Page 1

KEYSTART 9700 series

START

The Generator Controls Division of

R

MANUAL START ENGINE CONTROLLER WITH

AUTOMATIC FAULT PROTECTION SHUTDOWN

The Keystart 9700 range provides for the manual starting and

stopping of a standby engine - a generator, pump or other

application - with automatic monitoring and shutdown of the

engine in the event of a fault.

The 9700 series is pin compatible with the Autostart range:

this allows the use of standard wiring for both manual and

automatic control panels, simplifying panel design and

permitting easy upgrades from a manual to fully automatic

control system.

Key features

• Keyswitch operation for enhanced security

• Up to four fault inputs, configurable for use with contacts

which open or close on fault, with wiring to +ve or –ve DC

• Options for overspeed protection (magnetic pickup or

AC alternator driven) and preheat/auxiliary control.

• Pin compatible with Autostart 705, 710, 720 and 730 series.

• 96 x 96mm DIN standard, front panel mounted case

• Switchable 12 or 24 V DC power supply

Operation

The Keystart is powered from the engine battery or similar

low voltage DC source. A switch at the rear allows for 12V

or 24V operation.

Control of the Keystart and engine is by use of a 3 or 4

position keyswitch on the front facia:-

STOP Removes power from the Keystart, stopping the

engine and resetting a latched fault condition.

RUN Energises the Keystart’s RUN relay (enabling

the engine fuel or ignition). The fault ‘override’

timer begins as soon as the key is turned (or

spring returns) to this position. Once the engine

is fully running, Keystart monitors for faults and

shuts down the engine if a fault is detected.

Maintains fuel to the engine, and activates the

START output (used for controlling the starter

motor circuit). This position is spring-biased to

return to the RUN position when the operator

releases the key.

AUX (optional: 'A' models only) Provides a switched

+ve DC output, used for preheat circuits or

auxiliary control (remote power up) of Keystart.

The key is common to all Keystarts and is removable

only in the STOP position.

The front facia also has five LED and pictogram indicators

for the display of engine fault status:-

Low Oil Pressure

High Engine Temperature

Overspeed (or Plant Fail on non-overspeed units)

Charge Fail

Plant Fail

Issue 5, revised 04/99

Catalogue section 75

Product Specifications

Power supply:

Operating voltage:

Steady state

Brown out / cranking

Current consumption < 150mA

Inputs:

Fault switch inputs:- selectable: open or closed, + ve or – ve

+ ve input defined as:

– ve input defined as:

Speed sensing inputs:-

Magnetic pickup

AC alternator

Outputs: (all ratings for resistive load)

Run relay output volt-free SPCO relay contacts

Start output + ve DC (switched)

Auxiliary/preheat output + ve DC (switched)

Alarm output – ve DC (open collector transistor)

Tachometer / calibration To suit 0 – 1 mA, 75 Ohm meter,

Adjustable settings:

Fault Override timer < 10 to > 30 secs.

Overspeed trip level < 100 to >130 % of calibrated speed

General:

Overall dimensions (w x h x d) 96 x 96 x 130 mm

Panel cut-out size DIN 92 x 92 mm

Weight approx. 500 g

Operating ambient temperature –10oC to +55oC

Case sealing IP22

Vibration 1G, 50 Hz to 5 kHz.

Chemical/fire case: glass filled Noryl,

(12V setting)

9 – 20 V DC

<= 5V for 2 secs

80% to 100% of +ve DC supply

–1V to +2V w.r.t –ve DC supply

10 – 60 VAC peak, < 2300 to > 3400 Hz.

90 – 350 VAC rms, < 50 to > 60 Hz. nom.

16 A max. @ 24V DC

16 A max. @ 24V DC

15 A max. @ 24V DC

300mA max. @ 33V DC max.

output = 0.75mA at rated engine speed

self extinguishing, non-dripping.

facia: polycarbonate

(24V setting)

18 – 33 V DC

<= 10V for 2 secs

M010901

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

Page 2

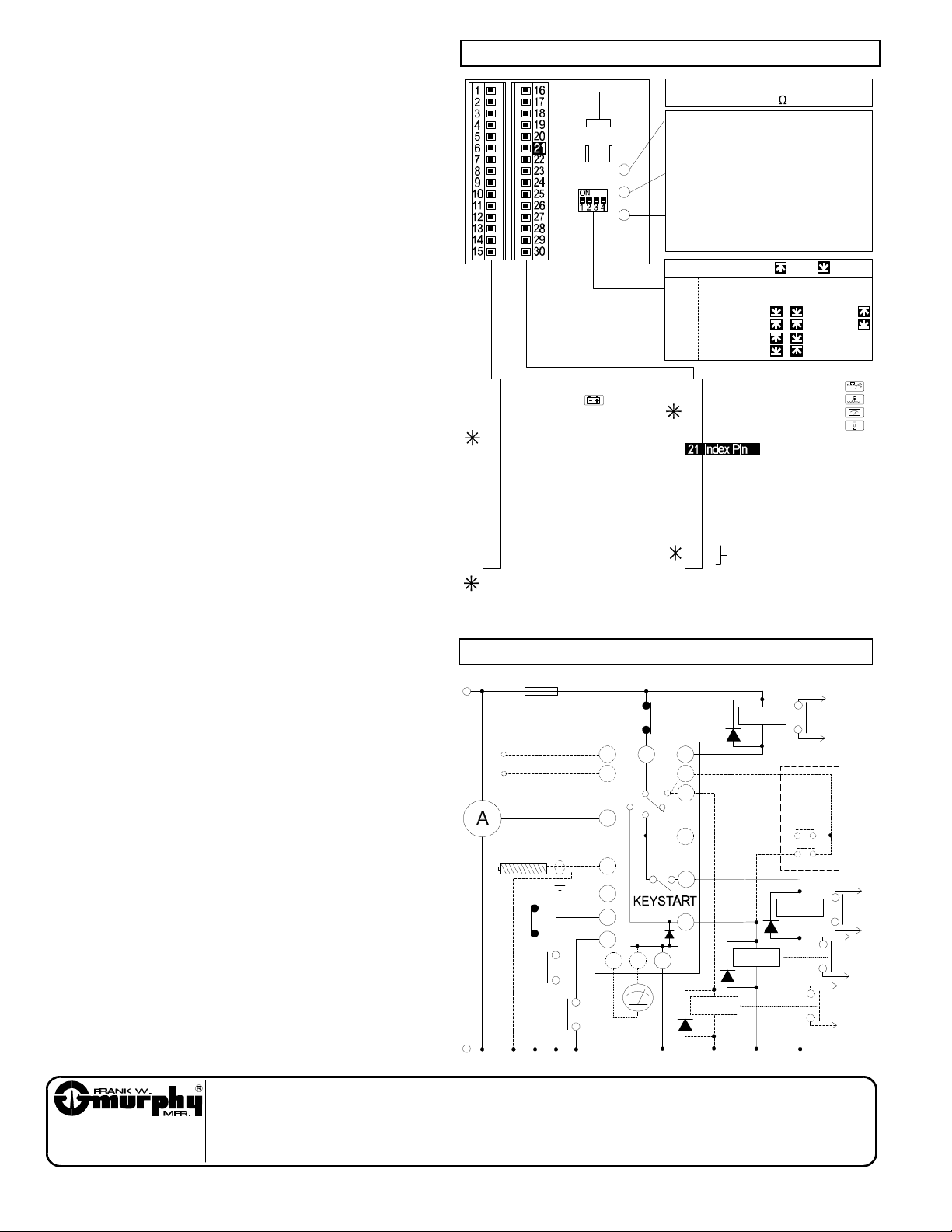

Control Outputs

– VE DC

+ VE DC

RUN

Run

Stop

Run

Remote

(’A’ option only)

Start

22

23

4

fuel

alarm

starter

preheat

(’A’ option

19

16

17

RPH

RAL

Aux

RST

RFL

Magnetic pickup

– ve DC power supply

Mag. pickup input (KEY9701 only)

Pin 5 is not used on models 9700 and 9702.

Pin 18 is not used on overspeed models 9701 and 9702.

Pins 29 and 30 are not used on models 9700 and 9701.

Input 1: Low Oil Pressure

Input 3: Plant Fail (9700 only)

Start output: + ve DC, 15A max.

Frank W. Murphy Manufacturer

Frank W. Murphy Southern Division

Frank W. Murphy Ltd.

Murphek Pty. Ltd.

Murphy Switch of California

Murphy de Mexico S.A. de C.V.

Frank W. Murphy Pte, Ltd.

Frank W. Murphy Ltd. en France

The following are provided:-

• Switched +ve RUN relay and START outputs, used for

controlling the engine fuel and starter motor circuits.

• A –ve DC (open collector transistor), common ALARM

output, used for remotely signalling a fault condition.

Fault protection and Alarm System

After the operator has started the engine and the fault

override timer has expired, the Keystart monitors for engine

and plant faults through remotely connected switch sensors.

Dedicated inputs are provided for Low Oil Pressure and

High Engine Temperature switch sensors. 1 or 2 additional

inputs may be used for general purpose ‘plant fail’ contacts.

Switches at the rear allow the inputs to be configured for

use with remote contacts which either open or close during

fault, with wiring polarity to either +ve or –ve DC.

The Keystart may optionally be fitted with an engine

overspeed trip, available in alternator sensing (generator

AC, 50/60Hz) or magnetic pickup sensing variants.

If any of the above faults occur, Keystart will:-

• turn off its RUN output (stopping the engine)

• indicate the fault on the appropriate front facia LED

• activate its Alarm output (to remotely signal that a

fault has occurred).

The automatic fault shutdowns operate on a first-up and

latching basis - subsequent faults are not indicated and the

displayed fault can only be cleared by switching the

Keystart to STOP.

Charge Fail Warning

A charge failure warning LED is provided for use with an

engine driven charge alternator. The charge alternator’s

WL terminal is connected to the Keystart, which will in turn

monitor the WL voltage and provide the alternator with

excitation current at engine start up.

Installation

The Keystart uses a DIN standard 96 x 96 mm casing,

designed for mounting in a control panel cut-out (92 x 92mm

DIN). Electrical connection is through a pair of ‘two-part’

type terminal blocks at the rear of the unit, with 2 separate

¼” blade terminals on overspeed versions for the

tachometer or calibration meter.

Also at the rear is are 4 switches for the setting of the

supply voltage and alarm input configurations, and up to 3

potentiometers: one to set the fault ‘override’ time (all units),

and 2 more to set the speed calibration and overspeed trip

level, where fitted.

Rear Facia Settings & Electrical Connection

Tachometer/calibration output:–

0 – 1mA into 75 meter

VR1: Nominal speed calibration:–

+ve

–ve

VR1

VR2

VR3

With engine running at normal

speed, adjust VR1 until calibration

meter reads 0.75mA.

VR2: Overspeed trip level:–

100 - 130% of nominal calibrated

speed, clockwise to increase

VR3: Fault override timer:–

< 10 to > 30 seconds

clockwise to increase

Switch Settings(N.B. = up = down)

S2 S3

Generator AC: 90 - 300 VAC

(KEY9702 only)

1

Charge fail input

2

+ve DC power supply

3

Aux. input ('A' option)

4

5

Alarm output: –ve DC, < 250mA

6

- No connection -

7

- No connection -

8

- No connection -

9

- No connection -

10

- No connection -

11

- No connection -

12

13

- No connection -

14

- No connection -

Aux./preheat output: +ve DC

15

('A' option only)

S1

Fault Inputs:–

Not

Used

closed –ve

closed +ve

open –ve

open +ve

16

Input 2: High Engine Temp.

17

18

19

Input 4: Plant Fail

20

- No connection -

22

Fuel output: + ve DC, 16A max.

23

24

- No connection -

25

- No connection -

26

- No connection -

- No connection -

27

- No connection -

28

29

L

30

N

Note:–

Typical Connection Circuit

Emergency

Stop

Generator AC

(KEY9702 only)

L

N

+

WL

–

(KEY9701 only)

29

30

Start

2

5

63

15

15

Start

Supply:–

12 V DC

24 V DC

S4

When ordering, please specify:–

a) Base unit type:-

Keystart 9700: no overspeed

Keystart 9701: magnetic pickup sensing overspeed

Keystart 9702: AC alternator (50/60Hz) overspeed

b) Options:-

‘A’: auxiliary control/preheat option

N.B: stock units are supplied with switch settings for 24VDC

power supply, inputs closing to –ve DC during fault.

Incorporating

Church Road, Laverstock, Salisbury U.K.

Since 1939

PO Box 470248, Tulsa, Oklahoma 74147, USA

Tel: + 1 918 627 3550 Fax: + 1 918 664 6146

email: sales@fwmurphy.com

web: http://www.fwmurphy.com

Tel: + 44 1722 410055 Fax + 44 1722 410088

Pour service en Français, tél: + 44 1722 410697

email: sales@fwmurphy.co.uk

web: http://www.fwmurphy.co.uk

Modex Automation

Tel: +33 (1) 30 76 26 26 Fax: +33 (1) 30 76 39 89

Direct usine Tel: + 44 1722 410697

email: sales@fwmurphy.co.uk

No. 2 Tuas South Street 2, Sprintecs Building

02-01/02, Singapore 637895

Tel: + 65 863 1398 Fax: + 65 863 0208

email: fwmsales@fwmurphy.com.sg

LOP

1

–

+

HET

RPM/Calib.

Meter

Plant Fail

PO Box 1819, Rosenberg, Texas 77471, USA

Tel: + 1 281 342 0297 Fax: + 1 281 341 6006

email: sales@fwmurphy.com

PO Box 900788, Palmdale, California 93590, USA

Tel: + 1 805 272 4700 Fax: + 1 805 947 7570

email: sales@murphyswitch.com

web: http://www.murphyswitch.com

only)

1620 Hume Highway, Campbellfield, Vic. 3061 Australia

Tel: + 61 3 9358 5555 Fax: + 61 3 9358 5558

email: murphy@macquarrie.com.au

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P. México 78384

Tel: + 52 48 206264 Fax: + 52 48 206336

email: murmexsl@sanluis.podernet.com.mx

Loading...

Loading...