Murdock BF11, BF12 Maintance Manual

Cooler Mounted Bottle Fillers

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

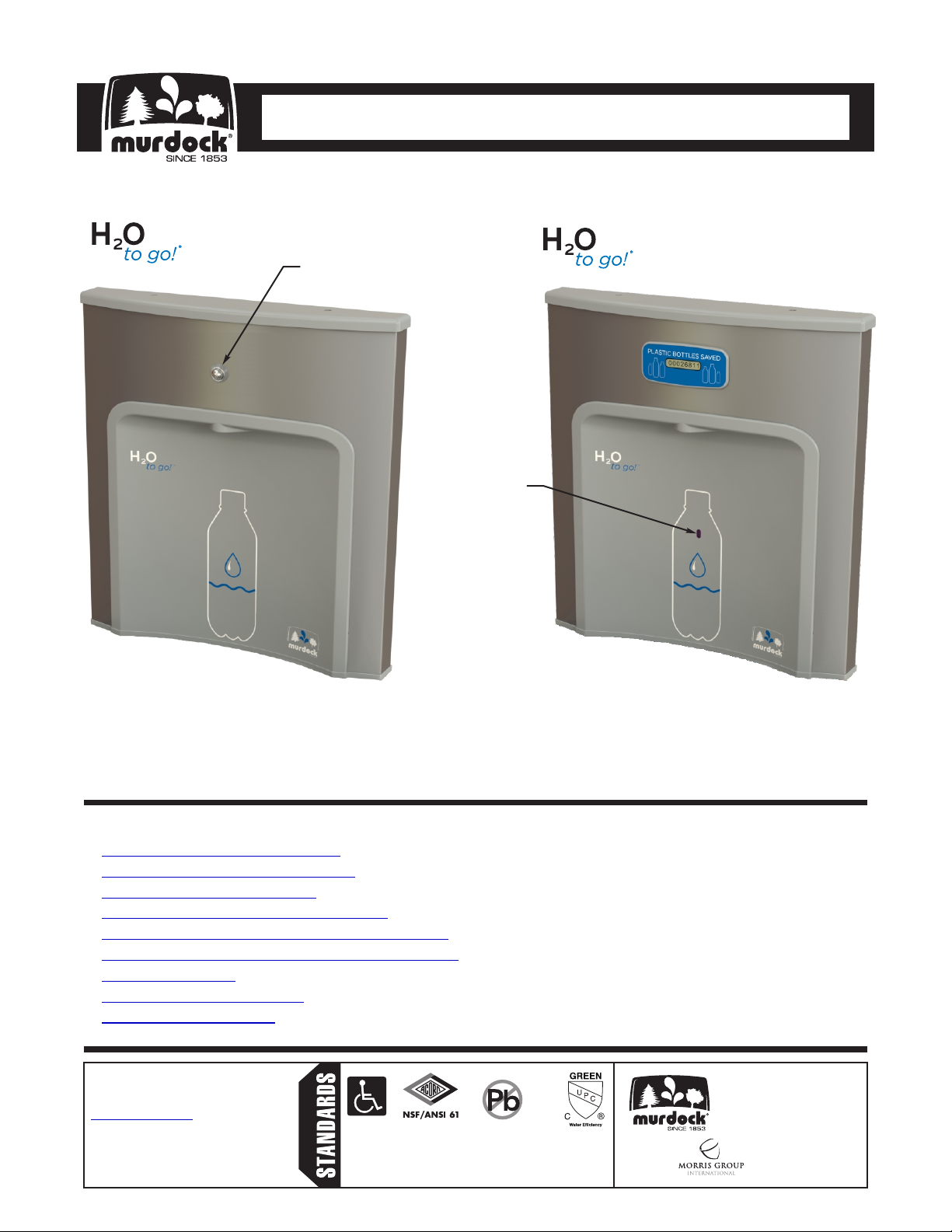

BF11 & BF12 Bottle Filler Series

Pushbutton

Actuated

Sensor

Operated

BF11

Please visit www.murdockmfg.com

for most current specifications.

BF12

TABLE OF CONTENTS

Dimensional Data/Rough-Ins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Prior to Installation Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Push-In Fitting Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11BF11/BF12 Bottle Filler Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12BF11/BF12 Water Supply Tubing Diagram

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14Optional -BCD Bottle Filler Counter Display

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-18BF11/BF12 Repair Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Warranty Information

Murdock™ assumes no responsibility for use

of void or superseded data. © Copyright

Murdock Mfg., City of Industry, CA Member of

Morris Group International. Please visit

www.murdockmfg.com for most current

specifications.

7020-956-001

Date: 12/11/18

COMPLIES WITH

Federal

Public Law

111-380

(No Lead)

Member of

www.murdockmfg.com

MURDOCK

15125 Proctor Ave.

City of Industry, CA

91746 U.S.A.

Phone 800-591-9360

626-336-4561

Fax 626-855-4894

Cooler Mounted Bottle Fillers

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

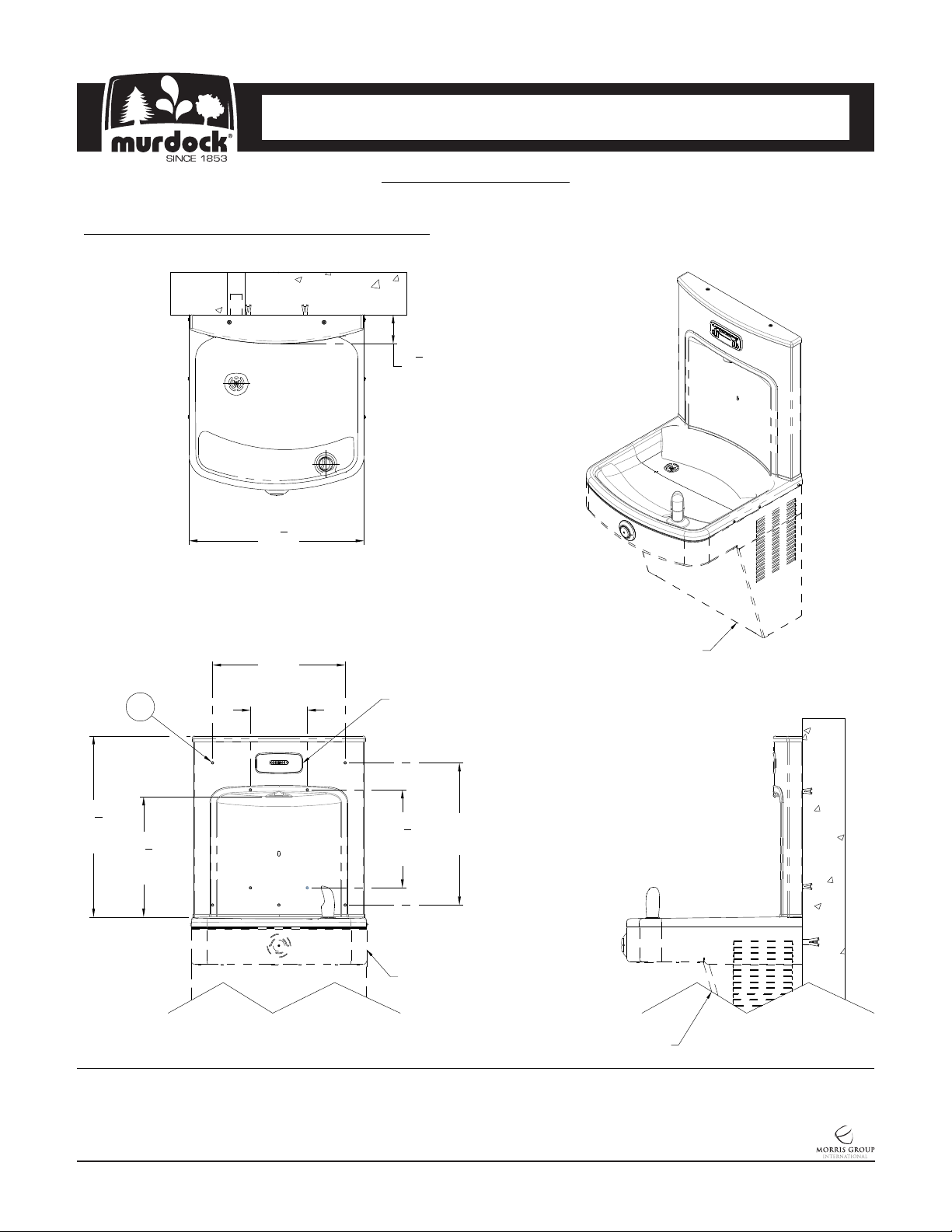

DIMENSIONAL DRAWING

Prior to roughing in, consult with local, state, and federal codes for proper mounting height.

Note: Rough-Ins are the same for BF11 & BF12

1

3

"

8

[79]

1

18

"

2

[470]

14"

[356]

6"

[152]

1

19

8

[486]

2

"

5

12

"

8

[321]

General Notes:

1. All dimensions are in inches [MM]

Optional -BCD

Bottle Counter

and Filter

Status Display

3

10

[264]

15"

"

8

[381]

Existing Fixture

Existing Fixture

Existing Fixture

2. Ø1/4" Holes, 10 Places for Anchoring Hardware,

provided by others

MURDOCK MFG. • 15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com

7020-956-001

Page 2 of 19

Member of

Revised: 12/11/18

Cooler Mounted Bottle Fillers

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

PRIOR TO INSTALLATION:

1. Some options may slightly alter installation. To ensure proper installation, review the Manual thoroughly and verify

rough-ins before beginning any work. File this Manual with the owner or maintenance personnel upon completion

of installation.

2. Carefully remove all fixture components from packaging, preventing scratching or damage. Inspect fixture and all

parts for damage.

3. Provide rough-ins as shown on the roughing-in and dimensional drawing. (See rough-in details)

4. Water Supply Service Stop Valve, Water Connections and Electrical Connections to be supplied and installed by

others in accordance with local codes.

5. Fixture mounting requirements: Industry standard wall construction, adequate to support the fixture and wall

anchors (installer provided) sufficient to secure the fixture.

6. Fixture operates within water pressure range of 20 to 105 PSIG. Murdock will not warranty fixtures damaged

when connected to supply lines with flow pressure lower than 20 PSIG or higher than 105 PSIG.

7. Water Supply inlet is 1/4” OD Polyethylene (PE) Tube.

8. Per UPC 609.10-All building water supply systems in which quick-closing Valves are installed shall be provided

with devices to absorb the hammer caused by high pressure resulting from the quick-closing of the Valve. These

pressure-absorbing devices shall be approved mechanical devices. Water pressure-absorbing devices shall be

installed as close as possible to the quick-closing Valve.

9. Completely flush supply of all foreign debris before connecting to fixture. Bottle Filler is designed to provide

trouble free drinking water unaffected by fixture connection tubing and fittings and will not cause problems with

taste, odor, color or sediment.

MURDOCK MFG. • 15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com

7020-956-001

Page 3 of 19

Member of

Revised: 12/11/18

Cooler Mounted Bottle Fillers

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

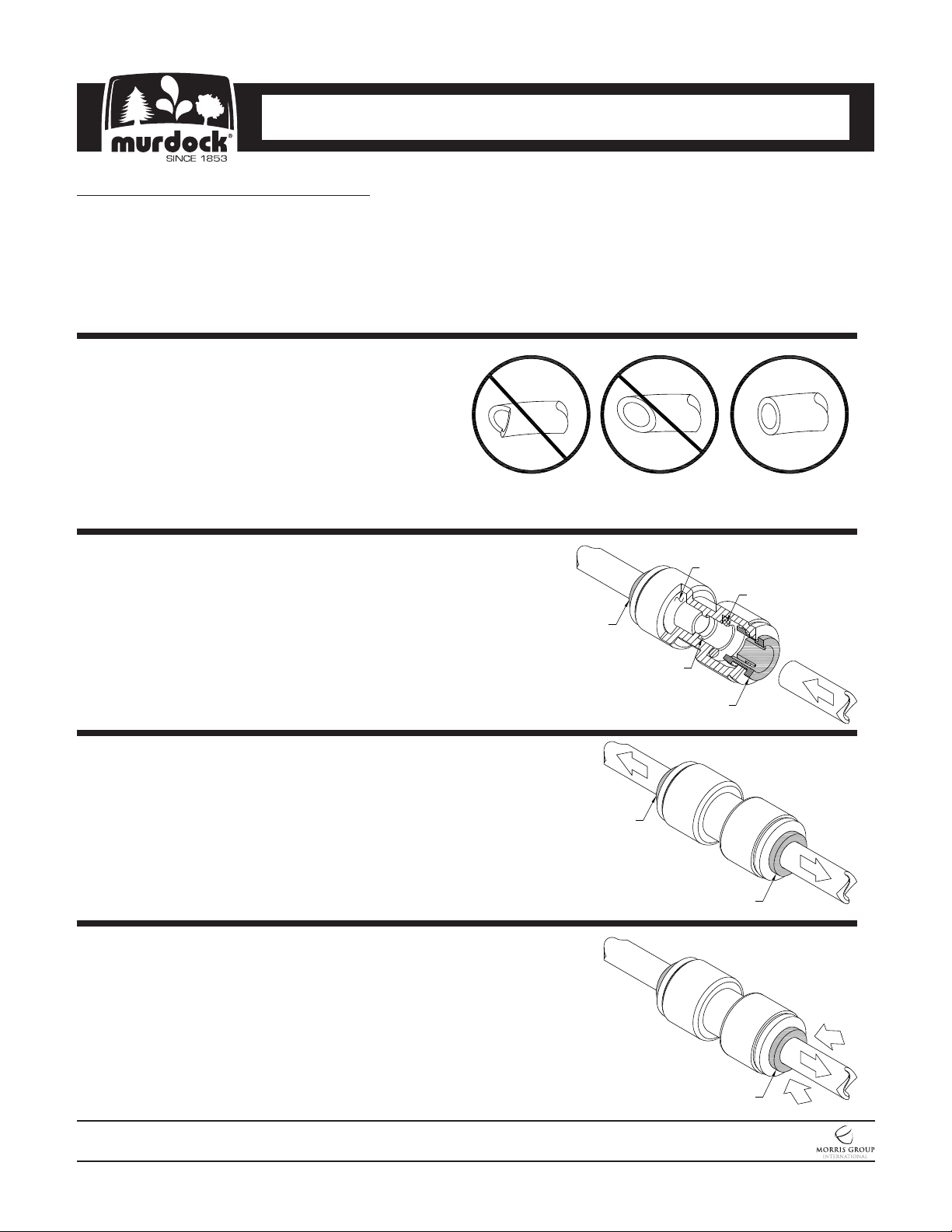

PUSH-IN FITTING INSTALLATION

NOTE: FITTINGS AND TUBE SHOULD BE KEPT

CLEAN, BAGGED AND UNDAMAGED PRIOR TO

INSTALLATION.

TO CUT TUBE:

Cut to fit length of 1/4” PE Tubing and remove any

burrs or sharp edges. Ensure that the outside diameter

is free from score marks. Tube ends should be square.

INSERTING THE TUBE:

1. Firmly and fully insert the Tubing end into the Push-In

Fitting up to the Tube Stop located approximately 1/2”

deep.

2. Pull on the fitted Tubing to ensure it is secure. Tube

should not come free from the Fitting. Water test the

connection assembly prior to leaving the site to ensure

there are no leaks.

DISCONNECTING THE TUBE:

Prior to disconnecting the Tube from the Fitting, ensure

that the Water Line is depressurized. Push Collet Square

towards the Push-In Fitting Body and hold. While holding

the Collet in, pull on the PE Tubing to remove from the

Push-In Fitting.

O-RING

O-RING

COLLET

TUBE STOP

COLLET

COLLET

COLLET

MURDOCK MFG. • 15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com

7020-956-001

Page 4 of 19

COLLET

Member of

Revised: 12/11/18

Cooler Mounted Bottle Fillers

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

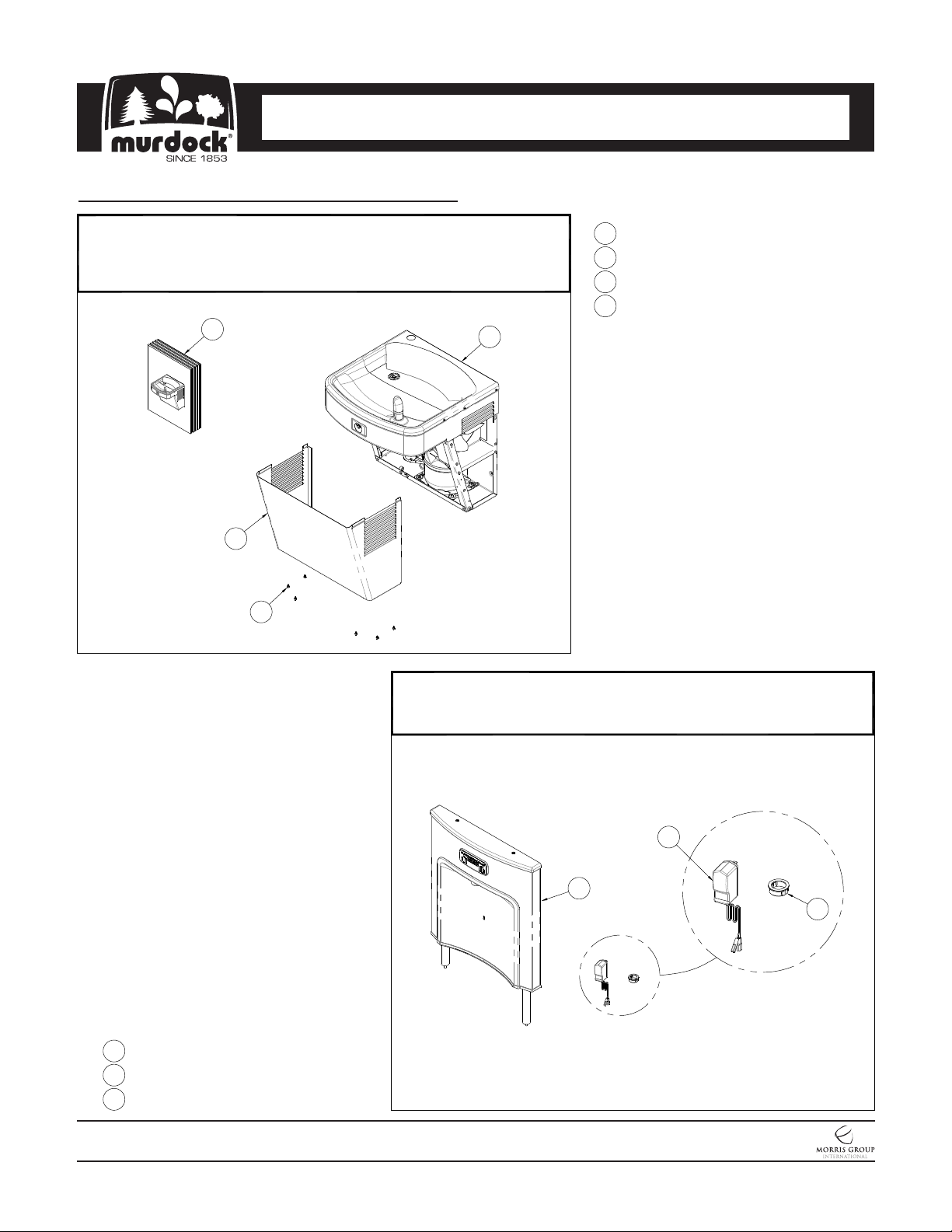

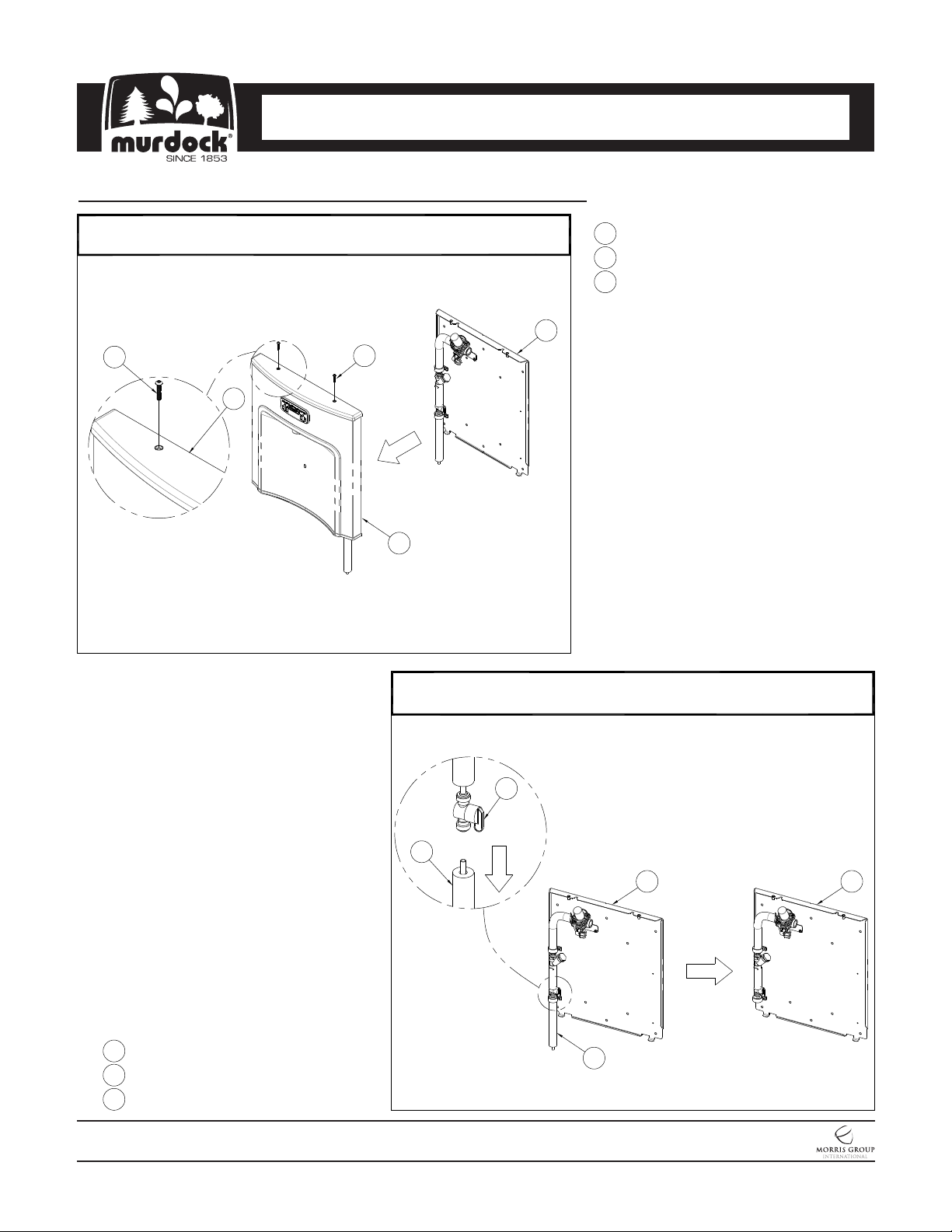

BF11/BF12 INSTALLATION INSTRUCTIONS

Install the newly obtained Water Cooler per the Installation Manual

1

provided with the unit. Do not install Access Panel at this time. Shut-off

water supply, then actuate Valve to relieve pressure. Place Screws and

Panel in secure location for further use in Manual.

4

2

3

1

1

Water Cooler Assembly

2

Access Panel

3

#8 x 3/8" Hex Washer Head Screw

4

Water Cooler Installation Manual

Remove Bottle Filler Assembly, Power Supply and Grommet from

2

packaging, careful to avoid damage to Fixture and Fixture Sub

Assemblies. Set Power Supply aside in a secure location.

1

1

Bottle Filler Assembly

2

Power Supply (Not provided with BF11)

3

Locking Grommet

MURDOCK MFG. • 15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com

7020-956-001

Page 5 of 19

2

3

Member of

Revised: 12/11/18

Cooler Mounted Bottle Fillers

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

BF11/BF12 INSTALLATION INSTRUCTIONS (CONTINUED)

Unfasten Screws that hold the Bottle Filler Housing to the Mounting

3

Panel. Place Bottle Filler Panel and Screws in a secure location.

3

2

3

1

1

Bottle Filler Housing

2

Mounting Panel

3

#10-32 x 1" Button Head Screw

2

Disconnect the Water Supply Insulation and Tubing from 1/4" Shut-Off

4

Valve that is located on the Mounting Panel.

2

3

1

Mounting Panel

2

Shut-Off Valve

3

1/4" OD Tubing & Insulation

MURDOCK MFG. • 15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com

7020-956-001

Page 6 of 19

3

1

Member of

Revised: 12/11/18

1

Loading...

Loading...