Munters Green Field ECO Installation Manual

Installation Manual

Green

Field ECO

Green Field ECO Controller

Irrigation Controller

Ag/MIS/UmEN-2735-05/19 Rev 1.3

P/N: 116785

Green Field ECO Controller

Installation Manual

Rev 1.3, 02/2021

This manual for use and maintenance is an integral part of the apparatus together with the attached

technical documentation.

This document is destined for the user of the apparatus: it may not be reproduced in whole or in part,

committed to computer memory as a file or delivered to third parties without the prior authorization of the

assembler of the system.

Munters reserves the right to effect modifications to the apparatus in accordance with technical and legal

developments.

© Munters AB, 2018 2

Index

chapter page

1

INTRODUCTION

1.1 Disclaimer

1.2 Introduction

1.3 Notes

2

GENERAL INSTRUCTIONS

----------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------ -----------

------------------------------------------------------------------------------------------------ ---------

-----------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------

2.1 Basic Requirements for On-Site Preparation

2.2 Frequency Inverters

2.3 General Dimensions

3

POWER SUPPLY WIRING

3.1 Main Power Wiring

3.2 Electrical Test

3.3 Firmware Upgrade

----------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------

---------------------------------------------------------------------------

--------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------

3.3.1 ntroduction to/Guidelines for Firmware Upgrades

3.3.2 Accessing the Application

3.3.3 Running the Application

---------------------------------------------------------------

.........................................................

.....................................................................................................

........................................................................................................

10

10

12

13

13

14

14

7

7

7

7

8

8

8

9

4

ELECTRICAL INSTALLATION

4.1 Input/Output Layout

4.2 Output Terminals

------------------------------------------------------------------------------------------------

------------------------------------------------------------------------

-------------------------------------------------------------------------------------------

4.2.1 Output Terminal Wiring

4.2.2 Example of Output Wiring

4.3 Input Terminals

--------------------------------------------------------------------------------------------------

4.3.1 Input Terminal Wiring

4.3.2 Digital Input Examples

4.4 PC and Inter-Controller Communication

4.4.1 Card Installation

.....................................................................................................................

4.4.2 Wiring and Controller Setup

5

CONTROLLER SETUP

5.1 Start-Up

------------------------------------------------------------------------------------------------------------

5.2 Device Layout

5.3 Device List

---------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------

.........................................................................................................

....................................................................................................

............................................................................................................

...........................................................................................................

------------------------------------------------------------------

................................................................................................

16

16

16

17

17

17

18

18

20

21

22

24

24

24

25

© Munters AB, 2018 3

5.4 Digital Input

5.5 Analog Input

------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------

5.6 Hot Keys and Status Screens

6

CONTROLLER TEST PROCEDURE

6.1 Relays

6.2 Digital Input

6.3 Analog Input

6.4 Temperature

6.5 Humidity

7

SYSTEM CONFIGURATION PROCEDURE

--------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------

7.1 Device Delay Configuration

7.1.1 Example of Device Startup & Shutdown Order

7.1.2 Example of Stagger Valve Delay – Multiple Shifts

7.2 Pump Station Configuration

7.3 Valve Configuration

7.4 Valve Flow Rate

7.5 Water Meter

-----------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------

7.6 Dosing Channel Configuration

7.7 Dosing Configuration

7.8 Drainage Configuration

7.9 EC/pH Configuration

7.10 Cooling Configuration

7.11 Misting Configuration

7.12 History Resolution

------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------

7.13 System Nutrigation™ Check

7.13.1 Check if EC/pH is on Target

7.13.2 Water Run Time

7.13.3 Start/Stop Valve

--------------------------------------------------------------------------------

------------------------------------------------------------------

-------------------------------------------------------

---------------------------------------------------------------------------------

................................................................

..........................................................

----------------------------------------------------------------------------------

------------------------------------------------------------------------------

---------------------------------------------------------------------------------

..........................................................................................

.................................................................................................................

...............................................................................................................

26

26

28

31

31

32

32

33

33

34

34

35

36

37

38

39

39

41

42

43

43

44

44

44

45

45

45

46

8

CONTROLLER ADVANCED SETTINGS

8.1 Pump Station Configuration

8.2 Multiple Water Meters

8.3 Various Dosing Configurations

8.3.1 Method 1

8.3.2 Method 2

8.3.3 Method 3

.................................................................................................................................

.................................................................................................................................

.................................................................................................................................

8.4 Dosing Configuration

8.4.1 EC/pH Control Step 1

8.4.2 EC/pH Control Step 2

----------------------------------------------------------------------------------

----------------------------------------------------------------------------------------

------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

...........................................................................................................

...........................................................................................................

------------------------------------------------------------

47

47

48

48

48

48

49

49

49

50

© Munters AB, 2018 4

9

PROGRAM MENU

9.1 Irrigation

9.1.1 Setting Irrigation that is Longer than 24 Hours

9.2 Influence Program

9.2.1 Using the Influences

9.2.2 Setting the Influences

9.3 Water Run Time

9.4 Dosing

9.4.1 Dosing Program

9.4.2 Dosing Injection Methods

9.5 Ext. Condition

9.6 Agitator

9.7 Selector

9.8 Filter Flushing

9.9 Cooling

9.10 Misting

9.11 Water Heating

------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------

.................................................................

----------------------------------------------------------------------------------------------

...............................................................................................................

.............................................................................................................

9.2.2.1

9.2.2.2

9.2.2.3

9.2.2.4

9.2.2.5

-------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------

Radiation Influence on EC

Drainage Influence on Target Radiation Sum

Drain Influence on Minimum Time

VPD Influence on Target EC

Temperature Influence on Target EC

-------------------------------------------------------------------------------------------------

......................................................................................................................

.....................................................................................................

----------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------

..................................................................

.........................................

........................................................

................................................................

.....................................................

51

52

56

56

56

56

57

58

59

59

60

61

62

62

63

64

65

66

66

67

70

71

10 MANUAL OPERATION MENU

10.1 Irrigation Pause

10.2 Start/Stop Program

10.3 Start/Stop Valve

10.4 Filter Flushing

11 SETUP MENU

------------------------------------------------------------------------------------------

11.1 Time and Date

11.2 System Setup

11.3 Temperature Calibration

11.4 Humidity Calibration

11.5 EC/pH Calibration

--------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------

11.5.1 Calibration of the EC/pH Monitor Transmitter

11.5.1.1 EC Calibration

11.5.1.2 pH Calibration

11.5.2 EC/pH Transmitter Monitor & Green Field ECO Correlation

11.6 Sensors Logging

11.7 Write to Data Plug

-------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------

---------------------------------------------------------------------

............................................................

.................................................................................

.................................................................................

..................................

72

72

73

73

74

75

75

76

78

78

78

79

79

80

82

82

83

© Munters AB, 2018 5

11.8 Read from Gold Data Plug

12 APPENDIX A: GREEN FIELD ECO PARTS LIST

13 APPENDIX B: TROUBLESHOOTING

13.1 Controller Display is Off

13.2 Output Malfunction

--------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------

----------------------------------------------------

---------------------------------------------------------------

--------------------------------------------------------------------------------------

14 APPENDIX C: REPLACEMENTS AND ADDITIONAL INSTALLATIONS

14.1 Power Supply Card

14.2 Relay Card

-------------------------------------------------------------------------------------------------------

15 APPENDIX D: SENSOR INSTALLATION AND DEFINITION

15.1 EC – pH Sensor Connection

15.1.1 EC Sensor Calibration

15.1.2 pH Sensor Calibration

15.2 Temperature/Humidity Sensor Connection

15.2.1 Humidity Sensor Definition

15.3 Sensor and Cable Specifications

--------------------------------------------------------------------------------------------

-----------------------------------

--------------------------------------------------------------------------------

......................................................................................................

.....................................................................................................

--------------------------------------------------------------

..............................................................................................

---------------------------------------------------------------------------

-----------------------

83

84

86

86

88

89

89

90

91

91

91

93

94

95

95

16 APPENDIX E: TECHNICAL SPECIFICATIONS

16.1 Technical Specifications

16.2 Controller Components

16.2.1 Keyboard & Display

16.2.2 Hardware Components

16.2.2.1 Components

16.2.2.2 Hardware Layout

16.2.3 Power Supply Card

16.2.3.1 Option A: 115 or 230 VAC Power Supply Card

16.2.3.2 Option B: 115VAC or 230VAC Power Supply Card with External 24VAC

Power for Output Devices

16.2.3.3 Option C: 12VDC Power Supply Card

16.2.4 Input and Output Card

17 APPENDIX F: MAIN MENU TREE

18 WARRANTY

------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------

.........................................................................................................

...................................................................................................

....................................................................................

..............................................................................

..........................................................................................................

...................................................................................

.................................................................................................

----------------------------------------------------------------

----------------------------------------------------

....................................

...............................................

96

96

96

97

97

97

98

99

99

100

101

102

103

104

© Munters AB, 2018 6

1 Introduction

1.1 Disclaimer

Munters reserves the right to make alterations to specifications, quantities, dimensions etc. for production

or other reasons, subsequent to publication. The information contained herein has been prepared by

qualified experts within Munters. While we believe the information is accurate and complete, we make no

warranty or representation for any particular purposes. The information is offered in good faith and with

the understanding that any use of the units or accessories in breach of the directions and warnings in this

document is at the sole discretion and risk of the user.

1.2 Introduction

Congratulations on your excellent choice of purchasing an Green Field ECO!

In order to realize the full benefit from this product it is important that it is installed, commissioned and

operated correctly. Before installation or using the fan, this manual should be studied carefully. It is also

recommended that it is kept safely for future reference. The manual is intended as a reference for

installation, commissioning and day-to-day operation of the Munters Controllers.

1.3 Notes

Date of release: July 2019

Munters cannot guarantee to inform users about the changes or to distribute new manuals to them.

All rights reserved. No part of this manual may be reproduced in any manner whatsoever without the

expressed written permission of Munters. The contents of this manual are subject to change without notice.

.

© Munters AB, 2018 7

2 General Instructions

•

Installation should be performed by authorized technicians only.

•

Verify that field components are working properly.

•

Apply all safety regulations.

•

Do not apply force or pressure on components during the installation procedure.

•

Refer to your supervisor if problems occur during installation procedure.

CAUTION

This unit must be installed inside, in a location protected from solar radiation and direct

rain.

•

2.1 Basic Requirements for On-Site Preparation

•

Verify power source between 115 VAC or 220 VAC ± 10%

•

On the unit is a silver label stating the unit’s voltage (110 or 230 VAC). Verify that your unit

supports the voltage supplied in your country.

•

Verify grounding connection < 10Ω

•

Environment temperature between -10° C / 14° F to +60° C / 140° F

•

Verify protection from damaging climate conditions

2.2 Frequency Inverters

•

Frequency inverters can cause severe electrical and electromagnetic interference. Therefore,

when employing a frequency inverter, it is critical that you carefully follow the manufacturer's

installation instructions.

•

In particular verify:

o

that the cable shielding between the inverter and any motor meets industry standards

o

proper grounding of the inverter's chassis and motor power cable

o

proper grounding of low voltage cable shield wire

o

that the controller and inverter cables are kept in separate conduits or wire bundles

© Munters AB, 2018 8

2.3 General Dimensions

•

© Munters AB, 2018 9

3 Power Supply Wiring

•

Main Power Wiring

•

Electrical Test

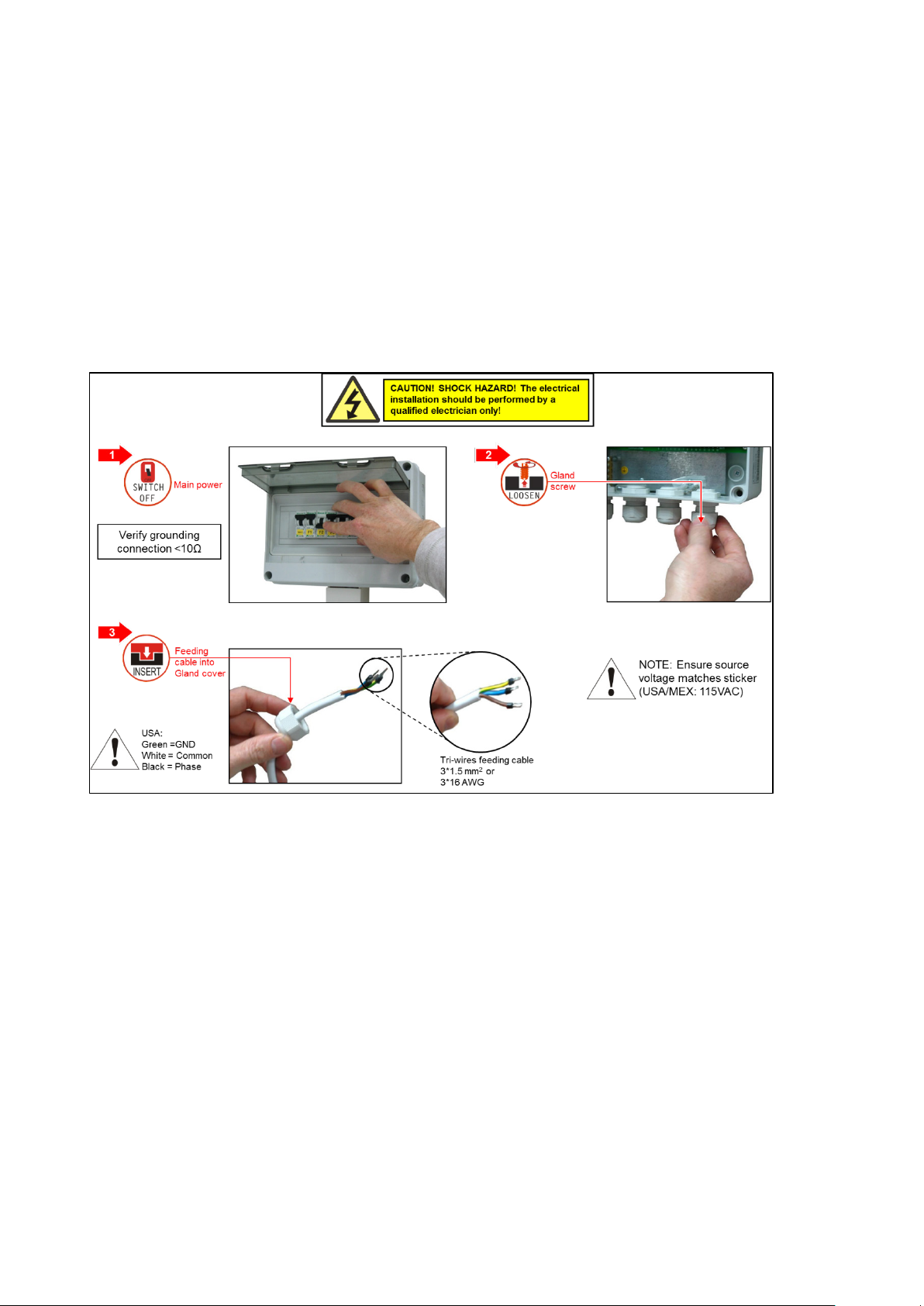

3.1 Main Power Wiring

© Munters AB, 2018 10

© Munters AB, 2018 11

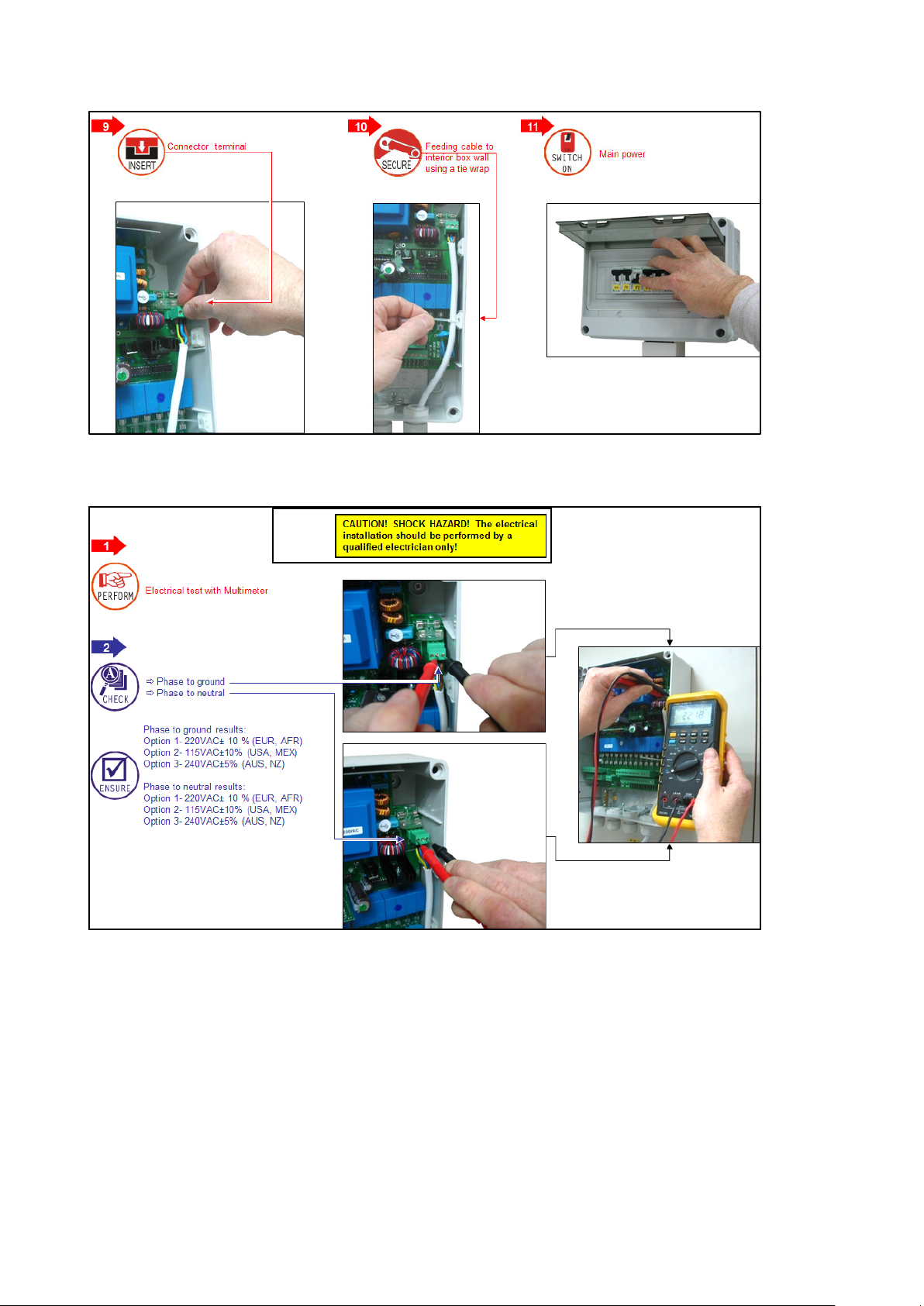

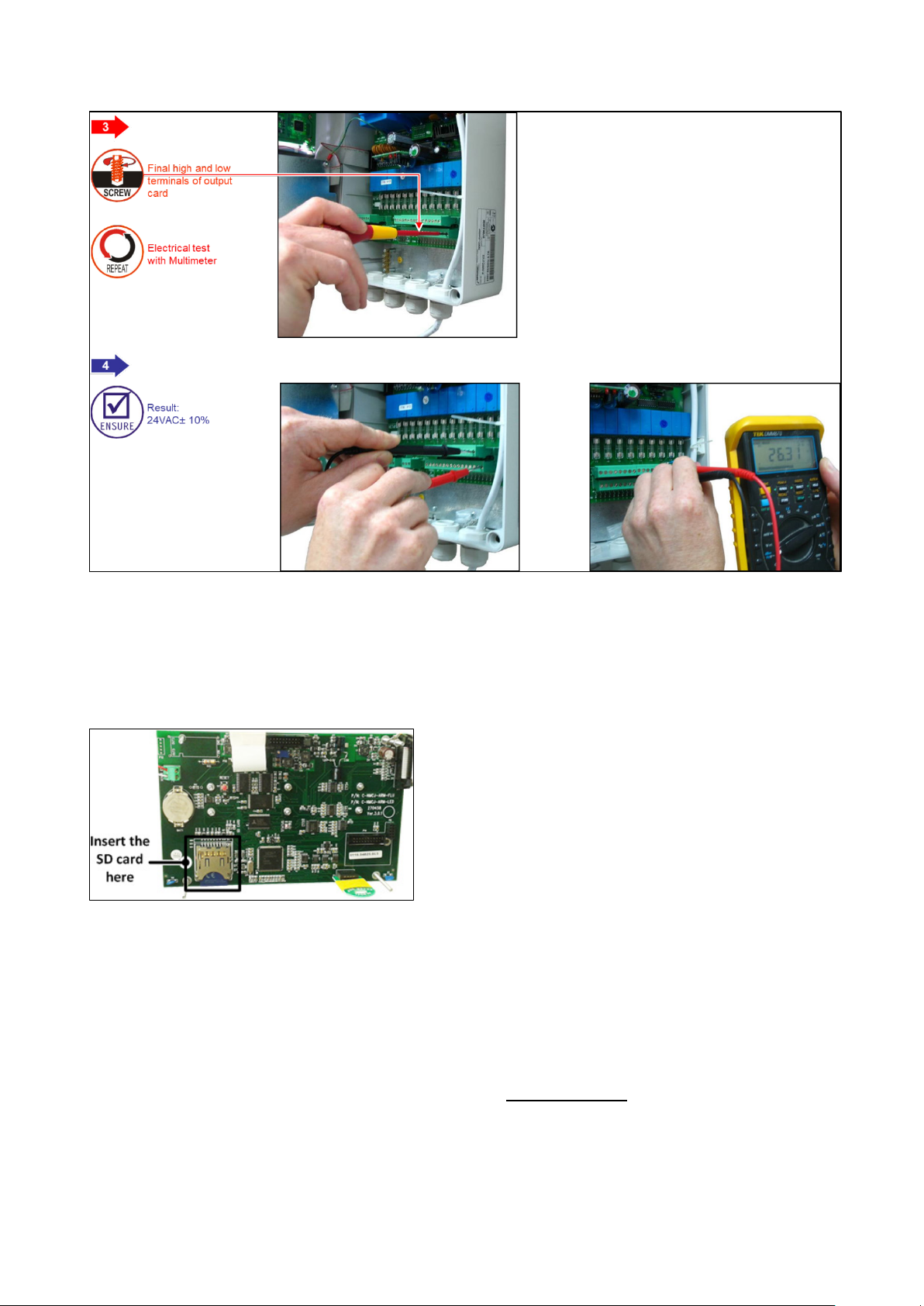

3.2 Electrical Test

© Munters AB, 2018 12

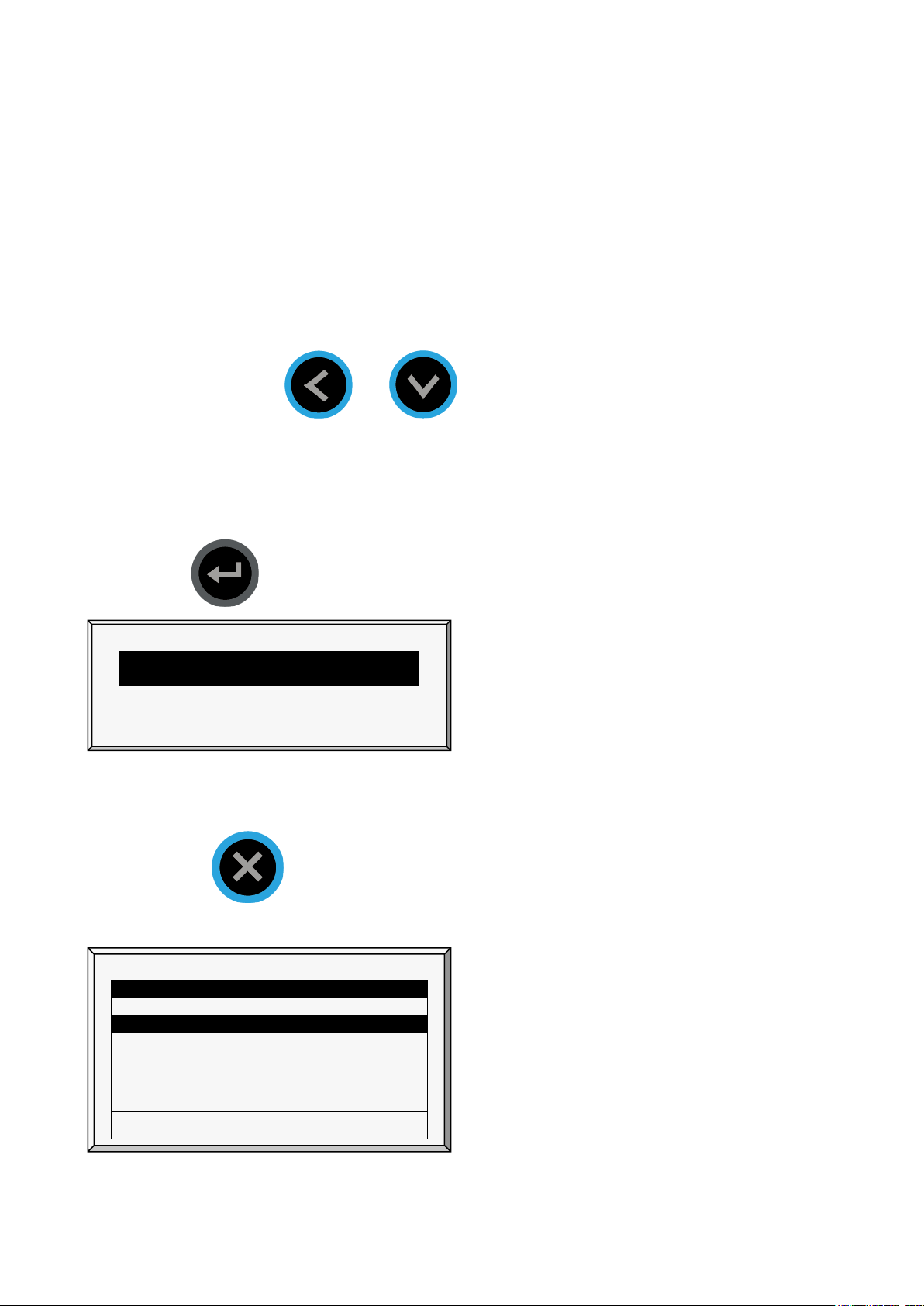

3.3 Firmware Upgrade

The Bootloader application enables installing or updating the system firmware. The application is menu

based and simple to use and enables updating the firmware from an SD card.

NOTE Verify that the card is in place before starting.

NOTE Green Field ECO supports up to 4 GB SD cards.

3.3.1

NTRODUCTION TO/GUIDELINES FOR FIRMWARE UPGRADES

•

While upgrading the firmware, a qualified Munters technician:

o

must be on site

o

must verify that the process is complete; verification includes checking all accessories

connected to the controller.

•

By default, in all sessions the controller returns to automatic mode. The technician must verify

that there are no manual mode devices in the field.

•

After upgrading the firmware the technician must upload settings and data from a data plug to

the controller.

© Munters AB, 2018 13

SELECT AN OPTION

Hardware Firmware

Hardware Test

Cancel Update

SELECT A FILE

Path: /

MUNTERS

<DIR>

12/Sept/2014

GREEN

FIELD~1

o

In the event that the controller sends a message regarding incomplete information, the

technician must enter the missing information manually and verify that the information is

correct in the field.

CAUTION Any upgrade that is not performed in accordiance with these guidelines could result in

unforseen malfunctions in the field equipment. Munters will not take responsibility for these

issues.

3.3.2 A

CCESSING THE APPLICATION

NOTE Before updating the firmware, save the settings to a data plug. Refer to Write to Data Plug,

page Error! Bookmark not defined..

1. Press and hold the and arrow keys.

2. Turn on the unit.

In the screen that appears, enter the password: 1948

NOTE If you enter the wrong password, an error message appears and the program goes to the Main

Screen. Repeat the process.

3. Press . The screen below appears.

NOTE Hardware Test is used for quality control only.

3.3.3 R

UNNING THE APPLICATION

NOTE Pressing you return to the previous menu.

1. Select Hardware Firmware. The following screen appears (example only):

GREEN FIELD <DIR> 13/Oct/2009

<DIR> 12/Sept/2014

Press ENTER to confirm selection or MENU to return.

2. Select the required directory.

© Munters AB, 2018 14

SELECT A FILE

Path: /

MUNTERSHEX1.04

<DIR>

12/Sept/2014

MUNTERSHEX1.06

<DIR>

12/Sept/2014

New Software Version

New Software Found

COLD START REQUIRED!!

Old Version:

8.02.00

New Version:

8.02.49

3. Press .

The following screen appears:

GREEN FIELD <DIR> 13/Oct/2009

4. Select the required software version.

5. Press .

6. A confirmation message appears. Select Yes.

7. Press .

NOTE Do not turn the unit off during the update! If there is an interruption (for example a power

outage), restart the process.

At the end of the process, the following screen appears (the version numbers are examples only):

Press ENTER To Continue.

8. Press and perform a Cold Start.

© Munters AB, 2018 15

4 Electrical Installation

•

Input/Output Layout, page 16

•

Output Terminals, page 16

•

Input Terminals, page 17

•

PC and Inter-Controller Communication, page 20

4.1 Input/Output Layout

4.2 Output Terminals

•

Output Terminal Wiring

•

Example of Output Wiring

© Munters AB, 2018 16

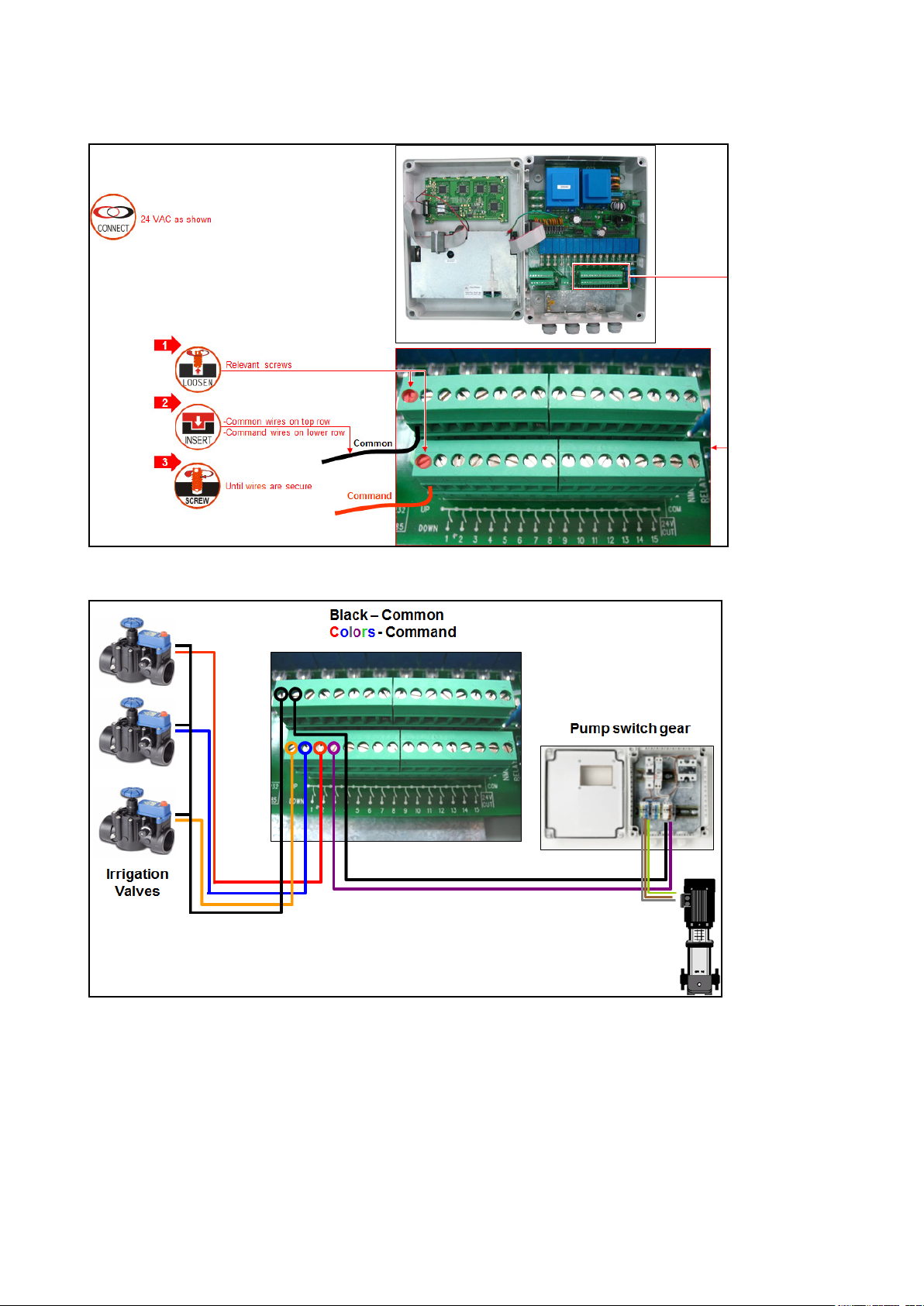

4.2.1 O

UTPUT TERMINAL WIRING

4.2.2 E

XAMPLE OF OUTPUT WIRING

NOTE Before switching the controller on, the technician should verify that there is no short circuit on

each output. (Resistance test)

4.3 Input Terminals

•

Input Terminal Wiring

•

Digital Input Examples

© Munters AB, 2018 17

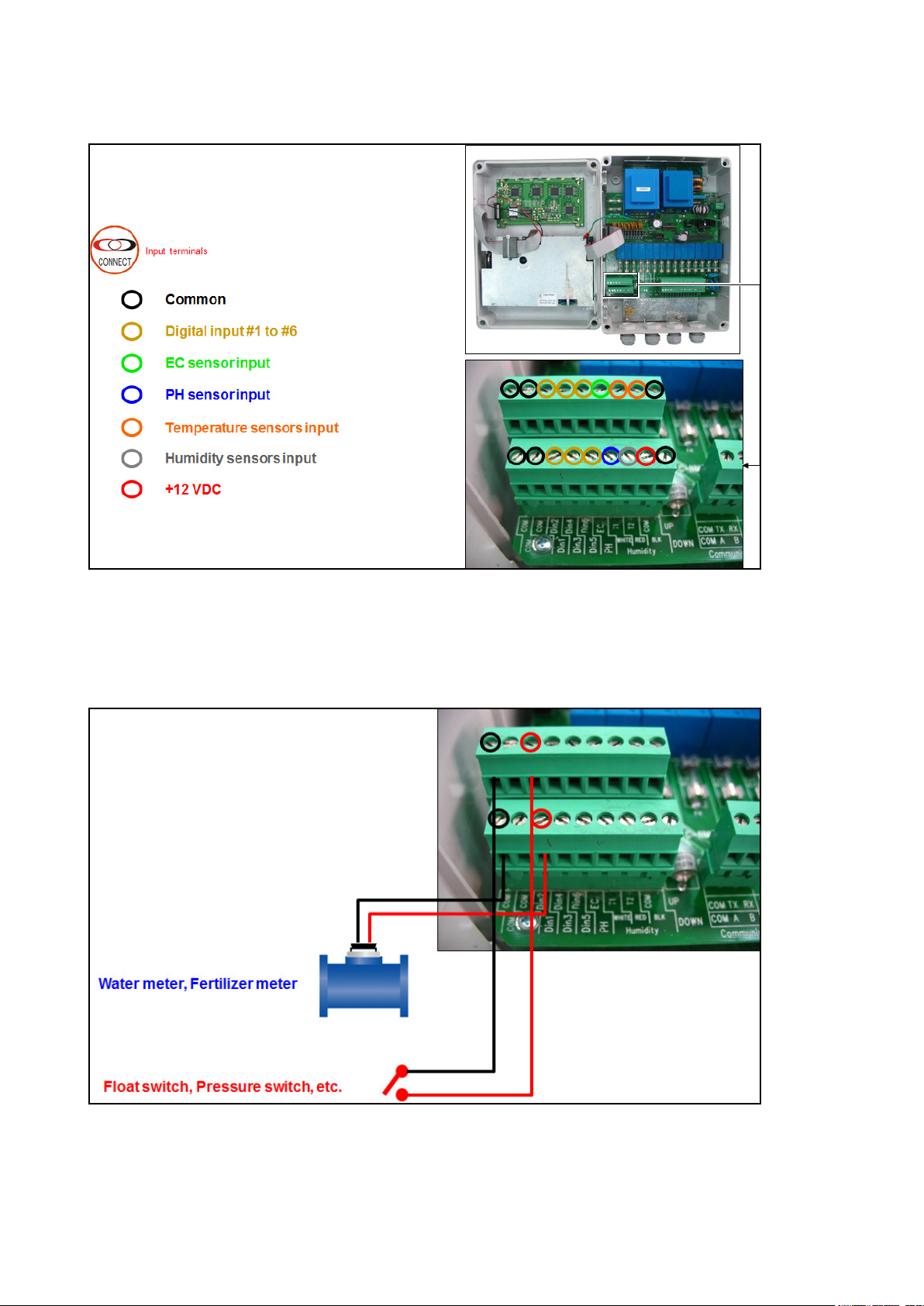

4.3.1 I

NPUT TERMINAL WIRING

4.3.2 D

•

IGITAL INPUT EXAMPLES

Example A

o

Digital input 1: Water meter, Fertilizer meter

o

Digital input 2: Float switch, Pressure switch

o

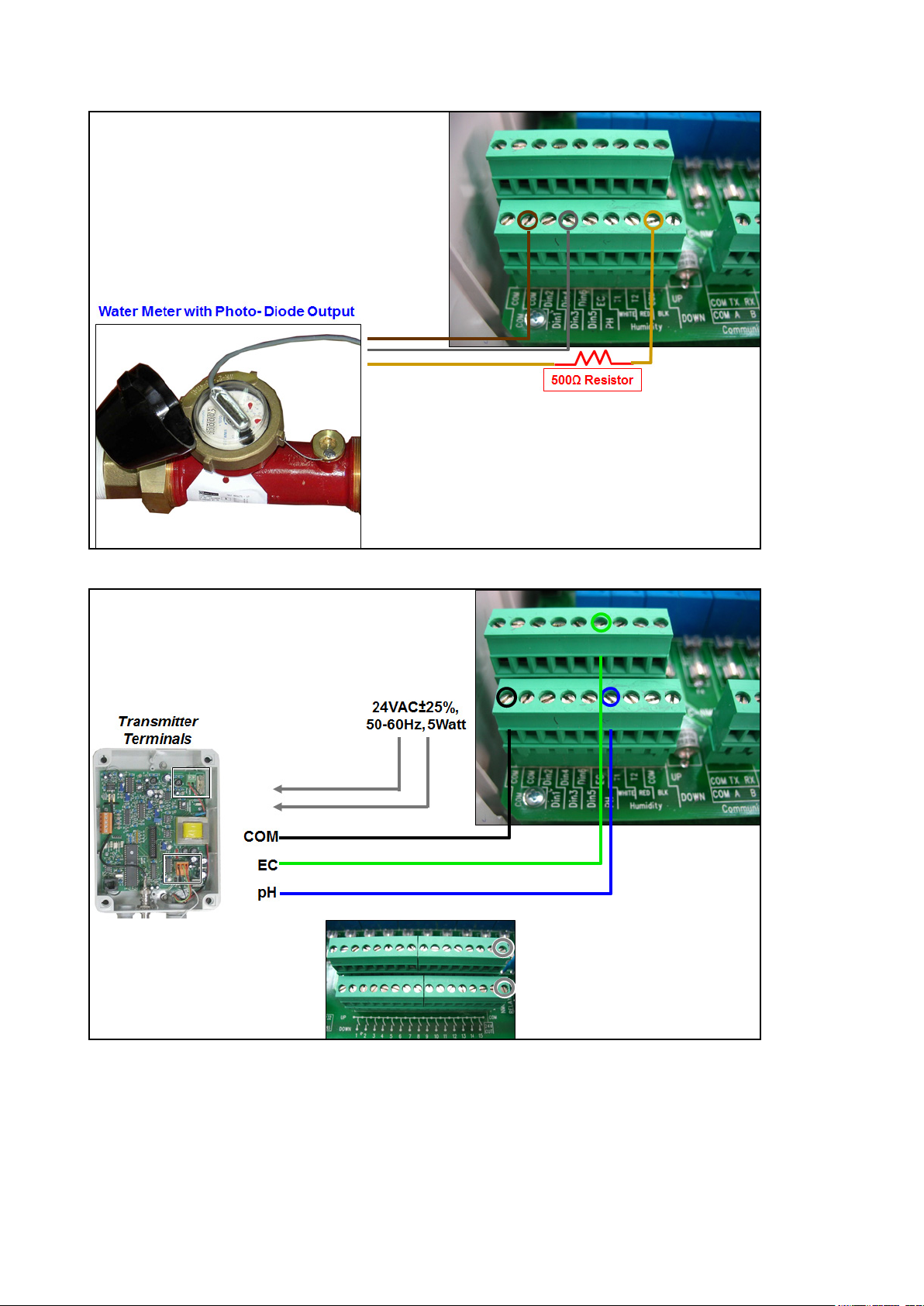

Digital Input 3: Water Meter with Photo-Diode Output

© Munters AB, 2018 18

•

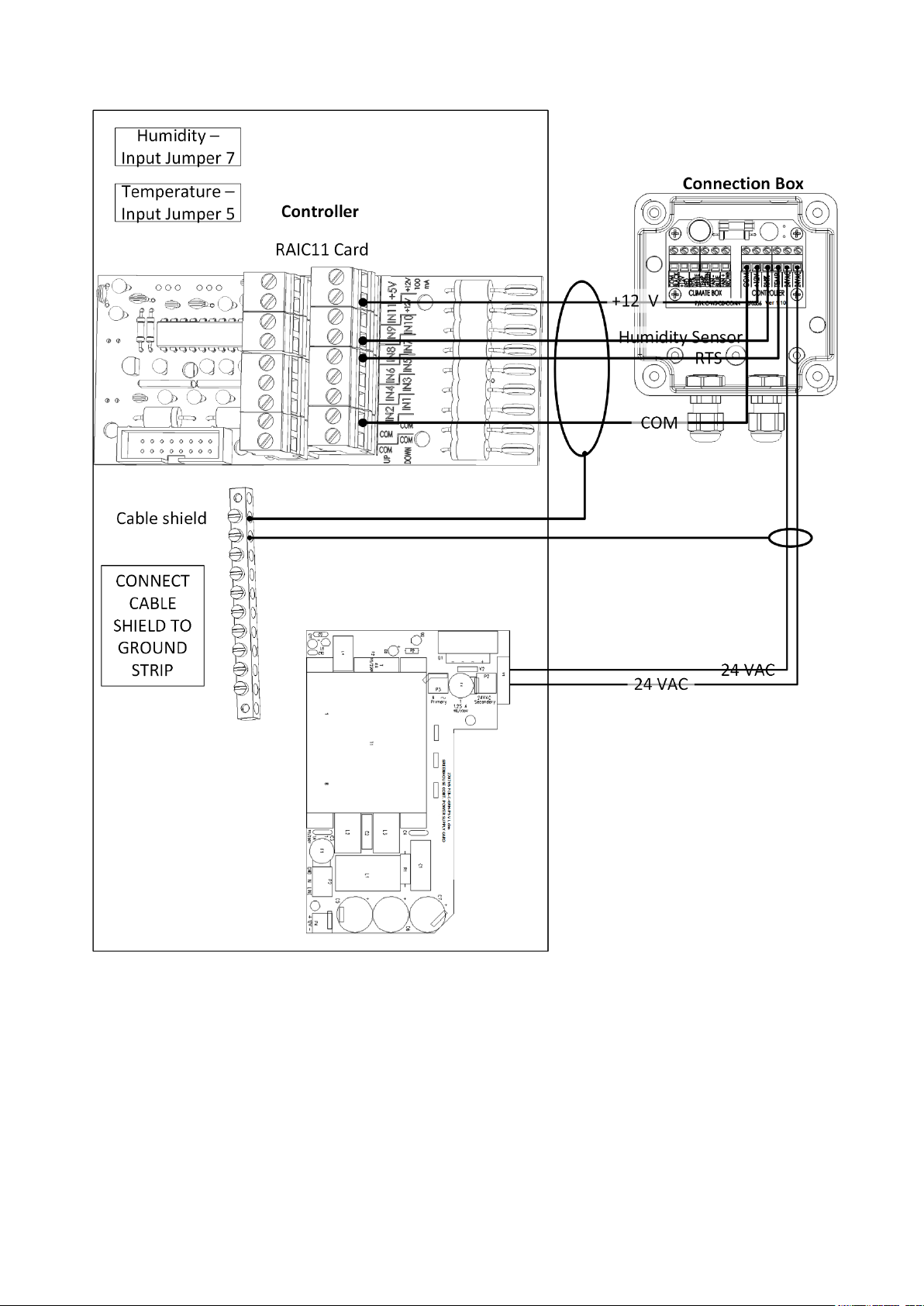

Example B: EC / pH sensors

NOTE Can wire EC/pH main power source to 24VAC on the output terminals.

•

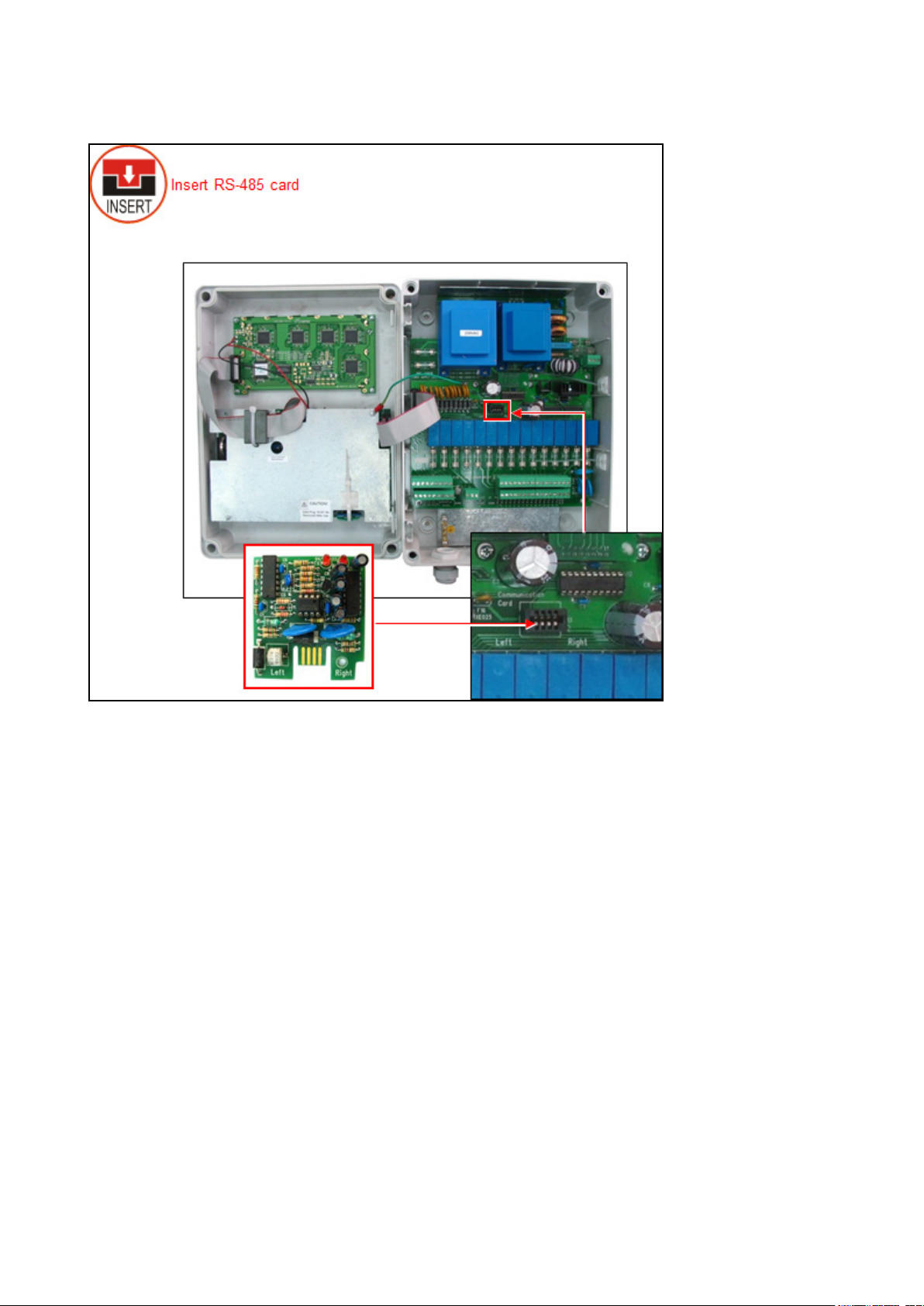

Example C: Temperature / Humidity Sensors

© Munters AB, 2018 19

NOTE Can wire 24VAC source in same way as on previous page.

4.4 PC and Inter-Controller Communication

•

Card Installation

•

Wiring and Controller Setup

© Munters AB, 2018 20

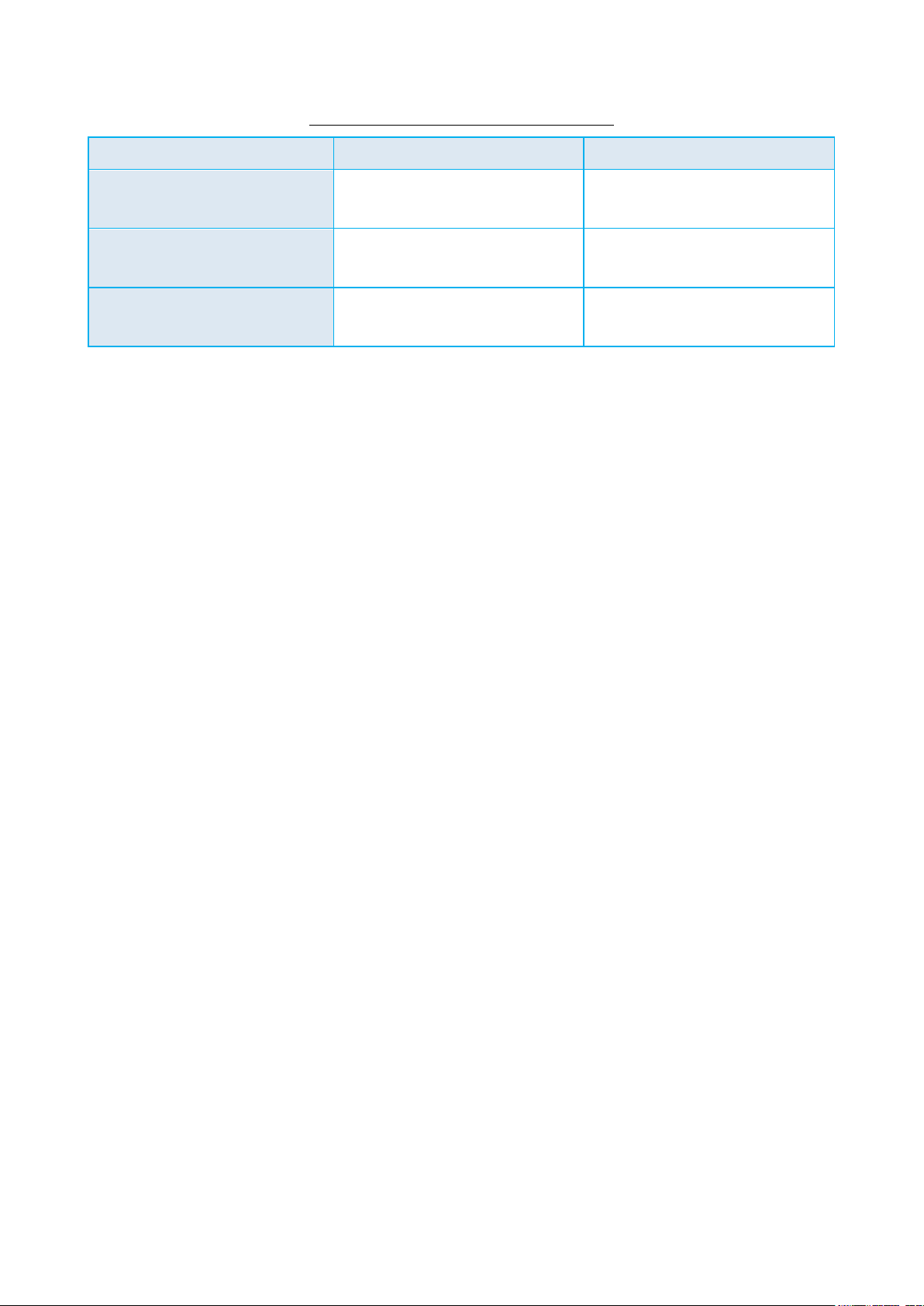

4.4.1 C

ARD INSTALLATION

© Munters AB, 2018 21

4.4.2 W

IRING AND CONTROLLER SETUP

The wiring is detailed in following table:

Number Color Wire

1 Red

2 Black

3 White

4 Green

5 Brown

COM Port Shield wire

Figure 1: RS-485 Wiring to Comm-Box

NOTE Refer to the Comm-Box Manual on wiring details, how to log-on to the Comm-Box and manage

the controller.

© Munters AB, 2018 22

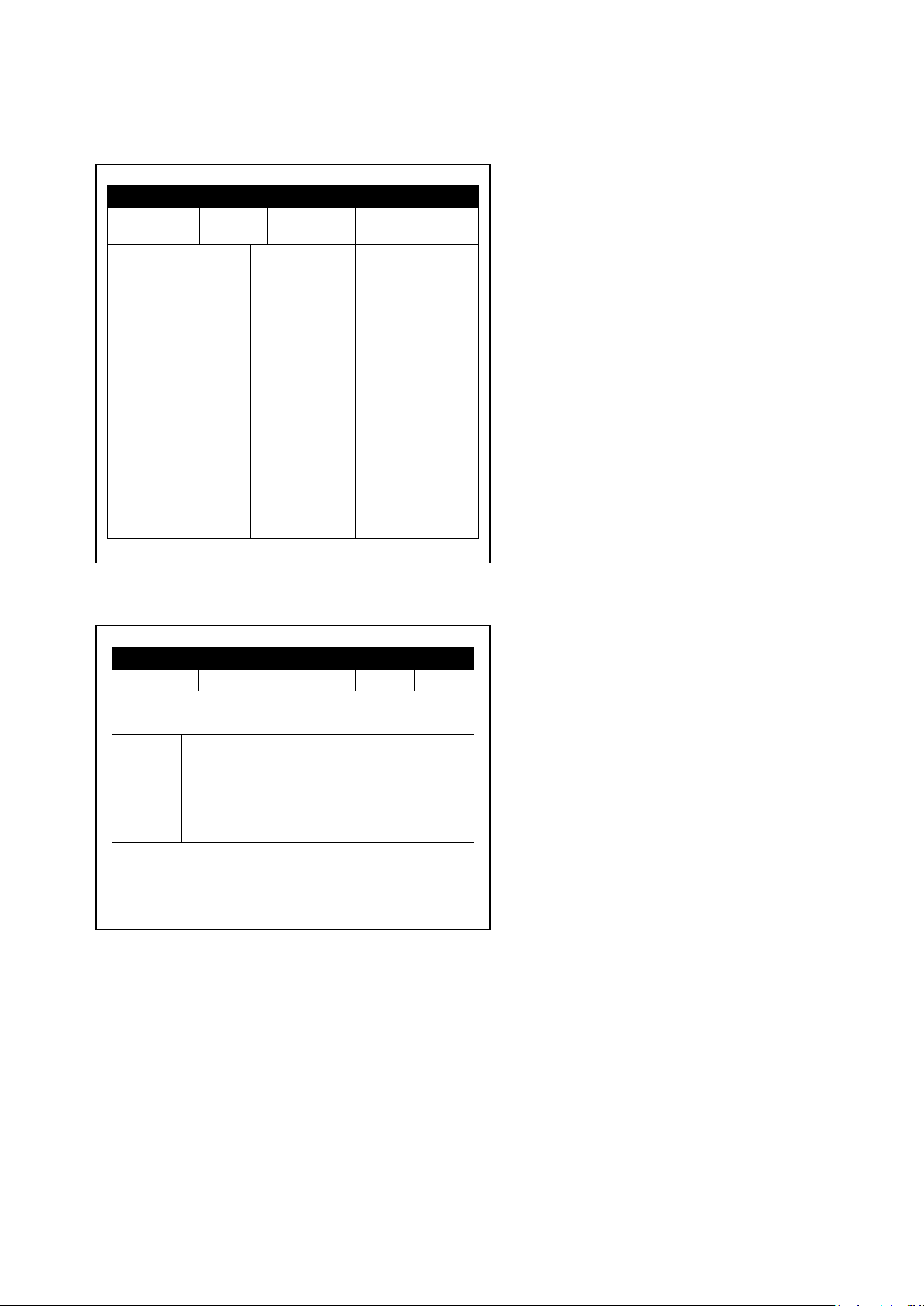

Baud Rate

One Controller

10 Controllers

9600 BPS

4800 BPS

2400 BPS

COMMUNICATION DISTANCE AND BAUD RATE

2000 meter

1.25 mile

2500 meter

1.55 mile

3000 meter

1.86 mile

1200 meter

0.75 mile

1800 meter

1.12 mile

2400 meter

1.49 mile

NOTE Baud rate is dependent on cable length and number of controllers.

© Munters AB, 2018 23

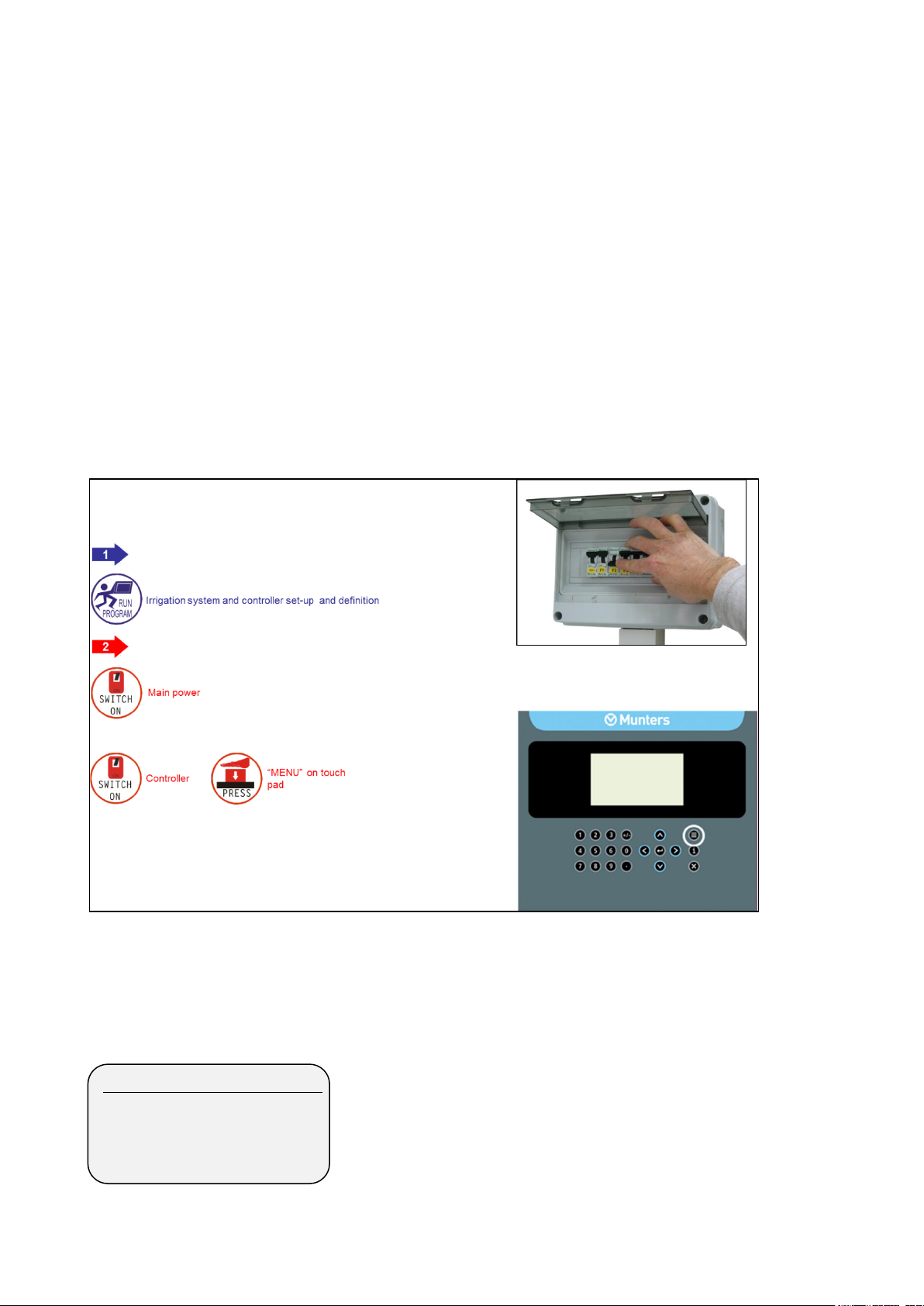

INSTALL ATION

5 Controller Setup

•

Start-Up

•

Device Layout

•

Device List

•

Digital Input

•

Analog Input

•

Hot Keys and Status Screens

5.1 Start-Up

•

Device Layout, page 24

•

Device List, page 25

•

Digital Input, page 26

5.2 Device Layout

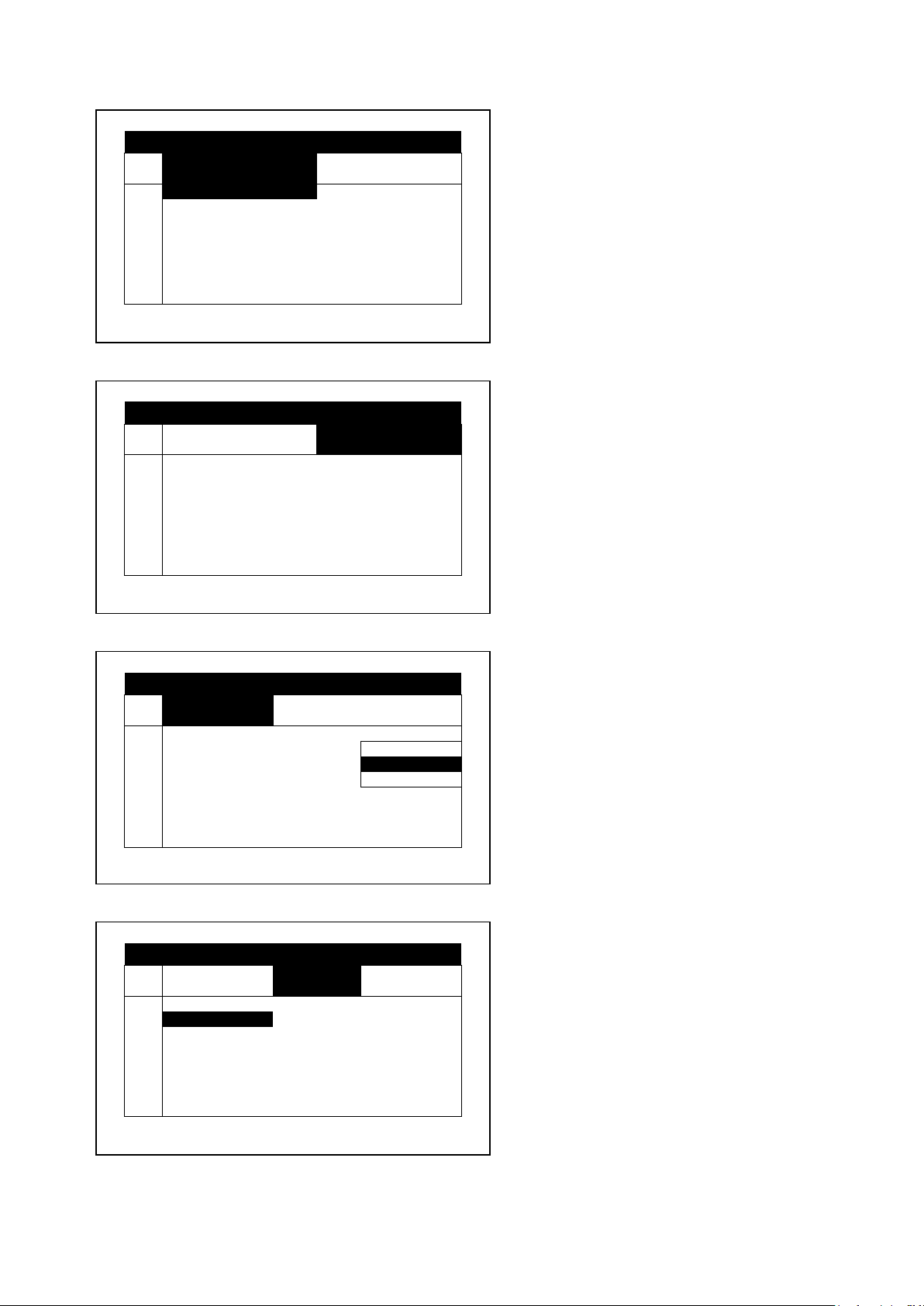

1. DEVICE LAYOUT

2. DEVICE LIST

3. DIGITAL INPUT

4. ANALOG INPUT

The device layout screen allows you to assign functions to each output (relay).

© Munters AB, 2018 24

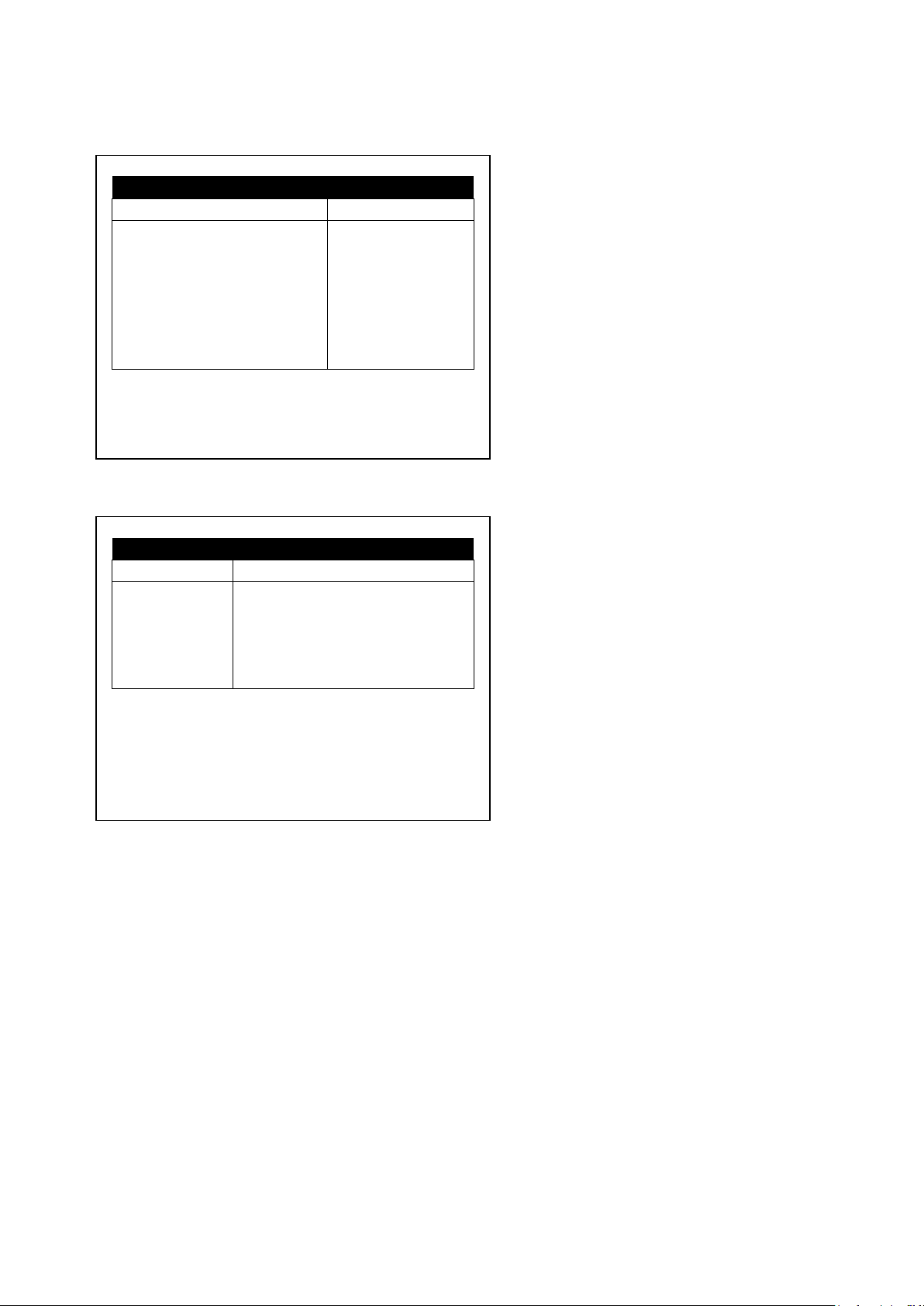

DEVICE LAYOUT

Relay

Function

No

1

Valve

99

2

Valve

00

3

Valve

01

4

Valve

02

5

Valve

03

6

Valve

04

7

Valve

05

8

None

--

9

Valve

06

10

Pump

1

1. Place the cursor on the Function column, use the arrow keys to reach the relevant line, and press

. A selection list including all available devices will appear.

2. Choose the required device and confirm by pressing . The cursor will move to the No.

column.

3. Specify the number of the device in the controller and press to confirm.

4. If you wish to define several devices of the same type, for example valves 1 to 10, configure the

first one and press a few times until you reach the required amount. The Green Field ECO

automatically continues with the same device until instructed otherwise, or until reaching the system

limitation for that device.

NOTE If 'Radio' is selected in table 6.2, the screen contains at least 64 outputs.

NOTE After making changes, be sure to exit and return again to check for errors. The Green Field ECO

will delete and replace conflicting assignments with ‘---‘.

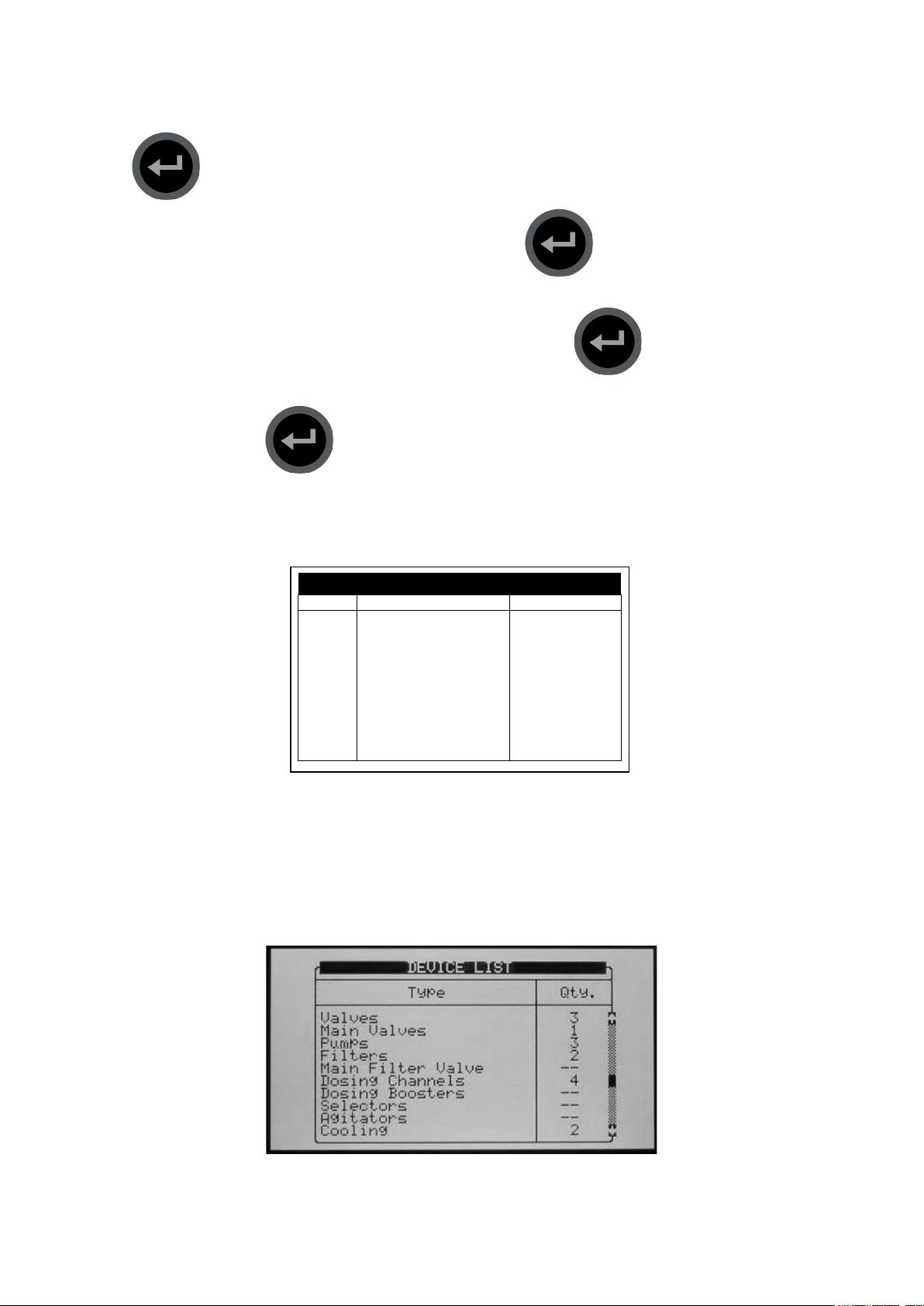

5.3 Device List

The Device List screen allows you to view what type, and how many devices are currently defined.

This screen automatically updates depending on the devices set in the 7.1 screen.

© Munters AB, 2018 25

a. Enter the beginning and ending time for each program.

DIGITAL INPUT

D-In

Input Function

1

Water Meter 1

2

Dosing Meter 1

3

Dosing Meter 2

4

< None >

5

< None >

6

Water Meter 2

Channel

Input Function

Valid

1

pH Sensor

NO

2

EC Sensor

YES

3

Humidity Sensor

YES

4

Temp. Sensor 1

YES

5

Temp. Sensor 2

YES

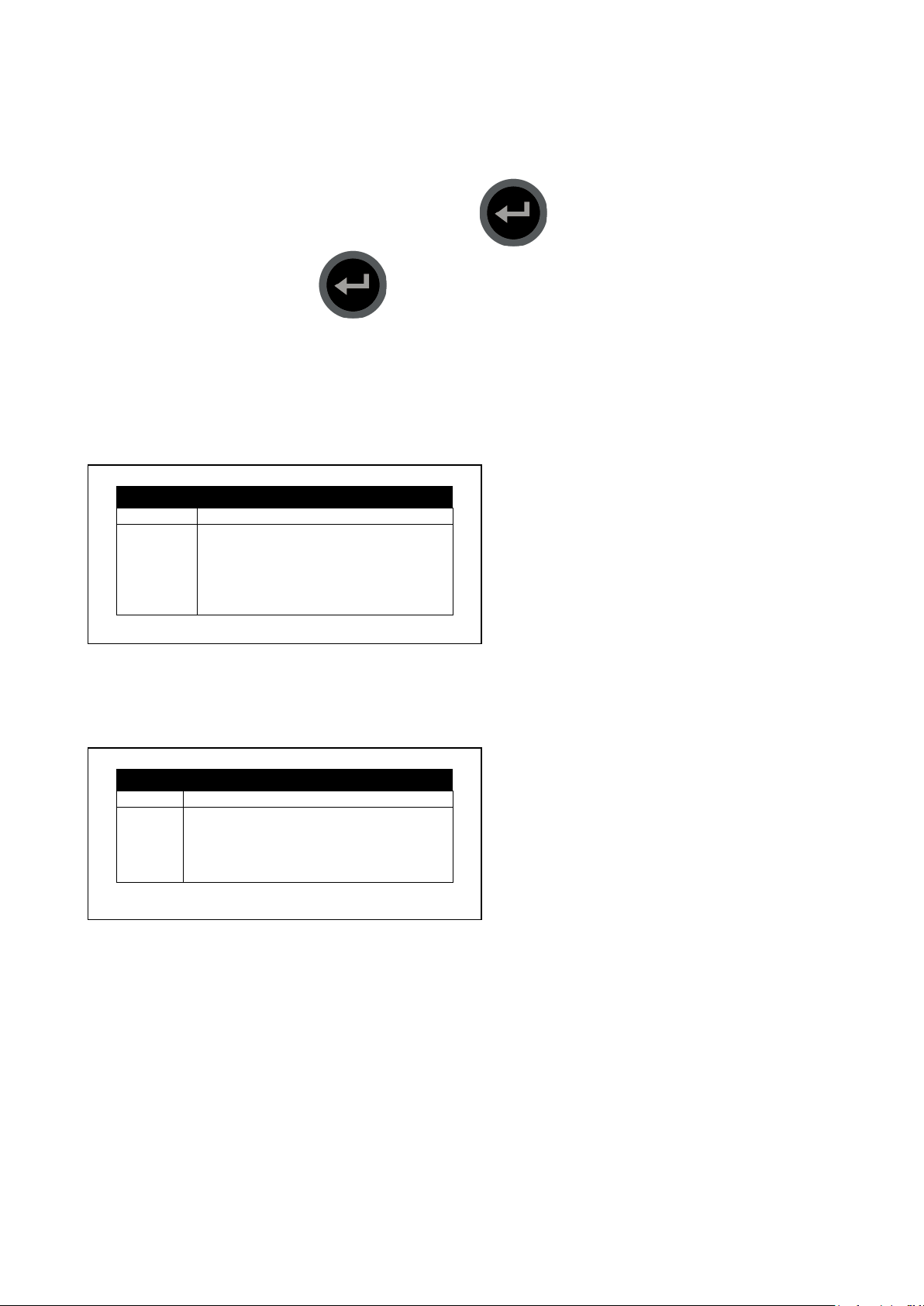

5.4 Digital Input

1. Go to Installation > Digital Input

2. Place the cursor on the relevant line and press . A selection list will open. Choose the

required sensor and press to confirm.

•

Inputs 1-32 are according to the following:

•

Card no. 1: inputs 1 – 8

•

Card no. 2: inputs 9 – 16

•

Card no. 3: inputs 17 – 24

•

Card no. 4: inputs 25 - 32

5.5 Analog Input

1. In

Installation > Analog Input

2. In

Setup > Analog Conversion Table

a. Select the sensor type

b. Under Valid, select YES.

, define input function(s) as Analog Sensors.

ANALOG INPUT

:

© Munters AB, 2018 26

3. In

Test > Analog Sensor

4. In

Program > Ext Condition

, view the actual sensor values.

, configure the External Condition Program for the analog sensors.

b. Under Start An. Dry Cont., define the input type.

c. Define The Trigger Type

d. Under Stop An. Dry Con., define the input type.

e. Under Oper. to Start, choose the required symbol.

EXTERNAL CONDITION PROGRAM

#

From

hh:mm

To hh:mm

Start An.

Dry Cont.

1

10:00

12:00

2

11:00

12:00

Dry Con 1

3

12:00

13:00

Dry Con 1

4

--:--

--:--

<NONE>

5

--:--

--:--

<NONE>

6

--:--

--:--

<NONE>

7

--:--

--:--

<NONE>

8

--:--

--:--

<NONE>

EXTERNAL CONDITION PROGRAM

#

From

hh:mm

To

hh:mm

Start An.

Dry Cont.

1 12:00

2 12:00

Dry Con 1

3 13:00

Dry Con 1

4 --:--

<NONE>

5 --:--

<NONE>

6 --:--

<NONE>

7 --:--

<NONE>

8 --:--

<NONE>

#

Trigger Type

Stop An

Dry Cont.

Oper.

to Start

1

Multi Shot

---

2

Multi Shot

Dry Con 2

One Shot

3

One Shot

Dry Con 14

Multi Shot

4

One Shot

<NONE>

Only If On

5

One Shot

<NONE>

---

6

One Shot

<NONE>

---

7

One Shot

<NONE>

---

8

One Shot

<NONE>

---

EXTERNAL CONDITION PROGRAM

#

Trigger Type

Stop An

Dry Cont.

Oper.

to Start

1

---

2 Dry Con 2

---

3 Dry Con 14

---

4 <NONE>

---

5 <NONE>

---

6 <NONE>

---

7 <NONE>

---

8 <NONE>

---

EXTERNAL CONDITION PROGRAM

© Munters AB, 2018 27

f. Under Start Value, enter the required value to start the analog sensor. Under Stop Value, entered the

EXTERNAL CONDITION PROGRAM

#

Stop An

Dry Cont.

Oper.

to Start

Start

Value

1

<NONE> >

2

Dry Con 2

---

3

Dry Con 14

---

4

<NONE>

---

5

<NONE>

---

6

<NONE>

---

7

<NONE>

---

8

<NONE>

---

SYSTEM SETUP

WATER

00:10:00

00:10:00

FLOW

100.00

100.00

pH 5.3

VALVE:

03-Apr-13

ALARM

MESSAGE

Set

Actual

Flow

Valve

Water

required value to stop the analog sensor.

5.6 Hot Keys and Status Screens

Hot Key 1: Next Irrigation

SET ACTUAL

CYCLE 1 1 START AT

EC 1.5 LEFT

STATUS ACTIVE

PROGRAM: 07:43:23 IRRIGATION

Hot Key 2: Irrigation Process

IRRIGATION PROCESS

Prog: Valve: Time: 08:07:23

© Munters AB, 2018 28

PROGRAM STATUS

13

Status

Wait

Time - Minimum

---

Measured/Limit

Given/Set

Time

Last Start

12:00

Elapsed Time

3:00

Next Start

15:43

WATER

EC/pH

Status

Wait

EC

pH

Nom. Flow

------

Target

---

---

Act. Flow

------

Actual

---

--- Open(%)

Min(%)

Prg(%)

Max(%)

Chan. 1

---

---

---

---

Chan. 2

---

---

---

---

Chan. 4

---

---

---

---

Hot Key 3: Program Status

Program: 1 3-Apr-

Time - Maximum ---

Rad Sum –

Clock Starts –

Starts Due to Rad

Sum

Starts Due to Max

Total Cycles Given 1

09:12:35

—/—

—/—

---

---

Hot Key 4: Water Flow & EC/pH Status

Chan. 3 --- --- --- ---

© Munters AB, 2018 29

FILTER FLUSHING STATUS

Time to Next Flush

--:--:--

Delta Pressure (Digital)

OFF

Remaining Filters Qty.

0

Delay

00:00

1

<NONE>

<NONE>

AVG.

<NONE>

<NONE>

Sen#T

H VPD

VPD SUM

<NONE>

0.0

Hot Key 5: Filter Flushing Status

Item

Flush Status OFF

Flushing Filter No. --

Current Delta Pressure ----

Hot Key 6: Temperature and Humidity Status

TEMP & HUMIDITY

No. Temp. Humidity

2 <NONE> ----

© Munters AB, 2018 30

Loading...

Loading...