Page 1

WM54F

Wall Mount Fan

Manual for use and maintenance

including assembling instructions

with Damper Door

+CE Declaration of conformity

WM54 Fiberglass Wall Mount Fan

wi

th Damper Door

Air extraction fan

A

g/MIT/UmGB-2483-07/17 Rev 1.0

1

Page 2

WM54F Fiberglass Wall Mount Fan with Damper

Manual for use and Maintenance

Thank You:

Thank you for purchasing a Munters WM54F Fiberglass with Damper! Munters equipment is designed to be the

highest performing, highest quality equipment you can buy. With the proper installation and maintenance it will

provide many years of service.

Please Note:

To achieve maximum performance and insure long life from your Munters product it is essential that it be installed

and maintained properly. Please read all instructions carefully before beginning installation.

This manual for use and maintenance is an integral part of the apparatus together with the attached technical

documentation and has been produced with reference to Directive 2006/42/EC, paragraph A, Annex II, and

to ErP Directive 2009/125/CE Commission Regulation 327/2011.

This document is destined for the user of the apparatus: it may not be reproduced in whole or in part, committed

to computer memory as a file or delivered to third parties without the prior authorisation of the assembler of the

system. Munters Italy S.p.A. reserves the right to effect modifications to the apparatus in accordance with

technical and legal developments and to make alterations to specifications, quantities, etc.,for production or

other reasons, subsequent to publication.

Conditions and Limitations:

Products and Systems involved in a warranty claim under the “Warranty Claims and Return Policy” shall have

been properly installed, maintained and operated under competent supervision, according to the instructions

provided by Munters.

Malfunction or failure resulting from misuse, abuse, negligence, alteration, accident or lack of proper installation

or maintenance shall not be considered a defect under the Warranty.

2

Page 3

Index

Chapters Page

1. CE Declaration

2. Unpacking the Equipment

2.1 Parts List

2.2 Fan Dimensions

2.3 Tools for Installation

3. Installation Instructions

3.1 Install

3.2 Damper Door Installation

3.3 Cone Installation

3.4 Motor Mounting

4. Electrical Wiring

4.1 Recommended Wiring

5. Operation

4

6

6

8

8

9

9

15

18

26

27

28

29

6. Maintenance

7. Winterizing

7.1 Winterizing

7.2 Winter Weather Protection

8. Troubleshooting

9. Exploded View and part list

10. Warranty

WARNING

!!

All the components and spare parts MUST be storaged in dry and clean environment.

30

32

32

32

33

34

37

3

Page 4

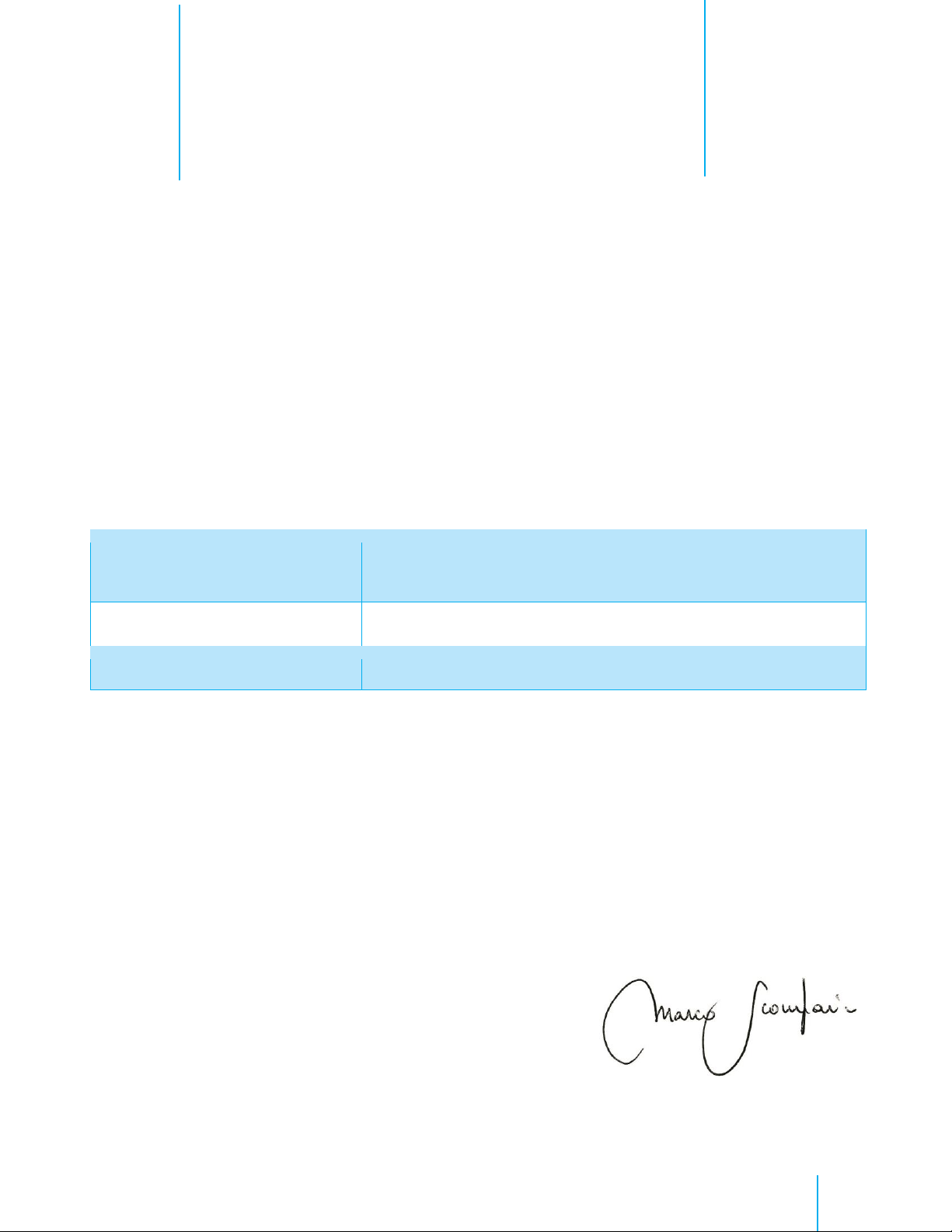

CE Declaration

1.

CE Declaration of conformity

(complies with Subparagraph A Annex II Directive 2006/42/EC)

Munters Italy S.pA.

with registered officies in Strada Piani, 2 - 18027 Chiusavecchia (IM) - Italy

(Company Registration nr. 00081050080)

declares on its own responsability that the apparatus:

Designation

Model

Year of Manufacture

conforms with the essential safety requirements stated by Apparatus Directive 2006/42/EC

and performance requirements comply with the ErP Directive 2009/125/CE,

with particular reference to the following provisions: UNI EN 953:2009, UNI EN ISO 12100:2010,

UNI EN ISO 12499:2009, UNI EN ISO 13857:2008, CEI EN 60204-1:2006 (CEI 44-5)

Fan designed for moving air to control temperature

and humidity in livestock.

WM54F

2017

UNI EN ISO 5801:2009

Chiusavecchia, 5th July 2017

Marco Scomparin

Legal Representative

4

Page 5

CE DeclarationChapter 1

1.1 Disclaimer

Munters reserves the right to make alternations to specifications, quantities, dimensions etc. for production or

other reasons, subsequent to publication. The information contained

herein has been prepared by qualified

experts within Munters. While we believe the information is accurate and complete, we make no warranty or

representation for any particular purposes. The information is offered in good faith and with the understanding

that any use of the units or accessories in breach of the directions and warnings in this document is at the sole

discretion and risk of the user.

1.2 Introduction

In order to realize the full benefit from this product it is important that it is installed, commissioned and operated

correctly. Before installation or using the fan, this manual should be studied carefully. It is also recommended that it

is kept safely for future reference. The manual is intended as a reference for installation, commissioning and

day-to-day operation of the Munters fans.

1.3 Data for Fan Eco Design Directive

optional

Product information requirements* →

(according to ANNEX I -3.2 of regulation)

Fan description(*

WM54F 1.5hp 3ph 50Hz OS

WM54F 2hp 3ph 50Hz OS

* Fans tested are configured according to COMMISSION REGULATION (EU) No 327/2011 of 30th March 2011 - ANNEX II - 1.5. Efficiency values, according to

Commission Regulation (EU) 327/2011, refers to exhaust fans only.

)

1 2 3

Overall efficiency η%

Efficiency grade

3

9,3

A static

A

static

39,8

4

Measurement category

Efficiency category

44,9

44,4 35,4

34,4 no 1310 30562 60,71

5

Target efficiency grade 2015

no

6

a

VSD must be installed with the fan

Motor power input at optimum

1852

6b

Flow rate at optimum energy

energy efficiency [W]

3

4755 76,

6c

efficiency [m3/h]

Pressure at optimum energy

efficiency [Pa]

510 1

35 566 1

7

RPM at optimum energy efficiency

8

Speific ratio

5

Page 6

Unpacking the Equipment

2.1 Parts List

Each WM54F Fan Requires:

1 – 54” Fiberglass Orifice

1 – 54” Propeller

1 – Central Support

1 – Motor

1 – Motor Pulley

1 – Drip Shield

1 – Main Frame Assembly

1 – Plastic Door Assembly

4 – Plastic Cone Sections

1 – Round safety mesh

1 – Flat safety mesh

1 – Motor slide

1 – Tensioner Bracket

4 – Cone Support Brackets

4 – Cone/Strut Mounting Bracket

1 – V-Belt (A61)

1 – Hub with Bearings & Shaft

1 – Central pulley

1 – Tensioner Pulley

1 – Belt Tensioner

1 – Motor Stiffener Bracket

2 – Tension spring

1 – Cable

Bolts and nuts

2.

6

Page 7

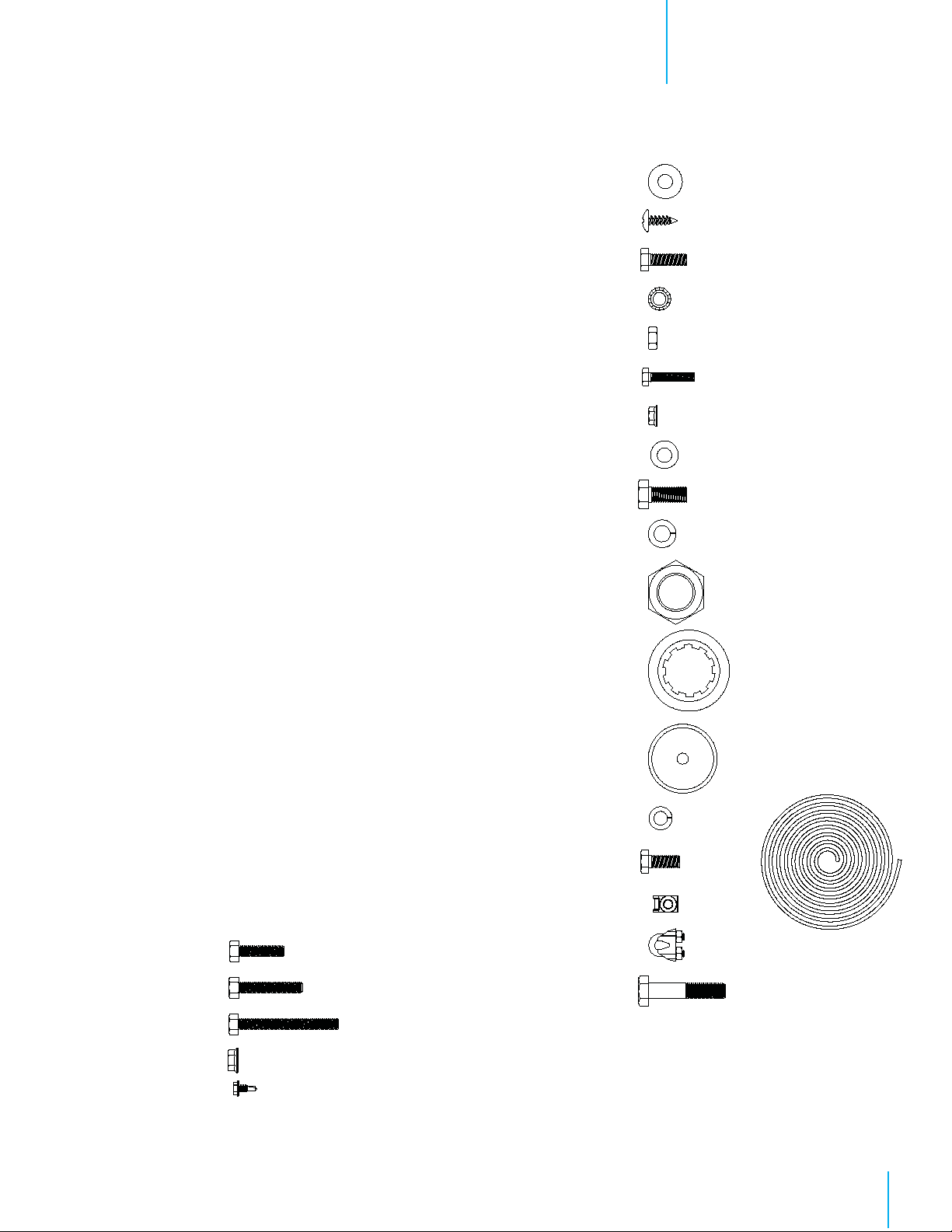

Bolts and nuts for 1 – WM54F Fan Installation

[A]….12 – Ø8x32 Washer

[B]…. 2 – Ø6.3x19 Self-tapping Screw

[C]…. 4 – M8x25 Hex Screw

[D]…. 4 – Ø8 Ext Toothed Washer

[E]…. 4 – M8 Hex Nut

[F]…. 4 – M6x30 Hex Screw

[G]…. 4 – M6 Hex Nut with Flange

[H]…. 4 – Ø8x24 Washer

[I]….. 1 – M10x25 Hex Bolt

[J]…. 1 – Spring Washer D10

[K]….. 1 – M25 Hex Nut

[L]…. 1 – Waterproof Distance Piece

[M]…. 1 – Cup Cover Nut

[N]…. 1 – Spring Washer D8

[O]…. 1 – M8x20 Hex Screw

[P]…..12 – Plastic Clip

[Q]…..1 – Cable

[R]…. 3 – Cable Clamp

[S]…. 1 – M10x50 Hex Bolt

Unpacking the EquipmentChapter 2

[A]

[B]

[C]

[D]

[E]

[F]

[G]

[H]

[I]

[J]

[AA]….18 – Ø8x30 Hex Screw

[BB]….. 4 – Ø8x45 Hex Screw

[CC]….. 7 – Ø8x65 Hex Screw

[DD]….37 – M8 Hex Nut with Flange

[EE]….. 4 – Ø4.8x13 Self-tapping Screw

[AA]

[BB]

[CC]

[K]

[L]

[M]

[N]

[O]

[P]

[R]

[S]

[Q

]

[DD]

[EE]

7

Page 8

Chapter 2

Unpacking the Equipment

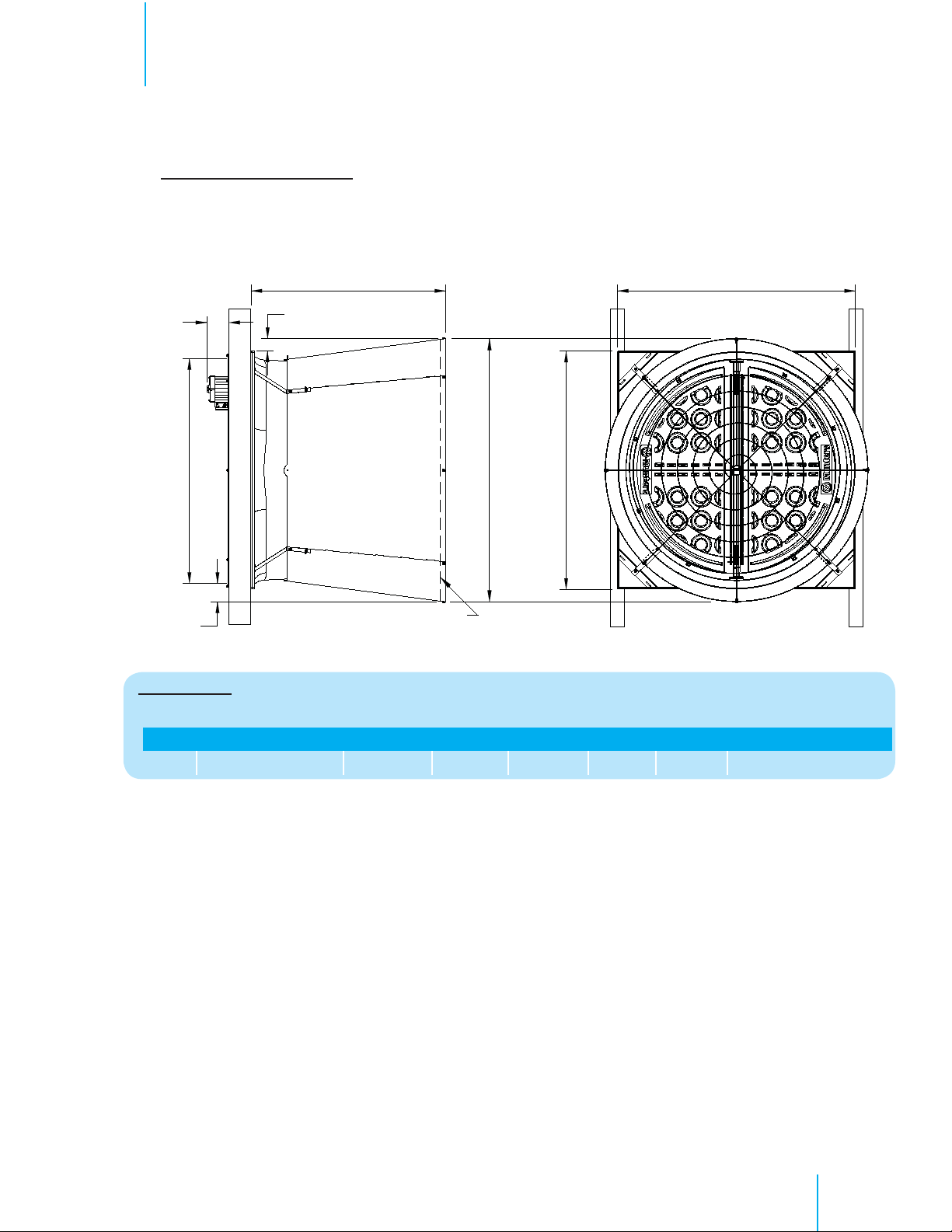

2.2 FAN DIMENSIONS

Fan Specifications: 50Hz shown

Voltage: 230/400 VAC

Phase: 3

AB

C

Wall Opening (W.O.)

F

E

A

D - Dia.

Guard

Dimensions:

Size A B C D - Dia. E F Wall Openings

54”

1524 x 1524

1245

185 max 1684 1435 x 1435

81

121

2.3 TOOLS REQUIRED FOR INSTALLATION

Pneumatic screwdriver

17mm Spanner

8mm Long Spanner

10mm Long Spanner

13mm Long Spanner

36mm Spanner

Screw Head Adaptor

Small Hammer

10mm Combination Spanner

Screwdriver

17mm Combination Spanner

8

Page 9

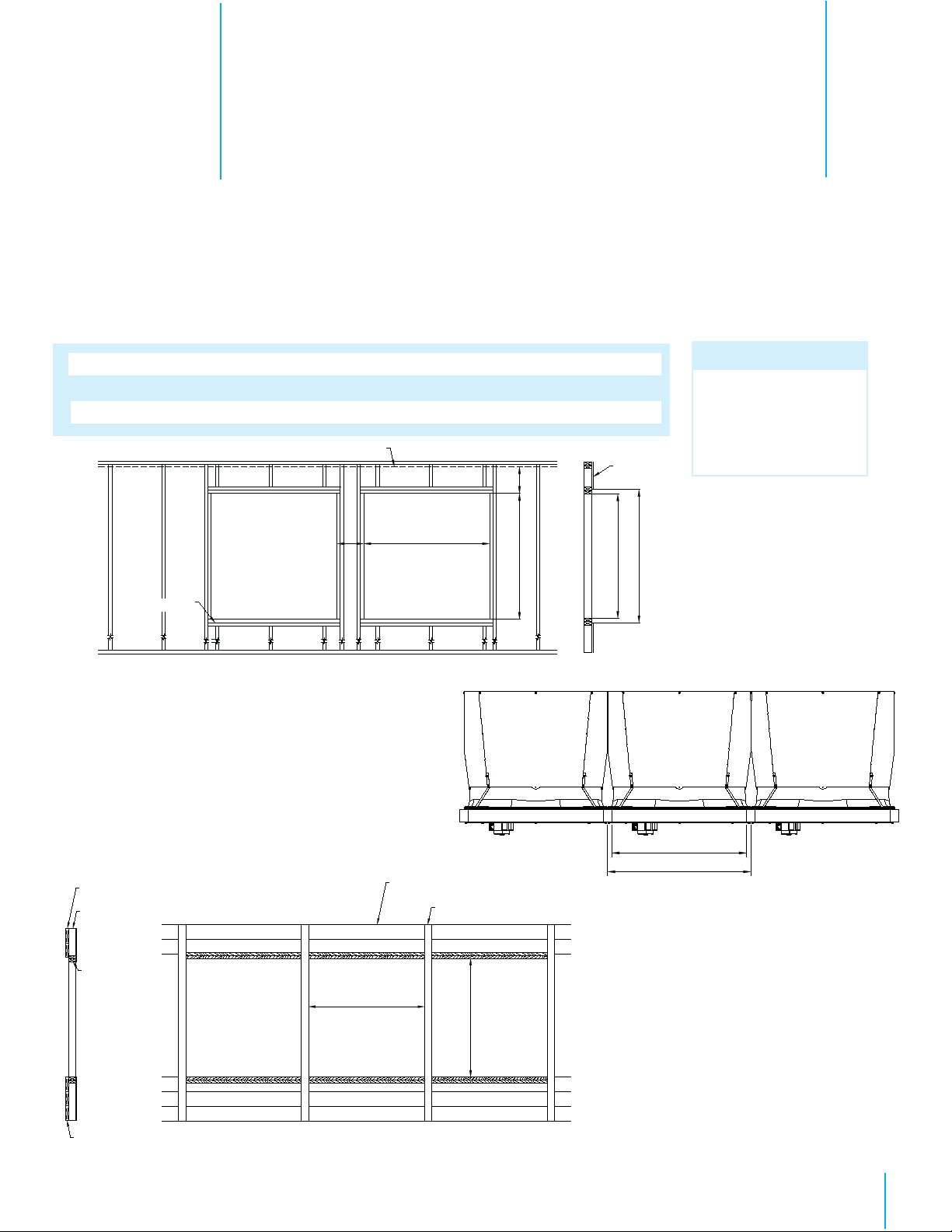

3.1 INSTALL

Step 1

Construct framed opening to correct size according to the Wall Opening listed in chart A below. See Figure 1A

and 1B. When installing exterior sheet metal before fan, leave 50mm of the framing exposed on all sides so the

orifice can mount flush to the frame.

Chart A

Installation Instructions

3.

Fan Dia.

54”

Wall Opening

(W. x H.)

1435 x 1435

Framing

Minimum Spacing

'Z'

305 recommended; 90 minimum

Ceiling

See minimum

spacing notes in

Chart A

Z

(see chart A)

Figure 1A Frame Construction

Center To Center

Dimension

1524

Minimum

Note:

Damper doors should

be carefully set aside

out of direct sunlight

until needed.

Stud Wall

305

W

H

(see chart A)

W x H Wall Opening

Sheet Metal Opening

Top View

50 x 200 Header boards

100 x 100 or

100 x 150 Posts

50 x 100

Framing

50 x 200 Banner boards

Figure 1B 100x100 Post Construction - Elevation View

W

(see chart A)

W

W O.C

Ceiling

100 x 100 or 100 x 150 Posts

H

(see chart A)

9

Page 10

Chapter 3

Installation Instructions

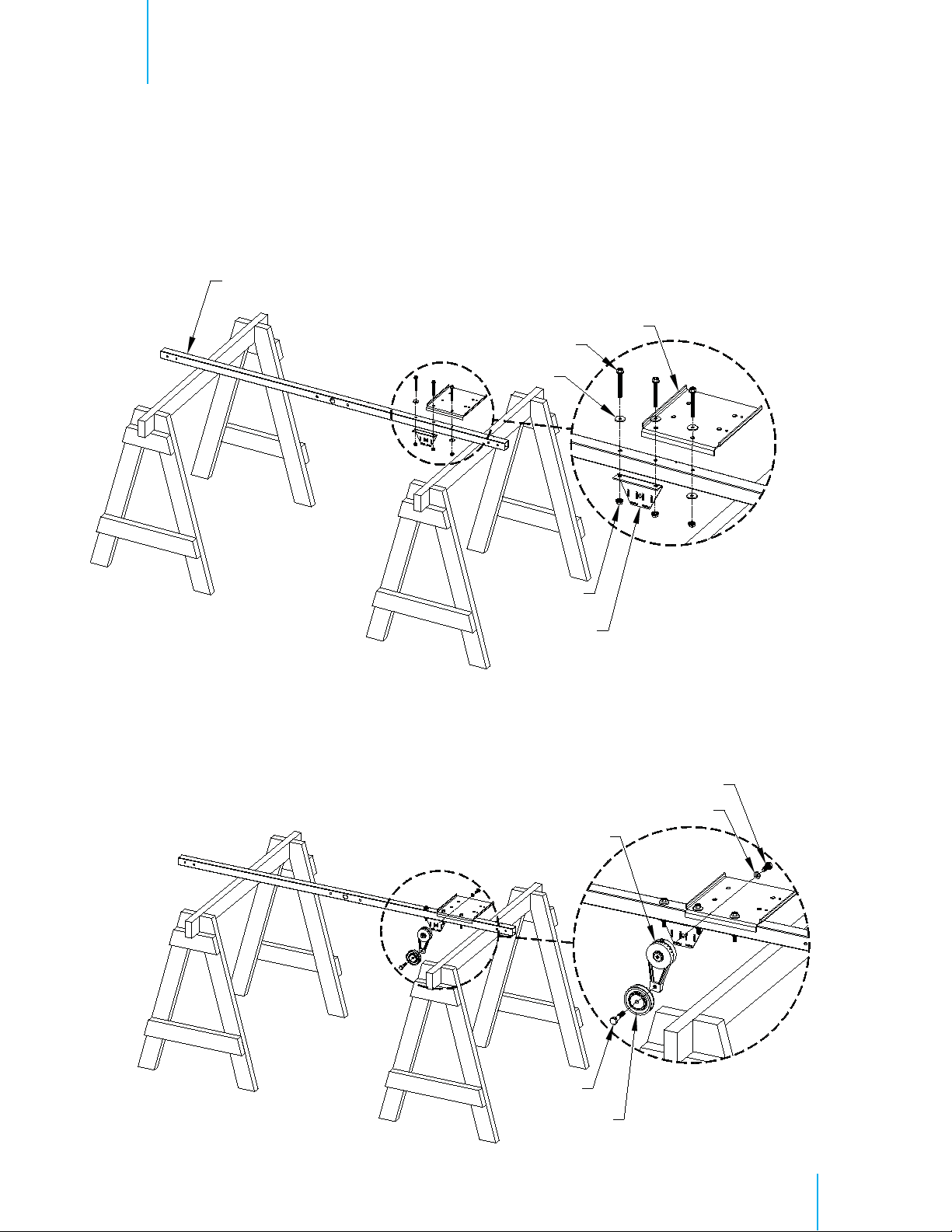

Step 2

Place the Central Support on saw horses or a flat work surface. The large center hole should be pointing

horizontally. Attach the Motor Slide and the Tensioner Bracket to the Central Support using (3) Long Bolts

[CC], (4) Washers [A] and (3) Nuts [DD]. The Motor Slide and the Tensioner Bracket share the middle

hole. See Figure 2A.

Central Support

Motor Slide

Long Bolts [CC]

Washer [A]

Nuts [DD]

Tensioner Bracket

Figure 2A

Step 2B

Attach the 3” Tensioner Pulley to the Belt Tensioner using Bolt [S]. Then attach the Belt Tensioner assembly

to the Tensioner Bracket using Bolt [I] and Washer [J]. Finger tighten only at this time. See Figure 2B.

Bolt [I]

Washer [J]

Belt Tensioner

Figure 2B

Bolt [S]

Tensioner Pulley

10

Page 11

Chapter 3

Installation Instructions

Step 3

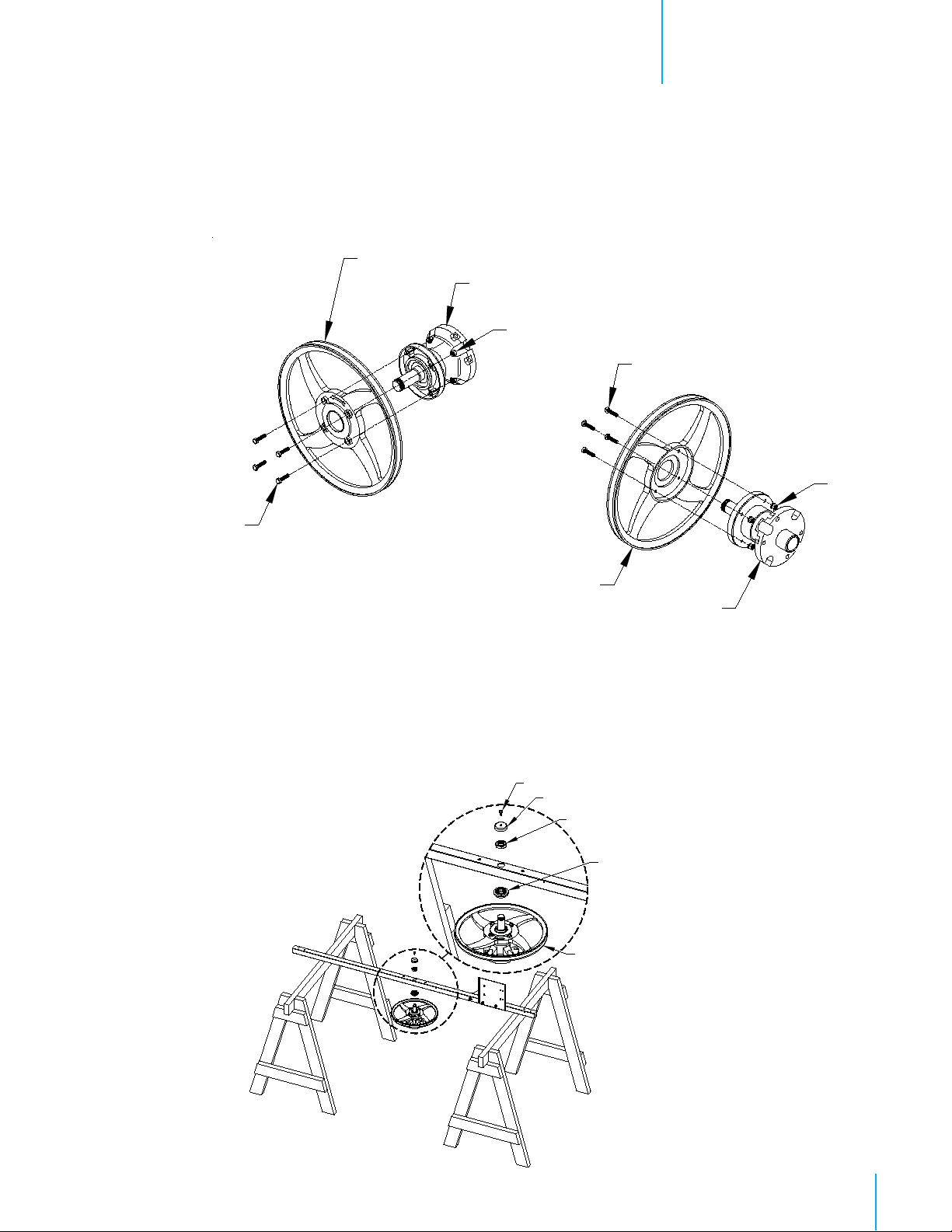

Attach Central Pulley to Hub using (4) Bolts [F] and Nuts [G] and tighten to 14 Nm.. See Figure 3.

Central Pulley

Hub

Nut [G]

Bolt [F]

Bolt [F]

Nut [G]

Central Pulley

Figure 3

Hub

Step 4

Rotate the Central Support on the saw horses so the Motor Slide is pointing up. Then slide the Waterproof

Distance Piece [M] over the hub shaft as shown in Figure 4. Attached the Pulley/Hub Assembly to the

Central Support using (1) Hex Nut [K] and tighten to 60 Nm. See Figure 4. Then place the Cup Cover Nut

[M] over the Hex Nut and fasten in place with (1) Tapping Screw [B]. See Figure 4. Set aside the

Support Assembly for use in a later step.

Tapping screw [B]

Cap Cover [M]

Hex Nut [K]

Waterproof Distance Piece [L]

Hub Assembly

Figure 4

1

1

Page 12

Chapter 3

Installation Instructions

Step 5

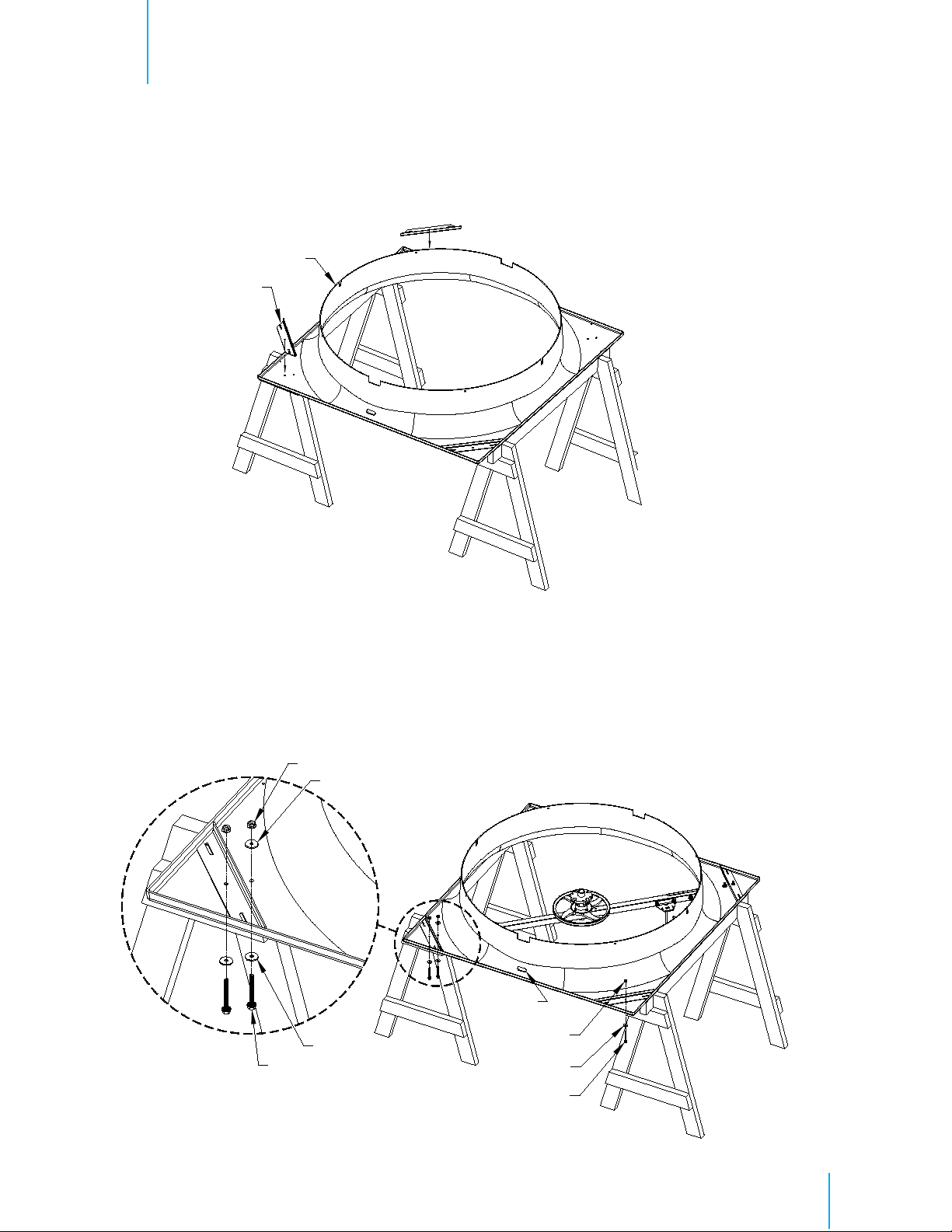

Place Fiberglass Orifice on saw horses with the round orifice pointing up and place (1) Cone/Strut Mounting Bracket in

each corner of the Fiberglass Orifice. See Figure 5.

Fiberglass Orifice

Mounting Bracket

Figure 5

Step 6

The corners of the Fiberglass Orifice with 2 holes are the corners where the Support Assembly attaches. Attach the Support

Assembly using (4) Long Bolts [CC], (6) Washers [A] and (4) Nuts [DD] and in the opposite corners attach the Cone/Strut

Mounting Bracket to the orifice using Short Bolt [AA], Washer [A] and Nut [DD]. See Figure 6

Nuts [DD]

Washer [A]

Drain Hole

Washer [A]

Long Bolt [CC]

Nuts [DD]

Washer [A]

Figure 6

Short Bolt [AA]

12

Page 13

Chapter 3

Installation Instructions

Step 7

Attach Propeller to Hub Assembly using (4) Bolts [C], Washers [D] and Nuts [E] and tighten to 22 Nm. See

Figure 7.

Bolt [C]

Washer [D]

Propeller

Nut [E]

3.2 Damper Door Installation

Step 8

Slide the Main Frame Assembly onto the Fiberglass Orifice with the pin on the Main Frame opposite the

drain hole. See Figure 8A. Line up the 4 holes in the Main Frame with the holes in the orifice and fasten

using (4) Self-tapping Screws [EE]. See Figure 8B.

Main Frame

Pin

Figure 7

Hole in Fiberglass Orifi ce

Self-tapping Screw [EE]

Fiberglass Orifi ce

Drain Hole

Figure 8A

Figure 8B

13

Page 14

Chapter 3

Installation Instructions

Step 9

Attach Drip Shield to bottom of framed opening using (3) proper Screws (Not Provided). See Figure 9A and 9B. If a

100mm wall is used a support board must be installed as shown in Figure 9B. Be sure not to deform Drip Shield when

installing screws.

Barn Screw Barn Screw

(Not

Drip plate

Screw

Provided)

150mm Wall

Drip Shield

Figure 9A

Drip plate

Support board

Figure 9B

100mm Wall

Step 10

Locate the Drain hole in the Fiberglass Orifice. This is the bottom of the Orifice. Set the bottom edge of the panel on the

Drip Shield ledge and center the panel on the opening. Then secure the Orifice

to the wall using (16) proper Screws (Not

Provided). See Figure10A and 10B.

NOTE: the proper type of fixing screw has to be selected depending on the material of the wall of the installation.

Orifi ce Panel

Drain hole

Drip Shield ledge

Figure 10A

Screws (Not Provided)

Figure 10B

14

Page 15

Chapter 3

Installation Instructions

Step 11A

Carefully remove folded door assembly from box. Open the doors enough to reach the latch pin and pull it down until the end

of the latch pin is flush with the top of the doors. Make sure the Long Hinge Pin does not fall out. See Figure 11A

Latch Pin

Figure 11A

15

Page 16

Chapter 3

Installation Instructions

Step 11B

Being careful not to let pin fall out, set Doors into Main Frame with the Hinge Pin in the hole at the bottom

plate of the Main Frame and push the top of the Doors into place. See Figure 11B.

Door

Hinge Pin

Figure 11B

Step 11C

Separate the doors and push them into the closed position. Now push Latch Pin up into place, then turn

the short leg of the Latch Pin into place against the door and secure in place using Self-tapping screw [B].

Latch Pin should extend up through the upper plate in the Main Frame. See Figure 11C.

Latch Pin

Latch Pin Leg

Self-tapping Screw [B]

Figure 11C

16

Page 17

Step 12A

Find the Cable [Q], insert it into the small hole

ferrule stops at the plate. See Figure 12A.

Chapter 3

Installation Instructions

in the upper plate of the Main Frame and pull it through until the

Cable [Q]

Hole in Main frame

Figure 12A

Step 12B

On the room side of each door drill a 3mm dia. Hole in each door through the center of the middle dimple

shown. See Figure 12B.

Drill Dimple

Figure 12B

17

Page 18

Chapter 3

Installation Instructions

Step 12C

From the inside attach each of the Tension Springs to the hole in the upper plate of the Main Frame using

the end of the spring with the loop, then stretch the spring and insert the other end of the spring into the hole

drilled in the door in the previous step. See Figure 12C

Hole in upper plate

Drilled Hole in Damper Door

Tension Spring

3.3 Cone Installation

Step 13

Place all 4 cone sections on a flat surface with the tabs from one facing the slots of the next. See Figure 13A.

Curl up the tab end of the first cone section and insert the tabs up into the slots in the next cone section, a

mallet may be needed to seat the slots over the tabs completely. See Figure 13B. Repeat this step until all

4 cone sections are connected and laying flat

Figure 12C

Figure 13A

Figure 13B

1

8

Page 19

Chapter 3

Installation Instructions

Step 14A

Fasten each of the joints in the single outer hole using (1) Short Bolt [AA], Washer [A] and Nut [DD], with

the nut on the side with the tabs. At the inner pair of holes of each joint attach (1) Cone Support Bracket

to the inner hole using (1) Bolt [AA], Washer [A] and Nut [DD] with the bolt head on the side with the

tabs. See Figure 14A.

Nut [DD]

Washer [A]

Outer holes

Short Bolt [AA]

Short Bolt [AA]

Washer [A]

Inner holes

Nut [DD]

Cone Support Bracket

Figure 14A

Step 14B

Stand the cone sections on end and curl ends around to form cone with the Cone Support Bracket on the outside

and the tabs on the inside. Then insert the remaining tabs into slots so the tabs are inside the cone and fasten

final joint using (1) Short Bolt [AA], Washer [A] and Nut [DD], with the nut on the inside of the cone. At the

inner pair of holes

attach (1) Cone Bracket to the inner hole using (1) Short Bolt [AA], Washer [A] and Nut

[DD] with the bolt head on the outside of the cone. See Figure 14B.

Figure 14B

Short Bolt [AA]

Washer [A]

Cone Bracket

Nut [DD]

Short Bolt [AA]

Washer [A]

Nut [DD]

19

Page 20

Chapter 3

Installation Instructions

Step 15A

Install cone onto fan by putting the top of the cone over the top of the fan. The hole in the tab of the upper cone

section should slide down over the pin in the Main Frame assembly, then allow the rest of the cone to slide over

the rest of the orifice panel making sure the cone brackets remain on the outside of the cone. See Figure 15A.

Hole in Tab of Cone Section

Frame Pin

Figure 15A

Step 15B

Place the end of the Cone Brackets with the single hole over the bolt holding the Cone/Strut Mounting Bracket

to the orifice and secure with Nut [DD]. See Figure 15B. Secure the Cone to the Fan installing Medium Bolt

[BB] and Washer [A] through the remaining hole in the Cone Brackets and fastening with Nut [DD]. A long

screwdriver may be needed to help align the holes through the Cone Bracket, Cone, Damper Frame and

Orifice. See Figure 15B..

Nut [DD]

Medium Bolt [BB]

Washer [A]

Nut [DD]

Figure 15B

20

Page 21

Chapter 3

Installation Instructions

Step 16

Insert guard into cone with the eyelets facing you. Install eyelets over bolts already installed in cone and fasten

with Nut [DD] and then secure remaining eyelets using Short Bolt [AA], Washer [A] and Nut [DD]. See Figure

16.

Previously installed - Bolt and Nut

Nut [DD]

Short Bolt [AA]

Washer [A]

Nut [DD]

Figure 16

Step 17

Loop Cable [Q] that was installed in a previous step, around the lower, middle joint in guard and fasten to itself

with Cable Clamp [R]. Make sure cable is pulled snug. See Figure 17.

Cable Clamp [R]

Cable [Q]

Figure 17

21

Page 22

Chapter 3

Step 18

If Fans are to be installed 1524mm O.C., cut the 3 o’clock and 9 o’clock guard wire in the position

shown and push the side of the cone in as far as possible and fasten the cut guard wire to the attached guard

wire using Clamp [R]. See Figure 18.

Installation Instructions

Cut Guard Wire Here

3.4 Motor Installation

Step 19

Find the Key provided with the Motor and place it in the Keyway on the motor shaft. Place the Motor Pulley on

the Motor shaft with the hub facing towards the motor. See Figure 19. Tighten the Motor Pulley using Bolt [O]

and Washer [N].

Motor

Clamp [R]

Figure 18

Sheave

Washer [N]

Motor Key

Bolt [O]

Figure 19

22

Page 23

Step 20

Set the Motor on the Motor Slide. See Figure 20

Braket Slots

Chapter 3

Installation Instructions

Figure 20

Step 21A

Secure Motor to Motor Slide and motor bracket stiffener using (4) Bolts [AA], Washers [H] and Nuts [DD].

The rear upper bolt is where the motor bracket stiffener is attached. See Figure 21A.

Stiffener

Bolts [AA]

Washer [H]

Nuts [DD]

Figure 21A

23

Page 24

Chapter 3

Installation Instructions

Step 21B

Using channel locks and/or a hammer twist the motor bracket stiffener so that the holes in the bracket lay flat against the

framing. Then attach bracket to framing using (1) proper Screw (Not Provided). See Figure 21B.

NOTE: the proper type of fixing screw has to be selected depending on the material of the wall of the installation.

Frame

Stiffener

Screw (not provided)

Level

Motor Pulley

T

ensioner Pulley

Pulley

Central

Figure 21B

Step 22

Use a straight edge or level to check the alignment of

the Central Pulley, Tensioner Pulley and the Motor

Pulley. T

ighten the set screw to 9 Nm. See

22.

Step 23A

Slide V-belt over Propeller and install by wrapping

it around the 2 smaller pulleys and starting it over the

larger pulley, continue rolling it onto the larger pulley

until it fits onto pulley. See Figure 23A.

Figure 22

Figure

Figure 23A

4

2

Page 25

Chapter 3

Step 23B

Installation Instructions

To adjust the belt tensioner to the proper setting, loosen 10 mm bolt (using 17mm spanner) to allow tensioner arm

to rotate. Turn spanner clockwise until the single mark on base of the belt tensioner is aligned with mark 2 on

the tensioner arm. Hold tensioner at this setting and tighten the 10mm bolt to 50 Nm. See Figure 23B.

Hex

10mm

Bolt

Step 24A

Take the flat mesh. See Figure 24A.

Figure 23B

1515

1566

Figure 24A

2

5

Page 26

Chapter 3

Installation Instructions

Step 24B

Place the mesh against the framing and fasten it in place using (12) Plastic clips [P] and proper Screws (Not Provided).

See Figure 24B.

NOTE: the proper type of fixing screw has to be selected depending on the material of the wall of the installation.

NOTE: The flat mesh can be installed in case of a thickness wall ≥ 120mm. For lower thicknesses, if the fan is at a height

of less than 2,7m from the ground, a dedicated mesh must be ordered separately.

Screw

Plastic Clip [P]

Figure 24B

6

2

Page 27

Electrical Wiring

4.

All wiring should be installed in accordance with all national and local electrical codes. Fans used to ventilate

livestock buildings or other rooms where continuous air movement is essential should be connected to individual

electrical circuits, with a minimum of two circuits per room. For electrical connection requirements, refer to

diagram on motor nameplate and to information enclosed with the Munters environmental control to be used.

Three Phase Fans: motor overload protection should be provided for each fan. A three-poles safety switch or slow

blow motor fuses must be used. See Figure 25.

If a frequency drive (inverter)

installation of line filters is recommended to reduce voltage spikes and harmonic distortion. Supplemental

motor overload protection is also recommended.

NOTE: A safety cut-off switch should be located adjacent to each fan.

L1

Three Phase

Power Supply for

Fan

L2

L3

G

is used, confirm that motors are rated for inverter duty at the voltage used. The

Saftey cut-off

switch

T1

T2

T3

G

Figure 25

Three Phase - Motor Overload Protection with Disconnect

KEY:

L1=Line 1

L2=Line 2

L3=Line 3

G=Ground

Three Phase

Power Out

to Fan Motor

2

7

Page 28

Chapter 4

4.1 Recommended Wiring

Step 1

Electrical Wiring

As the power cable exits the back of the motor form a drip loop and then run cable to power source. See

Figure 26A and 26B.

Drip loop

Drip loop

Figure 26A

Figure 26B

28

Page 29

Operation

4. Operation

1) INITIAL START-UP: With electrical power off, verify that the fan propeller

turns freely and that all fasteners are secure. Turn on electrical power and

confirm that the fan operates smoothly.

2) ADJUSTMENTS: Set the fan control to the temperature shown on your

Munters ventilation system drawing, or to a value which will provide the

desired environmental conditions.

Some models of our fans allow to adjust the number of revolutions through inverter ( also

called VFD). In case of adjustment made by VFD the installer has to pay particular attention

to the following aspects:

• it is necessary that the resistance of the ground line to which the equipment are

(about 15-20 ohm) in order to avoid high currents

WARNING

!

connected has a very low values

that can flow through the motor bearings and damage them.

• It is necessary to install the proper line filters, to avoid interference and allow proper

operation of the equipment.

• The minimum frequency of operation of the engines in the case of absence of a

forced external ventilation is 30 Hz. In the case of an operating frequency below 30

Hz is necessary to provide an external forced ventilation to the engine.

5.

!

WARNING

Moving parts, disconnect power

before servicing.

It is absolutely normal for the damper door not to open completely. The air flow is calculated in the

configuration with the two doors not completely open but with an angle of 20° between them.

Ambient temperature during operation

- 15°C / + 40 °C

Ambient humidity during operation

< 90%

29

Page 30

Maintenance

6. Maintenance

6.

The following inspection and cleaning procedures should be performed monthly:

Tools Needed for Maintenance:

Spanner 10mm, 13mm, 17mm, pneumatic screwdriver

1) INSPECT PROPELLER: Check that propeller is secure on drive hub and that

there are no signs of damage. The blades are of a self-cleaning design and should

not require maintenance.

2) CLEAN regularly for best results:

• FAN MOTOR: Remove any dust accumulation from motor using a brush or

cloth. (DO NOT use a pressure washer). A clean motor will run cooler and last

longer. At the same time, verify that the motor is secure in its mount.

• DAMPER: Carefully clean dust from damper door and frame so that damper

door opens and closes freely. A brush or cloth should be used.

• GUARD: Clean any dust or feathers from fan guards using a brush. Dirty guards can reduce

airflow.

3) CHECK FASTENERS: For safety, all fasteners should be inspected. Tighten any

loose connections.

!

WARNING

Moving parts, disconnect power

before servicing.

!

WARNING

High Voltage, disconnect power

before servicing.

4) INSPECT FAN CONTROL: With power disconnected, inspect all electrical connec-

tions. Wiring should be secure and in good condition. Remove any dust build-up

from control case and sensor using a soft brush or cloth. NEVER CLEAN

ELECTRICAL EQUIPMENT WITH A PRESSURE WASHER!

Keep motor body clean. Dust deposit on motor body will lead to overheating and failure of

WARNING

!!

WARNING

!!

bearings and motor itself.

Do not use water for motor cleaning. Use compressed air only. Water spraying will cause

rust inside the bearings and lead to their failure.

We recommend to avoid to use water for washing fans since the electric motors and the

bearings of the central hub and centrifugal system support might get damaged by water

infiltration.

In case there is an unbreakable need to use water for cleaning the fans, the electric motor,

the central hub and the centrifugal weight mechanism have to be adequately protected by

water sprays.

30

Page 31

Chapter 6

Maintenance

5) CHECKING PULLEYS: Roll the belt off and look at both pulleys. If the pulley has grooves in it or

is no longer smooth, it needs replacement. A loose or slipping belt will reduce fan performance up

to 60% and cause premature belt failure.

Smooth

Pulley

6) BELT TIGHTENING:

17mm

spanner) to allow tensioner arm to rotate. Turn

Grooved

Pulley

To adjust the belt tensioner to the proper setting, loosen 10 mm bolt (using

spanner clockwise until the single mark on

base of the belt tensioner is aligned with mark 2 on the tensioner arm. Hold tensioner at this

setting and tighten the 10mm bolt to 54 Nm.

!

WARNING

Do not power wash

electrical devices.

!

WARNING

Moving parts, disconnect

power before servicing.

Hex on tensioner

10mm

Bolt

Alignment Mark

on Base

Mark 2 on Tensioner Arm

31

Page 32

Winterizing

7.

7.1 Winterizing

In most climates, it is probable that the ventilation system will never need to operate at a total capacity

during the colder winter months. Consequently, it is advisable to “winterize” those fans which will not

be used in cold weather to avoid unnecessary heat loss and condensation.

To winterize, turn fan control “off”. Install the insulated closure panel over the fan intake. If you don’t

have an insulated closure panel, a piece of rigid insulation material can be used. Remember the

insulation panel must be removed before warmer weather returns.

NOTE: At least one single speed fan should be left uncovered and with power available to provide air

movement in the event of variable speed control difficulties.

7.2 Winter Weather Protection

To prevent cone or fan damage from snow or ice sliding off building roof, weather protection must be

provided. A weather shelter may be constructed to cover the entire fan, See Figure 27, or snow guards

may be placed on the roof, See Figure 28.

Figure 27

Provide Weather

Shelter Over Fans

150mm Min.

Fan with

Discharge Cone

Snow Guards located

per manufacturers

recommendations

Ceiling

Fan with

Discharge

Cone

Figure 28

!

IMPORTANT

Munters Product and System

Warranties do not cover cone or fan

damage from external sources.

Note: Snow guards are designed to prevent sudden, dangerous snow

and ice slides when attached to the building roof according to

manufacturers recommendations. The supplier listing above is given

as a reference only. Munters does not endorse any specific snow

guard product and no performance warranty is implied.

32

Page 33

Troubleshooting

7.1 Troubleshooting

8.

!

WARNING

High Voltage, disconnect power

before servicing.

SYMPTOM

Fan Not Operating

Fan OperatingInsuffi cient Airfl ow

Excessive Noise

!

WARNING

Moving parts, disconnect power

before servicing.

POSSIBLE CAUSES

1. Fan control set above room

temperature

2. Blown fuse or open circuit breaker

3. Propeller blade contacting fan housing

4. Fan control defective

5. Motor defective

1. Damper door jammed

2. Guard dirty

1. Propeller blade contacting fan housing

!

WARNING

Moving parts, disconnect

power before servicing.

CORRECTIVE ACTION

1. Set to a lower temperature

2. Replace fuse or reset breaker

3. Realign motor in fan housing

4. Repair or replace control

5. Repair or replace motor

1. Clean damper door & fan housing

2. Clean guard

1. Sand fan housing to remove high spot

Excessive

Vibration

Fan Never Turns

Off

It is normal that the damper does not open completely. No corrective actions are needed.

1. Motor loose on mount

2. Propeller damaged

3. Motor or propeller shaft bent

1. Override thermostat set incorrectly

2. Control set for continuous operation

1. Tighten fasteners

2. Replace propeller

3. Repair or replace motor or propeller shaft

1. Set to the correct temperature

2. Set control correctly

33

Page 34

Exploded View

18

1

2

9.

17

16

Fan Components

3

4

5

6

7

13

12

8

9

11

10

14

15

34

Page 35

19

Exploded ViewChapter 8

20

21

22

23

24

Damper/Cone Components

5

3

Page 36

Parts ListChapter 8

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Catalog No

WM54F

2200761 Fiberglass orifice

2515360 Propeller

2245861 V-belt (A61)

2465692

2248001 Central pulley

2472000 Waterproof distance piece

2273600 M25 Hex nut

2248711

2446040 Motor stiffener

2446010 Motor slide

2447080 Belt tensioner bracket

2515362-K Belt tensioner assembly with 3” pulley

2234035 3” tensioner pulley

2234050 Belt tensioner

2268110 Plastic clip 1

2200767 Flat safety mesh

273707P

2

2446030 Drip shield

2446020

2200763

2200762 Cone sector

2446050

2200765 Door Assembly 2

2200765 Main Frame Assembly

2200766 Tension spring

.

Part Name/Description

Hub with bearing and shaft 1

Motor pulley

*

Motor

entral support

C

one/Strut mounting

C

Round safety mesh

Cone support bracket

bracket

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

4

1

4

4

1

2

* The motor code changes depending on the configuration utilized.

3

6

Page 37

Warranty

10.

Warranty and technical assistance

Munters products are designed and built to provide reliable and satisfactory performance but cannot

be guaranteed free of faults; although they are reliable products they can develop unforeseenable

defects and the user must take this into account and arrange adequate emergency or alarm systems if

failure to operate could cause damage to the articles for which the Munters plant was required: if this

is not done, the user is fully responsible for the damage which they could suffer.

Munters extends this limited warranty to the first purchaser and guarantees its products to be free from

defects originating in manufacture or materials for 1 year from the date of delivery, provided that

suitable transport, storage, installation and maintenance terms are complied with. The warranty does

not apply if the products have been repaired without express authorisation from Munters, or repaired

in such a way that, in Munters’ judgement, their performance and reliability have been impaired, or

incorrectly installed, or subjected to improper use. The user accepts total responsibility for incorrect use

of the products.

The warranty on products from outside suppliers fitted to Breeze fan, (for example electric motors, etc.)

is limited to the conditions stated by the supplier: all claims must be made in writing within eight days

of the discovery of the defect and within 12 months of the delivery of the defective product. Munters

has thirty days from the date of receipt in which to take action, and has the right to examine the

product at the customer’s premises or at its own plant (carriage cost to be borne by the customer).

Munters at its sole discretion has the option of replacing or repairing, free of charge, products which it

considers defective, and will arrange for their despatch back to the customer carriage paid. In the

case of faulty parts of small commercial value which are widely available (such as bolts, etc.) for

urgent despatch, where the cost of carriage would exceed the value of the parts, Munters may

authorise the customer exclusively to purchase the replacement parts locally; Munters will reimburse

the value of the product at its cost price.

Munters will not be liable for costs incurred in demounting the defective part, or the time required to

travel to site and the associated travel costs. No agent, employee or dealer is authorised to give any

further guarantees or to accept any other liability on Munters’ behalf in connection with other Munters

products, except in writing with the signature of one of the Company’s Managers.

!

WARNING In the interests of improving the quality of its products and services, Munters reserves

the right at any time and without prior notice to alter the specifications in this manual.

The liability of the manufacturer Munters ceases in the event of:

• dismantling the safety devices;

• use of unauthorised materials;

• inadequate maintenance;

• use of non-original spare parts and accessories.

37

Page 38

WarrantyChapter 10

Barring specific contractual terms, the following are directly at the user’s expense:

• preparing installation sites;

• providing an electricity supply (including the protective equipotential

bonding (PE) conductor, in accordance with CEI EN 60204-1,

paragraph 8.2), for correctly connecting the equipment to the mains

electricity supply;

• providing ancillary services appropriate to the requirements of the plant

on the basis of the information supplied with regard to installation;

• tools and consumables required for fitting and installation;

• lubricants necessary for commissioning and maintenance.

It is mandatory to purchase and use only original spare parts or those recommended by the

manufacturer.

Dismantling and assembly must be performed by qualified technicians and according to the

manufacturer’s instructions.

The use of non-original spare parts or incorrect assembly exonerates the manufacturer from all liability.

Requests for technical assistance and spare parts must be made directly to the manufacturer, at the

following address:

Munters Italy S.p.A

Strada Piani, 2

18027 Chiusavecchia (IM), Italy

Tel: +39 0183 52 11

Fax: +39 0183 521 333

info@munters.it

3

8

Page 39

Ag/MIT/UmGB-2483-07/17 Rev 1.0

www.munters.com

Australia Phone + 61 2 8843 1594, agh.info@munters.com.au, Brazil Phone +55 41 3317 5050, contato@munters.com,

Canada Phone +1 517 676 7070, aghort.info@munters.com, China Phone +86 10 8048 3493, marketing@munters.cn,

Denmark Phone +45 98 623 311, aghort@munters.dk, India Phone +91 20 6681 8900, info@munters.in, Indonesia

Phone +66 2 642 2670, info@munters.co.th, Italy Phone +39 0183 5211, info@munters.it, Japan Phone +81 3 5970

0021, mkk@munters.jp, Korea Phone +82 2 7618 701, munters@munters.co.kr, Mexico Phone +52 818 2625 400,

dhinfo@munters.com, Singapore Phone +65 7 446 828, info@munters.com.sg, South Africa and Sub-Sahara Countries

Phone +27 11 997 2000, info@munters.co.za Spain Phone +39 0183 5211, info@munters.it, Sweden Phone +46 8

6266 300, info@munters.se, Thailand Phone +66 2 6422 670, info@munters.co.th, Turkey Phone +90 262 7513 750,

info@muntersform.com, USA Phone +1 517 676

7070, aghort.info@munters.com, Export & Other countries Phone +39

0183 5211, info@munters.it

Munters reserves the right to make alterations to specifications, quantities, etc., for production or other reasons, subsequent to publication.

© Munters AB, 2015

39

Loading...

Loading...