SPL-92106N page 1 of 4

Installation for 4-1/2 in. (114 mm) dial

®

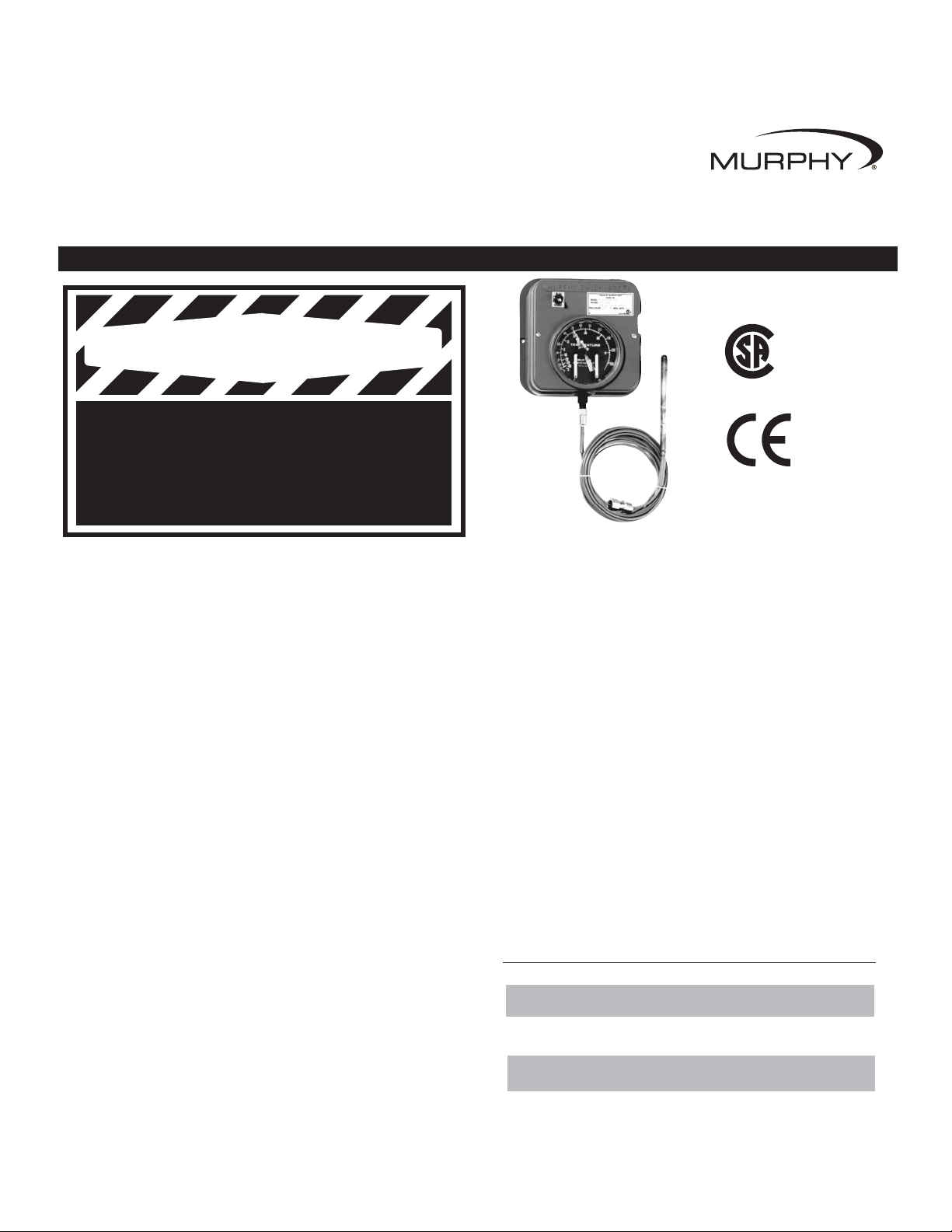

Temperature MURPHYGAGE

Model Series: SPLG, SPLC, SPLBP, 45TE and 45TEBP

Options: -OS and -ES

and SWICHGAGE

®

SPL-92106N

Revised 04-04

Section 10

(00-02-0167)

Please read the following instructions before installing.

A visual inspection is recommended before mounting.

General Information and these installation instructions are intended for all 4-1/2 in. (114 mm) dial temperature models.

GENERAL INFORMATION

*

WARNING

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔

Disconnect all electrical power to the machine.

✔

Make sure the machine cannot operate during installation.

✔

Follow all safety warnings of the machine manufacturer.

✔

Read and follow all installation instructions.

Specifications

SPLC and SPLFC

SWICHGAGE®instruments have high

and low limit contacts to monitor, alarm or shutdown. The SPLC

has a flanged case. SPLFC has a flush mount case intended for

installation within a panel. A method to override the low limit

contact for startup is provided on most models (see Operation

Test Instructions on page 3).

45TE and 45TEF Series

are versions of the SPL Series

with 2-snap acting SPDT switches instead of the pointer type contacts. The 45TE Series does not include low contact lockout.

SPLBP and 45TEBP

models are designed to start and stop

electric motor driven equipment. The pilot duty contacts are connected to a latching control relay for automatic ON/OFF control,

either directly or through a motor starter.

Options -OS and -ES

The -OS (oil sealed case) and the -ES (environment sealed case)

options for corrosive environment feature flush mount case design

to be installed within a panel.

Precautions

■

Do NOT exceed rated temperature range.

■

Use shock mounts as necessary to protect from vibration.

■

Cutting or sharp bending the capillary will cause permanent

damage to the SWICHGAGE

■

Excess capillary should be carefully coiled and secured

away from damage.

■

Do not route capillary along exhaust manifold.

■

Avoid routing capillary at level higher than gage mounting.

®

and will void the warranty.

Dial: White on black, dual scale, °F and °C standard,

4-1/2 in. (114 mm) diameter.

Case: Die cast aluminum, surface or panel mount.

Capillary: PVC armored copper tube, 5 ft. (1.5 m) long standard.

Sensing Bulb: Copper bulb std.: 1/2 in. (13 mm) OD;

Length 7 in. (178 mm). Pressure rating: 600 psi (4.1 MPa)

[41 bar]. Connection: 1/2 NPTM compression fitting.

NOTE: Use of thermowell is highly recommended.

Switch Reset Deadband: Approximately 10% FS.

Snap-Acting Switches: See wiring information (page 4).

Dry Relay Contact (“BP” Models): 10 A @ 28 VDC or

10 A @ 120 VAC.

Wire Connections (Surface Mount): 1/2 NPTF conduit/terminal block.

Wire Connections (Panel Mount): Wire leads, 18 AWG

(1.0 mm2) x 9 in. (229 mm) long.

Wire Connections (-ES, -OS, -CC): 1/2 NPTM conduit and wire leads,

24 AWG (0.22 mm2) x 33 in. (838 mm) long.

Overrange: Do not exceed 10% FS above full range.

Item Weight: 8 lbs (3.6 kg) approx. Explosion-proof models: 22 lb.

(10 kg) approx.

Item Dimensions: 16 x 11 x 5-1/2 in. (406 x 279 x 140 mm)

approximately. Explosion-proof: 12 x 12 x 9 in. (305 x 305 x 229 mm)

approximately.

Accuracy

*

Selected configurations are CSA approved. Consult factory for details.

**

Products covered by this literature comply with EMC Council directive 89/336/EEC

regarding electromagnetic compatibility as noted. Does not cover “BP” models.

Temperature Range Lower

15 to 250°F ± 8°F ± 2°F ± 2°F

(9 to 121°C) (± 4°C) (± 1°C) (± 1°C)

130 to 350°F ± 8°F ± 2°F ± 3°F

(54 to 177°C) (± 4°C) (± 1°C) (± 1.5°C)

260 to 450°F ± 8°F ± 2°F ± 3°F

(127 to 232°C) (± 4°C) (± 1°C) (± 1.5°C)

1

/

4 Middle

®

**

1

/

2 Upper

1

/

4

SPL-92106N page 2 of 4

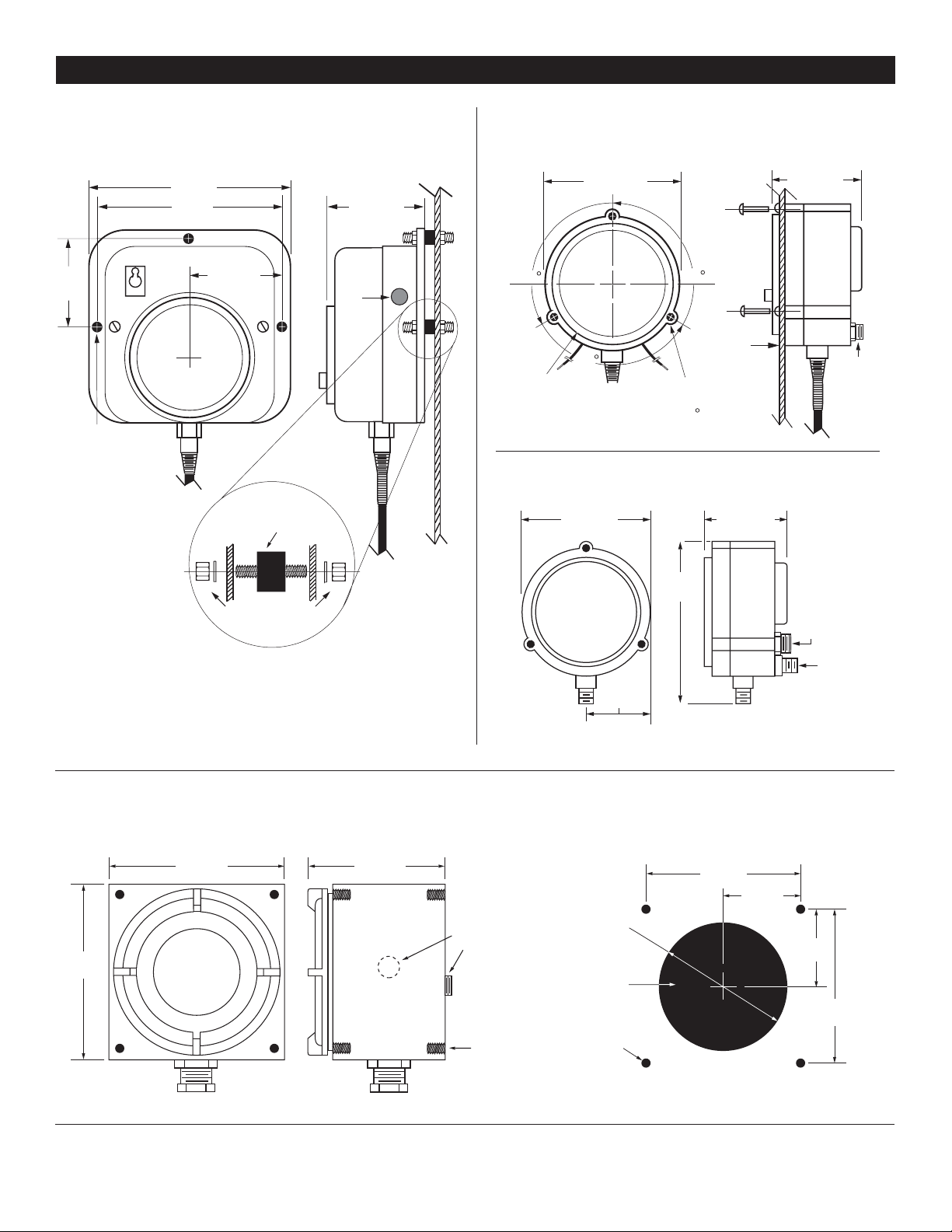

panel

gage

shock mount

DETAIL

1/4-20 nut & lockwasher

(2 each required)

8-7/16 in.

(214 mm)

3-3/8 in.

(86 mm)

7-7/8 in.

(200 mm)

3-15/16 in.

(100 mm)

4-1/32in.

(102 mm)

9/32 in.

(7 mm) dia.

3 holes

1/2 in.

(13 mm)

conduit

120

120

120

panel

5-7/16 in.

(138 mm)

2-57/64 in.

(73 mm)

1/4 in. (6 mm) dia.

holes (3 places.) on

5-13/64 in. (132 mm)

B.C.,120 apart,

clocking as shown

Mounting Hole

4-3/4 in.

(121 mm)

diameter

Optional

1/2 in.

(13 mm)

conduit

8 in.

(203 mm)

6-25/64 in.

(162 mm)

8 in.

(203 mm)

3/8-16 UNC-2B

thread

7/8 in. (22 mm)

deep, 8 plc's

6-3/4 in.

(171 mm)

6-3/4 in.

(171 mm)

13/32 in.

(10 mm)

diameter

4 places

7-35/64 in.

(192 mm)

diameter

3-3/8 in.

(86 mm)

3-3/8 in.

(86 mm)

*Mounting hole

not required for

Wall mount

1/2 in.NPT

optional

rear or side

conduit

5-7/16 in.

(138 mm)

2-23/32 in.

(69 mm)

6-3/4 in.

(171 mm)

2-57/64 in.

(73 mm)

1/2 in.

(13 mm)

conduit

Optional

Back

Connection

CASE MOUNTING

Wall Mount

Flanged case design intended for wall mount. Shown with shock

mounts (optional).

Flush Mount

A round case design to be mounted within a panel from

(1 mm) to

Options -OS, -ES (flush mount case)

1

/8in. (3 mm) thick.

1

/32in.

Explosion-proof Case Mount

Explosion-proof case can be mounted from face or rear.

Flush mount/Wall mount

*

Loading...

Loading...