Page 1

IA Inlet

Instruction Manual

Actuator

IA Inlet Actuator

Models: IA0090 • IA0090P • IA0250D • IA0250DP

QM1235r2

1© Munters Corporation, April 2019

Page 2

IA Inlet Actuator

Manual for use and Maintenance

Thank You:

Thank you for purchasing a Munters IA Inlet Actuator. Munters equipment is designed to be the highest performing,

highest quality equipment you can buy. With the proper installation and maintenance it will provide many years

of service.

Description:

The IA0090/IA0250D motor gearbox is a maintenance-free, compact drive unit for accurately opening and

closing air inlet flaps, air valves and ventilation curtains in livestock houses and crop storage buildings.

The IA0090/IA0250D motor gearbox features a self-braking worm gear transmission. This transmission ensures

that the drive shaft is not rotatable when the drive unit is stopped. The combination of carefully matched pinion and

worm reductions results in a quiet mechanical transmission.

The IA0090/IA0250D motor gearboxes feature a power switching integrated linear limit switch system with duty

and safety switches with an excellent switching precision of the end positions. The maximum switching range of the

limit switch system equates to 55 revolutions of the drive shaft. With use of an optional potentiometer built-in set, it

is possible to precisely feedback intermediate and end positions to a (climate) computer.

The IA0090/IA0250D motor gearboxes are finished with a blue powder coating and are supplied including

mounting bolts and spring washers.

IA0090 motor gearboxes: IA0250D motor gearboxes:

• Drive torques of 1000 lb.-in.; • Drive torques of 3540 lb.-in.;

• 1.2 at 60 Hz mains frequency; • 1.2 at 60 Hz mains frequency;

Suitable for intermittent use, duty class 3-30%, duty cycle maximum 25 minutes;

Provided with a two-sided output drive shaft for mounting one winch or belt drum or two 16-tooth

1/2”x5/16” zinc-plated sprockets for chain couplings;

• Manual drive enabled by means of a hexagon socket in electric motor shaft;

• Electric motors are standard tropic-proof and conform to protection class IP55;

• Available as 1-phase 115 V (60 Hz) electric motor with UL and CSA approval.

Please Note:

To achieve maximum performance and insure long life from your Munters product it is essential that it be installed

and maintained properly. Please read all instructions carefully before beginning installation.

Warranty:

For Warranty claims information see the “Warranty Claims and Return Policy” form QM1021 available from the

Munters Corporation office at 1-800-227-2376 or by e-mail at aghort.info@munters.com.

Conditions and Limitations:

• Products and Systems involved in a warranty claim under the “Warranty Claims and Return Policy” shall have

been properly installed, maintained and operated under competent supervision, according to the instructions

provided by Munters Corporation.

• Malfunction or failure resulting from misuse, abuse, negligence, alteration, accident or lack of proper installation

or maintenance shall not be considered a defect under the Warranty.

2

QM1235r2

© Munters Corporation, April 2019

Page 3

Index

Chapters Page

1. Unpacking the Equipment

1.1 Technical specifications IA0090 motor gearbox 4

1.2 Configurations IA0090 motor gearbox 4

1.3 Options for IA0090 motor gearbox 5

1.4 Dimensions IA0090 motor gearbox 5

2. Installation Instructions

2.1 Mounting the IA0090 motor gearbox. 6

2.2 Mounting the drum, winch belt and couplings (configuration 1) 7

2.3 Pre-winding the winch belt onto the belt drum (configuration 1) 8

3. Connection and Operations

3.1 Connection and operation - abbreviations 9

3.2 Connecting the control components: switch materials and cable lengths 9

3.3 Overview: connections and elements for “Operating & Setting” 9

3.4 Rotational directions and end positions IA0090 motor gearbox 11

3.5 Wiring diagrams IA0090 motor gearbox 11

3.6 Setting the limit switch system 14

3.7 Potentiometer installation set: installation 17

3.8 Potentiometer table IA0090 motor gearbox (i=1,0) 18

4. Maintenance

4.1 Maintenance IA0090 motor gearbox 19

QM1235r2

3© Munters Corporation, April 2019

Page 4

About the Equipment

1.1 Technical Specifications IA0090/IA0250D Motor Gearbox

Mechanical IA0090 IA0250D

Torque 1000 lb.-in. 3540 lb.-in.

Speed 1.2 rpm 1.2 rpm

Winch belt speed 6.2 - 6.9 inch/min 6.2 - 6.9 inch/min

Winch belt length 39.4 inch 39.4 inch

Drive unit Self-locking Self-locking

Weight 34.2 lb 66 lb

Electrical

Supply voltage (A - 532601) 115 V 115 V

Maximum current (A - 532601) 2.5 A 4 A

Power 90 W 180 W

Environment

Protection class IP55 IP55

Operating temperature 0 tot 40 °C (32 tot 104 °F) 0 tot 40 °C (32 tot 104 °F)

1.

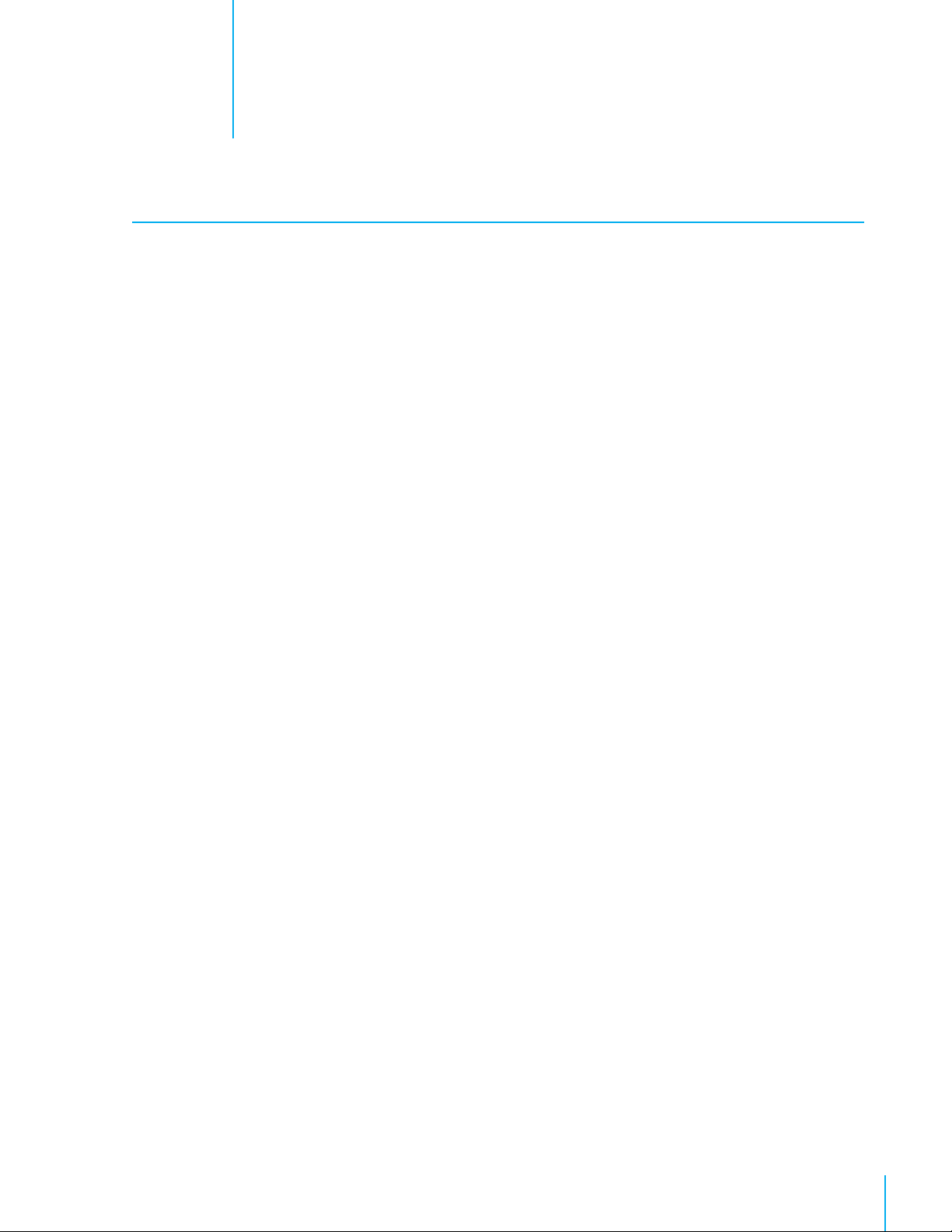

1.2 Configurations IA0090/IA0250D Motor Gearbox

The IA0090/IA0250D ships in 2 boxes, Box 1 of 2 is the Gear Motor and Box 2 of 2 is the installation kit.

• The IA0090/IA0250D is standard delivered with a 1-phase motor: A - 115V

• The IA0090/IA0250D is standard delivered with limit switch system and mounting kit.

• Configurations include double belt drum, Belt Drum w/option to use cables.

• Options: Potentiometer

Options and accessories are ordered separately.

CONFIGURATIONS: Belt drum

Ceiling Mount

4

QM1235r2

Wall Mount

© Munters Corporation, April 2019

Page 5

7.55"

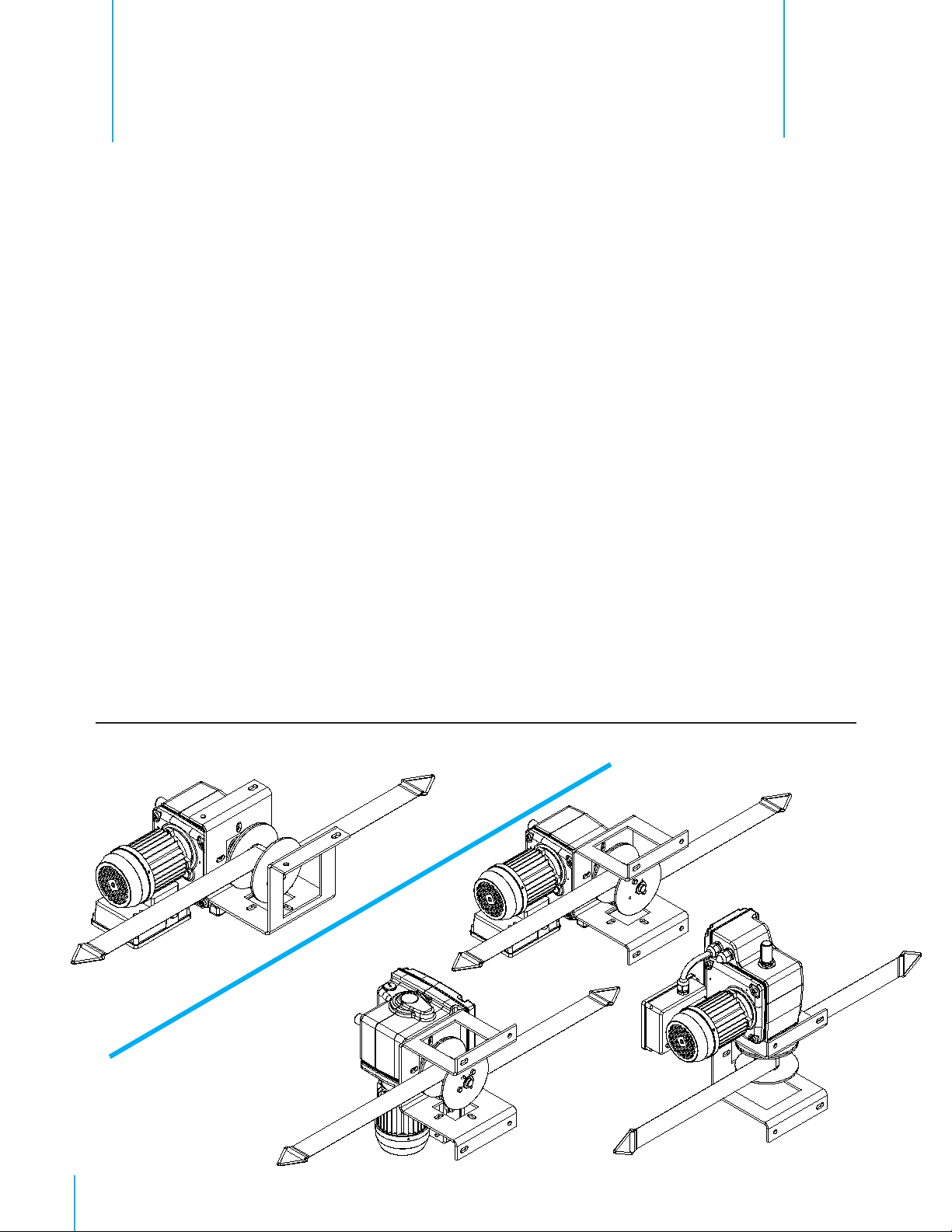

Items to Order Separately:

About the EquipmentChapter 1

IA0090, IA0090P

1.3 Options for IA0090 Motor Gearbox

Potentiometer: Position feedback IA0090P

An optional potentiometer built-in set (AC1429) for the IA0090 motor gearbox. Position feedback

which works in combination with the limit switch system.

The built-in set with potentiometer makes it possible to signal with precision to a (climate) computer, not

just the start and end positions of the limit switch system, but also all the intermediate positions of the

driven system.

AC1429

Specifications

Resistance: 5kΩ (R5K)

Revolutions: 10 (S10)

Drum Kit with Mounting Bracket AC2905

AC1429

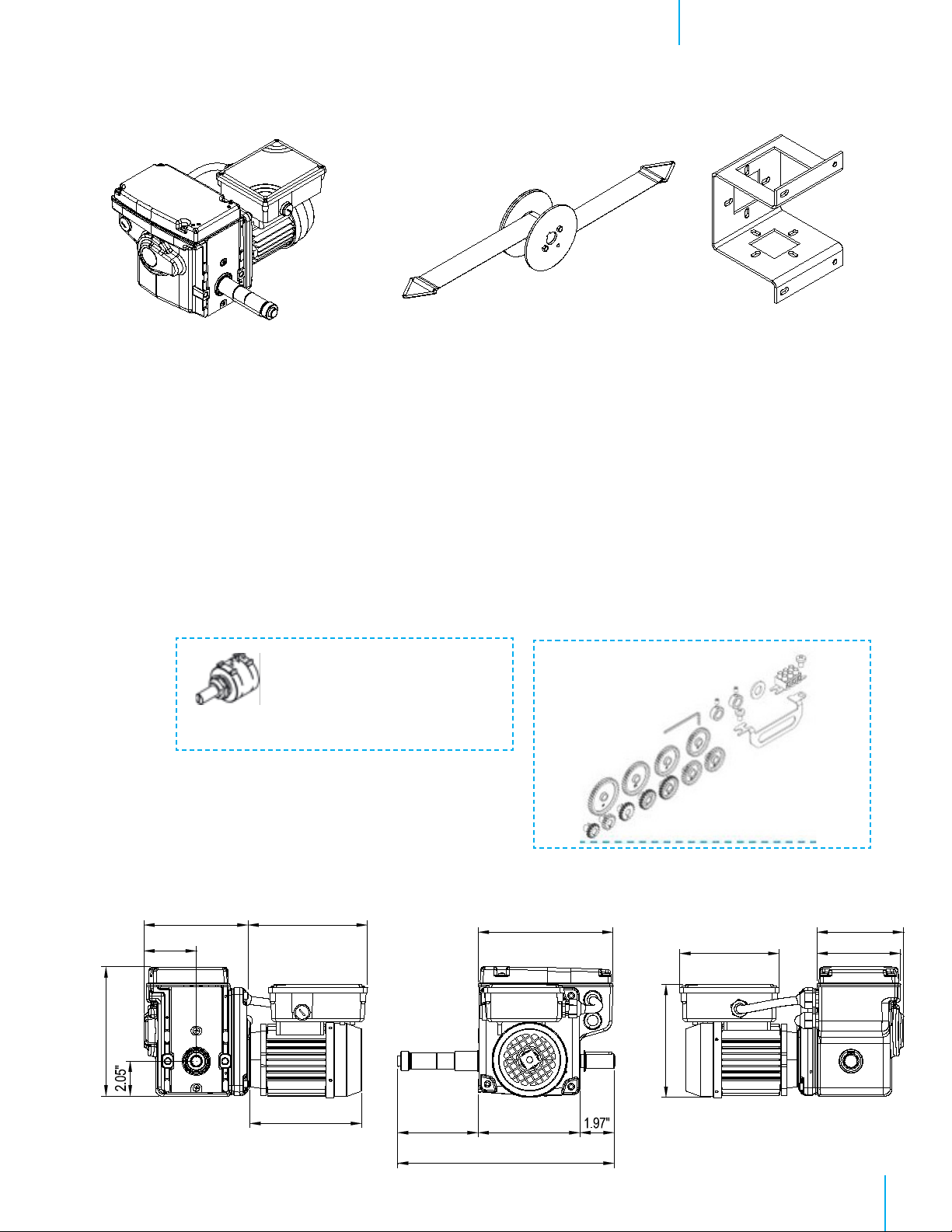

1.4 Dimensions IA0090 Motor Gearbox

6.2"

3.1"

6.9"

6.55"

4.72"

5.94"

12.64"

7.87"

6.61"

5.79"

5.05"

4.88"

QM1235r2

5© Munters Corporation, April 2019

Page 6

Installation Instructions

IA0090, ACTUATOR

2.1 Mounting the IA0090/IA0250D Motor Gearbox.

Mount the IA0090/IA0250D motor gearbox according to the following instructions:

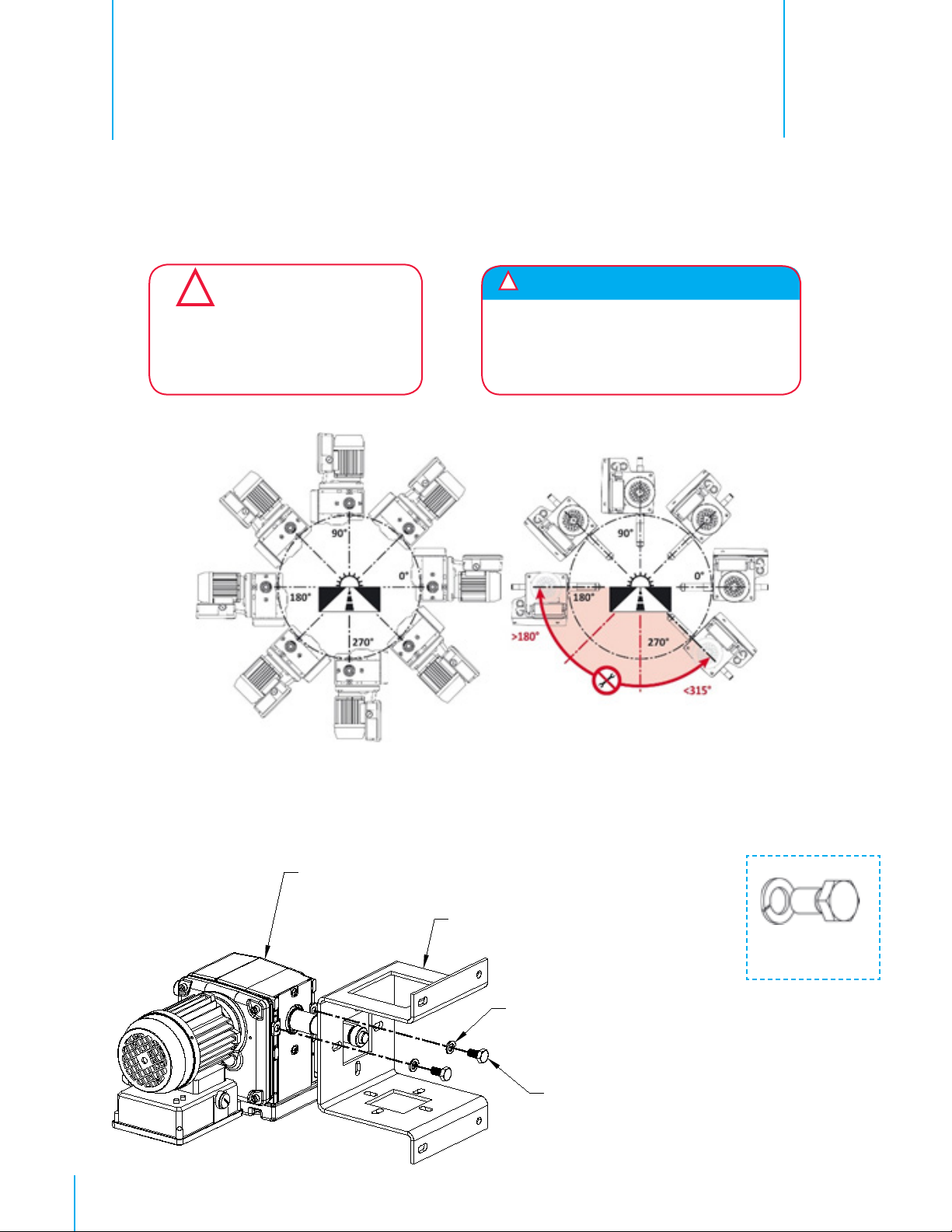

Always use an allowed mounting position as shown in image 3.1.

!

!

CAUTION

Please ensure that the IA0090 is

mounted securely, so that the building

structure can sufficiently absorb the

forces applied.

*Please observe the following allowed mounting positions when installing the IA0090 Motor Gearbox

When mounting the IA0090, ensure that the

Attention:

motor cover remains accessible so you will

have no problems connecting, setting and

operating the IA0090

2.

Image 2.1

Use the M10 bolt and washer from the mounting kit to mount the plates to the gearbox.

Mounting IA0090/IA0250D: Belt Drum - Wall Mount

Mount the mounting plate for wall assembly to the IA0090 as follows:

MOUNTING BRACKET

M10 SPLITLOCK WASHER

M10x20 BOLT

M10 bolt

6

QM1235r2

© Munters Corporation, April 2019

Page 7

KEY

SINGLE DRUM DISC

Installation InstructionsChapter 2

IA0090, ACTUATOR

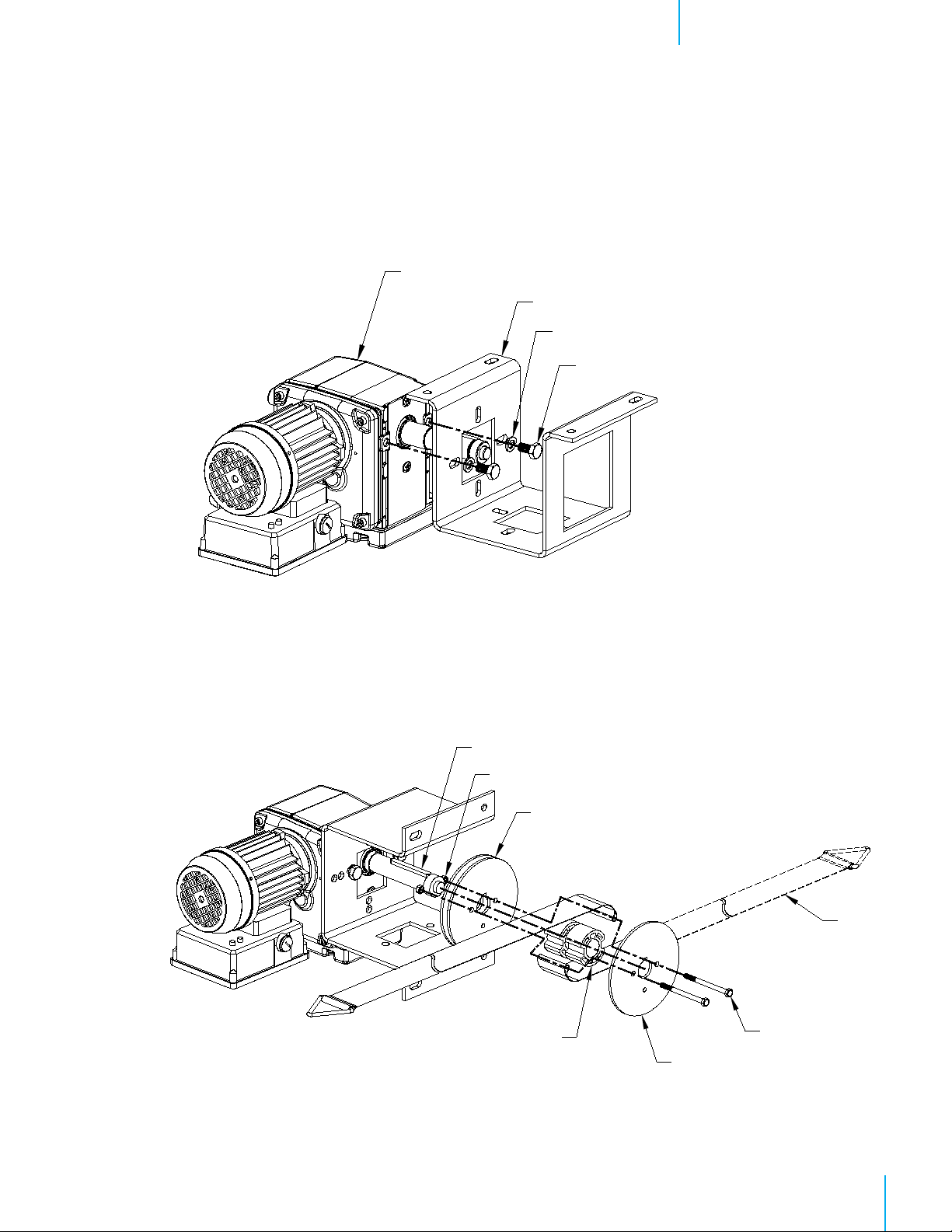

Mounting IA0090/IA0250D: Belt Drum - Ceiling Mount (Configuration 1)

Mount the square mounting plate to the IA0090 by choosing option 1 (side) or 2 (foot).

MOUNTING BRACKET

M10 SPLITLOCK WASHER

M10x20 BOLT

Configuration 1

2.2 Mounting the Drum, Winch Belt and Couplings

Mount the drum, winch belt (single or double) and couplings for the IA0090 as follows:

NUT

DOUBLE

DRUM DISC

(2) DRUM SPACERS

BELT

M6x80 BOLT

QM1235r2

7© Munters Corporation, April 2019

Page 8

Installation InstructionsChapter 2

2.3 Pre-winding the Winch Belt onto the Belt Drum

To safely use the belt drum and winch belt of the IA0090/IA0250D it is necessary to pre-wind the

belt at least ½ a revolution onto the drum.

Belt drum with single or double belt:

• At least ½ revolution

!

CAUTION

Not pre-winding the winch belt may result

in injury at high belt or drum loads.

8

QM1235r2

© Munters Corporation, April 2019

Page 9

Connection and Operations

3.1 Connection and Operation: Abbreviations

Symbol Description

A Endposition A

B Endposition B

CW (A) Clockwise rotational direction (A)

CCW (B) Counterclockwise rotational direction (B)

ESU Limit switch system

K1 Connection block

K2 Connection block Potentiometer

L1, L2 Power source

M Electric motor

N Neutral conductor

P Potentiometer

PS Potentiometer installation set

P71, P72* Contacts for automatic control (open or closed).

* Suitable for inductive load of 115/220 V - 2,5 A

PE Ground (Earth Contact)

Q41 Motor Safety Switch

S1 Toggle switch (3 positions)

S11 Duty switch limit switch system A

S12 Duty switch limit switch system B

S21 Safety switch limit switch system A

S22 Safety switch limit switch system B

S111 Manual switch Stop - Open - Close - Automatic

U1 Motor connection (U1)

V1 Motor connection (V1)

W1 Motor connection (W1)

Z1 Gear Wheel Threaded Shaft (Potentiometer Set)

Z2 Gear Wheel Potentiometer Shaft (Potentiometer Set)

PTO Protection Thermal Overload (Switch)

R Relay

3.

3.2 Connecting the control components: Switch Materials and cable lengths

ATTENTION:

Please use only suitable control components and switch materials. Make sure you are using the correct equipment by

consulting the information on the control components and switch materials.

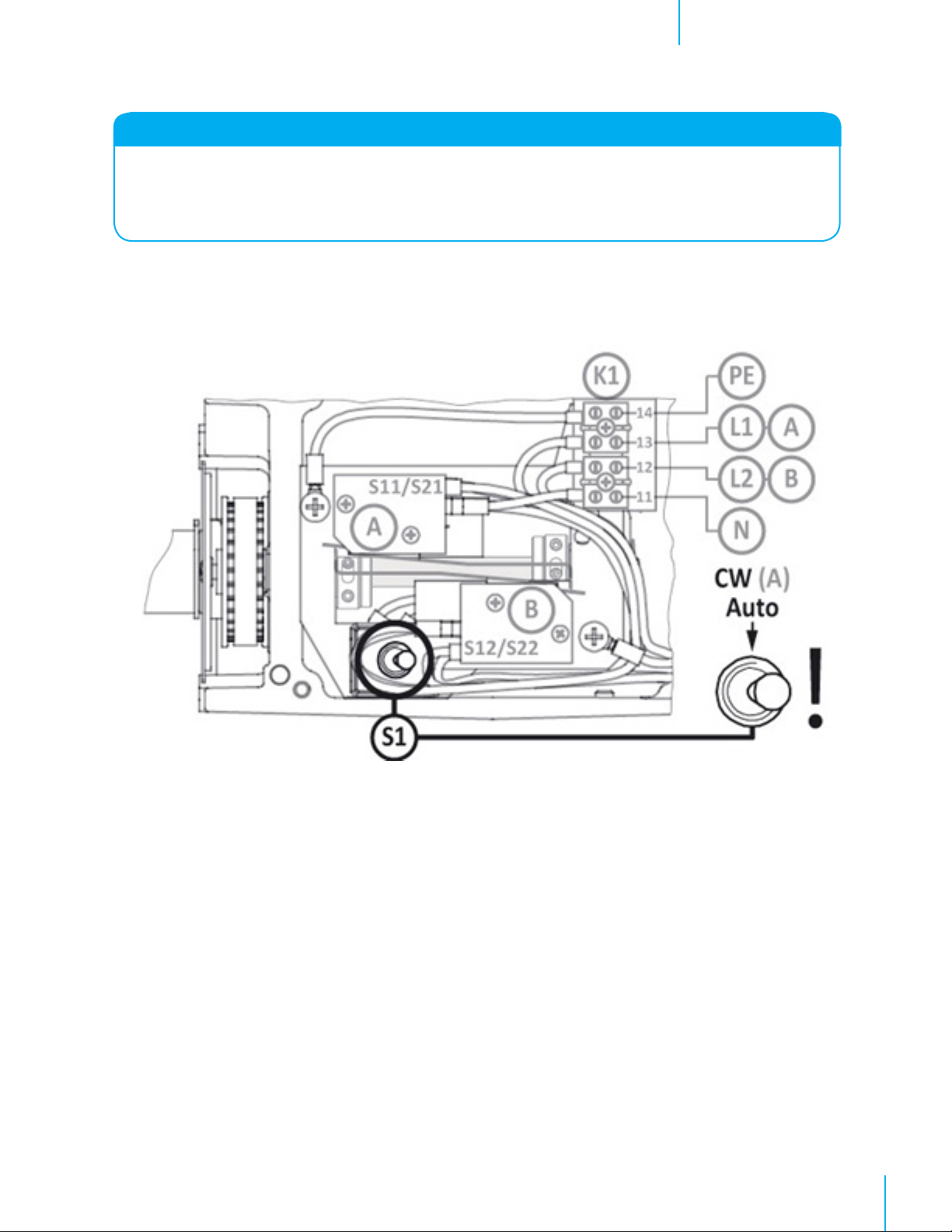

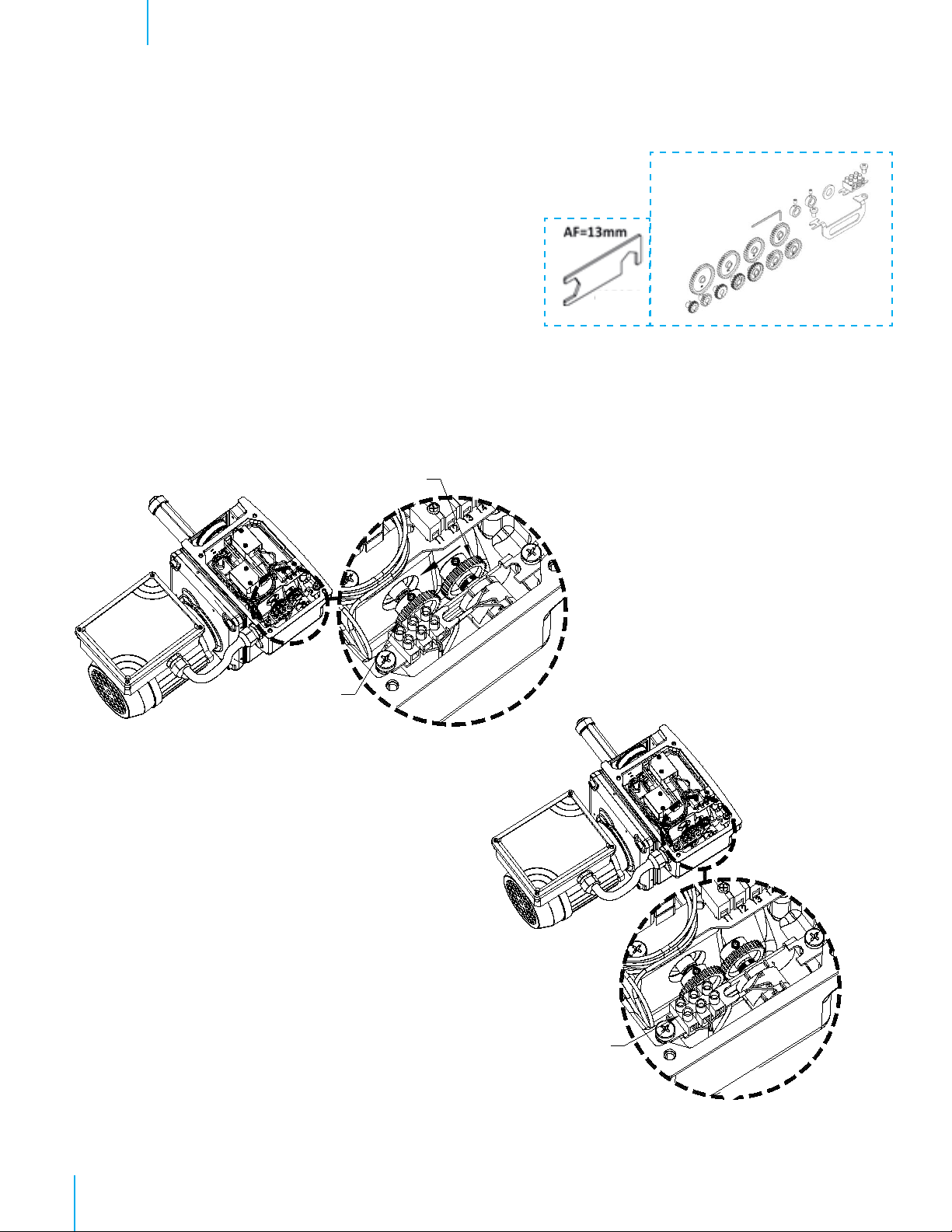

3.3 OVERVIEW: Connections and Elements for “Operating & Setting”

The overview in image 3.3.2 shows the most important connections, parts and elements for operating and setting a

IA0090 motor gearbox. As shown in image 3.3.1, remove the limit switch cover of the gearbox.

TIP: Cover in image 3.3.2 is also removed for a complete overview. However it is not necessary to remove cover in

this manual.

QM1235r2

9© Munters Corporation, April 2019

Page 10

Connection and OperationsChapter 3

Unscrew the four bolts and remove the limit switch cover while the gasket stays in place.

1. Limit switch cover

2. Gasket

3. Bolts

4. Cover electric motor

Image 3.3.1

The overview of a IA0090 motor gearbox. The detailed diagrams for connecting are shown in Step 3.5

10

QM1235r2

Image 3.3.2

© Munters Corporation, April 2019

Page 11

Connection and OperationsChapter 3

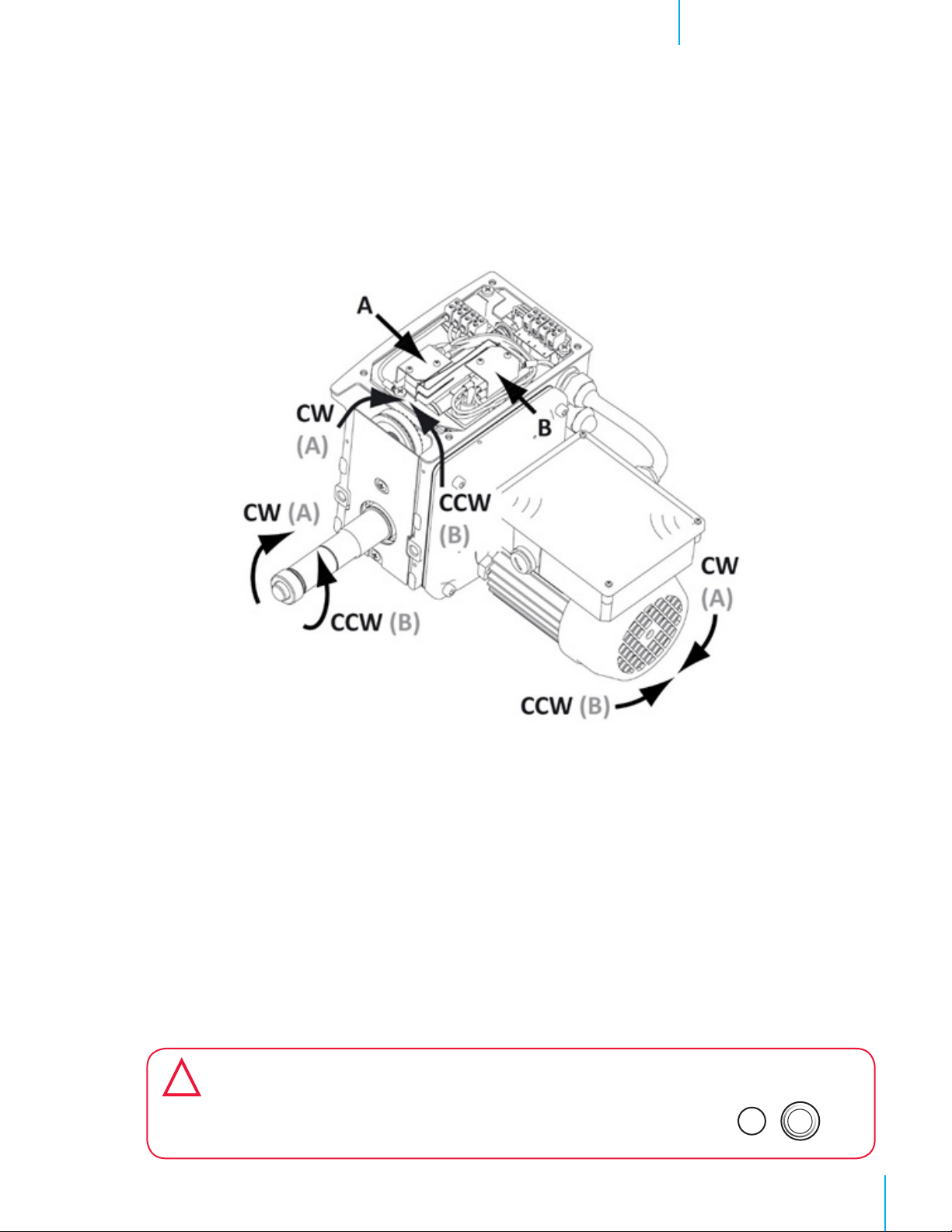

3.4 Rotational Directions and End Positions IA0090 Motor Gearbox

The rotational direction for the IA0090 is Clockwise [CW] (A) which is towards the motor and Counter

Clockwise [CCW] (B) which is away from the motor. Also visible are the corresponding limit switches for setting

the end positions A and B. See figure below.

Based on where the IA0090 and inlets are mounted and the direction the belt is wrapped on the drum,

determine which direction will be open and which will be close.

3.5 Wiring Diagrams IA0090 Motor Gearbox

Two wiring diagrams are applicable during installing and setting of the IA0090 gearbox. A temporary and a

permanent diagram are used in a number of steps according to Step 3.5.

Temporary connections (diagram 3.5.2):

This is only used for setting switch, according to Step 3.6, prior to making the permanent connections of the

IA0090 gearbox. Therefor a Temporary Power Cable is connected to the switch.

Permanent connections (diagram 3.5.4):

Make the permanent connections of the IA0090 gearbox after setting of the switch.

TIP: If the operation of position feedback is applicable, installation and setting of a potentiometer (P) is done separately in

Step 3.7 and Step 3.8.

!

CAUTION

The IA0090 motor gearbox is standard delivered with switch S1 in stop position. Switch S1

is still in STOP position when starting temporary or permanent connections!

Stop

S1

!

QM1235r2

11© Munters Corporation, April 2019

Page 12

Connection and OperationsChapter 3

● Connect the Temporary Power Cable.

The image and the diagram below show the connections of a Temporary Power Cable.

Image 3.5.1

● Go to Step 3.6 and set the Limit Switch System prior to the permanent connections.

● Remove the Temporary Power Cable.

12

QM1235r2

IA0090

Image 3.5.2

© Munters Corporation, April 2019

Page 13

Connection and OperationsChapter 3

CCW (Counter Clockwise)

● Make the permanent connections.

The image and the diagram below show the permanent connections of the IA0090 gearbox.

GROUND

CW (Clockwise)

NEUTRAL

Image 3.5.3

* Suitable for inductive load of 115V - 2,5 A

ATTENTION:

When setting the Limit Switch after the permanent

connections, make sure that S111 and P71 (or

equivalent parts) are configured toprovide power

to L1 (13) of connection block K1!

TIP: Reverse the direction of

rotation of the IA0090 if desired.

The direction of rotation can be

turned by changing connections

12 and 13 (L2 and L1) in the

connection block K1.

Diagram 3.5.4

IA0090

QM1235r2

13© Munters Corporation, April 2019

Page 14

Connection and OperationsChapter 3

Set Screws in Adjusting Ring

3.6 Setting the Limit switch system

Delivery:

Make the connections from the controller to the actuator terminal block (K1) depending on which direction is Open and

which is Close. See Image 3.5.3.

Terminal Block (K1)

Threaded Shaft

End Position (B)

End Position (A)

Toggle Switch (S1)

Textured Brass Nut

Image 3.6.1

Setting the Limits: See Image 3.6.1

1. Put switch (S1) into Stop position.

2. Apply power to the Clockwise [CW] (A) terminal 13.

3. Find the Allen Wrench that ships with the actuator.

4. Loosen the (2) Set Screws on each Adjusting Ring, at each end of the threaded shaft.

Setting the Clockwise [CW] (A) limit:

1. Put switch (S1) into CW (auto) position.

2. When end position [CW] (A) is reached put switch (S1) back to Stop.

3. On the [CW] (A) end, turn the Textured Brass Nut hand tight against the stop.

4. Now turn the Adjusting Ring over the Textured Brass Nut so far, that the working switch is just connected by the long

Adjusting Screw.

5. Now tighten the Set Screws firmly on the Textured Brass Nut. The Adjusting Ring cannot turn on the Brass Nut anymore.

Image 3.6.2

Setting the Counter Clockwise [CCW] (B) limit:

1. Put switch (S1) into CCW position.

2. When end position [CCW] (B) is reached put switch (S1) back to Stop.

3. On the [CCW] (B) end, turn the Textured Brass Nut hand tight against the stop.

4. Now turn the Adjusting Ring over the Textured Brass Nut so far, that the working switch is just contacted by the long Adjusting

Screw.

5. Now tighten the Set Screws firmly on the Textured Brass Nut. The Adjusting Ring cannot turn on the Brass Nut anymore.

The Limits are now set.

14

QM1235r2

© Munters Corporation, April 2019

Page 15

Connection and OperationsChapter 3

ATTENTION:

If the motor gearbox is manual operated by means of the hexagon socket in the electric motor shaft, with an limit switch

system which is set, it has to be checked that the end positions of the system will not be exceeded.

This can cause damage to the limit switch system, as a result of which the limit switch system will not function well

anymore.

Operating mode

Make sure the switch S1 is put in CW (A)/Auto position when permanent connections are done and

setting of the Switch is finished.

Image 3.6.3

Place the limit switch cover①, with the gasket ① still in place, and mount it with the four bolts.

See image 3.3.1.

TIP: If the feedback option is applicable, then first install and set the potentiometer (P) according to Step 3.4 and Step 3.5.

QM1235r2

15© Munters Corporation, April 2019

Page 16

Connection and OperationsChapter 3

3.7 Potentiometer Installation Set: Installation

For an IA0090P, the Potentiometer set comes pre-installed in the

unit for a typical installation with a 1m belt we recommend using the

gears Z1 – 25 and Z2 – 25.

1. Slide Potentiometer with gear towards the other gear without

turning the shaft of the pot, so that the teeth on each gear nest

together and tighten the pot nut with the hex key wrench. See

Figure A.

2. The Potentiometer is pre-wired to the terminal bock K2. Make

the connections between the controller and terminal block K2. See Figure B. If the Pot is changing voltage from low

in the open position to high in the closed position then reverse the red and black wire on the controller side of terminal

block K2.

The Potentiometer installation is now complete.

For a 2m belt use gear ?? on the ??? shaft.

For a 3m belt use gear ?? on the ??? shaft.

Potentiometer

with Gear

Gear on IA

Shaft

Figure A

Terminal

Block K2

Figure B

WHITE

BLACK

RED

16

QM1235r2

© Munters Corporation, April 2019

Page 17

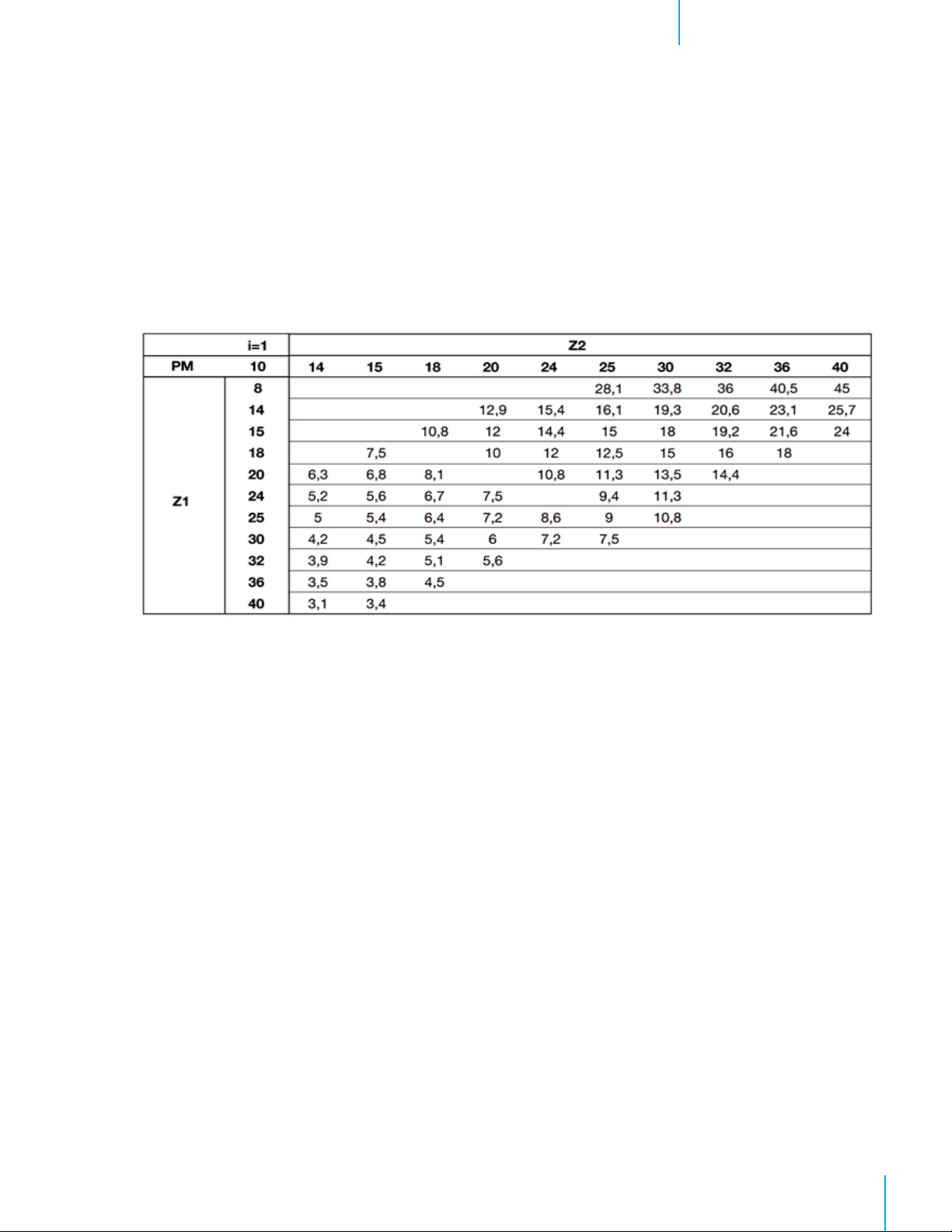

3.8 Potentiometer table IA0090 motor gearbox (i=1,0)

The table below can be used to select the necessary gearwheels when fitting a potentiometer and

installation set in an IA0090 motor gearbox. The table shows the maximum number of revolutions of

the drive shaft of the IA0090 motor gearbox.

A range of 9 revolutions of the potentiometer has been chosen for maximum precision and sufficient

reserve rotations when using a potentiometer. If the desired number of revolutions falls below the

minimum value given, a 5-turn potentiometer may be used. In that case, the values in the table that

give the maximum number of revolutions of the drive, should be divided by 2.

IA0090

Connection and OperationsChapter 3

QM1235r2

17© Munters Corporation, April 2019

Page 18

Maintenance

4.

4.1 Maintenance IA0090 Motor Gearbox

Regularly check your IA0090 motor gearbox for operation performance and possible grease leakage. Inform

your installer in case of grease leakage.

• Lubricant IA0090 – SPH grease – 1,9 lb

IA Actuator by Munters Corporation, Lansing, Michigan U.S.A. 1-800-227-2376

Munters Europe AB, Isafjordsgatan 1, P.O. Box 1150, SE-164 26 Kista, Sweden. Phone +46 08 626 63 00, Fax +46 8 754 56 66.

Munters Corporation 2691 Ena Drive Lansing, MI 48917 U.S.A. Phone +1 800-227-2376, Fax +1 517-676-7078

www.munters.us

Australia Munters Pty Limited, Phone +61 2 6025 6422, Brazil Munters Brasil Industria e Comercio Ltda, Phone +55 41 3317 5050, Canada/US Munters

Corporation Lansing, MI Phone +1 517 676 7070, China Munters Air Treatment Equipment (Beijing) Co. Ltd, Phone +86 10 80 481 121, Denmark Munters A/S,

Phone +45 9862 3311, India Munters India, Phone +91 20 3052 2520, Indonesia Munters, Phone +62 818 739 235, Italy Munters Italy S.p.A., Chiusavecchia,

Phone +39 0183 52 11, Japan Munters K.K., Phone +81 3 5970 0021, Korea Munters Korea Co. Ltd., Phone +82 2 761 8701, Mexico Munters Mexico, Phone

+52 818 262 54 00, Russia Munters AB, Phone +7 812 448 5740, Singapore Munters Pte Ltd., Phone +65 744 6828, South Africa and Sub-Sahara Countries

Munters (Pty) Ltd., Phone +27 11 997 2000, Spain Munters Spain S.A., Phone +34 91 640 09 02, Sweden Munters AB, Phone +46 8 626 63 00, Thailand

Munters Co. Ltd., Phone +66 2 642 2670, Turkey Munters Form Endüstri Sistemleri A.Ş, Phone +90 322 231 1338, USA Munters Corporation, Lansing MI Phone

+1 517 676 7070, Vietnam Munters Vietnam, Phone +84 8 3825 6838, Export & Other countries Munters Italy S.p.A., Chiusavecchia Phone +39 0183 52 11

18

QM1235r2

© Munters Corporation, April 2019

Loading...

Loading...