Page 1

®

A

AUTOMATIC ENGINE CONTROLLERS

MODELS A88 AND A88-F

INSTALLATION MANUAL

A88-8916N

Revised 01-97

Section 40

(00-02-0196)

Page 2

TABLE OF CONTENTS

®

FRANK W.

MFR.

SECTION PAGE

I INTRODUCTION 1

II SPECIFICATIONS 1

IIA Power Requirements 1

IIB Input Requirements 1

IIC Output Ratings 1

III FRONT PANEL DESCRIPTION 2

IIIA Description of LED Callouts 3

IIIB Description of AOT Switch, Crank Disconnect

Control & Rest/Crank Time Control 3

IV OPTIONAL HOOKUPS 4

V OPERATION 5

LIST OF ILLUSTRATIONS

TYPE DESCRIPTION PAGE

Illustration Face Plate, A88 and A88-F 2

Illustration Optional Hookup Schemes 4

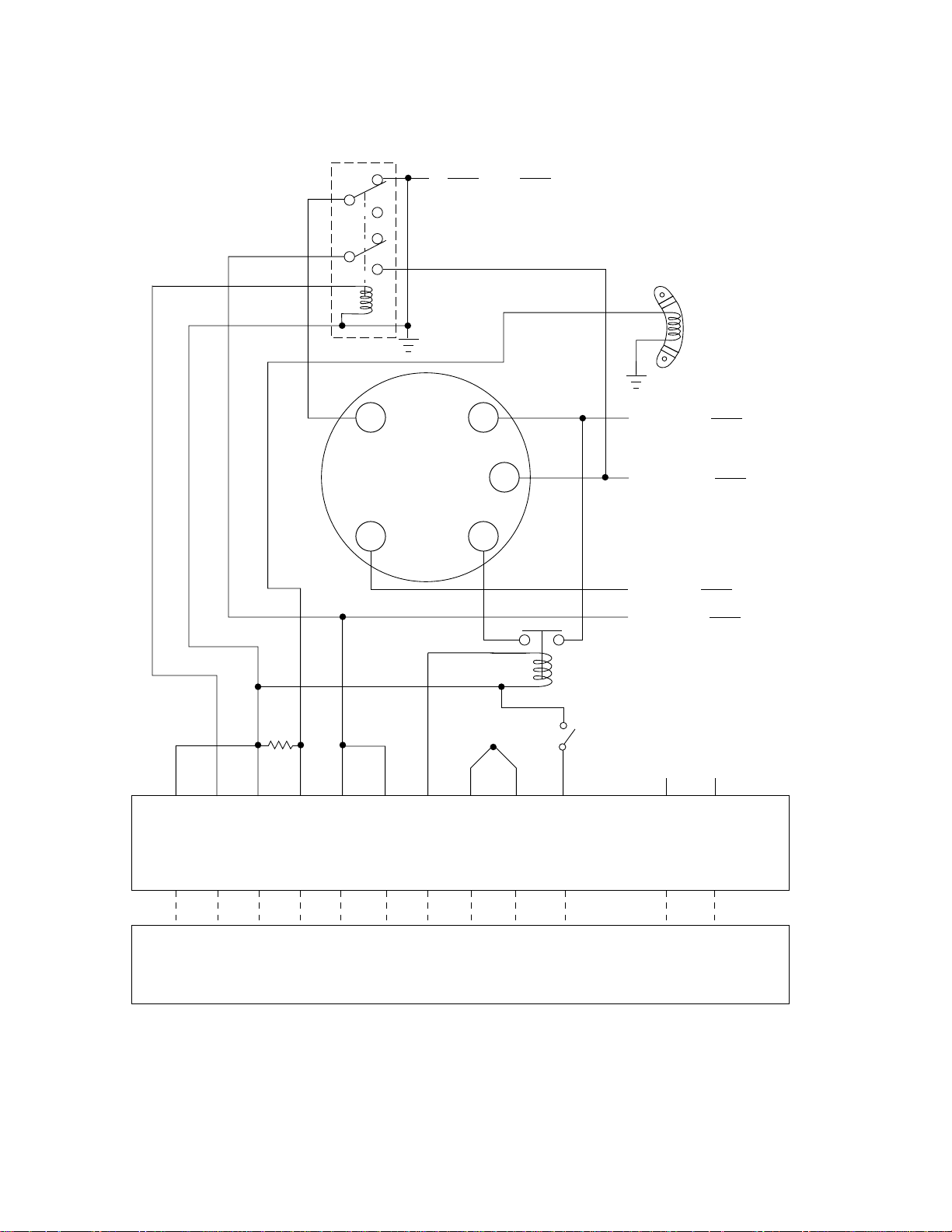

Diagram 1 Basic Wiring Hookup, A88 6

Diagram 2 A88 Wiring Harness 7

Diagram 3 Basic Wiring Hookup, A88-F 8

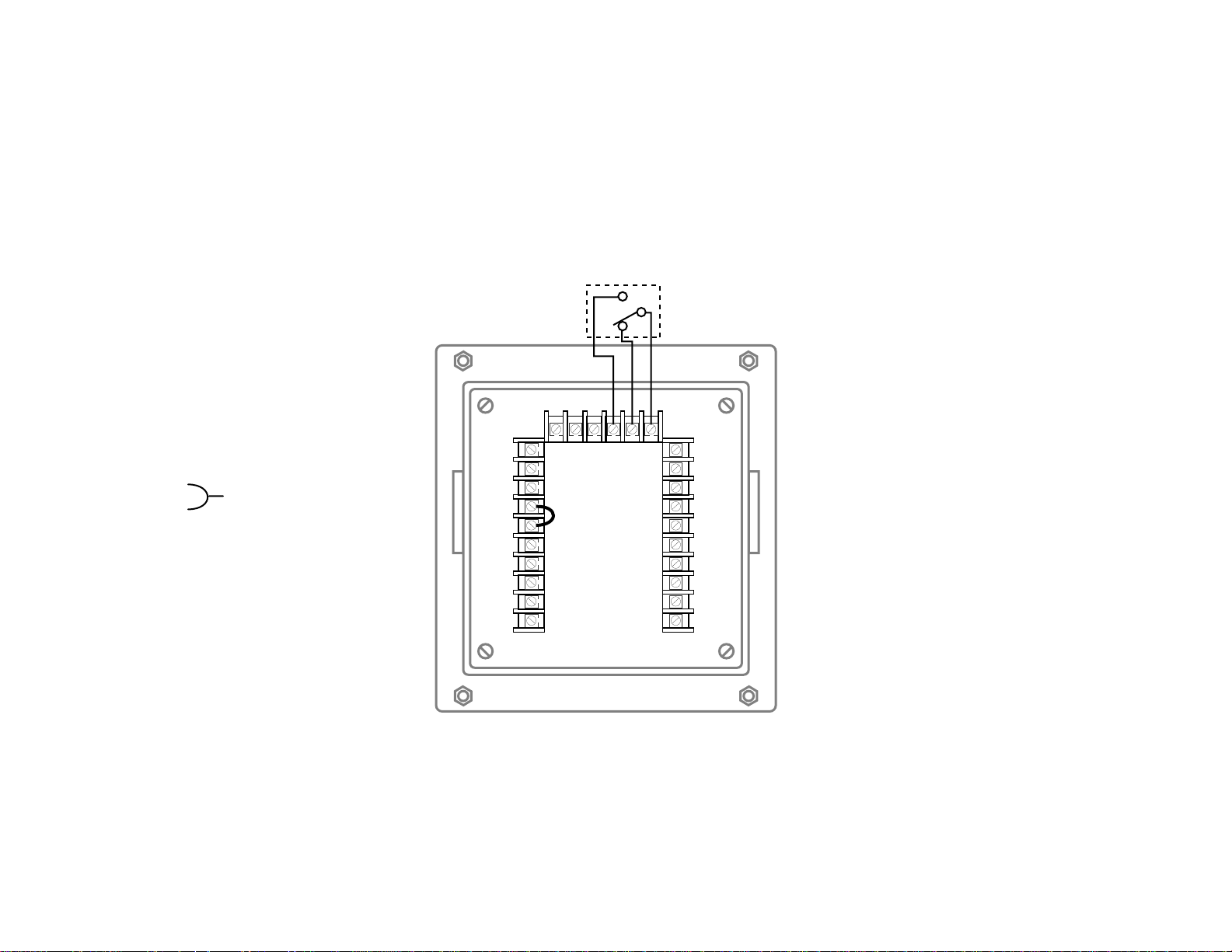

Diagram 4 A88-F Wiring Terminals 9

Diagram 5 Wiring for Honda Generator EM3500SX/EM5000SX 10

Diagram 6 Wiring for Honda Generator CXS360 11

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

■ Murphy de México, S.A. de C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P.; México 78384

tel. +52-48-206264 fax +52-48-206336

e-mail murmexsl@sanluis.podernet.com.mx

■ Murphy Switch of California

P.O. Box 900788; Palmdale, California 93590; USA

tel. (805) 272-4700 fax (805) 947-7570

e-mail sales@murphyswitch.com

■ Frank W. Murphy France

tel. +33 1 30 762626 fax +33 1 30 763989

Since 1939

■ Frank W. Murphy Manufacturer

P.O. Box 470248; Tulsa, Oklahoma 74147; USA

tel. (918) 627-3550 fax (918) 664-6146

e-mail fwmurphy@ionet.net

■ Frank W. Murphy Southern Division

P.O. Box 1819; Rosenberg, Texas 77471; USA

tel. (281) 342-0297 fax (281) 341-6006

e-mail murphysd@intertex.net

Printed in U.S.A.

■ Frank W. Murphy, Ltd.

Church Rd.; Laverstock, Salisbury SP1 1QZ; U.K.

tel. +44 1722 410055 fax +44 1722 410088 tlx 477088

e-mail sales@fwmurphy.co.uk

■ Frank W. Murphy Pte., Ltd.

26 Siglap Drive; Republic of Singapore 456153

tel. +65 241-3166 fax +65 241-8382

e-mail fwmsales@fwmurphy.com.sg

■ Murphek Pty., Ltd.

1620 Hume Highway; Campbellfield, Vic 3061; Australia

tel. +61 3 9358-5555 fax +61 3 9358-5558

Page 3

WARNING

BEFORE BEGINNING

INSTALLATION OF THIS

MURPHY PRODUCT

✔ Disconnect all electrical

power to the machine.

✔ Make sure the machine

cannot operate during

installation.

✔ Follow all safety warnings of

the machine manufacturer.

✔ Read and follow all

installation instructions.

Page 4

SECTION I: INTRODUCTION

A. The Automatic Engine Controller, Model A88 and

A88-F is designed to automatically start, monitor and stop

electric start engines. The A88 comes in an all-weather

case with a 5 foot cable and a plug for connection. The

A88-F is the same system, but housed in a panel-mount

case with terminals on back for connecting.

B. Features

1. Has a self-contained Auto-Off-Test Switch.

2. Rest and crank time selected by a single switch.

3. Adjustable crank disconnect speed switch.

4. Close a switch to run; open to stop feature.

5. Engine starts and runs when a contact closes and

stops when a separate set of contacts close.

6. Goes into a rest period in the event of a false start.

7. Alarm before start to alert personnel.

SECTION II: SPECIFICATIONS

A. Power Requirements:

1. Voltage 8-30 VDC, negative ground.

2. Current @ 12 volts less load current.

a. standby 10 ma

b. crank 140 ma

c. shutdown 32 ma

3. Maximum fuse size, 4 amp, slow blow.

B. Input Requirements:

1. Start-stop control switch

a. SPST N.O. dry contact; close to run, open to stop

b. SPDT dry contact

c. Two SPST N.O. dry contacts; one, momentary

close to run; one momentary close to stop

2. Magnetic pickup or alternator tach requirements:

a. voltage 2 volts, rms minimum

b. 25 to 2000 hz crank disconnect

c. maximum 100 volts Pk Pk

C. Output Ratings: Source = switch to battery

Sink = switch to ground

1. Ignition or run relay; SPDT dry relay contacts

rated 10 amp @ 30 VDC resistive, 6 amp @ 30

VDC inductive.

2. Crank output

a. transistor 1 amp source

b. transistor 1 amp sink

3. Choke

a. transistor 1 amp sink

4. Time delay

a. transistor 1 amp sink

5. Summary

a. transistor 1/2 amp sink

8. Crank disconnect circuitry accepts the following inputs:

a. breaker or electronic type ignition

b. magnetic pickup

c. alternator tach

d. flywheel alternator

e. mechanical switch

9. Has a built-in one minute time delay for customer use.

10. Five fixed crank attempts before shutdown.

11. An output to indicate that the engine is running

to be used as remote indication or in warm up

operation.

12. Has a summary of shutdown output.

13. Monitors the following engine functions and will

shut the engine down in event of a failure:

a. Overcrank

b. Oil Pressure

c. Engine Temperature

d. Spare

14. Has 30 second lockout feature for start up.

15. Output for choke actuator.

1

Page 5

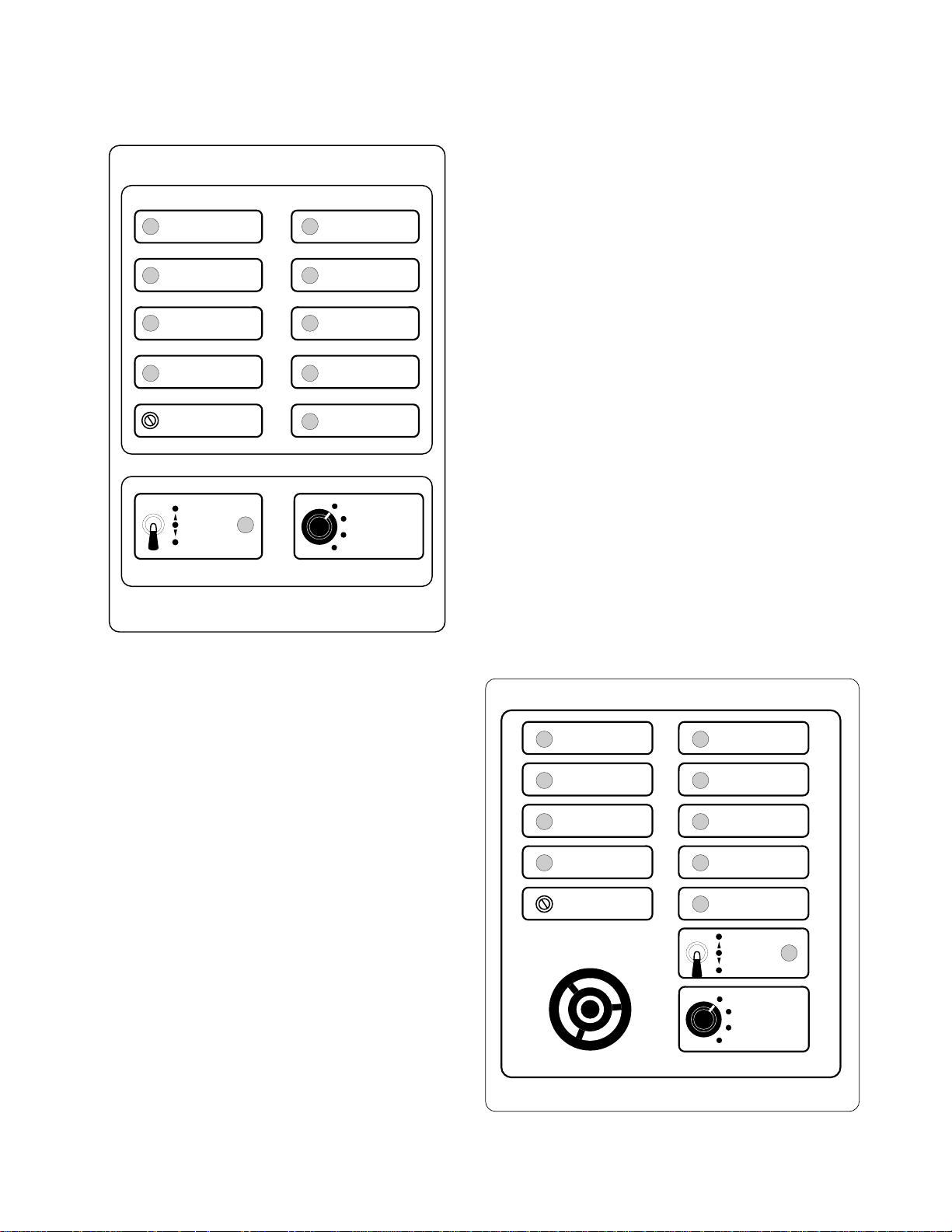

SECTION III: FRONT PANEL DESCRIPTION

20s

15s

10s

5s

CRANK

AND

REST

TIME

PICK UP

PRESENT

CRANK

CRANK

DISCONNECT

IGNITION

ON

CRANK

DISCONNECT

OVER

CRANK

ENGINE

TEMP.

CHOKE

OIL

PRESSURE

AUTO

OFF

TEST

CRANK

AND

REST

TIME

IGNITION

ON

PICK UP

PRESENT

CRANK

CRANK

DISCONNECT

CRANK

DISCONNECT

20s

15s

10s

5s

CHOKE

OVER

CRANK

OIL

PRESSURE

ENGINE

TEMP.

AUTO

OFF

TEST

A88

Automatic

Engine

Controller

(Shown without enclosure)

A88-F

Automatic

Engine

Controller

(Shown without enclosure)

2

Page 6

FRONT PANEL DESCRIPTION

Along with each description, an attempt has been made

to clarify output and input connections according to their

functions and terminals or wire color.

A. Description of LED Callouts

1. IGNITION

The ignition LED will come on when the system receives

a signal to start. If the alarm before start is used, this

ignition LED will NOT come on until the 5 second alarm

goes off.

2. PICKUP PRESENT

When the engine is cranking or running and the pickup is

connected properly with sufficient output voltage (2 volt

rms) this LED will come on. IMPORTANT - This LED

must come on or the unit will not operate properly.

Note: this LED will NOT be on if a mechanical switch is

used as a crank disconnect sensor.

3. CRANK

The crank LED is on when the engine is cranking and is

used to show that the crank circuitry is functioning

properly.

The crank solenoid will be connected to terminal 1 of the

A88-F or the white/brown wire of the A88, if the solenoid

is connected to positive to operate.

If the crank solenoid is grounded to operate, connect it to

terminal 2 of the A88-F or connect it to the white/red wire of

the A88.

4. CRANK DISCONNECT

This LED comes on when the crank disconnect

adjustment is adjusted to disengage the starter. When

this LED comes on, the crank LED goes out. (See item B2 for control setting adjustments)

5. CHOKE

This LED will come on for approximately 3-4 seconds at

the beginning of each crank cycle and then go out. If a

choke or compression release solenoid is connected from

battery positive to Terminal 3 (A88-F)or the violet wire

(A88) it will be energized when the LED comes on.

6. OVERCRANK

If the engine is called on to start and fails after 5 tries, this

LED will come on and stay on to indicate cause of

shutdown.

7. OIL PRESSURE

The oil pressure LED will come on if oil pressure is lost

during operation and remain on to indicate cause of

shutdown. Terminal 11 of the A88-F or the black/white

wire of the A88 are connected to the oil pressure switch.

8. ENGINE TEMPERATURE

If the unit is shutdown because of high engine temperature,

this LED will be on. The temperature sensor is connected to

Terminal 12 of the A88-F or the blue/white wire of the A88.

9. SPARE

This LED comes on to indicate cause of shutdown if the

spare is used. Connect the monitor to Terminal 13 of the

A88-F and the yellow/white wire of the A88.

Note: the overcrank, oil pressure, engine temperature

and spare circuits are locked out for 30 seconds during

start up. They require normally open sensors (close to

operate). A summary output is available (Terminal 20 on

the A88-F and the brown wire of the A88.) for remote

indication when a shutdown occurs.

B. Description of AOT Switch, Crank Disconnect

Control & Rest/Crank Time Control

1. AUTO-OFF-TEST

a. OFF

When a shutdown occurs, this unit must be removed

from power to reset. The Auto-Off-Test switch removes

power when placed in the off position. The green LED

will go off. The unit should be left off 8-10 seconds

to allow the circuitry to discharge and stabilize.

b. TEST

This position is used after all connections have been

made or for periodic checks that should be a part of a

preventive maintenance program. The start and stop

inputs are by-passed when this switch is placed in the

test position. The unit will automatically initiate the

crank cycle.

c. AUTO

For normal operation and after the system has been

tested, Place the switch in this position. It indicates

the controller will take over starting and stopping the

engine.

Note: these units may have a 4-5 second alarm before start.

The A88-F comes with the alarm hooked up by connection

of terminals 16 and 17. The A88 comes without the alarm

hooked up; if alarm is needed, ground the red/white wire.

Although it is an optional hook up, it is recommended that

this alarm be used to alert personnel of a start.

2. CRANK DISCONNECT CONTROL

Adjust this control to make the crank circuit disengage the

starter when the engine starts. Rotating it counterclockwise makes the starter drop out at lower RPM.

3. REST AND CRANK TIME

By placing this switch in one of the 4 positions, the rest

and crank time is selected. If the switch is placed in the

10 seconds position, the system will crank the engine for

10 seconds, then rest for 10 seconds.

Note: if the engine starts momentarily, then dies, it will go

into a 25-30 second rest period before it attempts another

crank. This is regardless of what position the crank and

rest switch is in.

When the system is called on to crank the first crank cycle

will be typically 50% longer than the remaining four tries.

This feature will aid in starting a cold engine.

3

Page 7

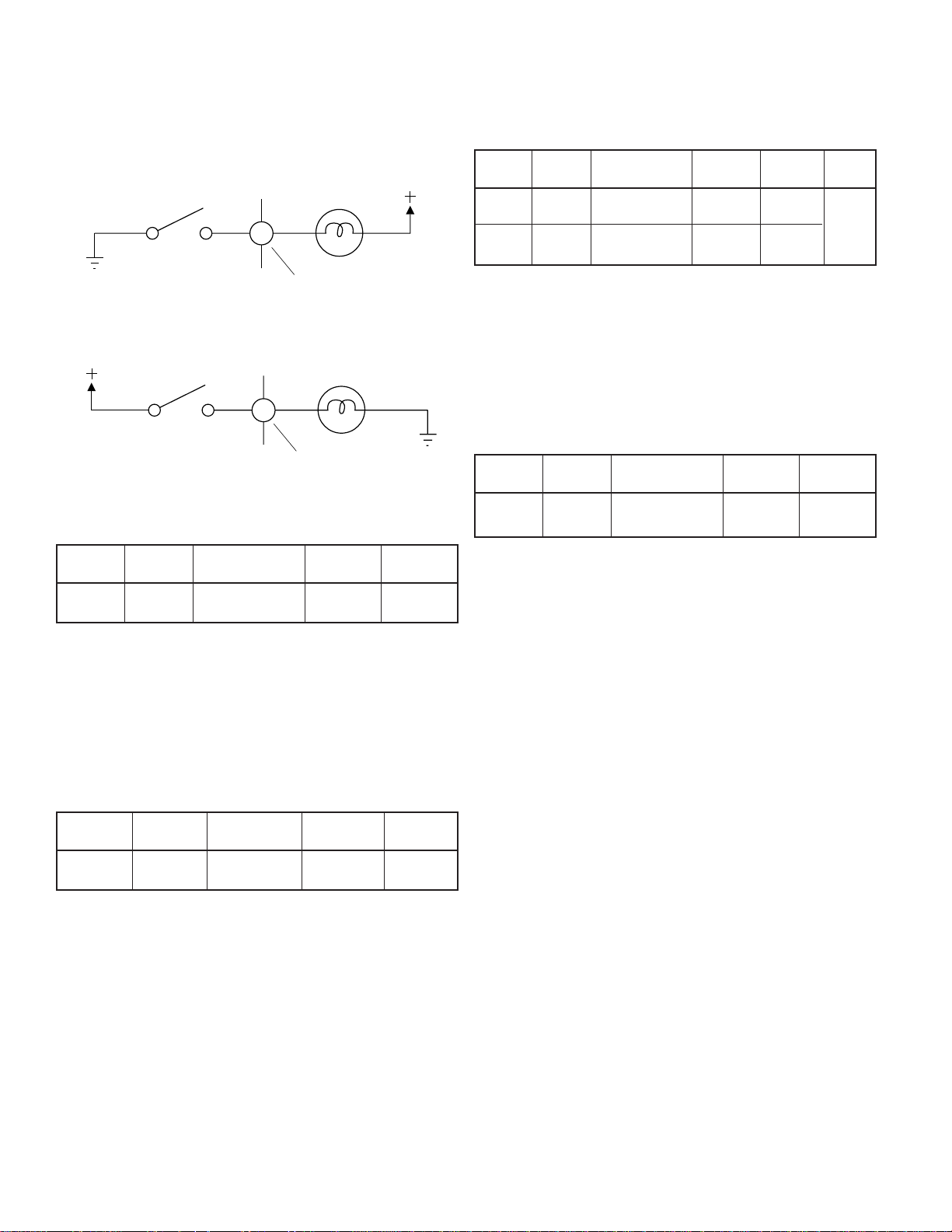

SECTION IV: OPTIONAL HOOKUPS

Switch

Lamp

Terminal

Switch

Lamp

Terminal

In this section the terms Sink and Source are used.

Sink: This terms refers to an output that switches to

ground to do work.

Source: This term will be used to refer to an output that is

switched to positive to do work.

1. CHOKE

To use this feature, connect the choke or compression

release solenoid to the battery positive and then to the

terminal or wire shown:

Output

A88-F

Terminal

A88 Wire color

Output

Operation

Max.

Current

3. CRANK CONNECTIONS

A Crank

B Crank

A88-F

Terminal

No. 1

No. 2

A88 wire color

White/Brown

White/Red

Connected

Solenoid

to Ground

Solen. to

batt. pos.

Output

Operation

Source

Sink

Max.

Current

1 A

If the crank solenoid is already connected to ground,

connect to the unit as indicated in "A" above.

If the crank solenoid is already connected to the battery

positive, connect it as in "B" above.

4. ENGINE RUNNING

If it is desirable to know or indicate when the engine is

actually running, connect the indicator to the battery

positive and then as below:

Output

Engine

Running

A88-F

Terminal

No. 18

A88 Wire color

Yellow

Output

Operation

After 30

sec. delay

Sink

Max.

Current

1 A

After the engine has been running for approximately 30

seconds, the indicator will be energized.

Choke

No. 3

Violet

Sink

1 A

At the beginning of each crank cycle, the choke or

compression release solenoid will pull in, remain in for 3

or 4 seconds. The maximum current this circuit can carry

is 1 amp.

2. SUMMARY

For a remote shutdown or alarm feature after a shutdown

occurs, connect the alarm or lamp to the battery positive

then to the terminal or wires shown:

Output

Summary

A88-F

Terminal

No. 20

A88

Wire color

Brown

Output

Operation

Sink

Max.

Current

1

/2 A

5. WARM UP

If it is desirable to have a warm up period or a 90 second

delay after the engine has started, connect the engine

running output to the time delay input and then connect

the time delay to the gas feed or clutch mechanism.

Terminal 18 to terminal 9 on the A88-F, the yellow wire to

the violet/white wire on the A88 unit.

Connect the clutch or gas feed solenoid to battery positive

then to the time delay output terminal 19 on the A88-F;

the orange wire on the A88.

After the engine starts and has been running for approximately 90 seconds, the clutch or gas feed will be energized.

4

Page 8

SECTION V: OPERATION

Batt.+

To

Clutch

Control

Orange

Violet/White

Yellow

Slave

Relay

Diode

Batt.+

18

9 19

To

Clutch

Control

Slave

Relay

Diode

A88

A88-F

+

Diode

Solenoid

or

Coil

Refer to Diagrams 1 and 3: Basic Wiring Hookup for

correct connections to your engine.

Diagram 2 shows wire colors that correspond to the A88

plug and hookup wire, in the event of two colors the first

color is the primary color and the other is a tracer color.

Diagram 4 identifies the A88-F wiring terminals.

Step No. 1, Pickup:

Determine the type of pickup to be used and connect

it to the controller as illustrated in the basic wiring

hookup.

Step No. 2, Starter Solenoid:

Determine the type of starter solenoid used on your

engine. In most cases it will be of the source type, that

is, one side of the pull in coil is connected to ground and

and the other has to be connected through the ignition

to positive. Do not connect the controller output directly

to the starter, always use a starter slave solenoid.

Step No. 3, Ignition:

The type of ignition must be determined and wired

accordingly . Most later models will be of the CDI type.

Step No. 4, Start/Stop

Select the type of Start/Stop control needed and wire

accordingly. If a close to run and open to stop is used

be sure and connect the brown/white and the

grey/white together. On the A-88-F connect terminals

16 and 17. It is recommended that the alarm before

start be used for safety .

Step No. 5, Choke:

If a choke or pressure release feature is needed connect the choke solenoid to battery positive then to

terminal 3 of the A-88-F or to the violet wire of the A-88.

Step No. 6, Shutdown:

Connect the shutdown circuits. The spare should be

marked or labeled on the blank space.

Step No. 7, Time Delay:

This system has a 60 second built-in time delay for

customer use. If the appropriate inputs are grounded, it

times out after the crank disconnect light comes on.

Input Delay Output

A88 ground

violet/white wire

A88-F ground

Terminal 9

seconds

seconds

60

60

Orange wire

Sinks to ground

Terminal 19

Sinks to ground

Step No. 8, Clutch or Warmup Operation:

If a warm up feature is desired see Section IV:

Optional Hookups paragraph 5

Clutch activates approximately 90 seconds after

engine has started—pulls in after engine stops.

Clutch activates approximately 90 seconds after

engine has started—pulls in after engine stops.

WARM UP.

Step No. 9, Crank disconnect adjustment:

To adjust the crank disconnect, disconnect the ignition

wire or leave the fuel cut off. That will let the engine

crank but not start.

Turn the crank disconnect control fully clockwise (15

turns). This control does not have a stop and it does

not hurt it to turn it more than 15 turns.

Place the the crank and rest time switch in the 10 or

15 second position. Switch the controller in the test

position. With the engine cranking, rotate the control

counter-clockwise until the starter drops out. Notice

that the engine will crank longer the first time.

When the starter kicks out, rotate the control clockwise for approximately 1(one) turn. The crank

disconnect is now set.

NOTE: When installing relays or solenoids that are

controlled by this controller always install a diode directly

across the coil windings to help eliminate the back EMF.

5

Page 9

123

Grey

Blue

White/Black

Green

White/Red

White/Brown

Yellow

Brown

Green/White

Brown/White

Grey/White

Red/White

White

White/Orange

White/Yellow

Violet/White

Orange

Red/White ground for

5 seconds Alarm On Start

Connect

SPST

For Momentary

Type Operation

Close to Run

Open to Stop

Ignition Connection

Breaker Type, 6 amp max

Ignition Connection

CDI Type 6 amp max

Ground to Kill

Wht/Ong

White

Wht/Yel

Wht/Ong

Stop

Grey/White No Connection

Red/White ground for

5 seconds Alarm On Start

Vacuum

Switch

Solenoid

Switched to

Ground(sink)

Solenoid

Switched to

Positive(source)

To StarterTo Starter

Starter Solenoid Connection

Use Only One, 1 amp max

Remote Annunciator Connection

1 amp max

Engine

Running

Shutdown

Summary

Pickup Signal Source Connection

Use Only One

Electronic or

Breaker Type

Ignition

Tach O/P

ALT

Magnetic

Pickup

A88

Mini Auto

Starter

Battery

SWICHGAGE® Inputs

Oil

Temperature

Spare

Black/White

Blue/White

Yellow/White

Violet

Grounding

Violet/White

will cause Orange

to Grnd 60 sec Later

Load

1/2 A

Red 18 GA

Blk 18 GA

Choke Connection

Pulls in for 3-4 sec.

NOTE: First is color of wire, second color is tracer.

EXAMPLE: (White/Red)

White is color, Red is trace color

Brown/White

Grey/White

N

S

Fly Wheel

ALT.

Diagram 1: A88 Basic Wiring Hookup

To Batt. + To Batt. +

To Batt. + To Batt. +

To Batt. +

Start/Stop Control Connection

(Use only one)

Ignition Connection

(Use only one)

To Batt. +

Start

Grn/Wht

Brn/Wht Grn/Wht

A88 cable

N.O.

C

N.C.

For Momentary

Type Operation

SPDT

6

Page 10

Pin 1-wire-Wht/Blk: Breaker ignition I/P

Pin 2-wire-Green: Vacuum switch I/P

Pin 3-wire-Viol/Wht: Grnd for time delay I/P

Pin 4-wire-Grey: Magnetic pickup I/P

Pin 5-wire-Blue: Tach alternator I/P

Pin 6-wire-Violet: Choke (sink) O/P

Pin 7-wire-Wht/Red: Crank (sink) O/P

Pin 8-wire-Yellow: Engine running (sink) O/P

Pin 9-wire-Grn/Wht: Start I/P

Pin 10-wire-Red/Wht: Connect #11 for alarm

Pin 11-wire-Ong/Wht: Connect #10 for alarm

Pin 12-wire-Black: Battery negative (–)

Pin 13-wire-Red: Battery positive (+)

Pin 14-wire-Brn/Wht: Stop I/P

Pin 15-wire-Grey/Wht: Connect to #14 for close to

run-open to stop operation

Pin 16-wire-Wht/Brn: Crank (source) O/P

Pin 17-wire-Yel/Wht: Spare I/P

Pin 18-wire-Blue/Wht: Water temp. I/P

Pin 19-wire-Blk/Wht: Oil pressure I/P

Pin 20-wire-Brown: Shutdown summary (sink) O/P

Pin 21-wire-Wht/Ong: Ignition relay Common

Pin 22-wire-White: Ignition relay N.O.

Pin 23-wire-Wht/Yel: Ignition relay N.C.

Pin 24-wire-Orange: Time delay (sink) O/P

Diagram 2: A88 Wiring Harness

7

Page 11

123

6

7

5

8

2

1

18

20

4

17

16

15

23

21

22

9

19

Ground for 5 seconds

Alarm On Start

Connect

SPST

For Momentary

Type Operation

Close to Run

Open to Stop

Ignition Connection

Breaker Type, 6 amp max

Ignition Connection

CDI Type 6 amp max

Ground to Kill

Stop

16 No Connection

Ground for 5 seconds

Alarm On Start

Vacuum

Switch

Solenoid

Switched to

Ground(sink)

Solenoid

Switched to

Positive(source)

To StarterTo Starter

Starter Solenoid Connection

Use Only One, 1 amp max

Use Continuous Duty Solenoid

Remote Annunciator Connection

1 amp max

Engine

Running

Shutdown

Summary

Pickup Signal Source Connection

Use Only One

Electronic or

Breaker Type

Ignition

Tach O/P

ALT

Magnetic

Pickup

A88-F

Mini Auto

Starter

Battery

SWICHGAGE® Inputs

Oil

Temperature

Spare

11

12

13

3

Grounding 9

will cause 19 to ground

60 seconds Later

Load

1/2 A

26

25

Choke Connection

Pulls in for 3-4 sec.

N

S

Fly Wheel

ALT.

Diagram 3: A88-F Basic Wiring Hookup

To Batt. + To Batt. +

To Batt. + To Batt. +

To Batt. +

Start/Stop Control Connection

(Use only one)

Ignition Connection

(Use only one)

To Batt. +

Start

NO

C

NC

Time Delay

Output

For Momentary

Type Operation

SPDT

8

Page 12

Terminal 1: Crank (source)

Diagram 4: A88-F Wiring Terminals

Terminal 2: Crank (sink)

Terminal 3: Choke (sink)

Terminal 4: Start I/P

Terminal 5: Breaker ignition I/P

Terminal 6: Magnetic pickup I/P

Terminal 21: Common

Terminal 22: Normally Closed (N.C.)

Terminal 23: Normally Open (N.O.)

Terminal 24: No Connection

Terminal 25: Negative (–)

Terminal 26: Positive (+)

Terminal 7: Alternator I/P

Terminal 8: Vacuum switch I/P

Terminal 9: Ground for time delay I/P

Terminal 10: No connection

Terminal 11: Oil pressure I/P

Terminal 12: Water temperature I/P

Terminal 13: Spare I/P

Jumper for alarm

before start

Terminal 14:

Terminal 15:

Terminal 16: Connect to #17 for

momentary operation

Terminal 17: Stop I/P

Terminal 18: Engine running (sink)

Terminal 19: Time delay (sink)

Terminal 20: Alarm summary (sink)

2326 25 24

Ignition Relay

22 21

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

9

Page 13

Fuel

Valve

Start

Float Switch

100 1/2 W

Ignition N.O.

Battery Pos.

Ground

Pickup

Oil

Level

Switch

Crank

Diagram 5: A88/A88-F Wiring for Honda Generator

Green

Yellow

Ground for Alarm

Before Start

IN4005

Oil Press. Shutdown

Grey/White

Brown/White

Stop

White/Yellow

White/Brown

Black

Blue

Red

Black/White

White

Red/White

Ignition N.C.

Green/White

A88

White/Orange

16

17

22

1

25

7

26

11

23

15

4

21

or

A88-F

Blue Grey

Charging

Coil

Close To Run

Open To Stop

Starter

Slave Relay

1 Amp Max

Customer Hookup for Honda Generator

Model EM3500SX/EM5000SX

*

R1

*

*

K1

D1

*

*

As shown, when float

closes the 4-5 seconds

alarm will then start.

*

Customer supplied.

10

Page 14

100 1/2 W

Diagram 6: A88/A88-F Wiring for Honda Generator

White

Black

Blue

Red 18 ga

White/Brown

Grey/White

Red/White

Red/White

A88

White/Orange

23

25

7

26

1

16

11

4

12

15

21

or

A88-F

E

IG BAT

LO

ST

Combination

Switch

Brown/White

Grey/White

Red/White

17

To Yellow/Red (OIL)

To Yellow/Grn (TEMP)

Closed to

Start

Open to

Stop

Connect

Black/Red

White/Black

Black/Yellow

Black/White

E Black

Charge

Coil

Customer Hookup for Honda Generator

Model CSX360

* Customer supplied.

** Starter solenoid or 10A 12V relay.

*

*

**

11

019699

Loading...

Loading...