Page 1

Version

Release Date

Comments

0.1

10/01/2018

Initial draft

0.2

11/08/2018

Revisions following first review

0.3

03/27/2019

Revised VBAT_FEM Max Current

0.4

07/01/2019

Added FCC Notice

Type1SC Hardware Design Guidelines

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 1 of 29 www.murata.com

Page 2

THIS PAGE INTENTIONALLY LEFT BLANK

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 2 of 29 www.murata.com

Page 3

TABLE OF CONTENTS

1 Introduction ................................................................................................................................................................ 6

1.1 Scope ....................................................................................................................................................... 6

1.2 Audience .................................................................................................................................................. 6

1.3 Contact Information and Support ............................................................................................................. 6

1.4 Text Conventions ..................................................................................................................................... 6

1.5 Acronyms ................................................................................................................................................. 6

1.6 Related Documents ................................................................................................................................. 7

2 Introduction ................................................................................................................................................................ 8

2.1 High Level Block Diagram ........................................................................................................................ 8

2.2 Supported bands ...................................................................................................................................... 8

2.3 Tx Output Power ...................................................................................................................................... 8

2.4 Rx Sensitivity ........................................................................................................................................... 8

2.5 Power Modes ........................................................................................................................................... 8

LS Power Mode ................................................................................................................................ 9

DS Power Mode ............................................................................................................................... 9

DH0 Power Mode ............................................................................................................................. 9

DH1 Power Mode ............................................................................................................................. 9

DH2 Power Mode ............................................................................................................................. 9

PSM Current Draw ........................................................................................................................... 9

eDRX Current Draw ........................................................................................................................ 10

2.6 Certification and Regulatory ................................................................................................................... 11

2.7 Power Supply Range ............................................................................................................................. 11

2.8 Temperature Range ............................................................................................................................... 11

2.9 Mechanical Specifications ...................................................................................................................... 12

2.10 Pin Layout and Descriptions .................................................................................................................. 13

2.11 Reference Circuit ................................................................................................................................... 22

3 Power ....................................................................................................................................................................... 22

3.1 Power Up Sequence .............................................................................................................................. 22

3.2 Power Down Sequence .......................................................................................................................... 22

3.3 Power Supply Scenarios (by Battery Type) ............................................................................................ 22

LiPo Battery (3.2 ~ 4.35 V) ............................................................................................................. 23

CR17450 Battery (2.2 ~ 3.0 V) ....................................................................................................... 23

AA Lithium Battery (1.0 ~ 1.5 V) ..................................................................................................... 23

3.4 PMU ....................................................................................................................................................... 23

PMU_SHUTDOWN ........................................................................................................................ 24

PMU_POWER_BUTTON ............................................................................................................... 24

PMU_WAKEUP .............................................................................................................................. 24

4 SIM Interface ............................................................................................................................................................ 24

5 Host Interface ........................................................................................................................................................... 24

6 Antenna Requirements ............................................................................................................................................ 25

6.1 Main Antenna ......................................................................................................................................... 25

6.2 MIPI RFFE for Antenna Tuning .............................................................................................................. 26

6.3 GPS Coexistence ................................................................................................................................... 26

7 APPLICATION PCB DESIGN .................................................................................................................................. 26

7.1 Solder Reflow ......................................................................................................................................... 26

Antenna Installation Guidelines ...................................................................................................... 27

PCB Design Guidelines .................................................................................................................. 27

Transmission line design ................................................................................................................ 28

8 FCC Notice ............................................................................................................................................................... 29

8.1 FCC Test Data........................................................................................................................................ 29

8.2 ISED Test Data....................................................................................................................................... 29

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 3 of 29 www.murata.com

Page 4

LIST OF FIGURES

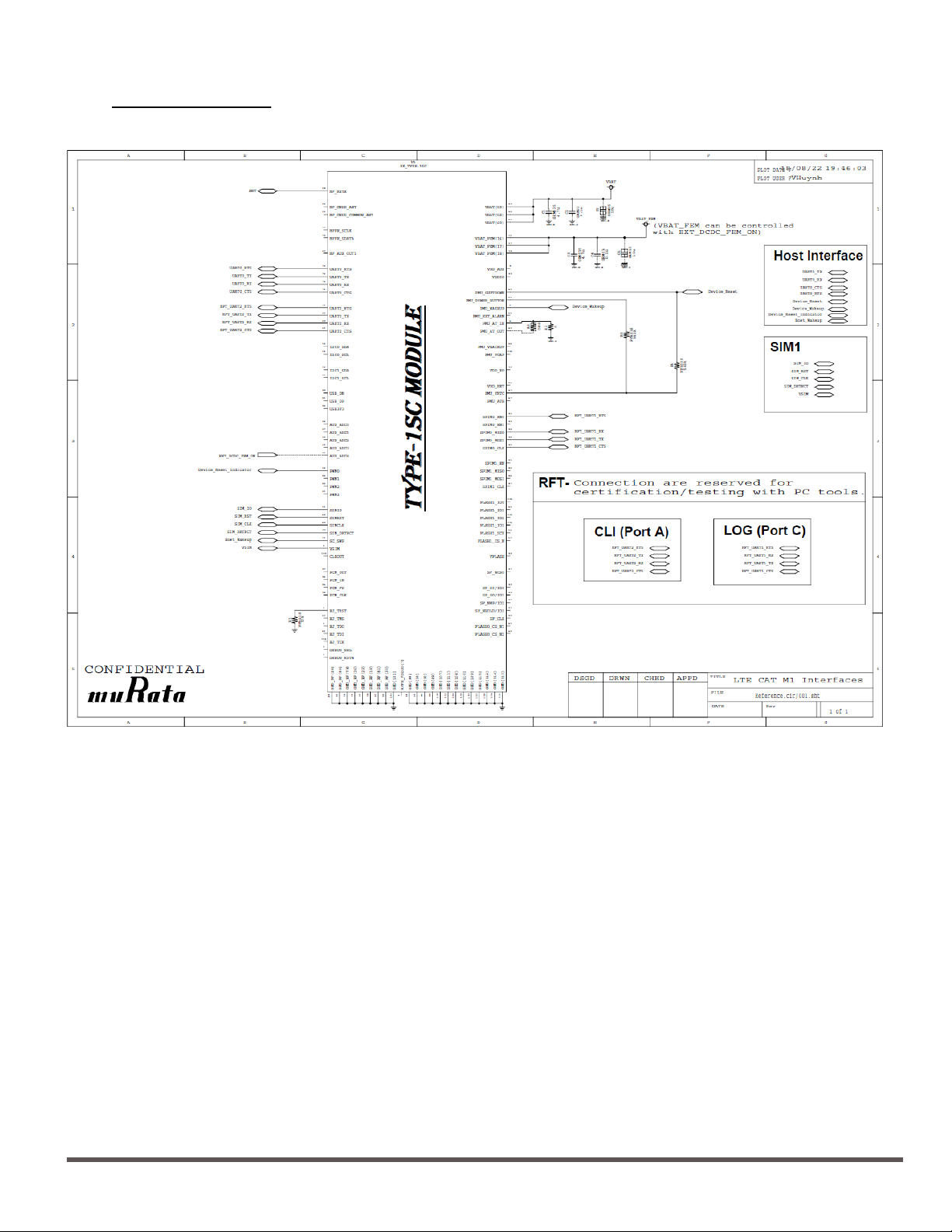

Figure 1 Module block diagram ........................................................................................................ 8

Figure 2 Land pattern: top view, in millimeters ................................................................................ 12

Figure 3 Pin layout: top view .......................................................................................................... 13

Figure 4 Power up sequence ......................................................................................................... 22

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 4 of 29 www.murata.com

Page 5

LIST OF TABLES

Table 1 Supported bands ................................................................................................................................................... 8

Table 2 Power supply range ............................................................................................................................................. 11

Table 3 Temperature range .............................................................................................................................................. 11

Table 4 Pin description ..................................................................................................................................................... 21

Table 5 I/Os with PU/PD ................................................................................................................................................... 21

Table 6 Special UART signals for certification/testing ..................................................................................................... 22

Table 7 PMU system signals ............................................................................................................................................ 23

Table 8 Host interface signals .......................................................................................................................................... 25

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 5 of 29 www.murata.com

Page 6

Acronym

Meaning

3GPP

3rd Generation Partnership Project

API

Application Programming Interface

CPU

Central Processing Unit

eDRX

Extended Discontinuous Reception

eMTC

enhanced Machine-Type Communication

EVB

Evaluation Board

FW

Firmware

GPIO

General Purpose Input/Output

FEM

Front End Module

HF

Hyper Frame (10.24s)

MIPI

Mobile Industry Processor Interface

IoT

Internet of Things

LiPo

Lithium-ion Polymer

LTE

Long Term Evolution

LPWA

Low Power Wide Area

PC

Personal Computer

PSM

Power Saving Mode

PTW

Paging Time Window

RF

Radio Frequency

RFFE

RF Front End

SoC

System on Chip

SW

Software

UART

Universal Asynchronous Receiver/Transmitter

USB

Universal Serial Bus

1 Introduction

1.1 Scope

This document introduces the Murata Type1SC LTE CatM1/NB1 module and presents some possible and

recommended guidelines for developing new products based on this module. The information given should be

used as a guide and a starting point for properly developing products with the Murata module.

1.2 Audience

This document is intended for Murata customers, especially system architects and HW engineers, to design

products based on the Murata Type1SC module.

1.3 Contact Information and Support

For general contact, technical support services, technical questions and report documentation errors contact

Murata Technical Support at techhelp@murata.com

Please keep us informed of your comments and suggestions for improvements. Murata will take into

consideration any and all feedback from the users of this information.

1.4 Text Conventions

Danger – This information MUST be followed or catastrophic equipment failure or bodily injury may occur.

Caution/Warning

Alerts the user to important points about using the product; if these points are not followed, the product

and end user equipment may fail or malfunction.

Tip/Information – Provides advice and suggestions that may be useful when using the product.

.

1.5 Acronyms

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 6 of 29 www.murata.com

Page 7

1.6 Related Documents

[1] Type1SC Reference Schematics

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 7 of 29 www.murata.com

Page 8

Product

LTE Bands

Regions

LBAD0XX1SC

LB: B5/B8/B12/B13/B14/B17/B18/B19/B20/B26/B28

MB: B1:B2/B3/B4/B25

Americas, EU and

2 Introduction

Type1SC is Murata’s new LTE series for IoT applications. The module can be used as a wireless communication

front-end for wearable products, offering mobile communication features to an external host CPU through its

interfaces.

Note: NB1 will be supported in a future firmware release.

2.1 High Level Block Diagram

The following block diagram illustrates the module which contains the ALT1250 LTE Cat M1/NB1 SoC, RF FEM,

128 MBits flash and clocks.

Figure 1 Module block diagram

2.2 Supported bands

The module supports the following bands:

Table 1 Supported bands

ASEAN

2.3 Tx Output Power

The LTE bands in the 1SC module meet the 3GPP spec for a Power Class 3 device (23 dBm).

2.4 Rx Sensitivity

The receive sensitivity of the module will be around -103 dBm.

2.5 Power Modes

The 1SC module has the following power modes

• LS: Provides very fast entry and recovery time and is mainly used for very short sleeps. It is used for CDRX

mode during the networking process.

• DS: Provides fast recovery and entry time and is mainly used during the IDRX networking mode.

• DH2: Provides medium entry and recovery time and is mainly used during the EDRX and IDRX networking

modes.

• DH1: Same as DH2, however IO logic is not retained.

• DH05: Provides long entry and recovery times and is mainly used for very long inactivity intervals like PSM.

The IO output values are retained in this mode.

• DH0: Same as DH05, however IO output values are not retained.

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 8 of 29 www.murata.com

Page 9

The device chooses the described power modes according to the networking state and the maximum allowed chip

power mode configuration.

An application note will be provided to show how to configure the module and the R&S CMW500 to test the different

power modes.

LS Power Mode

Only one of the following pins can be used to wake up the device

• RTC Expiration

• PMU_POWER_BUTTON

• PMU_WAKEUP

• PMU_SHUTDOWN

• AntiTamper

Other digital interface pins can also be configured to wake up the system (up to 10 GPIO’s can be used). Serial

interface pins are not active in this mode

DS Power Mode

This mode is the same as LS, but requires lower power consumption due to the unused reference clock.

The average current draw in this mode of operation is 2.5mA.

DH0 Power Mode

The following occurs in the DH0 power mode:

• All digital logic is powered down

• Memories are not retained

• IO’s are not stored

• The RTC is on

• One of the following dedicated pins is used to wake from this mode:

o RTC Expiration

o PMU_POWER_BUTTON

o PMU_WAKEUP

o PMU_SHUTDOWN

o AntiTamper

The average current draw in this mode of operation is 1.7uA.

DH1 Power Mode This mode is similar to DH0, however it enables memory retention to store the system sate. A Wakeup event will only initiate a boot flow in a case of state full configuration

The average current draw in this mode of operation is 48uA.

DH2 Power Mode This mode is similar to DH1, however it also enables output IOs to latch and wakeup from digital inputs (up to 10 GPIO’s can be used)

The current draw is similar to DH1, but will depend on the extra current draw of the GPIOs.

PSM Current Draw Currently the PSM mode of operation is not optimized so the current draw will vary. This will be fixed in a future version of firmware. This figure below represents the worst-case condition (This was tested with RK _50). Current ideal conditions the average current should be 33.76mA.

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 9 of 29 www.murata.com

Page 10

eDRX Current Draw The SIM card will have a major impact on this feature. Network Carriers will support different modes of operation. The R&S test SIM for the CMW500 does not support SIM deactivation during eDRX cycles. This caused the number to be significantly greater than a setup with a deactivation mode. The feature below shows result using the CMW500 test SIM. Under good conditions using a SIM that can be deactivated, the current draw could be as low as 86uA instead of 377uA for this setup. This setup was using an eDRX cycle of 81.92 s (8 HF).

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 10 of 29 www.murata.com

Page 11

Parameter

Range

Absolute maximum rating

VBAT

-0.3 V – 4.35 V

VBAT_FEM

-0.5 V – 5.2 V

Operating voltage range

VBAT

2.2 V – 4.35 V

VBAT_FEM

3.2 V – 4.5 V

I/O (1.8V typ)

1.7 V – 1.9 V

VIO

VDDIO

1.7 V – 1.9 V

V

VDD

1.0 V – 1.1 V

Range

Note

Storage temperature range

-40 ºC – 85 ºC

Storage and non-operational

Operating temperature range

-40 ºC – 85 ºC

Module is fully functional

†

-20 ºC – 55 ºC

Module is fully functional† and

fully meets 3GPP specification

(†) Functional: the module is able to connect to PDN and transfer data.

2.6 Certification and Regulatory

The module is certified to GCF 3.70.2 and PTCRB 5.36. The module is fully compliant to CAT M1 3GPP release

13.

The module is FCC/IC certified (HSW-xxxxx) and RED ETSI EN 301908-13 compliant.

2.7 Power Supply Range

RETENTION

2.8 Temperature Range

Table 2 Power supply range

Table 3 Temperature range

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 11 of 29 www.murata.com

Page 12

2.9 Mechanical Specifications

• Dimensions: 11.1 × 11.4 × 1.4 mm

• Weight: 443 mg

3

(typ)

Figure 2 Land pattern: top view, in millimeters

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 12 of 29 www.murata.com

Page 13

2.10 Pin Layout and Descriptions

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

1

DEBUG_RSTN

P4

DEBUG_RSTN

Digital

I/O

PU

VDDIO

Reserved (No Connection)

2

DEBUG_SEL

M4

DEBUG_SEL/

GPIO31

Digital

I/O

PD

VDDIO

Reserved (No Connection)

3

EJ_TDO

N5

EJ_TDO/

Digital

I/O

PU

VDDIO

Reserved (No Connection)

4

EJ_TRST

J5

EJ_TRST/

Digital

I/O

PD

VDDIO

Reserved (No Connection)

5

PMU_AT_IN

R3

PMU_AT_IN

Analog

I VRTC

Anti-tamper input; short to GND

6

PMU_WAKEUP

P2

PMU_WAKEUP

Analog

I VRTC

Device Wakeup active high;

7

VDD_RF

L1

PMU_VO_RF

Power

O

MIPI RFFE VIO (antenna tuning)

8

VSIM

R1

PMU_VO_SIM

Power

O

SIM LDO output

9

VDD_AUX

T2

PMU_VO_AUX_LDO

Power

O

SC2 LDO output

10

VDD_XO

N1

PMU_VO_XO

Power

O

Reserved (No Connection)

11

SIMIO

M10

SC_IO/

Digital

I/O

PD

VDDIO

SIM Data 1.8V

Pin

No

50 IC

Pin No

Name

GPIO22

GPIO20

GPIO14

Figure 3 Pin layout: top view

Output

Value

Domain/

Supply

if not used

Device Wake-Up

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 13 of 29 www.murata.com

Page 14

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

12

I2C1_SDA

H2

I2C1_SDA/

GPIO44

Digital

I/O

PU

VDDIO

Reserved (No Connection)

13

I2C1_SCL

H4

I2C1_SCL/

GPIO45

Digital

I/O

PU

VDDIO

Reserved (No Connection)

14

I2C0_SCL

L7

I2C0_SCL/

GPIO43

Digital

I/O

PU

VDDIO

Reserved (No Connection)

15

I2C0_SDA

J7

I2C0_SDA/

GPIO42

Digital

I/O

PU

VDDIO

Reserved (No Connection)

16

VBAT_FEM

Power

I

Input from battery to FEM

17

VBAT_FEM

Power

I

Input from battery to FEM

18

VBAT_FEM

Power

I

Input from battery to FEM

19

GND

20

UART2_RX

H14

UART2_RX/

GPIO27

Digital

I/O

PU

VDDIO

• Default is UART1 Receive

21

UART2_CTS

G15

UART2_CTS/

GPIO29

Digital

I/O

PD

VDDIO

• Default is UART1 Clear to

Pin

No

50 IC

Pin No

Name

SPIS_MRDY/

PWM 3/

MCU_I2C1_SDA/

MCU_FLA SH1_SCK/

UART0_RI/

MCU_S PIM1_CLK_A/

MCU_PWM3/

SPIS_CLK/

LED3/

M CU_I2C1_SCL/

MCU_FLASH1_ CS_N/

UART0_DTR/

MCU_SPI M1_EN0_A/

MCU_LED3/

SPIS_MISO/

KEYPA D9/

FEM19/

MCU_I2C0_SCL/

UART0_DSR/

SPIS_MOSI/

CLKO UT/

KEYPAD7/

MCU_I2C0_SD A/

UART0_DCD/

MCU_CLKOU T/

Output

Value

Domain/

Supply

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 14 of 29 www.murata.com

SPIS_MOSI_A/

P WM2/

EJ1_TDI_B/

UART1_RX/

MCU_UART1_RX/

MCU_SPIM1_MISO_A/

MCU_SPIM0_MISO_A/

UART3_RX_B/

MCU_PWM2/

SPIS_MRDY_A/

E J1_TRST_B/

UART1_CTS/

MCU_UART1_CTS/

MCU_SPIM1_CLK_A/

MCU_SPIM0_CLK_A/

U ART3_CTS_B/

Data

• Dedicated for debug

interface

Send

• Dedicated for debug

interface

Page 15

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

22

UART2_TX

G13

UART2_TX/

GPIO28

Digital

I/O

PU

VDDIO

• Default is UART1 Transmit

23

GND

24

RF_GNSS_COMM

RF O GNSS receiver output

25

RF_GNSS_ANT

RF I GNSS receiver input

26

GND 27

RF_AUX_OUT1

RF Reserved (No Connection)

28

GND 29

RF_RXTX

RF LTE RF in/out signal

30

GND

31

PWM3

N13

PWM3/

GPIO53

Digital

I/O

PU

VDDIO

TX Indicator

32

PWM0

P10

PWM0/

GPIO50

Digital

I/O

PD

VDDIO

Device reset status (HI)

33

AUX_ADC4

H12

AUX_ADC4/

GPIO5

Digital

I/O

PD

VDDIO

External DCDC control

34

AUX_ADC3

J13

AUX_ADC3/

GPIO4

Digital

I/O

PU

VDDIO

Reserved (No Connection)

35

AUX_ADC2

K14

AUX_ADC2/

GPIO3

Digital

I/O

PU

VDDIO

Reserved (No Connection)

Pin

No

ON_ANT

50 IC

Pin No

Name

SPIS_MISO_A/

FE M22/

EJ1_TMS_B/

UART1_TX/

MCU_UART1_TX/

MCU_SPIM1_MOSI_A/

MCU_SPIM0_MOSI_A/

UART3_TX_B/

I2C1_SDA/

SC_SWP/

F EM29/

MCU_CC_OUT3/

MCU_CC_IN3/

MCU_LED3/

MCU_P WM3/

Output

Value

Domain/

Supply

Data

• Dedicated for debug

interface

CLKOUT/

MCU_CC_O UT0/

MCU_CC_IN0/

MCU_CLK OUT/

FEM28/

MCU_PWM0/

FEM7/

PCM_OUT/

MCU_LED0/

MCU_CC_OUT1/

FEM6/

PCM_IN/

K EYPAD4/

MCU_SPIM1_CLK_B/

MCU_I2C1_SCL/

SWDAT/

MCU_CC_IN3/

FEM5/

PCM_FS/

K EYPAD7/

MCU_SPIM1_EN0_B/

MCU_I2C1_SDA/

SWCLK/

MCU_CC_IN2/

(DCDC_EN)

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 15 of 29 www.murata.com

Page 16

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

36

AUX_ADC0

L13

AUX_ADC0/

GPIO1

Digital

I/O

PU

VDDIO

Reserved (No Connection)

37

AUX_ADC1

M14

AUX_ADC1/

GPIO2

Digital

I/O

PD

VDDIO

GNSS coexistence indicator

38

GND

39

SF_SO/IO1

Y14

FLASH0_IO1/

Digital

I/O

PD

V_FLASH

Reserved (No Connection)

40

SF_SI/IO0

AA15

FLASH0_IO0/

Digital

I/O

PU

V_FLASH

Reserved (No Connection)

41

SF_nHOLD/IO3

Y12

FLASH0_IO3/

Digital

I/O

PU

V_FLASH

Reserved (No Connection)

42

SF_nWP/IO2

AA13

FLASH0_IO2/

Digital

I/O

PD

V_FLASH

Reserved (No Connection)

43

SPIM0_EN0

P12

SPIM0_EN0/

GPIO35

Digital

I/O

PU

VDDIO

Port C: UART RTS

44

SPIM0_EN1

R13

SPIM0_EN1/

GPIO36

Digital

I/O

PU

VDDIO

External LNA GNSS

45

SPIM0_MISO

T12

SPIM0_MISO/

GPIO34

Digital

I/O

PU

VDDIO

Port C: UART RX

46

SPIM0_MOSI

U13

SPIM0_MOSI/

/GPIO33

Digital

I/O

PU

VDDIO

Port C: UART TX

47

NC

Reserved (No Connection)

Pin

No

50 IC

Pin No

Name

I2C1_SCL/

MCU_ CC_IN0/

KEYPAD9/

MCU_LED 4/

PWM2/

MCU_PWM2/

FEM4/

PCM_CLK/

KEYPAD6/

CLKOUT/

MCU_LED 1/

MCU_CLKOUT/

MCU_CC_I N1/

GPIO71

GPIO70

GPIO73

Output

Value

Domain/

Supply

GPIO72

UART1_RTS/

MC U_PCM_OUT_A/

UART0_DSR/

MCU_SPIS_CLK_B/

SWDAT/

MCU_SPIM0_EN0_A/

SPIS_SRDY_ABC/

KEYPAD4/

FEM18/

MCU_SPIS_SRDY_AB/

MCU_CC_IN2/

MCU_FLASH1_CS_N1/

MCU_CC_ OUT2/

UART1_RX/

MC U_PCM_FS_A/

UART0_DTR/

MCU_SPIS_MOSI_B/

MCU_U ART1_RX/

MCU_SPIM0_MISO

_AB/

UART1_TX/

MC U_PCM_IN_A/

UART0_DCD/

MCU_SPIS_MISO_B/

SWCLK/

MCU_SPIM0_MOSI_AB

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 16 of 29 www.murata.com

Page 17

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

48

VFLASH

AA5

PMU_VO_FLASH

Power

O

Reserved (No Connection)

49

VDDIO

Y6

PMU_VO_IO

Power

O

IO reference

50

VDD_RET

V8

PMU_VO_RET

Power

O

Debug monitoring only

51

FLASH0_CS_N1

V14

FLASH0_CS_N1/

GPIO66

Digital

I/O

PU

V_FLASH

GNSS SFN indication

52

FLASH1_CS_N

M6

MCU_FLASH1_CS_N/

GPIO54

Digital

I/O

PU

VDDIO

Reserved (No Connection)

53

FLASH1_IO1

R7

MCU_FLASH1_IO1/

GPIO57

Digital

I/O

PU

VDDIO

Reserved (No Connection)

54

FLASH0_CS_N2

W11

FLASH0_CS_N2/

GPIO78

Digital

I/O

PU

V_FLASH

Reserved (No Connection)

55

FLASH1_SCK

U7

MCU_FLASH1_SCK/

GPIO55

Digital

I/O

PD

VDDIO

Reserved (No Connection)

56

PMU_VBACKUP

W7

PMU_VBACKUP

Power

I

Input from backup battery or NC

57

PMU_VRTC

W5

PMU_VRTC

Power

O

Use for PMU_SHUTDOWN and

58

VBAT

U3

PMU_VBAT_LDO

Power

I

Voltage from Battery

59

V2

PMU_VBAT_DCDC_V2

Power

I

60

W1

PMU_VBAT_DCDC_W1

Power

I

61

EJ_TDI

L5

EJ_TDI/

Digital

I/O

PD

VDDIO

Reserved (No Connection)

62

EJ_TMS

K4

EJ_TMS/

GPIO19

Digital

I/O

PD

VDDIO

Reserved (No Connection)

63

PMU_AT_OUT

N3

PMU_AT_OUT

Analog

O VRTC

Anti-tamper output; connect to

64

PMU_SHUTDOWN

M2

PMU_SHUTDOWN

Analog

I

PU

VRTC

Shutdown active low

65

PMU_EXT_ALARM

L3

PMU_EXT_ALARM/

GPO0

Analog

O VDDIO

Debug monitoring only

66

PMU_POWER_BUT

K2

PMU_POWER_BUTTO

Analog

I

PU

VRTC

Power button active low

67

PMU_ATB

J3

PMU_ATB

Test

I/O VBAT

Reserved (No Connection)

Pin

No

50 IC

Pin No

Name

FEM24/

PWM0/

KEYPAD5/

LED0/

MCU_LED0/

FLASH1_CS_N1/

MCU_PWM0/

I2C0_SCL/

UART0_TX/

KEYPAD1/

MCU_ I2C0_SCL/

MCU_CC_OUT1/

M CU_UART1_TX/

FEM27/

LED5/

MCU_LED5/

Output

Value

Domain/

Supply

PWM1/

K EYPAD8/

LED1/

MCU_LED1/

M CU_PWM1/

GPIO21

SWDAT/

ALARM/

3 2KHZ_CLK_OUT/

if not used

PMU_POWER_BUTTON pull

source

PMU_AT_IN or NC if not used

TON

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 17 of 29 www.murata.com

N

Page 18

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

68

SIMRST

M8

SC_RST/

Digital

I/O

PD

VDDIO

SIM Reset 1.8V

69

SIMCLK

L9

SC_CLK/

GPIO15

Digital

I/O

PD

VDDIO

SIM Clock 1.8V

70

SIM_DETECT

J11

SC_DET/

GPIO16

Digital

I/O

PD

VDDIO

SIM Detection 1.8V

71

SC_SWP

J9

SC_SWP/

GPIO17

Digital

I/O

PD

VDDIO

Host Wake-Up Active HI

72

UART0_RTS

K8

UART0_RTS/

GPIO26

Digital

I/O

PU

VDDIO

• Default is UART0 Request

73

UART0_TX

K10

UART0_TX/

GPIO24

Digital

I/O

PU

VDDIO

• Default is UART0 Transmit

74

UART2_RTS

K6

UART2_RTS/

GPIO30

Digital

I/O

PU

VDDIO

• Default is UART1 Request

75

UART0_RX

G11

UART0_RX/

GPIO23

Digital

I/O

PU

VDDIO

• Default is UART0 Receive

76

UART0_CTS

G9

UART0_CTS/

GPIO25

Digital

I/O

PU

VDDIO

• Default is UART0 Clear to

77

RFFE_SCLK

H6

RFFE_SCLK/

GPIO11

Digital

I/O

PD

VDDIO

MIPI RFFE Clock (antenna

Pin

No

50 IC

Pin No

Name

GPIO13

PWM0/

FEM12/

MCU_PWM0/

CLKOUT/

FEM13/

P WM3/

MCU_PWM3/

EJ1_TDO_AB/

CLK32KHZ_EXT/

MCU_CLKOUT/

MCU_CC_OUT3/

SPIM0_EN0_A/

I2C0_SDA/

UART2_RTS/

MCU_ UART0_RTS/

EJ1_TCK_A/

MC U_I2C0_SDA/

MCU_SPIM0_EN0_B/

UART3_RTS_A/

Output

Value

Domain/

Supply

to Send

• Data host interface; UART

RTS (HI)

SPIM0_MOSI_A/

FEM15/

UART2_TX/

MCU_UAR T0_TX/

EJ1_TMS_A/

UART3_T X_A/

SPIS_CLK_A/

FE M23/

EJ1_TCK_B/

UART1_RTS/

MCU_UART1_RTS/

MCU_SPI M1_EN_A/

MCU_SPIM0_EN0_A/

UART3_RTS_B/

SPIM0_MISO_A/

FEM14/

UART2_RX/

MCU_UA RT0_RX/

EJ1_TDI_A/

UART3_ RX_A/

SPIM0_CLK_A/

I2 C0_SCL/

UART2_CTS/

MCU_U ART0_CTS/

EJ1_TRST_A/

MCU_I2C0_SCL/

MCU_SPIM0_CLK_B/

UART3_CTS_A/

Data

• Data host interface; UART

TX (HI)

to Send

• Dedicated for debug

interface

Data

• Data host interface; UART

RX (HI)

Send

• Data host interface; UART

CTS (HI)

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 18 of 29 www.murata.com

FEM10/

tuning)

Page 19

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

78

RFFE_SDATA

H8

RFFE_SDATA/

GPIO12

Digital

I/O

PD

VDDIO

MIPI RFFE data (antenna

79

GND

Ground

80

GND

Ground

81

GND

Ground

82

PWM1

L11

PWM1/

GPIO51

Digital

I/O

PU

VDDIO

Reserved (No Connection)

83

PWM2

M12

PWM2/

GPIO52

Digital

I/O

PU

VDDIO

Reserved (No Connection)

84

SPIM1_MISO

N9

MCU_SPIM1_MISO/

GPIO39

Digital

I/O

PD

VDDIO

SC2_IO

85

SPIM1_EN

P8

MCU_SPIM1_EN/

GPIO40

Digital

I/O

PU

VDDIO

SC2_DET

86

SPIM1_MOSI

T8

MCU_SPIM1_MOSI/

GPIO38

Digital

I/O

PD

VDDIO

SC2_CLK

87

SPIM1_CLK

R9

MCU_SPIM1_CLK/

GPIO41

Digital

I/O

PD

VDDIO

SC2_RST

88

SF_CLK

W15

FLASH0_SCK/

GPIO67

Digital

I/O

PD

V_FLASH

Reserved (No Connection)

89

GND

90

USB_DN

J15

USB_DN/

GPI64_3V3

Digital

I USB_V3P

3

Reserved (No Connection)

Pin

No

50 IC

Pin No

Name

FEM11/

I2C0_SDA/

MCU_SPI

M1_MISO_AB/

KEYPAD5/

MC U_CC_OUT1/

MCU_CC_IN1/

MCU_PWM1/

I2C0_SCL/

MCU_SPIM1_MOSI_AB

/

FEM16/

MCU_C C_OUT2/

MCU_CC_IN2/

MCU_PWM2/

Output

Value

Domain/

Supply

tuning)

SPIS_M OSI_A/

KEYPAD6/

PWM1/

MCU_SPIS_MOSI_A/

SC_IO/

MCU_PCM_FS_B/

MCU_PWM1/

SPIS_CLK_A/

KEYPAD8/

PWM3/

MCU_SPIS_CLK_A/

SC_DET/

MCU_PCM_ IN_B/

MCU_PWM3/

SPIS_MI SO_A/

PWM2/

MCU_PWM2/

MCU_SPIS_MISO_A/

SC_CLK/

MCU_PCM_OUT_B/

SPIS_MRD Y_A/

PWM0/

MCU_CC_OUT0/

MCU_SPIS_MRDY_A/

SC_RST/

MCU_PCM_CLK_B/

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 19 of 29 www.murata.com

Page 20

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

91

USB_DP

L15

USB_DP/

GPI63_3V3

Digital

I/O USB_V3P

3

Reserved (No Connection)

92

GND

93

USB3V3

N15

USB_V3P3

Digital

I VDDIO

Reserved (No Connection)

94

SPIM0_CLK

V12

SPIM0_CLK/

GPIO37

Digital

I/O

PU

VDDIO

Port C: UART CTS

95

PCM_FS

R11

PCM_FS/

GPIO47

Digital

I/O

PU

VDDIO

Reserved (No Connection)

96

PCM_IN

N11

PCM_IN/

GPIO48

Digital

I/O

PU

VDDIO

Reserved (No Connection)

97

PCM_OUT

T10

PCM_OUT/

GPIO49

Digital

I/O

PU

VDDIO

Reserved (No Connection)

98

PCM_CLK

V10

PCM_CLK/

GPIO46

Digital

I/O

PD

VDDIO

Reserved (No Connection)

99

GND

100

CLKOUT

U9

CLKOUT/

GPIO60

Digital

O

PD

VDDIO

Reserved (No Connection)

101

GND

102

PMU_VCAP

V6

PMU_VCAP

Analog

O VBAT

Connecting external capacitor as

used

Pin

No

50 IC

Pin No

Name

UART1_CTS/

MC U_PCM_CLK_A/

UART0_RI/

MCU_SPIS_MRDY_B/

MCU_UA RT1_TX/

MCU_SPIM0_CLK_A/

UART1_RTS/

KEYPA D1/

FEM21/

MCU_FLASH1_IO 1/

MCU_LED5/

MCU_UART1_ RTS/

MCU_PCM_FS/

UART1_RX/

KEYPAD 2/

LED4/

MCU_FLASH1_IO2/

MCU_LED4/

MCU_UART1_RX/

MCU_PCM_IN/

Output

Value

Domain/

Supply

UART1_TX/

KEYPA D3/

PWM2/

MCU_FLASH1_IO 3/

MCU_PWM2/

MCU_UART1_TX/

MCU_PCM_OUT/

UART1_CTS/

KEYP AD0/

FEM20/

MCU_FLASH1_I O0/

MCU_LED2/

MCU_UART1_CTS/

MCU_PCM_CLK/

32KHZ_CLK_OUT/

PWM0/

FLASH1_CS_N1/

LED2/

MCU_CLKOUT/

MCU_CC_OU

T1/

MCU_PWM0/

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 20 of 29 www.murata.com

backup for VBAT or NC if not

Page 21

1SC

Module Pin Name

ALT12

ALT1250 IC Symbol Pin

Type

Input/

Reset

IO

Description

103

FLASH1_IO3

N7

MCU_FLASH1_IO3/

GPIO59

Digital

I/O

PU

VDDIO

Reserved (No Connection)

104

FLASH1_IO2

P6

MCU_FLASH1_IO2/

GPIO58

Digital

I/O

PD

VDDIO

Reserved (No Connection)

105

FLASH1_IO0

T6

MCU_FLASH1_IO0/

GPIO56

Digital

I/O

PU

VDDIO

Reserved (No Connection)

106

EJ_TCK

R5

EJ_TCK/

GPIO18

Digital

I/O

PD

VDDIO

Reserved (No Connection)

107-

GND_PAD

1SC Pin No

Module Pin Name

PD (KΩ)

PU (KΩ)

PU Source

Description

4

EJ_TRST

10

Reserved (No Connection)

5

PMU_AT_IN

Short to GND

Anti-tamper input; short to GND if not used

64

PMU_SHUTDOWN

560

VRTC

Shutdown active low; PU to PMU_VRTC

66

PMU_POWER_BUTTON

560

VRTC

Power button active low; PU to PMU_VRTC

Pin

No

115

50 IC

Pin No

Name

I2C1_SCL/

UART0_RTS/

KEYPAD3/

MCU_I2C1_SCL/

MCU_CC_OUT3/

MCU_UART1_RTS/

I2C1_SDA/

UART0_CTS/

KEYPAD2/

MCU_I2C1_SDA/

MCU_CC_OUT2/

MCU_UART1_CTS/

I2C0_SDA/

UART0_RX/

KEYPAD0/

MCU_ I2C0_SDA/

MCU_CC_OUT0/

MCU_UART1_RX/

SWCLK/

Output

Value

Domain/

Supply

Table 4 Pin description

If not used, all pins except the following should be left disconnected.

Table 5 I/Os with PU/PD

The PMU_VRTC pin must not be used by any external component other than pull-ups for the

PMU_SHUTDOWN and PMU_POWER_BUTTON pins. It is prohibited to use the PMU_VRTC pin for any

other purpose.

The UARTs Port A (20, 21, 22, 74) and Port C (43, 45, 46, 94) signals should be brought out for control and

logging during certification/testing with PC tools.

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 21 of 29 www.murata.com

Page 22

1SC Pin No

Module Pin Name

Port

Signal

20

UART2_RX

A

UART RX

21

UART2_CTS

A

UART CTS

22

UART2_TX

A

UART TX

74

UART2_RTS

A

UART RTS

43

SPIM0_EN0

C

UART RTS

45

SPIM0_MISO

C

UART RX

46

SPIM0_MOSI

C

UART TX

94

SPIM0_CLK

C

UART CTS

Table 6 Special UART signals for certification/testing

2.11 Reference Circuit

A reference circuit for the Type1SC is provided in [1].

3 Power

Type1SC requires two power supplies, one for the LTE modem (VBAT) and the other for the RF FEM (VBAT_FEM).

The power supply must be capable of peak current output of at least 400mA and 800mA, respectively, for

VBAT and VBAT_FEM.

3.1 Power Up Sequence

The power up sequence is shown below. Type1SC will power up automatically once VBAT is connected to the

power supply.

3.2 Power Down Sequence

The supply to VBAT and VBAT_FEM should be turned off at the same time.

3.3 Power Supply Scenarios (by Battery Type)

A typical Type1SC based design uses a battery supply. The following are some possible battery supply scenarios:

• LiPo Battery (3.2 ~ 4.35 V)

• CR17450 Battery (2.2 ~ 3.0 V)

• AA Lithium Battery (1.0 ~ 1.5 V)

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 22 of 29 www.murata.com

Figure 4 Power up sequence

Page 23

Signal

Functionality

Input/

Polarity

PMU_SHUTDOWN

HW Reset

Input

Active Low

PMU_POWER_BUTTON

Reserved

Input

Active High

PMU_WAKEUP

Wakeup

Input

Active High

LiPo Battery (3.2 ~ 4.35 V)

The battery can supply the entire system (ALT1250 + FEM), without additional external power conditioning circuits.

CR17450 Battery (2.2 ~ 3.0 V) The ALT1250 can be fully functional without additional external power conditioning circuits. However, the FEM requires a higher voltage supply, so an external boost circuit is required to supply VBAT_FEM.

Boost converter such as TPS61021A may be turned on/off by the DCDC enable signal, AUX_ADC4 (pin

33, active high).

AA Lithium Battery (1.0 ~ 1.5 V) For battery range of 1.0 – 1.5 V, both ALT1250 and FEM require an additional boost circuit.

VBAT: ultra low I

synchronous boost converter such as TPS61098x may be used

Q

VBAT_FEM: boost converter such as TPS61021A may be turned on/off by the DCDC enable signal,

AUX_ADC4 (pin 33, active high).

3.4 PMU

ALT1250 includes integrated PMU which supplies current for all ALT1250 blocks, IOs, Flash, TCXO and UICC.

Output

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 23 of 29 www.murata.com

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Table 7 PMU system signals

Page 24

PMU_SHUTDOWN This pin has the highest priority compared to other chip functionalities, therefore asserting it will always force a hard reset

3.4.1.1 External circuitry on PMU_SHUTDOWN

There are three use cases for PMU_SHUTDOWN pin connection:

1. Controlled by external host.

2. Controlled by mechanical switch.

3. Not used.

3.4.1.2 PMU_SHUTDOWN connected to external host

In this use case it is the responsibility of the host to drive this pin with proper voltage at all times (1.8V/0V).

In case of internal pull at the host IO, it is recommended to disable it when driving this pin to GND.

LTE CAT-M1/NB1 ALT1250 Based Chipset Power

Altair Semiconductor Proprietary and Confidential 45

3.4.1.3 PMU_SHUTDOWN connected to mechanical switch

In this case, when button is not pushed, the pin can be pulled up either by external 1.8V source or by PMU_VRTC.

If current during the time when button is pushed is a concern then some pullup disconnection circuitry should be

externally triggered when PMU_SHUTDOWN pin is being directed to GND

3.4.1.4 PMU_SHUTDOWN is not used

In this case PMU_SHUTDOWN pin should be tied directly to PMU_VRTC

This pin requires an external PU resistor, please see Table 5 more information.

The host connected to this pin should always keep the state of this pin (high/low) at a known state (not

floating) according to the required functionality.

PMU_POWER_BUTTON

This pin requires an external PU resistor, please see Table 5 more information.

The host connected to this pin should always keep the state of this pin (high/low) at a known state (not

floating) according to the required functionality.

PMU_WAKEUP This pin wakes-up the system from low power state.

4 SIM Interface

Since all digital IOs in Type1SC are in 1.8V domain, the module will support 1.8V SIM cards (Class-C).

For 3.0V SIM card support, an external voltage translator will be required.

5 Host Interface

Type1SC uses the following signals for the host interface. The UART interface is necessary for communication

between the host and Type1SC.

The device reset status signal can be used by the host to detect that the modem has completed a reset so

that the host can properly reset its internal state.

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 24 of 29 www.murata.com

Page 25

1SC Pin No

Module Pin Name

Direction

Description

Note

6

PMU_WAKEUP

HD

Device Wake-Up

Only needed if low power

32

PWM0

DH

Device reset status

64

PMU_SHUTDOWN

HD

Modem reset (active low)

Optional

71

SC_SWP

DH

Host Wake-Up

Only needed if low power

mode is required

72

UART0_RTS

DH

UART RTS

73

UART0_TX

DH

UART TX

75

UART0_RX

HD

UART RX

76

UART0_CTS

HD

UART CTS

Item

Value

Frequency range

Depending by frequency band(s) provided by

the most suitable antenna for that/those

band(s)

Bandwidth

LTE

Tx Band

(MHz)

Rx Band

(MHz)

Min

Max

Min

Max

B1

1920

1980

2110

2170

B2

1850

1910

1930

1990

B3

1710

1785

1805

1880

B4

1710

1755

2110

2155

B5

824

849

869

894

B8

880

915

925

960

B12

699

716

729

746

B13

777

787

746

756

B14

788

798

758

768

B17

704

716

734

746

B18

815

830

860

875

B19

830

845

875

890

B20

832

862

791

821

B25

1850

1915

1930

1995

B26

814

849

859

894

B28

703

748

758

803

mode is required

Table 8 Host interface signals

6 Antenna Requirements

The module has been FCC/IC/ETSI certified. However, since this is a module that does not have an RF

connector, an FCC Class 2 Permissive Change will be required to add the antenna to the grant.

6.1 Main Antenna

The antenna connection and board layout design are the most important aspect in the full product design as they

strongly affect the product overall performances, hence read carefully and follow the requirements and the

guidelines for a proper design. The antenna and antenna transmission line on PCB for a Type 1SC device shall

fulfill the following requirements:

the network operator, the customer shall use

Band

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 25 of 29 www.murata.com

Page 26

Impedance

50 ohm

Input power

> 23dBm Average power

VSWR absolute max

≤ 10:1 (limit to avoid permanent damage)

VSWR recommended

≤ 2:1 (limit to fulfill all regulatory

requirements)

Maximum permitted antenna gain including cable loss should be determined from Tables 8.1 and 8.2. Failure to

follow these guidelines wil result in radiated RF levels that exceed FCC MPE limits.

6.2 MIPI RFFE for Antenna Tuning

MIPI RFFE, is a dedicated control interface for the RF front-end subsystem. This interface allows antenna

designer to optimize antenna performance for different LTE bands. They can tune the antenna for different bands

by using a compliant MIPI RFFE switch. Currently the module only supports the Sony Switch (CXA4472GC-E).

The following signals are used for the MIPI interface.

RFFE_SCLK, RFFE_SDATA, RFFE_VDDIO_OUT

6.3 GPS Coexistence

Two pins are provided for GPS coexistence. AUX_ADC1 is used for GNSS coexistence indicator and

FLASH0_CS_N1 is used for GNSS SFN indication.

Other advanced GPS coexistence features will be available in a future firmware release.

7 APPLICATION PCB DESIGN

The Type 1SC modules have been designed to be compliant with a standard lead-free SMT process.

7.1 Solder Reflow

Recommended solder reflow profile:

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 26 of 29 www.murata.com

Page 27

Profile Feature

Pb-Free Assembly

Average ramp-up rate (TL to TP)

TBD

Preheat

– Time (min to max) (ts)

TBD

Tsmax to TL

– Ramp-up Rate

TBD

Time maintained above:

– Time (tL)

TBD

Peak Temperature (Tp)

TBD

Time within 5°C of actual Peak

Temperature (tp)

TBD

Ramp-down Rate

TBD.

Time 25°C to Peak

Temperature

TBD

Item

Value

Characteristic Impedance

50 ohm

Max Attenuation

0.3 dB

Coupling

Coupling with other signals shall be

avoided

Ground Plane

Cold End (Ground Plane) of antenna

ground pins

– Temperature Min (Tsmin)

– Temperature Max (Tsmax)

– Temperature (TL)

TBD

TBD

TBD

Antenna Installation Guidelines

• Install the antenna in a place covered by the LTE signal.

• If the device antenna is located farther than 20cm from the human body and there are no co-located

transmitter then the Murata FCC/IC approvals can be re-used by the end product.

• If the device antenna is located closer than 20cm from the human body or there are co-located transmitter

then the additional FCC/IC testing may be required for the end product (Murata FCC/IC approvals cannot

be reused).

• Antenna shall not be installed inside metal cases.

• Antenna shall be installed also according to antenna manufacturer instructions.

PCB Design Guidelines

When using the Type 1SC, since there's no antenna connector on the module, the antenna must be connected to

the Type 1SC antenna pad by means of a transmission line implemented on the PCB.

In the case the antenna is not directly connected at the antenna pad of the Type 1SC, then a PCB line is needed

in order to connect with it or with its connector.

This transmission line shall fulfil the following requirements:

The transmission line should be designed according to the following guidelines:

• Ensure that the antenna line impedance is 50 ohm;

• Keep the antenna line on the PCB as short as possible, since the antenna line loss shall be less than 0.3

dB;

• Antenna line must have uniform characteristics, constant cross section; avoid meanders and abrupt

curves;

• Keep, if possible, one layer of the PCB used only for the Ground plane;

• Surround (on the sides, over and under) the antenna line on PCB with Ground, avoid having other signal

tracks facing directly the antenna line track;

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 27 of 29 www.murata.com

shall be equipotential to the Type 1SC

Page 28

• The ground around the antenna line on PCB has to be strictly connected to the Ground Plane by placing

vias every 2mm at least;

• Place EM noisy devices as far as possible from Type 1SC antenna line;

• Keep the antenna line far away from the Type 1SC power supply lines;

• If you have EM noisy devices around the PCB hosting the Type 1SC, such as fast switching ICs, take

care of the shielding of the antenna line by burying it inside the layers of PCB and surround it with

Ground planes, or shield it with a metal frame cover.

• If you don't have EM noisy devices around the PCB of Type 1SC, by using a micro strip on the superficial

copper layer for the antenna line, the line attenuation will be lower than a buried one;

Transmission line design

The placement of components has been chosen properly, to keep the line length as short as possible, thus leading

to lowest power losses possible.

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 28 of 29 www.murata.com

Page 29

8 FCC Notice

This device has Single Modular Approval. This device is approved for mobile and fixed use with respect to RF

exposure compliance, and may only be marketed to OEM installers. The antenna(s) used for this transmitter, as

described in this filing, must be installed to provide a separation distance of at least 20 cm from all persons.

Installers and end-users must be provided with operating conditions for satisfying RF exposure

compliance. Maximum permitted antenna gain including cable loss should be determined from tables 8.1 and 8.2.

Failure to follow these guidelines will result in radiated RF levels that exceed FCC MPE limits

8.1 FCC Test Data

8.2 ISED Test Data

Copyright © Murata Manufacturing Co., Ltd. All rights reserved. September 2018

Application Note: LBAD0XX1SC, v0.4 7/1/19 Page 29 of 29 www.murata.com

Loading...

Loading...