezel to the mounting surface.

5.3 Power Supply Wiring

Power

Centurion C3-1 I/O Module

Requirements: (10 to 32) VDC: 30W (Max)

There are two screw terminal connectors for power hookup at

terminals 62 and 63, labeled B+ and B- respectively.

Centurion C3-2 Optional Expansion Module

Requirements: (10 to 32) VDC

There are three screw terminal connectors for power hookup

at terminals 134 to 136, labeled B+, B- and B- respectively.

BRACKET DETAIL

C3-1 Mounting

Bracket

DIN Type

Mounting Rail

To Panel

MOUNTING

2-1/2 in.

(64 mm)

C3-1

13-1/8 in. (333 mm)

6-1/2 in. (165 mm)

6-1/2 in.

(165 mm)

2-1/8 in. (54 mm)

5-1/4 in.

(134 mm)

6.0 in. (152 mm)

(140 mm)

5.50 in.

4-7/8 in.

(125 mm)

3 in. (76 mm)

0.156 in. (4 mm) dia. 4 places

Power Hook Up

C3-1

Power Hook Up

C3-2

Page 12

TTD-98055N page 12 of 44

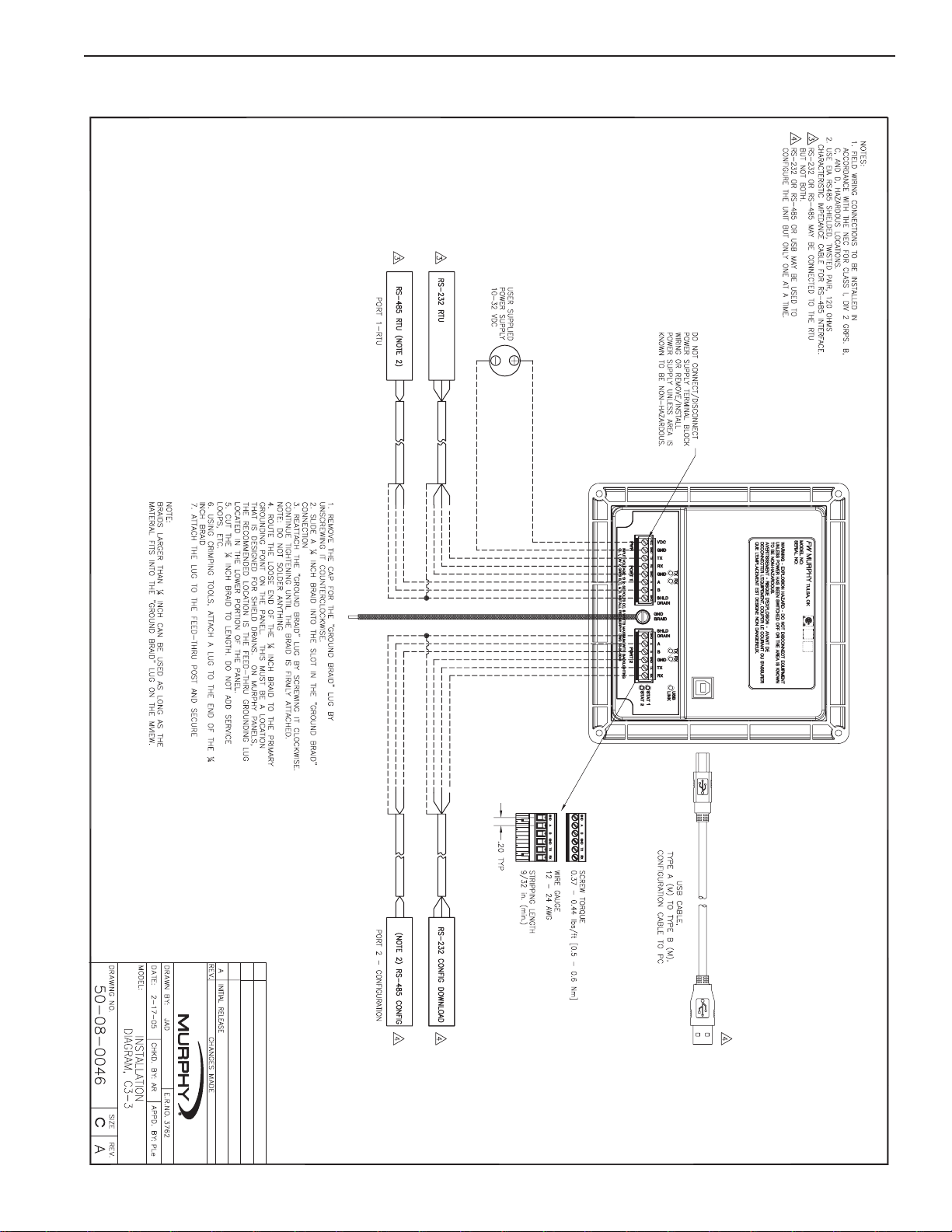

5.4 Wiring the Centurion C3-3 Display

Page 13

TTD-98055N page 13 of 44

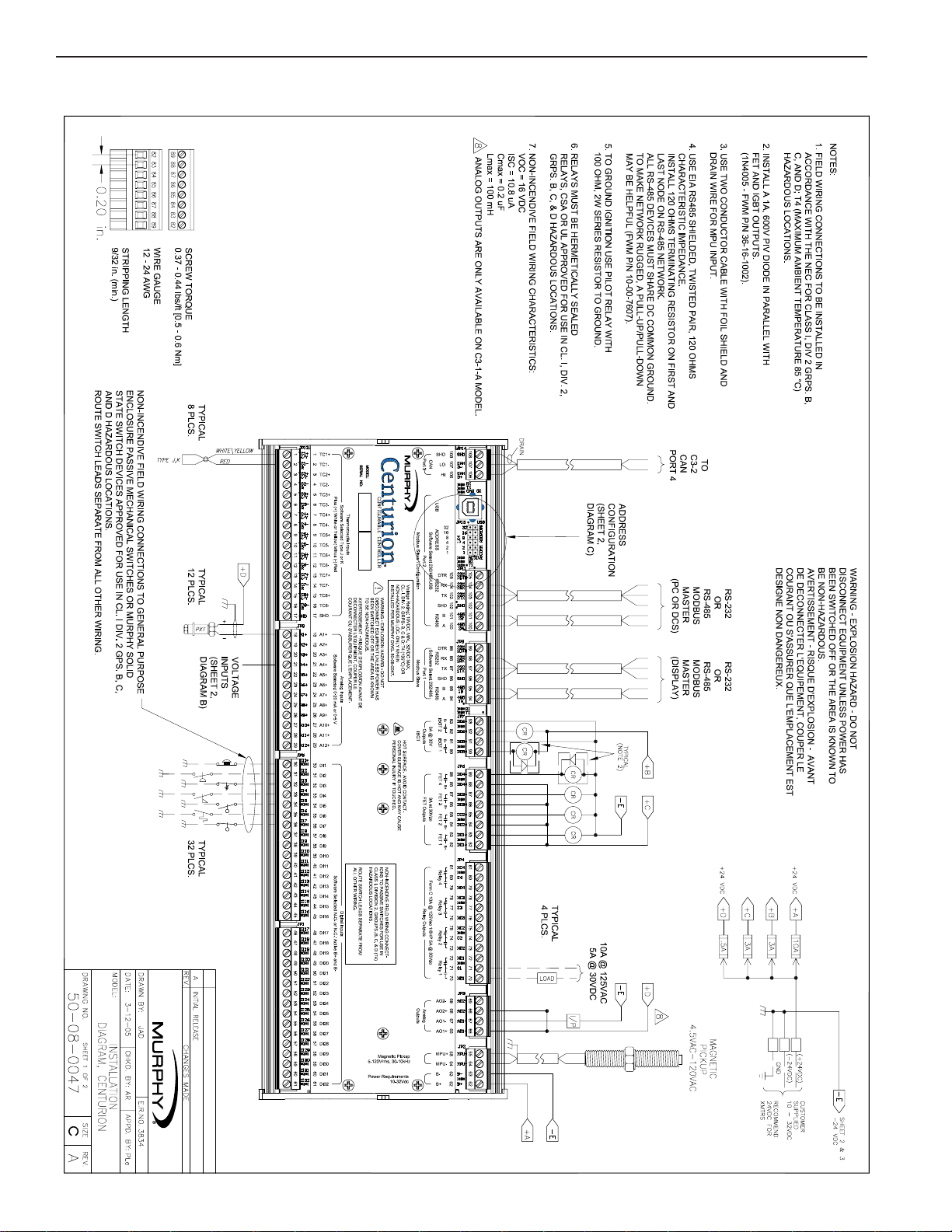

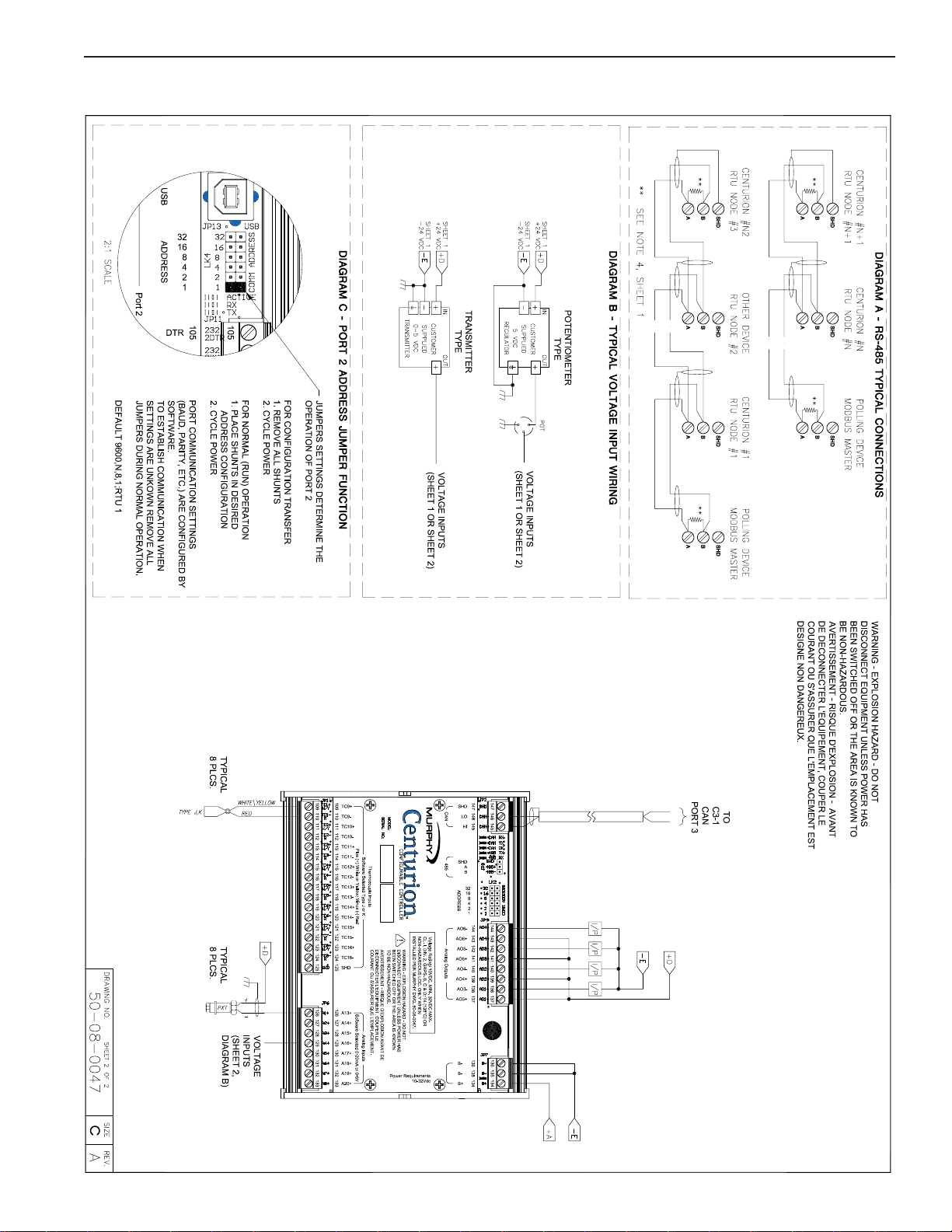

5.5 Wiring the Centurion C3-1/C3-2

Page 14

TTD-98055N page 14 of 44

5.5 Wiring the Centurion C3-1/C3-2

(continued)

Page 15

CE-05171N page 15 of 44

6.0 Using the C3-3 Display to View and Configure the Centurion

Controller Settings

The Murphy C3-3 Display module is a highly integrated operator interface specially programmed to complement and support Centurion controller. The primary purpose of C3-3

Display is to display operational and configuration parameters

and provide access to modify the configuration parameters

stored in the Centurion controller.

6.1 Features

• Power

– 10 - 32 VDC (LED active indication)

– Storage power able to withstand 12V crank

• Package and Design

– Same 5 x 5 design as annunciators

– 12 key keypad

• Familiar annunciator keys

• Easy navigation keys

– 128 x 64 graphic backlit display

– Configurable using PC Software

– Field Upgradeable (flash bootloader)

• Communications

– LED active indication for each port

– RS232/485 (Modbus Master)

– RS232/485/USB 1.1 Compliant Port

• Download Configuration/Monitoring

• Approvals

– Approvals for CSA, CLASS 1, DIVISION 2, Groups B, C and D are pending.

66..11..11 KKeeyyppaadd DDeessccrriippttiioonn aanndd NNaavviiggaattiioonn

The keypad for the C3-3 Display has 12 keys. The

following table generally describes the keys and

their function for each of the three screen types:

• Operating status screens

• Setup screens (Password required)

• Edit screens (Password required)

Many of the keys have a modified action relative to

the current location of the cursor and the current

page being displayed.

HOME

Fn

RESET

ESC

ACK

SETUP

ENTER

RUN

STOP

TEST

TIMER

“0”

COOLER TEMPERATURE 105° F

LOW ENGINE OIL LEVEL

REMOTE ▼▲ 0000.3H

WARMUP B2 TIME-140

___________________________________

___________________________________

Page 16

CE-05171N page 16 of 44

HOME

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Allows the user to get to the first line of the current screen, or if pressed again, to get to the default

operating status screen.

SSeett UUpp SSccrreeeenn

Allows the user to get to the first line of the current screen

EEddiitt SSccrreeeenn

No associated action.

ESC/ACK

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Acknowledge the active message/alarm that is currently displayed in the Alarm Banner.

Acknowledges all active messages and alarms displayed in the Active Alarm Screen.

SSeett UUpp SSccrreeeenn

Exit Setup mode.

EEddiitt SSccrreeeenn

Exit without saving changes to the current configuration.

Fn (Function Key)

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Enter “Function mode” and display a dialog box with additional available functions. Automatically cancels upon moving to the next mode, or if no subsequent function is chosen within five seconds.

SSeett UUpp SSccrreeeenn

Enter “Function mode” and display a dialog box with additional available functions. Automatically cancels upon moving to the next mode, or if no subsequent function is chosen within five seconds.

SETUP/ENTER

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Enter Setup Mode.

SSeett UUpp SSccrreeeenn

Enter Edit mode or Sub-menu.

EEddiitt SSccrreeeenn

Accept and save changes made to a current parameter before exiting Edit mode.

RESET

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Reset any active timers and alarms/faults.

SSeett UUpp SSccrreeeenn

No associated action.

EEddiitt SSccrreeeenn

No associated action.

HOME

ESC

ACK

Fn

SETUP

ENTER

RESET

Page 17

CE-05171N page 17 of 44

RUN/STOP

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Initiate or cancel a start sequence.

SSeett UUpp SSccrreeeenn

No associated action in either Shutdown mode, or Remote mode on standby. Initiate stop sequence

when held for two seconds, if equipment is running.

EEddiitt SSccrreeeenn

No associated action.

ARROW UP

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Scroll up one line. Automatically repeats if held down continuously until reaching the first line.

For history screens, scrolls up one history (for example: Shutdown or Event).

SSeett UUpp SSccrreeeenn

Scroll up one line. Automatically repeats if held down continuously until reaching the first line.

EEddiitt SSccrreeeenn

Increment the digit selected by the cursor (from 0 to 9). The user will not be allowed to increment the

selected digit if it would result in exceeding range limits.

ARROW DOWN

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Scroll down one line. Automatically repeats if held down continuously until reaching the final line.

For history screens, scrolls down one history (i.e. Shutdown or Event).

SSeett UUpp SSccrreeeenn

Scroll down one line. Automatically repeats if held down continuously until reaching the final line.

EEddiitt SSccrreeeenn

Decrement the digit selected by the cursor (from 0 to 9). The user will not be allowed to decrement the

selected digit if it would result in exceeding range limits.

ARROW LEFT

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Display previous screen. Automatically repeats if held down continuously until reaching the first screen.

SSeett UUpp SSccrreeeenn

Display previous screen. This key has no action when in a sub-menu.

EEddiitt SSccrreeeenn

Move the cursor to the previous digit.

RUN

STOP

Page 18

CE-05171N page 18 of 44

ARROW RIGHT

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Display next screen. Automatically repeats if held down continuously until reaching the final screen.

SSeett UUpp SSccrreeeenn

Display next screen. This key has no action when in a sub-menu.

EEddiitt SSccrreeeenn

Move the cursor to the next digit.

TEST

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Enter test mode and start test timer. This is not applicable in Shutdown mode.

SSeett UUpp SSccrreeeenn

No associated action.

EEddiitt SSccrreeeenn

No associated action.

TIMER “0”

OOppeerraattiinngg SSttaattuuss SSccrreeeenn

Zero displayed timer (Global Timers, State Timers, etc.)

SSeett UUpp SSccrreeeenn

No associated action.

EEddiitt SSccrreeeenn

No associated action.

TEST

TIMER

“0”

Page 19

CE-05171N page 19 of 44

66..11..22 DDiissppllaayy CCoonntteexxtt

The graphic LCD displays are organized around operating status screens and setup screens. The actual number of status

screens will be related to the total number of end devices configured for the controller. In either screen set, ten (10) lines

are visible at a time; with up and down arrow characters indicating more lines are available on the page. Also, for both

screen sets, navigation between screens is accomplished by pressing the left or right arrow keys.

66..11..33 NNuummeerriicc EEnnttrryy

The C3-3 Display uses a different approach to enter values than previous Murphy controllers. Instead of holding

in the arrow keys until the desired number is displayed, the Centurion display allows individual editing of each

position of the desired number. This is accomplished by entering the Edit Mode and using the UP/DOWN arrow

keys (1) to adjust the number above the blinking cursor (2) between 0 and 9. To edit another position, simply use

the LEFT/RIGHT (3) arrow keys to move the cursor to that position (4) and repeat the edit process until the

desired number is displayed.

In this way, values are “built” rather than “scrolled” through. Some digits may not be allowed to increment if it

would result in exceeding range limits. Values which can be positive or negative will have a sign (±) to the left of

the number. To change the sign value simply move the cursor to the sign using the LEFT arrow key and “toggle”

between + and – using the U and DOWN arrow keys. If the range of the value will exceed range limits the sign

may not be allowed to change. In this case, try reducing the numebr by decrementing the left most digit by one

or more and attempt to change the sign again.

In some instances, a word rather than a value is represented in the Edit Mode. This works like the sign value as

an ON/OFF or YES/NO prompt where the value is “toggled” between choices using the UP/DOWn arrow keys.

The value is not active in the controller until the ENTER key has been pressed to send the value to the controller.

Pressing the ESC key will discard any changes and keep the original value prior to entering the Edit Mode.

F

_

_

O

E

_

E

_

Operational/Process

Information Area

ALARM

STATUS

STATE

C

C

C

COMP. OIL PRESS. 74 PSI

SUCTION PRESS. 35.3 PSI

DISCHARGE PRESS. 265 PSI

DISC. PRESS. TARGET 270 PSI

COMP OIL TEMP 105° F

DISC. TEMPERATURE 130° F

COOLER TEMPERATURE 105° F

___________________________________

___________________________________

REMOTE ▼▲ 0000.3H

WARMUP B2 TIME-140

LOW ENGINE OIL LEVEL

TM

NAVIGATION TIMER

Status Area

HOURS

(1)

UP and DOWN

__________

__________

▼▲

▼

▼

RD

NUS

____________

____________

T

_

00000

Blinking Cursor

(2)

▼

(3)

LEFT and RIGHT

___________

___________

▼

▼

ORD

F

ENUS

_____________

_____________

00001

Blinking Cursor

_

(4)

▼

Page 20

CE-05171N page 20 of 44

6.2 Operational Screens

In addition to the set up screens reviewed in Section 7.3, the C3-3 Display offers a number of operational displays.

On the Operating Status screens, the two bottom lines display the state, hours, mode and active timer status.

This information is key to understanding the “status” of the controller.

Mode refers to the Operating Mode of the controller and can be LOCAL or REMOTE. Depending on the configuration

active in the controller, the operation may differ depending on what Mode the controller is currently displaying.

NNOOTTEE::

The Mode can be changed by pressing certain keys, if the configuration allows for REMOTE mode.

Pressing RESET or RUN/STOP is a Local function and will change the Mode to Local if it is in REMOTE.

Pressing Fn before pressing RESET or RUN/STOP is a REMOTE function and will change the Mode to REMOTE if it is in LOCAL.

66..22..11 DDeeffaauulltt OOppeerraattiinngg SSccrreeeenn

After turning on the power, the user will view the F W Murphy logo screen for three seconds before the next

screen displays, which is a software-configured default operating screen. The MConfigPro software allows

users to configure up to five screens with controller I/O groupings. Possible custom screen types that may have

been configured as a default operating screen, or which may be also displayed, include:

a) Custom Line by Line allows process data to be displayed in a list format with description and value.

b) Custom Gage allows user to display four (4) most important pieces of data on a 2 x 2 table in larger font.

c) Custom PID up to 4 PID screens.

For more information on configuring the optional screens through the MConfigPro software, please refer to the

Centurion Controller Programming Manual.

66..22..22 FF WW MMuurrpphhyy LLooggoo SSccrreeeenn

The F W Murphy Logo is the first screen in the sequence of

Display screens and can be viewed by holding down the left

arrow until scrolling left ceases.

66..22..33.. CCoorrppoorraattee aannd

d VVeerrssiioonn IInnffoorrmmaattiioonn SSccrreeeenn

Following the F W Murphy Logo screen is the F W Murphy

corporate contact information which also lists firmware version

information for the Centurion C3-3 Display, the C3-1 I/O

Module and the MConfigPro Software.

Info Screen

TM

C

C

C

FW MURPHY - MVIEW

WWW.FWMURPHY.COM

SALES@FWMURPHY.COM

(918) 317-4100

DISPLAY VER XI.XI.XI

CONTROLLER VERSION XI.XI.XI

MCONFIG PRO VER XI.XI.XI

C

C

C

TM

Logo Screen

Page 21

CE-05171N page 21 of 44

66..22..44.. SShhuuttddoowwnn HHiissttoorryy SSccrreeeenn

The history of the last twenty shutdowns is displayed on this

screen, with the most recent at the top of the list and the oldest at the bottom.

Each event is displayed with the shutdown label on one line

and the hour meter reading on the following line. Pressing the

up/down arrows will scroll up/down one shutdown at a time

rather than one line at a time.

The “1 / 3” at the right end of the top line means the user is

viewing shutdown one of a total of three stored. The newest

shutdown will always be number one and it will push the older

shutdowns further down the list.

66..22..55 EEvveenntt HHiissttoorryy SSccrreeeenn

The user easily can view the events (alarms, etc.) logged

before and after a shutdown of interest.

There will be a maximum of thirty two events in this history

and beyond that a new event will cause the oldest event to be

discarded.

66..22..44 AAccttiivvee AAllaarrmmss SSccrreeeenn

All active alarms and warnings will be displayed on this screen.

The top line is the screen heading and the next six lines display alarms. If there are more than six active alarms, there will

be up/down arrow icons at the bottom of the screen and the

user can press the up/down arrow keys to scroll up or down.

Unacknowledged alarms will be preceded by a musical note

character and acknowledged alarms will have a bar through

the staff of the note.

Pressing ACK on this screen will acknowledge all active alarms.

This screen shows the alarm annunciation as it will appear on a

status screen.

The alarm message(s) will overwrite the bottom line of the active

screen area and then briefly clear once a second. This will continue until it is acknowledged with the ACK, key unless it is a

self-clearing alarm. If there is more than one unacknowledged

alarm active, each alarm will be displayed for one second each

until acknowledged. The ACK key will acknowledge the alarm

currently displayed. Pressing the Fn key followed by the ACK

key will switch to the Alarms screen.

Alarms Screen

TM

C

C

C

ACTIVE ALARMS

LOW SUCT PRESS

LOW BATTERY VOLTS

ACK-ACK ALL ALARMS

___________________________________

___________________________________

Operating Status Screen 3

TM

C

C

C

COMP. OIL PRESS. 74 PSI

SUCTION PRESS. 35.3 PSI

DISCHARGE PRESS. 265 PSI

DISC. PRESS. TARGET 270 PSI

COMP OIL TEMP 105° F

DISC. TEMPERATURE 130° F

COOLER TEMPERATURE 105° F

LOW ENGINE OIL LEVEL

REMOTE ▼▲ 0000.3H

WARMUP B2 TIME-140

___________________________________

___________________________________

Event History Sreen

TM

C

C

C

EVENT HISTORY 1/3

PANEL ESD

00059:16:09

PANEL RESET

00059:15:58

LOW SUCT PRESS

00059:15:11

▼

___________________________________

Shutdown History Sreen

TM

C

C

C

SHUTDOWN HISTORY 1/3

___________________________________

00059:16:09

PANEL ESD

LOW SUCT PRESS

00059:15:11

OVERCRANK

00054:04:40

▼

Page 22

CE-05171N page 22 of 44

66..22..55 GGaaggee DDiissppllaayy

This is an example of a custom gage display. Configured software orders the data as needed. This display provides larger

characters for easier viewing as well as a means to prominently

display items of interest. Unacknowledged alarms will overwrite

the bottom half of the lower two gage boxes. The two bottom

lines are used to display the mode, hours, state and active

timer status.

66..22..66 LLiinnee BByy LLiinnee

This is an example of a line by line status screen for engine

parameters.

The MConfigPro software orders the available data as

needed.

Notice that there are no up/down arrows at the bottom of the

screen because there are no additional lines to be displayed

on this screen.

This is an example of a line by line status screen with more

parameters.

If the parameters do not fit on a single screen, up/down arrow

icons at the bottom of the screen can be used to scroll up or

down. The two bottom lines are used to display the mode,

hours, state and active timer status.

66..22..77 CCuussttoomm PPIIDD SSccrreeeenn

The user may choose to display any configured PID functions

in this convenient format. The control output will be displayed

as a percentage of the range. The bottom two lines are used

to display the mode, hours, state and active timer status.

TM

C

C

C

Operating Status Screen 2

COMP. OIL PRESS. 74 PSI

SUCTION PRESS. 35.3 PSI

DISCHARGE PRESS. 265 PSI

DISC. PRESS. TARGET 270 PSI

COMP OIL TEMP 105° F

DISC. TEMPERATURE 130° F

COOLER TEMPERATURE 105° F

AMBIENT TEMPERATURE 91° F

REMOTE ▼▲ 0000.3H

WARMUP B2 TIME-140

___________________________________

CUSTOM PID Sreen

TM

C

C

C

SETPOINT 75 PSI

75%

75%

80%

LINE PRESSURE 65 PSI

CONTROL OUTPUT

SUCTION PID

REMOTE ▼▲ 0000.3H

WARMUP B2 TIME=140

___________________________________

Operating Status Screen 1

TM

C

C

C

ENGINE SPEED 1140 RPM

ENGINE OIL PRESS. 47 PSI

INTAKE MFD PRESS. 7.5 ‘HG

JKT WTR TEMP 130° F

AUX WTR TEMP 92° F

REMOTE 0000.3H

WARMUP B2 TIME-140

___________________________________

Custom Gage Sreen

TM

C

C

C

OIL PRS WTR TEMP

PSI °F

BATTERY ENG SPEED

VDC RPM

42 145

13.7 1250

REMOTE 0000.5H

WARMUP B2 TIME=140

___________________________________

Page 23

CE-05171N page 23 of 44

6.3 Setup Screens and Menus

66..33..11 PPaasssswwoorrdd SSccrreeeenn

Some settings are password protected, including the setup screens.

This is the first screen seen when the SETUP/ENTER key is pressed.

The password need only be entered once during any editing

session. The password will reset when the editing session is

exited, or is timed-out due to keyboard inactivity.

The cursor begins at the last digit on the right. The user can

adjust the value of each digit with the up/down arrows while

the left/right arrows are used to select the digit to edit.

Passwords are assigned using the MConfigPro software and each

digit can range from zero to nine (except the first digit on the left)

for a total range of 00000 to 65535 for the complete password.

The user will not be allowed to increment the selected digit if it

would result in exceeding range limits.

There are three separate levels of passwords to accommodate

several security needs:

• “Standard” password – Allows access to every feature

except the Super User menu. Valid Standard passwords

can be zero or any number between 100 and 65535. If the

Standard password is set to zero, the result is that anyone

can have read/write access to setup menus.

• “Super User” password – Adds the Super User menu to the

Standard menus. Valid Super User passwords can be in the

range of 100 to 65535. The Super User password can not

be the same as the Standard password.

• “Download Only” password – This Special 35 Jump Code

allows access to a download menu and is set to a fixed

value of 35. This allows a configuration to be downloaded in

the event that the current passwords are lost or no initial

configuration has been downloaded.

If the Standard password is not zero and a password of all zeroes

is entered, the user will have “view only” access.

Inactivity Timeout: Setup procedures must be started and

completed in a timely manner. Note that after 3 minutes

without activity, the keypad returns the default operational

screen and a password must be re-entered to return to the

setup and edit menus.

Password Screen

TM

C

C

C

FOR SETUP MENUS

00000

ESC-CANCEL

▼▲ ENTER-ACCEPT

▼

▼

▼

___________________________________

ENTER PASSWORD

___________________________________

_

TM

C

C

C

Super User Menu Screen

___________________________________

▼▼

SUPER USER MENU

COM FAIL DISABLE

NO

SETUP T/O DISABLE

CONFIG FAIL DISABLE

RESET FAULT HISTORY

RESET EVENT HISTORY

▼▲ ENTER-EDIT

MORE MENUS

___________________________________

___________________________________

▼

▼

ESC-EXIT THIS MENU

TM

C

C

C

Download Only Screen

___________________________________

▼▼

CONFIRATION DOWNLOAD

COM 1 CONFIG DOWNLOAD

NO

COM 2 CONFIG DOWNLOAD

USB CONFIG DOWNLOAD

FIRMWARE DOWNLOAD

▼▲ ENTER-EDIT

___________________________________

___________________________________

Page 24

CE-05171N page 24 of 44

66..33..22 DDiiggiittaall IInnppuutt

Digital Input: For up to 32 configured Digital Input devices,

the user may select whether an input is normally open (N/O),

or normally closed (N/C).

66..33..33 DDiiggiittaall OOuuttppuutt

Digital Output: For up to 10 configured Digital Output

devices, the user may select whether an output is normally

open (N/O), or normally closed (N/C).

66..33..44 AAnnaalloogg IInnppuutt

For up to 20 configured Analog Input devices, the user may edit

aa))

Moving Average Samples. (1, 2, 4).

bb))

Determine Raw Count Offset, the lowest reading

expected from the device.

cc))

Determine Raw Count Span, the span from the lowest

to highest reading expected from the device.

dd))

Apply the appropriate Minimum engineering scale. In

most cases, 0% addresses a typical application and it

is the Centurion’s default value.

ee))

Apply the appropriate Maximum engineering scale.

In most cases, 100% addresses a typical application

and it is the Centurion’s default value.

TM

C

C

C

Digital Inputs Setup Screen 1

▼▼

▼

DIGITAL INPUTS

DIGITAL INPUT 1

DIGITAL INPUT 2

DIGITAL INPUT 3

DIGITAL INPUT 4

DIGITAL INPUT 5

D_IN_01 N/0

▼▲ ENTER-EDIT

MORE MENUS

___________________________________

___________________________________

___________________________________

Digital Inputs Setup Screen 2

TM

C

C

C

▼▼

DIGITAL INPUTS

DIGITAL INPUT 1

DIGITAL INPUT 2

DIGITAL INPUT 3

DIGITAL INPUT 4

DIGITAL INPUT 5

D_IN_01 N/0

ENTER-ACCEPT

▼▲ MODIFY SELECTION

___________________________________

___________________________________

___________________________________

Digital Outputs Setup Screen 1

TM

C

C

C

▼▼

▼

▼

DIGITAL OUTPUTS SETUP

DIGITAL OUTPUT 1

DIGITAL OUTPUT 2

DIGITAL OUTPUT 3

DIGITAL OUTPUT 4

R_OUT_01 N/O

DIGITAL OUTPUT 5

▼▲ ENTER-EDIT

MORE MENUS

___________________________________

___________________________________

___________________________________

Analog Inputs Setup Screen 1

TM

C

C

C

___________________________________

▼▼

▼

▼

ANALOG INPUTS SETUP

ANALOG INPUT 1

ANALOG INPUT 2

ANALOG INPUT 3

AN_IN_01

ANALOG INPUT 4

ANALOG INPUT 5

▼▲ ENTER-SUBMENU

MORE MENUS

___________________________________

___________________________________

Page 25

CE-05171N page 25 of 44

66..33..55 AAnnaalloogg OOuuttppuutt

User may edit:

aa))

Raw Count Offset, the lowest reading expected from

the device.

bb))

Determine Raw Count Span, the span from the lowest

to highest reading expected from the device.

cc))

Apply the appropriate Minimum engineering scale. In

most cases, 0% addresses a typical application and it is

the Centurion’s default value.

dd))

Apply the appropriate Maximum engineering scale.

In most cases, 100% addresses a typical application

and it is the Centurion’s default value.

TM

C

C

C

Analog Input 1 Setup Screen

___________________________________

▼▼

ANALOG INPUT 1 SETUP

MOVING AVERAGE SAMPLES

RAW COUNT OFFSET

RAW COUNT SPAN

MINIMUM

MAXIMUM

(1,2,OR 4) 1

▼▲ ENTER-EDIT

ESC EXIT THIS MENU

___________________________________

___________________________________

TM

C

C

C

▼

▼

Analog Input 1 Setup Screen

___________________________________

___________________________________

___________________________________

▼▼

ANALOG INPUT 1 SETUP

MOVING AVERAGE SAMPLES

RAW COUNT OFFSET

RAW COUNT SPAN

MINIMUM

MAXIMUM

(1,2,OR 4) 1

▼▲ ENTER-ACCEPT

ESC-CANCEL

–

Analog Output Setup Screen

TM

C

C

C

___________________________________

▼

▼

▼▼

ANALOG OUTPUTS SETUP

ANALOG OUTPUT 1

ANALOG OUTPUT 2

ANALOG OUTPUT 3

ANALOG OUTPUT 4

ANALOG OUTPUT 5

AN_OUT_01

▼▲ ENTER-SUBMENU

MORE MENUS

___________________________________

___________________________________

Analog Output 1 Setup Screen

TM

C

C

C

___________________________________

▼▼

ANALOG OUTPUTS 1 SETUP

RAW COUNT OFFSET

RAW COUNT SPAN

MINIMUM

MAXIMUM

00000

▼▲ ENTER-EDIT

ESC-EXIT THIS MENU

___________________________________

___________________________________

Page 26

CE-05171N page 26 of 44

66..33..66 TThheerrmmooccoouuppllee IInnppuutt

User may:

aa))

Identify whether the calibration Type should be set to J or K.

bb))

Assign the Offset value.

Thermocouple Setup Screen

TM

C

C

C

▼

▼

▼▼

THERMOCOUPLE SETUP

THERMOCOUPLE 1

THERMOCOUPLE 2

THERMOCOUPLE 3

THERMOCOUPLE 4

THERMOCOUPLE 5

TC1

▼▲ ENTER-SUBMENU

MOORE MENUS

___________________________________

___________________________________

___________________________________

TM

C

C

C

▼

▼

Analog Output 1 Setup Screen 1

___________________________________

▼▼

ANALOG OUTPUTS 1 SETUP

RAW COUNT OFFSET

RAW COUNT SPAN

00000

MINIMUM

MAXIMUM

▼▲ ENTER-ACCEPT

ESC-CANCEL

___________________________________

___________________________________

_

TM

C

C

C

Thermocouple 1 Setup Screen

▼▼

THERMOCOUPLE 1 SETUP

THERMOCOUPLE TYPE

THERMOCOUPLE OFFSET

(J OR K) J

▼▲ ENTER-EDIT

ESC-EXIT THIS MENU

___________________________________

___________________________________

___________________________________

TM

C

C

C

Thermocouple 1 Setup Screen 1

▼▼

THERMOCOUPLE 1 SETUP

THERMOCOUPLE OFFSET

- 00015

▼▲ ENTER-ACCEPT

ESC-CANCEL

___________________________________

___________________________________

___________________________________

▼

▼

Page 27

CE-05171N page 27 of 44

66..33..77 GGeenneerraall TTiimmeerr SSeettuupp

User may edit all general purpose timers. Generally, global timers

affect engine operation. They also help define an event.

aa))

B1: All event types can be associated with, and locked out

by, a Bx timer. B1 is the first global timer used for delaying

an event condition detection. The timer starts in a running

State (10 – 13) depending on which have been marked ‘In

Use’. B1 is also known as the “Lockout Timer.”

bb))

B2: The second global timer used for delaying an event

condition detection. B2 is also known as a secondary

“Lockout Timer.”

cc))

C: The delay allowing a clear reading before beginning

testing for the arming of Class C events. The default and

typical time for most applications is 2 seconds.

dd))

S: Users have up to five (5) options to assign additional

special global timers to signals. The Sx timers begin concurrently with the Bx timers.

ee))

No Flow: The global delay used for delaying the triggering of

a No Flow event. This global no flow timer is enabled after

B1 expires, and begins timing after any of the no flow transition times configured in the digital input dialog expires.

ff))

Test: Time given to allow for maintenance testing of end

devices without triggering a fault or shutdown condition.

The timer initiates when switched to test mode.

gg))

Ignition Off Delay: Time delay before the assigned ignition

output turns off. This is typically used to burn remaining

fuel vapors after the fuel valve is turned off.

hh))

Ignition On Delay: Time delay before the assigned ignition

output turns on. This is typically used to delay ignition

until engine crank rollover can occur.

ii))

Fuel On Delay: Time delay before the assigned fuel valve

output is turns on. This is typically used to delay fuel until

ignition has been turned on.

TM

C

C

C

General Timer Setup Screen

___________________________________

▼▼

GENERAL TIMER SETUP

B1 TIMER

B2 TIMER

C TIMER

S1 TIMER

S2 TIMER

(0 - 999) 00060

▼▲ ENTER-EDIT

MORE MENU

___________________________________

___________________________________

Page 28

CE-05171N page 28 of 44

66..33..88 MMaaiinntteennaannccee TTiimmeerr SSeettuupp

The user may access and edit the ten (10) maintenance settings for timer duration. The user may also access and reset

all timer duration and time remaining settings. Note that while

these are configured through MConfigPro, they must be manually initiated, or restarted, in C3-3 Display. All maintenance

timer units are in hours.

TM

C

C

C

▼

▼

Maintenance Timer Setup Screen

___________________________________

___________________________________

___________________________________

▼▼

MAINTENANCE TIMER SETUP

MAINTENANCE TIMER 1

MAINTENANCE TIMER 2

MAINTENANCE TIMER 3

MAINTENANCE TIMER 4

MAINTENANCE TIMER 5

CHANGE OIL

▼▲ ENTER-SUBMENU

MORE MENUS

Maint_1 Setup Screen

TM

C

C

C

___________________________________

MAINTENANCE TIMER SETUP

TIMER DURATION

TIME REMAINING

CHANGE OIL 00100

▼▲ ENTER-EDIT

ESC-EXIT THIS MENU

___________________________________

___________________________________

▼▼

TM

C

C

C

Maint_1 Setup Screen 1

___________________________________

MAINTENANCE TIMER SETUP

TIME REMAINING

CHANGE OIL 00091

▼▲ RESET-RESET TIMER

ESC-EXIT THIS MENU

___________________________________

▼▼

___________________________________

Page 29

CE-05171N page 29 of 44

66..33..99 SSeett ppooiinnttss SSeettuupp

User can edit any of the 128 set points that are configured.

Set points further configure analog inputs and thermocouple

inputs by defining a threshold, exception or any other out-oflimit event that may require action. Multiple set points are

often applied to a process and they may be configured as

often as needed to meet changing conditions.

Common alarm and shutdown set points a user might have

configured include:

High Shutdown

Low warning

Open Warning

High Warning

Low Shutdown

A user might also have configured other set point settings

which are not used to indicate alarm or shutdown. For example, a set point provides a less flexible, but simpler alternative

to controlling the pump’s start and stop functions.

To edit a configured set point:

aa))

Assign numeric threshold that if crossed, triggers the set point.

bb))

Adjust the sign of the threshold value as plus (+) or minus (-) by

moving the cursor to the sign symbol position and use the up

and down keys to toggle the sign.

For more on Set Points, please refer to the Centurion

Configurable Controller Programming Manual.

66..33..1100 CCoonnttrrooll OOuuttppuutt SSeettuupp

The Centurion controller allows users to define up to eight (8)

outputs to augment control not otherwise defined.

The Centurion controller can be configured through MConfigPro

software to define an analog output, a digital output, a single

pulsed digital output, or two pulsed digital outputs.

Note that Control Outputs 1 through 4, are directly related to

Proportional Integral Derivative (PID) calculation loops and are

further defined in the PID dialog screens described in Section

6.3.11. For example, PID 1 is assigned its control from

Control Output 1, PID 2 from Control Output 2, and so on.

If the configured output is a pulsed cycle, the user may edit

those behaviors by following the available steps:

aa))

Assign value to Increase Max On Time. (Set limit of maxi-

mum on-time for Increase pulses.)

bb))

Assign value to Increase Off Time. (Set fixed off-time for

Increase pulses.)

cc))

Assign value to Increase Changeover On Time. (Set fixed

on-time for single pulse on direction change for Increase).

dd))

Assign value to Increase Changeover Off Time. (Set fixed

off-time for single pulse on direction change for Increase).

ee))

Assign value to Decrease Max On Time. (Set limit of maxi-

mum on-time for Decrease pulses.)

ff))

Assign value to Decrease Off Time. (Set fixed off-time for

Decrease pulses.)

gg))

Assign value to Decrease Changeover On Time. (Set fixed on-

time for single pulse on direction change for Decrease).

TM

C

C

C

▼

▼

Setpoints Setup Screen

___________________________________

▼▼

SETPOINTS SETUP

SETPOINTS 1-16

SETPOINTS 17-32

SETPOINTS 33-48

SETPOINTS 49-64

SETPOINTS 65-80

▼▲ ENTER-SUBMENU

MORE MENUS

___________________________________

___________________________________

Setpoint Setup Screen 1

TM

C

C

C

▼▼

SETPOINTS SETUP

SETPOINTS 1

SETPOINTS 2

SETPOINTS 3

SETPOINTS 4

SETPOINTS 5

LO SUCT PRS 0008.0

▼▲ ENTER-EDIT

ESC-EXIT THIS MENU

___________________________________

___________________________________

___________________________________

TM

C

C

C

Control Output Setup Screen

▼

▼

▼

▼

CONTROL OUTPUT 1 SETUP

CONTROL OUTPUT 1

CONTROL OUTPUT 2

CONTROL OUTPUT 3

CONTROL OUTPUT 4

CONTROL OUTPUT 5

THROTTLE

▼▲ ENTER-MENU

MORE MENU

___________________________________

___________________________________

___________________________________

C

C

C

CONTROL OUTPUT 1 SETUP

___________________________________

INC MAX ON TIME

INC OFF TIME

INC CHANGEOVER ON TIME

INC CHANGEOVER OFF TIME

DEC MAX ON TIME

___________________________________

___________________________________

▼▲ ENTER-EDIT

ESC-EXIT THIS MENU

Control Output 1 Setup Screen

TM

01000

▼▼

Page 30

CE-05171N page 30 of 44

hh))

Assign value to Decrease Changeover Off Time. (Set fixed

off-time for single pulse on direction change for Decrease).

For more on Control Output, please refer to the Centurion

Configurable Controller Programming Manual.

66..33..1111 PPIIDD SSeettuupp

Users may view and edit up to four (4) MConfigPro software configured Proportional Integral Derivative (PID) calculation loops.

A PID provides a constant feed back loop, in which the PID

can correct for a measured process variable against a

desired set point, output the corrective action to the process

and wait for and recalculate the next measurement.

The ultimate goal of the PID is to reduce the error to zero.

During the time a PID is enabled, the PID always overrides a

control output. Recall that PID 1 is assigned its control from

control output 1, PID 2 from control output 2, and so on.

To View and Edit PID Settings:

11))

Over Ride Ramp Time: Assign a time interval value to wait

before making the next adjustment.

22))

Over Rid Ramp Amount: Determine the increments in a

given direction (positive or negative) that the set point

should be altered to regain balanced processes. In the

example of the discharge and suction pressure application,

this value would indicate how much the PID should resist

its goal in reaching the set point.

33))

Ramp Time: Assign a time interval for the PID to calculate error.

44))

Over Ride Max Change: Assign a maximum allowed

change. This represents the total amount of change

allowed into or out of the ramp amount from the set point.

The maximum change value should be large enough to

effect change.

55))

Set Point: Assign the desired goal—the target feedback

base value.

66))

DeadBand: Assign a value around the set point during

which the PID will not calculate error.

77))

Minimum Output: Assign a percentage as minimum output.

88))

Maximum Output: Assign a percentage as maximum output.

99))

Proportional: Adjust the output by a value that is proportional to the change of error.

1100))

Integral: To prevent the PID from oscillating or overshooting the set point, assign a value to “reset” the system

to produce zero error, or nudge the process variable to the

set point. This value is typically set to zero.

1111))

Derivative: Assign a value to the rate of change of error.

This value is typically set to zero.

1122))

Max Override Change: Assign a percentage rate of

change over which would cause harm to the system.

For more on PID, please refer to the Centurion Configurable

Controller Programming Manual.

TM

C

C

C

▼

▼

PID Setup Screen

___________________________________

▼▼

PID SETUP

PID 1

PID 1

_

PID 2

PID 3

PID 4

▼▲ ENTER-SUBMENU

MORE MENUS

___________________________________

___________________________________

TM

C

C

C

PID 1 Setup Screen

___________________________________

▼▼

PID 1 SETUP

OVERRIDE RAMP TIME

00004

OVERRIDE RAMP AMOUNT

RAMP TIME

MAX % OF CHANGE

SETPOINT

▼▲ ENTER-EDIT

ESC-EXIT THIS MENU

___________________________________

___________________________________

Page 31

CE-05171N page 31 of 44

66..33..1122 IInniittiiaall RRPPMM SSeettuupp

aa))

Assign value for Warmup RPM.

bb))

Assign value for Wait to Load RPM.

cc))

Assign value for Run Loaded RPM.

dd))

Assign value for Cooldown RPM.

66..33..1133 MMiisscceellllaanneeoouuss SSeettuupp

User can access and edit the miscellaneous settings.

aa))

Crank Attempts: Define a value for number of crank

attempts after which an over-crank sequence will be triggered in the Event logic.

bb))

Controller Slave Address: Provide the value for the Modbus

Address Port. The factory default is 1.

cc))

Port 1 Mode: Select Communication Port 1 as RS232, or RS485.

dd))

Port 1 Reply Delay: To ensure sufficient time for the

Modbus reply, assign appropriate time value for Delay

Modbus Reply Port 1.

ee))

Port 1 Baud Rate: Select appropriate transmission baud rate

ff))

Port 2 Mode: Select Communication Port 2 as RS232, or RS485.

gg

))

Port 2 Reply Delay: To ensure sufficient time for the

Modbus reply, assign appropriate time value for Delay

Modbus Reply Port 2.

hh))

Port 2 Baud Rate: Select appropriate transmission baud rate

ii))

Flywheel Teeth: Define a value for Flywheel Teeth used to

calculate RPM.

The following cold temperature offset values should only be adjusted by personnel with a full working knowledge of the

Centurion in conjunction with calibrated reference equipment.

jj))

Core Cold Temp Offset: Enter a non-zero Value for Core

Temperature Adjustment (in tenths) to adjust the temperature

readings for all Thermocouple inputs on both the Main I/O Module

(C3-1). Entering a non-zero value will adjust the Cold Junction

Compensation reading used to calculate temperature.

kk))

Exp Cold Temp Offset: Enter a non-zero Value for

Expansion Board Temperature Adjustment (in tenths) to

adjust the temperature readings for all Thermocouple inputs

on Expansion I/O (C3-2). Entering a non-zero value will

adjust the Cold Junction Compensation reading used to calculate temperature.

ll))

Hour Meter: The user may make hour meter adjustments.

The range is 0 – 65535 hours.

TM

C

C

C

Initial RPM Setup Screen

___________________________________

▼▼

INITIAL RPM SETUP

WARMUP RPM

00600

WAIT FOR LOAD RPM

RUN LOADED RPM

COOLDOWN RPM

▼▲ ENTER-EDIT

MORE MENUS

___________________________________

___________________________________

▼

▼

TM

C

C

C

Miscellaneous Setup Screen

___________________________________

▼▼

MISCELLANEOUS SETUP

NUMBER OF CRANK ATTEMPTS

00003

PORT 1 SLAVE ADDRESS

PORT 1 RS432/RS485

PORT 1 RESPONSE DELAY

PORT 1 BAUD RATE

▼▲ ENTER-EDIT

MORE MENUS

___________________________________

___________________________________

▼

▼

Page 32

CE-05171N page 32 of 44

66..33..1144 LLuubbee NNoo FFllooww SSeett UUpp

User can view and edit Lube No Flow set up. There are two

levels to this menu as there are two possible adjustments per

No-Flow input. The user will select an input from the first menu

and press Setup/Enter. This will display the submenu for the

selected digital input if it is used for No-Flow monitoring.

Otherwise, the text label on the left side of the edit box will display “NOT IN USE”, and pressing Enter will have no effect.

At the submenu level, the user may adjust the expected transition frequency and the total cycles count (which relates to

the wear rate of the sensor).

66..33..1155 LLuubbee NNoo FFllooww SSttaattuuss

The user may view information about the No-Flow inputs. If a

digital input is designated for use as a No-Flow input, it will

display how much time elapsed before the last transition, and

how much time has elapsed since that transition. If the input

is not designated as a No-Flow input, there will be zeros displayed. Both values have a maximum value of 999.

66..33..1166 SSuuppeerr UUsseerr MMeennuu

The Super User menu will only be visible if the Super User

password has been entered.

The first three selections (a – c) allow the user to temporarily

override the default behavior of the display. It may be helpful

to turn off a fault annunciation screen that prevents the viewing of information on operating status screens.

aa))

Com Fail Disable

bb))

Set up T/O Disable

cc))

Config Fail disable

Note that the reset history commands do not permanently switch

to Yes when entered, but instead toggle back to NO after sending

the command to the controller.

TM

C

C

C

Lube No-Flow Setup Screen

___________________________________

▼▼

LUBE NO-FLOW SETUP

NO-FLOW INPUT # 1

DI_1 NF

NO-FLOW INPUT # 2

NO-FLOW INPUT # 3

NO-FLOW INPUT # 4

NO-FLOW INPUT # 5

▼▲ ENTER-SUBMENU

MORE MENUS

___________________________________

___________________________________

▼

▼

TM

C

C

C

No-Flow # 1 Setup Screen

___________________________________

▼▼

NO-FLOW INPUT # 1 SETUP

CYCLE TIME (SEC)

00010

TOTAL CYCLES (X100)

▼▲ ENTER-EDIT

ESC-EXIT THIS MENU

___________________________________

___________________________________

TM

C

C

C

Lube No-Flow Status Screen

___________________________________

▼▼

LUBE NO-FLOW STATUS

CYCLE TIME-INPUT # 1

PREV 0 CURR 0

CYCLE TIME-INPUT # 2

CYCLE TIME-INPUT # 3

CYCLE TIME-INPUT # 4

CYCLE TIME-INPUT # 5

▼▲ CYCLE TIMER (SEC)

MORE MENUS

___________________________________

___________________________________

▼

▼

TM

C

C

C

Super User Menu Screen

___________________________________

▼▼

SUPER USER MENU

COM FAIL DISABLE

NO

SETUP T/O DISABLE

CONFIG FAIL DISABLE

RESET FAULT HISTORY

RESET EVENT HISTORY

▼▲ ENTER-EDIT

MORE MENUS

___________________________________

___________________________________

▼

▼

Page 33

CE-05171N page 33 of 44

Also, the message “History Cleared” will be displayed until another

key is pressed.

dd))

Reset Fault History

ee))

Reset Event History

The P1 and P2 signify Communication Port 1 and

Communication Port 2 and are for setting up the RS485 interfaces on the display’s serial ports. PU/PD designates the

pull-up and pull-down resistors.

ff))

P1 PU/PD

gg))

P2 Termination

hh))

P2 PU/PD

ii))

P2 Termination

New configurations can be downloaded to the display by

selecting the desired connection here. After enabling the

download, download progress is indicated on the left side of

the edit box as a percentage complete. After selecting Yes for

download, and until No is selected after download is complete, only the Enter key will be active. See Section 6.2 for further details about downloading configurations.

jj))

Com 1 Config Download

kk))

Com2 Config Download

ll))

USB Config Download

mm))

Factory Auto Test: For factory use ONLY.

nn))

Firmware Download: A firmware update mode screen will

remain until the unit has been reset by remote command or a

power cycle. See Section 7.2.5 for downloading new firmware.

66..33..1177 CCoonnffiigguurraattiioonn DDoowwnnllooaadd ((DDoowwnnllooaadd OOnnllyy SSc

crreeeenn))

This menu allows for download only and can be accessed

through the Special Jump Code 35. It is the only screen

available by entering the password 35.

aa

) Com 1 Config Download: Selecting Yes initiates configu-

ration download through Communication Port 1.

bb))

Com2 Config Download: Selecting Yes initiates configu-

ration download through Communication Port 2.

cc))

USB Config Download: Selecting Yes initiates configura-

tion download through USB port.

dd))

Firmware Download: Selecting Yes Initiates the download.

66..33..1188 DDiissppllaayy BBooaarrdd SSttaattuuss

The user may view diagnostic information that reflects the

operating conditions of the C3-3 Display only. The Heater

PWM% refers to the LCD heater which only operates in cold

temperature conditions. The reset source indicates the cause

of the last reset. Possible causes for reset include external

reset, power-up, brown-out and watch dog.

aa))

Battery Volts

bb))

Board Current

cc))

Temperature

dd))

Heater PWM %

ee))

Reset Source

TM

C

C

C

Super User Menu Screen 3

___________________________________

▼▼

SUPER USER MENU

COM 1 CONFIG DOWNLOAD

28% YES

COM 2 CONFIG DOWNLOAD

USB CONFIG DOWNLOAD

FACTORY AUTO TEST

FIRMWARE DOWNLOAD

▼▲ ENTER-EDIT

___________________________________

___________________________________

▼

▼

ESC-EXIT THIS MENU

TM

C

C

C

Download Only Screen

___________________________________

▼▼