Page 1

Originalinstructions

Usermanual

ML420,ML690,MLT800

ML1100,ML1350,MLT1400

Desiccantdehumidier

190TGB-1035-H1604©MuntersEuropeAB2016

Page 2

Importantuserinformation

Intendeduse

Muntersdehumidiersareintendedtobeusedforthe

dehumidicationofair.Anyotheruseoftheunit,or

usewhichiscontrarytotheinstructionsgiveninthis

manual,cancausepersonalinjuryanddamagetotheunit

andotherproperty.

Nomodicationoftheunitisallowedwithoutprior

approvalbyMunters.Attachmentorinstallation

ofadditionaldevicesisonlyallowedafterwritten

agreementbyMunters.

Warranty

Thewarrantyperiodisvalidfromthedatetheunit

leftourfactory,unlessotherwisestatedinwriting.

Thewarrantyislimitedtoafreeexchangeofpartsor

componentswhichhavefailedasaresultofdefectsin

materialsorworkmanship.

Allwarrantyclaimsmustincludeproofthatthe

faulthasoccurredwithinthewarrantyperiodand

thattheunithasbeenusedinaccordancewiththe

specications.Allclaimsmustspecifytheunittypeand

fabricationnumber.Thisinformationisstampedonthe

identicationplate,seesectionMarking.

Itisaconditionofthewarrantythattheunitforthefull

warrantyperiodisservicedandmaintainedbyaqualied

MuntersengineerorMuntersapprovedengineer.

Accesstospecicandcalibratedtestequipmentis

necessary.Theserviceandmaintenancemustbe

documentedforthewarrantytobevalid.

AlwayscontactMuntersforserviceorrepair.Operating

faultscanoccuriftheunitismaintainedinsufcientlyor

incorrectly.

Safety

Informationaboutdangersareinthismanualindicated

bythecommonhazardsymbol:

W

ARNING!

W W

ARNING! ARNING!

Indicatesapossibledangerthatcanleadtopersonalinjury .

CA

UTION!

CA CA

UTION! UTION!

Indicatesapossibledangerthatcanleadtodamagetothe

unitorotherproperty ,orcauseenvironmentaldamage.

NOTE!Highlightssupplementaryinformationforoptimal

useoftheunit.

ConformitywithDirectives

Thedehumidierisinconformitywiththeessential

safetyrequirementsoftheMachineryDirective

2006/42/EC,andinconformitywiththeprovisionsof

theEcodesignDirective(ErP)2009/125/EC,andof

theEMCDirective2004/108/EC.Thedehumidieris

manufacturedbyanorganizationcertiedaccordingto

ISO9001andISO14001.

Copyright

Thecontentsofthismanualcanbechangedwithout

priornotice.

NOTE!Thismanualcontainsinformationwhichis

protectedbycopyrightlaws.Itisnotallowedtoreproduceor

transmitanypartofthismanualwithoutwrittenconsentfrom

Munters.

Pleasesendanycommentsregardingthismanualto:

MuntersEuropeAB

TechnicalDocumentation

P.O.Box1150

SE-16426KISTASweden

e-mail:t-doc@munters.se

iiImportantuserinformation190TGB-1035-H1604

Page 3

Tableofcontents

Importantuserinformation...............ii

Intendeduse...........................

Warranty...............................

Safety..................................

ConformitywithDirectives............

Copyright..............................

Tableofcontents...........................iii

1Introduction.................................1

1.1Aboutthismanual.....................

1.2Unintendeduse........................

1.3Safetyandcautions...................

1.4Markings...............................

1.5Supervisionofoperation..............

1.6Faultindications.......................

2Dehumidierdesign.......................4

2.1Productdescription...................

2.2Functiondescription..................

2.3Maincomponents.....................

3Transport,inspectionandstorage.......6

3.1Transport..............................

3.2Inspectionofdelivery..................

3.3Storingtheequipment................

4Installation...................................7

4.1Safety..................................

4.2Siterequirements.....................

4.3Foundation............................

4.4Mirrorhandedductconnections......

4.5Ductinstallation.......................

4.5.1Generalrecommendations...

4.5.2Ductforoutdoorairinlet.......

4.5.3Ductforwetairoutlet...........

4.6Precautionarymeasuresforunitswith

LIdesiccantrotor......................

4.7Electricalconnections................

4.8Externalhumiditysensor.............

4.9Gasreactivation(ML1100units

only)....................................

5Commissioning.............................15

5.1Settingsbeforestart-up...............

5.1.1Continuousprocessairfan

operation.......................

5.1.2Single-stagehumiditysensor.

ii

ii

ii

ii

6Operation....................................18

ii

1

1

1

3

3

3

4

4

5

6

6

6

7

7

8

8

9

9

12

12

13

13

13

14

15

15

7Serviceandmaintenance.................24

8Faulttracing.................................28

9Technicalspecication....................31

10Scrapping....................................40

5.1.3Two-stagehumiditysensor...

5.1.4Remotefaultindication........

5.2Pre-startchecks.......................

5.3Airowcheckandadjustment........

6.1General................................

6.2Quickstop..............................

6.3Beforestarting.........................

6.4Operatorpanel........................

6.5RH98operatorpanel..................

6.6Operatingtheunit.....................

6.6.1Manualmode..................

6.6.2Automaticmode–humidity

sensorconnected..............

6.6.3Automaticmode-RH98or

VariDry(option)................

7.1Safety..................................

7.2General................................

7.3Serviceoptions........................

7.4Extendedwarranty....................

7.5Cleaning...............................

7.6Serviceandmaintenanceschedule..

7.7Filterchange...........................

8.1General................................

8.2Safety..................................

8.3Faulttracinglist........................

9.1Dimensionsandservicespace.......

9.2Capacitydiagrams....................

9.3Technicaldata.........................

9.4Sounddata.............................

9.4.1SounddataML420............

9.4.2SounddataML690............

9.4.3SounddataMLT800...........

9.4.4SounddataML1100...........

9.4.5SounddataML1350...........

9.4.6SounddataMLT1400..........

15

15

15

16

17

18

18

18

19

21

21

21

22

22

24

24

24

25

25

25

27

28

28

29

31

32

34

36

36

37

37

38

38

39

190TGB-1035-H1604Tableofcontentsiii

Page 4

Appendix1Options.............................41

1.1General................................

1.2Runningtimemeter...................

1.3Rotorstopalarm.......................

1.4Blockedlteralarm....................

1.5Filterbox-M5andF7..................

1.6Humiditycontrolsystem..............

1.6.1Introduction....................

1.6.2Transmitter.....................

1.6.3Controlunit.....................

41

41

41

41

41

42

42

42

2ContactMunters............................49

1.6.4Setpointsandcontrol

parameters.....................

1.6.5Display/changesetpointfor

relativehumidity...............

1.6.6Display/changeother

parameters.....................

1.6.7Processalarms................

42

43

44

44

47

ivTableofcontents190TGB-1035-H1604

Page 5

DehumidierML420-MLT1400

1Introduction

1.1Aboutthismanual

Thismanualiswrittenfortheuserofthedehumidier.Itcontainsnecessaryinformationforhowtoinstall

andusethedehumidierinasafeandefcientway.Readthroughthemanualbeforethedehumidieris

installedandused.

ContactyournearestMuntersofceifyouhaveanyquestionsregardingtheinstallationortheuseofyour

dehumidier.

Thismanualmustbestoredinapermanentlocationclosetothedehumidier.

1.2Unintendeduse

■Thedehumidierisnotintendedforoutdoorinstallation.

■Thedehumidierisnotintendedforuseinclassiedareaswhereexplosionsafetycompliantequipment

isrequired.

■Thedehumidiermustnotbeinstallednearanyheatgeneratingdevicesthatcancausedamagetothe

equipment.

1.3Safetyandcautions

Everymeasurehasbeentakeninthedesignandmanufactureofthedehumidiertoensurethatitmeetsthe

safetyrequirementsofthedirectivesandstandardslistedintheECDeclarationofConformity.

Theinformationinthismanualshallinnowaytakeprecedenceoverindividualresponsibilitiesorlocal

regulations.

Duringoperationandotherworkwithamachineitisalwaystheresponsibilityoftheindividualtoconsider

thefollowing:

■Thesafetyofallpersonsconcerned.

■Thesafetyoftheunitandotherproperty.

■Theprotectionoftheenvironment.

ThetypesofdangersthatareindicatedinthismanualaredescribedinthesectionImportantuserinformation.

190TGB-1035-H1604Introduction1

Page 6

DehumidierML420-MLT1400

W

ARNING!

W W

ARNING! ARNING!

-Theunitmustnotbesplashedwithorimmersedinwater.

-Theunitmustneverbeconnectedtoavoltageorfrequencyotherthanthatforwhichitwasdesigned.Refertothe

identicationplate.Linevoltagethatistoohighcancauseanelectricalshockhazardanddamagetotheunit.

-Donotinsertngersoranyobjectsintotheairvents.

-Allelectricalinstallationsmustbecarriedoutbyaqualiedelectricianandinaccordancewithlocalregulations.

-Thedehumidiercanrestartautomaticallyafterapowercut.Alwayssetandlockthemainpowerswitchinthe

OFFpositionbeforecarryingoutanyservicework.

-Useonlyapprovedliftingequipmenttopreventpersonalinjuryanddamagetotheequipment.

-AlwayscontactMuntersforserviceorrepair.

2Introduction190TGB-1035-H1604

Page 7

DehumidierML420-MLT1400

Reg.luft

Reac.air

Reg.Luft

Air de regeneration

'''

Processluft

Process air

Prozessluft

Air a traiter

`

Våtluft

Wet air

Nassluft

Air humide

Torrluft

Dry air

Trockenluft

Air sec

3

1

4

5

2

3

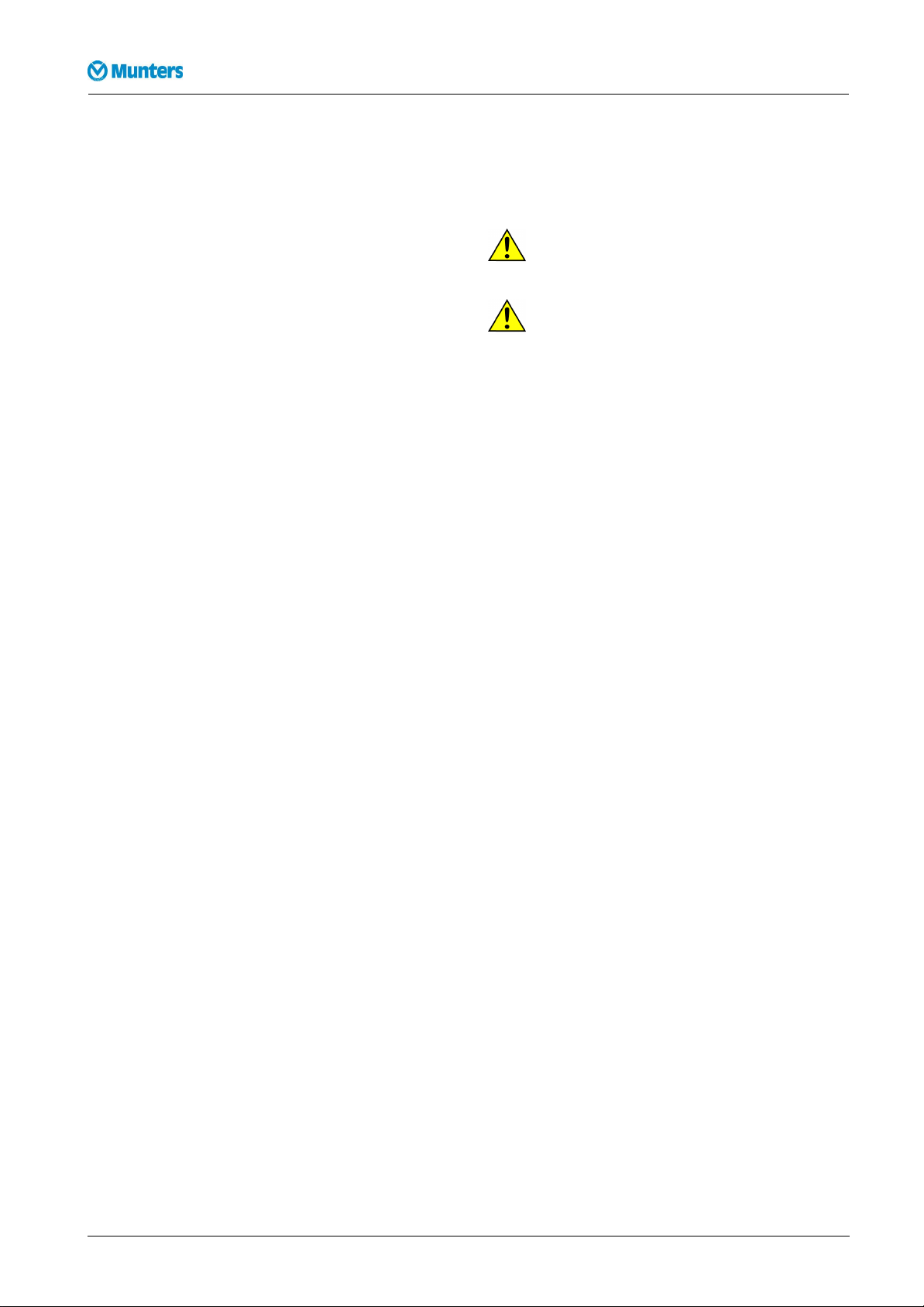

1.4Markings

Figure1.1Identicationplateandmarkings

Figure1.2Identicationplate,example

1.Unitidenticationplate

4.Processairinlet

Figure1.3Labelsforairinletsandoutlets

2.Dryairoutlet5.Reactivationairinlet

3.Wetairoutlet

Explanationof"Fabr.no"ontheidenticationplate:

09=yearofmanufacture,19=weekofmanufacture,190XXX=articlenumber,XXXXX=serialnumber

1.5Supervisionofoperation

Thedehumidieriscontrolledandmonitoredusingtheoperatorpanellocatedonthefrontoftheunit.

1.6Faultindications

Faultsareclearlyindicatedontheoperatorpanel,seesection6.4,Operatorpanel.

Alarmsrelatingtorelativeairhumidityaregiveninthedisplayofthehumiditycontrolsystem(ifinstalled),

seeappendix1.6,Humiditycontrolsystem.

190TGB-1035-H1604Introduction3

Page 8

DehumidierML420-MLT1400

2

4

3

1

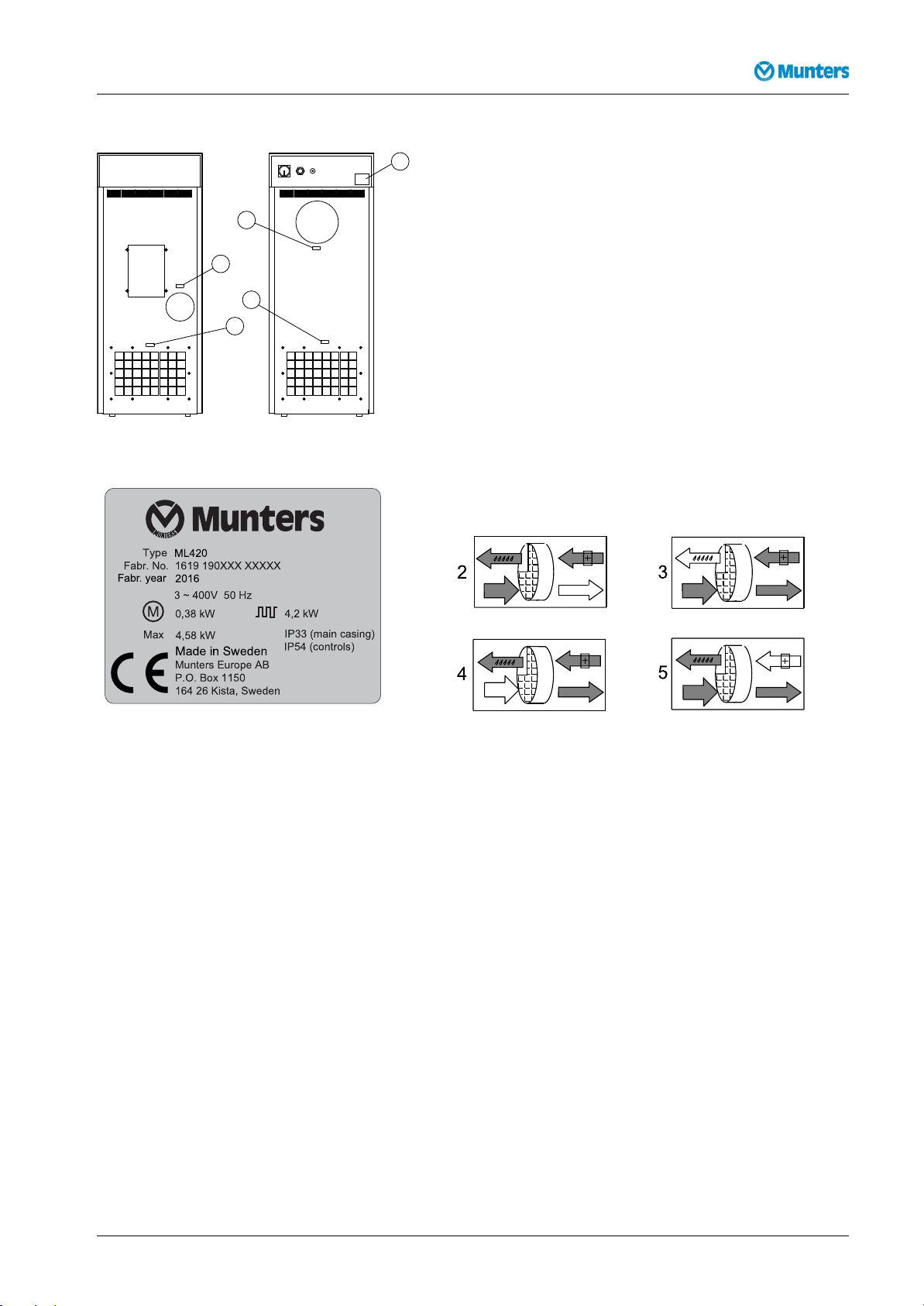

2Dehumidierdesign

2.1Productdescription

ThedesiccantdehumidiersintheMLserieshavebeendevelopedtoeffectivelydehumidifytheairin

environmentsrequiringlowairhumidity.

Thedehumidierisequippedwithanencapsulatedrotorunit.Therotorcasingisconstructedofdurable

thermosetplasticandcontainsisolatedsectionsthatprovideaprecisebalanceforthedehumidication,

reactivationandheatrecoveryairows.

ThedehumidierismanufacturedinaccordancewithuniformEuropeanstandardsandestablished

requirementsforCE-marking.

2.2Functiondescription

1.Processair

2.Dryair

3.Reactivationair

4.Wetair

Figure2.1Internalairows

Thedesiccantrotoristheadsorptiondehumidifyingcomponentintheunit.Therotorstructureis

comprisedofalargenumberofsmallairchannels.

Thedesiccantrotorismadeofacompositematerialthatishighlyeffectiveinattractingandretainingwater

vapour.Therotorisdividedintwozones.Theairowtobedehumidied,processair,passesthroughthe

largestzoneoftherotorandthenleavestherotorasdryair.Sincetherotorrotatesslowly,theincomingair

alwaysmeetsadryzoneontherotor,thuscreatingacontinuousdehumidicationprocess.

Theairowthatisusedtodrytherotor,reactivationair,isheated.Thereactivationairpassesthrough

therotorintheoppositedirectiontotheprocessairandleavestherotoraswetair(warm,moistair).This

principleenablesthedehumidiertoworkeffectively ,evenatfreezingtemperatures.

4Dehumidierdesign190TGB-1035-H1604

Page 9

DehumidierML420-MLT1400

11

1

4

5

6

8

9

2

16

3

12

14

13

15

10

7

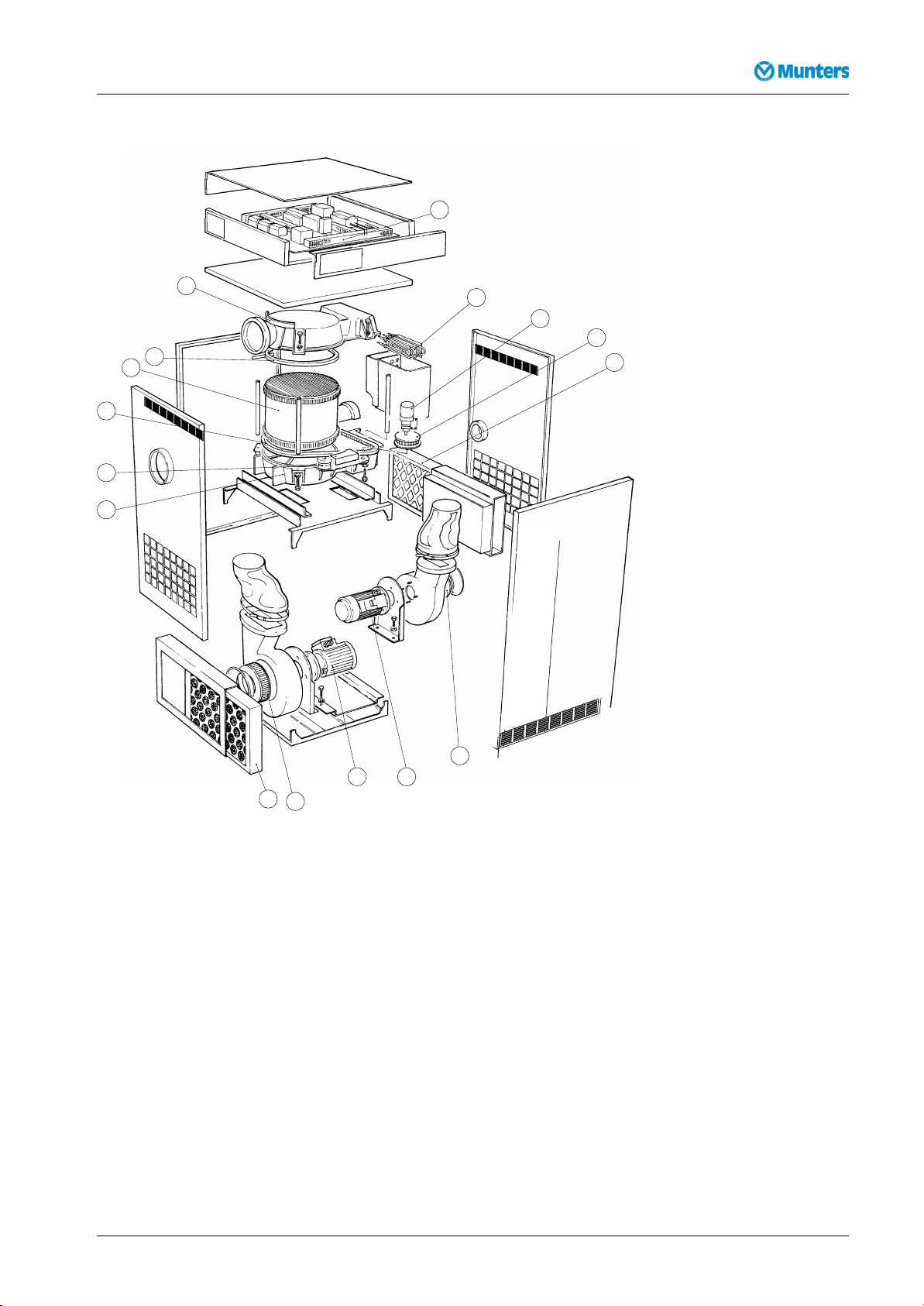

2.3Maincomponents

Figure2.2Maincomponents

1.Lowerrotorcover9.Drivemotor

2.Roller,beltguide10.Pulley,beltdrive

3.Drivebelt11.

4.Rotor12.Reactivationairimpeller

5.

Sealingring,rotor

6.Upperrotorcover14.

7.

Electricalcontrolpanel15.Processairimpeller

8.Reactivationheater16.

13.

Reactivationairlter

Reactivationfanmotor

Processfanmotor

Processairlter

NOTE!TheML420unithasonlyonefanmotorthatisplacedbetweentheprocessandreactivationimpeller.

190TGB-1035-H1604Dehumidierdesign5

Page 10

DehumidierML420-MLT1400

3Transport,inspectionandstorage

3.1Transport

Thedehumidierisdeliveredonapalletandmustbehandledcarefully .Allpaneldoorsontheunitmustbe

closedduringtransport.Providedthatthedehumidierisstillsecuredtoitsdeliverypallet,itcanbemoved

usingafork-lifttruck.

W

ARNING!

W W

ARNING! ARNING!

Movethedehumidiercarefullyasthereisariskofthedehumidiertippingover.

Figure3.1Correctlengthonforkliftarms

Weightofthedehumidiercanbefoundinsection9.1,Dimensionsandservicespace.

3.2Inspectionofdelivery

■Doaninspectionofthedeliveryandcomparewiththedeliverynote,orderconrmationorother

deliverydocumentation.Makesurethateverythingisincludedandnothingisdamaged.

■ContactMuntersimmediatelyifthedeliveryisnotcompleteordamagedinordertoavoidinstallation

delays.

■Removeallpackagingmaterialfromtheunit,andmakesurethatnodamagehasbeenmadeduring

transportation.

■AnyvisibledamagemustbereportedinwritingtoMunterswithin3daysandpriortoinstallationof

theunit.

■Discardthepackagingmaterialaccordingtolocalregulations.

3.3Storingtheequipment

Followtheseinstructionsifthedehumidieristobestoredpriortoinstallation:

■Placethedehumidierinanuprightpositiononahorizontalsurface.

■Re-usethepackagingmaterialtoprovideprotectionfortheunit.

■Protectthedehumidierfromphysicaldamage.

■Storethedehumidierundercoverandprotectitfromdust,frost,rainandaggressivecontaminants.

6Transport,inspectionandstorage190TGB-1035-H1604

Page 11

DehumidierML420-MLT1400

4Installation

4.1Safety

W

ARNING!

W W

ARNING! ARNING!

-Theunitmustnotbesplashedwithorimmersedinwater.

-Theunitmustneverbeconnectedtoavoltageorfrequencyotherthanthatforwhichitwasdesigned.Refertothe

identicationplate.Linevoltagethatistoohighcancauseanelectricalshockhazardanddamagetotheunit.

-Donotinsertngersoranyobjectsintotheairvents.

-Allelectricalinstallationsmustbecarriedoutbyaqualiedelectricianandinaccordancewithlocalregulations.

-Thedehumidiercanrestartautomaticallyafterapowercut.Alwayssetandlockthemainpowerswitchinthe

OFFpositionbeforecarryingoutanyservicework.

-Useonlyapprovedliftingequipmenttopreventpersonalinjuryanddamagetotheequipment.

-AlwayscontactMuntersforserviceorrepair.

CA

UTION!

CA CA

UTION! UTION!

Thewetairductmustalwaysbeinsulatedwhenthereisariskoffreezing.Condensationbuildsupeasilyonthe

insideoftheductbecauseofthehighmoisturecontentofthewetairleavingthedehumidier.

CA

UTION!

CA CA

UTION! UTION!

Thedehumidierhasbeendesignedtooperateatspecicprocessairowscorrespondingtothefansizes

installed.

4.2Siterequirements

Thedehumidierisonlyintendedforindoorinstallation.Avoidinstallingthedehumidierinadamp

environmentwherethereisariskofwaterenteringtheunitorinaverydustyenvironment.Ifindoubt,

contactMunters.Itisimportantthattheintendedinstallationsitemeetsthelocationandspacerequirements

fortheequipmentinordertoachievethebestpossibleperformance.

Fortheunitdimensionsandservicespacerequirements,seesection9.1,Dimensionsandservicespace.

NOTE!Ifthereisaneedforreductionofvibrationsfromthedehumidier,contactMuntersforinstructions.

190TGB-1035-H1604Installation7

Page 12

DehumidierML420-MLT1400

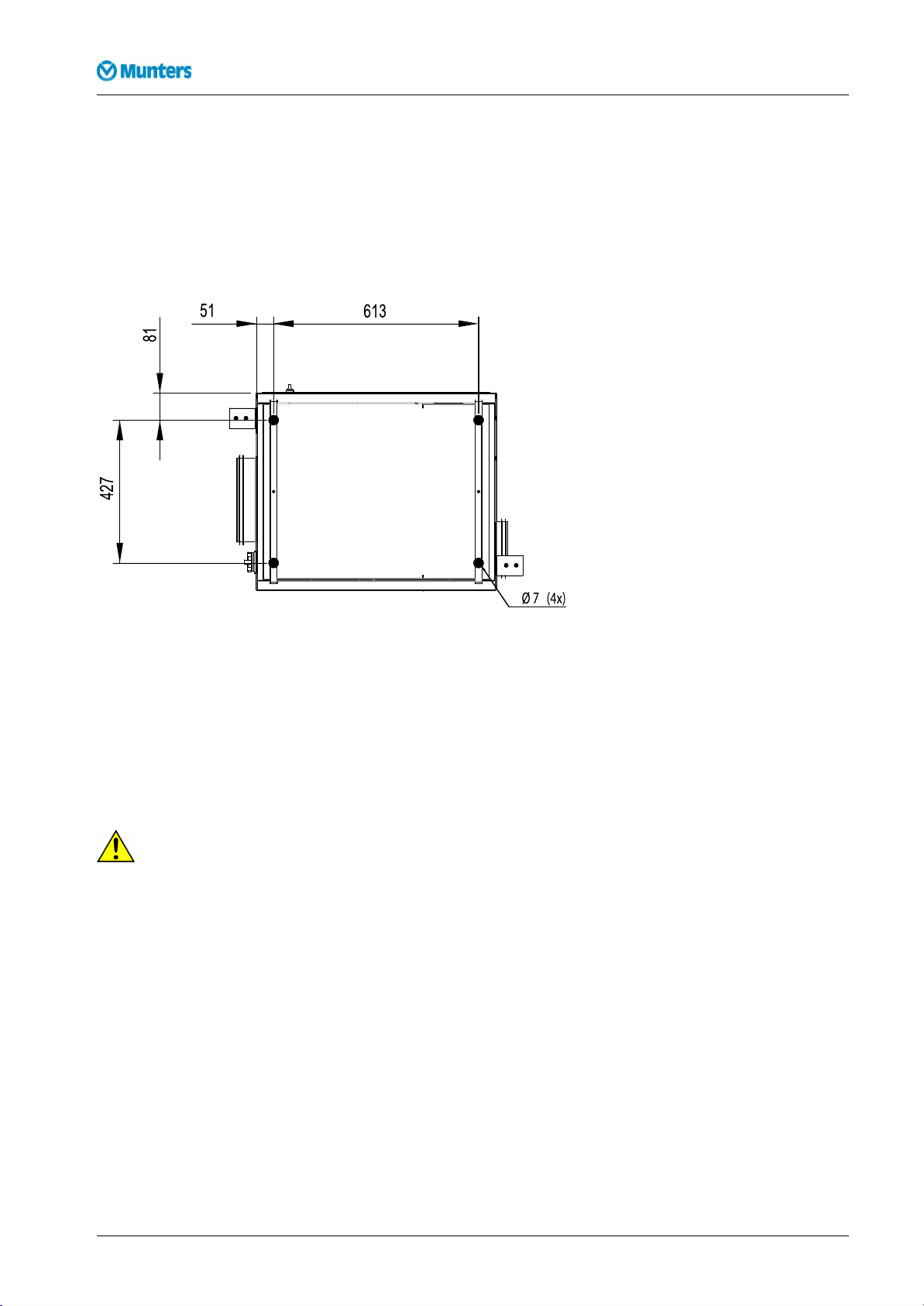

4.3Foundation

Thedehumidiermustbeinstalledonaleveloor,oronaplatformcapableofsupportingthemachine

weight.Ifthemaximumoorloadingweightisnotexceeded,specialfoundationsarenotrequired.

Whenthedehumidierhasbeeninstalled,checkthatitislevel.

Iflocalregulationsrequirethattheunitispermanentlyxedinposition,thexingholescanbeusedfor

boltingtheunittotheoor.

Figure4.1Drillingpattern

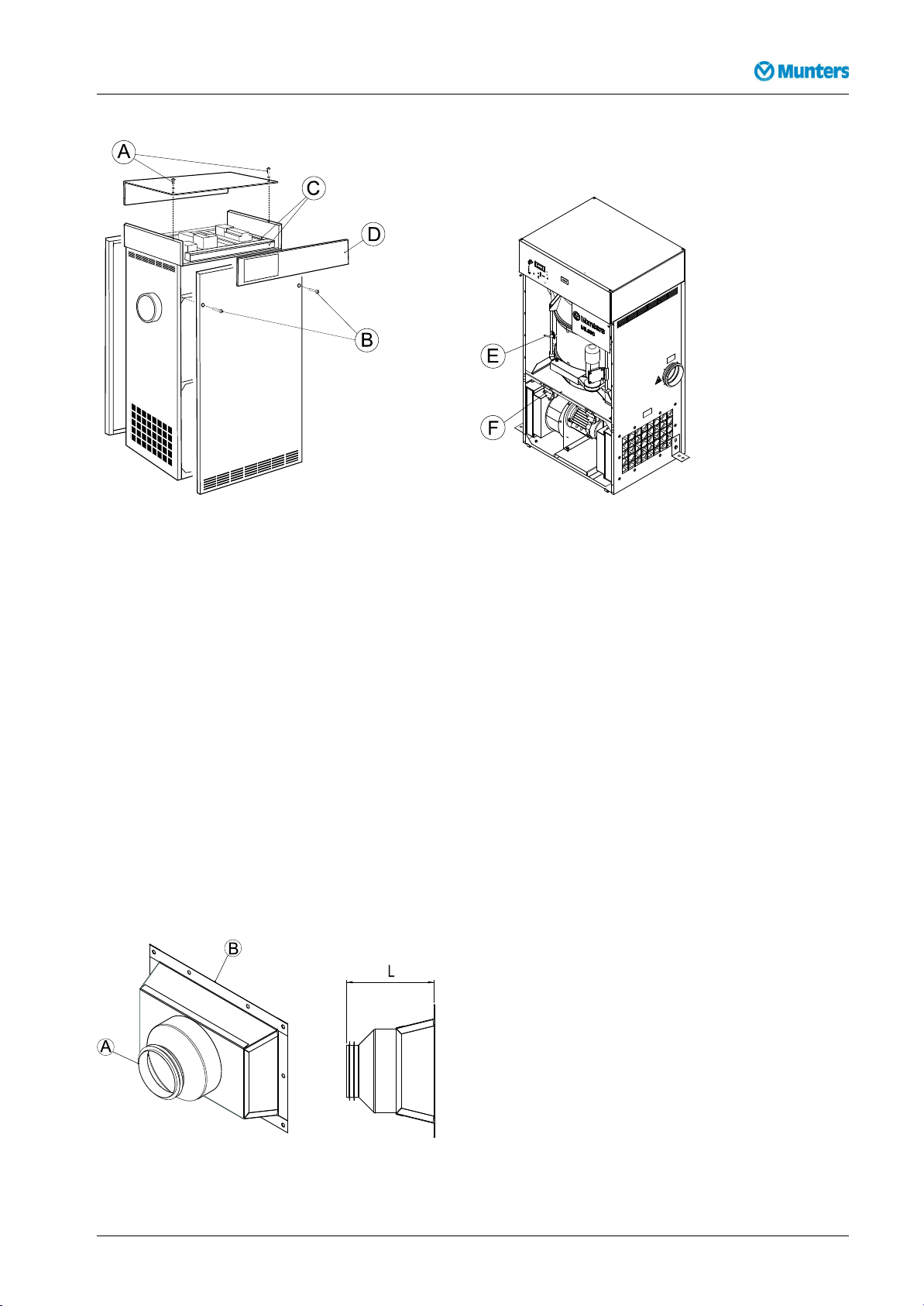

4.4Mirrorhandedductconnections

Thefrontandrearpanelsareinterchangeable,sothattheconnectionsforprocessairanddryairmaybe

situatedeitherontheleftorrightsideoftheunit.

Thedehumidiersaredeliveredwiththeprocessanddryairconnectionsontheleftsideoftheunit.If

itisrequiredtochangetheorientation,sothattheconnectionsareontherightsideoftheunit,proceed

asfollows.

W

ARNING!

W W

ARNING! ARNING!

Makesurethatthedehumidierisdisconnectedfromthemainspowerbeforechangingthepositionsofthe

processairanddryairconnections.

8Installation190TGB-1035-H1604

Page 13

DehumidierML420-MLT1400

Figure4.2ChangingpanelpositionsFigure4.3Rotorstop(E)andltermonitors(F)

1.Removethetwobolts(B)securingthefrontpanelandcarefullyremovethepanel.

2.Removethetwoboltssecuringtherearpanelandcarefullyremovethepanel.

3.Removethetwobolts(A)andwasherssecuringthecontrolandtoppanels,thencarefullyremovethe

toppanel.

4.Removethecableductcovers(C),re-routethecablesandtthecontrolpanel(D)ontotheoppositeside

oftheunit.Retthecableductcovers.

5.Loosentherotorstop(E)andthetwoltermonitors(F).Removethecableties.

6.Fittherotorstopandltermonitorsontheoppositesideoftheunit.Tiethecables.

7.Fitthefront,rearandtoppanelsintheirnewpositions.

4.5Ductinstallation

4.5.1Generalrecommendations

Theconnectionsforprocessandreactivationairaredesignedinaccordancewiththerecommendationsin

ISO13351.TherectangularductconnectionscontaintappedinsertsforM8screws.

Figure4.4Ductconnections

190TGB-1035-H1604Installation9

Page 14

DehumidierML420-MLT1400

Partnumber170-013448–005170-013448–004170-013448–003170-013448–002170-013448–001

A

B

L(mm)

ML420XX

ML690XX

MLT800XX

ML1100XX

ML1350XX

MLT1400XX

CA

UTION!

CA CA

UTION! UTION!

Ø100Ø125Ø160Ø200Ø250

Seesection9.1,Dimensionsandservicespace.

210210200140150

Thedehumidierhasbeendesignedtooperateatspecicprocessairowscorrespondingtothefansizes

installed.

■Theprocessairanddryairductsshouldbethesamediameter.Thesameappliestothereactivationair

andwetairducts.

■Thelengthofductworkmustbekeptasshortaspossibletominimisestaticairpressurelosses.

■Tomaintainperformance,allrigidprocessorreactivationairductworkjointsmustbeairandvapour

tight.

■Theprocessairductworkmustbeinsulatedtopreventcondensationdevelopingontheoutsideofthe

duct,wheneverthetemperatureoftheairwithintheductfallsbelowthedewpointtemperatureofthe

ambientairthroughwhichtheductworkisrouted.

■Theductsmustalwaysbeinsulatedwhenthereisariskoffreezing.

■Thewetairleavingthedehumidierwill,becauseofhighmoisturecontent,condenseontheinsideduct

walls.Byinsulatingtheducts,theamountofcondensateisreduced.

■Horizontalwetairductsmustbeinstalledwithaslightdecline(awayfromthedehumidier)todrain

awaypossiblecondensation.Suitablecondensationdrainsmustbeinstalledatlowpointsinthewet

airoutletduct,seeFigure4.7.

■Ensurethataccessforoperationandservicingisnotrestrictedwhendesigningandinstallingducting.

Formoreinformation,refertosection9.1,Dimensionsandservicespace.

■Toreducenoiseand/orvibrationbeingtransmittedalongrigidducts,goodquality,airtightexible

connectionscanbetted.

■Ductsmounteddirectlyontotheunitmustbeindependentlysupportedtominimisetheloadontheunit.

■Dampersforadjustingtheairowsmustbeinstalledinthesupplyairoutletandreactivationairinlet

ducts.Correctairowsareessentialfortheoperatingefciencyoftheunit.Forairowadjustment

instructions,seesection5.3,Airowcheckandadjustment.

■Thetotalpressuredropintheprocessandreactivationductworkmustnotexceedtheavailablepressure

ofthefansttedtothedehumidier.Fordetailsofminimumavailablestaticpressure,seesection

9.3,Technicaldata.

10Installation190TGB-1035-H1604

Page 15

DehumidierML420-MLT1400

ML

Munter s

420

1

2

3

5

5

4

C

B

D

A

Figure4.5Ductsrequiredforinstallation

A.Processairinlet1.Dryairdamper

B.Dryairoutlet

C.Reactivationairinlet

D.Wetairoutlet4.Reactivationairdamper

2.Externallterbox(option)

3.Ducttransition

5.Outlet/inletduct(wirenetting)

190TGB-1035-H1604Installation11

Page 16

DehumidierML420-MLT1400

4.5.2Ductforoutdoorairinlet

Whenbringingambientairfromoutdoorsintothedehumidier,theinletductopeningmustbelocated

sufcientlyhighabovegroundleveltopreventdustanddebrisfromentering.

Theductingmustbedesignedtopreventrainandsnowfrombeingdrawnintothedehumidier.Theair

inletmustbelocatedawayfrompossiblecontaminantssuchasengineexhaustgases,steamandharmful

vapours.

Topreventthewet(outlet)airfromhumidifyingthereactivation(inlet)air,theairinletforreactivationmust

belocatedatleast2mfromthewetairoutlet.

Attachawirenetwithameshwidthofapproximately10mmintheouterendoftheducttopreventanimals

fromenteringthedehumidierducting.

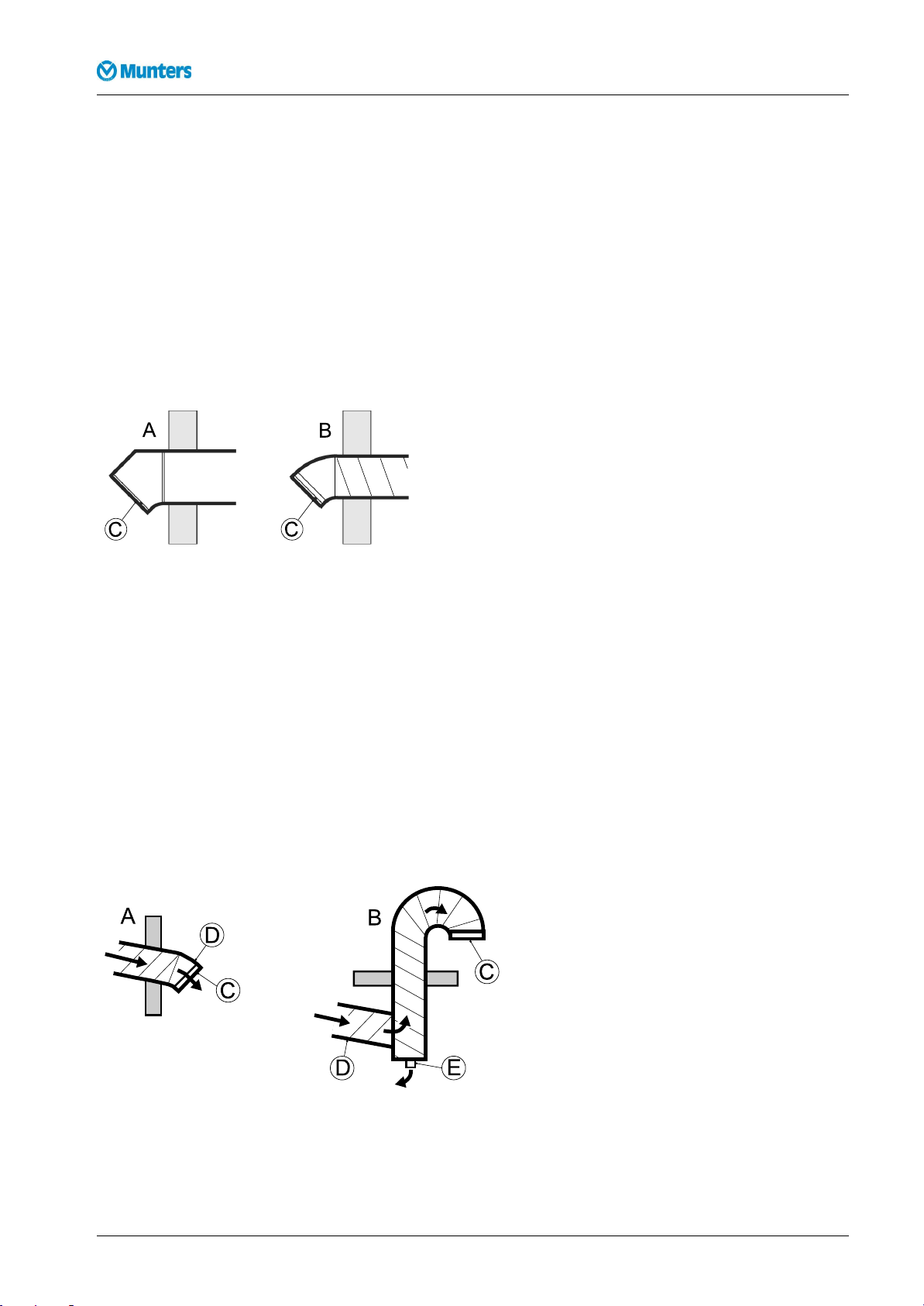

A.Rectangularducting

B.Roundducting

C.Wirenetting

Figure4.6Outdoorairinletdesign

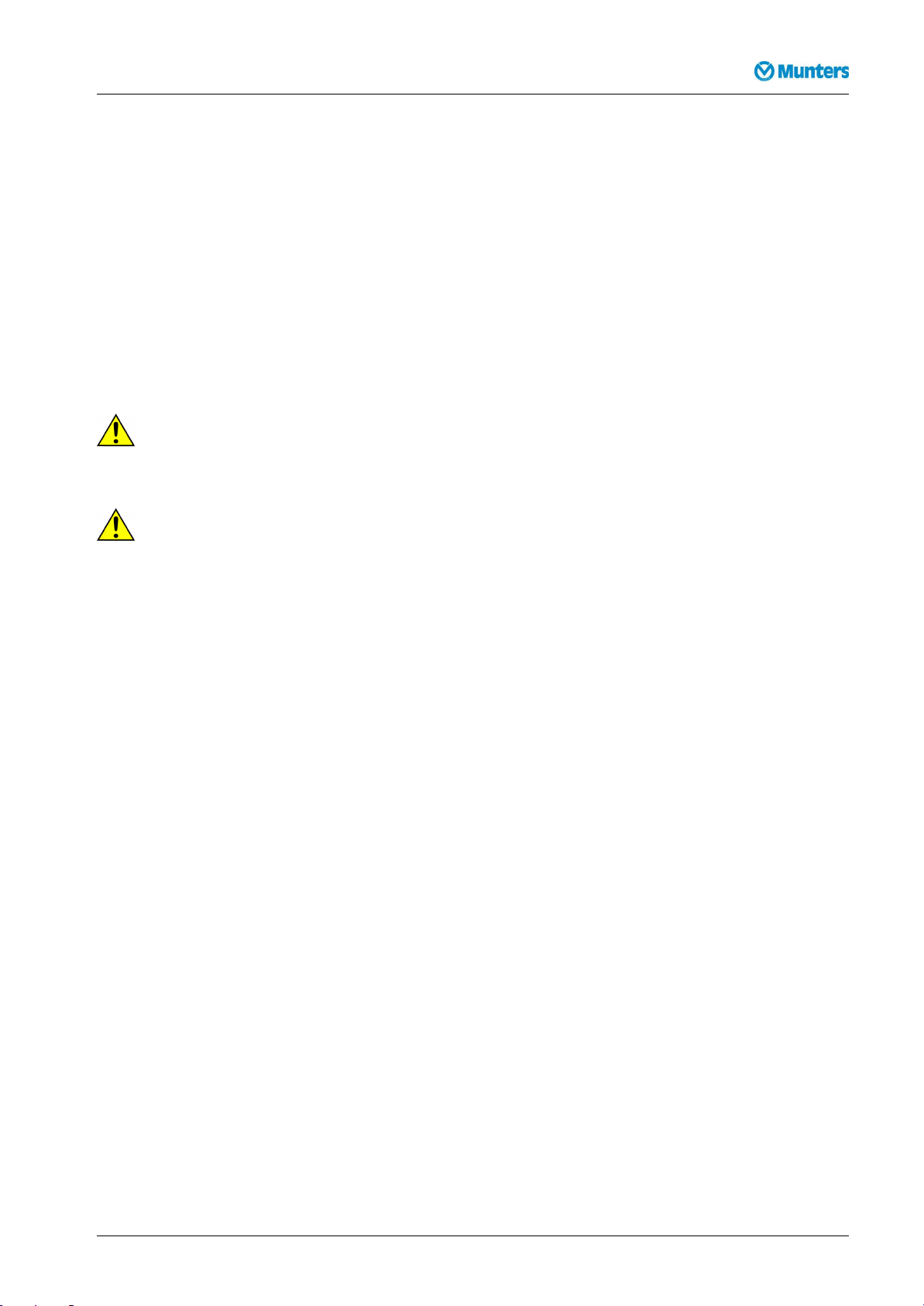

4.5.3Ductforwetairoutlet

Thematerialforthewetairductmustwithstandcorrosionandtemperaturesofupto100°C.Thewetair

ductingmustalwaysbeinsulatedifthereisariskofcondensation.Thewetairleavingthedehumidierwill

easilycausecondensationontheinsideoftheductwallsduetothehighmoisturecontent.

Horizontalductsmustbeinstalledslopingdownwards(awayfromthedehumidier)todrainawaypossible

condensation.Theductslopemustbeatleast2cm/m.Inaddition,drainageholes(5mm)shouldbemadeat

lowpointsintheducttopreventwateraccumulation.

Attachawirenetwithameshwidthofapproximately10mmintheouterendoftheducttopreventanimals

fromenteringthedehumidierducting.

A.Horizontalwetairoutlet

B.Verticalwetairoutlet

C.Wirenetting

D.Downwardslope

E.Condensatedrainage

Figure4.7Wetairoutletdesign

12Installation190TGB-1035-H1604

Page 17

DehumidierML420-MLT1400

4.6PrecautionarymeasuresforunitswithLIdesiccantrotor

ThestandarddeliveryisMuntershighperformancedesiccantrotorHPS(HighPerformanceSilicagel).

IfthedehumidierisdeliveredwithanLIrotor(lithiumchloride)itisimportantthattherotordoesnot

becomeloadedwithmoisturewhenthedehumidierisoff.

NOTE!Makesurethatnoairpassingthroughtherotorhasarelativehumiditygreaterthan80%.

Itisrecommendedtoinstallclosingdampersintheprocessandreactivationairinletstoavoidthatairwith

highrelativehumidityisdrawnthroughtherotorandintotheroom.

Thisisparticularlyimportantwhentheprocessairisdrawnfromoutdoors,orwhenthesystemhasbeen

ttedwithapre-cooler.

4.7Electricalconnections

W

ARNING!

W W

ARNING! ARNING!

Allelectricalequipmentconnectionsmustbecarriedoutinaccordancewithlocalregulationsandbyqualied

personnel.Riskofelectricalshock.

W

ARNING!

W W

ARNING! ARNING!

Theunitmustneverbeconnectedtoavoltageorfrequencyotherthanthatforwhichitwasdesigned.Refertothe

unitidenticationplate.

Eachunitissuppliedcompletewithalltheinternalwiringinstalledandconguredinaccordancewiththe

speciedvoltageandfrequencyontheidenticationplate.

NOTE!Thesupplyvoltagemustnotdifferfromthespeciedoperatingvoltagebymorethan+/-10%.

Forconnectiondetails,seetheidenticationplateandthewiringdiagramorsection9.3,Technicaldata.

4.8Externalhumiditysensor

ML-seriesdehumidiersarewiredsothatwhentheunitissettoAUTOmatic,itcanbecontrolledfrom

anexternallymountedhumiditysensor.

Allmodelshaveatwo-stageheater,andcanbecontrolledbyatwo-stagehumiditysensor.Thismethodis

moreefcientandallowsformoreaccuratedehumidicationcontrol.

Theelectricalconnectionsaremadeatterminalsintheelectricalcontrolpanel.Forwiringandconnection

details,seethewiringdiagram.

NOTE!Wherenohumiditysensorisconnectedtotheunit,thedehumidierwillbeoperatingatmaximumoutput

foraslongastheunitisswitchedon.

Aroomhumiditysensoristobemounted1-1.5mabovetheoor.Itmustbepositionedsothatitisnot

directlyexposedtodryairfromtheunitortohumidairowinginthroughopeningdoors.Positionitaway

fromheatsourcesanddirectsunlight.

■Thehumiditysensorconnectingcableshouldhaveaconductorareaofnotlessthan

0,75mm

■ThehumiditysensormustbedesignedsothatthecontactscloseonarisingRHtocompletethecontrol

2

andmusthaveaninsulationresistanceratinginexcessof500VAC.

circuitandstartthedehumidier.

190TGB-1035-H1604Installation13

Page 18

DehumidierML420-MLT1400

■Voltagedropscanoccurwhenusingexcessivelylongcables.

Ifthevoltageacrosstheterminalsusedforconnectingthehumiditysensorislessthan20VAC,aseparate

relaycontrolledbythehumiditysensormustbeused.

4.9Gasreactivation(ML1100unitsonly)

Forfurtherinformationoninstallation,start-upandmaintenanceofgasburners,seeappendixaboutgas

reactivationprovidedwiththeunit.

14Installation190TGB-1035-H1604

Page 19

DehumidierML420-MLT1400

5Commissioning

TheML420-MLT1400dehumidiershaveseveralstandardfunctionsthatneedtobesetbeforeinitial

start-up.Someofthefunctionsrequireconnectiontoexternalequipment.

Somefeaturesrequireconnectionofexternalequipment.Forwiringdetails,seethewiringdiagram.

5.1Settingsbeforestart-up

5.1.1Continuousprocessairfanoperation

Standardsettingsautomaticallyactivatetheprocessairfanonlywhendehumidicationisrequired.

However,continuousprocessairowcanbedesirableevenwhendehumidicationisnotrequired.

Continuousprocessairowcanbeset,seethewiringdiagram.

5.1.2Single-stagehumiditysensor

NOTE!Whennohumiditysensorisconnected,thedehumidierwillrunatmaximumeffectcontinuously.

Ifasingle-stagehumiditysensoristted,thiswillswitchthedehumidieronandoff.Asingle-stage

humiditysensorisconnectedaccordingtothewiringdiagram.

Tomaintainaircirculation,preselectcontinuousoperationoftheprocessairfaneventhough

dehumidicationisnotrequired.Forfurtherinformation,seesection5.1.1,Continuousprocessairfanoperation.

5.1.3Two-stagehumiditysensor

NOTE!Whennohumiditysensorisconnected,thedehumidierwillrunatmaximumeffectcontinuously.

Ifatwo-stagehumiditysensorisconnected,thiswillcontrolthereactivationheaterintwostages.The

reactivationpoweriscontrolledonthebasisofthehumiditysensorreadingandthesetpoint.Atwo-stage

humiditysensorisconnectedaccordingtothewiringdiagram.

Tomaintainaircirculation,preselectcontinuousoperationoftheprocessairfaneventhough

dehumidicationisnotrequired.Forfurtherinformation,seesection5.1.1,Continuousprocessairfanoperation.

5.1.4Remotefaultindication

ThePCBdisplaycanbeusedforageneralindicationofthefollowingfaultsonthedehumidier:

■Processairfan

■Reactivationairfan

■Drivemotor

■Heater

■Auxiliaryequipmentinput

■Rotorhasstopped(ifthisoptionisinstalled)

■Blockedprocessairlter(ifthisoptionisinstalled)

■Blockedreactivationairlter(ifthisoptionisinstalled)

190TGB-1035-H1604Commissioning15

Page 20

DehumidierML420-MLT1400

5.2Pre-startchecks

W

ARNING!

W W

ARNING! ARNING!

Installation,adjustments,maintenanceandrepairsmustonlybecarriedoutbyqualiedpersonnelwhoare

awareoftherisksinvolvedwhenworkingwithequipmentoperatingwithhighelectricalvoltageandhighmachine

temperatures.

Beforestartingthedehumidierforthersttime,ensurethatthemainspowersupplyisisolatedfromthe

dehumidierandcarry-outthefollowingchecks:

1.CheckthattheModeswitchonthedehumidierisinthe“OFF”position,seesection6.4,Operatorpanel.

2.Checktheairintakeltersfordamageandproperxationandalsocheckthatallareasinsidetheunitare

clean.

3.Visuallyinspectallductingandductconnectionstomakesurethatallconnectionshavebeencorrectly

installedandthattherearenosignsofdamagetothesystem.Alsocheckthatallductsarefreefrom

obstaclesblockingtheairpassage.

4.Removethetoppanelandcheckthatnoneofthemaincontactbreakersintheelectricaloperatorpanel

havebeentripped.Fordetailsrefertothewiringdiagramsprovidedwiththeunit.

5.Checkthattheincomingpowersupplyvoltageiscorrectandthatthecablesarecorrectlyconnected.

6.Checktherotationdirectionofthefanimpellerafterconnectiontothepowersupply.Openthefront

panelofthedehumidierandtakeouttheprocesslter.Startthedehumidierandcheckthatthefan

impellerisrotating.Switchoffthedehumidierandwatchthefanimpellerjustbeforeitstopsrotating.

Checkthatitisrotatingclockwise.

7.Ifanexternalhumiditysensorisused,checkthatthesensoriscorrectlypositionedintheroomandis

correctlyconnectedtotheunit,seesection4.8,Externalhumiditysensor.

8.Settheprocessandreactivationairowdamperstothefullyopenposition.

16Commissioning190TGB-1035-H1604

Page 21

DehumidierML420-MLT1400

5.3Airowcheckandadjustment

Toobtainthedesignperformance,thedryairandreactivationairowdampersmustbecorrectlyadjustedin

accordancewiththeratedairow,seesection9.3,Technicaldata.

Ifnecessary,contactMuntersforassistanceconcerninginstallationandsettings.Munterscontactaddresses

areprovidedonthebackcoverofthismanual.

CA

UTION!

CA CA

UTION! UTION!

Incorrectlysetprocessandreactivationairowscancausetheunittomalfunction.

Anydamagetotheunitresultingfromincorrectadjustmentoftheairowscaninvalidatethewarrantyoftheunit.

Theunitmustnotberunformorethanafewminutesbeforesettingupthecorrectairows.

1.Adjustthedampersinstalledinthedryairoutletandreactivationairinletductstothecorrectrated

airows.

2.Startthedehumidierandrunatfullpowerfor8minutestoallowthereactivationheatertoreachits

normaloperatingtemperature.

3.Verifythatthetemperaturedifferencebetweenthereactivationinletairandthereactivationtemperature

is95°C(tolerancelimit±5°C).Ifthetemperaturedifferenceliesoutsideofthe5%tolerancelimit,the

reactivationairdampercanbeadjustedinsmallstepsuntilthereactivationtemperatureiswithinthe

speciedtolerances.Allowthetemperaturetostabiliseaftereachadjustment.

Example:

Inletairtemperature=15°C

Reactivationairtemperature=110°C

Temperatureincrease=95°C

190TGB-1035-H1604Commissioning17

Page 22

DehumidierML420-MLT1400

6Operation

6.1General

ML420-MLT1400dehumidiersareequippedwithanoperatorpanelwithamodeselectorswitchand

LEDindicators.

Themodeselectoroftheoperatorpanelhastwooperatingpositions:

MAN(Manualmode)

Thedehumidierfans,rotorandreactivationheateroperatecontinuouslyatfullcapacity.

AUTO(Automaticmode)

Thedehumidierfans,rotorandreactivationheateroperatewhentherelativehumidityexceedsthedesired

value.

6.2Quickstop

Undernormaloperatingconditions,themodeswitchisusedtostopandstarttheunit.Inanemergency

situation,stopthedehumidierusingthemainpowerswitchontheside.

CA

UTION!

CA CA

UTION! UTION!

Onlyusethemainpowerswitchtostoptheunitinthecaseofanemergency.Thenormalshutdownsequencewill

notbefollowed.Thefansstopandtheheatercanbeveryhot,whichcanresultindamagetotheheaterandother

componentsclosetoit.

6.3Beforestarting

Followtheinstructionsinsections5.2,Pre-startchecksand5.3,Airowcheckandadjustmentbeforeinitial

start-upofthedehumidier.

18Operation190TGB-1035-H1604

Page 23

DehumidierML420-MLT1400

1

150 C

100 C

50 C

o

o

o

AU T

MAN

2

14

12

13

11

9

10

8

7

6

5

0

3

4

SET

RH 98

% RH

OUT.1

OUT.2

ALARM

6.4Operatorpanel

Figure6.1Mainpowerswitch

Figure6.2Operatorpanelwithbuilt-inRH98

190TGB-1035-H1604Operation19

Page 24

DehumidierML420-MLT1400

Item

Switch/Indicator

Function

1MainpowerswitchWhenthemainpowerswitchissetto”0”,thereisnopowerinthecontrolcircuit,

andtheunitcannotbestarted.Whenthemainpowerswitchissetto”1”,poweris

suppliedtothecontrolcircuit,andthedehumidiercanbestartedusingthemode

switch.

2Modeswitch

Whenthemodeswitchissetto”MAN”thedehumidierisinmanualmode.Itthen

runscontinuously(fullcapacity).

Withthepowerswitchsetto”0”,thedehumidierisswitchedoff.

Whenthemodeswitchissetto”AUT”thedehumidierisinautomaticmode.Inthis

mode,asingleortwostagehumiditysensormustbeconnectedtotheunitifitisnot

equippedwithaRH98oraVariDrycontrolsystem.Thehumiditysensor ,RH98or

VariDrydictateswhenthedehumidierstopsandstarts.

3

ReactivationairfanindicatorThereactivationairfanindicatorlamplightswhenthefanisrunning.Itashesifthere

isafaultinthefan.

4Reactivationairtemperature

Indicatesthereactivationairtemperature.

display

5

Mainssupplyconnection

indicator

6Unitrunningindicator

Indicatesthatmainssupplyisconnectedtothedehumidierandthemainpower

switchissetto”1”.

Indicatesthattheunitisrunning,orisreadytostartuponasignalfromthehumidity

sensor,RH98orVariDry(automaticmode).

7

Faultindicator

Aashingfaultwarningindicatorlampindicatesthattheunithasshut-downduetoa

faultinoneofthefollowing:

-Processairfan

-Reactivationairfan

-Drivemotor

-Reactivationheater(stage1)(electricreactivationheatermodelsonly)

-Reactivationheater(stage2)(electricreactivationheatermodelsonly)

-Rotorhasstopped

-Auxiliaryequipment

(1)

(2)

Thecorrespondingindicatorsashtofacilitatefaulttracing.Inaddition,therelay

fortheremoteindicationoffaultsisactivated.Forfurtherinformationseesection

8.3,Faulttracinglist.

8Auxiliaryequipmentindicator

Thisisauserdenedoption.Theindicatorlightsinnormaloperationalmodeand

ashestoindicateafault.Thedehumidierisautomaticallyswitchedoff,andthe

faultandremoteindicatorsareactivatedifafaultoccursintheauxiliaryequipment.

Forunitsttedwithanair-cooledcondenser,theauxiliaryequipmentindicatorlamp

isonwhenthecondenserisinnormaloperationalmodeandashesifafaultoccurs

inthecondenserfanorheater.

9

Processairlterblocked

indicator

(1)

Whentheindicatorforblockedprocessairlterlights,thelterisblocked.Ablocked

lterdoesnotmeanthattheunitmustbeswitchedofforthatthefaultindicatoris

activatedTheremotefaultindicator(ifinstalled)isactivatedwhenablockedlteris

detected.

10DrivemotorindicatorThedrivemotorindicatorlamplightswhentherotor'sdrivemotorisrunning.It

asheswhenthereisafaultinthedrivemotorortherotorhasstopped.

11

ProcessairfanindicatorTheprocessairfanindicatorlamplightswhenthefanisrunning.Itashesifthere

isafault.

12Reactivationheaterindicator

(stage1)

13Reactivationheaterindicator

(stage2)

14

Reactivationairlterblocked

indicator

(1)

Theindicatorlightswhentheheaterstarts.Itashesifthereisafaultintheheater

(stage1).

Theindicatorlightswhentheheaterstarts.Itashesifthereisafaultintheheater

(stage2).

Whentheindicatorforablockedreactivationairlterlights,thelterisblocked.

Ablockedlterdoesnotmeanthattheunitmustbeswitchedofforthatthefault

indicatorisactivatedTheremotefaultindicator(ifinstalled)isactivatedwhena

blockedlterisdetected.

(1)Options.

(2)Forunitsttedwithanair-cooledcondenser,theauxiliaryequipmentindicatorlampisonwhenthecondenserisinnormal

operationalmodeandashesifafaultoccursinthecondenserfanorheater.

Table6.1Operatorpanelfunction

20Operation190TGB-1035-H1604

Page 25

DehumidierML420-MLT1400

SET

RH 98

%RH

OUT.1

OUT.2

ALARM

6.5RH98operatorpanel

Figure6.3RH98operatorpanel

Checkingandchangingsetpointsandcontrolparameterscanbemadeduringoperationorinstand-by

mode.

ButtonFunction

Display/changeacertainvalueandresetthealarm

Increasethevalue

Decreasethevalue

%RH:Displaypositionofcontrolstepsforreactivationheater(0=off;1=on).

Table6.2RH98operatorpanelfunctions

Duringnormaloperationandinanypositionofthemodeswitchthecurrentrelativeairhumidityis

displayed.

6.6Operatingtheunit

6.6.1Manualmode

1.Setthemainpowerswitchto”1”(on)andcheckthatthemainsconnectionindicationlamplights.

2.SetthemodeswitchonthecontrolpaneltoMAN.Checkthatthefollowingindicatorlampslight:

■Mainssupplyconnectionindicator

■Unitrunningindicator

■Bothindicatorsforthereactivationheater

■Bothprocessairandreactivationairfanindicators

■Drivemotorindicator

3.Lettheunitrunforabout8minutestoallowtheoperatingconditionstostabilise.Thencheckthatthe

reactivationheaterisworking(temperatureindicatorshowsthetemperatureofthereactivationair).

190TGB-1035-H1604Operation21

Page 26

DehumidierML420-MLT1400

4.Setthemodeswitchonthecontrolpanelto”0”andcheckthatboththeindicatorlampsforthe

reactivationheatergoout.

NOTE!Inordertodissipateanyresidualheat,thereactivationairfan,processairfanandthedrivemotorwill

continuetorun(aftertheunithasbeenswitchedoff)untilthetemperaturehasfallenbelow50°C.

5.Checkthattheprocessairfan,reactivationairfananddrivemotorindicatorsgooutwhenthe

temperaturefallsbelow50°C,andthatthepowerconnectedindicatorremainson.

Fordetailsontheoperatorpanel,seesection6.4,Operatorpanel

6.6.2Automaticmode–humiditysensorconnected

Asingleortwostagehumiditysensormustbeconnectedfortheunittoberuninautomaticmode.For

furtherinformation,seesection5.1.2,Single-stagehumiditysensorand5.1.3,Two-stagehumiditysensor.

1.SetthemodeswitchtoAUT.

2.AdjustthehumiditysensorsetpointtothelowestRHvalue.Setthemainpowerswitchto”1”(on).

Checkthatthefollowingindicatorlampsareonandthattheunitisrunning.

■Mainssupplyconnectionindicator

■Unitrunningindicator*

■Bothreactivationheaterindicators*

■Bothprocessairandreactivationairfanindicators*

■Drivemotorindicator*

NOTE!IfthecurrentRHvalueintheroomtobedehumidiedislowerthanthesetpointonthehumiditysensor,

theaboveindicatorswillnotlightandthedehumidierwillnotstart.

3.Slowlyincreasethehumiditysetpointandcheckthattheunitswitchesoffwhenthesetpointmatchesthe

RHintheroomwherethehumiditysensorisinstalled.

4.Slowlydecreasethehumiditysetpointandcheckthattheunitswitchesonwhenthesetpointfallsbelow

theRHintheroomwherethehumiditysensorisinstalled.

5.Setthemodeswitchonthecontrolpanelto”0”andcheckthatboththeindicatorlampsforthe

reactivationheatergoout.

NOTE!Inorderfortheunit’sheaterstocooldown,thereactivationairfan,processairfanandthedrivemotorwill

continuetorun(aftertheunithasbeenswitchedoff)untilthetemperaturehasfallenbelow50°C.

6.Checkthattheprocessairfan,reactivationairfananddrivemotorindicatorsgooutwhenthe

temperaturefallsbelow50°Candtheunitisrunning,andthatthepowerconnectedindicatorremains

on.

7.AdjustthehumiditysetpointtothedesiredRHvalue.

Fordetailsontheoperatorpanel,seesection6.4,Operatorpanel

6.6.3Automaticmode-RH98orV ariDry(option)

IftheunitisttedwithafactoryinstalledRH98orVariDry(option)humiditycontrolsystem,theexternal

humiditysensormustbeinstalledandcorrectlyconnectedtotheunit.Thesamesiterequirementsapplyto

thehumiditysensorandRH98orVariDry,seesection4.8,Externalhumiditysensor.

Formoreoperationaldetails,seeappendix1.6,Humiditycontrolsystem.

1.SetthemodeswitchtoAUT.

22Operation190TGB-1035-H1604

Page 27

DehumidierML420-MLT1400

2.AdjusttheRH98orVariDrysetpointtothelowestRHvalue,seesection6.5,RH98operatorpanel.

3.Setthemainpowerswitchto”1”(on).Checkthatthefollowingindicatorlampsareonandthatthe

unitisrunning.

■Mainssupplyconnectionindicator

■Unitrunningindicator*

■Bothreactivationheaterindicators*

■Bothprocessairandreactivationairfanindicators*

■Drivemotorindicator*

NOTE!*IfthecurrentRHvalueintheroomtobedehumidiedisbelowthesetpoint(factorysetting50%RHof

RH98orVariDry),theaboveindicatorswillnotlightandthedehumidierwillnotstart.

4.Slowlyincreasethehumiditysetpointandcheckthattheunitswitchesoffwhenthesetpointmatchesthe

RHintheroomwherethehumiditysensorisinstalled.

5.Slowlydecreasethehumiditysetpointandcheckthattheunitswitchesonwhenthesetpointfallsbelow

theRHintheroomwherethehumiditysensorisinstalled.

6.Setthemodeswitchonthecontrolpanelto”0”andcheckthatboththeindicatorlampsforthe

reactivationheatergoout.

7.Checkthattheprocessairfan,reactivationairfananddrivemotorindicatorsgooutwhenthe

temperaturefallsbelow50°Candtheunitisrunning,andthatthepowerconnectedindicatorremains

on.

8.AdjustthehumiditysetpointtothedesiredRHvalue.

190TGB-1035-H1604Operation23

Page 28

DehumidierML420-MLT1400

7Serviceandmaintenance

7.1Safety

Figure7.1ElectricalhazardFigure7.2Secureagainstreconnection

W

ARNING!

W W

ARNING! ARNING!

Adjustments,maintenanceandrepairsmustonlybecarriedoutbyqualiedpersonnel.

W

ARNING!

W W

ARNING! ARNING!

Beforedoinganyserviceormaintenanceworkontheunitmakesurethatallelectricalequipmentisdisconnected

fromthepowersupply,andsecuredagainstreconnection.

7.2General

Muntersdehumidiersaredesignedforlong-term,continuoususagewithahighdegreeofreliability.

Aswithallmachinery,regularserviceandmaintenanceisrequiredtokeepthedehumidierinoptimal

conditionsothatitworksmostefciently.

Serviceandmaintenanceintervallengthsareprimarilydeterminedbyoperatingconditionsandthe

environmentinwhichtheunitisinstalled.Forexample,iftheprocessaircontainsalotofdust,preventative

maintenanceshouldbecarriedoutatshorterintervals.Thesamealsoappliesiftheunitworksintensively .

7.3Serviceoptions

Inadditiontocommissioningoftheunittherearefourserviceoptions(A-D)asstandard.

S.Commissioning/start-up.

A.Inspectionandifnecessarychangeoflter.Generalfunctioncheck.

B.InadditiontoA,safetycheckandcapacity ,temperatureandhumidityregulationmeasurements.

C.InadditiontoB,preventivereplacementofsomecomponentsafter3yearsofoperation.

D.InadditiontoC,preventivereplacementofsomecomponentsafter6yearsofoperation.

NOTE!AlwayscontactMuntersforserviceorrepair.Operatingfaultscanoccuriftheunitismaintained

insufcientlyorincorrectly.

NOTE!Commissioning/Start-upinspection"S"byMuntersismandatorytovalidatethefullwarranty.

Muntersserviceengineershavespecialequipmentandrapidsparepartsaccesstohandleserviceonall

Muntersproducts.Alltestequipmentusedbyourpersonneltoensurepropersystembalancingiscertied

foraccuracy .

MuntersServicecanofferaserviceplanadaptedtosuittheconditionsofaspecicinstallation.Seecontact

addressesonthebackpageofthismanual.

24Serviceandmaintenance190TGB-1035-H1604

Page 29

DehumidierML420-MLT1400

7.4Extendedwarranty

MuntersoffersanextendedwarrantytothestandardtermswhentheCustomersignsaserviceagreement

withMunters.Detailsareavailableonrequest.

7.5Cleaning

UseonlyapH-neutralsoapywatersolutionandasoftspongeforcleaningoftheunitcasing.

Whencleaningtheinside,avoidcontactwiththerotorandwipethesurfacesdry.

Useavacuumcleanerwithabrushheadfortherotor.ContactMuntersforinstructionsifvacuumcleaning

isnotsufcient.

7.6Serviceandmaintenanceschedule

Service

work

Checkandreplacelterifnecessary,

checkfunctions

Capacitycheck,rotorinspectionXXXXXXX

Preventiveinspectionincl.safetycheckXXXXXXX

Replacehightemperaturecut-outXX

Checkdrivebeltandsupportrollersand

replaceifnecessary

ReplacedrivemotorX

Checkfans,impellers,motor,bearingsX

Checkelectricalandcontrolsystems,

checkfunction

ServiceoptionSABABACABABAD

Operatingtime

inhours

Calendartime

inmonths

04000800012000160002000024000280003200036000400004400048000

061218243036424854606672

XXXXXXXXXXXXX

XX

XXXXXXX

Calibratehumiditycontrolequipment

andsensors

Calibratetemperaturecontrol

equipmentandsensors

Checkrotorhousing,replacerotor

gasketsifnecessary

Replacetherotoronlywhenacapacitycheckshowsthatitisnecessary .

XXXXXXX

XXXXXXX

Table7.1Serviceandmaintenanceschedule

190TGB-1035-H1604Serviceandmaintenance25

X

Page 30

DehumidierML420-MLT1400

NOTE!Serviceworkshouldbeperformedatindicatedoperatinghoursorcalendartime,whicheverisreached

rst.

NOTE!MaintenanceschedulerestartsagainaftermaintenancetypeD.

26Serviceandmaintenance190TGB-1035-H1604

Page 31

DehumidierML420-MLT1400

7.7Filterchange

Replacetheltersifnecessaryevery6months,seedescriptionbelow.

1.Loosenthetwoscrewsonthetopofthefrontpanel.

UseAllenKeyNo.5.

2.Liftthepanelandremoveitfromtheunit.

3.Pullouttheltercartridge.

4.Cleanthelterhousing.

5.Putinanewlter.Followthearrowtogetthecorrect

airowdirection.

6.Liftthepanelinplace.Makesurethetwobottom

hookstintothepanel.

7.Tightenthetwotopscrews.

190TGB-1035-H1604Serviceandmaintenance27

Page 32

DehumidierML420-MLT1400

8Faulttracing

8.1General

Thepurposeofthischapteristoprovideguidanceinbasicfaulttracingandprovideinstructionsfor

correctiveactionstoremedyanyfaults.Gothroughthelistinsection8.3,Faulttracinglistbeforecontacting

Munters.Thelistprovideshelpinidentifyingtypesoffaultsthatareeasytoremedywithouttheassistance

ofspeciallytrainedpersonnel.

8.2Safety

W

ARNING!

W W

ARNING! ARNING!

Installation,adjustments,maintenanceandrepairsmustonlybecarriedoutbyqualiedpersonnelwhoare

awareoftherisksinvolvedwhenworkingwithequipmentoperatingwithhighelectricalvoltageandhighmachine

temperatures.

W

ARNING!

W W

ARNING! ARNING!

Beforedoinganyserviceormaintenanceworkontheunitmakesurethatallelectricalequipmentisdisconnected

fromthepowersupply,andsecuredagainstreconnection.

28Faulttracing190TGB-1035-H1604

Page 33

DehumidierML420-MLT1400

8.3Faulttracinglist

ThecontrolpanelLEDaretheprimarysourceofinformationforfaulttracingwhentheunithasgivenan

alarmandstoppedautomatically.

GothroughthefaulttracinglistbelowbeforecontactingMuntersservicedepartment.Thelistcontains

informationforidentifyingfaultsthatareeasytorepairwithoutthehelpofatechnician.

IftheunitisequippedwiththehumidityregulationsystemRH98,seealsoappendix

1.6,Humiditycontrolsystem.

SymptomIndicatorsPossiblecauseCorrectiveaction

Unithas

stopped.

stopped.

Unithas

stopped.

Nolights.

No.12

doesnot

ash.

No.12,6

and7are

ashing.

Powersupplyfailure.Checkpowersupplytotheunit.

Mainssupplyswitch(no.1)issetto

”0”.

TransformerTC25fuseFU26

failure.

CircuitbreakerQM25trippeddue

toawiringfault.

Theunithasbeensetto

AUTomaticmodebymistakewith

nohumiditysensorconnected.

Humiditysensorfault(AUTomatic

mode).

Ifbothindicatorsareashing,

itindicatesthatone(orboth)of

thehightemperaturecut-outs

(BT27andBT30)havetripped,

duetoeitheranobstructioninthe

reactivationairow,orbecausethe

reactivationairowhasbeenset

toolow.

Setthemainssupplyswitchto”1”andcheckthatthemains

connectionindicator(no.14)ison.

Investigatethecauseofthefaultandrectify.Replacethefuse.

Investigatethecauseofthefault,andrectify.

ResetQM25.Ifthefaultre-occurs,contactMunters.

SetthemodeswitchtoMANual,andcheckthattheunitstarts. Unithas

SetthemodeswitchtoMANual,andcheckthattheunitstarts.Ifthe

unitstarts,thefaultisprobablyinthehumiditysensor.

SetthemodeswitchtoAUTomaticmode,andcheckthehumidity

sensorbyseeingifthedehumidierstartswhenthehumiditysensor

setpointisreduced.Thenresetthehumiditysensorsetpoint.

Calibratethehumiditysensor(accordingtothemanufacturer's

recommendations)ifnecessary ,orreplaceit.

Switchoffthemainssupplyandallowtheunittocooldown.

ResetQM12andQM14circuitbreakersasrequired.

Checkthattheairinlet,outletductsandltersarefreefrom

obstructionsandarenotblockedwithdirt.

Switchonthemainssupplyatthemainssupplyswitchtoresetthe

faultwarning.Checkandadjustthereactivationairow ,seesection

5.3,Airowcheckandadjustment.

Unithas

stopped.

190TGB-1035-H1604Faulttracing29

Either

No.12,6

and7are

ashing.

Safetydeviceshavetrippeddueto

aheaterelementorwiringfault.

Switchoffthemainssupplyandallowtheunittocooldown.

Investigatethecauseofthefault,andrectify.

ResetQM12andQM14asrequired.

Switchonthemainssupplyatthemainssupplyswitchtoresetthe

faultwarning.

Page 34

SymptomIndicatorsPossiblecauseCorrectiveaction

DehumidierML420-MLT1400

Unithas

stopped.

Unithas

stopped.

No.12,2,8

and/or9are

ashing.

No.1 1and

12.

OnlyNo.

12.

Safetydevicehastrippeddueto

oneofthefollowing:

FanmotorfaultInvestigatethecauseofthefault,andrectify.

DrivemotorfaultML420:ResetQM16-drivemotor ,reactivationfanandprocessfan.

RotorstopwarningInvestigatethecauseofthe“rotorstopped”warningandrectifythe

WiringfaultSwitchonthemainssupplyatthemainssupplyswitch,andstartthe

Unitsttedwithanair-cooled

condenser:

Safetydeviceshavetrippeddueto

acondenserfanfault.

Safetydeviceshavetripped

duetoacondenserheaterfault

(reactivationairtemperature)

Switchoffthemainssupplyandallowtheunittocooldown.

ML690-MLT1400:ResetQM16-reactivationfan.

ResetQM21-drivemotororprocessfan.ResetQM18forunitswitha

condenser.

fault.

unittoresetthefaultwarning.Ifthefaultreoccurs,contactMunters.

Switchoffthemainssupplyandallowtheunittocooldown.Investigate

thecauseofthefault,andrectify .

ResetQM21.

Investigatethecauseofthefault,andrectify.

ResetQM23.

Lossof

performance:

Dehumidier

appearsto

beoperating

correctly,

butisnot

controlling

thehumidity

Table8.1Faulttracinglist

Temperatureincreaseacrossthe

reactivationbatteryistoolow .

Reactivationandprocessairows

donotcorrespondtotherated

airows.

Rotordrivefailure.Checkrotordrivebeltanddrivemotor.

Incorrectfunctioningofhumidity

sensor,RH98orV ariDry

(AUTomaticmode).

Checkthefunctionofthereactivationheater .

Checkandadjustthereactivationairow,seesection

5.3,Airowcheckandadjustment.

Checktheoperationandconnectionofthehumiditysensor ,RH98or

VariDryinaccordancewiththemanufacturer’srecommendations.

30Faulttracing190TGB-1035-H1604

Page 35

DehumidierML420-MLT1400

s

420

ML

Munter

J

9Technicalspecication

9.1Dimensionsandservicespace

1.Processairinlet3.Reactivationairinlet

2.Dryairoutlet4.Wetairoutlet

Figure9.1RequiredservicespaceFigure9.2Holepatternforductconnection

Dimensions(mm)

Model

(1)

(1)

ABCØDØEFGHJLMNPX

ML42071959313051601002722426501 122423734529670050050128

ML69071959314052001252722427501 122423724529670050050146

MLT80071959313051601002722426501122423734529670050050128

ML110071959315052501602702428501252423734529670050050156

ML135071959315052501602702428501252423724529670050050156

MLT140071959314052001252722427501122423724529670050050146

(1)Spaceforservice.

Y

(1)

Z

Weight

(kg)

Table9.1Dimensionsandservicespacerequirements

190TGB-1035-H1604Technicalspecication31

Page 36

DehumidierML420-MLT1400

5.0

1.0

2.0

3.0

4.0

ML420

5

10

15

20

25

80%

60%

40%

5.0

1.0

2.0

3.0

4.0

MLT800

5

10

15

20

25

80%

60%

40%

12.5

2.5

5.0

7.5

10.0

kg/h

15.0

ML690

0 5

10

15

20

25

80%

60%

40%

12.5

2.5

5.0

7.5

10.0

kg/h

15.0

ML1100

0 5

10

15

20

25

80%

60%

40%

9.2Capacitydiagrams

Approximatecapacityinkg/h.PleasecontactyournearestMuntersofceformoredetailedinformation.

NOTE!Thebelowguresarebasedonaratedairow.

32Technicalspecication190TGB-1035-H1604

Page 37

DehumidierML420-MLT1400

12.5

2.5

5.0

7.5

10.0

kg/h

15.0

ML1350

0 5

10

15

20

25

80%

60%

40%

12.5

2.5

5.0

7.5

10.0

kg/h

15.0

MLT1400

0 5

10

15

20

25

80%

60%

40%

1Processairtemperature(°C)

2Processairrelativehumidity(%RH)

3Dehumidicationcapacity(moistureremovalperhour)(kg/h)

190TGB-1035-H1604Technicalspecication33

Page 38

DehumidierML420-MLT1400

9.3Technicaldata

Thefollowingisapplicabletounitsttedwithelectricreactivationheater.

ModelML420ML690MLT800ML1100ML1350MLT1400

Processair

Ratedairow(m

Ratedairow(m

Minimumavailablestaticpressure(Pa)

Fanmotorpower(kW)at50Hz

Fanmotorpower(kW)at60Hz

Reactivationair

Ratedairow(m

Ratedairow(m

Minimumavailablestaticpressure(Pa)200300200300300300

Fanmotorpower(kW)at50Hz

Fanmotorpower(kW)at60Hz

Ratedcurrent

Current(amps/phase)3~50Hz200V14,925,5-40,2--

Current(amps/phase)3~60Hz200V14,925,5-40,1--

Current(amps/phase)3~50Hz220V12,62214,936-24,3

Current(amps/phase)3~60Hz220V12,622,515,436,4-24,6

Current(amps/phase)3~50Hz230V12,121,614,935,1-24

Current(amps/phase)3~50Hz380V7,312,78,620,824,414,1

Current(amps/phase)3~60Hz380V7,3138,92124,914,2

Current(amps/phase)3~50Hz400V712,48,520,223,613,8

Current(amps/phase)3~50Hz415V6,712,28,419,823,113,5

Current(amps/phase)3~60Hz440V6,411,37,818,622,312,7

Current(amps/phase)3~60Hz460V6,1117,61821,712,4

Current(amps/phase)3~60Hz480V5,910,87,517,621,112,2

Reactivationheater

Temperatureincreaseacrossheater(°C)959595959595

Reactivationheaterpower(kW)4,26,94,21 1,113,56,9

Miscellaneousdata

Drivemotorpower(W)20

FiltersG3

IECprotectionclass(unit)IP33

IECprotectionclass(electricalpanel)IP54

FanmotorwindinginsulationclassClassF

DrivemotorwindinginsulationclassClassF

Hightemperaturecut-out(°C)160±5

Burnercontrollersupplyvoltage1~50Hz(V AC)---220/240--

Contactorcoilvoltage(VAC)24

(1)

3

/s)0,1160,1920,2220,3050,3750,388

3

/h)420690800110013501400

(2)

(3)

(3)

(1)

3

/s)0,0430,0710,0430,1130,1360,071

3

/h)155254155408490254

(3)

(3)

200300200300300300

0,370,550,551,11,11,1

0,370,560,661,321,321,32

-0,370,370,550,550,37

-0,440,440,660,650,44

34Technicalspecication190TGB-1035-H1604

Page 39

DehumidierML420-MLT1400

External(potential-free)outputcontacts

4

2A,50VAC(max.)

Corrosionclass,outsidecasingC4(painted,AluZink150,ISO12944)

Corrosionclass,insidecasingC3(unpainted,AluZink150,ISO12944)

Environmentalconditions

Operatingtemperature(°C)

Maximuminstallationaltitude,abovesealevel(m)

Transportandstoragetemperature(°C)

(1)Figuresquotedarebasedonfaninlettemperatureof20°C,andanairdensityof1,2kg/m

(2)WithoutoptionalF5orF7lterboxes.

(3)ML420dehumidiershaveasinglemotordrivingbothprocessairandreactivationairfans.

(4)ContactsonthePCBusedtogiveanexternalindicationtotheunit(output).

-20...+40

2000

-20...+70

Table9.2Technicaldata

3

.

190TGB-1035-H1604Technicalspecication35

Page 40

DehumidierML420-MLT1400

9.4Sounddata

Figure9.3Ductconnections

1.Ductworkfordryair

2.Ductworkforprocessair

3.Ductworkforreactivationair

4.Ductworkforwetair

Denitions:

Lp(A)=Soundpressure(freeeld,DirectivityfactorQ=2,d=1distancefromsourceinmeter)

Lp(A)=Lw(A)+10Log(Q/(4πd²))

Lw(A)=SoundpowerleveldB(A-weighted)

9.4.1SounddataML420

Lp(A)at1mLw(A)Measurerange(Hz)

dBdB631252505001000200040008000

58667272656057605554

Table9.3Soundtoroom,allinletsandoutletsducted

DuctLw(A)Measurerange(Hz)

dB631252505001000200040008000

1.Dryair688879686157534841

2.Processair719380725959595250

3.Reactair769384807364575448

4.Wetair739583765748434027

Table9.4Soundinducts

36Technicalspecication190TGB-1035-H1604

Page 41

DehumidierML420-MLT1400

9.4.2SounddataML690

Lp(A)at1mLw(A)Measurerange(Hz)

dBdB631252505001000200040008000

60687276696462585551

Table9.5Soundtoroom,allinletsandoutletsducted

DuctLw(A)Measurerange(Hz)

dB631252505001000200040008000

1.Dryair698975726458564739

2.Processair739183786461625954

3.Reactair769383797168625851

4.Wetair719383735950463924

Table9.6Soundinducts

9.4.3SounddataMLT800

Lp(A)at1mLw(A)Measurerange(Hz)

dBdB631252505001000200040008000

59677575686459585857

Table9.7Soundtoroom,allinletsandoutletsducted

DuctLw(A)Measurerange(Hz)

dB631252505001000200040008000

1.Dryair718478756860605448

2.Processair759086786663656259

3.Reactair769384807364575448

4.Wetair739583765748434027

Table9.8Soundinducts

190TGB-1035-H1604Technicalspecication37

Page 42

DehumidierML420-MLT1400

9.4.4SounddataML1100

Lp(A)at1mLw(A)Measurerange(Hz)

dBdB631252505001000200040008000

64727581736865635856

Table9.9Soundtoroom,allinletsandoutletsducted

DuctLw(A)Measurerange(Hz)

dB631252505001000200040008000

1.Dryair778988817164625345

2.Processair798987806971726964

3.Reactair849391878176706863

4.Wetair799692836958544840

Table9.10Soundinducts

9.4.5SounddataML1350

Lp(A)at1mLw(A)Measurerange(Hz)

dBdB631252505001000200040008000

67757783747268666159

Table9.11Soundtoroom,allinletsandoutletsducted

DuctLw(A)Measurerange(Hz)

dB631252505001000200040008000

1.Dryair809389847768665646

2.Processair808886817272746860

3.Reactair839389858177716762

4.Wetair759287787062565243

Table9.12Soundinducts

38Technicalspecication190TGB-1035-H1604

Page 43

DehumidierML420-MLT1400

9.4.6SounddataMLT1400

Lp(A)at1mLw(A)Measurerange(Hz)

dBdB631252505001000200040008000

63717480736763635856

Table9.13Soundtoroom,allinletsandoutletsducted

DuctLw(A)Measurerange(Hz)

dB631252505001000200040008000

1.Dryair789184817468726055

2.Processair828587827373777166

3.Reactair768983797269636052

4.Wetair709380715849484130

Table9.14Soundinducts

190TGB-1035-H1604Technicalspecication39

Page 44

DehumidierML420-MLT1400

10Scrapping

Theunitmustbescrappedinaccordancewithapplicablelegalrequirementsandregulations.Contactyour

localauthorities.

Iftherotororltershavebeenexposedtochemicalsthataredangeroustotheenvironmenttheriskmust

beassessed.Thechemicalscanaccumulateinthematerial.Takethenecessaryprecautionstocomplywith

applicablelocallegalrequirementsandregulations.

Therotormaterialisnotcombustible,andshouldbedepositedlikeglassbrematerials.

W

ARNING!

W W

ARNING! ARNING!

Iftherotoristobecutinpieces,wearasuitableCEmarkedfacemaskselectedandttedinaccordancewiththe

applicablesafetystandardstoprotectfromthedust.

40Scrapping190TGB-1035-H1604

Page 45

DehumidierML420-MLT1400

Appendix1Options

1.1General

TheML-seriesdehumidiersaredesignedsothatoptionalproductscanbeeasilyttedtothem.

Thisappendixcontainsinformationaboutalloptionalcongurationsandcomponentsthatcanbeadded

whenorderingMLdehumidiers.

NOTE!Voltagedropscanoccurwhenusingexcessivelylongcables.Ifthereislessthan20Vsupplyatthe

connectionpointsofthehumiditysensor(onthedehumidier),aseparaterelaycontrolledbythehumiditysensor

mustbeused.

1.2Runningtimemeter

Therunningtimemeterrecordsthetotalnumberofhoursthedehumidierhasrun.Thelasttwodigits

representapercentagepartofanhour.Therunningtimemetercannotbereset.

Example:0000475representsfourhoursand45minutes.

1.3Rotorstopalarm

Anoptionalreedswitchmomentarilysendsapulseonceperrevolutionoftherotor,i.e.onceevery8

minutes.Theswitchisactivatedbyamagnetmountedontherotortoproducea0VDCpulse.

Ifthepulsedoesnotoccurwithin10minutes,thedrivemotorandfaultwarningindicatorsashtoshowthat

afaulthasoccurred.Theunitisautomaticallyswitchedoff.

1.4Blockedlteralarm

Adifferentialpressureswitchcanbettedtotheprocessairandreactivationairlters.Whenthepressure

differentialacrossthelterexceedsthebelowpresetvalue,theswitchcloses,whichsendsamessage

(blockedlter)tothePCBcard.Theprocessairorreactivationairlterindicatorlightsuptoindicatethe

specicblockedlter.

1.5Filterbox-M5andF7

ML420-MLT1400dehumidierscanbeequippedwithexternallterboxesM5orF7.

Forinstructionsonhowtoattachthelterboxtotheprocessairinletorreactivationairinlet,refertothe

instructionssuppliedwiththedeliveryofthelterbox.

Thediagrambelowshowsthepressuredrop(Pa)acrossthelterinthelterbox.

190TGB-1035-H1604Options41

Page 46

500

700

900

1100

1300

1500

20

0

40

60

80

100

120

F5

F7

400

Pa

m3/h

M 5

F7

Figure1.1Pressuredrop,lterinthelterbox

DehumidierML420-MLT1400

NOTE!Thepressuredropforthereactivationsideisnotshownonthediagramsincethevaluesaresosmallthat

theydonotaffecttheperformanceoftheunit.

1.6Humiditycontrolsystem

1.6.1Introduction

MuntersRH98andVariDryarehumiditycontrolsystemsintendedforusewithMuntersdehumidiers.

Theycontroltheairhumiditybyregulatingthepowertotheunitreactivationheater.

Thesystemcomprisesahumiditytransmitterandacontrolunit.Thehumiditytransmitterisatruetwo

wiretransmitter,whichispositionedwheretheairhumidityistobecontrolled,eitherintherelevantroom

orintheairduct.

Thecontrolunitsendscontrolsignalstothedehumidier.Thepowercontrolisperformedinoneortwo

steps.

Thesystemhasapotentialfreecontacttowhichanexternalalarmdevicecanbeconnected.

1.6.2Transmitter

Thehumiditytransmittersareavailableintwodifferenttypes,wallorductmounted.

Thehumiditytransmittersensoremitsasignalproportionaltotheairhumidity.

Thesignalisampliedandsenttothecontrolunitbycable.

Thehumiditytransmittersensorissensitiveandmustbehandledwithcare.

1.6.3Controlunit

Thecontrolunitcontainsacontroller,whichreceivesthesignalfromthehumiditytransmitter.The

controllerthensendsacontrolsignaltothedehumidierwhichdeterminesthereactivationheateroutput.

42Options190TGB-1035-H1604

Page 47

DehumidierML420-MLT1400

Thereisalsoanoperatorpanelwithadisplayonthecontrolunit.Duringnormaloperation,thedisplay

showsthecurrentmeasuredairhumidity.

Differentparameterscanbesetusingthepushbuttonsonthepanel.Examplesaresettingsforairhumidity,

controllerlimitsandalarmlimits.

Thecontrolunitconstantlyreceivesasignalfromthehumiditytransmitter,andcontrolstheairhumidity

byregulatingthepowertotheunitreactivationheaterinoneortwosteps.Intheeventoftwoheatersteps,

abasicstep2/3ofthereactivationoutputisachieved,afterwhich1/3ofthereactivationoutputcanbe

controlledasafollowingstep.

Thecontrolunitisprovidedwithapotentialfreecontacttowhichanexternalalarmdevicecanbe

connected.Theexternalalarmisactivatedtogetherwiththeinternalalarm.

1.6.4Setpointsandcontrolparameters

Checkingandchangingsetpointsandcontrolparameterscanbemadeduringoperationorinstand-bymode.

Figure1.2Operatorpanel

ButtonFunction

Display/changeacertainvalueandresetthealarm

Increasethevalue

Decreasethevalue

%RH:Displaypositionofcontrolstepsforreactivationheater(0=off;1=on).

Duringnormaloperationandinanypositionofthemodeswitchthecurrentrelativeairhumidityis

displayed.

CA

UTION!

CA CA

UTION! UTION!

Damageduetoincorrectadjustmentofthesystemmayinvalidatethewarranty.

190TGB-1035-H1604Options43

Page 48

DehumidierML420-MLT1400

1.6.5Display/changesetpointforrelativehumidity

1.Press/release.Thevalueinthelowerrightcornerstartsashingandshowsthecurrentsetpoint.The

displayautomaticallyreturnstonormalafterabouttwentyseconds,i.e.showscurrentvalueforrelative

humidity.

2.Pressandholddownandthecurrentsetpointlightsupwithaxedlight.Whenthebuttonisreleased

again,thedisplayashesbeforeautomaticallyreturningtonormal.

3.Pressandholddownandatthesametimepress

ortosetthedesiredsetpoint.

4.Releaseandthedisplaystartstoash,indicatingthenewsettingbeforeitautomaticallyreturnsto

normali.e.showsthecurrentairhumidity.

1.6.6Display/changeotherparameters

Theoperatorpanelsetpointsarepresetatthefactoryto50%RH.Severalotherinternalparameterscanbe

setinadditiontothesetpoint,e.g.differential,sensoroffsetandsetpointrange,seeTable1.1.

1.Pressandholddown

formorethantensecondstoshowtheparametermenu.Thecharactersinthe

topandbottomsegmentsintheleft-handdisplaystarttoash.Parameter10isshown.Release.

2.Pressortoselectaparameter.

3.Pressandholdtoshowthecurrentvaluefortheselectedparameter.

4.Pressandholdandpress

ortochangetheparametervalue.

5.Release.Thenewsettingsaresavedautomatically .Thedisplayautomaticallyreturnstonormalafter

abouttwentyseconds,i.e.showscurrentvalueforrelativehumidity.

44Options190TGB-1035-H1604

Page 49

DehumidierML420-MLT1400

ParameterDescriptionPossibleparameterselectionDefaultsetting

05Correctionofthehumiditytransmitter’sread-offvalue0%RHNosettings

10OFF/ONinterval,stage11-15%RH2%RH

11Offsetstage1-15-+15%RH-1%RH

12OFF/ONinterval,stage21-15%RH6%RH

13Offsetstage2-15-+15%RH-1%RH

14OFF/ONintervalalarmoutput1-15%RH1%RH

15Offsetfromsetpoint,alarmoutput-15-+15%RH0%RH

30Alarmthresholdtype:0=Notactivated;1=Absolute;2

2=Relative

31Minimumalarmthreshold-100-+100%RH-50%RH

32Maximumalarmthreshold-100-+100%RH10%RH

33Delayforminimumalarm0-99minutes0min.

34Delayformaximumalarm0-99minutes0min.

35Functionofalarmoutput0=monitoralarm1=check1

36Resetalarmwhenthecauseofthealarmisrectied0=No;1=Y es1

37AlarmresettingwhentheSETbuttonispressed0=No;1=Yes1

(1)

(2)

(displayonly)

40Powerdelayafterpowerfailure0-99minutes0min.

41Forcedrelayfunctionathumiditytransmitterfailure0=Off;1=Humidication;2

2=Dehumidication

(1)ActivatedwhenRHexceeds2%ofthesetpoint,deactivatedwhenRHfallsbelow1%ofthesetpoint.

(2)ActivatedwhenRHexceeds6%ofthesetpoint,deactivatedwhenRHfallsbelow1%ofthesetpoint.

Table1.1Operatorpanelsystemparameters–RH98

190TGB-1035-H1604Options45

Page 50

DehumidierML420-MLT1400

ParameterDescriptionPossibleparameterselectionDefaultsetting

01Proportionalband1-15%RH5

02Integrationtime0-99seconds0(=off)

03Differentialaction,percentage0-100%RH0(=off)

04Cycletime0-999seconds20

05Correctionofthehumiditysensors’svalue-15-+15%RHNosettings

10Offset,relay-20-20%RH10

11Differential,relay-21-5%RH1

20Minimumsetpoint0-100%RH0

21Maximumsetpoint0-100%RH100

40Delayinregainingsupplyafterapowercut0-99min.0

41Forcedsolid-stateoutputwheresensorfault0=No;1=100%output0

42Forcedrelay-2outputwheresensorfault0=No;1=Y es0

Table1.2Operatorpanelsystemparameters–VariDry

46Options190TGB-1035-H1604

Page 51

DehumidierML420-MLT1400

1.6.7Processalarms

Theoperatorpanelisequippedwithaninternalalarmthatisactivatedwhenthealarmthresholdsare

exceeded.Thealarmisindicatedinthedisplayontheoperatorpanel.

Alarmmessages

Thedisplayontheoperatorpanelshowsthefollowingmessages(steadilylit):

rHI

rLO

E1

EEE

Upperalarmlimitexceeded

Loweralarmlimitexceeded

Faultyhumiditytransmitterorincorrectconnections

Allparametersettingsarelost

AcknowledgealarmonRH98

Acknowledgethealarmbypressingontheoperatorpanel.Thedisplaynowstartstoashanddisplays

thealarmmessageandthecurrentrelativeairhumidityalternately.Thefunctionfortheresetbuttonis

dependentontheparametersettings,seeTable1.1.

Sensorcalibration

Thehumiditytransmitter'sreadoffvaluecanbecalibratedusingtheoperatorpanelsensoroffset,se

parameter05,Table1.1.

Example:If3%RHistoomuch,theoffsetshouldbereducedby3%.

ContactMuntersforcalibrationofthehumiditytransmitter.

190TGB-1035-H1604Options47

Page 52

Page 53

DehumidierML420-MLT1400

2ContactMunters

AUSTRIA

BELGIUM

CZECHREPUBLIC

DENMARK

FINLAND

FRANCE

GERMANY

ITAL Y

NETHERLANDS

POLAND

SPAIN

SWEDEN

SWITZERLAND

UNITEDKINGDOM

MuntersGmbH

AirTreatment

ZweigniederlassungWien

MuntersBelgiumnv

AirTreatment

MuntersCZ,organizacnislozka

AirTreatment

MuntersA/S

AirTreatment

MuntersFinlandOy

Kuivaajamyynti

MuntersFranceSAS

AirTreatment

MuntersGmbH

AirTreatment-Zentrale

MuntersItalyS.p.A

AirTreatment

MuntersVochtbeheersingEnergieweg69

MuntersSp.zo.o.

OddzialwPolsce

AirTreatment

MuntersSpainSA

AirTreatment

MuntersEuropeAB

AirTreatment

MuntersGmbH

AirTreatment

ZweigniederlassungRümlang

MuntersLtd

AirTreatment

Eduard-Kittenberger-Gasse56,

Obj.6

A-1235Wien

Blarenberglaan21c

B-2800Mechelen

Slevacská2368/68

CZ-61500BRNO

Ryttermarken4

DK-3520Farum

Hakamäenkuja3

FI-01510V ANTAA

106,BoulevardHéloise

F-95815ArgenteuilCedex

Hans-Duncker-Str.8

D-21035Hamburg

StradaPiani2

I-18027Chiusavecchia

IM

NL-2404HEAlphena/dRijn

ul.Swietojanska55/11

81-391Gdynia

EuropaEpresarial.EdicioLondres.

C/PlayadeLiencres2.

28230LasMatas.Madrid

P .O.Box1150

SE-16426Kista

Glattalstr.501

CH-8153Rümlang

KnowledgeCentre,WybostonLakes

GreatNorthRoad,Wyboston

BedfordshireMK443BY

Tel:+4316164298–9251

luftentfeuchtung@munters.at

www.munters.at

Tel:+321528561 1

service@muntersbelgium.be

www.muntersbelgium.be

Tel:+420775569657

info@munters-odvlhcovani.cz

www.munters-odvlhcovani.cz

Tel:+4544953355

info@munters.dk

www.munters.dk

Tel:+358207768230

laitemyynti@munters.

www.munters.

Tel:+33134115757

dh@munters.fr

www.munters.fr

Tel:+49(0)40879690-0

mgd@munters.de

www.munters.de

Tel:+390183521377

marketing@munters.it

www.munters.it

Tel:+31172433231

vochtbeheersing@munters.nl

www.munters.nl

Tel.:+48583053517

dh@munters.pl

www.munters.com.pl

Tel:+34916400902

marketing@munters.es

www.munters.es

Tel:+4686266300

avfuktning@munters.se

www.munters.se

Tel:+41523438886

info.dh@munters.ch

www.munters.ch

Tel:+441480432243

info@munters.co.uk

www.munters.co.uk

AUSTRALIA

BRAZIL

CANADA

CHINA

INDIA

JAPAN

KOREA

190TGB-1035-H1604ContactMunters49

Tel:+61288431588

dh.info@munters.com.au

Tel:+551150540150

www.munters.com.br

Tel:+1-800-843-5360

dhinfo@munters.com

Tel:+861080418000

marketing@munters.cn

Tel:+912066818900

info@munters.in

Tel:+81359700021

mkk@munters.jp

Tel:+8227618701

munters@munters.kr

MEXICO

SINGAPORE

SOUTHAFRICA

TURKEY

UAE(Dubai)

USA

Tel:+527222704029

munters@munters.com.mx

Tel:+6567446828

singapore@muntersasia.com

Tel:+27119972000

info@munters.co.za

Tel:+902165481444

info@muntersform.com

Tel:+97148813026

middle.east@munters.com

Tel:+1-800-843-5360

dhinfo@munters.com

Page 54

.

Page 55

.

Page 56

www.munters.com

Loading...

Loading...