Page 1

MWI

Munters

Instruction Manual

Wall Inlet

6-pack

MWI Munters Wall Inlet

Models: MWI4108B-6PK • MWI4113B-6PK •

MWI4408B-6PK • MWI4413B-6PK

QM1115r0

1© Munters Corporation, July 2018

Page 2

MWI Munters Wall Inlet

Instructions for Use and Maintenance

Thank You:

Thank you for purchasing a Munters MWI Munters Wall Inlet. Munters equipment is designed to be the highest

performing, highest quality equipment you can buy. With the proper installation and maintenance it will provide

many years of service.

Please Note:

To achieve maximum performance and insure long life from your Munters product it is essential that it be installed

and maintained properly. Please read all instructions carefully before beginning installation.

Warranty:

For Warranty claims information see the “Warranty Claims and Return Policy” form QM1021 available from the

Munters Corporation office at 1-800-227-2376 or by e-mail at aghort.info@munters.com.

Conditions and Limitations:

• Products and Systems involved in a warranty claim under the “Warranty Claims and Return Policy” shall have

been properly installed, maintained and operated under competent supervision, according to the instructions

provided by Munters Corporation.

• Malfunction or failure resulting from misuse, abuse, negligence, alteration, accident or lack of proper installation

or maintenance shall not be considered a defect under the Warranty.

2

QM1115r0

© Munters Corporation , July 2018

Page 3

Index

Chapters Page

1. Unpacking the Equipment 4

2. Installation Instructions 6

3. Cabling 13

1.1 Parts List 4

1.2 Inlet Dimensions 5

QM1115r0

3© Munters Corporation, July 2018

Page 4

Unpacking the Equipment

1.

1.1 Parts List

Before beginning installation, check the overall condition of the equipment. Remove packing materials, and examine all

components for signs of shipping damage. Any shipping damage is the customer's responsibility and should be reported

immediately to your freight carrier.

Each Box Includes Parts to build 6 Inlets:

[A]

Each MWI Inlet Requires:

ID Qty. Cat. No. Description

1 1 Left Side End Cap, PL

2 1 Right Side End Cap, PL

3 2 Top/Bottom Header, PL

4 1 Brush Seal

5 2 2¹⁄₂” x 3⁷⁄₈” L-Screw

6 1 Door, Curved, PL

7 1 ¹⁄₂” x ¹⁄₂” Mesh Guard, GAW

Optional Lift Kit (FA1500)

A 1 AC0211/AC0212 Azuma Bolt and Nut, PL

B 1 KS2601 6 GA. x 1.875” Open Eye Lag Screw, ZP

C 1 AC1054 Nylon Guide Link

D 1 AC1039 ³⁄₁₆” Dia. Cable Clamp, ZP

E 1 AC1009 ¹⁄₈”x36”L. Braided Polyester Lift Line

[B]

[C]

[D]

[E]

4

QM1115r0

© Munters Corporation , July 2018

Page 5

1.2 Inlet Dimensions

Unpacking the EquipmentChapter 1

Door

Size Cat. No.

8”

13”

MWI4108 41” 8" 443⁄16” 111⁄8" 41⁄2” 97⁄8” 81⁄2"H. x 411⁄2"W.

MWI4408 44” 8" 473⁄16” 111⁄8” 41⁄2” 97⁄8” 81⁄2"H. x 441⁄2"W.

MWI4113 41" 13" 443⁄16" 161⁄8” 41⁄2” 147⁄8” 131⁄2”H. x 411⁄2”W.

MWI4413 44" 13" 473⁄16" 161⁄8” 41⁄2” 147⁄8" 131⁄2”H. x 441⁄2”W.

Nominal Size

A B C D E F Wall Opening

QM1115r0

5© Munters Corporation, July 2018

Page 6

Installation Instructions

2.1 Inlet Assembly

Step 1

Insert (2) Top/Bottom Header pieces onto the Right Side End Cap. See Figure 1.

Right Side End Cap

Top/Bottom Header (Bottom)

2.

Top/Bottom Header (Top)

Figure 1

Step 2

Slide the Curved Door Hinge into the rounded opening in the Bottom Header. See Figure 2.

Top/Bottom Header (Top)

Rounded Opening

Top/Bottom Header (Bottom)

Curved Door Hinge

Curved Door

6

QM1115r0

Figure 2

© Munters Corporation , July 2018

Page 7

Step 3

Press the Brush Seal into the Slot in the Top Header. See Figure 3.

Top/Bottom Header (Top)

Brush Seal

Installation InstructionsChapter 2

Figure 3

Step 4

Slide the Wire Mesh Guard into the Slot in the Top and Bottom Headers. See Figure 4.

Top/Bottom Header (Top)

Top/Bottom Header (Top)

Slot in Top

Header

Brush Seal

Wire Mesh Guard

Wire Mesh Guard

Figure 4

QM1115r0

7© Munters Corporation, July 2018

Page 8

Installation InstructionsChapter 2

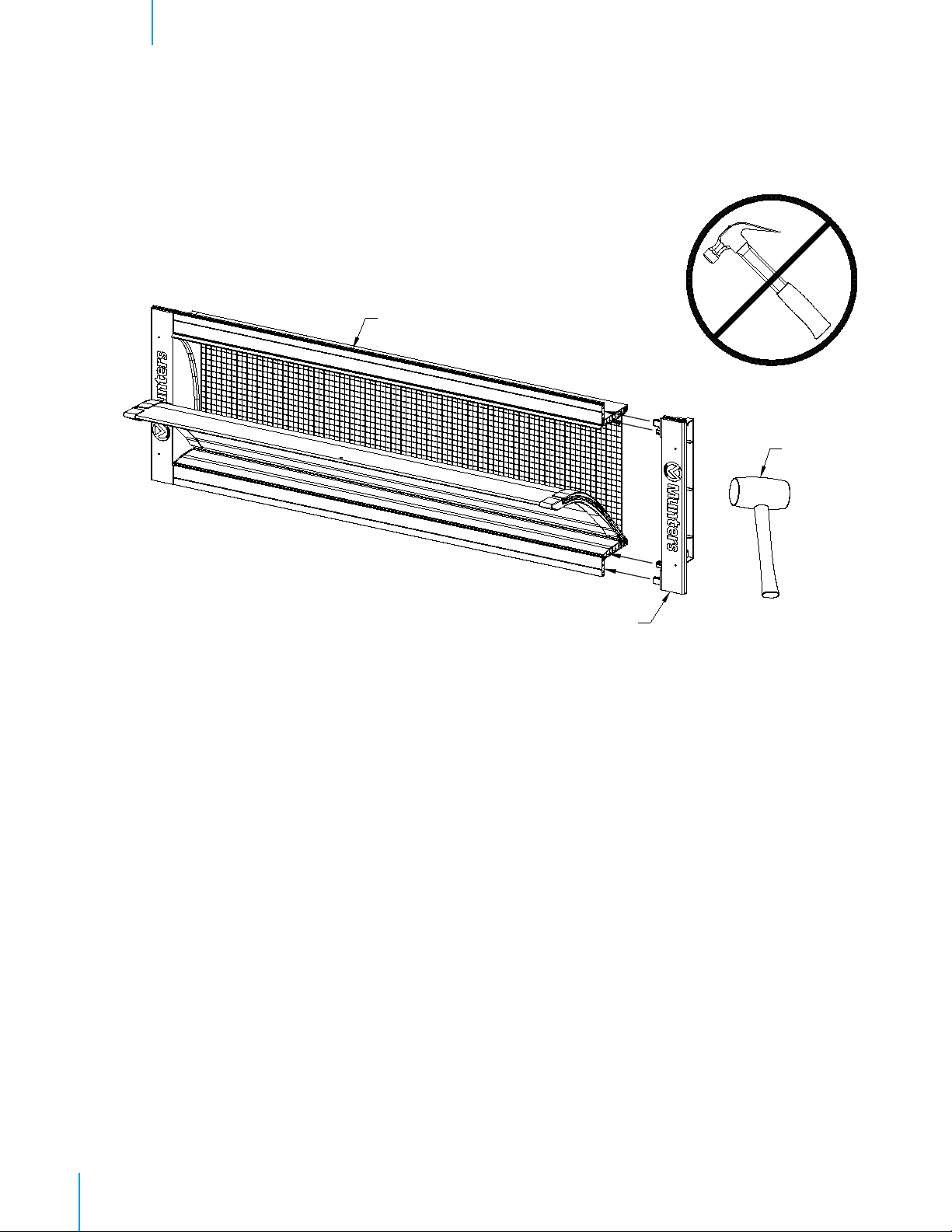

Step 5

Secure the Left Side End Cap onto the Top and Bottom Headers using a Rubber Mallet. Use caution when doing

this and NEVER use a Framing Hammer. See Figure 5.

Partially Assembled Inlet

Rubber Mallet

Figure 5

Left Side End Cap

8

QM1115r0

© Munters Corporation , July 2018

Page 9

2.2 Inlet Installation

Step 6

Construct a framed opening to correct size according to Wall Opening listed in chart on Page 5. A minimum of

10” - 12” from ceiling to the top inside of framing is required. See Figure 6A and 6B.

10" - 12" Min.

Opening

Spacer

Framed

(H.)

Framed Opening (W.)

Framed

Opening (H.)

Framed

Opening (W.)

Frame Construction

Figure 6A

Post Construction

Figure 6B

QM1115r0

9© Munters Corporation, July 2018

Page 10

Installation InstructionsChapter 2

Step 7

Slide Inlet into framed opening from inside building. See Figure 7A and 7B.

Framing

MWI Inlet

MWI Inlet

Frame Construction

Figure 7A

10

QM1115r0

Post Construction

Figure 7B

© Munters Corporation , July 2018

Page 11

Installation InstructionsChapter 2

Step 8

Secure inlet into opening using (4) Polebarn Screws or other appropriate fasteners (not provided). Locate

screws in dimples in side flanges. DO NOT overtighten screws. See Figures 8A and 8B.

Polebarn Screws (not provided)

Dimples in Flanges

Dimples in Flanges

Polebarn Screws

(not provided)

Frame Construction

Figure 8A

Post Construction

Figure 8B

QM1115r0

11© Munters Corporation, July 2018

Page 12

Installation InstructionsChapter 2

Step 9

Secure bottom header of inlet using (1) Polebarn Screws or other appropriate fasteners (not provided) in the

center of the groove of the flange. Make sure the bottom flange is straight when fastening. Push up slightly on

center of top header ¹⁄₄” or 0.6cm and secure using (1) Polebarn Screw (not provided). DO NOT overtighten

screws. See Figures 9A and 9B.

Polebarn Screws (not provided)

Groove in fl ange

Groove in fl ange

Polebarn Screws (not provided)

Frame Construction

Figure 9A

12

QM1115r0

Post Construction

Figure 9B

© Munters Corporation , July 2018

Page 13

Cabling

Step 10

Attach pulleys in line with screw hooks at each endwall. See Figure 10A and 10B.

Ceiling

3.

SPRING END

AC1264 Single Pulley

Bracket. Provide adequate

support.

Figure 10A

Truss

AC1039 Cable Clamps. Thread cable

through loop at end of spring and

fasten with (2) cable clamps.

WINCH/ ACTUATOR END

Building Wall

Fasten spring into stud with lag

screw or bolt and nut.

AC1195 Baffl e return spring

SPRING TENSION:

with baffl e fully closed and cable pulled tight,

stretch spring 12" - 14" and fasten.

AC1264 Single Pulley Bracket.

Recess pulley into ceiling in order

to keep cable in line with rod.

Figure 10B

AC1013 or

AC1044 Cable

Building Wall

Ceiling

QM1115r0

13© Munters Corporation, July 2018

Page 14

CablingChapter 3

Step 11

Install Screw Hooks 2” above top flange of Inlet, in line with Lift Line hole in door. See Figures 11A and 11B.

For Post Frame Construction, also, install a screw hook on each post near ceiling. See Figure 11C.

Flange of Inlet

2”

Screw Hook

Lift Line Hole

in Door

Figure 11A Figure 11B

Screw Hook

Flange of Inlet

14

QM1115r0

Screw Hook

Figure 11C

© Munters Corporation , July 2018

Page 15

CablingChapter 3

Step 12

Pull main rod or cable from winch or actuator through pulleys and screwhooks to weights or return spring on

opposite end wall. See Figures 10A, 10B, 12A and 12B. Be sure to coil approximately 1' of cable on winch.

Screw Hook

Main Rod

or Cable

Main Rod or Cable

Figure 12A

Screw Hook

Figure 12B

QM1115r0

15© Munters Corporation, July 2018

Page 16

CablingChapter 3

Note: If optional kit, Lift Package (FA1500) was purchased, hardware mentioned below in Step 13 is included. If

not purchased, hardware provided by others.

Step 13

Put a Nylon Guide Link [C] (black) on each Screw Hook [B] that is directly above the center of each inlet.

Attach one Lift Line [E] to Main Cable using (1) Cable Clamp [D]. Lift line should be attached 14” back

from hook toward the winch end. Run each lift line through the adjacent Nylon Guide Link [C] and attach

Azuma Bolt and Nut [A]. See Figure 13A and 13B.

Cable Clamp [D]

Figure 13A

Eye Screw [B]

Nylon Guide Link [C]

Lift Line [E]

Azuma Bolt & Nut [A]

16

QM1115r0

© Munters Corporation , July 2018

Page 17

CablingChapter 3

Cable Clamp [D]

Figure 13B

Eye Screw [B]

Nylon Guide Link [C]

Lift Line [E]

Azuma Bolt & Nut [A]

QM1115r0

17© Munters Corporation, July 2018

Page 18

CablingChapter 3

Step 14

With the winch at its fully closed position, go back, check and readjust each baffle door tightly to inlet frame.

Use winch or baffle machine to open and close inlets a few times to make sure baffle moves smoothly and

each door remains even over the total length of house. See Figure 14.

To Weights or

Return Spring

Figure 14

Step 15

Locate (2) L-Screws ¹⁄₂” [1.2cm] above Top Header and evenly space across the inlet. Thread L-Screws in far

enough to hold the door in the close position. Make sure L-Screw does not interfere with the Lift Line or Main

Rod or Cable. See Figure 15A and 15B.

L-Screw (provided)

18

QM1115r0

Figure 15A

© Munters Corporation , July 2018

Page 19

L-Screw (provided)

CablingChapter 3

UNLATCHED POSITION

L-Screw (provided)

LATCHED POSITION

Figure 15B

QM1115r0

19© Munters Corporation, July 2018

Page 20

MWI Inlets are Sold by Munters Corporation, Lansing, Michigan U.S.A. 1-800-227-2376

Munters Europe AB, Isafjordsgatan 1, P.O. Box 1150, SE-164 26 Kista, Sweden. Phone +46 08 626 63 00, Fax +46 8 754 56 66.

Munters Corporation 2691 Ena Drive Lansing, MI 48917 U.S.A. Phone +1 800-227-2376, Fax +1 517-676-7078

www.munters.us

Australia Munters Pty Limited, Phone +61 2 6025 6422, Brazil Munters Brasil Industria e Comercio Ltda, Phone +55 41 3317 5050, Canada/US Munters

Corporation Lansing, MI Phone +1 517 676 7070, China Munters Air Treatment Equipment (Beijing) Co. Ltd, Phone +86 10 80 481 121, Denmark Munters A/S,

Phone +45 9862 3311,

Phone +39 0183 52 11, Japan Munters K.K., Phone +81 3 5970 0021, Korea Munters Korea Co. Ltd., Phone +82 2 761 8701, Mexico Munters Mexico, Phone

+52 818 262 54 00, Russia Munters AB, Phone +7 812 448 5740, Singapore Munters Pte Ltd., Phone +65 744 6828, South Africa and Sub-Sahara Countries

Munters (Pty) Ltd., Phone +27 11 997 2000, Spain Munters Spain S.A., Phone +34 91 640 09 02, Sweden Munters AB, Phone +46 8 626 63 00, Thailand

Munters Co. Ltd., Phone +66 2 642 2670, Turkey Munters Form Endüstri Sistemleri A.Ş, Phone +90 322 231 1338, USA Munters Corporation Lansing, MI Phone

+1 517 676 7070, Vietnam Munters Vietnam, Phone +84 8 3825 6838, Export & Other countries Munters Italy S.p.A., Chiusavecchia Phone +39 0183 52 11

India Munters India, Phone +91 20 3052 2520, Indonesia Munters, Phone +62 818 739 235, Italy Munters Italy S.p.A., Chiusavecchia,

20

QM1115r0

© Munters Corporation , July 2018

Loading...

Loading...