Page 1

Assembly manual

Spare part list + Assembling guideline

EC52

Exhaust fan

EC52

Ag/MIT/IGB-2206-08/14 rev 1.0

Page 2

© Munters AB, 2014

2

EC52

Assembly manual

Original instructions

This document is destined for the user of the apparatus: it may not be reproduced in whole or in part, committed

to computer memory as a file or delivered to third parties without the prior authorisation of the assembler of the

system.

Munters Italy S.p.A. reserves the right to effect modifications to the apparatus in accordance with technical and

legal developments.

Page 3

© Munters AB, 2014

3

Index

chapter page

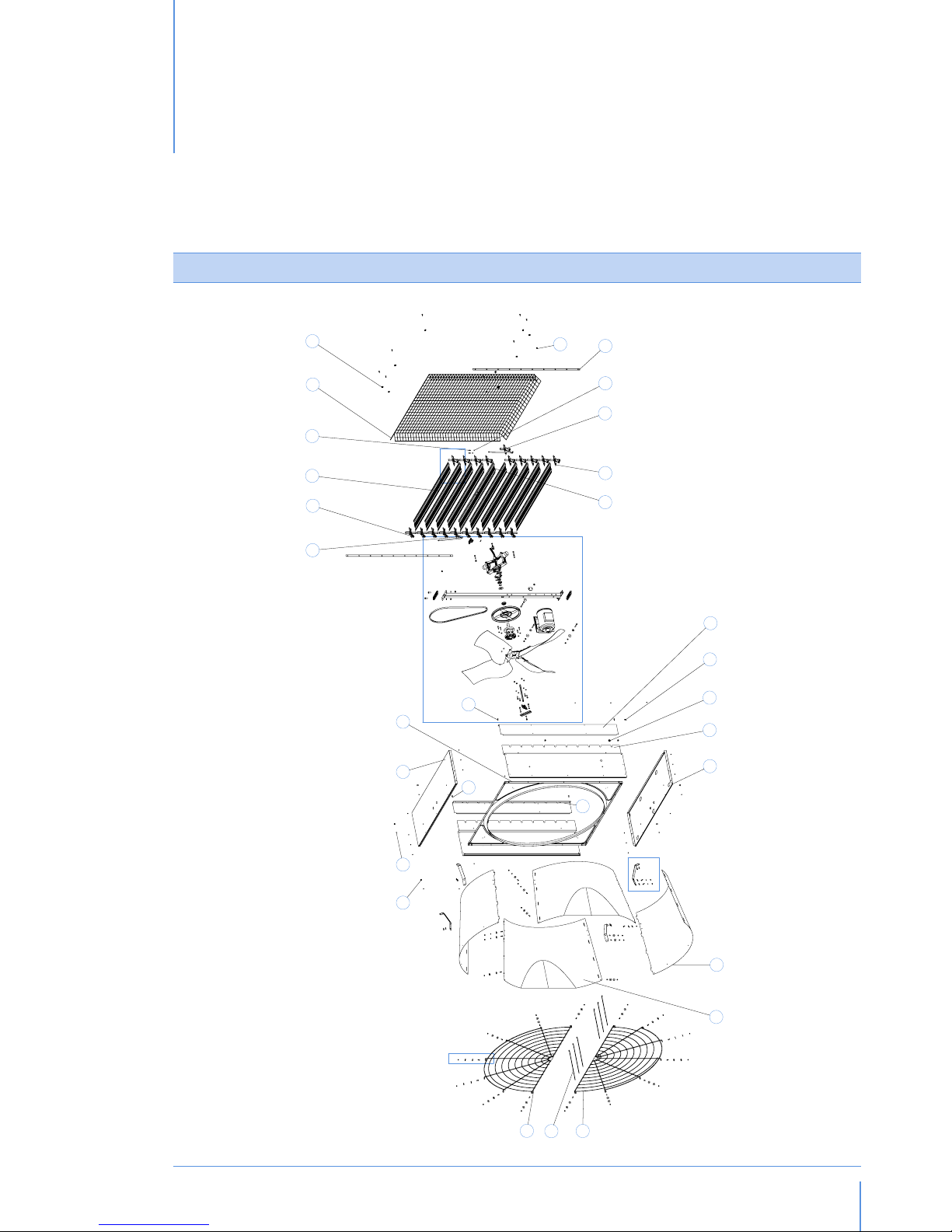

1. SPARE PART LIST 4

EC52 exploded view 4

Spare parts 6

2. ASSEMBLING TOOLS 16

3. ASSEMBLING GUIDELINES 19

Housing assembling 19

Centrifugal system and pulley to propeller assembling 21

Propeller and motor to central support assembling 22

Shutter blades assembling 28

Cone discharge assembling 31

Optional belt tensioner assembling 33

Optional pyramidal shape mesh assembling 35

All the components and spare parts MUST be storaged in dry and clean

environment.

WARNING

!

Page 4

© Munters AB, 2014

4

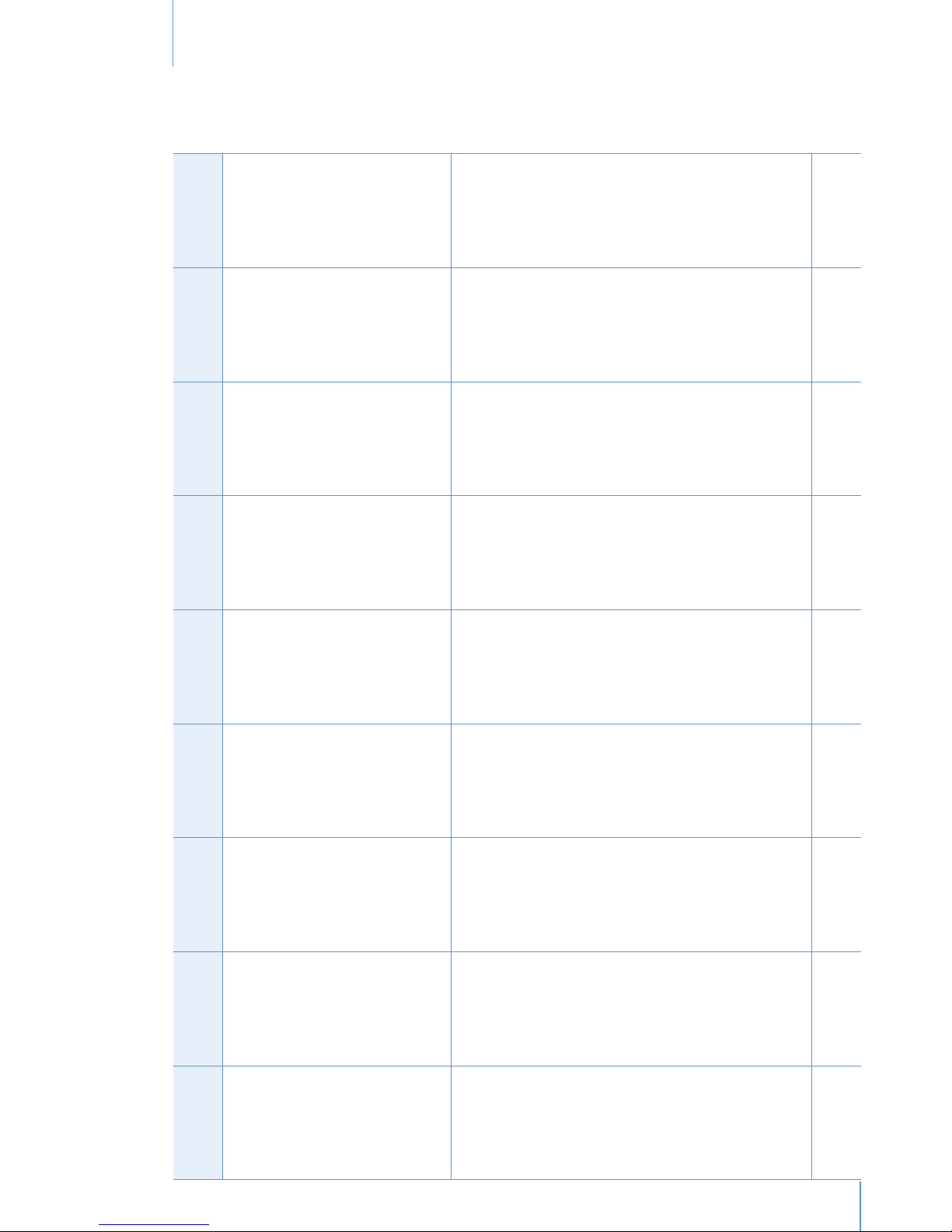

A

B

C

D

1

6

5

10

14

7

12

11

15

19

21

17

4

20

22

23

24

26

3

18

2

9

16

17

3131

13

8

25

A

Spare part list

EC52

fig.1

Page 5

© Munters AB, 2014

5

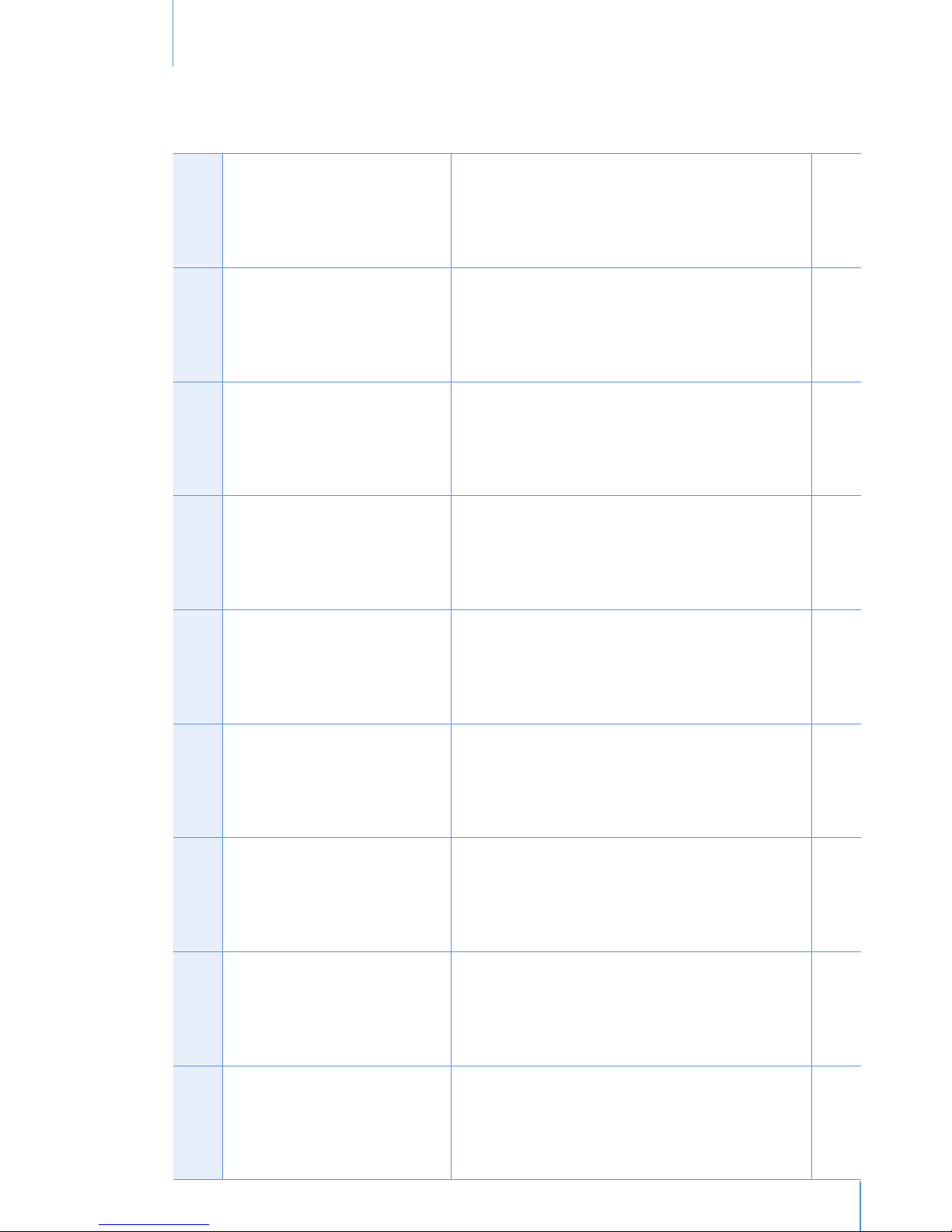

57

56

46 60

58

59

60

55

66

65

67

64

6362

38

48

52

553848 54 53

55

38

48

54

53

40

37

3938

50

434942 44

47

38

46

32

33

34

35

41

36

51

61

45

48

3938

68

27

28

8

30

31

28

8

29

27

DETAIL A

fig.2

DETAIL B

fig.3

DETAIL C

fig.4

Spare part listChapter1

Page 6

© Munters AB, 2014

6

DETAIL D: ALIGNEMENT OF SHUTTER BLADE

fig.5

POSITIONING OF REINFORCEMENT

fig.6

ALIGNEMENT OF BELLEVILLE SPRING

fig.7

Spare parts

Ref. Picture Description Q.ty

1 THREADED BUSH M8X12.5 8

2 POP UP RIVET 4.9X7 STEEL 26

Spare part listChapter1

Hex socket screw M8

with spring washer D8 to

fix reinforcement

Page 7

© Munters AB, 2014

7

3 TOP PANEL 1

4 CONVEYOR 1

5 CENTRAL RIGHT PLASTIC BEARING 1

6 RIGHT PLASTIC BEARING 9

7 SHUTTER BLADE 9

8 HEXAGON SCREW M6X16 28

9 PYRAMIDAL REAR SAFETY MESH 1

10 PLASTIC CLIP FOR MESH 10

11 STOP COLLAR D7X17 2

Spare part listChapter1

Page 8

© Munters AB, 2014

8

12 TIE ROD 2

13 HEXAGON NUT M6 2

14 CENTRAL LEFT PLASTIC BEARING 1

15 LEFT PLASTIC BEARING 9

16 CENTRAL SHUTTER BLADE 1

17 COVER PLATE 2

18 SPRING HOOK 2

19 RUBBER GROMMET 1

20 SIDE PANEL 2

Spare part listChapter1

Page 9

© Munters AB, 2014

9

21 BOTTOM PANEL 1

22 CONE SECTOR 2

23 CONE SECTOR CUT 2

24 CONE MESH INTERRUPTED WIRE 1

25 PLASTIC TIE LEGRAND MM9X357 6

26 CONE MESH CONTINUOUS WIRE 1

27 HEXAGON NUT THICK M6 26

28 PLAIN WASHER Ø6.4X24 44

29 SPRING WASHER D6 8

Spare part listChapter1

Page 10

© Munters AB, 2014

10

30 CONE BRACKETS 4

31 SELF TAPPING SCREW 6.3X19 22

32 HEXAGON SOCKET COUNTERSUNK HEAD SCREW M10X30 4

33 OVAL PLATE 2

34 CENTRAL SUPPORT 1

35 EXTERNAL TOOTHED WASHER D10 4

36 HEXAGON NUT M10 4

37 PLAIN WASHER D8X16 2

38 SPRING WASHER D8 8

Spare part listChapter1

Page 11

© Munters AB, 2014

11

39 HEXAGON SOCKET HEAD CAP SCREW M8X35 4

40 PLASTIC FORK 1

41 BRASS PIN 1

42 HEXAGON NUT M25 1

43 SPACER WASHER D25.2X29.5 1

44 REAR FLANGE 1

45 CENTRIFUGAL SYSTEM 1

46 HEXAGON SCREW M8X20 2

47 WASHER D8.2X27.8 THK 3.0MM 1

Spare part listChapter1

Page 12

© Munters AB, 2014

12

Spare part listChapter1

48 PLAIN WASHER D8X32 5

49 BEARING 16005-2RS 1

50 BELLEVILLE SPRING 1

51 HEXAGONAL NUT M8 WITH FLANGE 1

52 BELT TENSIONING ADJUSTER 1

53 HEXAGON SCREW M8X65 3

54 PLAIN WASHER D8X24 2

55 HEXAGONAL NUT M8 8

56 MOTOR 1

Page 13

© Munters AB, 2014

13

Spare part listChapter1

57 PROPELLER* 1

58 FLANGE FOR PROPELLER 1

59 HEXAGON SCREW M8X30 4

60 EXTERNAL TOOTHED WASHER D8 5

61 HEXAGONAL AXLE WITH M8 HOLES 1

62 HUB 1

63 HEXAGONAL NUT M6 WITH FLANGE 4

64 HEXAGON SCREW M6X30 4

65 CENTRAL PULLEY 1

Page 14

© Munters AB, 2014

14

66 V-BELT A61 1

67 WATERPROOF DISTANCE PIECE 1

68 FRONT FLANGE REINFORCEMENT 1

69 EUROEMME STICKER 24.6X180 2

70 WARNING STICKER A-1997 35X210 2

71 WARNING STICKER B-1997 70X105 1

72 PRODUCT LABEL G-1998 95X115 1

73 NO HIGH PRESSURE STICKER 42X118 2

74 MUNTERS PROTECT STICKER 70X46 1

Spare part listChapter1

Page 15

© Munters AB, 2014

15

75 TENSIONER (OPTIONAL) 1

76 METAL SPACER FOR BELT TENSIONER (OPTIONAL) 1

77 ALUMINUM POP UP RIVET 3.9X7(OPTIONAL) 2

78 HEXAGON SCREW M10X90 (OPTIONAL) 1

79 EXTERNAL TOOTHED WASHER 10.5×18 (OPTIONAL) 1

80 PLAIN WASHER 10.5×40 (OPTIONAL) 1

Spare part listChapter1

Page 16

© Munters AB, 2014

16

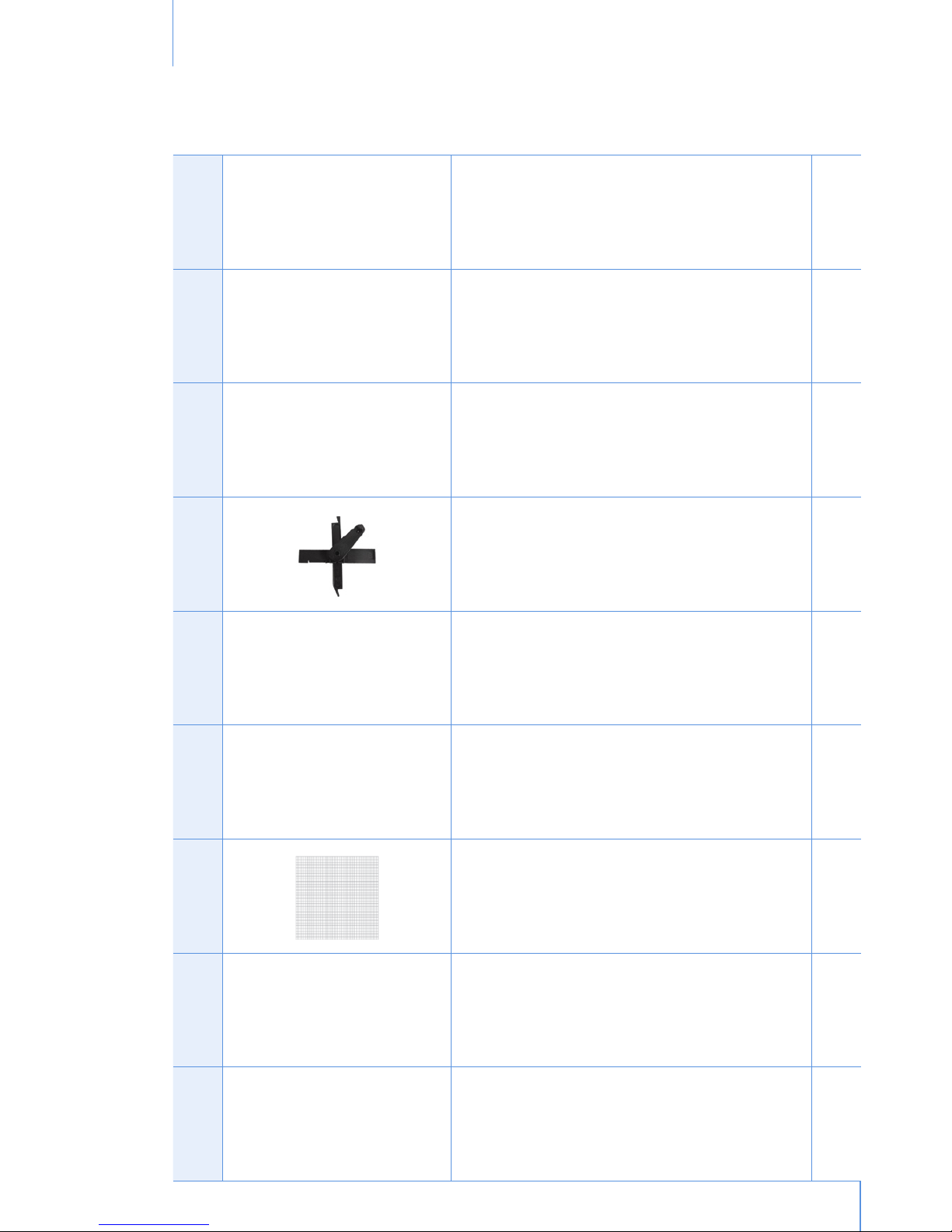

Ref. Picture Description Q.ty

1 RIVETING MACHINE RAC171 1

2 INSERTING MACHINE KJ 45 1

3 PNEUMATIC SCREWDRIVER 1

4 17mm SPANNER 1

5 10mm LONG SPANNER 1

6 13mm LONG SPANNER 1

7 6mm LONG ALLEN SPANNER 1

Assembling tools

2.

Page 17

© Munters AB, 2014

17

8 36mm SPANNER 1

9 PHILLIPS SCREW HEAD ADAPTOR 1

10 13mm RING SPANNER 1

11 SMALL HAMMER 1

12 10mm COMBINATION SPANNER 2

13 SCREWDRIVER 1

14 RATCHET DRIVE EXTENSION 1

15 17MM COMBINATION SPANNER 1

Assembling toolsChapter2

Page 18

© Munters AB, 2014

18

16 10MM ALLEN KEY 1

Assembling toolsChapter2

Page 19

© Munters AB, 2014

19

Assembling guidelines

3.

HOUSING ASSEMBLING

Take the bottom panel (ref. 21), the side panels (ref.

22) and place them taking care that slot for the plastic

bearing is downward.

Before fixing the bottom and the side panels make

sure that these pieces are in the right position as in the

picture (place the edge of the bottom panel outside

the side panel).

Join bottom panel with side panels and fix qty. 3 pop

rivets (ref. 2) for each edge by using riveting machine

(ref. 1/Assembling tools). To make the mounting of

the Venturi (ref. 4) easy take care to fix the signed

pop rivet after the Venturi assembling (see arrow in the

previous picture).

Insert Venturi into the housing on the right side as in

the picture. Fix Venturi to bottom panel and then to

side panels with qty. 3 pop rivets for side. Fix the last

pop rivets of the previous step. Qty. 1 pop rivet for

each edge.

Place the top panel (ref. 3) as in the picture (place the

edge of the bottom panel outside the side panel).

Page 20

© Munters AB, 2014

20

Fix it to side panels with qty. 4 pop rivets for side: qty.

3 lateral + qty. 1 frontal.

Fix it to Venturi with qty. 3 pop rivets.

Place the threaded bushes (ref. 1) in correspondence

of proper holes around the housing. Qty. 2 threaded

bushes for each panel.

The propeller central support (ref. 34) shall be fixed

to housing by means of qty. 4 bolts (ref. 32, qty. 4

washers (ref. 35), qty. 4 nuts (ref. 36) and qty. 2 oval

plates (ref. 33). The holes for motor slide and optional

belt tensioner have to be on lower side of the fan (near

to bottom panel).

Place the oval plates between propeller central support

and panels. The conic surface of the holes shall face

the metal panels (top and bottom).

Assembling guidelinesChapter3

Page 21

© Munters AB, 2014

21

Place the oval plates over support frame and then start

to screw the nuts. Tighten it by using pneumatic screwdriver (ref. 3/Assembling tools).

CENTRIFUGAL SYSTEM AND PULLEY TO PROPELLER ASSEMBLING

Take the pulley (ref. 65) and insert qty. 4 M6x30

screws (ref. 64) on external part of it.

Turn the pulley upside down and place the hub

(ref. 62) on it.

Insert and fix qty. 4 nuts with flange (ref. 63) over the

bolts.

Tighten the nuts by using pneumatic screw-driver (ref.

3/Assembling tools).

Place the waterproof distance piece (ref. 67) on the

axle and then place the axle on a support.

Assembling guidelinesChapter3

Page 22

© Munters AB, 2014

22

Assembling guidelinesChapter3

Place the v-belt (ref. 66) on the central pulley.

Before assembling the propeller make sure that the hub

is oriented as shown in the picture. The 4 highlighted

holes are used to fix the propeller to the hub.

Place the propeller (ref. 57) on the hub as shown in

pictures. Make sure that the holes with the pop rivets

are correctly oriented. The 4 highlighted holes are

used to fix the propeller to the hub.

Fix qty. 4 screws M8x30 (ref. 59), qty. 4 external

toothed washers (ref. 60) and qty. 4 M8 nuts (ref.

55) in order to fix the propeller.

Tighten the nuts by using pneumatic screw-driver (ref.

3/Assembling tools).

PROPELLER AND MOTOR TO CENTRAL SUPPORT ASSEMBLING

Place the propeller on the fan, by inserting the axle

through the central support hole.

Page 23

© Munters AB, 2014

23

Insert the belleville spring

(ref. 50) on the propeller

axle. Pay attention to

place it with its concave

side facing the central

support (see picture).

Insert the spacer washer D25.2x29.5 (ref. 43).

Insert the bearing (ref. 49).

Insert the M25 nut (ref. 42).

Tighten the nut by using a pneumatic screw-driver (ref.

3/Assembling tools) equipped with a 36 mm spanner

(ref. 8/Assembling tools) by applying a torque of

60Nm .

Put qty. 1 D8x32 plain washer (ref. 48) on back side

of the rear flange (ref. 44).

Assembling guidelinesChapter3

Page 24

© Munters AB, 2014

24

Insert the rear flange (ref. 44) into the centrifugal

system base (ref. 45).

Insert qty. 2 M8x35 screws (ref. 39), qty. 2 D8 spring

washers (ref. 38) and qty. 2 D8x16 plain washers

(ref. 37) to fix the centrifugal system to the rear flange.

Tighten them by means of a 6mm long allen spanner

(ref. 7/Assembling tools), closing torque 20Nm.

Place qty. 1 D8,2x27,8 washer (ref. 47) inside the

hole on the centrifugal system base (ref. 45).

Insert the hexagonal axle (ref. 61) on the bottom

side of the assembly. If necessary, push it hardly until

it touches the D8x32 plain washer (ref. 48), already

placed on the back side of the rear flange (ref. 44).

Fix the hexagonal axle (ref. 61) by using qty. 1

M8x20 screw (ref. 46), qty. 1 D8 spring washer (ref.

38) and qty. 1 D8x32 washer (ref. 48).

Assembling guidelinesChapter3

Page 25

© Munters AB, 2014

25

Tighten them by means of a 13mm ring spanner (ref.

10/Assembling tools).

On the front side of propeller mount the flange for

propeller (ref. 58) inserting its pins on the proper hole

of the propeller.

Put in position the front flange reinforcement (ref. 68).

Fix it by means of qty. 2 M8x35 screws (ref. 39) and

qty. 2 D8 spring washers (ref. 38).

Tighten them by means of a 6mm long allen spanner

(ref. 7/Assembling tools).

Insert the complete assembly on rear side of the central

pulley (ref. 65).

Assembling guidelinesChapter3

Page 26

© Munters AB, 2014

26

Insert a qty. 1 M8x20 screw (ref. 46) and qty. 1 D8

external toothed washer (ref. 60) and screw it on

thread present on hexagonal axle.

Tighten them by means of a 13mm ring spanner (ref.

10/Assembling tools).

Turn the fan and place the central support in horizontal

position. Place the assembled motor (ref. 56) on the

central support.

Fix motor slide on central support by qty. 2 M8×65

screws (ref. 53) and qty. 2 D8×24 washers (ref. 54)

as shown in the picture.

Insert qty. 2 D8×32 washers (ref. 48), qty. 2 D8

spring washers (ref. 38) and qty. 2 M8 nuts (ref. 55).

Screw the bolts without tightening.

Assembling guidelinesChapter3

Page 27

© Munters AB, 2014

27

Place the D8 spring washer (ref. 38) and the D8x32

plain washer (ref. 48) onto the M8x65 screw (ref.

53). Insert it in the proper hole* of the support and

tight it through the belt tensioning adjuster (ref. 52) by

using qty. 1 M8 nut with flange (ref. 51).

Please note that the round part of the belt tensioning

adjuster has to be oriented towards the propeller, as

shown in the pictures.

*NOTE: for M80 Motor/Hp1 use the hole nearest

to the central pulley (no. 1 in the picture); for M90

Frame Motor/Hp1.5 use the hole furthest from the

central pulley (no. 2 in the picture).

Bring motor in the nearest position toward central

pulley.

Put the v-belt on both central and motor pulley.

Assembling guidelinesChapter3

2

1

Page 28

© Munters AB, 2014

28

Give proper tension to v-belt by using a 10mm allen

key (ref. 16/Assembling tools).

CHECK TENSIONING: right tensioning is obtained

when maximum deflexion on one side only (half-way

from motor and central pulley) is about 10 mm.

TENSIONING VALUES:

Hp1 = 250 N, corresponding to a vibration frequency

55 Hz +/- 2%

Hp2 = 320 N, corresponding to a vibration frequency

60 Hz +/- 2%

NOTE: in case of installation of belt tensioner (optional)

please refer to ‘Optional belt tensioner assembling’

chapter (see p. 34).

Fix motor slide in its proper position by tightening the

motor slide screws by using two 13 mm spanners (ref.

10/Assembling tools).

Place the rubber grommet (ref. 19) on the left side

panel for electric cable protection.

SHUTTER BLADES ASSEMBLING

Insert the plastic bearings (ref. 6 and ref. 15) without

spring on all thin shutter blades (thickness 0.6 mm

- ref. 7). Plastic bearings marked with “DX” are for

right side, the ones marked with “SX” are for left side

(seeing the fan from its rear side). Be sure to assemble

the bearings with the right orientation (see picture).

Insert qty. 2 M6 nuts (ref. 13) in the slots of the plastic

fork (ref. 40) as shown in the picture.

Assembling guidelinesChapter3

Page 29

© Munters AB, 2014

29

Assemble the plastic fork (ref. 40) and the central

shutter blade (thickness 1.2 mm - ref. 16) with qty.

2 M6×16 screws (ref. 8) by using two 10 mm

combination spanners (ref. 12/Assembling tools).

Insert the plastic bearing with spring (ref. 5 and 14)

on the central shutter blade (ref. 17). “DX” is for right

side, “SX” is for left side.

Fit the assembled central shutter blade on the central

slot (fifth position from the top) of the housing.

Insert the spring hooks (ref. 18) in the holes of the side

panels (ref. 20).

Insert the free terminal of the spring on the hook.

Connect the centrifugal system to the fork of the central

shutter blade with the knurled brass pin (ref. 41). To

insert the pin use a small hammer (ref. 11/Assembling

tools).

Assembling guidelinesChapter3

Page 30

© Munters AB, 2014

30

Insert qty. 9 shutter blades (ref. 7) in the free slots of

the housing and then place the fan horizontally.

Fix the pvc tie-rod (ref. 12) on plastic bearing pivots.

The tie-rod must be fixed on the central plastic berings

(the ones with the spring) by using a stop collar (ref.

11).

Put the cover plates (ref. 17) over the plastic bearing

mechanism.

By means of a screw-driver (ref. 13/Assembling tools)

insert the cover plate over the fan housing.

Fix the cover plate on each side by using the 6.3×19

screws (ref. 31) with a pneumatic screw-driver (ref. 3/

Assembling tools).

Assembling guidelinesChapter3

Page 31

© Munters AB, 2014

31

CONE DISCHARGE ASSEMBLING

Assemble the cone sectors (ref. 22 and 23) as shown

in the pictures, inserting the wings of the first sector in

the slots of the second one. Repeat the operation for

all four sectors.

To obtain the discharge cone join the first sector with

the last one.

Make sure that the sectors wings are correctly inserted

in the slots and that the holes of the sectors are

coincident (see arrows).

Place the half mesh (ref. 24 or 26) on the discharge

cone. In order to fix it, use qty. 1 M6×16 screw (ref. 8)

with qty. 1 D6.4×24 washer (ref. 28) for the internal

side and qty. 1 D6.4×24 washer (ref. 28) with qty.

1 M6 nut (ref. 27) for the external side of the cone.

Repeat the operation for each of the seven spokes of

the half mesh.

Tighten the screws by using two 10 mm combination

spanners (ref. 12/Assembling tools) or similar 10mm

tool.

Assembling guidelinesChapter3

Page 32

© Munters AB, 2014

32

Complete the assemblage of the cone sectors by using

qty. 1 M6×16 screw (ref. 8) with qty. 1 D6.4×24

washer (ref. 28) for the internal side and qty. 1

D6×24 washer (ref. 28) with qty. 1 M6 nut (ref. 27)

for the external side of the cone, as previosly done.

Repeat the operation for each of the four sectors of

the discharge cone.

Tighten the screws by using two 10 mm spanners (ref.

12/Assembling tools).

Assemble the remaining half mesh in the same way.

Fix the cone bracket (ref. 30) to the discharge cone

by using qty. 1 M6×16 screw (ref. 8) with qty. 1

D6.4×24 washer (ref. 28) for the internal side and

qty. 1 D6 spring washer (ref. 29) with qty. 1 M6 nut

(ref. 27) for the external side of the cone.

Make sure that the bracket is assembled in the correct

way, as shown in the picture, and tighten the screw

with two 10 mm combination spanners (ref. 12/

Assembling tools). Repeat the operation for each of

the four brackets of the discharge cone.

Place the complete assembly on the conveyor.

Make sure that the discharge cone is positioned

outside of the conveyor edge.

Assembling guidelinesChapter3

Page 33

© Munters AB, 2014

33

Assembling guidelinesChapter3

Fix the discharge cone to the conveyor with q.ty. 8

D6.3×19 screws (ref. 31) by using a pneumatic

screw-driver (ref. 3/Assembling tools) and its proper

adapter (ref. 9/Assembling tools).

Join together the half meshes by tightrning the plastic

ties as shown in the pictures.

Joint firmly the 2 meshes together by means of the 6

plastic ties (ref. 25) supplied.

OPTIONAL BELT TENSIONER ASSEMBLING

Insert the pop up rivet 3.9x7 (ref. 77) in the metal

spacer by using a pneumatic screw-driver (ref. 3/

Assembling tools).

Place the metal spacer on the tensioner (ref. 76),

making sure to insert the pins of the spacer in the slots

of the tensioner.

Page 34

© Munters AB, 2014

34

2

1

Insert the D10.5 toothed washer (ref. 79) and the

D10.5 plain washer (ref. 80) in the M10×90 screw

(ref. 78) and fix the tensioner to the central support

by means of a 17mm combination spanner (ref. 3/

Assembling tools).

Place the D8 spring washer (ref. 38) and the D8x32

plain washer (ref. 48) onto the M8x65 screw (ref.

53). Insert it in the proper hole* of the support and

tight it through the belt tensioning adjuster (ref. 52) by

using qty. 1 M8 nut with flange (ref. 51).

Please note that the round part of the belt tensioning

adjuster has to be oriented towards the propeller, as

shown in the pictures.

*NOTE: for M80 Motor/Hp1 use the hole nearest

to the central pulley (no. 1 in the picture); for M90

Frame Motor/Hp1.5 use the hole furthest from the

central pulley (no. 2 in the picture).

Place the V-belt on the pulleys.

Assembling guidelinesChapter3

Page 35

© Munters AB, 2014

35

Assembling guidelinesChapter3

Tighten with a 10 mm allen key (ref. 16/Assembling

tools).

TENSIONING VALUES:

Hp1 = 250 N, corresponding to a vibration frequency

55 Hz +/- 2%

Hp2 = 320 N, corresponding to a vibration frequency

60 Hz +/- 2%

Check the final position of the tensioner. If the tensioner

looks like the picture (mark on the 2nd slot) it will be in

the right position.

Otherwise repeat this step by changing motor position.

OPTIONAL PYRAMIDAL SHAPE MESH ASSEMBLING

Put the pyramidal shape mesh (ref. 9) on the fan like

the picture. The rectangular holes must have the long

side in horizontal position.

Fix it to the bottom and top panels by means of qty.

10 plastic clips (ref. 10) and qty. 10 D6.3x19 screws

(ref. 31).

The clips must be fixed in the same position as shown

in the picture.

Fix it by using a pneumatic screwdriver (ref. 3/

Assembling tools) and its proper adapter (ref. 9/

Assembling tools).

Page 36

Euroemme® EC52 extraction fan is developed and produced by Munters Italy S.p.A., Italy

Euroemme

®

is a trademark of Munters AB

www.munters.com

Australia Munters Pty Limited, Phone +61 2 8843 1594, Brazil Munters Brasil Industria e Comercio Ltda, Phone +55 41 3317 5050, Canada Munters Corporation

Mason, Phone +1 517 676 7070, China Munters Air Treatment Equipment (Beijing) Co. Ltd, Phone +86 10 80 418 000, Denmark Munters A/S, Phone

+45 9862 3311, India Munters India, Phone +91 20 6681 8900, Indonesia Munters, Phone +62 818 739 235, Italy Munters Italy S.p.A., Chiusavecchia,

Phone +39 0183 52 11, Japan Munters K.K., Phone +81 3 5970 0021, Korea Munters Korea Co. Ltd., Phone +82 2 761 8701, Mexico Munters Mexico, Phone

+52 818 262 54 00, Russia Munters AB, Phone +7 812 448 5740, Singapore Munters Pte Ltd., Phone +65 744 6828, South Africa and Sub-Sahara Countries

Munters (Pty) Ltd., Phone +27 11 997 2000, Spain Munters Spain S.A., Phone +34 91 640 09 02, Sweden Munters AB, Phone +46 8 626 63 00, Thailand

Munters Co. Ltd., Phone +66 2 642 2670, Turkey Munters Form Endüstri Sistemleri A.Ş, Phone +90 262 751 3750, USA Munters Corporation Mason, Phone

+1 517 676 7070, Vietnam Munters Vietnam, Phone +84 8 3825 6838, Export & Other countries Munters Italy S.p.A., Chiusavecchia Phone +39 0183 52 11

© Munters AB, 2014

Ag/MIT/IGB-2206-08/14 rev 1.0

Loading...

Loading...