Page 1

Preliminary and RFM Confidential

DR-WLS1273L-102

FCC/ETSI/IC Certified

WLAN/Bluetooth

Multifunction Module

Data Sheet

www.RFM.com Technical support +1.972.448.3700 Page 1 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 2

Preliminary and RFM Confidential

Scope

This specification applies to the IEEE802.11a/b/g/n WLAN and Bluetooth 4.0 standards.

Interfaces

WLAN: 4-bit SDIO

Bluetooth: UART, PCM

IC and Firmware

WLAN/BT RF/BB/MAC IC: TI WL1273L PG 3.1

Front-end IC for WL1273L: TriQuint TQP6M9002 ES1.8

Clocks and Compliance

Sleep Clock: External 32.768 kHz oscillator required

RoHS: This module is compliant with the RoHS directive

Bluetooth: Qualified Design Listing: B017989

Certifications FCC, ETSI and Industry Canada

For mobile operating conditions (greater than 20 cm to the body) - This equipment complies with FCC

radiation exposure limits set forth for an uncontrolled environment. This equipment should be installed

and operated with minimum distance 20 cm between the radiator and your body. This transmitter must

not be co-located or operating in conjunction with any other antenna or transmitter.

For portable operating conditions (less than 20 cm to the body) - This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment. This equipment may operate in direct contact with the body of the user under normal operating conditions. This transmitter must not be co-located

or operating in conjunction with any other antenna or transmitter.

Certification testing conducted with Antenna Factor ANT-RAF-RPS 2.4/5 GHz antenna, RSMA connector.

Part Numbers

Module: DR-WLS1273L-102

www.RFM.com Technical support +1.972.448.3700 Page 2 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 3

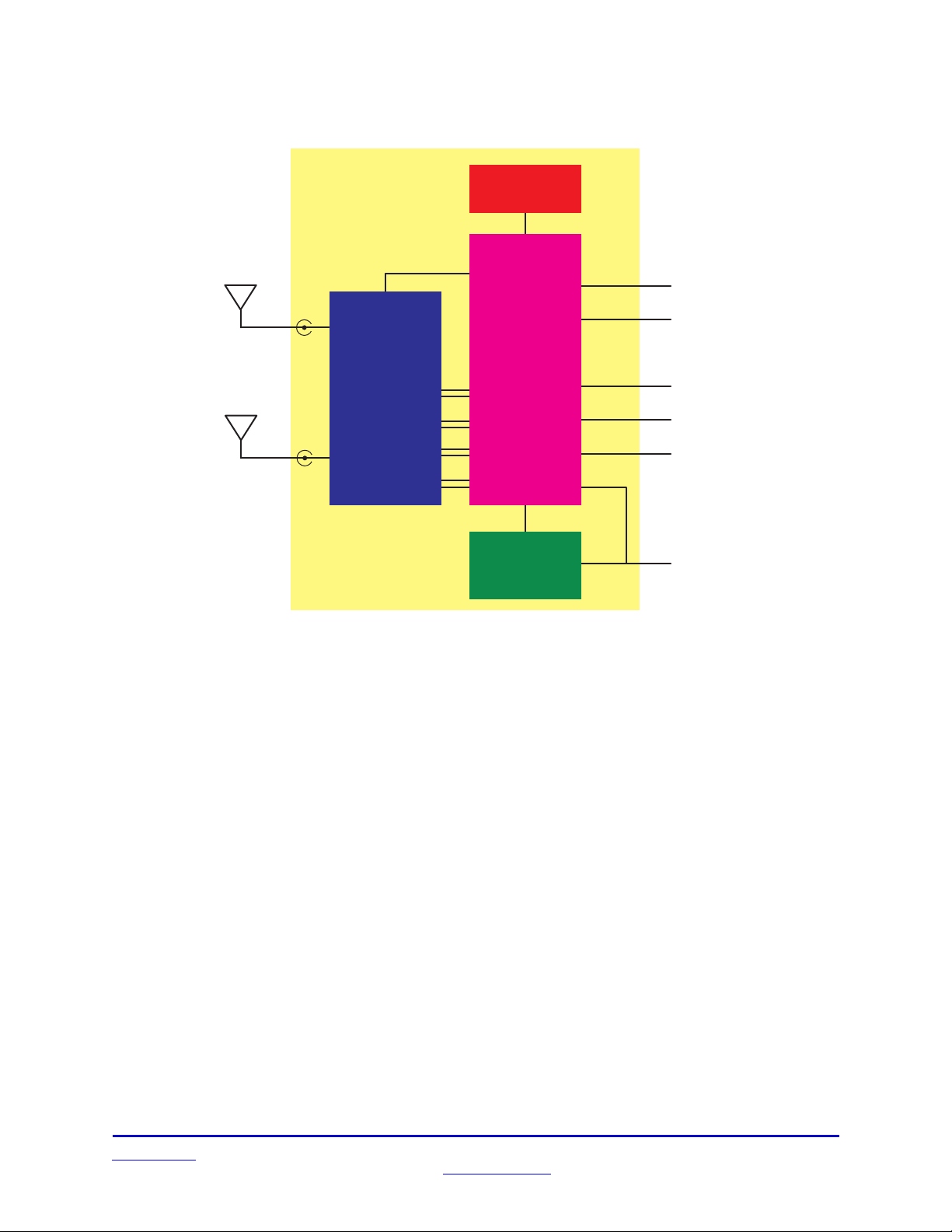

Block Diagram

5 . 8 G H z

W L A N

Preliminary and RFM Confidential

3 8 . 4 M H z

F a s t C L K

S l o w C L K

S D I O

2 . 4 G H z

W L A N / B T

F r o n t E n d

I C a n d R F

F i l t e r i n g

W L 1 2 7 3 L

P C M

U A R T

V I O

D C - D C

V B A T

C o n v e r t e r

DR-WLS1273L-102 WLAN Features

• WLAN MAC baseband processor and RF transceiver which are IEEE802.11a/b/g and IEEE802.11n

PICS compliant

• Optimized for ultra-low current consumption in all operating modes

• Accepts 19.2, 26, 38.4 or 52 MHz reference clock inputs for easy integration into cellular handsets, etc.

• IEEE Standard 802.11d, e, h, i, k, r, PICS compliant

• Support for Cisco Client eXtensions (CCX) standard

• Serial debug interface

• Support for Secure Digital Input/Output (SDIO) host interface

• Medium Access Controller (MAC)

– Embedded ARM™ central processing unit (CPU)

– Hardware-based encryption/decryption using 64-, 128- or 256-Bit WEP, TKIP or AES keys

– Supports Wi-Fi protected access (WPA and WPA2.0) and IEEE Standard 802.11i, including

hardware accelerated Advanced Encryption Standard (AES)

– Designed to work with IEEE Std 802.1x for Virtual Private Network (VPN) solutions

www.RFM.com Technical support +1.972.448.3700 Page 3 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 4

Preliminary and RFM Confidential

• Baseband Processor

– IEEE Std 802.11n single-stream data rates (MCS0-7) and SGI support

• 2.4/5.8 GHz Radio

– Digital Radio Processor (DRP) implementation

– Integrated LNA

– Supports IEEE Std 802.11a/b/g and 802.11n

DR-WLS1273L-102 Bluetooth Features

• V4.0 + EDR, Power Class 1.5 + BLE

• Bluetooth Qualified Design Listing: B017988

• BT Enhanced Data Rates - 2 and 3 Mbps

• Enhanced UART host interface

• Very low power consumption

• On-chip Embedded radio

– Integrated 2.4 GHz RF transceiver

– All digital PLL transmitter with digitally controlled oscillator

– Near-zero IF architecture

– On-chip TX/RX switch

– Support for Class-1.5 applications

• Embedded ARM microprocessor system

– High rate four wire UART HCI (H4) and three wire UART HCI (H5)

– Automatic clock-detection mechanism

• Flexible PCM interface - full flexibility for data order, sampling and positioning

• Temperature detection and compensation mechanism ensures minimal variation in the RF performance

over the entire operating temperature range

• Low-power scan achieves paging and inquiry scans at 1/3 normal power

• Digital Radio Processor (DRP) single-ended 50 ohm I/O for easy RF interfacing

• Patch trap mechanism and reserved RAM enables easy bug fixes

• Advance Audio Interfaces and capabilities

– A2DP support

– A2DP internal loopback

– Wide-band speech support

– On board SBC encoder/decoder - offloads host for A2DP and wide-band speech processing

– Full support for Bluetooth low energy (BLE) standard. BLE can operate in parallel with standard

Bluetooth function.

WLAN Functional Blocks

The DR-WLS1273L-102 WLAN architecture includes a digital radio processor and a point-to-multipoint

baseband core function. The architecture is based on a single-processor ARM core. The device includes

on-chip peripherals to enable easy communication between a host system and the WLAN core function.

www.RFM.com Technical support +1.972.448.3700 Page 4 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 5

Preliminary and RFM Confidential

WLAN SDIO Transport Layer

SDIO is the WLAN host interface in the DR-WLS1273L-102. This interface is a standard SDIO interface

(SDIO spec Version 2.0). The DR-WLS1273L-102 SDIO also supports the following features:

• 4-bit data bus

• Functions number 0 and 2

• Multi-Block data transfer

• The SDIO interface is used for WLAN. The WLAN block uses function 2. Function 0 is used for the

common I/O area.

WLAN MAC

The DR-WLS1273L-102 MAC implements the IEEE standard 802.11 MAC sub-layer using both dedicated

hardware and embedded firmware. The MAC hardware implements real-time functions, including access

protocol management, encryption and decryption.

WLAN Baseband Processor

The DR-WLS1273L-102 baseband processor sits between the on-chip MAC and the radio. The DRWLS1273L-102 baseband processor implements the IEEE 802.11a/b/g/n PHY sub-layers and has been

optimized to perform well in conditions of high multipath and noise.

WLAN RF Radio

The DR-WLS1273L-102 radio is a highly integrated Digital Radio Processor (DRP) designed for

802.11a/b/g/n applications. The DR-WLS1273L-102 RF interfaces are designed for direct, “glueless” connection to single-band RF front ends for 2.4 and 5.8 GHz 802.11a/b/g/n applications.

BT Functional Blocks

The DR-WLS1273L-102 BT architecture comprises a digital radio processor and a point-to-multipoint

baseband core function. The architecture is based on a single-processor ARM core. The device includes

on-chip peripherals to enable easy communication between a host system and the Bluetooth core function.

BT HCI UART Transport Layers

The DR-WLS1273L-102 incorporates one UART module dedicated to the Host Controller Interface (HCI)

transport layer. The HCI interface is used to transport commands, events, ACL and data between the

Bluetooth device and its host using HCI data packets. The DR-WLS1273L-102 supports the following HCI

transport layers, detected automatically when communication starts:

• UART transport layer - HCI four-wire (H4) and HCI three-wire (H5)

• HCI interface has a 256 byte receive buffer

The HCI UART supports most baud rates (including all PC rates) for all fast-clock frequencies - up to a

maximum of 4 Mbps. After power-up, the baud rate is set for 115.2 kbps. The maximum baud rate deviation supported is -2.5%, +1.5%. The baud rate can thereafter be changed with a VS command. The DRWLS1273L-102 responds with a Command Complete Event (still at 115.2 kbps), after which the baud rate

change takes place. The only parameter needed is the desired baud rate. HCI hardware includes the following features:

www.RFM.com Technical support +1.972.448.3700 Page 5 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 6

Preliminary and RFM Confidential

• Receiver detection of break, idle, framing, FIFO overflow, and parity error conditions

• Transmitter underflow detection

• CTR/RTS hardware flow control

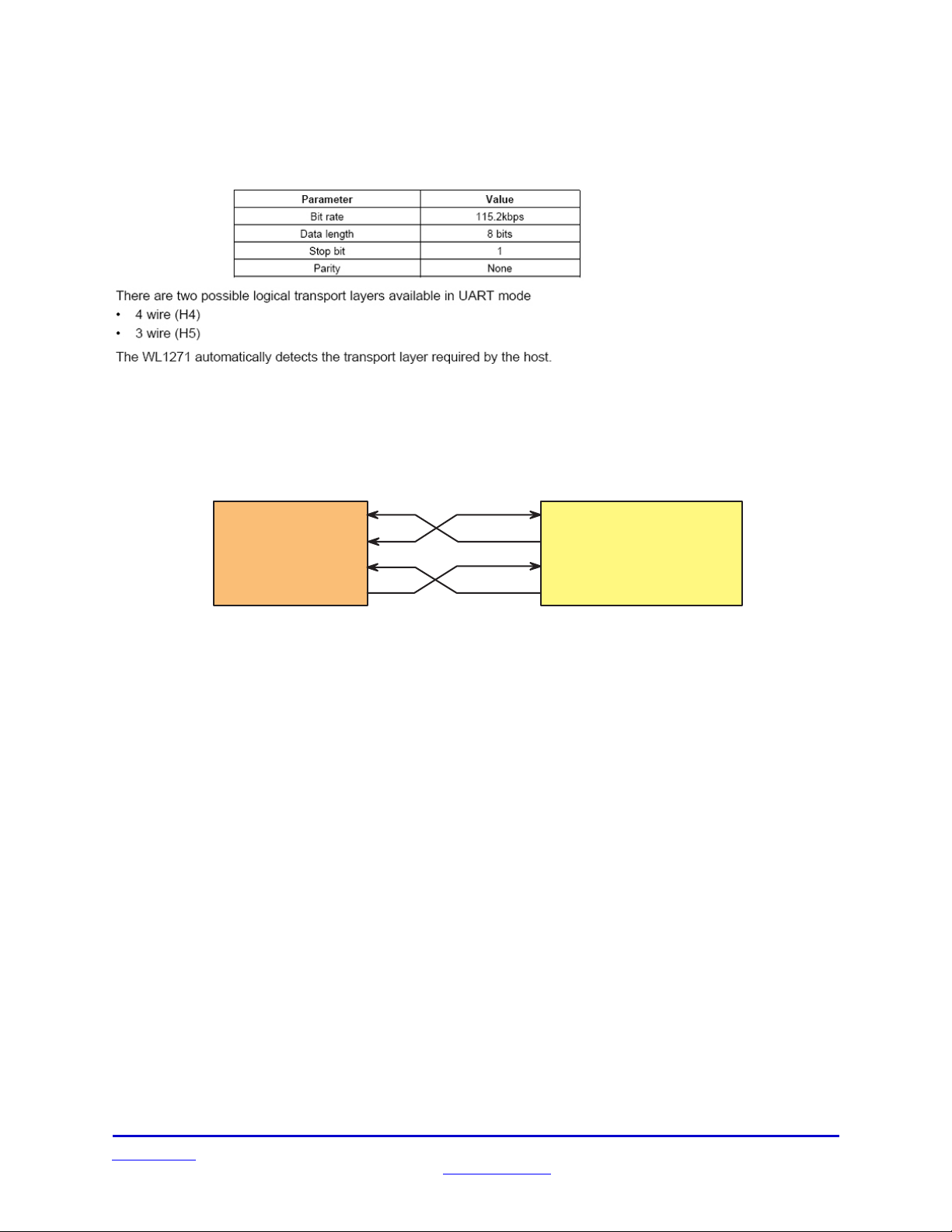

BT UART 4-Wire Interface - H4

The interface includes four signals: TXD, RXD, CTS and RTS. Flow control between the host and the

DR-WLS1273L-102 is byte-wise by hardware. Flow control is obtained by the following:

H O S T _ R X

H o s t

P r o c e s s o r

H O S T T X

H O S T _ C T S

H O S T _ R T S

H C I _ R X

H C I _ T X

H C I _ C T S

H C I _ R T S

D R - W L S 1 2 7 3 L - 1 0 2

When the UART RX buffer asses the “flow control” threshold, it sets the UART_RTS signal high to stop

transmission from the host. When the UART_CTS signal is set high, the DR-WLS1273L-102 stops transmitting on the interface. In case HCI_CTS is set high in the middle of transmitting a byte, the DRWLS1273L-102 finishes transmitting the byte and stops the transmission.

BT UART 3-Wire Interface - H5

This interface consists of three signals: TXD, RXD and GND:

HCI_RX Receive Data on the UART Interface

HCI_TX Transmit Data on the UART Interface

GND Ground

XON/XOFF software flow control is normally used.

The DR-WLS1273L-102 also supports a four-wire mode for H5, with RTS/CTS hardware flow control.

Since the same UART module is used for the 3- and 4-wire HCI UART interface, all features supported by

the 4-wire interface are also supported for the 3-wire interface. H5 features:

• Flow control configured with HCI_VS command, software XON/XOFF, hardware (RTS/CTS), or none

• Power management

• Configurable timers for re-transmission management

• CRC

www.RFM.com Technical support +1.972.448.3700 Page 6 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 7

Preliminary and RFM Confidential

BT Audio CODEC Interface

The CODEC interface is a fully dedicated programmable serial port that provides the logic to interface to

several kinds of PCM codecs. The interface supports:

• Two voice channels

• Master/slave modes

• Coding schemes: μ-Law, A-Law, Linear, Transparent

• Long & short frames

• Different data lengths, orders and positions

• UDI profile

• High rate PCM interface for EDR

• Enlarged interface options to support a wider variety of codecs

• PCM bus sharing

PCM Hardware Interface

The PCM interface is one implementation of the codec interface. It contains the following four lines:

• Clock - configurable direction (input or output)

• Frame Sync - configurable direction (input or output)

• Data In - Input

• Data Out - Output/Hi-Z

The DR-WLS1273L-102 device can be either the master of the interface where it generates the clock and

the frame-sync signals, or slave where it receives these two signals. The PCM interface is fully configured

by means of a VS command. For slave mode, clock input frequencies of up to 16 MHz are supported. At

clock rates above 12 MHz, the maximum data burst size is 32 bits. For master mode, the DR-WLS1273L102 can generate any clock frequency between 64 kHz and 4.096 MHz.

Data Format

The data format is fully configurable:

• The data length can be from 8 to 320 bits, in 1-bit increments, when working with two channels, or up to

640 bits when using 1 channel. The data length can be set independently for each channel.

• The data position within a frame is also configurable with 1-clock (bit) resolution, and can be set independently (relative to the edge of the Frame Sync signal) for each channel.

• The Data_In and Data_Out bit order can be configured independently. For example; Data_In can start

with MSB while Data_Out starts with LSB. Each channel is separately configurable. The inverse bit order

(i.e. LSB first) is supported only for sample sizes up to 24 bits.

• The data in and data out size do not necessarily have to be the same length.

• The Data_Out line is configured as a ‘high-Z’ output between data words. Data_Out can also be set for

permanent high-Z, irrespective of data out. This allows the DR-WLS1273L-102 to be a bus slave in a multi-slave PCM environment. At power up, Data_Out is configured as high-Z.

Frame-Idle Period

The CODEC interface has the capability for frame-idle periods, where the PCM clock can “take a break”

and become ‘0’ at the end of the PCM frame, after all data has been transferred. The DR-WLS1273L-102

supports frame-idle periods both as master and slave of the PCM bus. When DR-WLS1273L-102 is the

master of the interface, the frame-idle period is configurable. There are 2 configurable parameters:

• Clk_Idle_Start - indicates the number of PCM clock cycles from the beginning of the frame till the beginning of the idle period. After Clk_Idle_Start clock cycles, the clock becomes ‘0’.

www.RFM.com Technical support +1.972.448.3700 Page 7 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 8

Preliminary and RFM Confidential

• Clk_Idle_End - indicates the time from the beginning of the frame till the end of the idle period. This time

is given in multiples of PCM clock periods. The delta between Clk_Idle_Start and Clk_Idle_End is the

clock idle period, e.g., for PCM clock rate = 1 MHz, frame sync period = 10 kHz, Clk_Idle_Start = 60,

Clk_Idle_End = 90. Between each two-frame sync there are 70 clock cycles (instead of 100). The clock

idle period starts 60 clock cycles after the beginning of the frame and lasts 90-60=30 clock cycles. This

means that the idle period ends 100-90=10 clock cycles before the end of the frame. The data transmission must end prior to the beginning of the idle period.

Audio Encoding

The DR-WLS1273L-102 CODEC interface can use one of four audio coding patterns:

• A-Law (8-bit)

• m-Law (8-bit)

• Linear (8 or 16-bit)

• Transparent

www.RFM.com Technical support +1.972.448.3700 Page 8 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 9

Mechanical

Preliminary and RFM Confidential

D R - W L S 1 2 7 3 L - 1 0 2 P a c k a g e D r a w i n g

2 . 4 G H z

5 . 8 G H z

0 . 5 0

( 1 . 3 )

0 . 2 5 6

( 6 . 5 )

0 . 3 6 2

( 9 . 2 )

0 . 0 8 0

( 2 . 0 )

0 . 1 0 0

( 2 . 5 )

0 . 7 3 5

( 1 8 . 7 )

T o p

0 . 0 8 0

( 2 . 0 )

0 . 1 3 0

( 3 . 3 )

0 . 0 3 0

( 0 . 8 )

0 . 0 4 0

( 1 . 0 )

0 . 0 3 0

( 0 . 8 )

0 . 0 4 0

( 1 . 0 )

V i e w f r o m T o p

D i m e n s i o n s i n i n c h e s ( m m )

S i d e

0 . 1 5 ( 3 . 8 )

M a x i m u m H e i g h t

0 . 5 4 2

( 2 . 1 7 )

0 . 5 7 8

( 1 4 . 7 )

0 . 4 8 2

( 1 2 . 2 )

0 . 0 4 3

( 1 . 1 )

B o t t o m

0 . 1 2 0

( 3 . 0 )

0 . 0 8 0

( 2 . 0 )

4 1

4 2

4 0

5 1

2

5 0

1

0 . 0 3 0

( 0 . 8 )

0 . 0 2 8

( 0 . 7 )

2 8

1 4

2 6

2 7

0 . 0 4 1

( 1 . 0 )

1 5

0 . 1 0 5

1 6

( 2 . 7 )

www.RFM.com Technical support +1.972.448.3700 Page 9 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 10

Preliminary and RFM Confidential

Module Terminal Description

Num Terminal Name Type System IC Terminal Connection Description

1 PCM SYNC I/O BT WL1273L AUD_FSYNC PCM I/F

2 PCM CLK I/O BT WL1273L AUD_CLK PCM I/F

3 PCM OUT I/O BT WL1273L AUD_OUT PCM I/F

4 PCM IN I/O BT WL1273L AUD_IN PCM I/F

5 HOST WAKE I/O BT WL1273L BT_FUNC5 Host Wake Up

6 VBAT IN P SOC

7 BT ENABLE I BT WL1273L BT_EN BT Enable/Reset

8 WLAN IRQ O WLAN WL1273L WLAN_IRQ WLAN interrupt request

9 NOT USED Mechanical Connection

10 NOT USED Mechanical Connection

11 NOT USED Mechanical Connection

12 NOT USED Mechanical Connection

13 NOT USED Mechanical Connection

14 WLAN TX I/O WLAN WL1273L WL_RS232_TX RS232_RX

15 WLAN RX I/O WLAN WL1273L WL_RS232_RX RS232_TX

16 WLAN EN I WLAN WL1273L WL_EN WLAN Enable/Reset

17 SDIO D2 I/O WLAN WL1273L SDIO_D2 SDIO DATA 2

18 SDIO D1 I/O WLAN WL1273L SDIO_D1 SDIO DATA 1

19 SDIO CMD I/O WLAN WL1273L SDIO_CMD SDIO CMD

20 NOT USED Mechanical Connection

21 GND SOC Ground

22 SDIO CLK I WLAN WL1273L SDIO_CLK SDIO CLK

23 UART DBG I/O WLAN WL1273L WL_UART_DBG WL_UART_DBG

24 SDIO D0 I/O WLAN WL1273L SDIO_D0 SDIO mode: DATA 0

25 NOT USED Mechanical Connection

26 SDIO D3 I/O WLAN WL1273L SDIO_D3 SDIO mode: DATA 3

27 BT UART DBG I/O BT WL1273L BT_UART_DBG

28 NOT USED Mechanical Connection

29 NOT USED Mechanical Connection

30 SLEEP CLOCK I - WL1273L SLOWCLK SLEEP_CLK Input

31 BT WAKE I/O BT WL1273L BT_FUNC2 BT_WU/BT

32 NOT USED Mechanical Connection

33 VIO IN P SOC WL1273L VDDS Power Supply Input

34 NOT USED Mechanical Connection

WL1273L,

TPS62601

PMS_VBAT, VIN Power supply input

BT_UART_DBG, connect to

TP for software debug

www.RFM.com Technical support +1.972.448.3700 Page 10 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 11

Preliminary and RFM Confidential

Num Terminal Name Type System IC Terminal Connection Description

35 BT CTS I/O BT WL1273L HCI_CTS BT UART CTS

36 NOT USED Mechanical Connection

37 BT RTS I/O BT WL1273L HCI_RTS BT UART RTS

38 NOT USED Mechanical Connection

39 BT TX I/O BT WL1273L HCI_TX BT UART TX

40 NOT USED Mechanical Connection

41 BT RX I/O BT WL1273L HCI_RX BT UART RX

42 GND SOC Ground

43 GND SOC Ground

44 2.4 GHZ ANT I/O

45 GND SOC Ground

46 GND SOC Ground

47 GND SOC Ground

48 GND SOC Ground

49 5.8 GHZ ANT I/O WLAN

50 GND SOC Ground

51 GND SOC Ground

BT,

WLAN

RF receiver input

RF transmitter output

RF receiver input

RF transmitter output

www.RFM.com Technical support +1.972.448.3700 Page 11 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 12

Preliminary and RFM Confidential

Absolute Maximum Ratings

Ratings Minimum Maximum Units

Temperature -40 +85

Supply Voltage

VBAT -0.5 +5.5 V

VIO -0.5 +2.1 V

Operating Conditions

Specifications Minimum Typical Maximum Units

Temperature

Supply Voltage

1, 2

-40 +25 +85

VBAT 3.0 3.6 4.2 V

VIO3 1.70 1.80 1.90 V

Digital I/O Requirements

Specifications Symbol Minimum Maximum Units

Logic High Input Voltage VIH 0.65 * VIO VIO V

Logic Low Input Voltage VIL 0 0.35 * VIO V

Logic High Output Voltage

Logic Low Output Voltage

Input Transition Time TR/T

from 10% to 90%4

@ 4.00 mA

VOH

@ 0.30 mA VIO - 0.033 VIO

@ 4.00 mA

VOL

@ 0.09 mA 0 0.01

F

< 50 fF TR/TF 0 25 ps

C

L

VIO - 0.450 VIO

0 0.450

O

C

O

C

V @ 1.00 mA VIO - 0.112 VIO

V @ 1.00 mA 0 0.112

Output Rise Time TR

from 10% to 90%

Output Fall Time TF

from 90% to 10%

4

4

< 25 pF TR - 5.3 ns

C

L

< 25 pF TF - 4.9 ns

C

L

Notes:

1. The device can be reliably operated for 5,000 active WLAN hours cumulative at T ambient of 85 °C.

2. BIP (calibration) must be run to achieve full power output when temperatures changes more than 20 °C

from the last BIP

3. Minimum ramp time for IO power supply is 100 µs

4. Applies to all digital lines except SDIO, UART, PCM and slow clock lines.

www.RFM.com Technical support +1.972.448.3700 Page 12 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 13

Preliminary and RFM Confidential

External Slow Clock Requirements

Specifications1 Minimum Typical Maximum Units

Slow Clock Frequency 32.768 kHz

Slow Clock Accuracy - - ±150 ppm

Clock Transition Time, Tr/Tf 10 to 90% - - 100 ns

Clock Duty Cycle 15 50 70 %

0.65 * VIO - VIO

V

Input Voltage Limits, Square

Wave, DC-coupled

Input Impedance 1 - -

Input Capacitance - - 5 pF

Rise and Fall Time - - 100 ns

Phase Noise @ 1 kHz offset - - -125 dBc/Hz

Jitter, Integrated over 300 to 15000 Hz - - 1 Hz

1. The slow digital clock is a fail-safe input.

IH

VIL 0 - 0.35 * VIO

V

M

www.RFM.com Technical support +1.972.448.3700 Page 13 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 14

Preliminary and RFM Confidential

WLAN Power-up Sequence

V B A T , 2 . 3 t o 5 . 5 V

V I O , 1 . 8 V

S L O W C L K

W L _ E N

D C _ R E Q

D C 2 D C , 1 . 8 V

< 1 0 0 µ s

C L K _ R E Q

S D I O C L K

W L A N _ I R Q

F

R E F

T 1 T 2

T

W A K E U P

The following sequence describes device power up from shutdown. Only the WLAN Core is enabled; the BT core is disabled.

1. No signals are allowed on the IO pins if no IO power supplied, because the IOs are not fail-safe. Exceptions are CLQ_REQ,

SLEEP_CLK, XTALP, and PCM_xxx, which are fail-safe and can tolerate external voltages with no VIO and DC2DC.

2. VBAT,VIO and SLEEP_CLK must be available before WLAN ENABLE.

3. T

The duration of T2 depends on:

Operating system

Host enumeration for the SDIO

PLL configuration

Firmware download

Releasing the core from reset

Firmware initialization

= T1+T2. The duration of T1 is the time from WLAN ENABLE high until F

WAKE-UP

is valid (55 ms typical).

REF

www.RFM.com Technical support +1.972.448.3700 Page 14 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 15

Preliminary and RFM Confidential

WLAN Power-down Sequence

V B A T , 2 . 3 t o 5 . 5 V

V I O , 1 . 8 V

S L O W C L K

W L _ E N

D C _ R E Q

D C 2 D C , 1 . 8 V

C L K _ R E Q

S D I O C L K

W L A N _ I R Q

1. DC_REQ will go low only if WLAN is the only core working. Otherwise if the BT core is working, it will stay high.

2. CLK_REQ will go low only if WLAN is the only core working. Otherwise if the BT core is working and using the F

high.

3. If WLAN is the only core that is operating, WLAN ENABLE must remain de-asserted for at least 64 µs before it is re-asserted.

it will stay

REF

www.RFM.com Technical support +1.972.448.3700 Page 15 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 16

Preliminary and RFM Confidential

Bluetooth Power-up Sequence

V B A T

V I O

S L E E P C L O C K

B T _ R E S E T X

D C _ R E Q

( i n t e r n a l )

D C 2 D C

( 1 . 8 V )

< 1 0 0 µ s

C L K _ R E Q

F

R E F

U A R T _ R T S

T 1

T

W A K E U P

The following sequence describes device power-up from shutdown. Only the BT core is enabled; the WLAN

are disabled.

1. No signals are allowed on the IO pins if no IO power supplied, because the IOs are not failsafe. Exceptions are CLK_REQ,

SLEEP_CLK, XTALP and PCM_xxx, which are failsafe and can tolerate external voltages with no VIO and DC2DC.

2. VIO and SLEEP_CLK must be stable before releasing BT ENABLE (BT_RESETX).

3. Fast clock must be stable maximum 55ms after BT ENABLE goes HIGH.

4. The duration of T1 is defined as the time from BT ENABLE=high until F

5. The duration of T

The WL1273L indicates completion of BT power up sequence by asserting RTS low. This occurs up to 100 ms after BT ENABLE

goes high.

is defined as the time from the rising edge of BT ENABLE to the falling edge of UART_RTS.

WAKE-UP

is valid (55 ms typical).

REF

www.RFM.com Technical support +1.972.448.3700 Page 16 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 17

Preliminary and RFM Confidential

Bluetooth Power-down Sequence

V B A T

V I O

S L E E P C L O C K

B T _ R E S E T X

D C _ R E Q

( i n t e r n a l )

D C 2 D C

( 1 . 8 V )

C L K _ R E Q

U A R T _ R T S

B l u e t o o t h i n a c t i v e

The DR-WLS1273L-102 indicates completion of BT power up sequence by asserting RTS low. This occurs up to 100 ms after BT

ENABLE (BT_RESETX) goes high.

www.RFM.com Technical support +1.972.448.3700 Page 17 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 18

Preliminary and RFM Confidential

Host Interface Combination

WLAN BT

4-bit SDIO UART

All core functions support automatic host-interface recognition. The user does not need to configure it in advance.

SDIO Interface Switching Characteristics, 25 pF Load Capacitance

Symbol Parameter Minimum Maximum Units

F

Clock Frequency 0 25 MHz

CLOCK

DC Low/High Duty Cycle 40 60 %

tWL Pulse Duration, Clock Low 10 ns

tWH Pulse Duration, Clock High 10 ns

t

Clock Rise Time 4.3 ns

TLH

t

Clock Fall Time 3.5 ns

THL

t

Set-up Time, Input Valid before Clock 5 ns

ISU

tIH Hold Time, Input Valid after Clock 5 ns

t

Delay Time, Clock Falling Edge to Output Valid 0 14 ns

ODLY1

t

Delay Time, Clock Falling Edge to Output Invalid 0 14 ns

SDIO Timing

ODLY2

C l o c k

I n p u t

O u t p u t

t

W L

0.7

0.2

t

T L H

t

T H L

t

t

I S U

O D L Y 1

t

W H

V

I H

V

I L

t

I H

V

I H

V

I L

t

O D L Y 2

V

O H

V

O L

www.RFM.com Technical support +1.972.448.3700 Page 18 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 19

Preliminary and RFM Confidential

SDIO Interface Read

C M D

( I n p u t / O u t p u t )

S D 0 - S D 3

( I n p u t / O u t p u t )

Symbol Parameter Minimum Maximum Units

SDIO Interface Write

tCR

tCC

tRC

tAC

R e a d C o m m a n d

Delay Time, Assign Relative Address or

Data Transfer Mode; Read command CMD invalid

to card response CMD valid

Delay Time, CMD command invalid to

CMD command valid

Delay Time, CMD response invalid to

CMD command valid

Access Time, CMD command invalid to

SD0-SD3 read data valid

t

C C

t

C R

C a r d R e s p o n s e

R e a d

t

A C

t

R C

C o m m a n d

2 64 Clock Cycles

8 - Clock Cycles

8 - Clock Cycles

8 - Clock Cycles

C M D

( I n p u t / O u t p u t )

S D 0 - S D 3

( I n p u t / O u t p u t )

C a r d R e s p o n s e

t

d 1

W r i t e C R C S t a t u s

t

d 2

Symbol Parameter Minimum Maximum Units

Td1

Td2

Delay Time, CMD Card Response Invalid to

SD0-SD3 Write Data Valid

Delay Time, SD0-SD3 Write Data Invalid to

CRC Status Valid

2 - Clock Cycles

2 2 Clock Cycles

B u s y

www.RFM.com Technical support +1.972.448.3700 Page 19 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 20

Preliminary and RFM Confidential

BT Audio CODEC/PCM Interface Switching Characteristics

A U D _ I N / F S Y N C _ I N

A U D _ O U T / F S Y N C _ O U T

PCM Master

Symbol Parameter Minimum Maximum Units

T

CLK

TW

tis

tih

top

top

PCM Slave

Symbol Parameter Minimum Maximum Units

T

CLK

TW

tis

tih

tis

tih

top

T

c l k

A U D _ C L K

t

t

i h

i s

Clock Period

High/Low Pulse Width

AUD_IN Setup Time

AUD_IN Hold Time

AUD_OUT Propagation Time, 40 pF Load

FSYNC_OUT Propagation Time, 40 pF Load

Clock Period

High/Low Pulse Width

AUD_IN Setup Time

AUD_IN Hold Time

FSYNC_IN Setup Time

FSYNC_IN Hold Time

AUD_OUT Propagation Time, 40 pF Load

T

W

t

o p

166.7 (6 MHz) 15625 (64 kHz) ns

50% of T

62.5 (16 MHz) ns

40% of T

CLK

25

0

0 10

0 10

CLK

8

0

8

0

0 21

ns

ns

www.RFM.com Technical support +1.972.448.3700 Page 20 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 21

Preliminary and RFM Confidential

UART Interface Timing

H C I _ R T S

t

1

H C I _ R X

H C I _ C T S

t

H C I _ T X

Symbol Parameter Condition Minimum Typical Maximum Units

BR

t5, t7

Baud Rate

Baud Rate Accuracy

CTS Low to TX_DATA

t3

CTS High to TX_DATA

t4

CTS High Pulse Width

t6

RTS Low to RX_DATA ON

t1

RTS High to RX_DATA OFF

t2

t

5

3

t

7

1 0 b i t s

Most Standard Rates 37.5 - 4000 kbps

Receive/Transmit -2.5 - 1.5 %

0 2 - µs

Hardware Flow Control - - 1 byte

1 - - bit

0 2 - µs

Interrupt set to 1/4 FIFO - - 16 byte

t

2

t

6

t

4

DR-WLS1273L-102 IRQ Operation

1. The default state of the WLAN_IRQ prior to firmware initialization is 0.

2. During firmware initialization, the WLAN_IRQ is configured by the SDIO module; a WLAN_IRQ

changes its state to 1

3. A WLAN firmware interrupt is handled as follows:

(a) The WLAN firmware creates an Interrupt-to-Host, indicated by a 1-to-0 transition on the WLAN_IRQ

line (host must be configured as active-low or falling-edge detect).

(b) After the host is available, depending on the interrupt priority and other host tasks, it masks the

firmware interrupt. The WLAN_IRQ line returns to 1 (0-to-1 transition on the WLAN_IRQ line).

(c) The host reads the internal register status to determine the interrupt sources - the register is cleared

after the read

(d) The host processes in sequence all the interrupts read from this register

(e) The host unmasks the firmware interrupts.

4. The host is ready to receive another interrupt from the WLAN device.

DR-WLS1273L-102 BT Function Low Power Mode Protocols

The DR-WLS1273L-102 includes a mechanism that handles the transition between operating mode and

deep sleep low-power mode. The protocol is done via the UART and is known as eHCILL (enhanced HCI

Low Level) power management protocol. This protocol is backward compatible with the

BRF6150/BRF6300 /BRF6350/WL1273 HCILL Protocol, so a Host that implements the HCILL for

BRF6150/BRF6350 does not need to change anything in order to work with the DR-WLS1273L-102. The

"Enhanced" portion of the HCILL introduces changes that allow a simpler host implementation of this protocol. See BT-SW-0024 (BRF Enhanced HCILL 4 wire Power Management Protocol). In addition to the

HCILL protocol, the DR-WLS1273L-102 also supports the power management schemes inherent in the

UART H5 transport layers.

www.RFM.com Technical support +1.972.448.3700 Page 21 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 22

Preliminary and RFM Confidential

DC and RF Characteristics for IEEE 802.11b Operation, 11 Mbps, 2.4 GHz

Conditions: 25 C, VBAT=3.6 V, VIO=1.8 V, VDD_LDO_IN_CLASS1P5 connected to VBAT

System Specifications Data

Standard IEEE802.11b

Mode DSSS/CCK

Frequency, Spacing 2412 to 2462 MHz, 5 MHz

Data Rate 1, 2, 5.5, 11 Mbps

DC Specifications Minimum Typical Maximum Units

DC Current:

TX Mode - 265 350 mA

RX Mode - 100 150 mA

Sleep Mode - 89 200 µA

Transmitter Specifications Minimum Typical Maximum Units

RF Output Power 16 18 20 dBm

Spectrum Mask:

1st Sidelobes - -46 -30 dBr

2nd Sidelobes - -55 -50 dBr

Power-on and Power-off Ramp - 0.06 2.00 µs

RF Carrier Suppression - - -15 dB

Modulation Accuracy (EVM) - 7 35 %

Out-of-Band Spurious Emissions:

0.03 to 1 GHz - -96 -36 dBm

1 to 12.75 GHz - -55 -30 dBm

1.8 to 1.9 GHz - -96 -47 dBm

Receiver Specifications Minimum Typical Maximum Units

Sensitivity:

Minimum Input Level, 11 Mbps, FER 8%

Maximum Input Level, FER 8%

Adjacent Channel Rejection, FER 8%

- -87 -76 dBm

-10 - - dBm

35 - - dB

www.RFM.com Technical support +1.972.448.3700 Page 22 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 23

Preliminary and RFM Confidential

DC and RF Characteristics for IEEE 802.11g Operation, 54 Mbps, 2.4 GHz

Conditions: 25 C, VBAT=3.6V, VIO=1.8V, VDD_LDO_IN_CLASS1P5 is connected to VBAT

System Specifications Data

Standard IEEE802.11g

Mode OFDM

Frequency, Spacing 2412 to 2462 MHz, 5 MHz

Data Rate 6, 9, 12, 24, 36, 48, 54 Mbps

DC Specifications Minimum Typical Maximum Units

DC Current:

TX Mode - 180 270 mA

RX Mode - 100 150 mA

Sleep Mode - - 200 µA

Transmitter Specifications Minimum Typical Maximum Units

RF Output Power 11 13 15 dBm

Spectrum Mask:

at fC ±11 MHz - -31 -20 dBr

at fC ±20 MHz - -39 -28 dBr

at fC ≥ ±30 MHz - -50 -40 dBr

Constellation Error (EVM) - -34 -25 dB

Out-of-Band Spurious Emissions:

0.03 to 1 GHz - -96 -36 dBm

1 to 12.75 GHz - -58 -30 dBm

1.8 to 1.9 GHz - -96 -47 dBm

Receiver Specifications Minimum Typical Maximum Units

Sensitivity:

Minimum Input Level, 54 Mbps, PER 10%

Maximum Input Level, PER 10%

Adjacent Channel Rejection, 54 Mbps, PER 10%

- -74 -65 dBm

-20 - - dBm

-1 - - dB

www.RFM.com Technical support +1.972.448.3700 Page 23 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 24

Preliminary and RFM Confidential

DC and RF Characteristics for IEEE 802.11a Operation, 54 Mbps, 5 GHz

Conditions: 25 deg C, VBAT=3.6 V, VIO=1.8 V, VDD_LDO_IN_CLASS1P5 is connected to VBAT

System Specifications Data

Standard IEEE802.11a

Mode OFDM

Frequency, Spacing 5180 to 5320 MHz, 20 MHz

Data Rate 6, 9, 12, 24, 36, 48, 54 Mbps

DC Specifications Minimum Typical Maximum Units

DC Current:

TX Mode - 213 270 mA

RX Mode - 100 150 mA

Transmitter Specifications Minimum Typical Maximum Units

RF Output Power 10 12 14 dBm

Spectrum Mask:

at fC ±11 MHz - -31 -20 dBr

at fC ±20 MHz - -39 -28 dBr

at fC ≥ ±30 MHz - -50 -40 dBr

Constellation Error (EVM) - -30 -25 dB

Out-of-Band Spurious Emissions:

0.03 to 1 GHz - -92 -36 dBm

1 to 12.75 GHz - -54 -30 dBm

1.8 to 1.9 GHz - -96 -47 dBm

Receiver Specifications Minimum Typical Maximum Units

Sensitivity:

Minimum Input Level, 54 Mbps, PER 10%

Maximum Input Level, PER 10%

Adjacent Channel Rejection, 54 Mbps, PER 10%

- -72 -65 dBm

-30 - - dBm

-1 - - dB

www.RFM.com Technical support +1.972.448.3700 Page 24 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 25

Preliminary and RFM Confidential

DC and RF Characteristics for IEEE 802.11n Operation, 65 Mbps, 2.4 GHz

Conditions: 25 C, VBAT=3.6 V, VIO=1.8 V, VDD_LDO_IN_CLASS1P5 is connected to VBAT

System Specifications Data

Standard IEEE802.11n-2.4G

Mode OFDM

Frequency, Spacing 2412 to 2462 MHz, 5 MHz

Data Rate 6.5, 13, 19.5, 26, 39, 52, 58.5, 65 Mbps

DC Specifications Minimum Typical Maximum Units

DC Current:

TX Mode - 180 250 mA

RX Mode - 100 150 mA

Transmitter Specifications Minimum Typical Maximum Units

RF Output Power 10 12 14 dBm

Spectrum Mask:

at fC ±11 MHz - -30 -20 dBr

at fC ±20 MHz - -33 -28 dBr

at fC ≥ ±30 MHz - -49 -45 dBr

Constellation Error (EVM) - - -28 dB

Out-of-Band Spurious Emissions:

0.03 to 1 GHz - -95 -36 dBm

1 to 12.75 GHz - -71 -30 dBm

1.8 to 1.9 GHz - -96 -47 dBm

Receiver Specifications Minimum Typical Maximum Units

Sensitivity:

Minimum Input Level, 65 Mbps, PER 10%

Maximum Input Level, PER 10%

- -70 -64 dBm

-20 - - dBm

www.RFM.com Technical support +1.972.448.3700 Page 25 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 26

Preliminary and RFM Confidential

DC and RF Characteristics for IEEE 802.11n Operation, 65 Mbps, 5 GHz

Conditions: 25 C, VBAT=3.6 V, VIO=1.8 V, VDD_LDO_IN_CLASS1P5 is connected to VBAT

System Specifications Data

Specification IEEE802.11n-5G

Mode OFDM

Frequency, Spacing 5180 to 5320 MHz, 5 MHz

Data Rate 6.5, 13, 19.5, 26, 39, 52, 58.5, 65 Mbps

DC Specifications Minimum Typical Maximum Units

DC Current:

TX Mode - 225 270 mA

RX Mode - 107 150 mA

Transmitter Specifications Minimum Typical Maximum Units

RF Output Power 10 12 14 dBm

Spectrum Mask:

at fC ±11 MHz - -30 -20 dBr

at fC ±20 MHz - -34 -28 dBr

at fC ≥ ±30 MHz - -49 -45 dBr

Constellation Error (EVM) - TBD TBD dB

Out-of-Band Spurious Emissions:

0.03 to 1 GHz - -96 -36 dBm

1 to 12.75 GHz - -55 -30 dBm

1.8 to 1.9 GHz - -96 -47 dBm

Receiver Specifications Minimum Typical Maximum Units

Sensitivity:

Minimum Input Level, 65 Mbps, PER 10%

Maximum Input Level, PER 10%

- -67 -64 dBm

-30 - - dBm

www.RFM.com Technical support +1.972.448.3700 Page 26 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 27

Preliminary and RFM Confidential

DC and RF Characteristics for Bluetooth Operation, 2.4 GHz

Conditions: 25 C, VBAT=3.6 V, VIO=1.8 V, VDD_LDO_IN_CLASS1P5 is connected to VBAT

System Specifications Data

Bluetooth Standard Version 4.0

Channel Spacing 1 MHz

Number of RF Channels 79

Power Class 1.5

Operating Mode

DC Specifications Minimum Typical Maximum Units

DC Current:

DH1 Packet, 50% RX/TX Slot Duty Cycle - 38 60 mA

DH3 Packet, 50% RX/TX Slot Duty Cycle - 45 60 mA

DH5 Packet, 50% RX/TX Slot Duty Cycle - 48 60 mA

Transmitter Specifications Minimum Typical Maximum Units

RF Output Power 4.5 8.5 - dBm

Frequency Range, RX/TX 2400 to 2483.5 MHz

-20 dB Bandwidth - 0.925 1 MHz

Adjacent Channel Power1:

M - N = 2 - -45 -20 dBm

M - N ≥ 3 - -46.5 -40 dBm

Modulation Characteristics:

Modulation f1 average

Modulation f2 average

Modulation f2 average / f1 average

Initial Frequency Tolerance -75 - +75 kHz

Frequency Drift:

1 Slot -25 +11 +25 kHz

3 Slots -40 +11.5 +40 kHz

5 Slots -40 +11.5 +40 kHz

Maximum Frequency Drift Rate -20 ±5 +20 kHz/50 µs

Out-of-Band Spurious Emissions:

0.03 to 1 GHz - -64 -36 dBm

1 to 12.75 GHz - -47 -30 dBm

1.8 to 1.9 GHz - - -47 dBm

5.15 to 5.30 GHz - - -47 dBm

ERD Relative Power -4 -0.2 1 dB

EDR Carrier Frequency Stability and

Modulation Accuracy, /4-DQPSK:

RMS DEVM - 4 20 %

99% DEVM - - 30 %

Peak DEVM - 9 35 %

Frequency hopping spread spectrum, pseudorandom hopping pattern,

time division multiple access on transmit or receive,

frequency hop after each RX/TX cycle

140 160 175 kHz

115 132 - kHz

0.8 0.9 - -

-75 - +75 kHz

-10 - +10 kHz

-75 - +75 kHz

www.RFM.com Technical support +1.972.448.3700 Page 27 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 28

Preliminary and RFM Confidential

Transmitter Specifications (continued) Minimum Typical Maximum Units

EDR Carrier Frequency Stability and

Modulation Accuracy, 8DQPSK:

RMS DEVM - 4 13 %

99% DEVM - - 20 %

Peak DEVM - 11.5 25 %

Receiver Specifications Minimum Typical Maximum Units

Sensitivity, BER 0.1%:

2402 MHz - -90 -70 dBm

2441 MHz - -90 -70 dBm

2480 MHz - -90 -70 dBm

C/I Performance, BER 0.1%2:

Co-channel ratio, -60 dBm Input - 8 11 dB

1 MHz ratio, -60 dBm Input - -8 0 dB

2 MHz ratio, -60 dBm Input - -46 -30 dB

3 MHz ratio, -67 dBm Input - -49 -40 dB

Image ratio, -67 dBm Input - -26 -9 dB

Image ±1 MHz ratio, -67 dBm input - 47 -20 dB

Blocking Performance, BER 0.1%3:

30 to 2000 MHz -10 - - dBm

2000 to 2400 MHz -27 - - dBm

2500 to 3000 MHz -27 - - dBm

3000 to 12750 MHz -10 - - dBm

Intermodulation Performance, -64 dBm Input,

BER 0.1%

Maximum Input Level -20 - - dBm

EDR Sensitivity, BER 0.01%:

/4-DQPSK

8DPSK - -83.5 -70 dBm

1. Up to three spurious responses within Bluetooth limits are allowed.

2. Up to five spurious responses within Bluetooth limits are allowed.

3. Up to twenty-four spurious responses within Bluetooth limits are allowed.

-75 - +75 kHz

-10 - +10 kHz

-75 - +75 kHz

-39 -11 - dBm

- -90 -70 dBm

www.RFM.com Technical support +1.972.448.3700 Page 28 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 29

Preliminary and RFM Confidential

Storage Conditions

This product should be stored without opening the packing in an ambient temperature range of 5 to 35 C

and humidity range from 20 to 70% RH, and be used within six months of receipt. Packing materials can

be deformed at temperatures above 40 C. If the product is not used six months or more after receipt, its

solderbility should be tested before being used. The product should be stored in non-corrosive gas. Any

excess mechanical shock such as sticking the packing materials with a sharp object or dropping the

product, etc., must be avoided in order not to damage the packing materials. This product is applicable to

MSL3, based on JEDEC Standard J-STD-020.

After the packing is opened, the product should be stored at an ambient temperature below 30 C and at

humidity level less than 60% RH. The product should be used within 168 hours. If the color of the indicator in the packing has changed, the product should be baked before soldering at 125 to 130 C for 24

hours. The products should be baked on the heat-resistant tray, as the tape and reel materials are not

heat-resistant.

Handling Conditions

Use care in handling or transporting this product as excessive stress or mechanical shock can crack or

break the product. Do not touch this product with bare hands as this can result in poor solderability.

Standard PCB Design (Land Pattern and Dimensions)

All the ground terminals should be connected to the ground patterns, and unconnected terminals should

be soldered to unconnected PCB pads for mechanical strength. The best land pattern depends on the

pattern generation method, grounding method, land dimensions, land forming method of the unconnected

terminals and the PCB material and thickness. Contact RFM technical support if you have any questions

about adapting the recommend land pattern to your application specifics or before using non-standard

land dimensions, etc.

Module PCB Placement

This product can be broken by uneven forces from a worn-out chucking locating claw or a suction nozzle.

To prevent damage, be sure to follow the specifications for the maintenance of the chip placer being

used. Be aware that mechanical chucking can damage this product when used for mounting it on a PCB.

Module Soldering

Preheat so that the temperature difference T between the solder and module surface is less than

130 C. If the module is immersed in solvent after mounting, care should be taken to limit the temperature

difference to 100 C. These provisions are necessary to prevent damage due to excessive differential expansion. Contact RFM technical support if you have any questions about soldering methods or are considering other soldering conditions.

www.RFM.com Technical support +1.972.448.3700 Page 29 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 30

Preliminary and RFM Confidential

Using a Soldering Iron

A soldering iron of 18 W or less, using a ceramic heater is recommended. The soldering iron tip diameter

should be 3 mm maximum, and the tip temperature should be 350 C or less. The iron contact time at

each terminal should be limited to 3 seconds. The soldering iron should be applied to the land pattern

next to the module terminal, not directly on the module ceramic substrate.

Example Reflow Soldering Profile

Use rosin flux or a weakly active flux with a chlorine content of 0.2 wt% or less.

www.RFM.com Technical support +1.972.448.3700 Page 30 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Page 31

Preliminary and RFM Confidential

Solder Paste Amount and Assembly Standards

Ensure that solder is applied smoothly to a minimum height of 0.2 to 0.5 mm at the end surface of the

module’s external pads. If too much or little solder is applied, the mechanical strength can be insufficient.

P r o p e r A m o u n t o f S o l d e r P a s t e

M o d u l e

S o l d e r

F i l l e t

U n a c c e p t a b l e A s s e m b l y

C h a s s i s

S a t i s f a c t o r y A s s e m b l y u s i n g S o l d e r M a s k i n g

S o l d e r G r o u n d

W i c k i n g t o M o d u l e

S o l d e r M a s k

B l o c k s W i c k i n g

t o M o d u l e

S o l d e r W i c k i n g

f r o m W i r e o f

L e a d e d C o m p o n e n t

S o l d e r M a s k

B l o c k s W i c k i n g t o

C o m p o n e n t L e a d

P C B

L a n d

P C B

S u b s t r a t e

H e i g h t

S o l d e r i n g

I r o n

S o l d e r M a s k

W i r e L e a d o f

C o m p o n e n t

M o u n t e d L a t e r

Cleaning

This product is moisture sensitive and not suitable for water-based cleaning.

Operational Conditions

This product is designed to work under normal environmental conditions - ambient temperature, humidity

and pressure. If this product is used under the following circumstances, erratic operation or complete failure can occur:

Atmosphere containing a corrosive gas ( Cl2, NH3, SOx, NOx, etc.)

Atmosphere containing a combustible or volatile gas

Dusty location

Location with direct sunlight

Location subject to water splashes, high humidity or condensation

If the customer’s application could subject a module to one or more of the above conditions, consult with

RFM technical support before use. Do not apply static electricity or excessive voltage while assembling

this module on a PCB or testing it.

Power Supply Voltages

Power supply voltages applied to this product must conform to the specifications for the module. Contact

RFM technical support if you have any questions about power supply requirements.

www.RFM.com Technical support +1.972.448.3700 Page 31 of 31

© 2012 by RF Monolithics, Inc. E-mail: tech_sup@rfm.com DR-WLS1273L-102 Data Sheet - 12/13/12

Loading...

Loading...