Page 1

CANdrive™ Module

Installation and Operations Manual

00-02-0618

04-10-07

Section 78

Page 2

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our

specifications and designs at any time. The latest version of this manual can be found at www.fwmurphy.com.

Warranty - A two year warranty on materials and workmanship is given with this FW Murphy product. A copy of

the warranty may be viewed or printed by going to www.fwmurphy.com/support/warranty.htm. In the event of a

fault or technical query, please contact your Murphy representative for technical support.

Please read the following information before installing.

BEFORE BEGINNING INSTALLATION OF THIS MURPHY

PRODUCT:

• A visual inspection of this product for damage during shipping

is recommended before installation.

• It is your responsibility to ensure that qualified mechanical and

electrical technicians install this product.

• Disconnect all electrical power to the machine.

• Make sure machine cannot operate during installation.

• Follow all safety warnings of the machine manufacturer.

• Read and follow all installation instructions.

• Please contact FW MURPHY immediately if you have any

questions.

Page 3

T able of Conte nt s

General Information................................................................................................................ 1

Introduction ..................................................................................................................1

Installation Instructions...................................................................................................... ....2

Configuration................................................................................................................2

Electrical Connection ...................................................................................................3

Panel Mounting............................................................................................................5

Operation and Maintenance................................................................................................... 6

Gage Driver Outputs....................................................................................................6

Indicating LEDs............................................................................................................6

Maintenance.................................................................................................................7

Specifications.......................................................................................................................... 8

Power Supply...............................................................................................................8

Inputs ...........................................................................................................................8

Outputs.........................................................................................................................8

General ........................................................................................................................8

Page 4

(THIS PAGE INTENTIONALLY LEFT BLANK)

Page 5

General Information

Introduction

As part of the MurphyLink® family, the Murphy CANdrive™ offers a cost effective instrument

solution for modern electronic engines. CANdrive acts as an interface between ECU

CANbus/J1939 transmitted data and standard electric indicating gages. CANdrive and electric

gages are an alternative solution to retrofitting of engine senders, magnetic pickups and

associated wiring.

CANdrive has dedicated outputs for a tachometer, oil pressure, and coolant temperature

electric gages. User configurable links allow for selectivity between 12 or 24 VDC systems,

and for all gage outputs to be selected for Murphy, VDO, or Datcon.

CANdrive is packaged in a compact, surface mounted case with epoxy encapsulation for

maximum durability and environmental sealing. Electrical connection is via a 12-way

automotive-type connector.

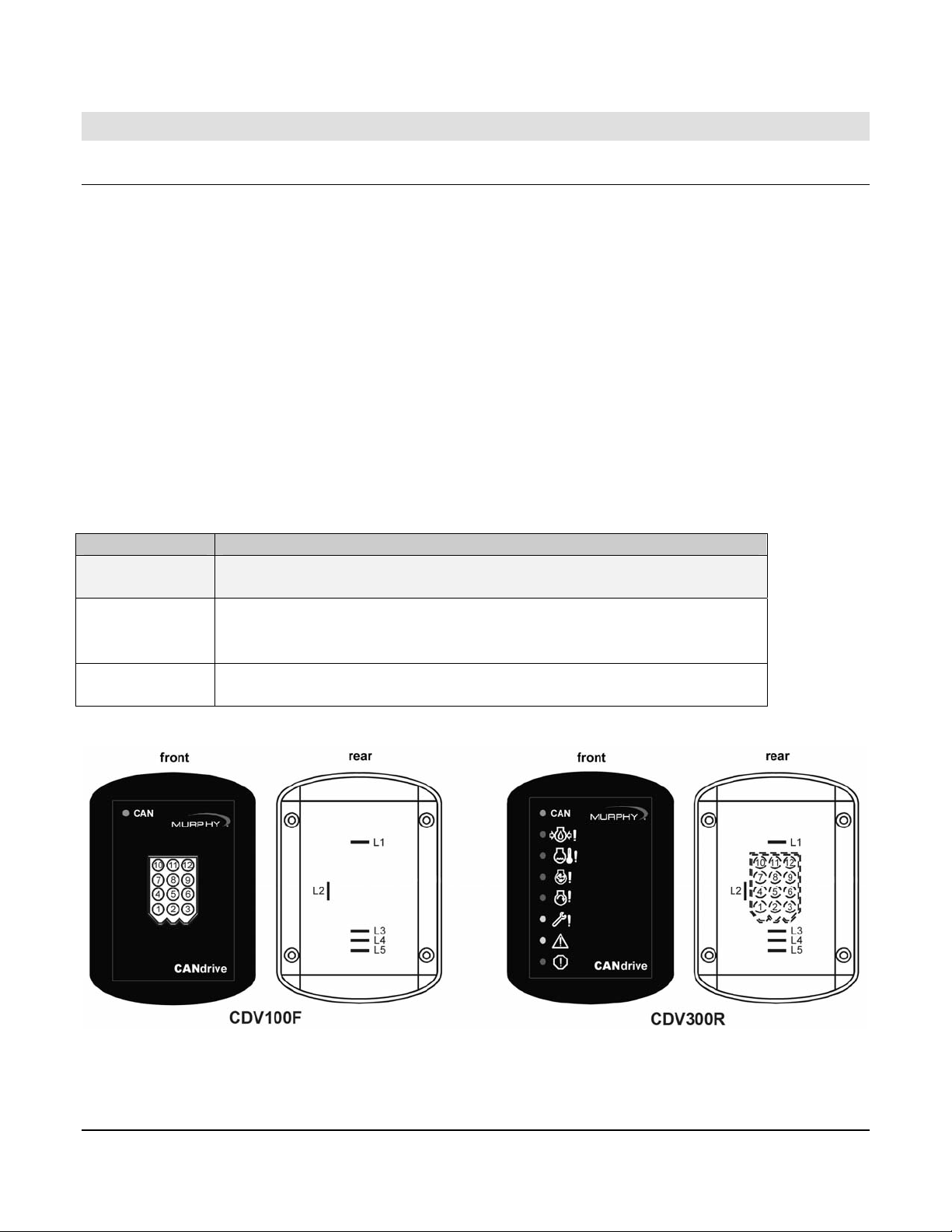

Standard Model Options

Stock Code Model / Description

78-70-0363

78-70-0364

78-00-0437

CDV100F, CAN drive J1939 to electric gage interface. 1 x CAN

status LED, connector forward

CDV300R, CANdrive J1939 to electric gage interface. 8 x

status/fault LEDs, connector rearward. Model CDVG sealing

gasket included.

CDV-PW-30, CANdrive power and CAN harness. Length: 30 in.

(0.762m). Included with CDV100F and CDV300R

Section 78 00-02-0618

04-10-07 - 1 -

Page 6

Installation Instructions

Configuration

CANdrive modules are supplied with 5 circuit board links soldered in place. These wire links,

labeled L1 through L5, are located on the back side of the unit.

The links allow configuration of operating options by snipping the appropriate wire according to

the following configuration table.

WARNING: The configuration links are one-time breakable and are

not replaceable. Care must therefore be taken to select the

correct options before cutting links.

Configuration Table

Link Function Link Options

L1 CANbus 120 Ohm resistor Cut L1 to remove 120 Ohm terminating resistor.

Leave L2 intact for 12V operation L2 DC supply voltage

Cut L2 for 24V operation

L3

L4

Section 78 00-02-0618

04-10-07 - 2 -

Gage output options

Leave L3 and L4 intact for Murphy gages (see

compatibility table)

Cut L3 only for Datcon gages (see compatibility table)

Cut L4 only for VDO gages (see compatibility table)

Leave L5 intact for 0-7 bar gages L5 VDO pressure gage range

Cut L5 for 0-10 bar gages

Page 7

Gage Compatibility Tables

Electrical Connection

CANdrive modules electrical connection is through a 12-way automotive type receptacle

shown right. CANdrive models are available with the connector facing forward through the front

label (‘F’ option, e.g. model CDV100F), or rearward through the epoxy encapsulation (‘R’

option, model CDV300R).

CANdrive electrical connection is through a 12-way automotive type receptacle. A 30-inch

connector harness is included with each CANdrive model, and has each wire individually

labeled for ease of installation.

Typical Connection

Section 78 00-02-0618

04-10-07 - 3 -

Page 8

Terminal Functions

PIN Function

1 Negative DC, power supply

2 Positive DC, power supply

3 Negative DC, gage common return

CANdrive modules are supplied for use with 12V (7 to 16V) DC operation. If 24V

(19 to 30V) DC operation is required, remove (cut) rear link L2.

Connect a 1 Amp anti-surge fuse in the positive DC line (pin 2).

4 Oil pressure gage output

6 Coolant temperature gage output

Pins 4 and 6 give a variable current output for driving oil pressure and coolant

temperature electric gages. The current versus pressure/temperature curve is

specific to each gage type, and must be selected by cutting appropriate links L3, L4

and L5 - see Configuration section above.

7 Tachometer output

Pin 7 gives a square wave output (0V to battery positive DC), with a frequency that

is proportional to engine speed. At 1500 RPM engine speed, the output is

approximately 121 Hz, suitable for driving charge alternator based tachometers

such as the Murphy AT(H)A series. Pin 7 gives no output below 100 RPM engine

speed.

Connect each output to the appropriate gage/ tachometer signal input.

Gage/tachometer negative terminals should be common to battery negative, ideally

via dedicated wiring to terminal 3. (The use of dedicated return wiring to pin 3

rather than a ground return will minimize gage inaccuracies caused by ground

noise.)

5 CAN Hi

8 CAN Lo

Connect these terminals to the engine CANbus, taking care to observe the correct

polarity. The CANbus cable screen/shield is typically connected to ground at the

ECU end: refer to the engine manufacturer’s installation guidelines.

CANdrive modules are supplied with a 120 Ohm network terminating resistor fitted

in-circuit between CAN Hi and CAN Lo. If CANdrive module is not positioned at the

end of the CANbus network, remove the resistor by snipping out rear link L1.

9 Reserved for future use

10 Factory use

11 Factory use

12 Factory use

NOTE: Connection Pins 9, 10, 11, and 12 are reserved for future use, or

are used in the factory setup of CANdrive modules. Do not connect wiring

or equipment to these terminals. Connection can result in permanent

damage to CANdrive modules.

Section 78 00-02-0618

04-10-07 - 4 -

Page 9

Panel Mounting

WARNING: Do not install the CANdrive module near exhaust

manifolds, turbochargers or other engine locations th at migh t

exceed the maximum allowable operating temperature of 185°F

(85°C).

CANdrive modules are surface-mounted with four no.4 screws, fixing center dimensions as

shown. Select screw length according to panel thickness, ensuring a maximum of 1/2 inch

(13mm) screw depth into the CANdrive module fixing holes.

Model CDV100F, with forward facing connector, is designed for surface-mounting inside an

enclosed panel.

Model CDV300F, with additional LEDs and rearward facing connector, is designed for front-ofpanel mounting: these modules require an additional 2.4” x 1.6” (60 x 40mm) cut-out for rear

access to connector and links. The CDV300F includes a CDVG gasket (fitted into a well

behind the rim of the case) to provide front environmental sealing to IP65.

Before mounting, ensure that the final position allows access for:

• Connection of the included wire harness.

• Configuration of links L1 to L5 (position as shown). Alternatively, ensure that the links

are set correctly before mounting. See Configuration section below for full details.

Section 78 00-02-0618

04-10-07 - 5 -

Page 10

Operation and Maintenance

Gage Driver Outputs

Gage outputs operate when CANdrive module reads valid J1939 data for engine speed, oil

pressure and coolant temperature. If CANdrive module stops receiving valid data, the gage

outputs are maintained at the last known value for approximately five seconds, after which time

the outputs are turned off.

Indicating LEDs

All standard models have a green CAN status LED. A flashing CAN status LED indicates that

CANdrive module is powered, but is not receiving any J1939 data. A constantly lit CAN status

LED indicates a good CANbus connection and J1939 activity. (Note: J1939 activity can

originate from ANY device on the CANbus network, and may not be valid data from the engine

ECU.)

Model CDV300R has additional LEDs for indication of engine faults, as transmitted from the

ECU. CANdrive modules respond to single DM1 (active fault code) messages that contain a

Suspect Parameter Number (SPN), Fault Mode Indicator (FMI) and warning/stop lamp data.

CANdrive modules also read multi-packet transport messages broadcast using the broadcast

address message (BAM) protocol.

LEDs typically light continuously to indicate a shutdown fault, and flash to indicate a (nonshutdown) warning fault.

CANdrive modules can handle up to 8 simultaneous faults at one time; additional fault

messages are not registered. When a fault becomes inactive and is no longer broadcast, the

appropriate LED goes out after approximately two seconds.

Section 78 00-02-0618

04-10-07 - 6 -

Page 11

Maintenance

CANdrive modules have no user-serviceable parts. Maintenance is therefore limited to the

following preventative checks:

• Check that electrical connections are secure.

• Check that the CANdrive module is securely mounted and kept free from

exposure to water or build up of excessive dust/dirt. The front label and casing

may be wiped with a clean, damp cloth. Do not use cleaning solvents.

Section 78 00-02-0618

04-10-07 - 7 -

Page 12

Specifications

Power Supply

• Operating voltage:

• 12V range (link L2-in place) 7-16 VDC

• 24V range (link L2-cut) 19-30 VDC

• Current consumption:

• CDV100F: 25mA typical

• CDV300R: 50mA, typical (2 LEDs lit)

Inputs

• CANbus:

• SAE J1939 protocol, Input fitted with 120 Ohm terminating resistor, removable by cutting link L1.

Outputs

• Oil pressure gage, coolant temperature gage

• Link selectable for Murphy, VDO or Datcon electric gages

• Tachometer

• Pulsed DC, approximately 121 Hz @ 1500 RPM

General

• Overall dimensions (W x H x D)

• Case: 2.7x3.8x0.9 inch (68x96x22mm) (allow 2 inches (50mm) depth with connector)

• Weight: approximately .18 lbs (80g)

• Environmental sealing

• IP60

• CDV300R: IP65 from front with CDVG gasket (included)

• Operating ambient temperature: -40° F to 185° F (-40°C to +85°C)

• Storage temperature: -67°F to 221°F (-55°C to 105°C)

• Operating Vibration: .02 lbs (10g) (5-2000 Hz)

• Operating Shock: .11 lbs (50g) (3-axis)

Section 78 00-02-0618

04-10-07 - 8 -

Page 13

MURPHY, the Murphy logo, and CANdrive are registered and/or common law trademarks of Murphy Industries,

Inc. This document, including textual matter and illustrations, is copyright protected by Murphy Industries, Inc.,

with all rights reserved. (c) 2007 Murphy Industries, Inc. Other third party product or trade names referenced

herein are the property of their respective owners and are used for identification purposes o nly.

Section 78 00-02-0618

04-10-07 - 9 -

Page 14

Loading...

Loading...