Page 1

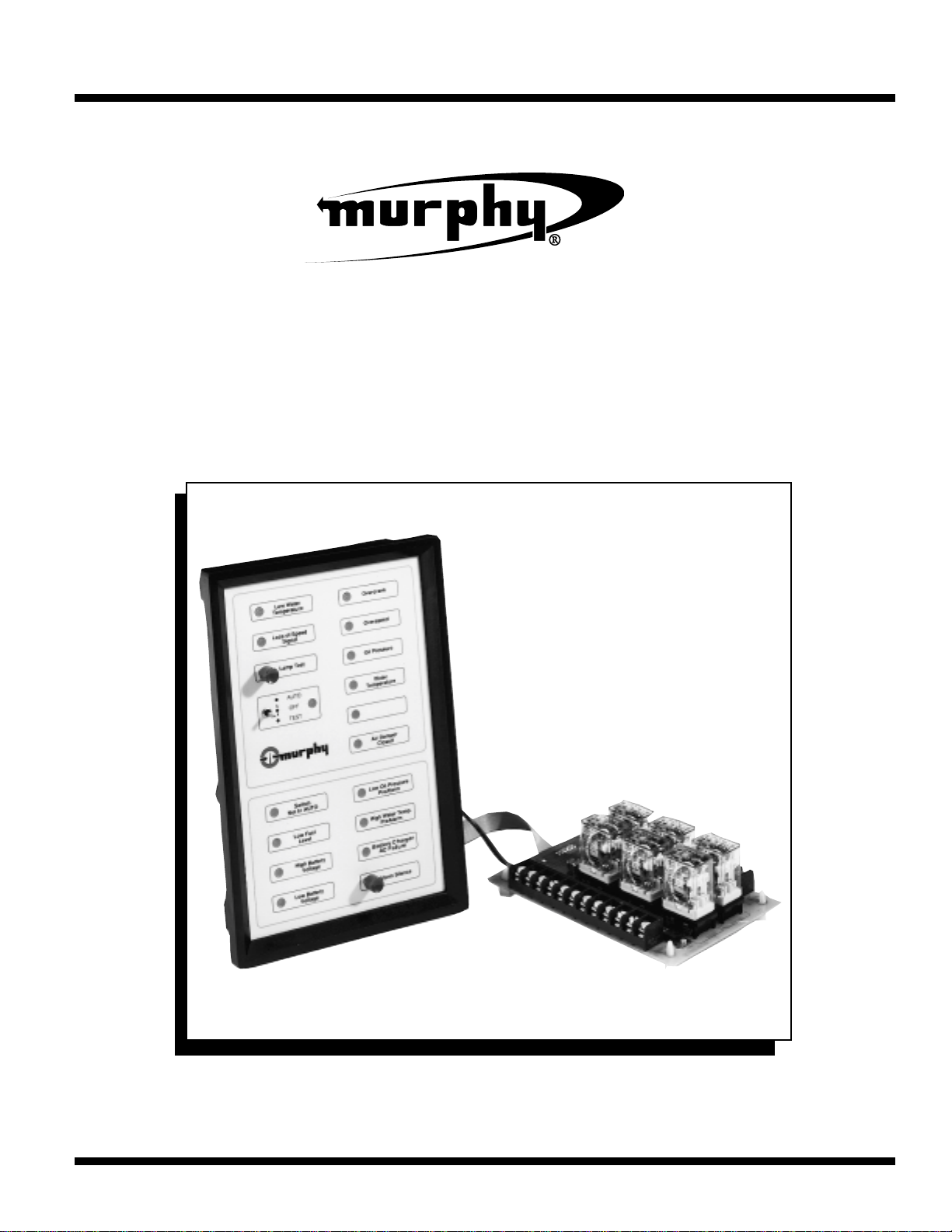

SERIES A900

MURPHYMATIC

®

GENERATOR

ENGINE CONTROL SYSTEM

DESIGN, INSTALLATION

AND OPERATING MANUAL

A900-9025N

Revised 10-99

Section 40

(00-02-0197)

Page 2

BEFORE BEGINNING

INSTALLATION OF THIS

MURPHY PRODUCT

✔ Disconnect all electrical

power to the machine.

✔ Make sure the machine

cannot operate during

installation.

✔ Follow all safety warnings of

the machine manufacturer.

✔ Read and follow all

installation instructions.

Certain danger to human safety and to equipment

may occur if some equipment is stopped without prewarning. It is recommended that monitored functions

be limited to alarm-only or to alarm before shutdown.

WARNING

Page 3

Table of Contents

Section 1: Introduction page 1

1-1 System 1

1-2 Models 1

1-3 Purpose 1

1-4 Definitions 1

1-5 How To Use This Manual 1

Section 2: Specifications 1

2-1 Enclosure Type 1

2-2 Power Requirements 1

2-3 Input Ratings 1

2-4 Output Ratings 1

2-5 Field Wiring Connections 1

2-6 Operating Temperature 1

Section 3: Model Identification 1

3-1 Model Numbers 1

3-2 A901 2

3-3 A901-2 5

3-4 A902 7

3-5 A902-2 8

3-6 A903 10

3-7 A903-2 12

Section 4: Installation 14

4-1 Location 14

4-2 Wiring 14

4-3 Crank Disconnect 19

4-4 Pre-Operational Check-Out 19

Section 5: Operation 21

5-1 Operator Controls 21

5-2 Operating Modes 21

Section 6: Routine Maintenance and Operational Tests 21

6-1 Routine Maintenance 21

6-2 Operational Tests 21

Section 7: Troubleshooting and Repair 21

7-1 Tools Required 21

7-2 A900 SELECTRONIC®Control Operation and Shutdown 21

7-3 A900 SELECTRONIC®Control Alarm Circuit Operation 23

Section 8: Service Parts 24

8-1 Table 8-1: Replacement Components of the A900 Series Generator Controls 24

8-2 Table 8-2: Replacement Components of the A900 Controls for Detroit Diesel 24

Page 4

Section 1: Introduction

1-1 System.

1-1.1 The MURPHYMATIC®Generator Engine Control System,

Series A900 is designed to meet the requirements of the engine

control, shutdown and alarm section of NFPA-110 “Emergency

And Standby Power Systems” specification. The controller also

meets the minimum requirements of NFPA99 “Health Care

Facilities” and the Canadian standard CAN/CSA-C282-M89

“Emergency Electrical Power Supply for Buildings” for engine

control, shutdown and alarm systems. By combining one of the

A900 series controls with generator instruments, a complete engine

generator control panel meeting the above specifications can be

provided.

1-2 Models.

1-2.1 The Series A900 is available in three basic configurations:

1-2.1.1 Model A901 for automatic start and stop generator sets

which includes the minimum shutdowns and alarms per NFPA110 Level 1.

1-2.1.2 Model A902 for automatic start and stop generator sets

which includes the minimum shutdowns and alarms per NFPA110 Level 2.

1-2.1.3 Model A903 for automatic start and stop generator sets

which includes the minimum shutdowns and alarms per NFPA110 Level 2 and seven unlabeled alarm lights for additional

customer specified alarms.

1-2.2 All models are available for 12 or 24 V DC operation.

1-2.3 All models are available for use on either two cycle or four

cycle engines. Models for two cycle engines include an alarm

light for “Air Damper Closed” and an “Overspeed Relay” to

operate the air shutoff solenoid for overspeed shutdown.

1-2.4 Each model is made up of two parts, a Control/Display

module and a Relay module.

1-3 Purpose.

1-3.1 This manual is directed to the installation, maintenance and

operating personnel who will be in day to day contact with the

A900 system. However the basic knowledge gained with this

material will allow those personnel to easily adjust to special

circumstances.

1-4 Definitions.

1-4.1 Throughout this manual, reference is made to organi-

zations, trade names and trademarks which may not be familiar to

the reader. Some of these are:

1-4.1.1 CSA: Canadian Standards Association.

1-4.1.2 CAN/CSA-C282-M89: The standard for Emergency

Electrical Power Supply for Buildings, 1989 Edition.

1-4.1.3 NFPA: National Fire Protection Association.

1-4.1.4 NFPA-70: The National Electrical Code.

1-4.1.5 NFPA-99-1990: The standard for Health Care Facilities,

1990 Edition.

1-4.1.6 NFPA-110-1988: The standard for Emergency And

Standby Power Systems, 1988 Edition.

1-4.1.7 Several terms used in this manual are registered

trademarks of Frank W. Murphy Mfr .

(a) MURPHYMATIC®: Refers to all Murphy automatic controls.

(b) SELECTRONIC®: A name that is applied to all electronic

controls manufactured by Murphy.

(c) SWICHGAGE®: A combination indicating gauge and switch.

(d) T ATTLET ALE®: A term that refers to a shutdown indicating

device or circuit in the control panel.

1-5 How to use this manual.

1-5.1 Section 1, 2, 4, 5, 6 and 7 contain general information that

applies to all A900 models.

1-5.2 Section 3, Model Identification, is broken into seven sub

sections. Section 3-1 allows you to chose the model that best

fits your requirements and Section 3-2 through 3-7 explain each

models features in detail.

Section 2: Specifications

2-1 Enclosure Type.

2-1.1 The A900 Series enclosure is designed to be mounted in a

standard electrical enclosure for indoor use.

2-2 Power Requirements.

2-2.1 The engine controls, shutdown circuits, alarm and shut-

down indicators are powered from the engine starting battery.

The A900 series is available in either 12 or 24 V, negative ground.

2-2.2 The A900 is fused for 3 A maximum current.

2-3 Input Ratings.

2-3.1 All input switches should be dry contact type, maximum

current is 2 mA, 8 V DC or less.

2-3.2 Frequency signal for the speed sensing circuit requires a

minimum input of 2 V rms from a magnetic pickup (preferred) or

from the tachometer terminal of the battery charging alternator .

2-3.2.1 Frequency range of the speed sensing circuits is 25 Hz to

10,000 Hz.

2-4 Output Ratings.

2-4.1 The A900 Control / Display Module has outputs for remote

indication of alarm and shutdowns. These outputs are transistors

that close to the negative supply (sink) and are rated at 1 amp, 30

V DC maximum.

2-4.2 The Control / Display Module also has an output for an

auxiliary starter contactor which is rated 1 A, 30 V DC maximum.

This is a transistor that closes to the positive supply (source).

2-4.3 The Relay Module includes 3 engine control relays with

contact ratings of 7 A, 30 V DC inductive. These powered

contacts must be supplied from an 8 A fuse or circuit breaker

(customer supplied). The 3 alarm relays have dry contacts, also

rated at 7 A, 30 V DC maximum.

2-5 Field Wiring Connections.

2-5.1 All field wiring connections are barrier terminal blocks, UL

rated for 15 A, 300 V.

2-6 Operating Temperature.

2-6.1 The operating temperature range of the A900 is -4°F to

158°F (-20°C to 70°C.)

Section 3: Model Identification

3-1 Model Numbers.

3-1.1 A901-12 and A901-24: These models are designed for an

automatic start four cycle engine driven generator, and

include the shutdown and alarm points recommended in NFPA110-1988 “Emergency and Standby Generator Systems” for Level

1 installations. These controllers also meet or exceed the

minimum requirements of NFPA99-1990 “Health Care Facilities”

and with the addition of a Low Water Level alarm, the Canadian

standard CAN/CSA-C282-M89 “Emergency Electrical Power

Supply for Buildings”. The suffix numbers -12 and -24 indicate

the engine starting battery voltage.

3-1.2 A901-2-12 and A901-2-24: These models are designed for

1

Page 5

an automatic-start, two-cycle, engine-driven generator, and

include the shutdown and alarm points recommended in NFPA110-1988 “Emergency and Standby Generator Systems” for

Level 1 installations. These controllers also meet or exceed the

minimum requirements of NFPA-99-1990 “Health Care

Facilities” and with the addition of a Low Water Level alarm,

the Canadian standard CAN/CSA-C282-M89 “Emergency

Electrical Power Supply for Buildings”. The suffix numbers -12

and -24 indicate the engine starting battery voltage.

3-1.2.1 The A901-2 series control includes an “Air Damper

Closed” light and “Overspeed Relay” to trip the air shut-off

solenoid on overspeed of a two-cycle engine.

3-1.3 A902-12 and A902-24: These models are designed for an

automatic-start, four-cycle, engine-driven generator, and include

the shutdown and alarm points recommended in NFPA-1101988 “Emergency and Standby Generator Systems” for Level 2

installations. The suffix numbers -12 and -24 indicate the

engine starting battery voltage.

3-1.4 A902-2-12 and A902-2-24: These models are designed

for an automatic-start, two-cycle, engine-driven generator, and

include the shutdown and alarm points recommended in NFPA110-1988 “Emergency and Standby Generator Systems” for

Level 2 installations. The suffix numbers -12 and -24 indicate

the engine starting battery voltage.

3-1.4.1 The A902-2 series control includes an “Air Damper

Closed” light and “Overspeed Relay” to trip the air shut-off

solenoid on overspeed of a two-cycle engine.

3-1.5 A903-12 and A903-24: These models are designed for an

automatic-start, four-cycle, engine-driven generator, and include

the shutdown and alarm points recommended in NFPA-1101988 “Emergency and Standby Generator Systems” for Level 2

installations plus seven unlabeled alarms that the user may

specify and an “Alarm Silence Switch”. The suffix numbers -12

and -24 indicate the engine starting battery voltage.

3-1.6 A903-2-12 and A903-2-24: These models are designed for

an automatic-start, two-cycle, engine driven generator, and

include the shutdown and alarm points recommended in NFPA110-1988 “Emergency and Standby Generator Systems” for

Level 2 installations plus seven unlabeled alarms that the user

may specify and an “Alarm Silence Switch”. The suffix numbers

-12 and -24 indicate the engine starting battery voltage.

3-1.6.1 The A903-2 series control includes an “Air Damper

Closed” light and “Overspeed Relay” to trip the air shut-off

solenoid on overspeed of a two-cycle engine.

3-1.7 Table 3-1.7 illustrates the alarm and shutdown requirements of NFPA-110, NFPA99 and CAN/CSA-C282-M89 and

compares the features of the A900 series controls to those

requirements.

3-2 A901.

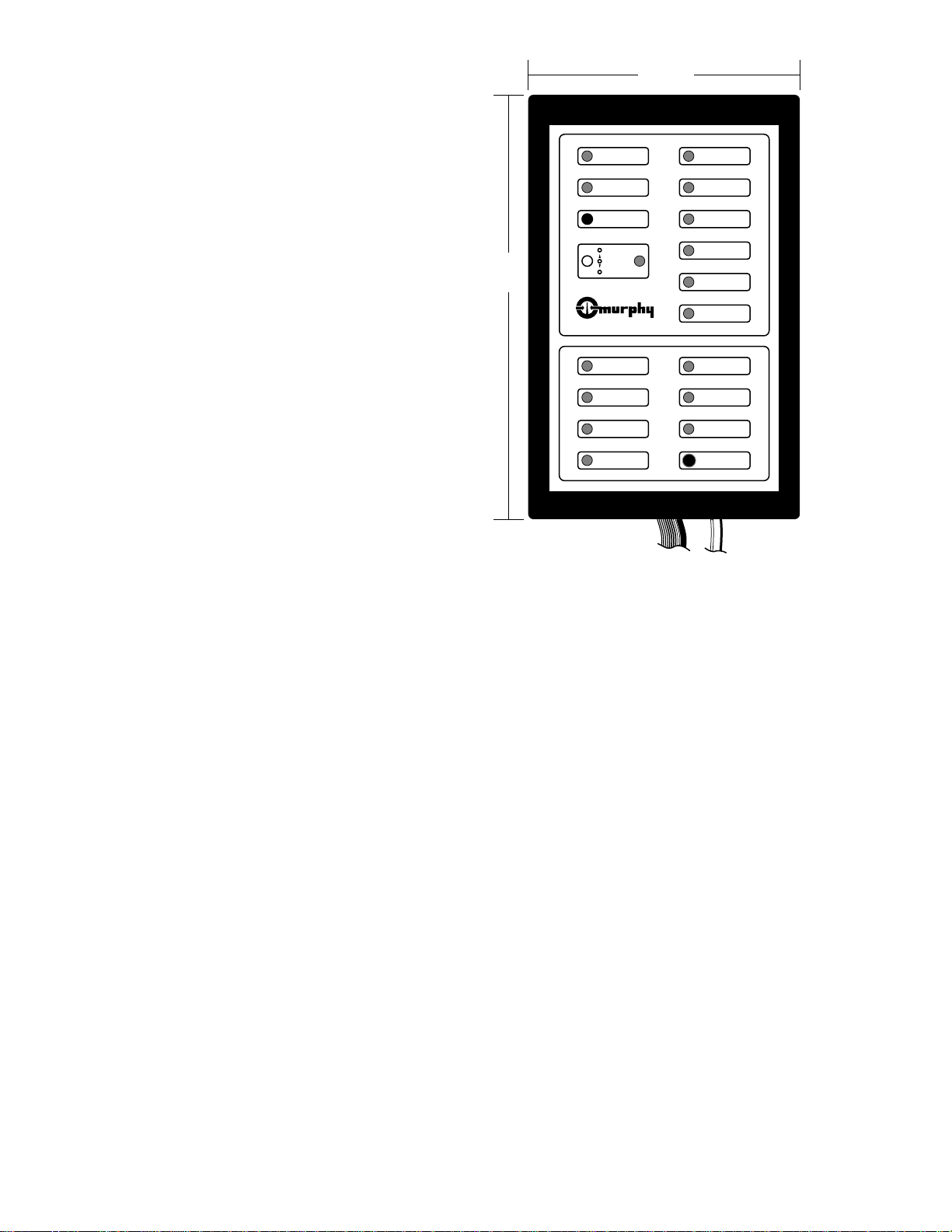

3-2.1 Control / Display Module. The Control / Display Module,

figure 3-2.1, includes the control and test switches, the solid state

logic elements, shutdown and alarm TATTLETALE®lights that

make up the generator engine control for a four-cycle engine.

3-2.1.1 Mode Selector Switch, OFF-AUTO-TEST :

(a) OFF; turns off the control system and resets any shutdown

circuits.

(b) AUTO; turns on the engine controls and shutdown circuits.

System is on standby waiting for a contact closure to start

engine.

(c) TEST; turns on the engine controls and shutdown circuits.

A start signal is applied to the automatic control and the

engine start sequence begins.

3-2.1.2 Lamp Test Pushbutton: Tests the lights on the A901

module.

3-2.1.3 Alarm Silence Pushbutton: Turns off any audible alarm

that is connected to the Local or Remote Audible Alarm Relays.

The indicating light will remain on as long as the condition

exists. If the Alarm Silence pushbutton is not operated, the

audible alarm will turn off when the alarm contact clears.

3-2.1.4 The A901 SELECTRONIC®Control Module includes

the following engine control features:

(a) Cycle crank circuit; will crank the engine for 15 seconds

then rest for 15 seconds until the engine starts. The

crank/rest time can be selected for either 10, 15, 20, 25 or

30 seconds. If the engine false starts, goes above crank

disconnect speed then drops below that speed, the control

will rest for a fixed 10 second period before cranking again.

(b) Crank Disconnect Speed Switch; this circuit detects

engine speed and terminates cranking when engine speed

rises above the speed switch setting. The speed switch is

adjustable, 25 Hz to 2000 Hz, and is factory set at 1180

Hz. This would be 600 RPM on an engine with 118 teeth

on the flywheel ring gear.

(c) Auxiliary Crank Disconnect Circuit; this circuit, required by

NFPA-110, is provided as a back up for the Crank

Disconnect Speed Switch. It is operated by an external

switch sensing either speed, generator voltage or some other

variable that could be used to terminate cranking. Either

circuit will disconnect the starter when the engine starts.

Low Water

Temperature

AUTO

OFF

TEST

Loss of Speed

Signal

Lamp Test

Water

Temperature

Low Battery

Voltage

Alarm Silence

High Battery

Voltage

Low Fuel

Level

High Water Temp.

PreAlarm

Battery Charger

AC Failure

Switch

Not In AUTO

Low Oil Pressure

PreAlarm

Oil Pressure

Overspeed

Overcrank

6-1/2 in.

(165 mm)

9-3/4 in.

(248 mm)

Figure 3-2.1

2

Page 6

Table 3-1.7

3

Level 1

C.V.

S

L.A.

R.A.

R.V.

Level 2

C.V.

S

L.A.

R.A.

R.V.

NFPA-110

NFPA99

C.V.

S

L.A.

R.A.

R.V.

②

CAN/CSA

C282-M89

C.V. S L.A. R.A. R.V.

A901

C.V.

S L.A. R.A. R.V.

A902

C.V. S L.A.

R.A.

R.V.

④ ④

A903

C.V.

S

L.A.

R.A. R.V.

④ ④

a. Overcrank X X X X X X X X O O X X X X X X X X X X X X X X X X X X O O X X X O O

b. Low Water Temperature X — X X X X — X O O X — X X X X — X X X X — X X X X — X O O X — X O O

c. High Engine Temp. Prealarm X — X X X O — O — O X — X X X O — O O O X — X X X — — — — — — X O O

d. High Engine Temperature X X X X X X X X O O X X X X X X X X X X X X X X X X X X O O X X X O O

e. Low Lube Oil Pressure Prealarm X — X X X X X O — O X — X X X O — O O O X — X X X — — — — — — X O O

f. Low Lube Oil Pressure X X X X X X X X O O X X X X X X X X X X X X X X X X X X O O X X X O O

g. Overpeed X X X X X X X X O O X X X X X X X X X X X X X X X X X X O O X X X O O

h. Low Fuel Main Tank X — X X X O — O O O X — X X X X — X X X X — X X X — — — — — — X O O

i. Control Switch not set in Auto X — X X X O — O — O — — — — — X — X X X X — X X X — — O — O — — — —

j. High Battery Voltage X — X — X O — O — O — — — — — — — — — — X — X — X — — O — O — — — —

k. Low VoltageBattery X — X — X O — O — O — — — — — X — X X X X — X — X — — O — O — — — —

l. Lamp Test X — — — X X — — — — — — — — — X — — — — X — — — — X — — — — X — — — —

m. Audible Alarm Silencing switch — — X X — — — — O — — — — — — — — X X — — — — X — — — — O — — — X O —

n. Low Starting Air Pressure X — X — X O — O — O — — — — — X — X X X — — — — — — — — — — — — — — —

o. Low Starting Hydraulic Pressure X — X — X O — O — O — — — — — X — X X X — — — — — — — — — — — — — — —

q. Remote Emergency Stop — X — — — — X — — — — — — — — — O — — — — X — — — — X — — — — X — — —

r. Low Coolant Level — — — — — — — — — — — — — — — X — X X X — — — — — — — — — — — — — — —

s. Battery Charger AC Failure X — X — X O — O — O — — — — — — — — — — X — X — X — — O — O — — — —

③③ ③③ ③

③

③

⑤

⑤

⑤

⑤

⑤

⑤

①

①

KEY

C.V.: Control panel-mounted Visual indication.

S: Shutdown of EPS

L.A.: Local Audible contacts.

R.A.: Remote Audible contacts.

R.V.: Remote Visual contacts.

X: Required

O: Optional

①: Items “N” or “O” apply only when applicable as

a starting method.

②: NFPA99 requires an audible alarm for all alarm and

shutdown functions. May be connected to L.A. contacts.

③: Air Damper Closed and is available on -2 models only.

④: R.A. and R.V. relays not supplied in model A902 or

A903, optional.

⑤: Circuits and indicators supplied without labels.

p. Air shutdown dampner when used X X X X X X X X O O — — — — — X X X — X X X X X O O X O O

Page 7

(d) Overcrank circuit; will stop automatic cranking and

indicate overcrank if engine fails to start after 3 attempts.

The number of cranks are selectable for 1, 2, 3, 4 or 5

cycles before shutdown. The overcrank circuit may also

be turned off so no overcrank shutdown occurs.

(e) Shutdown Time Delay Bypass; this delay prevents the oil

pressure, water temperature and loss of speed signal

shutdown circuits from operating for 15 seconds after the

engine starts as detected by the crank disconnect circuit.

This same delay also locks out the Low Oil Pressure Pre-

alarm and High Water Temperature Pre-alarm circuits

when the engine is not running.

(f) Overspeed Speed Switch;

1. Provides a signal to the overspeed shutdown circuit if

the engine exceeds the preset speed. The factory

setting is approximately 3894 Hz, or 1980 RPM on an

engine with 118 teeth on the flywheel ring gear. The

adjustment range is 300 Hz to 10,000 Hz.

2. A push-to-test switch is provided to allow testing of the

overspeed circuit without overspeeding the engine.

When switch is depressed, the set point of the speed

switch is lowered approximately 10%.

3. The push-to-test switch can also be used to set the

overspeed switch at approximately 110% of running

speed. Hold the switch depressed while adjusting the

setting until the overspeed trips. When switch is

released, the set point will be 10% above normal running

speed. This is the method used to make the factory

setting. With engine speed at 1800 RPM or 3540 Hz.

(g) Cooldown circuit; this circuit keeps the engine running

for five minutes after the transfer switch has removed

the load from the generator and signaled the A901 to

stop the engine. This feature may be selected (turned

On, standard setting is Off) with a switch on the back of

the Control / Display Module.

3-2.1.5 Seven (7) First-out Shutdown Circuits; provide first-out

indication of cause of shutdown. These circuits deactivate the

fuel relay and lockout the A901 until reset. Shutdown circuits

are activated by the crank disconnect circuit and are not active

when the engine is stopped. Six (6) Red Shutdown Indicating

Lights are provided. The Remote Shutdown circuit does not

have an indicator light.

(a) Overcrank; tripped by the overcrank sensing circuit which

counts the number of cranking attempts.

(b) Overspeed; tripped by overspeed switch when engine

exceeds a preset speed.

(c) Oil Pressure; tripped by the oil pressure SWICHGAGE

®

if pressure drops below preset point while the engine is

running.

(d) Water Temperature; tripped by the water temperature

SWICHGAGE®if engine coolant temperature exceeds the

switch setting.

(e) Spare Shutdown; tripped by an external switch. This

circuit is provided for an additional shutdown that may be

recommended by the engine supplier.

(f) Loss of Speed Signal; tripped by an internal sensing

circuit that detects the loss of the Magnetic Pickup

frequency signal for the speed switches while the engine

is still running. Since the Overspeed shutdown circuit is

activated by the frequency input, it prevents the engine

from running without overspeed protection.

(g) Remote Shutdown; this circuit is provided to shutdown

the engine generator from a remote location. No

indicating light is provided.

3-2.1.6 Nine (9) Alarm Indicating Circuits; provide indication of

cause of alarm. These circuits activate the alarm relays. Alarm

circuits are active as long as power is applied to the A901. All are

active when the engine is running, shutdown or on standby except

Low Oil Pressure Pre- alarm and High Water Temperature Prealarm. Nine (9) Amber Alarm Indicating Lights are provided.

(a) Low Water Temperature; operated by low water temp-

erature SWICHGAGE®.

(b) Spare Alarm; operated by an external switch. This circuit

is provided for an additional alarm that may be required by

the user.

(c) Switch Not In Automatic; operated by the OFF-AUTO-

TEST mode selector switch.

(d) Low Fuel Level; operated by level switch on fuel tank.

(e) High Battery Voltage; operated by relay contact in

battery charger.

(f) Low Battery Voltage; operated by low voltage sensing

device in battery charger .

(g) Low Oil Pressure Pre-alarm; operated by pre-alarm

switch in oil pressure SWICHGAGE®.

(h) High Water Temperature Pre-alarm; operated by pre

alarm switch in water temperature SWICHGAGE®.

(i) Battery Charger AC Failure: operated by a relay contact in

the Battery Charger .

3-2.2 Relay Module. The Relay Module, figure 3-2.2, includes

all of the control, alarm and shutdown relays that are required to

make up the generator engine control. Relays are available for

operation on either 12 or 24 volt battery systems. Five (5) relays

are included for:

3-2.2.1 Fuel Relay; this relay provides two outputs, one to

energize the engine fuel solenoid and a separate circuit to

4

DC12V

3A Fuse

1A

4

5

6

7

8

9

16

17

18

19

20

21

22

23

24

25

RH2V2

-U

DC12V

RH2V2

-U

DC12V

RH2V2

-U

DC12V

RH2V2

-U

DC12V

RH2V2

-U

6-1/4 in.

(159 mm)

4-1/2 in.

(114 mm)

Figure 3-2.2

Page 8

energize the battery charging alternator field.

3-2.2.2 Shutdown Relay; this relay is operated by the shutdown

circuits of the Control / Display Module and provides an output

that can be used to trip the generator circuit breaker on an

emergency shutdown.

3-2.2.3 Local Audible Alarm Relay; provides a contact closure

to operate a local audible alarm as required by NFPA-110, Level

1 and Level 2.

3-2.2.4 Remote Audible Alarm Relay; provides a contact

closure to operate a remote audible alarm as required by NFPA110, Level 1.

3-2.2.5 Remote Visual Alarm Relay; provides a contact closure

to operate a remote visual alarm as required by NFPA- 110,

Level 1.

3-2.3 Status Signals. The relay module also includes three

outputs that can be used with external circuits for signaling or

control functions.

3-2.3.1 The Control On function at terminal 12 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test. When the Mode Selector is turned Off, the

Control On signal is open. This can be used to signal switch

position or to reset an external circuit when the Mode Selector

is turned Off.

3-2.3.2 The System Ready signal at terminal 13 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test and no shutdown Tattletale circuit is latched on.

This can be used to signal that the generator engine is ready to

automatically start or is running in Test.

3-2.3.3 The Control On function at terminal 14 is on (closed

to positive) as long as the Mode Selector Switch is in either

Auto or Test. When the Mode Selector is turned Off, the

Control On signal is open. This can be used to signal switch

position or to reset an external circuit when the Mode Selector

is turned Off.

3-3 A901-2.

3-3.1 Control / Display Module. The Control / Display Module,

figure 3-3.1, includes the control and test switches, the solid state

logic elements, shutdown and alarm TATTLETALE®lights that

make up the generator engine control for a two-cycle engine.

3-3.1.1 Mode Selector Switch, OFF-AUTO-TEST :

(a) OFF; turns off the control system and resets any shutdown

circuits.

(b) AUTO; turns on the engine controls and shutdown

circuits. System is on standby waiting for a contact

closure to start engine.

(c) TEST; turns on the engine controls and shutdown circuits.

A start signal is applied to the automatic control and the

engine start sequence begins.

3-3.1.2 Lamp Test Pushbutton: Tests the lights on the A- 901-2

module.

3-3.1.3 Alarm Silence Pushbutton: Turns off any audible alarm

that is connected to the Local or Remote Audible Alarm Relays.

The indicating light will remain on as long as the condition

exists. If the Alarm Silence pushbutton is not operated, the

audible alarm will turn off when the alarm contact clears.

3-3.1.4 The A901-2 SELECTRONIC

®

Control Module includes

the following engine control features:

(a) Cycle crank circuit; will crank the engine for 15 seconds

then rest for 15 seconds until the engine starts. The

crank/rest time is selectable for either 10, 15, 20, 25 or 30

seconds. If the engine false starts, goes above crank

disconnect speed then drops below that speed, the control

will rest for a fixed 10 second period before cranking again.

(b) Crank Disconnect Speed Switch; this circuit detects

engine speed and terminates cranking when engine speed

rises above the speed switch setting. The speed switch is

adjustable, 25 Hz to 2000 Hz, and is factory set at 1180

Hz. This would be 600 RPM on an engine with 118 teeth

on the flywheel ring gear.

(c) Auxiliary Crank Disconnect Circuit; this circuit, required by

NFPA-110, is provided as a back up for the Crank Disconnect Speed Switch. It is operated by an external switch

sensing either speed, generator voltage or some other

variable that could be used to terminate cranking. Either

circuit will disconnect the starter when the engine starts.

(d) Overcrank circuit; will stop automatic cranking and

indicate overcrank if engine fails to start after 3 attempts.

The number of cranks are selectable for 1, 2, 3, 4 or 5

cycles before shutdown. The overcrank circuit may also

be turned off so no overcrank shutdown occurs.

(e) Shutdown Time Delay Bypass; this delay prevents the oil

pressure, water temperature and loss of speed signal

shutdown circuits from operating for 15 seconds after the

engine starts as detected by the crank disconnect circuit.

This same delay also locks out the Low Oil Pressure Prealarm and High Water Temperature Pre-alarm circuits

when the engine is not running.

Low Water

Temperature

AUTO

OFF

TEST

Loss of Speed

Signal

Lamp Test

Water

Temperature

Air Damper

Closed

Low Battery

Voltage

Alarm Silence

Battery Charger

AC Failure

High Battery

Voltage

Low Fuel

Level

High Water Temp.

PreAlarm

Switch

Not In AUTO

Low Oil Pressure

PreAlarm

Oil Pressure

Overspeed

Overcrank

6-1/2 in.

(165 mm)

9-3/4 in.

(248 mm)

Figure 3-3.1

5

Page 9

(f) Overspeed Speed Switch;

1. Provides a signal to the overspeed shutdown circuit if

the engine exceeds the preset speed. The factory

setting is approximately 3894 Hz, or 1980 RPM on an

engine with 118 teeth on the flywheel ring gear. The

adjustment range is 300 Hz to 10,000 Hz.

2. A push to test switch is provided to allow testing of the

overspeed circuit without overspeeding the engine.

When switch is depressed, the set point of the speed

switch is lowered approximately 10%.

3. The push to test switch can also be used to set the

overspeed switch at approximately 110% of running

speed. Hold the switch depressed while adjusting the

setting until the overspeed trips. When switch is

released, the set point will be 10% above normal running

speed. This is the method used to make the factory

setting. With engine speed at 1800 RPM or 3540 Hz.

(g) Cooldown circuit; this circuit keeps the engine running

for five minutes after the transfer switch has removed

the load from the generator and signaled the A901-2 to

stop the engine. This feature may be selected (turned

On, standard setting is Off) with a switch on the back of

the Control / Display Module.

3-3.1.5 Seven (7) First-out Shutdown Circuits; provide first-out

indication of cause of shutdown. These circuits deactivate the

fuel relay and lockout the A901-2 until reset. Shutdown circuits

are activated by the crank disconnect circuit and are not active

when the engine is stopped. Six (6) Red Shutdown Indicating

Lights are provided. The Remote Shutdown circuit does not

have an indicator light.

(a) Overcrank; tripped by the overcrank sensing circuit which

counts the number of cranking attempts.

(b) Overspeed; tripped by overspeed switch when engine

exceeds a preset speed.

(c) Oil Pressure; tripped by the oil pressure SWICHGAGE®if

pressure drops below preset point while the engine is running.

(d) Water T emperature; tripped by the water temperature

SWICHGAGE®if engine coolant temperature exceeds the

switch setting.

(e) Spare Shutdown; tripped by an external switch. This

circuit is provided for an additional shutdown that may be

recommended by the engine supplier.

(f) Loss of Speed Signal; tripped by an internal sensing

circuit that detects the loss of the Magnetic Pickup

frequency signal for the speed switches while the engine

is still running. Since the Overspeed shutdown circuit is

activated by the frequency input, it prevents the engine

from running without overspeed protection.

(g) Remote Shutdown; this circuit is provided to shutdown

the engine generator from a remote location. No

indicating light is provided.

3-3.1.6 Nine (9) Alarm Indicating Circuits; provide indication

of cause of alarm. These circuits activate the alarm relays.

Alarm circuits are active as long as power is applied to the

A901-2. All are active when the engine is running, shutdown or

on standby except Low Oil Pressure Pre- alarm and High Water

Temperature Pre-alarm. Nine (9) Amber Alarm Indicating

Lights are provided.

(a) Low Water Temperature; operated by low water temp-

erature SWICHGAGE®.

(b) Air Damper Closed; operated by an external switch or by

the Overspeed Relay circuit. This circuit is provided with

a selector switch to allow the user to determine the source

of the signal.

(c) Switch Not In Automatic; operated by the OFF-AUTO-

TEST mode selector switch.

(d) Low Fuel Level; operated by level switch on fuel tank.

(e) High Battery Voltage; operated by relay contact in battery

charger .

(f) Low Battery Voltage; operated by low voltage sensing

device in battery charger .

(g) Low Oil Pressure Pre-alarm; operated by pre-alarm

switch in oil pressure SWICHGAGE®.

(h) High Water Temperature Pre-alarm; operated by pre-

alarm switch in water temperature SWICHGAGE®.

(i) Battery Charger AC Failure; operated by relay contact in

Battery Charger .

3-3.2 Relay Module. The Relay Module, figure 3-3.2, includes

all of the control, alarm and shutdown relays that are required to

make up the generator engine control. Relays are available for

operation on either 12 or 24 volt battery systems. Six (6) relays

are included for:

3-3.2.1 Fuel Relay; this relay provides two outputs, one to

energize the engine fuel solenoid and a separate circuit to

energize the battery charging alternator field.

3-3.2.2 Shutdown Relay; this relay is operated by the shutdown

circuits of the Control / Display Module and provides an output

that can be used to trip the generator circuit breaker on an

emergency shutdown.

3-3.2.3 Overspeed Relay; operates only on an Overspeed

shutdown. This relay provides an output to trip an air shut off

solenoid to close the air damper on a two-cycle engine.

3-3.2.4 Local Audible Alarm Relay; provides a contact closure

DC12V

3A Fuse

1A

4

5

6

7

8

9

16

17

18

19

20

21

22

23

24

25

DC12V

DC12V DC12V

DC12V DC12V

6-1/4 in.

(159 mm)

4-1/2 in.

(114 mm)

Figure 3-3.2

6

Page 10

7

to operate a local audible alarm as required by NFPA- 110,

Level 1 and Level 2.

3-3.2.5 Remote Audible Alarm Relay; provides a contact

closure to operate a remote audible alarm as required by NFPA110, Level 1.

3-3.2.6 Remote Visual Alarm Relay; provides a contact closure

to operate a remote visual alarm as required by NFPA- 110,

Level 1.

3-3.3 Status Signals. The relay module also includes three

outputs that can be used with external circuits for signaling or

control functions.

3-3.3.1 The Control On function at terminal 12 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test. When the Mode Selector is turned Off, the

Control On signal is open. This can be used to signal switch

position or to reset an external circuit when the Mode Selector

is turned Off.

3-3.3.2 The System Ready signal at terminal 13 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test and no shutdown Tattletale circuit is latched on.

This can be used to signal that the generator engine is ready to

automatically start or is running in Test.

3-3.3.3 The Control On function at terminal 14 is on (closed

to positive) as long as the Mode Selector Switch is in either

Auto or Test. When the Mode Selector is turned Off, the

Control On signal is open. This can be used to signal switch

position or to reset an external circuit when the Mode Selector

is turned Off.

3-4 A902.

3-4.1 Control / Display Module. The Control / Display

Module, figure 3-4.1, includes the control and test switches, the

solid state logic elements, shutdown and alarm TATTLETALE

®

lights that make up the generator engine control for a four-cycle

engine.

3-4.1.1 Mode Selector Switch, OFF-AUTO-TEST :

(a) OFF; turns off the control system and resets any shutdown

circuits.

(b) AUTO; turns on the engine controls and shutdown

circuits. System is on standby waiting for a contact

closure to start engine.

(c) TEST; turns on the engine controls and shutdown circuits.

A start signal is applied to the automatic control and the

engine start sequence begins.

3-4.1.2 Lamp Test Pushbutton: Tests the lights on the A902

module.

3-4.1.3 The A902 SELECTRONIC®Control Module includes

the following engine control features:

(a) Cycle crank circuit; will crank the engine for 15 seconds

then rest for 15 seconds until the engine starts. The

crank/rest time is selectable for either 10, 15, 20, 25 or 30

seconds. If the engine false starts, goes above crank

disconnect speed then drops below that speed, the control

will rest for a fixed 10 second period before cranking

again.

(b) Crank Disconnect Speed Switch; this circuit detects

engine speed and terminates cranking when engine speed

rises above the speed switch setting. The speed switch is

adjustable, 25 Hz to 2000 Hz, and is factory set at 1180

Hz. This would be 600 RPM on an engine with 118 teeth

on the flywheel ring gear.

(c) Auxiliary Crank Disconnect Circuit; this circuit, required

by NFPA-110, is provided as a back up for the Crank

Disconnect Speed Switch. It is operated by an external

switch sensing either speed, generator voltage or some

other variable that could be used to terminate cranking.

Either circuit will disconnect the starter when the engine

starts.

(d) Overcrank circuit; will stop automatic cranking and

indicate overcrank if engine fails to start after 3 attempts.

The number of cranks are selectable for 1, 2, 3, 4 or 5

cycles before shutdown. The overcrank circuit may also

be turned off so no overcrank shutdown occurs.

(e) Shutdown Time Delay Bypass; this delay prevents the oil

pressure, water temperature and loss of speed signal

shutdown circuits from operating for 15 seconds after the

engine starts as detected by the crank disconnect circuit.

(f) Overspeed Speed Switch;

1. Provides a signal to the overspeed shutdown circuit if

the engine exceeds the preset speed. The factory

setting is approximately 3894 Hz, or 1980 RPM on an

engine with 118 teeth on the flywheel ring gear. The

adjustment range is 300 Hz to 10,000 Hz.

2. A push to test switch is provided to allow testing of the

overspeed circuit without overspeeding the engine.

When switch is depressed, the set point of the speed

switch is lowered approximately 10%.

3. The push to test switch can also be used to set the

overspeed switch at approximately 110% of running

speed. Hold the switch depressed while adjusting the

Low Water

Temperature

AUTO

OFF

TEST

Loss of Speed

Signal

Lamp Test

Water

Temperature

Oil Pressure

Overspeed

Overcrank

6-1/2 in.

(165 mm)

9-3/4 in.

(248 mm)

Figure 3-4.1

Page 11

8

setting until the overspeed trips. When switch is

released, the set point will be 10% above normal

running speed. This is the method used to make the

factory setting. With engine speed at 1800 RPM or

3540 Hz.

(g) Cooldown circuit; this circuit keeps the engine running

for five minutes after the transfer switch has removed the

load from the generator and signaled the A902 to stop

the engine. This feature may be selected (turned On,

standard setting is Off) with a switch on the back of the

Control / Display Module.

3-4.1.4 Seven (7) First-out Shutdown Circuits; provide first-out

indication of cause of shutdown. These circuits deactivate the

fuel relay and lockout the A902 until reset. Shutdown circuits

are activated by the crank disconnect circuit and are not active

when the engine is stopped. Six (6) Red Shutdown Indicating

Lights are provided. The Remote Shutdown circuit does not

have an indicator light.

(a) Overcrank; tripped by the overcrank sensing circuit which

counts the number of cranking attempts.

(b) Overspeed; tripped by overspeed switch when engine

exceeds a preset speed.

(c) Oil Pressure; tripped by the oil pressure SWICHGAGE®if

pressure drops below preset point while the engine is

running.

(d) Water Temperature; tripped by the water temperature

SWICHGAGE®if engine coolant temperature exceeds the

switch setting.

(e) Spare Shutdown; tripped by an external switch. This

circuit is provided for an additional shutdown that may be

recommended by the engine supplier.

(f) Loss of Speed Signal; tripped by an internal sensing

circuit that detects the loss of the Magnetic Pickup

frequency signal for the speed switches while the engine

is still running. Since the Overspeed shutdown circuit is

activated by the frequency input, it prevents the engine

from running without overspeed protection.

(g) Remote Shutdown; this circuit is provided to shutdown

the engine generator from a remote location. No

indicating light is provided.

3-4.1.5 Two (2) Alarm Indicating Circuits; provide indication

of cause of alarm. These circuits activate the alarm relay. Alarm

circuits are active as long as power is applied to the A902. All

are active when the engine is running, shutdown or on standby.

T wo (2) Amber Alarm Indicating Lights are provided.

(a) Low Water Temperature; operated by low water

temperature SWICHGAGE®.

(b) Spare Alarm; operated by an external switch. This circuit

is provided for an additional alarm that may be required

by the user.

3-4.2 Relay Module. The Relay Module, figure 3-4.2, includes

all of the control, alarm and shutdown relays that are required to

make up the generator engine control. Relays are available for

operation on either 12 or 24 volt battery systems. Three (3)

relays are included for:

3-4.2.1 Fuel Relay; this relay provides two outputs, one to

energize the engine fuel solenoid and a separate circuit to

energize the battery charging alternator field.

3-4.2.2 Shutdown Relay; this relay is operated by the shutdown

circuits of the Control / Display Module and provides an output

that can be used to trip the generator circuit breaker on an

emergency shutdown.

3-4.2.3 Local Audible Alarm Relay; provides a contact closure

to operate a local audible alarm as required by NFPA- 110, Level

1 and Level 2.

3-4.3 Status Signals. The relay module also includes three

outputs that can be used with external circuits for signaling or

control functions.

3-4.3.1 The Control On function at terminal 12 is on (closed to

negative) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

3-4.3.2 The System Ready signal at terminal 13 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test and no shutdown TATTLETALE

®

circuit is

latched on. This can be used to signal that the generator engine

is ready to automatically start or is running in Test.

3-4.3.3 The Control On function at terminal 14 is on (closed to

positive) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

3-5 A902-2.

3-5.1 Control / Display Module. The Control / Display Module,

figure 3-5.1, includes the control and test switches, the solid state

logic elements, shutdown and alarm TATTLETALE

®

lights that

make up the generator engine control for a two-cycle engine.

3-5.1.1 Mode Selector Switch, OFF-AUTO-TEST :

(a) OFF; turns off the control system and resets any shutdown

circuits.

(b) AUTO; turns on the engine controls and shutdown circuits.

System is on standby waiting for a contact closure to start

engine.

DC12V

3A Fuse

1A

4

5

6

7

8

9

16

17

18

19

20

21

22

23

24

25

DC12V

DC12V

6-1/4 in.

(159 mm)

4-1/2 in.

(114 mm)

Figure 3-4.2

Page 12

9

(c) TEST; turns on the engine controls and shutdown circuits.

A start signal is applied to the automatic control and the

engine start sequence begins.

3-5.1.2 Lamp Test Pushbutton: Tests the lights on the A- 902-2

module.

3-5.1.3 The A902-2 SELECTRONIC®Control Module includes

the following engine control features:

(a) Cycle crank circuit; will crank the engine for 15 seconds

then rest for 15 seconds until the engine starts. The

crank/rest time is selectable for either 10, 15, 20, 25 or 30

seconds. If the engine false starts, goes above crank

disconnect speed then drops below that speed, the control

will rest for a fixed 10 second period before cranking

again.

(b) Crank Disconnect Speed Switch; this circuit detects

engine speed and terminates cranking when engine speed

rise above the speed switch setting. The speed switch is

adjustable, 25 Hz to 2000 Hz, and is factory set at 1180

Hz. This would be 600 RPM on an engine with 118 teeth

on the flywheel ring gear.

(c) Auxiliary Crank Disconnect Circuit; this circuit, required

by NFPA-110, is provided as a back up for the Crank

Disconnect Speed Switch. It is operated by an external

switch sensing either speed, generator voltage or some

other variable that could be used to terminate cranking.

Either circuit will disconnect the starter when the engine

starts.

(d) Overcrank circuit; will stop automatic cranking and

indicate overcrank if engine fails to start after 3 attempts.

The number of cranks are selectable for 1, 2, 3, 4 or 5

cycles before shutdown. The overcrank circuit may also

be turned off so no overcrank shutdown occurs.

(e) Shutdown Time Delay Bypass; this delay prevents the oil

pressure, water temperature and loss of speed signal

shutdown circuits from operating for 15 seconds after the

engine starts as detected by the crank disconnect circuit.

(f) Overspeed Speed Switch;

1. Provides a signal to the overspeed shutdown circuit if

the engine exceeds the preset speed. The factory

setting is approximately 3894 Hz, or 1980 RPM on an

engine with 118 teeth on the flywheel ring gear. The

adjustment range is 300 Hz to 10,000 Hz.

2. A push to test switch is provided to allow testing of the

overspeed circuit without overspeeding the engine.

When switch is depressed, the set point of the speed

switch is lowered approximately 10%.

3. The push to test switch can also be used to set the

overspeed switch at approximately 110% of running

speed. Hold the switch depressed while adjusting the

setting until the overspeed trips. When switch is

released, the set point will be 10% above normal

running speed. This is the method used to make the

factory setting. With engine speed at 1800 RPM or

3540 Hz.

(g) Cooldown circuit; this circuit keeps the engine running

for five minutes after the transfer switch has removed

the load from the generator and signaled the A902-2 to

stop the engine. This feature may be selected (turned

On, standard setting is Off) with a switch on the back of

the Control / Display Module.

3-5.1.4 Seven (7) First-out Shutdown Circuits; provide first-out

indication of cause of shutdown. These circuits deactivate the

fuel relay and lockout the A902-2 until reset. Shutdown circuits

are activated by the crank disconnect circuit and are not active

when the engine is stopped. Six (6) Red Shutdown Indicating

Lights are provided. The Remote Shutdown circuit does not

have an indicator light.

(a) Overcrank; tripped by the overcrank sensing circuit which

counts the number of cranking attempts.

(b) Overspeed; tripped by overspeed switch when engine

exceeds a preset speed.

(c) Oil Pressure; tripped by the oil pressure SWICHGAGE

®

if pressure drops below preset point while the engine is

running.

(d) Water Temperature; tripped by the water temperature

SWICHGAGE®if engine coolant temperature exceeds the

switch setting.

(e) Spare Shutdown; tripped by an external switch. This

circuit is provided for an additional shutdown that may be

recommended by the engine supplier.

(f) Loss of Speed Signal; tripped by an internal sensing

circuit that detects the loss of the Magnetic Pickup

frequency signal for the speed switches while the engine

is still running. Since the Overspeed shutdown circuit is

activated by the frequency input, it prevents the engine

from running without overspeed protection.

(g) Remote Shutdown; this circuit is provided to shutdown

the engine generator from a remote location. No

indicating light is provided.

3-5.1.5 Two (2) Alarm Indicating Circuits; provide indication

Low Water

Temperature

AUTO

OFF

TEST

Loss of Speed

Signal

Lamp Test

Water

Temperature

Air Damper

Closed

Oil Pressure

Overspeed

Overcrank

6-1/2 in.

(165 mm)

9-3/4 in.

(248 mm)

Figure 3-5.1

Page 13

of cause of alarm. These circuits activate the alarm relay.

Alarm circuits are active as long as power is applied to the

A902-2. All are active when the engine is running, shutdown or

on standby. Two (2) Amber Alarm Indicating Lights are

provided.

(a) Low Water Temperature; operated by low water

temperature SWICHGAGE®.

(b) Air Damper Closed; operated by an external switch or by

the Overspeed Relay circuit. This circuit is provided with

a selector switch to allow the user to determine the source

of the signal.

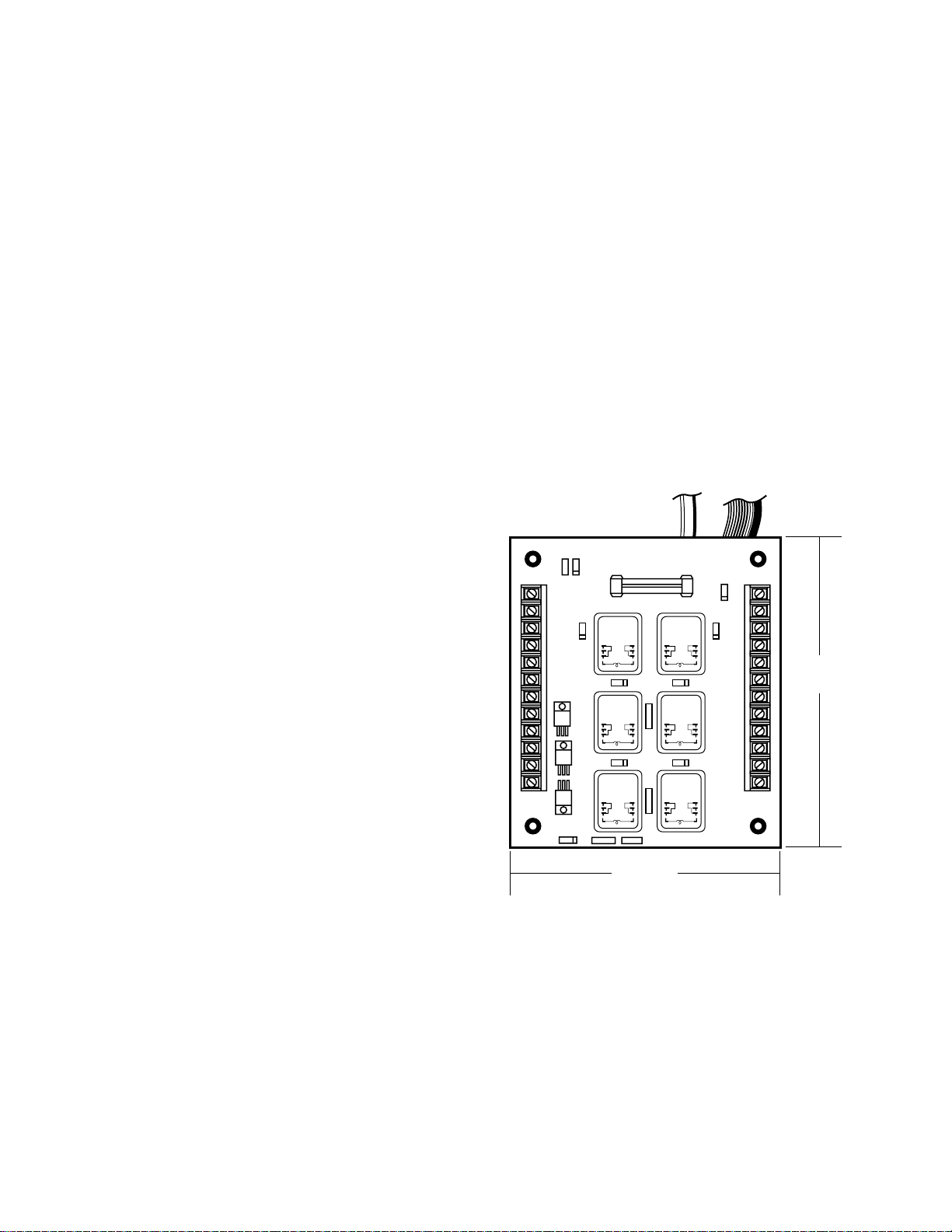

3-5.2 Relay Module. The Relay Module, figure 3-5.2, includes

all of the control, alarm and shutdown relays that are required to

make up the generator engine control. Relays are available for

operation on either 12 or 24 volt battery systems. Four (4)

relays are included for:

3-5.2.1 Fuel Relay; this relay provides two outputs, one to

energize the engine fuel solenoid and a separate circuit to

energize the battery charging alternator field.

3-5.2.2 Shutdown Relay; this relay is operated by the shutdown

circuits of the Control / Display Module and provides an output

that can be used to trip the generator circuit breaker on an

emergency shutdown.

3-5.2.3 Overspeed Relay; operates only on an Overspeed

shutdown. This relay provides an output to trip an air shut off

solenoid to close the air damper on a two-cycle engine.

3-5.2.4 Local Audible Alarm Relay; provides a contact closure

to operate a local audible alarm as required by NFPA- 110, Level

1 and Level 2.

3-5.3 Status Signals. The relay module also includes three

outputs that can be used with external circuits for signaling or

control functions.

3-5.3.1 The Control On function at terminal 12 is on (closed to

negative) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

3-5.3.2 The System Ready signal at terminal 13 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test and no shutdown TATTLETALE®circuit is

latched on. This can be used to signal that the generator

engine is ready to automatically start or is running in Test.

3-5.3.3 The Control On function at terminal 14 is on (closed to

positive) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

3-6 A903.

3-6.1 Control / Display Module. The Control / Display Module,

figure 3-6.1, includes the control and test switches, the solid

state logic elements, shutdown and alarm TATTLETALE®lights

that make up the generator engine control for a four cycle

engine. This module is the same as Model A- 901 except 7 of

the alarm circuits are un-labeled. This allows the customer to

specify labels other than those recommended in NFPA-110.

This model has shutdown and alarm circuits labeled to meet the

requirements of NFPA-110, Level 2.

3-6.1.1 Mode Selector Switch, OFF-AUTO-TEST:

(a) OFF; turns off the control system and resets any shutdown

circuits.

(b) AUTO; turns on the engine controls and shutdown circuits.

System is on standby waiting for a contact closure to start

engine.

(c) TEST; turns on the engine controls and shutdown circuits.

A start signal is applied to the automatic control and the

engine start sequence begins.

Figure 3-6.1

10

DC12V

3A Fuse

1A

4

5

6

7

8

9

16

17

18

19

20

21

22

23

24

25

DC12V

DC12V

DC12V

6-1/4 in.

(159 mm)

4-1/2 in.

(114 mm)

Figure 3-5.2

Page 14

3-6.1.2 Lamp Test Pushbutton: Tests the lights on the A903

module.

3-6.1.3 Alarm Silence Pushbutton: Turns off any audible alarm

that is connected to the Local or Remote Audible Alarm Relays.

The indicating light will remain on as long as the condition

exists. If the Alarm Silence pushbutton is not operated, the

audible alarm will turn off when the alarm contact clears.

3-6.1.4 The A903 SELECTRONIC®Control Module includes

the following engine control features:

(a) Cycle crank circuit; will crank the engine for 15 seconds

then rest for 15 seconds until the engine starts. The

crank/rest time is selectable for either 10, 15, 20, 25 or 30

seconds. If the engine false starts, goes above crank

disconnect speed then drops below that speed, the control

will rest for a fixed 10 second period before cranking

again.

(b) Crank Disconnect Speed Switch; this circuit detects

engine speed and terminates cranking when engine speed

rises above the speed switch setting. The speed switch is

adjustable, 25 Hz to 2000 Hz, and is factory set at 1180

Hz. This would be 600 RPM on an engine with 118 teeth

on the flywheel ring gear.

(c) Auxiliary Crank Disconnect Circuit; this circuit, required

by NFPA-110, is provided as a back up for the Crank

Disconnect Speed Switch. It is operated by an external

switch sensing either speed, generator voltage or some

other variable that could be used to terminate cranking.

Either circuit will disconnect the starter when the engine

starts.

(d) Overcrank circuit; will stop automatic cranking and

indicate overcrank if engine fails to start after 3 attempts.

The number of cranks are selectable for 1, 2, 3, 4 or 5

cycles before shutdown. The overcrank circuit may also

be turned off so no overcrank shutdown occurs.

(e) Shutdown Time Delay Bypass; this delay prevents the oil

pressure, water temperature and loss of speed signal

shutdown circuits from operating for 15 seconds after the

engine starts as detected by the crank disconnect circuit.

This same delay also locks out alarm circuit #7 and #8

when the engine is not running.

(f) Overspeed Speed Switch;

1. Provides a signal to the overspeed shutdown circuit if

the engine exceeds the preset speed. The factory

setting is approximately 3894 Hz, or 1980 RPM on an

engine with 118 teeth on the flywheel ring gear. The

adjustment range is 300 Hz to 10,000 Hz.

2. A push to test switch is provided to allow testing of

the overspeed circuit without overspeeding the

engine. When switch is depressed, the set point of the

speed switch is lowered approximately 10%.

3. The push to test switch can also be used to set the

overspeed switch at approximately 110% of running

speed. Hold the switch depressed while adjusting the

setting until the overspeed trips. When switch is

released, the set point will be 10% above normal

running speed. This is the method used to make the

factory setting. With engine speed at 1800 RPM or

3540 Hz.

(g) Cooldown circuit; this circuit keeps the engine running

for five minutes after the transfer switch has removed

the load from the generator and signaled the A903 to

stop the engine. This feature may be selected (turned

On, standard setting is Off) with a switch on the back of

the Control / Display Module.

3-6.1.5 Seven (7) First-out Shutdown Circuits; provide firstout indication of cause of shutdown. These circuits deactivate

the fuel relay and lockout the A903 until reset. Shutdown

circuits are activated by the crank disconnect circuit and are not

active when the engine is stopped. Six (6) Red Shutdown

Indicating Lights are provided. The Remote Shutdown circuit

does not have an indicator light.

(a) Overcrank; tripped by the overcrank sensing circuit

which counts the number of cranking attempts.

(b) Overspeed; tripped by overspeed switch when engine

exceeds a preset speed.

(c) Oil Pressure; tripped by the oil pressure SWICHGAGE

®

if pressure drops below preset point while the engine is

running.

(d) Water Temperature; tripped by the water temperature

SWICHGAGE®if engine coolant temperature exceeds

the switch setting.

(e) Spare Shutdown; tripped by an external switch. This

circuit is provided for an additional shutdown that may

be recommended by the engine supplier.

(f) Loss of Speed Signal; tripped by an internal sensing

circuit that detects the loss of the Magnetic Pickup

frequency signal for the speed switches while the engine

is still running. Since the Overspeed shutdown circuit is

activated by the frequency input, it prevents the engine

from running without overspeed protection.

(g) Remote Shutdown; this circuit is provided to shutdown

the engine generator from a remote location. No

indicating light is provided.

3-6.1.6 Nine (9) Alarm Indicating Circuits; provide indication

of cause of alarm. These circuits activate the alarm relays.

Alarm circuits are active as long as power is applied to the

A903. All are active when the engine is running, shutdown or

on standby except alarm circuit #7 and #8 which are locked out

until the engine is running. Nine (9) Amber Alarm Indicating

Lights are provided however only two circuits are labeled. The

other 7 are for customer specified alarms.

(a) Low Water Temperature; operated by low water

temperature SWICHGAGE

®

.

(b) #2 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(c) Switch Not In Automatic; operated by the OFF-AUTO-

TEST mode selector switch.

(d) #4 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(e) #5 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(f) #6 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(g) #7 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

11

Page 15

(h) #8 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(i) #9 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

3-6.2 Relay Module. The Relay Module, figure 3-6.2, includes

all of the control, alarm and shutdown relays that are required to

make up the generator engine control. Relays are available for

operation on either 12 or 24 volt battery systems. Three (3)

relays are included for:

3-6.2.1 Fuel Relay; this relay provides two outputs, one to

energize the engine fuel solenoid and a separate circuit to

energize the battery charging alternator field.

3-6.2.2 Shutdown Relay; this relay is operated by the shutdown

circuits of the Control / Display Module and provides an output

that can be used to trip the generator circuit breaker on an

emergency shutdown.

3-6.2.3 Local Audible Alarm Relay; provides a contact closure

to operate a local audible alarm as required by NFPA- 110, Level

1 and Level 2.

3-6.3 Status Signals. The relay module also includes three

outputs that can be used with external circuits for signaling or

control functions.

3-6.3.1 The Control On function at terminal 12 is on (closed to

negative) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

3-6.3.2 The System Ready signal at terminal 13 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test and no shutdown TATTLETALE

®

circuit is

latched on. This can be used to signal that the generator

engine is ready to automatically start or is running in Test.

3-6.3.3 The Control On function at terminal 14 is on (closed to

positive) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

3-7 A903-2.

3-7.1 Control / Display Module. The Control / Display Module,

figure 3-7.1, includes the control and test switches, the solid

state logic elements, shutdown and alarm TATTLETALE

®

lights

that make up the generator engine control for a two-cycle

engine. This module is the same as Model A901-2 except 6 of

the alarm circuits are un-labeled. This allows the customer to

specify labels other than those recommended in NFPA-110.

This model has shutdown and alarm circuits labeled to meet the

requirements of NFPA-110, Level 2.

3-7.1.1 Mode Selector Switch, OFF-AUTO-TEST:

(a) OFF; turns off the control system and resets any shutdown

circuits.

(b) AUTO; turns on the engine controls and shutdown

circuits. System is on standby waiting for a contact

closure to start engine.

(c) TEST; turns on the engine controls and shutdown circuits.

A start signal is applied to the automatic control and the

engine start sequence begins.

3-7.1.2 Lamp Test Pushbutton: Tests the lights on the A- 903-2

module.

3-7.1.3 Alarm Silence Pushbutton: Turns off any audible alarm

that is connected to the Local or Remote Audible Alarm Relays.

The indicating light will remain on as long as the condition

exists. If the Alarm Silence pushbutton is not operated, the

Figure 3-7.1

12

DC24V

3A Fuse

1A

4

5

6

7

8

9

16

17

18

19

20

21

22

23

24

25

DC24V

DC24V

6-1/4 in.

(159 mm)

4-1/2 in.

(114 mm)

Figure 3-6.2

Page 16

audible alarm will turn off when the alarm contact clears.

3-7.1.4 The A903-2 SELECTRONIC®Control Module includes

the following engine control features:

(a) Cycle crank circuit; will crank the engine for 15 seconds

then rest for 15 seconds until the engine starts. The

crank/rest time is selectable for either 10, 15, 20, 25 or 30

seconds. If the engine false starts, goes above crank

disconnect speed then drops below that speed, the control

will rest for a fixed 10 second period before cranking again.

(b) Crank Disconnect Speed Switch; this circuit detects

engine speed and terminates cranking when engine speed

rises above the speed switch setting. The speed switch is

adjustable, 25 Hz to 2000 Hz, and is factory set at 1180

Hz. This would be 600 RPM on an engine with 118 teeth

on the flywheel ring gear.

(c) Auxiliary Crank Disconnect Circuit; this circuit, required by

NFPA-110, is provided as a back up for the Crank

Disconnect Speed Switch. It is operated by an external

switch sensing either speed, generator voltage or some other

variable that could be used to terminate cranking. Either

circuit will disconnect the starter when the engine starts.

(d) Overcrank circuit; will stop automatic cranking and

indicate overcrank if engine fails to start after 3 attempts.

The number of cranks are selectable for 1, 2, 3, 4 or 5

cycles before shutdown. The overcrank circuit may also

be turned off so no overcrank shutdown occurs.

(e) Shutdown Time Delay Bypass; this delay prevents the oil

pressure, water temperature and loss of speed signal

shutdown circuits from operating for 15 seconds after the

engine starts as detected by the crank disconnect circuit.

This same delay also locks out alarm circuit #7 and #8

when the engine is not running.

(f) Overspeed Speed Switch;

1. Provides a signal to the overspeed shutdown circuit if

the engine exceeds the preset speed. The factory

setting is approximately 3894 Hz, or 1980 RPM on an

engine with 118 teeth on the flywheel ring gear. The

adjustment range is 300 Hz to 10,000 Hz.

2. A push to test switch is provided to allow testing of the

overspeed circuit without overspeeding the engine.

When switch is depressed, the set point of the speed

switch is lowered approximately 10%.

3. The push to test switch can also be used to set the

overspeed switch at approximately 110% of running

speed. Hold the switch depressed while adjusting the

setting until the overspeed trips. When switch is

released, the set point will be 10% above normal running

speed. This is the method used to make the factory

setting. With engine speed at 1800 RPM or 3540 Hz.

(g) Cooldown circuit; this circuit keeps the engine running

for five minutes after the transfer switch has removed the

load from the generator and signaled the A903-2 to stop

the engine. This feature may be selected (turned On,

standard setting is Off) with a switch on the back of the

Control / Display Module.

3-7.1.5 Seven (7) First-out Shutdown Circuits; provide first-out

indication of cause of shutdown. These circuits deactivate the

fuel relay and lockout the A903 until reset. Shutdown circuits are

activated by the crank disconnect circuit and are not active when

the engine is stopped. Six (6) Red Shutdown Indicating Lights

are provided. The Remote Shutdown circuit does not have an

indicator light.

(a) Overcrank; tripped by the overcrank sensing circuit which

counts the number of cranking attempts.

(b) Overspeed; tripped by overspeed switch when engine

exceeds a preset speed.

(c) Oil Pressure; tripped by the oil pressure SWICHGAGE®if

pressure drops below preset point while the engine is

running.

(d) Water Temperature; tripped by the water temperature

SWICHGAGE®if engine coolant temperature exceeds the

switch setting.

(e) Spare Shutdown; tripped by an external switch. This

circuit is provided for an additional shutdown that may be

recommended by the engine supplier.

(f) Loss of Speed Signal; tripped by an internal sensing

circuit that detects the loss of the Magnetic Pickup

frequency signal for the speed switches while the engine is

still running. Since the Overspeed shutdown circuit is

activated by the frequency input, it prevents the engine

from running without overspeed protection.

(g) Remote Shutdown; this circuit is provided to shutdown

the engine generator from a remote location. No

indicating light is provided.

3-7.1.6 Nine (9) Alarm Indicating Circuits; provide indication

of cause of alarm. These circuits activate the alarm relays.

Alarm circuits are active as long as power is applied to the

A903-2. All are active when the engine is running, shutdown or

on standby except alarm circuit #7 and #8 which are locked out

until the engine is running. Nine (9) Amber Alarm Indicating

Lights are provided however only three circuits is labeled. The

other 6 are for customer specified alarms.

(a) Low Water Temperature; operated by low water

temperature SWICHGAGE®.

(b) Air Damper Closed; operated by an external switch or by

the Overspeed Relay circuit. This circuit is provided with

a selector switch to allow the user to determine the source

of the signal.

(c) Switch Not In Automatic; operated by the OFF-AUTO-

TEST mode selector switch.

(d) #4 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(e) #5 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(f) #6 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(g) #7 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(h) #8 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

(i) #9 Spare Alarm; operated by an external switch. This

circuit is provided for an additional alarm that may be

required by the user.

3-7.2 Relay Module. The Relay Module, figure 3-7.2, includes

all of the control, alarm and shutdown relays that are required to

13

Page 17

make up the generator engine control. Relays are available for

operation on either 12 or 24 volt battery systems. Four (4)

relays are included for:

3-7.2.1 Fuel Relay; this relay provides two outputs, one to

energize the engine fuel solenoid and a separate circuit to

energize the battery charging alternator field.

3-7.2.2 Shutdown Relay; this relay is operated by the shutdown

circuits of the Control / Display Module and provides an output

that can be used to trip the generator circuit breaker on an

emergency shutdown.

3-7.2.3 Overspeed Relay; operates only on an Overspeed

shutdown. This relay provides an output to trip an air shut off

solenoid to close the air damper on a two-cycle engine.

3-7.2.4 Local Audible Alarm Relay; provides a contact closure

to operate a local audible alarm as required by NFPA- 110, Level

1 and Level 2.

3-7.3 Status Signals. The relay module also includes three

outputs that can be used with external circuits for signaling or

control functions.

3-7.3.1 The Control On function at terminal 12 is on (closed to

negative) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

3-7.3.2 The System Ready signal at terminal 13 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test and no shutdown TATTLETALE®circuit is

latched on. This can be used to signal that the generator

engine is ready to automatically start or is running in Test.

3-7.3.3 The Control On function at terminal 14 is on (closed to

positive) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

Section 4: Installation

4-1 Location.

4-1.1 The A900 series is designed to mount in a

MURPHYMATIC®Generator Control panel with the Control /

Display module on the front panel and the Relay module on the

inside bottom surface. Other types of installation is possible as

long as the relationship of the two modules are maintained.

4-1.2 Clearance for Installation and Service; The modules must

be accessible for wiring to the terminal blocks and adjustment of

the user controls on the back of the Control / Display module.

Figure 4-1.2 shows the mounting dimensions and the minimum

clearances recommended for installation.

4-1.3 Wiring Terminals; Terminal blocks are provided on both

sides of the Control / Display enclosure and the Relay Module.

T orque all terminal screws to 12 inch pound maximum.

4-2 Wiring.

4-2.1 After the A900 has been located and installed, the wiring

connections can be made. This work should be done with all

electrical power disconnected from the engine. BE SURE THAT

THE BATTERY IS DISCONNECTED.

4-2.2 All electrical installation work should be done in

accordance with the National Electrical Code, NFPA-70, and all

applicable local codes.

4-2.3 In general, the following connections will be made:

(a) Battery positive and negative. An 8 A fuse or circuit

breaker must be provided to protect powered relay contact

circuits.

(b) Engine run device, such as a fuel shutoff solenoid.

(c) Engine speed sensor, such as a magnetic pickup or the

tachometer output of a battery charging alternator .

(d) Auxiliary crank disconnect device, such as a voltage

sensing relay contact wired to the generator output.

(e) Engine starter circuit; an auxiliary starter solenoid is

required to handle most starter solenoid requirements.

(f) Remote start contact. This is normally from the automatic

transfer switch but other sources are possible.

(g) Alarm and shutdown sensing switches as required.

4-2.3.1 The complete wiring of a Model A901 control is shown

in figure 4-2.3.1. Provision is made in the A900 series to

operate remote lights for all of the alarm and shutdown circuits

however these circuits do not have to be wired for the A900 to

function. Alarm input switches are not required but the alarm

circuits will not work without them.

4-2.3.2 Figure 4-2.3.2 is for wiring of the A902 control. The

same provisions as for the A901 are made.

4-2.3.3 The A903 wiring is shown in figure 4-2.3.3.

4-2.3.4 Wire Termination; the terminal blocks that are supplied

requires that all wires be terminated with #6 stud size forked

spade solderless wire connectors or stripped and inserted under

the captive terminal plates. Torque all terminal screws to 12

inch pound maximum.

4-2.3.5 All inductive loads (relays-soleniods-coils-etc.) that are

connected to the A900 must have reverse diodes wired across

the coil to supress reverse voltage that is generated whenever the

inductive load is de-energized. This will protect the electronic

components in the A900 and should prevent operating

malfunction due to noise. The “rule of thumb” for sizing the

reverse diode is to use one with a PIV (Peak Inverse Voltage)

rating equal to the operating voltage, or at least 100 volts and a

14

DC12V

3A Fuse

1A

4

5

6

7

8

9

16

17

18

19

20

21

22

23

24

25

DC12V

DC12V

DC12V

6-1/4 in.

(159 mm)

4-1/2 in.

(114 mm)

Figure 3-7.2

Page 18

5-1/2 in.

(140 mm)

3-3/4 in.

(95 mm)

3/16 in.

(5 mm) dia.

4 places

5-5/8 in.

(143 mm)

2-13/16 in.

(71 mm)

3 in.

(76 mm)

3-3/8 in.

(86 mm)

6-3/4 in.

(171 mm)

9-3/8 in.

(238 mm)

6 in.

(152 mm)

4-15/32 in.

(114 mm)

Mounting

Holes

1/8 in.

(3 mm)

diameter

1-1/2 in.

(38 mm)

clearance

5 in. (127 mm) maximum

between A-900 Series module

& relay module when mounting

1-7/8 in. (48 mm)

clearance

1-7/8 in. (48 mm)

clearance