Page 1

Farm Center

Pro / Farm

Manual for use and maintenance

Master Pro

Farm Center Pro, Farm Master Pro

Controllers

Ag/MIS/UmGB-2288-10/15 Rev. 1.2

P/N: 110504

Page 2

Revision

Product Software

Farm Center Pro, Farm Master Pro

Manual for use and maintenance

This manual for use and maintenance is an integral part of the apparatus together with the attached

technical documentation.

This document is destined for the user of the apparatus: it may not be reproduced in whole or in part,

committed to computer memory as a file or delivered to third parties without the prior authorization of the

assembler of the system.

: N.1.2 of 12/2016

: 2.0

Munters reserves the right to effect modifications to the apparatus in accordance with technical and legal

developments.

© Munters AB, 2015 2

Page 3

1

INTRODUCTION

6

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

2

PRECAUTIONS

7

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------

3

BEFORE USING

8

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

4

MECHANICAL INSTALLATION GUIDE

15

---------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------

5

TECHNICAL SPECIFICATIONS

24

6

CONTROL MENU

25

---------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------

Index

chapter page

1.1 Disclaimer

1.2 Introduction

1.3 Notes

2.1 Grounding

----------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

2.2 Checking the Battery Level

2.3 Filtering

2.4 Frequency Inverters

3.1 Components

-----------------------------------------------------------------------------------------

3.2 General Description

3.2.1 Farm Center Pro

3.2.2 Farm Master Pro

3.3 Features

3.4 Network Diagrams

3.5 Farm Center Pro Keyboard

3.6 Farm Center Pro Main Screen

3.7 Main Menu

...............................................................................................................................

..............................................................................................................................

10

11

12

13

6

6

6

7

7

7

7

8

8

8

8

9

4.1 Environmental Protection

4.2 Sensors and Shielded Wiring

4.3 Installation and Electrical Connections

4.4 Farm Center Pro/Farm Master Pro Wiring Diagrams

4.5 Dip Switch Configuration

------------------------------------------------------------------------------------

6.1 Temperature Curve

6.2 Minimum / Maximum Levels

6.2.1 Day

© Munters AB, 2015 3

....................................................................................................................................................

---------------------------------------------------------------------

-----------------------------------------------------------

15

15

16

16

23

25

26

26

Page 4

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

7

MANAGEMENT MENU

36

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------------------

8

HISTORY MENU

39

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

9

SYSTEM MENU: VENTILATION LEVELS

43

--------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

10 SYSTEM MENU: CALIBRATION

47

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

6.2.2 Time

6.2.3 Soft Minimum / Maximum by Day

6.2.4 Soft Minimum / Maximum by Time

6.2.5 Maximum Cold, Warm by Day

6.2.6 By Weight

6.3 Humidity

6.4 Static Pressure

6.5 Heaters

6.6 Cool Pad

6.7 Fogger Pad

6.8 Light

6.9 Feeding Schedule

6.10 Timers

6.11 Extra System

7.1 Alarm Reset

7.2 Animal Inventory

7.3 Day & Group

7.4 Alarm Setting

...................................................................................................................................................

.......................................................................................

......................................................................................

..............................................................................................

.......................................................................................................................................

-----------------------------------------------------------------------------

27

27

28

28

29

30

31

32

33

33

34

34

35

35

36

36

37

37

8.1 Temperature

8.2 Humidity

8.3 Water

8.4 Feed

8.5 Mortality

8.6 Heater

8.7 Alarm

8.8 Event

9.1 Ventilation Levels

9.2 Variable Fan Levels

9.3 Curtain Levels

9.4 Stir Fan

--------------------------------------------------------------------------------------

-----------------------------------------------------------

--------------------------------------------------------------------

39

39

40

40

40

41

41

42

43

45

46

46

10.1 Temperature

10.2 Humidity

10.3 Static Pressure

© Munters AB, 2015 4

47

47

48

Page 5

---------------------------------------------------------------------------------------------------------------------------------------------------------------

11 SYSTEM MENU: INSTALLATION

49

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

12 FARM MASTER PRO FUNCTIONS

54

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

13 WARRANTY

56

10.4 Water and Feed

11.1 Relay Layout

11.2 Analog Sensors Layout

11.3 Digital Input

11.4 Analog Output

11.5 Variable Speed Fan

11.6 Temperature Definition

11.7 Curtain Setup

11.8 Fan Air Capacity

11.9 About

12.1 Cold Start

12.2 Set Unit Number

12.3 Main Menu

12.4 Calibration

12.4.1 Temperature Sensor Calibration

12.4.2 Calibration Procedure

12.5 Test

-------------------------------------------------------------------

-----------------------------------------------------------------

.............................................................................................

................................................................................................................

48

49

50

50

51

51

51

52

53

53

54

54

54

54

54

54

55

--------------------------------------------------------------------------------------------

© Munters AB, 2015 5

Page 6

1 Introduction

1.1 Disclaimer

Munters reserves the right to make alterations to specifications, quantities, dimensions etc. for production

or other reasons, subsequent to publication. The information contained herein has been prepared by

qualified experts within Munters. While we believe the information is accurate and complete, we make no

warranty or representation for any particular purposes. The information is offered in good faith and with

the understanding that any use of the units or accessories in breach of the directions and warnings in this

document is at the sole discretion and risk of the user.

1.2 Introduction

Congratulations on your excellent choice of purchasing an Farm Center Pro/Farm Master Pro!

In order to realize the full benefit from this product it is important that it is installed, commissioned and

operated correctly. Before installation or using the fan, this manual should be studied carefully. It is also

recommended that it is kept safely for future reference. The manual is intended as a reference for

installation, commissioning and day-to-day operation of the Munters Controllers.

1.3 Notes

Date of release: July 2010

Munters cannot guarantee to inform users about the changes or to distribute new manuals to them.

NOTE All rights reserved. No part of this manual may be reproduced in any manner whatsoever

without the expressed written permission of Munters. The contents of this manual are subject to

change without notice.

© Munters AB, 2015 6

Page 7

2 Precautions

•

Grounding

•

Checking the Battery Level

•

Filtering

•

Frequency Inverters

2.1 Grounding

•

Always connect temperature and sensor shields to earth ground. Avoid mixing high voltage

wiring with sensor and low voltage wiring.

•

Keep the controller as far as possible from heavy contactor boxes and other sources of

electrical interference.

•

Do not connect communication wire shields, which go from one house to another at both ends.

Connect them at one end only. Connection at both ends can cause ground loop currents to

flow, which reduce reliability.

•

The COM connection for communications is not the shield wire. The COM, RX and TX wires

must connect to each other at all controllers.

2.2 Checking the Battery Level

Check the battery once a year. The output must be 2.7 volts (minimum). Authorized personnel only must

replace the battery if the output is below the minimum required level or every five years.

2.3 Filtering

If this installation includes a power inverter to drive variable speed fans, install an EMI filter in front of the

inverter, according to the specifications provided by the inverter manufacturer. Referto the inverter

documentation.

2.4 Frequency Inverters

Frequency inverters can cause severe electrical and electromagnetic interference. Therefore, when

employing a frequency inverter, it is critical that you carefully follow the manufacturer's installation

instructions.

In particular verify:

•

that the cable shielding between the inverter and any motor meets industry standards

•

proper grounding of the inverter's chassis and motor power cable

•

proper grounding of low voltage cable shield wire

•

that the controller and inverter cables are kept in separate conduits or wire bundles

© Munters AB, 2015 7

Page 8

3 Before using

The following section provides an introduction to the Farm Center Pro / Farm Master Pro Climate Controller

units.

•

Components

•

General Description

•

Features

•

Network Diagrams

•

Farm Center Pro Keyboard

•

Farm Center Pro Main Screen

•

Main Menu

3.1 Components

•

Farm Center Pro

•

Farm Master Pro

•

Extension Box (optional)

•

Farm Communication 485 Communication / Farm Guard (optional)

3.2 General Description

•

Farm Center Pro

•

Farm Master Pro

3.2.1 F

Farm Center Pro provides you maximum capability with minimal complexity in programming and

controlling up to 10 Farm Master Pro units.

Farm Center Pro is the ultimate pig house controller. Equipped with an easy programming interface, it

provides programmable outputs for all major features and an advanced graphic user interface that

provides simple, fast navigation, informative main screen, display feedback on the programming and

device status.

ARM CENTER PRO

The Farm Center Pro communicates with up to ten Farm Master Pro units to access history, collect events

and alarms for each and all relevant data up to 100 days.

3.2.2 F

ARM MASTER PRO

Farm Master Pro is Munters’s latest advance in environmental controllers specially designed for the pig

house industry.

The user-friendly has high performance and quick response time. Farm Master Pro features accurate

temperature and humidity sensors, secure transmission of data even in noisy environments and the added

convenience of eight output relays as well as four analog outputs.

© Munters AB, 2015 8

Page 9

5020

5021

5022

Each Farm Master Pro can operate independently in case of Farm Center Pro malfunction or loss of

power. Using an internal battery when the Farm Master Pro is operating “alone”, there is no history

collection or possibility to change parameters.

There are three Farm Master Pro models:

•

: No variable speed

•

: One channel variable speed

•

: Two channels variable speed

3.3 Features

•

Farm Center Pro

o

Easy programming

o

Graphic user interface screens

o

Positioning scrollbar

o

Swift device and feature selection

o

USB data port

o

Large numeric keypad

o

Communication with up to ten Farm Master Pro units

o

Extensive history of events & alarms

o

Data collection

o

Real time visual outlook

o

Alarm system (for every Farm Master Pro unit)

o

Multi language Support

o

PC communication

•

Farm Master Pro:

o

Easy programming

o

Programmable outputs

o

Alarm system

o

Large display

o

Up to 4 temperature sensors

o

Up to 8 heavy duty relays (1 HP)

o

On/Off/Auto override switches

o

Static pressure control (optional)

o

4 analog outputs (0 - 10 volts)

o

Variable speed fan output with bypass

o

Water, feed, and humidity control

o

Automatic calibration of curtains

© Munters AB, 2015 9

Page 10

3.4 Network Diagrams

The following diagrams illustrate sample Farm Center Pro – Farm Master Pro networks.

Figure 1: Farm Center Pro – Farm Master Pro – MUX Network

Figure 2: Farm Center Pro – Farm Master Pro – Farm Guard Network

© Munters AB, 2015 10

Page 11

Room,

Enter

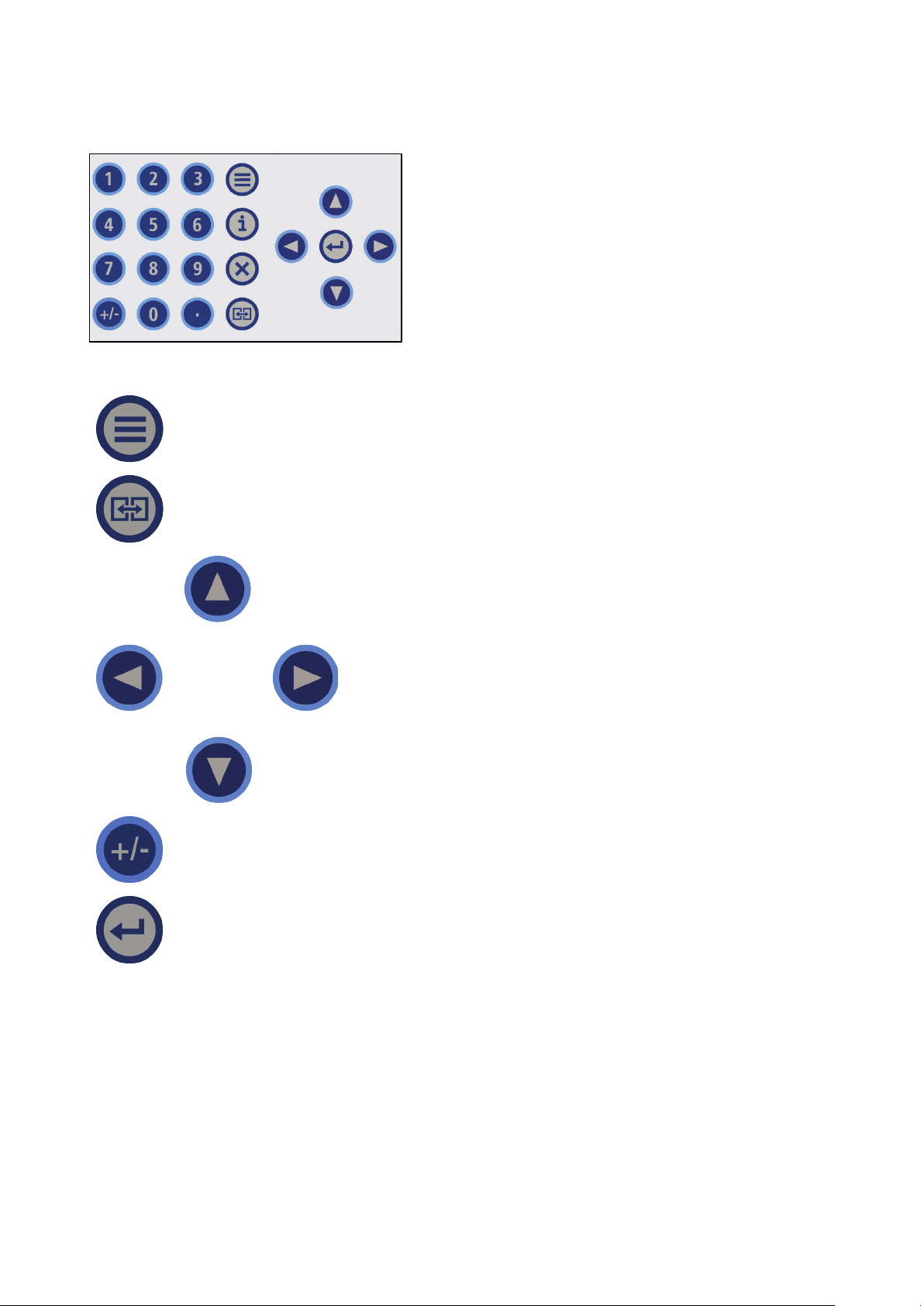

3.5 Farm Center Pro Keyboard

Table 1: Keyboard Functions

Menu Toggles the menu function

Room The Room key is used to switch between rooms. Press

press a number to reach the required room then

.

Arrows Use the arrows to scroll a short press in any direction

moves one notch.

+/- The +/- key is used to scroll between options (Yes/No,

Enter The Enter key is a confirmation key.

On/Off and '-').

© Munters AB, 2015 11

Page 12

Numeric

Pad

The Number keys are pressed to type a number and

when numbers should be selected.

Delete The 'Delete' key erases typing mistakes.

Help

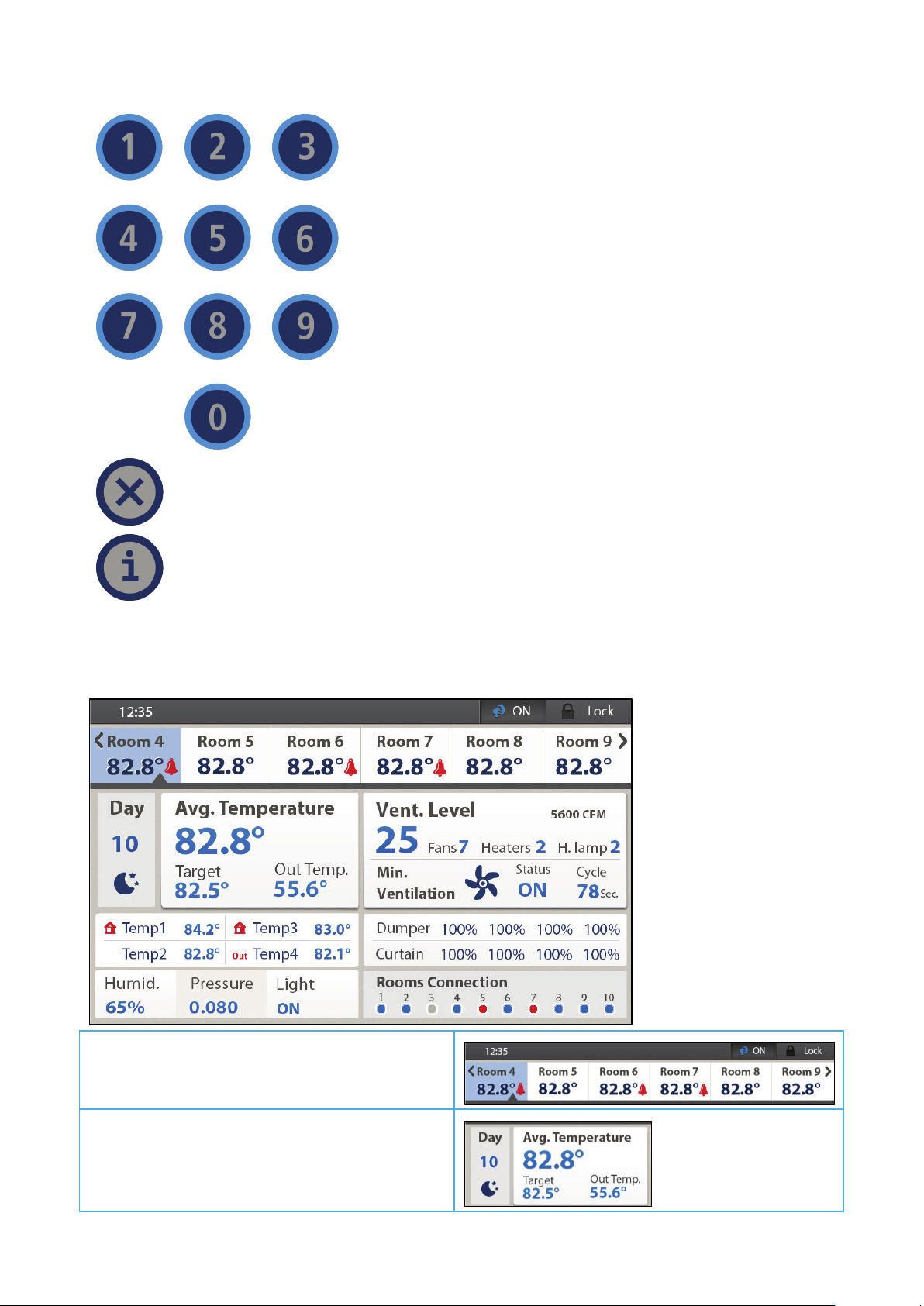

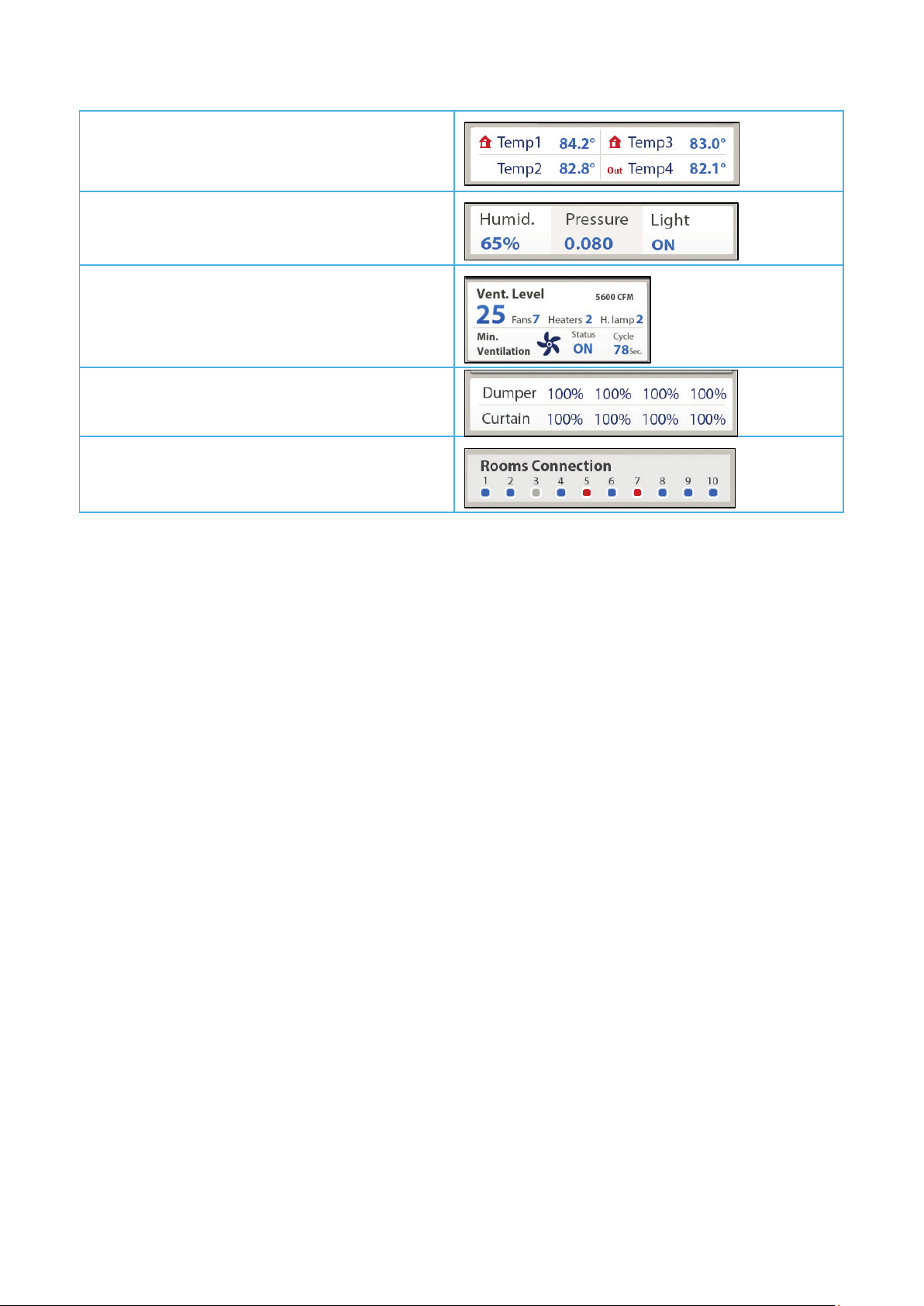

3.6 Farm Center Pro Main Screen

Room Temperatures

Growth day, Temperature data

© Munters AB, 2015 12

Page 13

CAUTION

Current temperature sensor readings

Current humidity, static pressure, light status

Ventailation data

Current curtain/dumper openinigs

Connectivy between controllers

In case of an alarm, a blinking message appears on the main screens in addition to the

siren. Pressing "0" on the main screen, when the alarm message is on, directs you to the

room with the alarm. Resetting the alarm is possible, but it only stops the siren and not the

screen message. Only by fixing the problem stops the message.

NOTE Once communication is off there is no history accumulation in the Farm Center Pro.

A dotted lined square indicates N/A (not available).

•

3.7 Main Menu

Table 2and Table 3 detail the complete Farm Center Pro main menu structure. The menu has two levels.

1. Press the left/right arrow keys to scroll between menus.

2. Press Enter to use the each menu's items.

3. To enter the second level, scroll to System Menu and press Enter.

4. Scroll to the required menu item and press Enter.

© Munters AB, 2015 13

Page 14

Control

Management

History

System

System

Levels of Ventilation

Calibration

Installation

About

Table 2: Menu (Level One)

1. Temperature

1. Alarm Reset 1. Temperature 1. Levels of Ventilation

Curve

2. Min/Max Levels 2. Animal Inventory 2. Humidity 2. Calibration

3. Humidity 3. Group Setting 3. Water 3. Installation

4. Static Pressure 4. Alarm Setting 4. Feed 4. About

5. Heaters 5. Mortality

6. Cool Pad 6. Heaters

7. Fogger 7. Alarms

8. Light 8. Events

9. Feeder

10. Timers

11. Extra System

Table 3: Menu (Level Two)

1. Ventilation levels 1. Temperature 1. Relays 1. Help About

2. Var. Speed Fan Levels 2. Humidity 2. Analog Sensors

3. Curtain Levels 3. Static Pressure 3. Digital Sensors

4. Stir Fans 4. Water and Feed 4. Analog Output

5. Variable Fans Setup

6. Temperature

Definition

7. Curtain Setup

8. Fan Air Capacity

© Munters AB, 2015 14

Page 15

CAUTION

CAUTION

Recycle raw materials instead of disposing as waste. The controller, accessories and

one end

4 Mechanical Installation Guide

These units must be installed by an authorized electrician. Power must be disconnected to

avoid electrical shock and damage.

To avoid exposing the controllers to harmful gases or high humidity, it is recommended to

install it in the service room.

NOTE Installation Category (Over voltage Category) II

•

The power supply to the controller should be protected by 10 amps circuit breaker

All electrical connections should comply with National Electrical code (NEC)

•

1. Screw the metal sheet on the back of the box using the 4 supplied screws. Mount the Farm

Master Pro through the mounting holes (see next page).

2. Open the enclosure lid by unfastening the four screws.

3. Drill holes at bottom of the box and place cable holders.

4. Place the required cables through the cable holders at the bottom of the unit. Connect the wires

according to the wiring diagrams.

5. Make sure that you use wires large enough for the load of the variable speed.

6. To connect temperature and humidity sensors use shielded two or four conductor #18-#24

gauge cables. Connect the shields to the Ground metal strip. Do not connect the shields to more

than one point, or you may induce ground loop currents.

7. Close the Farm Master Pro enclosure lid carefully and tightly. Use RTV silicon or equivalent

sealant to seal the cable holders.

8. After installation is completed, operate the Farm Master Pro for a few hours and re- check for

proper operation.

4.1 Environmental Protection

packaging should be sorted for environmental-friendly recycling. The plastic components

are labeled for categorized recycling.

4.2 Sensors and Shielded Wiring

•

For long shielded wires, connect the shield to ground at

•

From the ground terminal, run a heavy wire directly to the ground rod. It is acceptable, if

necessary, to run the heavy ground wire to the electrical service grounding system rather than

directly to the ground rod.

•

Do not use light wires for these ground connections. They must carry heavy lightning currents,

sometimes exceeding thousands of amperes. Certainly, do not use the shielding of sensor and

low voltage wiring for this purpose.

only.

© Munters AB, 2015 15

Page 16

one end

waterproof

•

Ensure that all ground connections go to a single local point. When lightning strikes, grounds a

meter or two apart will be at significantly different voltages. If you have several electronic

boxes with individual grounds, connect all these together to a single point (If Possible),

preferably to the surge protector ground. This should continue to the ground rod or the

electrical service. In particular, avoid grounding any controls remotely through shield wiring.

•

Do not use shields to create a path for lightning. For long shield wires, such as building to

building runs, connect the shield to ground at

only, to reduce the chance of

conducting lightning from one building to another.

•

When splicing sensors to longer wires, ensure that the splice is

. Use adhesive lined

heat shrink (marine grade) to make waterproof connections.

•

Use a good compression connector for splicing. This is better than soldering. Do not simply

twist wires together and then cover with electrical tape.

•

Keep sensor wiring separate from other power distribution and high voltage wiring. Ensure that

lightning on other wiring will not transfer to the sensors.

•

Install outside temperature sensors so that the sun will not cause false readings, and so that

exhaust air from the building will not affect the sensor.

4.3 Installation and Electrical Connections

•

Install computerized electronic controls at least one meter (three feet) away from interference

sources such as high voltage wiring to motors, variable speed, light dimmers, relays.

•

Install electronic controls in a separate ventilated control room that is protected from extreme

temperatures and dirty environments. Place the controls so that the operators can conveniently

use the control and read indicators and displays.

•

Give your installation a professional appearance, with all wiring in conduit or neatly installed.

Keep low voltage wires separate from high voltage wires.

•

Use shielded wiring for low level signals. For buried wiring (building to building runs) use high

grade jell filled cables that are impervious to moisture.

•

Seal cable entry points and control boxes to prevent contamination and corrosion. If you use

silicon sealant with acetic acid cure, keep the control open and ventilated until cured.

Otherwise, the acetic acid will attack the metal parts, including circuitry.

•

Drill cable entry holes on the bottom of the box only.

4.4 Farm Center Pro/Farm Master Pro Wiring Diagrams

•

Figure 3: Communication Wiring Diagram (Farm Communication Box)

•

Figure 4: Communication Wiring Diagram (Farm Guard)

•

Figure 5: Communication Wiring Diagram (Farm Master Pro)

•

Figure 6: Farm Master Pro Wiring Diagram (Analog Output Devices, Digital Sensors)

•

Figure 7: Farm Master Pro Wiring Diagram (Variable Speed Fans, Grounding)

•

Figure 8: Wiring Diagram of Main Voltage Section Showing Filtering

•

Figure 9: Farm Master Pro Wiring Diagram (Relays, RTS-2)

•

Figure 10: Farm Master Pro's CPU

© Munters AB, 2015 16

Page 17

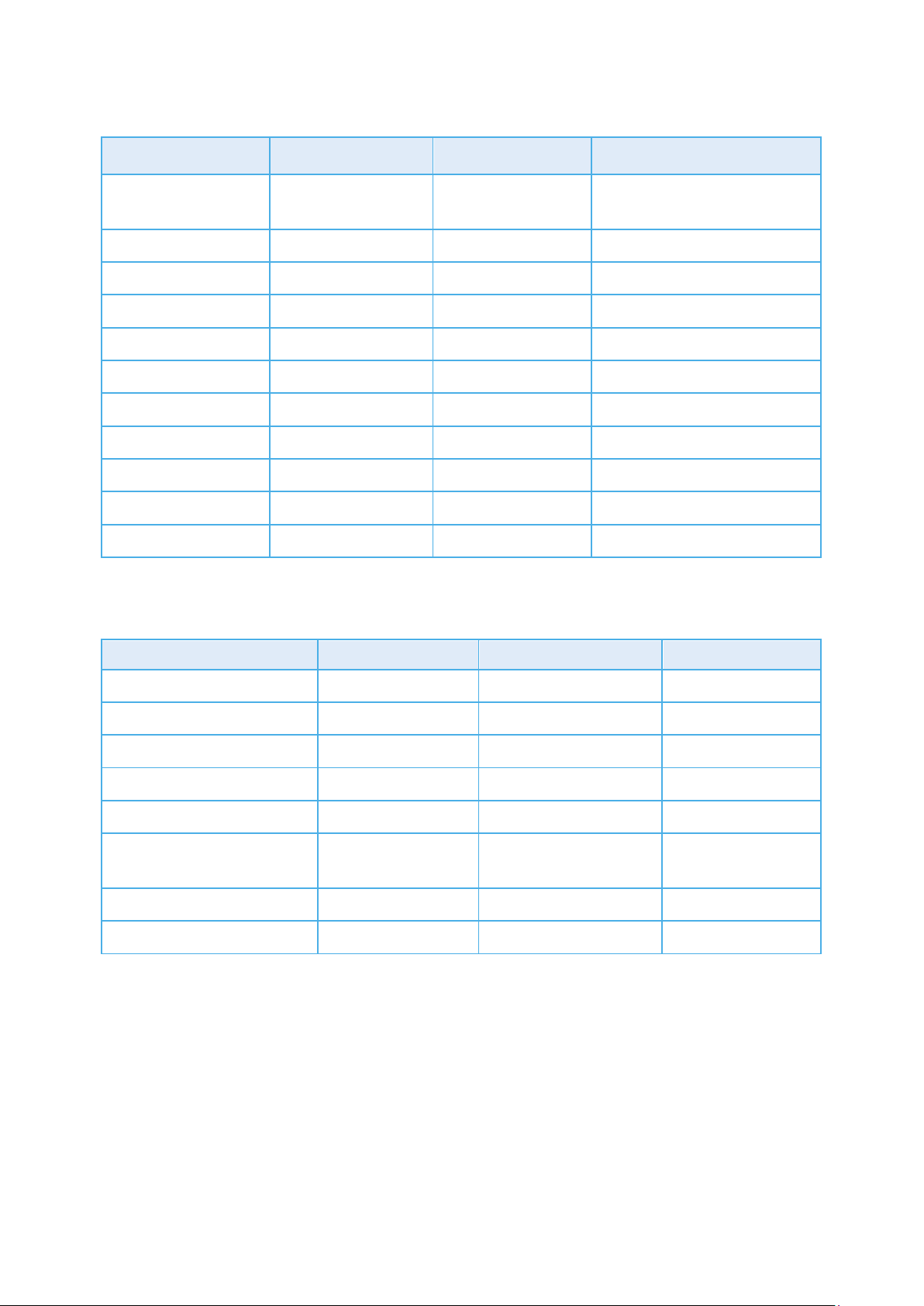

Figure 3 key

Figure 4 key

Figure 3: Communication Wiring Diagram (Farm Communication Box)

1 Modem 4 Farm Center Pro Board

2 Farm Communication Box PCB 5 Farm Center Pro Board Communication Card

3 PC

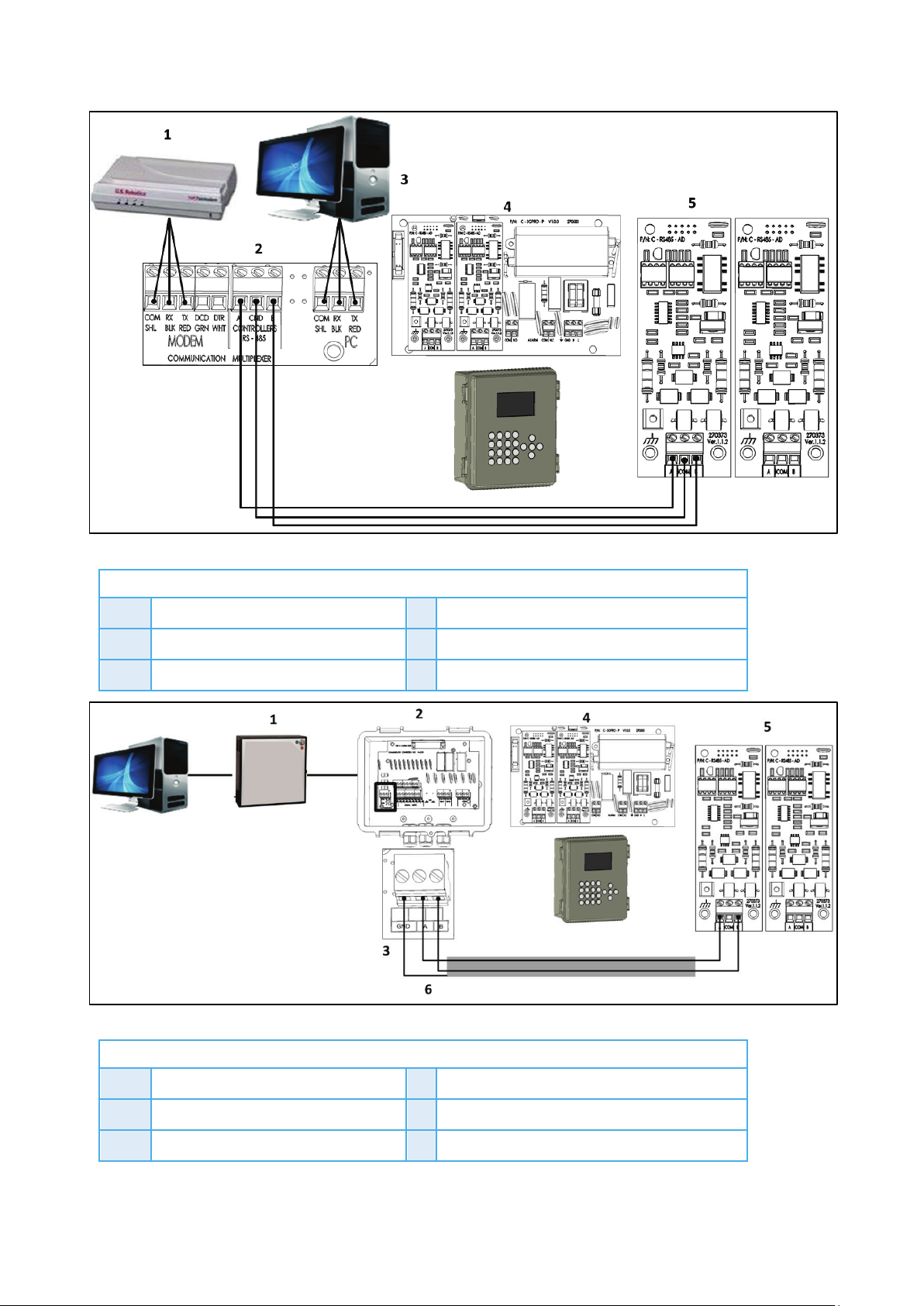

Figure 4: Communication Wiring Diagram (Farm Guard)

1 Farm Guard unit 4 Farm Center Pro Board

2 Farm Guard external box 5 Farm Center Pro Board Communication Card

3 External box communication ports 6 Shield is connected on one side only

© Munters AB, 2015 17

Page 18

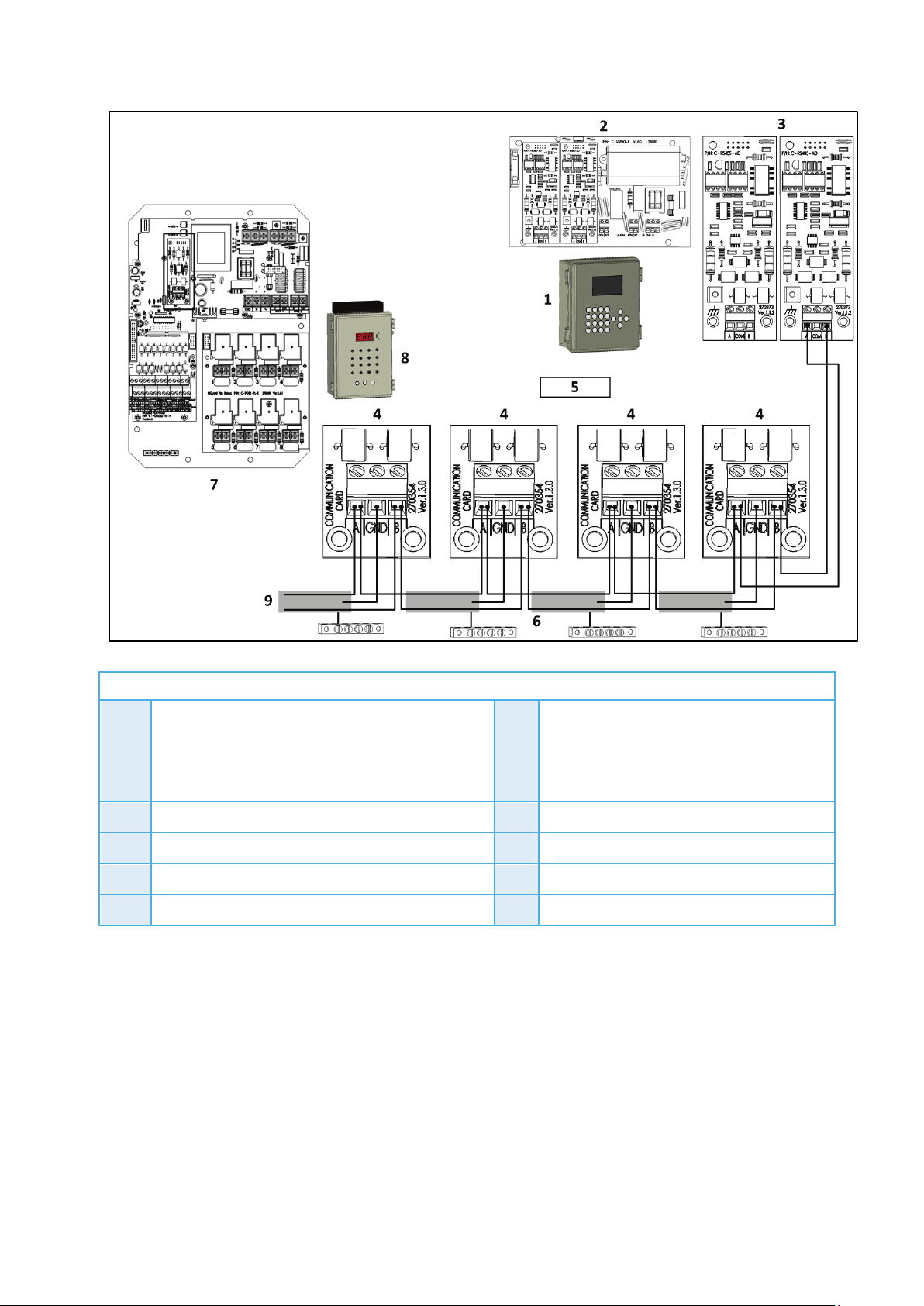

Figure 5 key

Figure 5: Communication Wiring Diagram (Farm Master Pro)

1 Farm Center Pro unit 5 Wiring connections:

A to A

•

B to B

•

Shield to ground on one end only!

•

2 Farm Center Pro Board 6 Farm Master Pro ground strip

3 Farm Center Pro Board Communication Card 7 Farm Master Pro Board

4 Farm Master Pro communication ports 8 Farm Master Pro unit

9 Continue wiring to other units

© Munters AB, 2015 18

Page 19

Figure 6 key

Figure 6: Farm Master Pro Wiring Diagram (Analog Output Devices, Digital Sensors)

1 Digital inputs 6 Inlets

2 COM port 7 Ground strip

3 RHS Plus SE 8 RHS white wire

4 Variable fan 9 RHS red wire

5 Variable heater 10 RHS black wire

The following table details the inputs.

© Munters AB, 2015 19

Page 20

Figure 7 key

CAUTION

Table 4: Wiring Diagram Inputs

Number Wire

25 COM

Digital Input

Humidity

Analog Output

26 Dig 1

27 Dig 3

28 Dig 2

12 White

14 Red

16 Black

3 COM

2

5 +

4 COM

1

6 +

7 COM

4

9 +

8 COM

3

10 +

1 Variable

fans

Figure 7: Farm Master Pro Wiring Diagram (Variable Speed Fans, Grounding)

© Munters AB, 2015 20

To ensure compliance with EMC 61000-6-3, install an appropriate filter; for example a

Munters' filter (P/N: P-EMI), TDK-RSHN-2016 L or similar devices.

Page 21

Figure 8: Wiring Diagram of Main Voltage Section Showing Filtering

NOTE All the remaining wiring to the main voltage section remains as illustrated in the Farm Master

Pro Variable Speed Wiring Diagram.

© Munters AB, 2015 21

Page 22

CAUTION

Figure 9: Farm Master Pro Wiring Diagram (Relays, RTS-2)

Each output requires a 16 amp circuit breaker!

Table 5: Wiring Diagram Inputs (B)

Number Wire

18, 19 COM (Black)

20 T1 (Red)

Temperature Sensor

21 T2 (Red)

22 T3 (Red)

23 T4 (Red)

© Munters AB, 2015 22

Page 23

4.5 Dip Switch Configuration

On the Farm Master Pro's CPU there are two parallel red dip switches, located on the left hand side of

the PCB. If you want hardware protection during curtains' activity, make sure you connect the curtains in

pairs, according relay numbers (1, 2; 3, 4; 5, 6; etc.) and to move the three matching dipswitches to off

position. On the PCB is written which switch goes with the relay. Not doing so may result in the motors

closing and opening the curtains simultaneously, due to bad configuration or programming on behalf of

the user.

Figure 10: Farm Master Pro's CPU

© Munters AB, 2015 23

Page 24

Power Supply

Analog Inputs

Digital Inputs

Relays Outputs

Variable Speed Output

Housing

Ambient Climate

Indoor Applications

Certification

5 Technical Specifications

Mains voltage Single phase, 115/230 VAC

Main fuse 315 mA

Secondary fuse 1 A

Maximum power consumption 22 VA

Available power for peripheral equipment

3 analog inputs for temperature sensors RTS-2 (Thermistor)

4 analog outputs 20 mA, 0-:-10V

1 humidity sensor input 0-:-3V

2 analog inputs 0-:-5V

3 digital inputs Dry contact, 5 V/2 mAmp

8 Normally open power relay 2 HP, 12 Amps, 250 VAC

2.2 KW 10 Amps, 230 VAC; 2.8 HP

1.1 KW 10 Amps, 115 VAC; 1.4 HP

Dimensions (L x W x H) 92.5 x 73 x 36

Operating temperature range 32º to 122º F (0º to 50º C)

Storage temperature range 14º to 158º F (-10º to 70º C)

The equipment is designed for use in indoor applications only!

© Munters AB, 2015 24

Page 25

Install temperature sensors.

20:29:08

04-Jan-15

Temperature

Room 1

Day

Target

Heat

Tunnel

Low

Al-m

High

Al-m

1

80.0

78.0

86.0

70.0

90.0

4

0.0

0.0

0.0

0.0

0.0

6

0.0

0.0

0.0

0.0

0.0

8

0.0

0.0

0.0

0.0

0.0

11

0.0

0.0

0.0

0.0

0.0

6 Control menu

•

Temperature Curve, page 25

•

Minimum / Maximum Level, page 26

•

Humidity, page 30

•

Static Pressure, page 31

•

Heaters, page 32

•

Cool Pad, page 33

•

Fogger Pad, page 33

•

Light, page 34

•

Feeding Schedule, page 34

•

Timers, page 35

•

Extra System, page 35

6.1 Temperature Curve

Farm Center Pro provides separate temperature curves for growth day, target temperature, heat

temperature, tunnel temperature and low/high alarm temperatures. The controller creates a curve for

each one and uses it as a reference. The program alters at midnight prior to the next day on the next row

programmed. The controller maintains yesterday’s settings for every empty line; therefore it is not

necessary to fill the entire table.

1. In Install > Analog Sensors (page 50), define the temperature sensors as required. When using

more than one sensor, Farm Center Pro begins treatments based on the average.

2. In Install > Relays Layout, define the required number of relays as Heaters.

3. If required, go to System > Calibration > Temperature, and calibrate the sensors (page 47).

4. In Control > Temperature Curve, define the parameters

NOTE Set up to 20 lines, 999 growth days. When a curve is not required (for example when growing

layers), enter temperatures in the first line only.

© Munters AB, 2015 25

Page 26

Day:

Target:

Heat:

Tunnel:

Low & High / Alarm:

Temperature Offset

Temperature Band

Cool Factor (%)

Cold Above Target

Cold Below Target

20:29:08

04-Jan-15

Min Max Levels: by Day

Room 1

Day

Minimum

Maximum

1

20

o

Set the growth day. You can program negative growth days up to -2 for prewarming. Range: 0 - 999 To enter a negative growth day, type the day number followed

by the ± key.

o

o

o

o

Set the required target temperature. Range: Target: 0 - 40° C

Set the temperature at which heating stops.

Set the temperature at which tunnel ventilation to begin.

Set low and high temperature alarm limits. Range: Alarm low: 0 -

40° C (without floating point)

5. In Control > Temperature Curve, define the parameters (option)

o

: Use this parameter to change the offset target temperature up or

down for any purpose.

o

: This refers to the target temperature zone range. The User’s Manual

refers to this as the Happy Zone.

o

: The minimum correction towards target happy zone during each

increase ventilations delay (patience factor). If the temperature does not improve by this

amount, the controller increases one level.

o

: Temperature change in a minute to be considered as quick drop in

degrees, to reduce a level to reach above target temp (degrees).

o

: Temperature change in a minute to be considered as quick drop in

degrees, to reduce a level to reach below target temp (degrees).

6. Press Help to confirm the changes.

6.2 Minimum / Maximum Levels

The Minimum/Maximum Level menu sets the current absolute minimum and maximum ventilation levels

available. Define levels by:

•

Day or Time

•

Day / Soft Minimum

•

Time / Soft Minimum

•

Day / Maximum Cold, Warm

•

Day / Weight

1

3

6

10

12

15

17

19

21

AY

1

1

4

4

7

7

7

7

22

25

27

30

30

30

30

30

6.2.1 D

Minimum / Maximum by Growth Day defines the ventilation by the growth day.

•

© Munters AB, 2015 26

In Control > Min/Max Levels define:

Page 27

Day

Minimum

Maximum

Time:

Minimum

Maximum:

Day:

Soft Minimum:

Minimum:

Maximum:

20:29:08

04-Jan-15

Min Max Levels: Soft Min

Room 1

Day

Soft Minimum

Minimum

Maximum

1

1

20

20:29:08

04-Jan-15

Min Max Levels: by Day

Room 1

Time

Minimum

Maximum

0:00

23:00

1

7

20

30

o

: Set growth day

o

o

: Set minimum ventilation level for controller

: Set maximum ventilation level for controller

6.2.2 T

IME

Minimum / Maximum by Time of Day define the ventilation by the time of day.

6:00

8:00

10:00

14:00

16:00

18:00

20:00

6.2.3 S

1

1

4

4

7

7

7

•

In Control > Min/Max Levels define

o

o

o

22

25

27

30

30

30

30

Set time of day (hh:mm) in 24 hour format

: Set minimum ventilation level for controller

Set maximum ventilation level for controller

OFT MINIMUM / MAXIMUM BY DAY

Soft Minimum / Maximum by Day enable decreasing the minimum level of ventilation in extreme cold.

Define the Soft Minimum level that operates according to outside or inside temperature.

3

6

10

12

15

17

19

21

1

1

4

4

7

7

7

7

3

3

4

6

6

8

8

22

25

27

30

30

30

30

30

1. In Control > Min/Max Levels define:

o

Set growth day

o

Set minimum ventilation level for when temperature drops below heat

temperature

o

o

Set minimum ventilation level for when temperature is above heat temperature

Set maximum ventilation level for controller

2. In Control > Min/Max > Help define:

o

Soft Min Temp: Choice whether to use the current inside temperature or the outside

temperature to determine when to use the soft minimum.

o

Soft Min. Temp. Band: Difference below heat temperature to set temperature at which to

enforce low temperature minimum ventilation level

© Munters AB, 2015 27

Page 28

20:29:08

04-Jan-15

Min Max Levels: Cold/Warm

Room 1

Day

Minimum

Maximum Cold

Maximum Warm

1

1

20

20:29:08

04-Jan-15

Min Max Levels: Time (Soft Min)

Room 1

Time

Soft Minimum

Minimum

Maximum

0:00

23:00

1

7

3

8

20

30

6.2.4 S

6:00

8:00

10:00

14:00

16:00

18:00

20:00

OFT MINIMUM / MAXIMUM BY TIME

1

1

4

4

7

7

7

3

4

6

6

8

8

8

22

25

27

30

30

30

30

1. In Control > Min/Max Levels define:

o

Time: Set time of day (hh:mm) in 24 hour format

o

Soft Minimum: Set minimum ventilation level for when temperature drops below heat

temperature

o

Minimum: Set minimum ventilation level for when temperature is above heat temperature

o

Maximum: Set maximum ventilation level for controller

2. In Control > Min/Max Levels > Help define:

o

Soft Min Temp: Choice whether to use the current inside temperature or the outside

temperature to determine when to use the soft minimum.

o

Soft Min. Temp. Band: Difference below heat temperature to set temperature at which to

enforce low temperature minimum ventilation level

6.2.5 M

AXIMUM COLD, WARM BY DAY

Maximum Cold, Warm by Day is used to limit the ventilation levels when temperatures are extremely cold

or hot. These settings override any other definitions when temperatures reach the levels defined in the

Help parameters.

3

6

10

12

15

17

19

21

1

1

4

4

7

7

7

7

3

3

4

6

6

8

8

22

25

27

30

30

30

30

30

1. In Control > Min/Max Levels define:

o

Day: Set the growth day

o

Minimum: Set the minumum ventilation level.

o

Maximum Cold: Set the maximum ventilation level when temperatures are below Outside

Temperature Cold parameter.

o

Maximum Warm Set the maximum ventilation level when temperatures are above the

Outside Temperature Warm parameter.

2. In Control > Min/Max Levels > Help definet:

© Munters AB, 2015 28

Page 29

Important:

inside

outside

How does it work?

o

Outside Temperature Cold: This parameter defines the temperature below which

ventilation is reduced to the minimal level defined when using Cold/Warm Min Max

Ventilation. default: -5° C, minimum -20° C, maximum +20° C)

o

Outside Temperature Warm: This parameter defines the temperature above which

ventilation is increased to the minimal level defined when using Cold/Warm Min Max

Ventilation. default: +20° C, minimum 0° C, maximum +40° C)

If the outside temperature is above 70° F (heat temperature) the controller operates according to the Min

Warm levels.

If the inside temperature is below 66° F (Soft Temp) the controller works according to Min Cold levels.

When the temperature is between 70° F and 66° F the controller creates a curve between the Min Cold

and Min Warm levels. For example, in 68° F the controller operates in level 5.

•

When using Soft Min according to

temperature there is a curve between min warm and

min cold, while decreasing levels. When temperature increases the level remains at the lowest

level reached, until reaching the heat temperature.

•

When using Soft Min according to

temperature there is a curve between min warm and

min cold while decreasing and increasing levels.

To select the type of minimum/maximum go to system parameters and change the level control.

6.2.6 BY W

EIGHT

The By Weight option enables controlling the minimum air flow depending on the number of pigs, their

weight and the current outside temperature. When using the Weight option, Farm Center Pro takes

several parameters and calculates the air speed, level of ventilation and cycle time needed to supply the

required volume. As opposed to the other ventilation methods, the Weight option is dynamic, with the

ventilation changing according to the current parameters (quantity of air required, weight of animals and

number of pigs, outside air temperature). In addition, Ventilation by Weight sends out an alarm if the

current ventilation is below the minimum required level.

© Munters AB, 2015 29

Page 30

To set up the Weight Option:

Weight

Install humidity sensors (Figure 6, page 19).

20:29:08

04-Jan-15

Humidity

Room 1

Parameter

Value

Humidity Target

0

Delay (minutes)

0

Duration (seconds)

0

Humidity Band (%)

2

Diff From Heat to Stop

0.0 20:29:08

04-Jan-15

Min Max Levels: Cold/Warm

Room 1

Day

Minimum Level

Air Per Cold Kg/Lb

Air Per Warm Kg/Lb

Maximum Level

Animal Weight

1

21

1

7

0.5

1.1

1.5

1.7

16

21

4.0

240

3

6

10

12

15

17

19

1

1

4

4

7

7

7

0.5

0.5

1.1

1.1

1.1

1.1

1.1

1.5

1.5

1.7

1.7

1.7

1.7

1.7

16

16

16

21

21

21

21

15.0

30.0

45.0

55.0

80.0

120

170

1. In System > Installation > Fan Air Capacity menu, define the air capacity / hour (page 53).

2. In the Control > Min. Max Level > Help , select By

.

3. Set the parameters as required.

o

Day: Set growth day

o

Min Level: Set the minimum level of ventilation (refer to Ventilation Levels, page 43)

default: 1; range 1 - 30

o

Air Per Cold Kg/Lb: Volume of air (kilogram/pound per hour per pig) supplied when the

outside temperature goes down to Outside Temp. Warm (see the following section).

default : 0.5; range 0.1 - 99.9

o

Air Per Warm Kg/Lb: Volume of air (kilogram/pound per hour per pig) supplied when

the outside temperature goes down to Outside Temp. Warm. default : 0.5; range 0.1 -

99.9

o

Max Level: Set the maximum level of ventilation (refer to Ventilation Levels, page 43).

o

Animal Weight Curve: This curve enables defining the animal average weight per day.

The curve provides the day's current animal weight to be used when calculating the total

livestock weight:

Total Weight = (Average Animal Weight) x (Total Animals Count)

default: 10.0; range 1.0 - 999

4. In the Management > Animal Inventory menu, type the number of pigs.

Ventilation by Weight is configured.

6.3 Humidity

This screen sets the humidity specifications. Humidity treatment forces an increase in ventilation level when

the humidity is too high. It holds the increase for ‘Duration Seconds.. After the duration, the ventilation

level comes back down automatically.

© Munters AB, 2015 30

Page 31

Humidity Target

Delay (minutes)

Duration (seconds)

Humidity Band (%)

Diff From Heat to Stop

Low Outside Temperature:

Pressure at Low Temperature:

High Outside Temperature:

Pressure at High Temperature:

Tunnel Pressure:

Pressure Band:

Low Pressure Alarm:

High Pressure Alarm:

20:29:08

04-Jan-15

Static Pressure

Room 1

Parameter

Value

Low Outside Temperature

40.0

Pressure at Low Temperature

0.120

High Outside Temperature

70

Pressure at High Temperature

0.080

Tunnel Pressure

0.080

Pressure Band

0.040

Low Pressure Alarm

0.048

High Pressure Alarm

0.149

1. In Install > Analog Sensors (page 50), designate a sensor as indoor humidity sensors.

2. If required, go to Service > Humidity Calibration, and calibrate the sensors (page 47).

3. In Control > Humidity Treatment define the parameters.

o

o

: Set the humidity target.

: Delay time before humidity treatment. The controller checks during the

delay time whether the humidity is above the target.

o

o

o

: Humidity treatment duration time.

: Band zone to balance the treatment.

: Enter the difference from the target temperature at which the

humidity treatment begins. The difference can be positive or negative.

6.4 Static Pressure

This screen sets the Static Pressure target parameters at high and low outside temperatures, as well as

alarms for high and low static pressure.

1. In Control > Static Pressure define the parameters.

o

Set outside low temperature definition for low pressure

target.

o

Static pressure target for the outside low temperature

(See graph below, point 1).

o

Set outside high temperature definition for high pressure

target.

o

Static pressure target for outside high temperature (See

graph below, point 2).

o

o

o

o

Static pressure target during tunnel ventilation mode.

Set band zone to balance the system.

If static pressure drops below the set point, an alarm is activated.

If static pressure rises above the set point, an alarm is activated.

2. In Control > Static Pressure > Help, define the parameters (option)

o

Pressure Enable: Enable the inlet (when in minimum ventilation) or the tunnel curtain

(when in tunnel mode) to maintain pressure control.

o

Wind Delay (sec): Static pressure is affected by wind. This parameter ensures that an

alarm is given due to a stable change in pressure and not an accidental one that may

have been caused by a wind gust.

© Munters AB, 2015 31

Page 32

20:29:08

04-Jan-15

Static Pressure

Room 1

Device

Band

Heat Target Diff

End Day

Heater 1

1.0

0.0

0

Heater 2

1.0

0.0

0

Heat Lamp 1

1.0

0.0

0

Heat Lamp 2

1.0

0.0

0

Var. Heater 1

10.0

0.0

0

Var. Heater 2

10.0

0.0

0

o

Advance Open (sec): Time setting for curtains to open before fans activate. This

o

Low Pressure Alarm Minimum Level: From what level you wish to activate low static

6.5 Heaters

parameter ensures that the curtains are open before fan activity.

pressure alarm.

This screen defines the heater parameters.

Device lists the different heaters.

1. Define the:

o

Heat Band: Set the happy zone for the heaters on/off.

o

Heat Lamp Diff: Differential from heat temperature to initiate heat lamps.

2. In Control > Heater > Help define:

o

Variable heaters: For each variable heater define the minimum and maximum ouput

percentage; this is a safety measure.

© Munters AB, 2015 32

Page 33

Day:

From Time:

To Time:

Target Differential:

To Humidity:

On Sec:

Off Sec:

From Level

Temperature Band

Humidity Band

Day:

From Time:

To Time:

20:29:08

04-Jan-15

Fogger

Room 1

No.

From

Time

To

Time

Target

Diff

To

Hum.

On (sec)

Off (sec)

1

0:00

0:00

0.0 0 0

0

2

0:00

0:00

0.0 0 0

0

3

0:00

0:00

0.0 0 0

0

4

0:00

0:00

0.0 0 0

0

5

0:00

0:00

0.0 0 0

0

20:29:08

04-Jan-15

Cool Pad

Room 1

No.

From

Time

To

Time

Target

Diff

To

Hum.

On (sec)

Off (sec)

1

0:00

0:00

0.0 0 0

0

2

0:00

0:00

0.0 0 0

0

3

0:00

0:00

0.0 0 0

0

4

0:00

0:00

0.0 0 0

0

5

0:00

0:00

0.0 0 0

0

6.6 Cool Pad

This menu defines the cool pad operating conditions.

1. Define the parameters:

o

Set growth day.

o

o

o

use negative differential temperatures.

o

100%.

o

o

The cool pad begins operating at this time.

The cool pad ceases to operate at this time.

Set difference from target temperature to use this setting. You can

Set maximum humidity allowed before stopping cool pad. You can enter

Set the maximum on time for each cycle of cool pad operation.

Set the minimum off time for each cycle of cool pad operation.

2. In Control > Cool Pad > Help, set the parameters:

o

: From what ventilation level to begin cool pad operation. 0 disables the cool

pad. 0

o

: On/off differential or Happy Zone with respect to temperature for

the ‘Cool #’ and ‘Cool Pad #’ relays. These normally control the water pump for the cool

cells. 1.0

o

: On/off differential or Happy Zone with respect to inside humidity for the

‘Cool #’ and ‘Cool Pad #’ relays. 2.0

6.7 Fogger Pad

This menu defines the Fogger operating conditions.

1. Define the parameters:

o

Set growth day.

o

o

© Munters AB, 2015 33

The cool pad begins operating at this time.

The cool pad ceases to operate at this time.

Page 34

Target Differential:

To Humidity:

On Sec:

Off Sec:

Day:

From Time:

20:29:08

04-Jan-15

Feeder

Room 1

Day

From

Time

To

Time

0

0:00

0:00

0

0:00

0:00

0

0:00

0:00

0

0:00

0:00

0

0:00

0:00

20:29:08

04-Jan-15

Light

Room 1

Day

From

Time

To

Time

0

0:00

0:00

0

0:00

0:00

0

0:00

0:00

0

0:00

0:00

0

0:00

0:00

o

Set difference from target temperature to use this setting. You can

use negative differential temperatures.

o

100%.

o

o

Set maximum humidity allowed before stopping cool pad. You can enter

Set the maximum on time for each cycle of cool pad operation.

Set the minimum off time for each cycle of cool pad operation.

2. In Control > Cool Pad > Help, set the parameters:

o

From Level: From what ventilation level to begin cool pad operation. 0 is no operation.

Default: 0

o

Temp Band: On/off differential or Happy Zone with respect to temperature for the ‘Cool

#’ and ‘Cool Pad #’ relays. These normally control the water pump for the cool cells.

Default: 1.0

o

Humidity Band: On/off differential or Happy Zone with respect to inside humidity for the

‘Cool #’ and ‘Cool Pad #’ relays. Default: 2.0

6.8 Light

This menu defines the lighting schedule. There are up to five programmable lines.

•

Define the parameters:

o

Day: Set growth day.

o

From Time: Lights turn on.

o

To Time: Lights turn off.

6.9 Feeding Schedule

This menu defines the feeding schedule. There are up to five programmable lines.

•

Set growth day.

•

© Munters AB, 2015 34

Lights turn on.

Page 35

To Time:

From

To

To/From Temperature (From T./To T.)

On/Off

20:29:08

04-Jan-15

Extra System

Room 1

Extra

Sys

Start

Time

End

Time

From

Temp

To

Temp

On

(sec)

Off

(sec)

1

10:00

12:00

32.0

32.0

20

40

2

14:00

16:00

32.0

32.0

30

50

3

17:00

19:00

32.0

32.0

40

60

20:29:08

04-Jan-15

Timers

Room 1

Timers

From

Time

To

Time

On

(sec)

Off

(sec)

1

0:00

0:00

20

50

2

0:00

0:00

30

60

3

0:00

0:00

40

60

4

0:00

0:00

50

60

5

0:00

0:00

60

60

•

Lights turn off.

6.10 Timers

This is a simple device definition table with operation time and cycle. There are up to five functions

(relays) available to program as time clocks.

6.11 Extra System

Any relay can be set as an extra system. There are up to three functions (relays) available to program as

extra system.

The extra system’s relays activate according to the settings in this table and regardless of the conditions,

or other devices.

•

: (HH:MM) Start time.

•

: (HH:MM) End time.

•

•

: (sec) On/off cycle by seconds.

: The temperature range for extra system activity.

This table consists of up to three programs.

© Munters AB, 2015 35

Page 36

Enter

Enter

Add Mortality

Animals Placed

Animal Update

20:29:08

04-Jan-15

Animal Inventory

Room 1

Parameter

Value

Add Morality

2

Animals Placed

50

Animals Updated

48

20:29:08

04-Jan-15

Alarm Reset

Room 1

Parameter

Value

Alarm Reset

No

7 Management menu

•

Alarm Reset, page 36

•

Animal Inventory, page 36

•

Day & Group, page 37

•

Alarm Setting, page 37

7.1 Alarm Reset

This screen resets the alarms.

1. To reset the alarm, press

2. Use the up/down arrow keys to change from NO to YES.

3. Press

.

7.2 Animal Inventory

This table enables updating the animal inventory.

NOTE If incorrect figures are entered, it is possible to correct them by entering negative figures.

© Munters AB, 2015 36

•

•

•

: Insert number of dead animals.

: Insert animals placed.

: Updates the number of animals.

Page 37

Growth Day

New Group

CAUTION

Group No

Control Mode

Alarm Delay (sec)

20:29:08

04-Jan-15

Alarm Settings

Room 1

Parameter

Value

Alarm Delay (sec)

Low Temperature Alarm Diff

High Temperature Alarm Diff

Emergency Temperature

Variable Fan Stop

Min Water/Hour

Max Water/ Hour

Min Feed/Hour

Max Feed/Hour

Auxiliary Alarm Related History

20:29:08

04-Jan-15

Day and Group

Room 1

Parameter

Value

Growth Day 6

New Group ?

No

Group No. 1

Control Mode

Full House

7.3 Day & Group

This screen sets the day, designates a group as new, and sets the group number.

•

age.

•

automatically increases the group number by one and sets the growth day to 1.

: Set the number of growth day. This parameter can help determine the animals’

: To start a new group, select YES under a new group fragment and the controller

When starting a new group, history is deleted!

•

•

.: You can manually change the group number.

: This parameter enables system operations (Normal mode) or disables

operations (Empty mode). In this screen, chose one of the following modes:

o

Normal

o

Empty: Empty mode is applied in cases of empty houses. When Empty mode is selected:

All alarms are disabled

A flashing massage appears while displaying temperature.

"E" appears in Farm Master Pro and "Empty House" in Farm Center Pro.

NOTE Setting controller to Normal or Empty mode inserts an event to History/Event table.

7.4 Alarm Setting

This screen sets the alarm parameters.

•

operation.

© Munters AB, 2015 37

: represents the number of seconds between failure detection and the alarm

Page 38

Low Temperature Alarm Diff

High Temperature Alarm Diff

Out Compensation:

Example:

.

Emergency Temperature

Variable Fan Stop

Water & Feed

NOTE If the problem is solved before the delay time ends, no alarm is recorded in the history log.

•

•

•

This parameter is added to the high temperature alarm when outside

: Low temperature range beyond which alarm is activated.

: High temperature range beyond which alarm is activated.

temperatures are high, like noontime in desert countries. This feature ensures an alarm is not

triggered just because it is a hot day. The emergency temperature has no compensation, so the

compensation feature only works when temperatures do not exceed the emergency

temperature.

Outdoor+comp. >Alarm then Alarm=Outdoor+Comp

For example: IF the pre set compensation is 2°F, the outside temperature is 75°F and alarm is set

to 76°F, the controller adds the outside temperature to the comp, and the alarm rises to 77.

(75+2=77)

Figure 11: Out Temperature Compensation

•

: The temperature beyond which the controller goes into emergency

mode and an alarm is activated.

•

: When in low temperature alarm, decide whether to keep variable speed in

minimum operation or totally shut down the function.

•

o

Min/Max Water/Hour: The quantity of water per hour, below or above which the alarm

:

is activated.

o

Min/Max Feed/Hour: The quantity of feed per hour, below or above which the alarm is

activated.

•

Auxiliary Alarm Related History: When assigning a related function, alarm occurs if the

associated digital input fails to follow the relay. Digital input must be active when its associated

relay is on.

If there is no related function the alarm turns on when digital input is active.

© Munters AB, 2015 38

Page 39

Sensors:

20:29:08

04-Jan-15

History Humidity

Room 1

Day

Average

Minimum

Maximum

6

70

65

75

5

81

65

75

20:29:08

04-Jan-15

History Temperature

Room 1

Day

Average

Minimum

Maximum

6

82.1

79.2

82.9

5

82.1

81.7

82.2

8 History menu

The history section maintains a memory of activity of the last 100 days and 100 events or alarms.

•

Temperature

•

Humidity

•

Water

•

Feed

•

Mortality

•

Heater

•

Alarm

•

Event

8.1 Temperature

8.2 Humidity

•

the last 100 days

Data collection for minimum, maximum and average in temperature and humidity for

© Munters AB, 2015 39

Page 40

Day

Daily Water

Daily %

Day

Daily

Daily %

Day

Daily Mortality

Total Animals

20:29:08

04-Jan-15

History Mortality

Room 1

Day

Daily Mortality

Total Animals

6 0 0 5 0 0

20:29:08

04-Jan-15

History Feed

Room 1

Day

Daily Feed

Daily %

6 0 0

5 0 0

20:29:08

04-Jan-15

History Water

Room 1

Day

Daily Water

Daily %

6 0 0 5 0 0

8.3 Water

•

•

•

8.4 Feed

: Growth day

: Daily consumption

: Percent change from previous day

•

: Growth day

•

•

8.5 Mortality

•

: Growth day

•

•

: Daily consumption

: Percent change from previous day

: Daily mortality

: Mortality total since growth day one

© Munters AB, 2015 40

Page 41

1. Ana. In Fail

2. High Temp

3. Low Temp

4. Hum.Sen Fail

5. Lost Comm

6. W. Overflow

7. F. Overflow

8. Sn. 1 Fail

9. Sn. 2 Fail

10. Sn. 3 Fail

11. Sn.1 Def Err

12. Sn.2 Def Err

13. Sn.3 Def Err

14. Sn.1 Out Rng

15.

16.

17. Sn. Not Def

18. Aux Alarm

20:29:08

04-Jan-15

History Alarm

Room 1

No

Alarm

Day

Time

Date

1

Low Temp

2

1:00

02 JAN 15

2

W. Overflow

2

1:30

02 JAN 15

3

Low Temp

2

1:30

02 JAN 15

4

High Temp

2

9:30

02 JAN 15

5

20:29:08

04-Jan-15

History Heaters

Room 1

Day

Heat-1

Heat-2

Heat L-1

Heat L-2

6

1:00

11:00

1:00

11:00

5

1:30

12:00

1:30

12:00

8.6 Heater

The history heater displays the amount of time each heater (Heat-1/2) or heat lamp (Heat L-1/2) was on

that growth day.

8.7 Alarm

There are 21 possible alarm messages:

: Analog input failure

: High temperature alarm

: Low temperature alarm

: Humidity sensor failure

: Lost communication

: Water over flow

: Feed over flow

: Sensor #1 failure

Sn.2 Out Rng

Sn.3 Out Rng

: Sensor not defined

: Auxiliary alarm

: Sensor definition error

: Sensor out of range

© Munters AB, 2015 41

Page 42

19.

20.

21.

Power up

Reset

Cold

Menu

20:29:08

04-Jan-15

History Event

Room 1

No

Event

Day

Time

Date

1

Menu #11

2

1:00

02 JAN 15

2

Menu #11

2

1:30

02 JAN 15

3

Menu #11

2

2:30

02 JAN 15

4

Power Up

2

9:30

02 JAN 15

5

Press. Fail

Low S. Press

High S. Press

8.8 Event

Besides the menu number event message there are three kinds of events:

•

•

•

: How many times the controller was turned on

: How many times the controller was reset

: How many cold starts were performed

•

#: Which menu number has been changed

The events table is similar to the alarms table but without icons. For example: in the table above “Menu

#11” means that there was a change of settings in CONTROL Menu 1, Temp Curve Table.

© Munters AB, 2015 42

Page 43

20:29:08

04-Jan-15

Levels of Ventilation

Room 1

No.

Diff

Deg.

On

(sec)

Off

(sec)

Fans

1 2 3 4 5 6 7 8

1

0.0

30

240

2

0.0

0

0

3

0.0 0 0

4

0.0

0

0

5

0.0

0

0

9 System menu: Ventilation Levels

The following sections detail the Device Menu.

•

Ventilation Levels, page 43

•

Variable Fan Levels, page 45

•

Curtain Levels, page 46

•

Stir Fan, page 46

9.1 Ventilation Levels

The Farm Center Provides up to 30 programmable ventilation levels.

NOTE When employing the Ventilation by Weight option, the On/Off times don't appear.

1. Define:

o

Diff Deg.

o

On/Off

o

Fans

The usual way to program them is to start the first level with the least amount of air to be

used.

The full circle represent continues fan operation.

The empty full circle represents cycle operation according to the on/off time set for each stage.

A dot represents no operation at all.

2. In System > Ventilation Levels > Help define:

o

Tunnel Exit Diff: Set the relative temperature for the outside sensor at which to exit tunnel.

The controller cannot exit tunnel until the outside temperature is less than tunnel

temperature plus this differential. This number can be positive or negative. To eliminate

the effect of this parameter on tunnel exit, enter a large positive number such as 90.0.

Default: 0.0

© Munters AB, 2015 43

Page 44

Lev

Tunnel Fans

On Off Diff 1 2 3 4 5 6 7 8

o

Tunnel Exit – Out T Diff from Tunnel: This parameter sets amount below the tunnel entry

temperature at which to exit tunnel ventilation. Tunnel temperatures are determined by the

sensors specified in Temperature Definition. Entry and exit is also controlled by these

sensors. The controller can not exit tunnel until the tunnel temperature is this much less

than the tunnel entry temperature. It must be a positive number. Default: 2.0

o

Tunnel Exit Delay (min): Delay time after satisfying tunnel exit conditions. Default: 5

(minutes)

o

Inc Delay Time: This is the standard minimum delay before increasing ventilation levels.

Default: 120 (sec)

o

Decrease Level Delay Time: This is the standard minimum delay before decreasing

ventilation levels. 180 (sec)

o

First Tunnel Level: Switching into and out of tunnel ventilation is a major change in

ventilation. For tunnel ventilation, enter the first tunnel level here. If set on 0 there is no

tunnel level. Default: 0

The following table is an example of a proper ventilation setting. Note that tunnel is not noticeable on the

current table and is set according to the system parameter- 1st tunnel level.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

90 510 0.0

30 270 0.0

40 260 0.0

52 248 0.0

70 230 0.0

30 570 0.0

40 560 0.0

52 548 0.0

70 530 0.0

90 210 0.0

120 180 0.0

160 140 0.0

225 75 0.0

300 0.0

15

16

17

18

© Munters AB, 2015 44

90 210 0.0

120 180 0.0

100 200 0.0

70 230 0.0

Page 45

Lev

Tunnel Fans

On Off Diff 1 2 3 4 5 6 7 8

20:29:08

04-Jan-15

Variable Fan Levels

Room 1

Lvl

-1-

-2-

-3-

-4-

1

50

50

50

50

2

30

30

30

30

3

40

40

40

40

4

40

40

40

40

5

40

40

40

40

19

20

21

22

23

24

25

26

160 140 0.0

225 75 0.0

0 0 0.0

0 0 1.0

0 0 2.0

0 0 3.0

0 0 4.0

0 0 5.0

27

28

29

30

9.2 Variable Fan Levels

This screen sets the variable fan levels.

•

Define:

o

Percentage

o

Working mode

The percentage for a full circle represents the fan operation percentage from the maximum. If set

on 30% it will operate up to 30% of the maximum.

The percentage for a half full circle represents the fan operation percentage in off mode during

cycle operation.

© Munters AB, 2015 45

Page 46

Sensors Dif

From/To Time

From Level

To Level

20:29:08

04-Jan-15

Stir Fan Program

Room 1

Parameter

Value

Sensor Diff.

3.1

From Time

0:00

To Time

0:00

From Level

0 To Level

0 20:29:08

04-Jan-15

Curtain Levels

Room 1

Lvl

Curt 1 Curt 2 Curt 3 Curt 4 Tunnel

Inlet

Damp

1

Damp

2

Damp

3

Damp

4

1 0 0 0 0

55

15

60

60

60

60

2 0 0 0 0

55

15

60

60

60

60

3 0 0 0 0

55

15

60

60

60

60

4 0 0 0 0

55

15

60

60

60

60

5 0 0 0 0

55

15

60

60

60

60

9.3 Curtain Levels

This screen sets the levels to which the curtains are opened.

Set the curtain levels to correspond with the ventilation levels. Some producers will want to open the

tunnel curtain prior to the actual tunnel. This is convenient to control pressure in retrofit houses which may

not have sufficient side inlets for the number of fans required in side ventilation.

You can also run the tunnel curtain under pressure control. In that event, the percent open settings

become minimum settings. When the side vents are at 100%, if pressure requires, the controller opens the