Page 1

Originalinstructions

Usermanual

ComDryM160L

Desiccantdehumidier

190TEN-1098-D1404©MuntersEuropeAB2014

Page 2

Importantuserinformation

Intendeduse

Muntersdehumidiersareintendedtobeusedforthe

dehumidicationofair.Anyotheruseoftheunit,or

usewhichiscontrarytotheinstructionsgiveninthis

manual,cancausepersonalinjuryanddamagetotheunit

andotherproperty.

Nomodicationoftheunitisallowedwithoutprior

approvalbyMunters.Attachmentorinstallation

ofadditionaldevicesisonlyallowedafterwritten

agreementbyMunters.

Warranty

Thewarrantyperiodisvalidfromthedatetheunit

leftourfactory,unlessotherwisestatedinwriting.

Thewarrantyislimitedtoafreeexchangeofpartsor

componentswhichhavefailedasaresultofdefectsin

materialsorworkmanship.

Allwarrantyclaimsmustincludeproofthatthe

faulthasoccurredwithinthewarrantyperiodand

thattheunithasbeenusedinaccordancewiththe

specications.Allclaimsmustspecifytheunittypeand

fabricationnumber.Thisinformationisstampedonthe

identicationplate,seesectionMarking.

Itisaconditionofthewarrantythattheunitforthe

fullwarrantyperiodisservicedandmaintainedas

describedinsectionServiceandmaintenance.Theservice

andmaintenancemustbedocumentedforthewarranty

tobevalid.

Safety

Informationaboutdangersareinthismanualindicated

bythecommonhazardsymbol:

W

ARNING!

W W

ARNING! ARNING!

Indicatesapossibledangerthatcanleadtopersonalinjury .

CA

UTION!

CA CA

UTION! UTION!

Indicatesapossibledangerthatcanleadtodamagetothe

unitorotherproperty ,orcauseenvironmentaldamage.

NOTE!Highlightssupplementaryinformationforoptimal

useoftheunit.

ConformitywithDirectives

Thedehumidierisinconformitywiththeessential

safetyrequirementsoftheMachineryDirective

2006/42/EC,theLowVoltageDirective2006/95/EC,

theRoHSDirective2011/65/ECandtheEMC

Directive2004/108/EC.Thedehumidieris

manufacturedbyanISO9001:2008accredited

manufacturingorganisation.

Copyright

Thecontentsofthismanualcanbechangedwithout

priornotice.

NOTE!Thismanualcontainsinformationwhichis

protectedbycopyrightlaws.Itisnotallowedtoreproduceor

transmitanypartofthismanualwithoutwrittenconsentfrom

Munters.

Pleasesendanycommentsregardingthismanualto:

MuntersEuropeAB

TechnicalDocumentation

P.O.Box1150

SE-16426KISTASweden

e-mail:t-doc@munters.se

iiImportantuserinformation190TEN-1098-D1404

Page 3

Tableofcontents

Importantuserinformation...............ii

Intendeduse...........................

Warranty...............................

Safety..................................

ConformitywithDirectives............

Copyright..............................

Tableofcontents...........................iii

1Introduction.................................1

1.1Aboutthismanual.....................

1.2Unintendeduse........................

1.3Safety..................................

1.4Marking................................

2Principleofoperation......................4

3Transport,inspectionandstorage.......5

3.1Transport..............................

3.2Inspectionofdelivery..................

3.3Storingtheequipment................

4Installation...................................6

4.1Safety..................................

4.2Closedsystem.........................

4.3Opensystem..........................

4.4Siterequirements.....................

4.5Installationoftheunit..................

4.6Ductsandhoses.......................

4.7Connectingthedrainhose............

4.8Electricalconnections................

4.9Expandingthesystem................

4.10Accessories...........................

5Controlpaneloverview....................13

6Operation....................................14

6.1Safety..................................

6.2Introduction............................

6.2.1Humiditycontrol................

6.2.2Fanmodes.....................

6.2.3Fanspeed......................

6.3Initiationandstart.....................

6.3.1Bootthecontrolsystem........

6.3.2Startthedehumidier..........

6.4Stopthedehumidier.................

6.5Emergency............................

ii

ii

ii

ii

ii

1

1

1

3

5

5

5

6

6

7

7

8

9

9

10

11

12

14

14

14

14

14

15

15

15

16

6.6Automaticstartafterpowerfailure....

6.7Navigatethemenus...................

6.8Accessthecontrolsystem............

6.9Changethesystemsettings..........

6.10Resetanalarm........................

6.11Resetthecounters....................

6.12Serviceintervalalarm.................

6.13Restorethedefaultsettings...........

6.14Accesslevels..........................

7Menusandparameters....................24

7.1Humidity...............................

7.1.1Internalcontrollingsensor.....

7.1.2Externalcontrollingsensors..

7.2Runtime...............................

7.3Power..................................

7.4Temperature...........................

7.5Functions..............................

7.5.1Processfanspeed.............

7.5.2Processfanmode..............

7.5.3Humiditycontrolandunits.....

7.5.4Displayinformation............

7.6Alarm...................................

7.7Min,maxanddefaultvalues..........

7.7.1Humidity........................

7.7.2Servicetime....................

7.7.3Functions.......................

8Serviceandmaintenance.................35

8.1General................................

8.2Maintenanceschedule................

8.3Processairlterchange..............

9Faulttracing.................................37

10T echnicalspecication....................39

10.1Dimensionsandservicespace.......

10.2Capacitydiagram.....................

10.3Fancurveprocessair.................

10.4T echnicaldata.........................

11Scrapping....................................42

12ContactMunters............................44

16

16

17

18

19

20

21

22

23

23

24

25

25

26

27

28

30

30

30

30

31

33

34

34

34

34

35

35

36

39

40

40

41

190TEN-1098-D1404Tableofcontentsiii

Page 4

ComDryM160L

1Introduction

1.1Aboutthismanual

Thismanualiswrittenfortheuserofthedehumidier.Itcontainsnecessaryinformationforhowtoinstall

andusethedehumidierinasafeandefcientway.Readthroughthemanualbeforethedehumidieris

installedandused.

ContactyournearestMuntersofceifyouhaveanyquestionsregardingtheinstallationortheuseofyour

dehumidier.

Thismanualmustbestoredinapermanentlocationclosetothedehumidier.

1.2Unintendeduse

■Thedehumidierisnotintendedforoutdoorinstallation.

■Thedehumidierisnotintendedforuseinclassiedareaswhereexplosionsafetycompliantequipment

isrequired.

■Thedehumidiermustnotbeinstallednearanyheatgeneratingdevicesthatcancausedamagetothe

equipment.

NOTE!Whenadehumidierisplacedinabuildingwithradonitisnecessarytocontactanexperttosecurethe

bestoverallsolution.Allchangesaffectingtheventilationorthepressurebalanceinthebuildingcanresultina

changedconcentrationofradon.

CA

UTION!

CA CA

UTION! UTION!

Donotsit,stand,orplaceanyobjectsontheunit.

1.3Safety

Everymeasurehasbeentakeninthedesignandmanufactureofthedehumidiertoensurethatitmeetsthe

safetyrequirementsofthedirectivesandstandardslistedintheECDeclarationofConformity.

Theinformationinthismanualshallinnowaytakeprecedenceoverindividualresponsibilitiesorlocal

regulations.

Duringoperationandotherworkwithamachineitisalwaystheresponsibilityoftheindividualtoconsider:

■Thesafetyofallpersonsconcerned.

■Thesafetyoftheunitandotherproperty.

■Theprotectionoftheenvironment.

ThetypesofdangersthatareindicatedinthismanualaredescribedinsectionImportantuserinformation.

1Introduction190TEN-1098-D1404

Page 5

ComDryM160L

W

ARNING!

W W

ARNING! ARNING!

-Theunitmustnotbesplashedwithorimmersedinwater.

-Allelectricalinstallationsmustbecarriedoutbyaqualiedelectricianandinaccordancewithlocalregulations.

-Theunitmustbeconnectedtoanearthedelectricaloutlet.

-Donotconnecttheunittoothermainsvoltagethanspeciedontheidenticationplate.

-Donotoperatetheunitifthepowerplugorcordisdamaged,riskofelectricalshock.

-Donotpulltheplugwithwethands,riskofelectricalshock.

-Donotinsertngersoranyotherobjectsintotheairvents,rotatingfansareinside.

-Donotcovertheunitasthatcanblockairintakeoroutletandcauseare.

-Iftheunithasoverturned,cutthepowerimmediately.

-AlwayscontactMuntersforserviceorrepair.

190TEN-1098-D1404Introduction2

Page 6

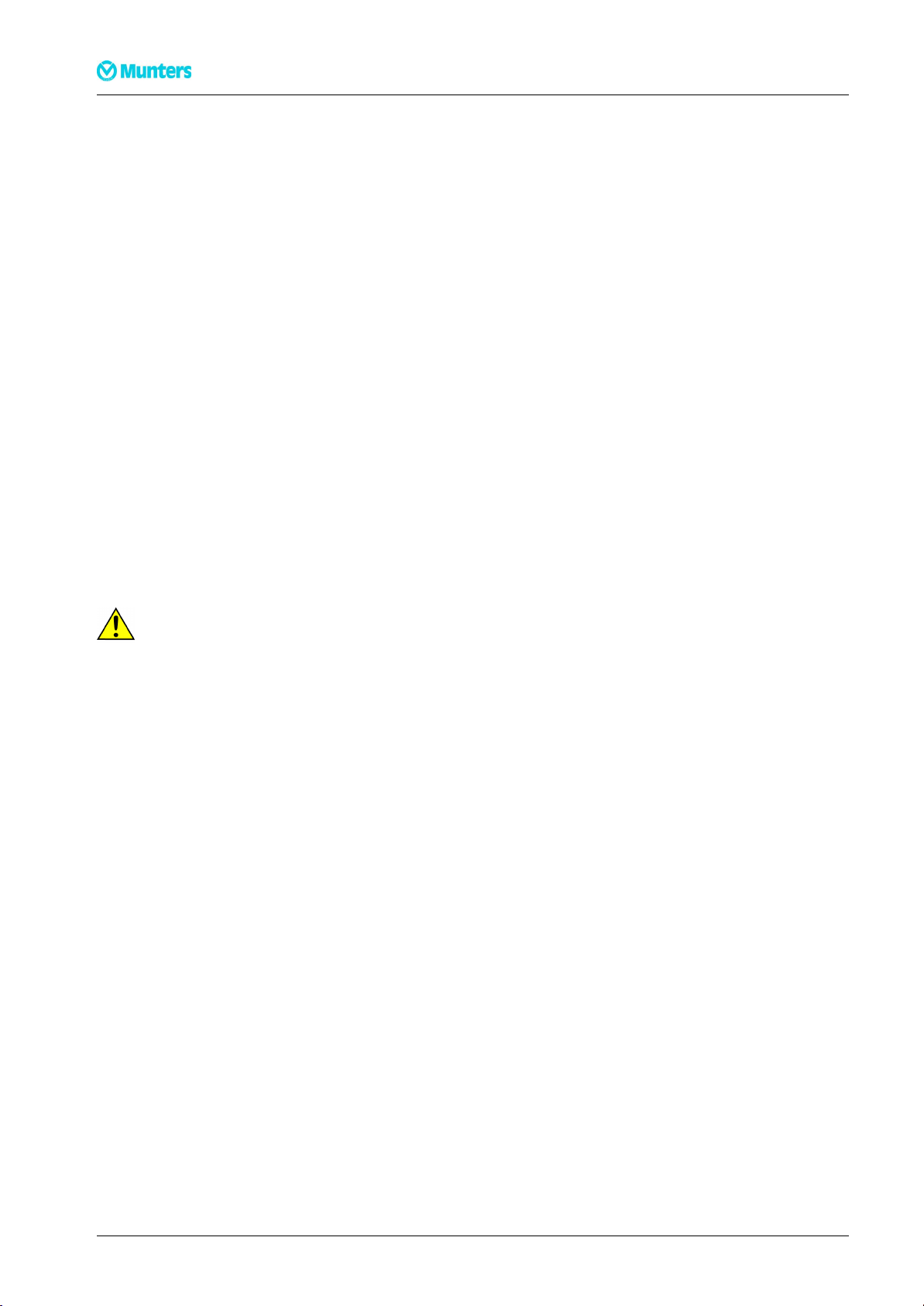

1.4Marking

Type

Fa b r. No.

Fa b r. year

0,17 kW

Max 1,01 kW

1015 170XXX XXXXX

2010

ComDry M160L

00·

·

230V 50/60 Hz

Mad e in S we de n

Munte rs E urop e AB

Isa fjord sga tan 1

16 4 2 6 Kista , S wede n

Weigh t: 17 kg

IP3 3

0,84 kW

oHS

M

Figure1.1Identicationplateposition

ComDryM160L

Figure1.2Identicationplate,anexample

Explanationof"Fabr.No."ontheidenticationplate:

10:Yearofmanufacture

15:Weekofmanufacture

170XXX:Articlenumber

XXXXX:Serialnumber

3Introduction190TEN-1098-D1404

Page 7

ComDryM160L

1

3

2

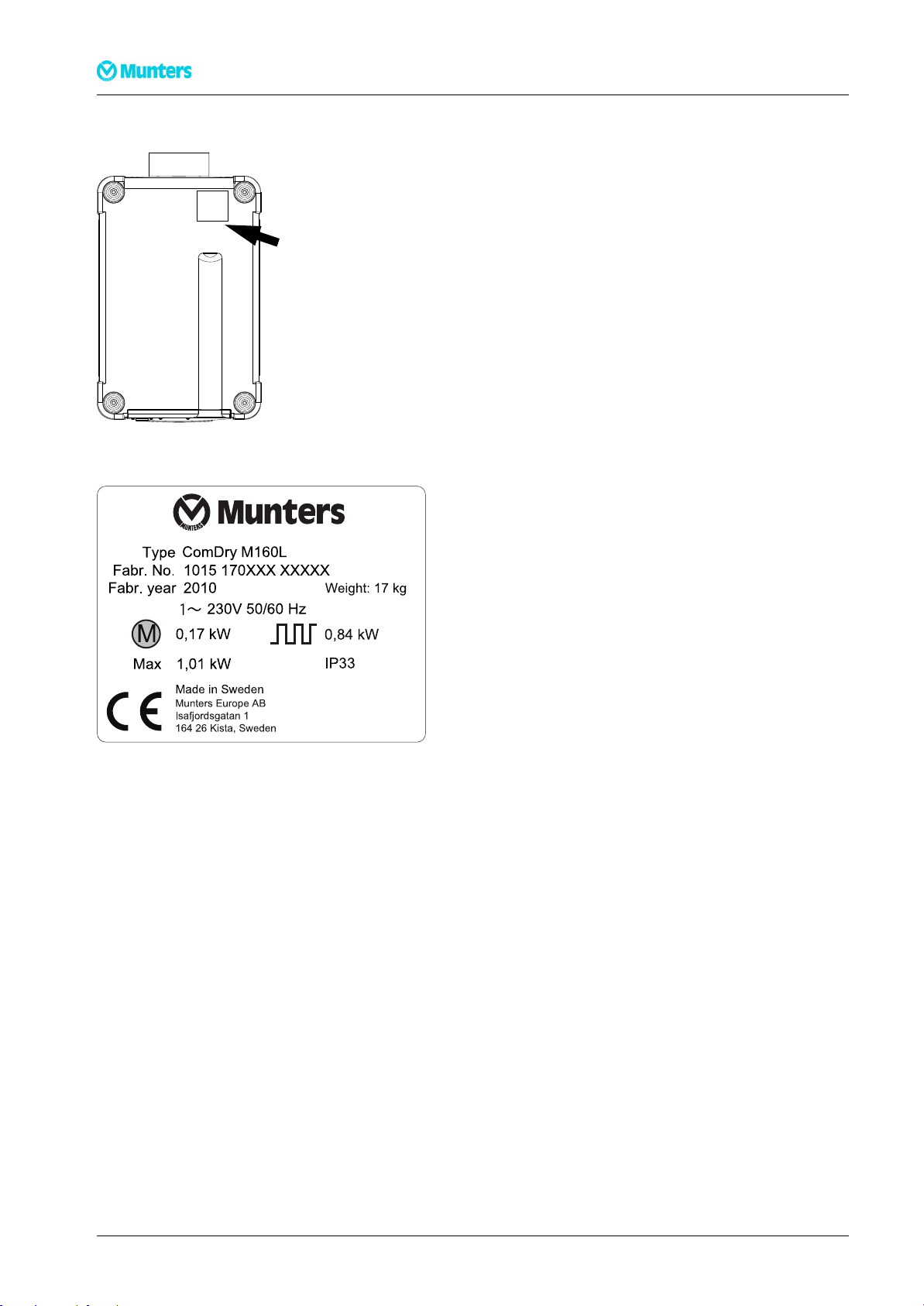

2Principleofoperation

Thedesiccantrotoristheadsorptiondehumidifyingcomponentintheunit.Therotorstructureis

comprisedofalargenumberofsmallairchannels.

Thedesiccantrotorismadeofacompositematerialthatishighlyeffectiveinattractingandretainingwater

vapour.Therotorisdividedintwozones.Theairowtobedehumidied,processair,passesthroughthe

largestzoneoftherotorandthenleavestherotorasdryair.Sincetherotorrotatesslowly,theincomingair

alwaysmeetsadryzoneontherotor,thuscreatingacontinuousdehumidicationprocess.

Theairowthatisusedtodrytherotor,reactivationair,isheated.Thereactivationairpassesthrough

therotorintheoppositedirectiontotheprocessairandleavestherotoraswetair(warmhumidair).The

wetairre-circulatesthroughacondenserthatcoolsdowntheairtocondensethewaterusingapartofthe

processair.

Thecondensedwaterisdischargedbygravitythroughahose.

Thisprincipleenablesthedehumidiertoworkeffectively,evenatlowtemperaturesfrom±0°C.

Figure2.1Principleofoperation

1.Processair

2.Dryair

3.Coolingairout

190TEN-1098-D1404Principleofoperation4

Page 8

ComDryM160L

3Transport,inspectionandstorage

3.1Transport

Beforemovingthedehumidier,makesurethereisnowaterleftinthedrainbypullingthedrainplugout.

CA

UTION!

CA CA

UTION! UTION!

Removethedrainpipefromthetraytoavoiddamage,seesection4.5,Installationoftheunit.

Transportthedehumidierbycarryingitbyitshandleorintheoriginalpackaging.Theunitmustalwaysbe

placedinanuprightpositionduringtransport.Failuretocomplywiththiscancausetheunittomalfunction.

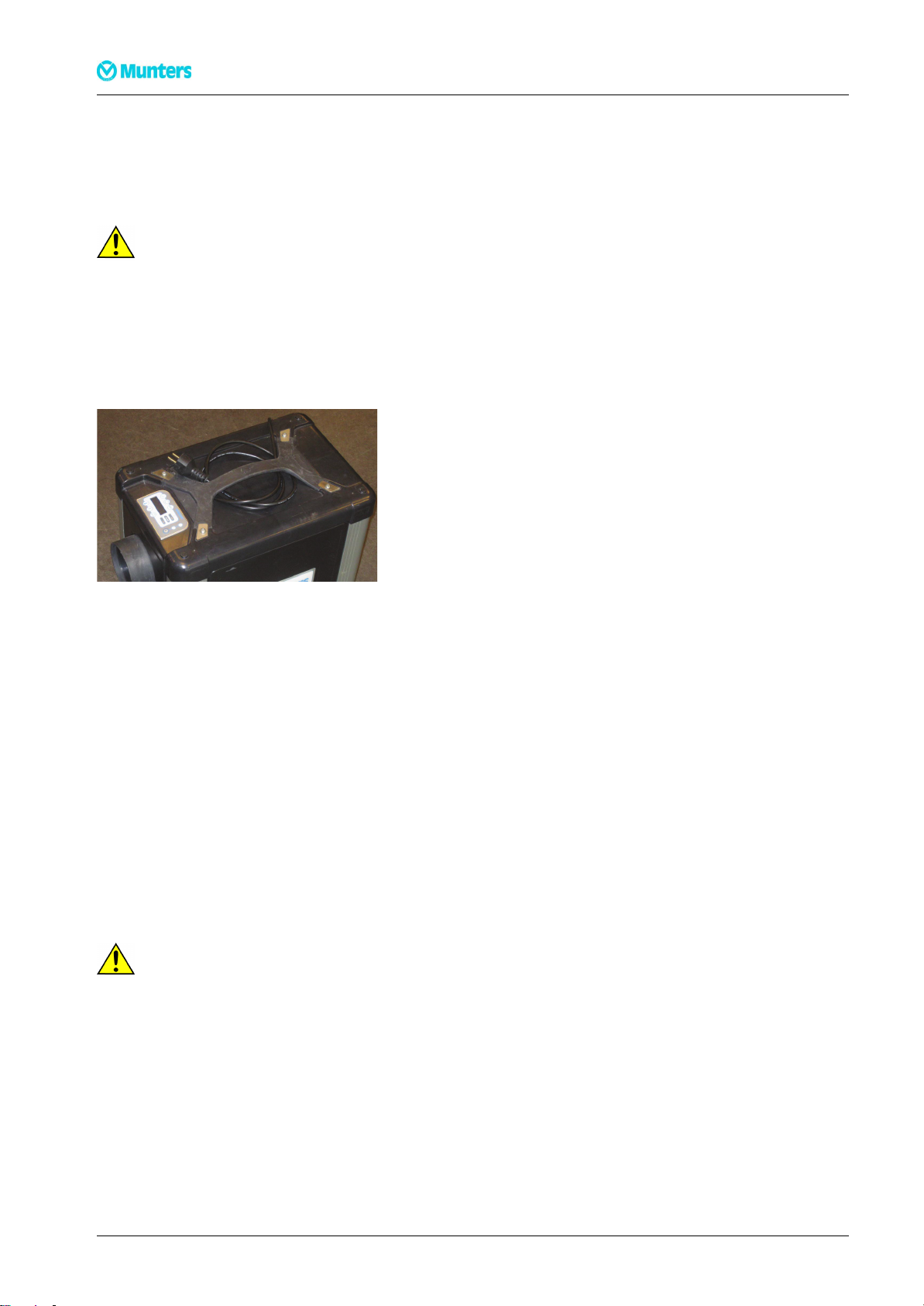

Thepowercordshouldberolledupandplacedunderthehandlewhencarryingthedehumidier,see

Figure3.1.

Figure3.1Powercordplacement

3.2Inspectionofdelivery

1.Inspectthedeliveryandcomparewiththedeliverynote,orderconrmationorotherdelivery

documentation.Makesurethateverythingisincludedandnothingisdamaged.

2.ContactMuntersimmediatelyifthedeliveryisnotcompleteinordertoavoidinstallationdelays.

3.Iftheunitistobeputintostoragepriortoinstallation,seesectionStoringtheequipment.

4.Removeallpackagingmaterialfromtheunit,andmakesurethatnodamagehasoccurredduring

transportation.

5.AnyvisibledamagemustbereportedinwritingtoMunterswithin5daysandpriortoinstallationof

theunit.

6.Disposeofthepackagingmaterialaccordingtolocalregulations.

3.3Storingtheequipment

CA

UTION!

CA CA

UTION! UTION!

Alwaysunplugtheunitfromthepowersupplywhennotinuse.

Followtheseinstructionsifthedehumidieristobestoredpriortoinstallation:

■Placethedehumidierinanuprightpositiononahorizontalsurface.

■Re-usethepackagingmaterialtoprovideprotectionfortheunit.

■Protectthedehumidierfromphysicaldamage.

■Storethedehumidierundercoverandprotectitfromdust,frost,rainandaggressivecontaminants.

5Transport,inspectionandstorage190TEN-1098-D1404

Page 9

ComDryM160L

1

2

Com Dry M160L

3

4Installation

4.1Safety

W

ARNING!

W W

ARNING! ARNING!

Donotconnecttheunittoothermainsvoltagethanspeciedontheidenticationplate.

Theunitmustbeconnectedtoanearthedelectricaloutlet.

Donotoperatetheunitifthepowerplugorcordisdamaged.

CA

UTION!

CA CA

UTION! UTION!

Donotsit,stand,orplaceanyobjectsontheunit.

NOTE!Whenadehumidierisplacedinabuildingwithradonitisnecessarytocontactanexperttosecurethe

bestoverallsolution.Allchangesaffectingtheventilationorthepressurebalanceinthebuildingcanresultina

changedconcentrationofradon.

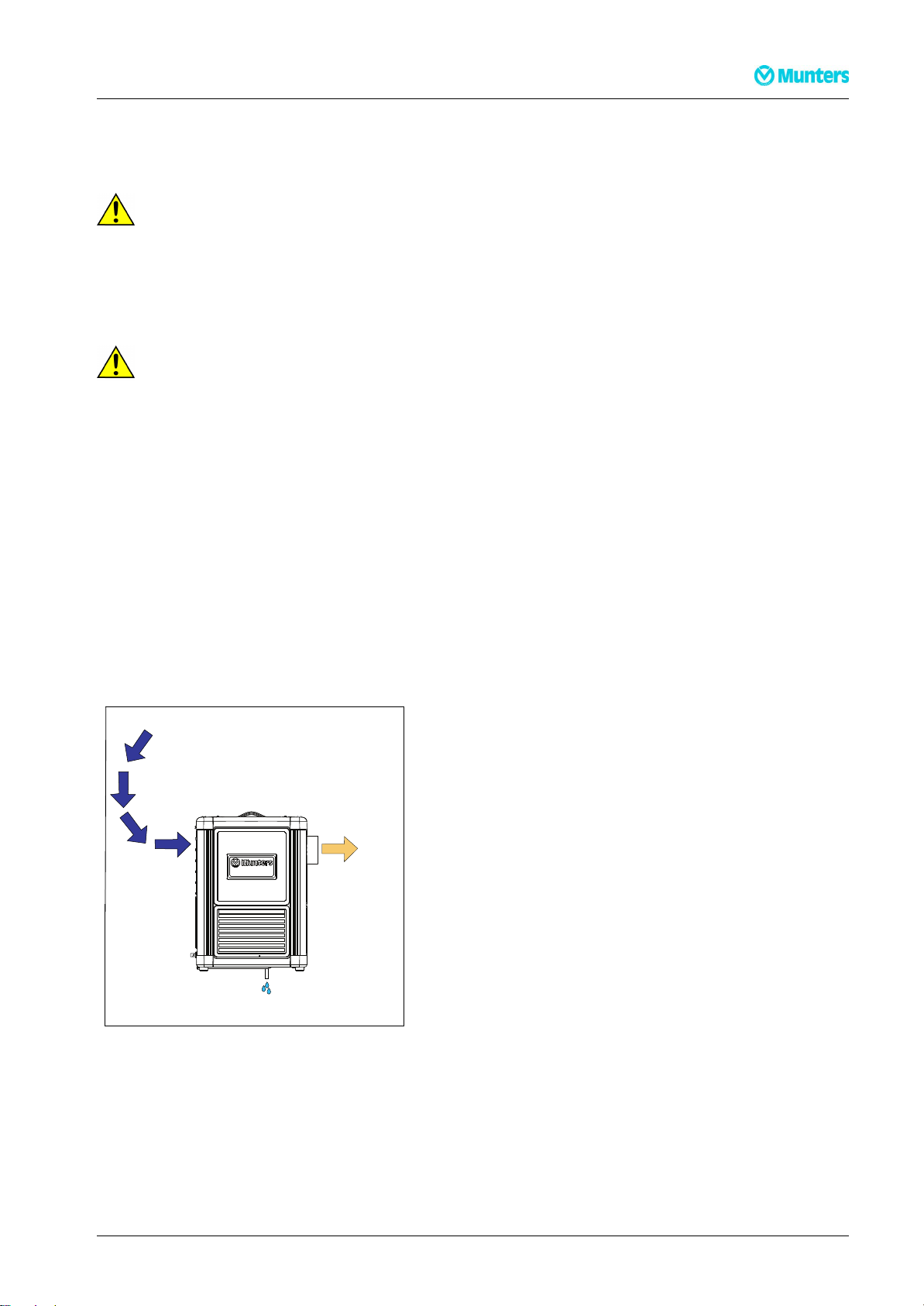

4.2Closedsystem

Thedehumidierisplacedinthespacetobedehumidied.T oensurethatthedryairisdistributedevenly

inthespacetobedehumidiedaductingcanbeconnectedtothedryairoutletofthedehumidier.The

condensedwaterisdrainedthroughahose.

Aclosedsystemispreferablewhenthereisaneedfordehumidicationtoaverydryclimate.Itismore

economicaltoruncomparedtoanopensystem.

1.Process/Reactivationair

2.Dryair

3.Condensedwater

Figure4.1Closedsystemprinciple

190TEN-1098-D1404Installation6

Page 10

ComDryM160L

2

1

3

Com Dry M160L

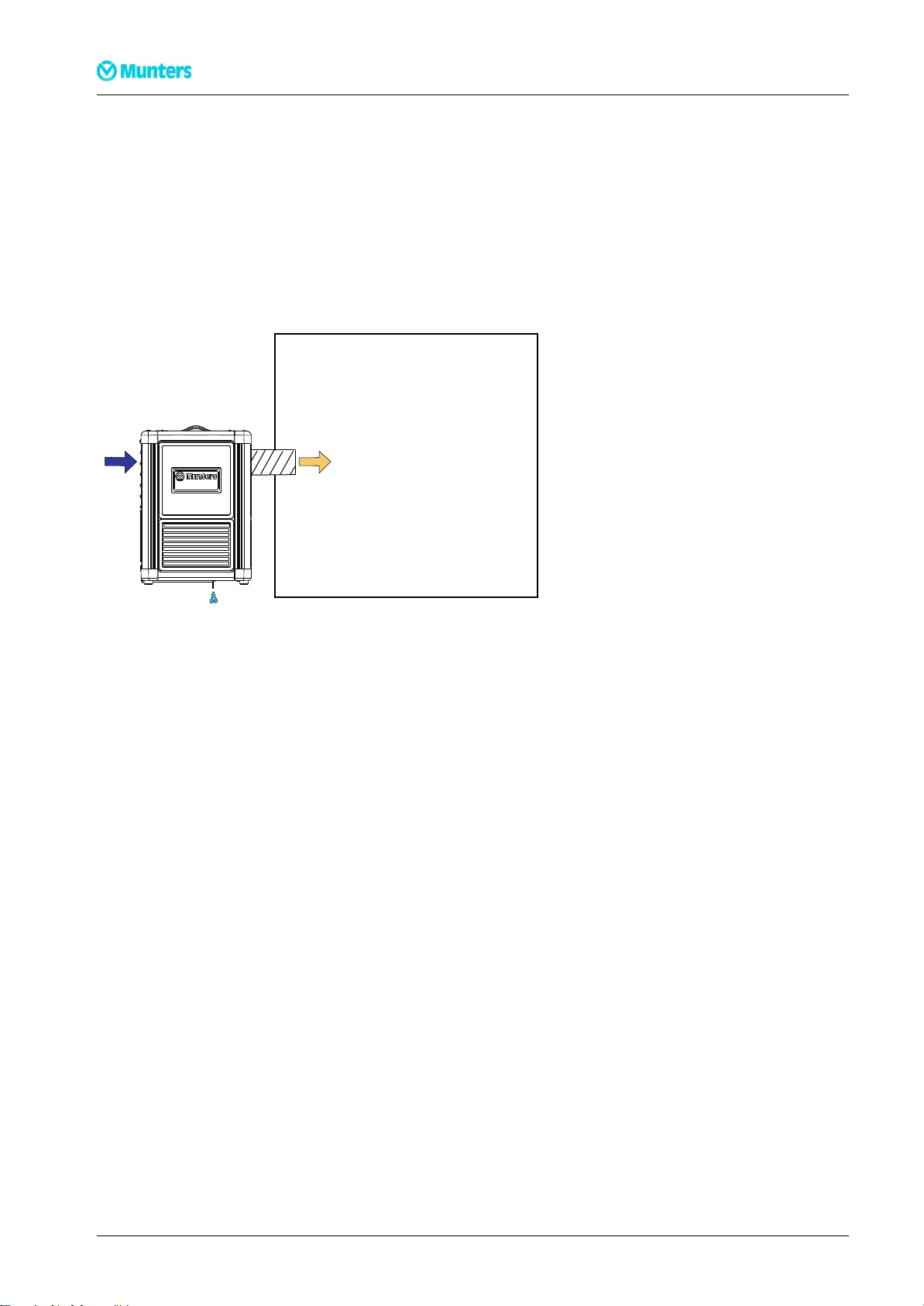

4.3Opensystem

Thedehumidierisplacedoutsidetheareatobedehumidied.Dryairistransportedwithductingtothe

spacetobedehumidied.Thecondensedwaterisdrainedthroughahose.Theinstallationisusedtosolve

thefollowingproblems:

-Whenmoisturedamagedobjectsaretobedehumidied.

-Dustorcorrosioncausingparticlesarepresentinaspacewheredryairwillbesupplied.

-Topreventmoisturefromenteringthedehumidiedspace/object.

1.Process/Reactivationair

2.DryAir

3.Condensedwater

Figure4.2,Opensystemprinciple

4.4Siterequirements

Thedehumidierisonlyintendedforindoorinstallation.Avoidinstallingthedehumidierinadamp

environmentwherethereisariskofwaterenteringtheunitorinaverydustyenvironment.Ifindoubt,

seekadvicefromMunters.Itisimportantthattheintendedinstallationsitemeetsthelocationandspace

requirementsfortheequipmentinordertoachievethebestpossibleperformanceandtrouble-free

operation.Forspacerequirements,seesection10.1,Dimensionsandservicespace.

7Installation190TEN-1098-D1404

Page 11

ComDryM160L

1

2

4.5Installationoftheunit

ComDryM160Lisdesignedtobemountedonawallusingthewallbracketincludedinthedeliveryofthe

unit.Seetheseparatewallbracketleaet.

1.Assemblethethreemainpartsofthewallbracket.Seeitem1,2and3intheleaet.Usethefourscrews

included.

2.Markfourwallholesusingtheencloseddrillpattern.Makesuretogetatleast25cmspacebetweenthe

dehumidierandtheoor.

3.Usefourscrewswithamaximumdiameterof7mm(notincluded)tomountthebracketonthewall.

4.Screwthewallbracketontothewall.

5.Laydownthedehumidier.

Figure4.3Figure4.4

6.InserttheO-ring(1)intothedrainpipesleeve(2).PresstheO-ringsoitisproperlyseatedinthegroove

seeFigure4.3

7.Pushthedrainpipeontothedrainconnectionofthetray,seeFigure4.4

8.Fastenthedrainpipewiththetwoenclosedscrews.

9.Therearetwoslotsintheshelfenablingalashingstraptobemountedifthedehumidieristobexed

byastrap.

10.Alternativelythefourfeetcanbelockedsimplybychangingthescrewineachfoottoalonger(not

included)andusethefourpre-drilledholesinthebracket.Fournewwasherswillalsobeneeded.

11.Finallyputthehoseontothedrainpipeandlockthehoseusingahoseclamp.

12.Ifductsorhosesaretobeinstalled,seesection4.6,Ductsandhoses.

190TEN-1098-D1404Installation8

Page 12

ComDryM160L

4.6Ductsandhoses

Wheninstallingductworkbetweenthedehumidierandtheinletandoutletconnections,thefollowing

recommendationsshouldbeobserved:

■Ductlengthmustbekeptasshortaspossibletominimisestaticpressureloss.

■Allductandhoseconnectionsmustbeairtightandvapourtighttoensurefullperformance.

■Thetotalresistanceintheductworkmustnotexceedtheperformanceratingofthefansttedinthe

dehumidier.

NOTE!Maximumlengthofdryairhoseis25metres.

4.7Connectingthedrainhose

Beforeconnectingthedrainhosethedehumidiermustbemountedonthewallusingtheenclosedwall

bracket.Theminimumdistancebetweenthebottomofthedehumidierandtheooris25cm.

Figure4.5Drainhoseconnection

9Installation190TEN-1098-D1404

Page 13

ComDryM160L

4.8Electricalconnections

Thedehumidierisdeliveredwitha2,7metrepowercable,equippedwithanearthedplug.Themain

electricalcomponentsareinstalledintheupperpartoftheunit.

CA

UTION!

CA CA

UTION! UTION!

Donotconnecttheunittoothermainsvoltagethanspeciedontheunit’sidenticationplate.

Themainsfrequencycanbeadjusted,seeTable7.5.

NOTE!Incaseofaxedinstallationwheretheplugisreplacedbyacircuitbreaker,checkthatthefuserating

inthecircuitbreakeriscorrect.

190TEN-1098-D1404Installation10

Page 14

ComDryM160L

4.9Expandingthesystem

CA

UTION!

CA CA

UTION! UTION!

NeverconnectComDrydirectlytoastandardEthernetnetwork,eveniftheconnectortypeisthesame(RJ45-8,

modularconnector).DoingsomightdamageboththeComDrycontrolsystemand/orthecomputernetwork.

AllComDrydehumidiersareequippedwithtwoCANBUSports,locatedbehindacovernexttothe

applianceinlet.Anindoorremotecontrol,externalhumidity/temperaturesensorsoranexternalsignalbox

canbeconnectedtotheseCANBUSports.Itdoesnotmatterwhichoftheabovedeviceswillbeconnected

towhichport.Whennoportisusedthetwoemptyterminationplugsmustbettedtotheports.

Figure4.6RemovethecoverFigure4.7,2CANBUSportswithemptyplugstted

11Installation190TEN-1098-D1404

Page 15

ComDryM160L

kWh

C

f

X

4.10Accessories

Therearesomeaccessoriesavailableasoptionstothedehumidier.

WallBracket.Astheunitmustbemountedonthewallthisisincludedinthesupply .

StubPipeKitisusedwhenthereisaneedtoconnectaninletductorhosetothedehumidier.

RemoteControlmakesitpossibletocontroltheunitfromdistance,deliveredwitha10metrecable.

Externalsignalboxisusedwhenthereisaneedtoconnecttoanexternalcontrolsystem.

RemoteRH/Tsensorforexternalmeasuringofhumidityandtemperature.

WallBracket

StubPipeKit

RemoteControl

Externalsignalbox

RemoteRH/Tsensor

190TEN-1098-D1404Installation12

Page 16

5Controlpaneloverview

C

f

X

kWh

1

2

3

4

5

6

A

B

C

RH1 55%

*

ComDryM160L

Menuindicators1-6

1.Humiditymenu4.T emperaturemenuA.Alarmindicator

2.Timemenu5.FunctionsmenuB.Operationindicator

3.Powermenu6.AlarmmenuC.On/Offbutton

MenubuttonFunction

Table5.1Menubuttonfunctions

Up/Rightbutton

Enter/Conrmationbutton

Down/Leftbutton

13Controlpaneloverview190TEN-1098-D1404

Page 17

ComDryM160L

6Operation

6.1Safety

W

ARNING!

W W

ARNING! ARNING!

Donotoperatetheunitifthepowerplugorcordisdamaged.

Donotinsertngersoranyotherobjectsintotheairvents.

Theunitcanrestartautomaticallywithoutwarningfollowingapowerfailure.

CA

UTION!

CA CA

UTION! UTION!

Donotsit,stand,orplaceanyobjectsontheunit.

6.2Introduction

6.2.1Humiditycontrol

TheComDrydehumidierisequippedwithasophisticatedmicroprocessorbasedcontrolsystem.This,in

combinationwiththebuilt-inhumidity/temperaturesensorintheprocessairinlet,makesitpossibletoset

boththecontrolandpresentationofthehumiditytoeitherrelativehumidity(RH%),dewpoint(Dp°C)or

absolutehumidity(Xgr/kg).Thecontrolsystemadditionallychecksthetemperaturesbeforeandafterthe

heater,aswellasinthewetairaftertherotor.Ahighsafetylevelisobtainedbyvarioustemperaturesensors.

Toohightemperaturesgivesareductionoftheheaterpower,whileexcessivetemperatureswillmakethe

systemissueanalarmandshutthedehumidierdowninacontrolledway.Forfurtherexplanation,see

7.1,Humidityand7.5,Functions.

NOTE!Thedehumidieralwaysoperatesinautomaticmode(moisturebasedoperation).Asdefaultitwilluse

thebuilt-inhumidity/temperaturesensor,asoptionanexternalsensor.

6.2.2Fanmodes

Dependingontheapplication,ifxedortemporarilyinstalledetc.,thedehumidiercanberunindifferent

processfanmodes:Fan“ON”(continuous),“INT”(INTermittent)or“DEM”(onDEMand).Forfurther

explanation,see7.5,Functions.

6.2.3Fanspeed

Therearethreeprocessfanspeedsettingsavailable:“HIGH”,“NORM”and“LOW”.Thespeedis

manuallysetbytheoperator.Forfurtherexplanation,see7.5,Functions.

190TEN-1098-D1404Operation14

Page 18

ComDryM160L

C

B

B

6.3Initiationandstart

6.3.1Bootthecontrolsystem

Connectthedehumidiertomains.Result:ThecontrolsystemwillinitiatebyashingallLEDsforafew

seconds,andthedisplayrstshowstheComDrymachinetype[[M160L],thenthesetfrequency ,e.g.[50Hz]

andnallythesoftwareversionnumber,e.g.[VER:1.00]andthecurrenthumiditylevel,e.g.[*RH146%].

NOTE!Thebootsequencetakesabout10seconds.Letthecontrolsystemnishthebootingbeforeattempting

tostartthedehumidier.

6.3.2Startthedehumidier

Followthesestepstostartthedehumidier:

StepActionIllustration

1PresstheOn/Offbutton(C)oncetostartthedehumidier.

Result:IfthemeasuredhumidityislowerthantheSetValue,

thegreenoperatingindicator(B)willstarttoashinalong

on/shortoffsequence.Dependingonfanmodesetting,the

processfanwillrunornot.Theunitisnowinstand-bymode.

2Thedehumidierstartstodehumidifywhenthemeasured

humidityisequalorgreaterthantheSetV alue,andthe

operatingindicator(B)willshifttocontinuouslylit.

15Operation190TEN-1098-D1404

Page 19

ComDryM160L

6.4Stopthedehumidier

CA

UTION!

CA CA

UTION! UTION!

Donotunplugthedehumidierwhileitiscoolingdown.Ifunpluggeditmightleadtopermanentunitdamage.

Followthesestepstostopthedehumidier:

Step

1

2

Action

PressOn/Offoncetostopthedehumidier.Thegreenoperatingindicatorstartsashing

Theunitcontinuestorunforawhileinordertocooldownand

thenstops.

Result/Illustration

withequallylongandshortonandoffperiods.

6.5Emergency

CA

UTION!

CA CA

UTION! UTION!

Onlyquickstopthedehumidierinthecaseofanemergency.Thefanstopsandtheheatercanbeveryhot,which

canresultindamagetotheheaterandothercomponentsclosetoit.

Incaseofemergency,stopthedehumidierbypullingthemainsplugor,ifitispermanentlyconnected

tomains,byusingtheexternalswitch.

6.6Automaticstartafterpowerfailure

Ifthedehumidierisswitchedonitwillreverttooperationafterapowerfailure,regardlessofifitwas

runningorinstand-by .

190TEN-1098-D1404Operation16

Page 20

ComDryM160L

f

X

6.7Navigatethemenus

Thethreebuttons,andonthecontrolpanelmakeitpossibletonavigatethemenus.

Followthesestepstonavigatethemenus:

Step

Action

1

Toselectamenu,pressor.untiltheselectedmenuappears.

2

Toenterthemenu,press.

3

Useortoscrollthroughthemenu.

4

Leavethemenubyusingandgoto[EXIT].

Press.

NOTE!Allmenulistsarecircular.Attheendofeachmenuyouwillnd

thereistopress

onetimeafterhavingenteredamenu.

[

EXIT

Result/Illustration

Theselectedmenuindicatorislit.

Themenuindicatorstarts

ashing.

Themenuindicatorstops

ashing.

]

.Thequickestwayofnavigating

17Operation190TEN-1098-D1404

Page 21

ComDryM160L

f

X

C

f

X

kWh

f

X

ACCE S S

f

X

6.8Accessthecontrolsystem

Thecontrolsystemsettingsandcountersareprotectedagainstunauthorizedchangeusingtwoaccesslevels.

Seealsosection6.14,Accesslevels.

Followthesestepstoaccessthesystem:

StepActionResult/Illustration

1T ochangethesettingsyoumusthave“one-star”access.Gotomenu

Functions,seesection6.7,Navigatethemenus.

2

Scrollupto[ACCESS]using.

3

Pressandholduntil[ACCESS]changesto[ACCESS*].

4Ahigher ,PIN-codeprotected,“two-star”accesslevelexists.Ifanattempt

togethigheraccessismadewiththemachineswitchedoff,thedisplaywill

changeto[0000].

Press

fourtimesuntil[ACCESS*]isvisibleagain.

Themenuindicatorisashing.

Thesystemisnowunlocked,

anditispossibletomakenew

settingsalternativelyresetthe

counters.

NOTE!Thesystemwillreturntolockedmodeautomaticallyafterveminuteswithoutanyactivity.

NOTE!Thesystemalwaysstartsinlockedmodeafterpower-up(orpowerfailure),regardlessofaccesslevel

priortounpluggingtheunit.

Followthesestepstoforcethesystemintolockedmode:

StepActionResult/Illustration

1Makesuretheunitisswitchedoff.

2Gotomenu"Functions"

3Navigateto[ACCESS*].Seegeneral

instructioninsection6.7,Navigatethemenus.

4StarttheunitbypressingOn/Off.Thegreenlightilluminates

5Pressandhold

until[ACCESS*]changesto[ACCESS].

Thesystemisnowlocked,anditisnotpossibletomakenew

settingsortoresetthecounters.

190TEN-1098-D1404Operation18

Page 22

6.9Changethesystemsettings

Tochangesettingsyoumusthave“one-star”access,see6.8,Accessthecontrolsystem.

Followthesestepstochangethesystemsettings:

ComDryM160L

Step

Action

1

Navigatetotheparameteryouwanttochangebyusingor.

2

Press.

3

Changethevaluewithand.

4

Conrmthenewsettingwith.

Result/Illustration

Thesettingstartstoash.

Thesettingstopstoash.

NOTE!Ifthenewsettingisnotconrmedwithin30seconds,thedisplaychangesbacktotheoldsetting.

NOTE!Read-onlyvaluesarenotchangeable.Theywillnotstarttoashif

level.Tondoutifaparameterischangeableorread-only,seesection7,Menusandparameters.

ispressed,regardlessofaccess

19Operation190TEN-1098-D1404

Page 23

ComDryM160L

C

f

X

kWh

f

X

Rs t

NO

6.10Resetanalarm

Followthesestepstoresetanalarm:

StepActionResult/Illustration

1Writedownthealarmmessagebeforeresettingthealarm.The

informationmightbehelpfulwhentroubleshooting.

2Waituntilthedehumidierhasstopped.

Press.

3

Toggle[NO]to[YES]bypressingeitheror.

Conrmbypressing

.

Thedisplaychangesto[RstNO]and[NO]

isashing.

Whenthealarmhasbeenreset,themenu

systemreturnstoitsstartposition.

NOTE!Ifthecauseofanalarmisstillpresent,thealarmmightbere-issuedafterresetting,evenifthe

dehumidierisstopped.

190TEN-1098-D1404Operation20

Page 24

6.11Resetthecounters

C

f

X

kWh

f

X

Rs t

NO

Toresetcountersyoumusthave“one-star”access,see6.8,Accessthecontrolsystem.

Followthesestepstoresetthecounters:

ComDryM160L

Step

Action

1

Navigatetothecounteryouwanttoreset.Seesection

6.7,Navigatethemenus.

2

Press

3

Toggle[NO]to[YES]bypressingeitheror.

NOTE!If

[

RstNO

]/[

RstYES

seconds,thedisplayautomaticallychangesbacktothestored

countervalue.

4

Conrmtheresettingwith

NOTE!PressingENTERwhenthedisplayshows

again.

]

isleftwithoutactionfor30

.

Result/Illustration

Thedisplaychangesto

[RstNO]and[NO]isashing.

Thecounterisreset.

[

RstNO

]

willreturnthestoredcountervalueinthedisplay

21Operation190TEN-1098-D1404

Page 25

ComDryM160L

6.12Serviceintervalalarm

TheServiceinterval[T-xxxxh]issettablebetween500and8.000hours.Seealsosection

8.2,Maintenanceschedule.

Toresetcountersyoumusthave“one-star”access.Followthesestepstochangetheserviceinterval(see

also6.9,Changethesystemsettings):

Step

Action

1

GototheTimemenu.

2

Navigateto"Serviceinterval"[T-xxxxh]

2

Adjustthe"Serviceinterval"[T-xxxxh]instepsof100hours

3

Resetthe"Timetoservice"counter[Sxxxxh].

Result/Illustration

NOTE!The"Timetoservice"countercanberesetatanytime.Whenthecounterisreset,itstartscountingupor

downagainfromthepre-setvalue[T-xxxxh]dependingonhowthe"Serviceinterval"hasbeenadjusted.

TheTimetoservicecounter[Sxxxxh]countsdowntozero.Whenitreacheszero,thesystemissuesa"soft

alarm"thenexttimetheunitisswitchedon.Thealarmonlymakesthealarmmenusymbolash,notthe

redalarmindicator,and[TIMEFORSERVICE]isshowninthedisplay.Thealarmwillnotmaketheunit

stop.Theunitcanstillbeoperatedasnormalwiththealarmpresent.

Followthesestepstochecktheserviceparametersandstoptheservicealarm:

Step

Action

1Toseeorcheckparameters,eitherresetthealarmbypressing

andresetit,orleavetheAlarmmenuwith[EXIT].

2

Tostopthealarmcompletely ,navigatetothe"Timetoservice"counter[S

0000]inthismenuandresetit.

Result/Illustration

NOTE!EvenifthealarmhasbeenresetintheAlarmmenu,itwillbere-issuedthenexttimetheunitisswitched

on.

See8.2,Maintenancescheduleforpropermaintenanceaction.

190TEN-1098-D1404Operation22

Page 26

ComDryM160L

C

f

X

kWh

f

X

Rs t

NO

6.13Restorethedefaultsettings

Torestorethefactorydefaultsettingsyoumusthave“one-star”access,see6.8,Accessthecontrolsystem.

Followthesestepstorestoreallthedefaultfactorysettings:

Step

Action

1

GototheFunctionsmenuandnavigatetoDefault.

2

Press

3

Toggle[NO]to[YES]bypressing

eitheror

4

Conrmbypressing.

6.14Accesslevels

Thefollowingaccesslevelsandactionsareavailableinthecontrolsystem:

AccesslevelAvailableactions

ACCESS

ACCESS*

ACCESS**

Viewallprocessingdata

■Viewallprocessingdata

■Adjustrelevantparameters(fanspeed,set

valueRH,resethorkWhetc.)

Result/Illustration

Thedisplaychangesto[RstNO]and[NO]isashing.

Allvaluesrevertstofactorysettings.

Comment

■Level2isfordedicatedpersonnelonly

(qualiedpersonnelorMuntersService)

■Ifyouhaveaccidentallyreachedthislevelthe

codeis0000forreturningtolevel1.

23Operation190TEN-1098-D1404

Page 27

ComDryM160L

C

f

X

kWh

f

X

*RH1 49%

C

f

X

kWh

f

X

RH2 35 %

C

f

X

kWh

f

X

RH3 35 %

C

f

X

kWh

f

X

S V RH 5

7Menusandparameters

Tosetthesystemparameters,see6.9,Changethesystemsettingsand6.11,Resetthecounters.Forlimitswhen

settingparameters,see7.7,Min,maxanddefaultvalues.

7.1Humidity

Thedehumidierisalwaysoperatinginautomaticmode.Itwilldehumidifyuntilthedesiredhumiditylevel

(SetValueminusHysteresisvalue)isreached.Thenthegreenoperatingindicatorwillstarttoashinalong

onandshortoffsequence,indicatingthatthedehumidierisinstand-by.Itwillstarttodehumidifyagain

whenthehumidityisequalto,orgreaterthantheSetValue.

Typeofhumiditycontrol(relativehumidity,dewpointorabsolutehumidity)andunitsystem(metricor

imperial)governsthereadingsandsettingsinthismenu.See7.5,Functionsforreferenceandexplanation.

ThistableshowsthedisplayviewsandpossiblesettingsoftheHumiditymenu:

Displayview

Internalsensorreading

(Externalsensorreading)

(Externalsensorreading)

DescriptionType

READONLYD1.../X1...

1

1

READONLYD2.../X2...

READONLYD3.../X3...

Settingoption

SetValueHumidityADJUSTABLEHIGHER/LOWER

190TEN-1098-D1404Menusandparameters24

Page 28

ComDryM160L

C

f

X

kWh

f

X

HYS 2%

C

f

X

kWh

f

X

RH1

*

Displayview

1)

Onlywhenexternalhumiditysensorsareconnected

Table7.1Humiditymenu

7.1.1Internalcontrollingsensor

DescriptionType

Hysteresis

Controllingsensor(ADJUSTABLE)

ADJUSTABLEHIGHER/LOWER

Settingoption

1

1

(*RH2)

1

,(*RH3)

Theinternalhumiditysensoristhecontrollingsensorasdefault.Thisisindicatedbya(*)beforethereading

inthedisplay(*RH1…/*D1…/*X1…).

7.1.2Externalcontrollingsensors

Optionally,uptotwoexternalsensorscanbeconnected.Theywillautomaticallybedesignated

(RH2/D2/X2)and(RH3/D3/X3)bythesystem(numbertwobeingtherstconnectedinthechain).

Whenconnected,itispossibletochooseoneoftheexternalsensorsascontrol.Thedisplaywillthenshow

(*RH/D/X2…)or(*RH/D/X3…).

Withanexternalsensorsetascontrolsensor,itispossibletodisconnectandreconnecttheexternal

sensor/-swithoutlosingthecontrolsetting,e.g.[*RH2…]whiletheunitisswitchedoff(butpowered).

Whenswitchedon,thesystemmakesveattempts(duringapprox.20seconds)tocontacttheexternal

controllingsensor.Ifthisfails,thesystemrevertstotheinternalRH1-sensor.Subsequentlyanyrenewed

assignmentoftheexternalsensorascontrolmustbecarriedoutmanually.

25Menusandparameters190TEN-1098-D1404

Page 29

ComDryM160L

f

X

kWh

f

X

261 h

C

C

f

X

kWh

f

X

341 h

C

C

f

X

kWh

f

X

S 39 99 h

C

C

f

X

kWh

f

X

T-400 0 h

C

C

7.2Runtime

Runtimeisregisteredaslongastheprocessairfanisoperating.Itstopscountingwhentheunitisinstand

bymodeorisswitchedoff.Thesystemhastworuntimecounters,oneresettabletripmeterandone

non-resettabletotalruntimecounter.

ThistableshowsthedisplayviewsandtypeofinformationoftheTimemenu:

Displayview

DescriptionType

Runtimetripmeter

Totalruntime(Displayjumps

from“TOT AL”todisplayview

andback).

Timetoservice

Settingoption

RESETTABLEY es/No

READONLY

RESETTABLEY es/No

Table7.2Timemenu

ServiceintervalADJUSTABLE

Every100hours

190TEN-1098-D1404Menusandparameters26

Page 30

ComDryM160L

f

X

kWh

f

X

411 kWh

C

C

kWh

f

X

kWh

f

X

88 7 W

C

C

kWh

f

X

kWh

f

X

3.88 229

C

C

7.3Power

TheComDrydehumidierisequippedwithanintegrated,resettablekWhcounter.Theenergy

consumptionisregisteredwhenthedehumidierisconnectedtomains,regardlessofbeingswitchedon,off

orinstand-bymode.ThecountershowstheconsumptionaswholekW-hours.

ItisalsopossibletomonitorrealtimePower(W),current(A)andvoltage(V)measurementsinthismenu.

NOTE!Resettingisalwaysperformedmanually.Unpluggingtheunit(orapowerfailure)willnotresetthekWh

counter.

ThistableshowsthedisplayviewsandtypeofinformationofthePowermenu:

DisplayviewDescriptionType

kWhcounter

RealtimePower

RESETTABLEYes/No

READONLY

RealtimeCurrent/V oltageREADONLY

Settingoption

Table7.3Powermenu

27Menusandparameters190TEN-1098-D1404

Page 31

ComDryM160L

f

X

kWh

f

X

T1 28 C

C

C

f

X

kWh

f

X

T2 23 C

C

C

f

X

kWh

f

X

T3 23 C

C

C

f

X

kWh

f

X

Rt 121 C

C

C

7.4Temperature

Theairtemperatureismeasuredindifferentpositionsinthedehumidier.Allvaluesareread-only.

Ifexternalhumidity/temperaturesensorsareconnected,thesewillalsobefoundinthelist.Thereactivation

inlettemperature(Ri)beforetheheaterandreactivationtemperature(Rt)aftertheheater,aswellasthewet

airtemperature(Wt)andtheprocessairinlettemperature(T1)ismeasured.

NOTE!ThetemperaturewillbeshowninCelsius(metric,SI)orFahrenheit(imperial,IP),dependingontheunits

settingintheFunctionsmenu.

ThistableshowsthedisplayviewsandtypeofinformationoftheTemperaturemenu:

DisplayviewDescriptionT ype

Processairinlettemperature(internal

READONLY

sensor)

(Externalsensor)

(Externalsensor)

1

1

READONLY

READONLY

Settingoption

Reactivationtemperature

190TEN-1098-D1404Menusandparameters28

READONLY

Page 32

ComDryM160L

f

X

kWh

f

X

Wt 3 9 C

C

C

f

X

kWh

f

X

Ri 3 1 C

C

C

DisplayviewDescriptionT ype

1

)Onlyifexternalsensorisconnected

Table7.4Temperaturemenu

Wetairtemperature

Reactivationinlettemperature

Settingoption

READONLY

READONLY

29Menusandparameters190TEN-1098-D1404

Page 33

ComDryM160L

7.5Functions

7.5.1Processfanspeed

Tosetfanspeedyoumusthave“one-star”access,see6.8,Accessthecontrolsystem.Theprocessfanspeedcan

besetto[SpdHIGH],[SpdNORM]or[SpdLOW].Thecapacitiesandfancurvesinsectionandaregiven

atHIGHspeed.NORMALspeedwillreducethecapacityslightly,whileLOWspeedgivesapproximately

50%capacity .

See7.5.2,Processfanmodeforhowtosetthefanparameters.

7.5.2Processfanmode

Therearethreeprocessfanmodes:

FanmodeDescription

[FanON]In[FanON]mode,thedehumidierwillruntheprocessfancontinuously,regardlessofthereisa

dehumidicationneedornot.Thisisthedefaultmode.

[FanINT]

(INTermittent)

[FanDEM](on

DEMand)

In[FanINT](INT ermittent)mode,thefanwillstopwhenthedesiredhumidity(SetV alueminusHysteresis)

isreached.IfthehumidityreadingstaysbelowtheSetValue,theprocessfanwillanyhowstartafter30

minutestoletthebuilt-insensormoreaccuratelysensetheconditionoftheincomingprocessair.The

fanwillrunforaminutetoproduceapropermeasurement.IfthehumidityisstillbelowtheSetV alue,

thefanwillstopagain.ThisisrepeateduntilthehumidityreachestheSetV alue,whichwillmakethe

dehumidicationstartagain.

In[FanDEM](onDEMand)mode,thefanwillstopwhenthedesiredhumidity(SetValueminus

Hysteresis)isreached.Itwillstartagainwhenthesensedhumidityisequalto,orgreaterthantheSet

Value.Thisgivesinpracticeacontrolwithgreaterhysteresisthan“FanINT”,dependingonthefollowing:

Whenthedehumidierhasreachedthedesiredhumiditylevel,itwillshifttostand-byandstoptheprocess

fan.Afterawhile,internalmachineheatwillincreasethetemperatureofthehumiditysensor .Thismakes

thesensorreadingevenlower ,i.e.thesystemfunctionsasiftherewasa“negativehysteresis”.Asa

result,agreaterhumidityloadwillbenecessarytomakethedehumidierstartcomparedwiththe“Fan

INT”mode.

7.5.3Humiditycontrolandunits

Theinternalhumidity/temperaturesensor,“RH1”(locatedbehindtheprocessairlter),makesitpossible

tosetthecontrol/presentationofthehumiditytoeitherRelativehumidity(RH%),Dewpoint(Dp°C)

orabsolutehumidity(Xgr/kg).Dependingonunitsystemsetting,SIformetricorIPforImperial,the

readingswillbeshowninCelsiusandg/kg,orFahrenheitandgrain/lb.Allthesesettingsaremadeinthe

Functionsmenu.

190TEN-1098-D1404Menusandparameters30

Page 34

7.5.4Displayinformation

f

X

kWh

f

X

Spd NORM

C

C

f

X

kWh

f

X

FAN ON

C

C

f

X

kWh

f

X

S I

C

C

f

X

kWh

f

X

RH (%)

C

C

f

X

kWh

f

X

ID999 999

C

C

f

X

kWh

f

X

ACCE S S

C

C

ThistableshowsthedisplayviewsandtypeofinformationoftheFunctionsmenu:

ComDryM160L

DisplayviewDescriptionType

ProcessfanspeedADJUSTABLESpdHIGH,NORM,LOW

ProcessfanrunningmodesADJUSTABLEFanON,INT ,DEM

Metricorimperialunits

ADJUSTABLESI,IP

Settingoption

Humidity

Unitserialno

ADJUSTABLE

READONLY

RH,Dp,Absolutehumidity

IDno

ACCESSLevelADJUSTABLEACCESS*

31Menusandparameters190TEN-1098-D1404

Page 35

ComDryM160L

f

X

kWh

f

X

De fault

C

C

f

X

kWh

f

X

50Hz

C

C

Table7.5Functionsmenu

DisplayviewDescriptionType

Restoretodefaultsettings

RESETTABLE

(onlypossiblewhen

dehumidierisOFF).

MainsfrequencyADJUSTABLE

Settingoption

YesorNo

50or60Hz

190TEN-1098-D1404Menusandparameters32

Page 36

ComDryM160L

f

X

kWh

f

X

HEATER

C

C

f

X

kWh

f

X

No Ala rm

C

C

7.6Alarm

Shouldanoperationfaultoccur,theredalarmindicatorandthealarmmenuindicatorwillstarttoash.

Thecauseofthealarmwillbeshowninthedisplayandthedehumidierwillstopafterithascooleddown,

whichmighttakeacoupleofminutes.

CA

UTION!

CA CA

UTION! UTION!

Donotunplugthedehumidierwhileitiscoolingdown–theunderlyingreasonforthealarmmightbeoverheating.

ThistableshowsthedisplayviewsandtypeofinformationoftheAlarmmenu:

DisplayviewDescriptionType

SourceofalarminfulltextRESETTABLE

Table7.6Alarmmenu

Alarmstatus

READONLY

33Menusandparameters190TEN-1098-D1404

Page 37

ComDryM160L

7.7Min,maxanddefaultvalues

7.7.1Humidity

Thistableshowstheminimum,maximumanddefaulthumidityvalues:

Parameter

SV_RH50%

(setvalue)

(hysteresis)

Max.95404099300

Default

Min.

Max.10101,01010

HYS2%

Default

Min.000,000

RH(%)Dp(°C)X(gr/kg)Dp(°F)X(grain/lb)

5097,34951

5

220,222

-300,5-202

Table7.7Minimum,maximumanddefaulthumidityvalues

7.7.2Servicetime

Thistableshowstheminimum,maximumanddefaultservicetimevalues:

Parameter

T-4000h(servicetime)

Defaultsetting

40008000500

Table7.8Time,min/maxanddefaultservicetimevalues

7.7.3Functions

Max.Min.

ThistableshowsthedefaultsettingsandsettingoptionsoftheFunctionsmenu:

Parameter

SpdNORMSpdNORMSpdHIGH,SpdLOW

FanONFanON

SI(unit)SI(metricunits)IP(imperialunits)

RH(%)RH(%)

DefaultsettingOptions

Table7.9DefaultsettingsandsettingoptionsoftheFunctionsmenu

FanINT ,FanDEM

Dp(°C/°F)

X(gr/kg)/(grain/lb)

190TEN-1098-D1404Menusandparameters34

Page 38

ComDryM160L

8Serviceandmaintenance

8.1General

W

ARNING!

W W

ARNING! ARNING!

-Donotattempttorepair,dismantleormodifythisunit.

-Removethemainsplugfromthesocketbeforestartinganymaintenancework.

Thedehumidierisdesignedforcontinuoususeoveralongperiodoftimewithaminimalamountof

supervision.Undernormaloperatingconditions,maintenancerequirementsareminimal.Theservice

intervaldependsmainlyontheoperationalconditionsandworkingenvironment.

NOTE!ItisrecommendedtocontactMuntersforserviceorrepair.Operatingfaultscanoccuriftheunitis

maintainedinsufcientlyorincorrectly.

MuntersServicecanofferaserviceplanadaptedtosuittheconditionsofaspecicinstallation.Seecontact

addressesonthebackpageofthismanual.

8.2Maintenanceschedule

Muntersrecommendsthefollowingmaintenanceschedule.Theschedulecontainsinspectionand

maintenanceproceduresaswellastherecommendedintervalsforunitsusedundernormaloperatingand

environmentalconditions.Iftheprocessaircontainsalotofdust,preventativemaintenanceshouldbe

performedatshorterintervalsthanthosespeciedbelow.

Component

ProcesslterCleantheltercartridge.Cleanthelterhousing

Unitcasing

HumiditysensorNocorrectiveactionorcheck.

Functionalityandperformance

check

andreplacethelterifnecessary.

Checkforphysicaldamageandcleanthe

outsideoftheunitasnecessary.

Nocorrectiveactionorcheck.

4000hours/6months8000hours/12months

Inspection/maintenance

Cleanthelterhousingandreplacethelter.

Checkforphysicaldamageandcleanthe

outsideoftheunitasnecessary.Checkany

lineconnectionstoensuretheyareproperly

attachedandthatthereisnoairleakage.

Checkthesensorfunctionandreplaceas

necessary.

Performacompletefunctionalityand

performancecheck,andreplacewornpartsas

necessary.

Table8.1Maintenanceschedule

35Serviceandmaintenance190TEN-1098-D1404

Page 39

ComDryM160L

8.3Processairlterchange

1.Pushthelterframedown.

2.Pullthelterholderoutwardsandremoveitfromthe

unit.

Figure8.1

3.Removetheoldlter.

4.Replaceitwithanewlter.

Figure8.2

Figure8.3

190TEN-1098-D1404Serviceandmaintenance36

Page 40

ComDryM160L

9Faulttracing

W

ARNING!

W W

ARNING! ARNING!

Theunitmustnotbeopenedbyanyoneotherthantrainedandqualiedpersonnel,duetotheriskofelectrical

shock.

Thischapterisintendedtofacilitatebasictroubleshootingandtoprovideinstructionsforcorrectiveactions.

Gothroughthetroubleshootinglistbelow .ContactMuntersiftheproblemcannotberectied.

SymptomIndication/Alarmmessage

Unithasstopped

Nodisplaytext

GreenLEDisashing:

longon,shortoff

sequence

Alarmmessage:

[SENSORFAILURE]

Alarmmessage:

[HEATERFAILURE]or

[HIGHRiTEMP]or

[HIGHRtTEMP]

Alarmmessage:

[HIGHWtTEMP]

Alarmmessage:

[DRAINFAILURE]

PossiblecauseAction

Powersupplyfault.Checkpowersupplytotheunit.

BlownfuseReplacethefuse.Forcorrecttypeandrating,seelabel

Thereisnoneedfor

dehumidication.Measured

humidityisbelowtheset

point

(modeFan"DEM"or"INT").

Brokensensor

-Overtemperature

protectionfusemighthave

tripped

-Blockedlter ,hoseorduct

-Blockedimpeller

SetValueRHistoolowindry

environment

RotordrivemechanismfaultCheckrotordrivebeltanddrivemotor.

Condensatedrainhose

clogged

abovepowersupplycordconnectiontotheunit.

None.Theunitisinstand-by.Itwillstartwhenthe

measuredhumidityreachestheSetValue.

ContactMunters.

Waituntiltheunithasstopped.Thendisconnectthe

powersupply.Checkthatthelters,hosesorductsarenot

clogged.

Toresettheovertemperatureprotectionfuse,theunitmust

bedisconnectedfromthemainsandallowedtocooldown.

Ifthealarmisreissuedaftertheunithascooleddownand

thealarmhasbeenreset,contactMunters.

CheckiflowSetV alueRHisnecessary.Adjusttohigher

value.

Checkthroughthedryairoutletthattherotorrotatesat

approximatelytenrevolutionsperhour .Ifrotordoesnot

rotate,contactMunters.

Cleanorreplacethehose

KinksonthehoseMakesuretherearenokinksonthehose.Installtheunitat

Alarmmessage:

[MAINSVOLTAGELOW]

Alarmmessage:

[LONGSTOPTIME]

Alarmmessage:

[TIMEFORSERVICE]

Indication

Alarmmessage:

[NOCOM]

Unitisconnectedtothe

wrongvoltage,orproblem

withthesupply

Brokenfan

Heaterison

CANBUSemptyplugs

orexternalconnection

missing.

least25cmabovetheoorlevel.

Checkmainssupply .

ContactMunters.

SeesectionServiceintervalalarm.

Reinstallplugsorconnectioncable.Ifalarmremains,

contactMunters.

37Faulttracing190TEN-1098-D1404

Page 41

ComDryM160L

SymptomIndication/Alarmmessage

Lossof

performance.

Thedehumidier

isrunningbutis

notcontrolling

thehumidity.

Table9.1Faulttracinglist

PossiblecauseAction

Lowreactivation

temperature

LowreactivationairowCheckthelterandanyhosesorductsforleakageor

CheckthatthehumiditySetValueislowerthanthe

measuredhumidity.

blockage.Theuseofarestrictingangeincombination

withwallpipescancausetoolittlereactivationairow.

190TEN-1098-D1404Faulttracing38

Page 42

10Technicalspecication

B

A

C

F

2

1

3

ComDr y M160L

G

G

10.1Dimensionsandservicespace

ComDryM160L

Figure10.1Dimensions,ComDryM160L

1.Processairinlet

2.Dryairoutlet

3.Coolingair

Width

(A)

445mm270mm

Width

(B)

Height

(C)

555mm

Diameter

(Dryair)

100mm12.5mm350mm500mm17kg

Diameter

Drainhose

Service

space

(F)

Service

space

(G)

Weight

Table10.1Dimensionsandweight

39Technicalspecication190TEN-1098-D1404

Page 43

ComDryM160L

ComDry M160L

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0 5 °C 10 °C 15 °C 20 °C 25 °C 30

(kg/h )

40 %

60 %

80 %

°C

3

1

2

ComD ry M160L High speed

0

20

40

60

80

100

120

140

160

180

200

220

240

B m³/h

A (Pa)

0

25

50

75 100

125

150

175

200

10.2Capacitydiagram

Figure10.2Capacitydiagram

10.3Fancurveprocessair

1.T emperature,

processair(°C)

2.RelativeHumidity,

processair(%RH)

3.Dehumidicationcapacity

(kg/h)

(moistureremoval(kg/hour))

Figure10.3Fancurve

190TEN-1098-D1404Technicalspecication40

Density1,2kg/m

A.Staticpressure(Pa)

B.Airow(m

3

3

/hour)

Page 44

10.4Technicaldata

ComDryM160L

Processair

Free-blowingair50/60Hz(m³/h)

Ratedairowat40Pa(m³/h)

Max.staticpressure50/60Hz(Pa)

Fanmotorpower(kW)

Reactivationair

Heaterpower(kW)

Factorysetreactivationtemperature(Rt)limit(°C)

Temperatureincreaseacrossheater(°C)

Fanmotorpower(kW)

Other

DriveMotorPower(W)

Soundpressurelevel,Lowspeedfree-blowingprocessfan(dBA)

Soundpressurelevel,Normalspeedfree-blowingprocessfan(dBA)

Soundpressurelevel,Highspeedfree-blowingprocessfan(dBA)

Electricalprotectionclass(casing)

Electricalprotectionclass(electricpanel)

FanMotorWindingInsulationClassClassB

DriveMotorWindingInsulationClassClassB

Rotortype

AirlterG3,articlenumber

Environmentalconditions

Operatingtemperature(°C)

Maximuminstallationaltitude,abovesealevel(m)

Transportandstoragetemperature(°C)

Totalpower,voltageandcurrentVersion

(1)

160

150

225

0,09

0,84

130

100

0,08

5

55

61

67

IP33

IP54

HPS

150-012054-001

0...+30

2000

-20...+70

Voltage(V)

Frequency(Hz)50/6050/60

Totalpower(W)

Current(A)

Fuse

(1)

Thespeciedperformanceisbasedon20°Candairdensityof1.2kg/m³.

115230

10101010

8,84,4

3AG,250VAC,10ASlow3AG,250V AC,6ASlow

Table10.2TechnicaldataM160L

41Technicalspecication190TEN-1098-D1404

Page 45

ComDryM160L

11Scrapping

Theunitmustbescrappedinaccordancewithapplicablelegalrequirementsandregulations.Contactyour

localauthorities.

Therotormaterialisnotcombustible,andshouldbedepositedlikeglassbrematerials.

Iftherotorhasbeenexposedtochemicalsthataredangeroustotheenvironmenttheriskmustbeassessed.

Thechemicalscanaccumulateintherotormaterial.Takethenecessaryprecautionstocomplywith

applicablelegalrequirementsandregulations.

W

ARNING!

W W

ARNING! ARNING!

Iftherotoristobecutinpieces,wearasuitableCEmarkedfacemaskselectedandttedinaccordancewiththe

applicablesafetystandardstoprotectfromthedust.

190TEN-1098-D1404Scrapping42

Page 46

Page 47

ComDryM160L

12ContactMunters

AUSTRIA

BELGIUM

CZECHREPUBLIC

DENMARK

FINLAND

FRANCE

GERMANY

ITAL Y

NETHERLANDS

POLAND

SPAIN

SWEDEN

SWITZERLAND

UNITEDKINGDOM

MuntersGmbH

AirTreatment

ZweigniederlassungWien

MuntersBelgiumnv

AirTreatment

MuntersCZ,organizacnislozka

AirTreatment

MuntersA/S

AirTreatment

MuntersFinlandOy

Kuivaajamyynti

MuntersFranceSAS

AirTreatment

MuntersGmbH

AirTreatment-Zentrale

MuntersItalyS.p.A

AirTreatment

MuntersV ochtbeheersingEnergieweg69

MuntersSp.zo.o.

OddzialwPolsce

AirTreatment

MuntersSpainSA

AirTreatment

MuntersEuropeAB

AirTreatment

MuntersGmbH

AirTreatment

ZweigniederlassungRümlang

MuntersLtd

AirTreatment

Eduard-Kittenberger-Gasse56,

Obj.6

A-1235Wien

Blarenberglaan21c

B-2800Mechelen

Slevacská2368/68

CZ-61500BRNO

Ryttermarken4

DK-3520Farum

Hakamäenkuja3

FI-01510V ANTAA

106,BoulevardHéloise

F-95815ArgenteuilCedex

Hans-Duncker-Str.8

D-21035Hamburg

StradaPiani2

I-18027Chiusavecchia

IM

NL-2404HEAlphena/dRijn

ul.Swietojanska55/11

81-391Gdynia

EuropaEpresarial.EdicioLondres.

C/PlayadeLiencres2.

28230LasMatas.Madrid

POBox1150

S-16426Kista

Glattalstr.501

CH-8153Rümlang

PathnderPlace10RamsayCourt

HinchingbrookeBusinessPark

HuntingdonPE296FYCambs

Tel:+4316164298–9251

luftentfeuchtung@munters.at

www.munters.at

Tel:+321528561 1

service@muntersbelgium.be

www.muntersbelgium.be

Tel:+420775569657

info@munters-odvlhcovani.cz

www.munters-odvlhcovani.cz

Tel:+4544953355

info@munters.dk

www.munters.dk

Tel:+358207768230

laitemyynti@munters.

www.munters.

Tel:+331341 15757

dh@munters.fr

www.munters.fr

Tel:+49(0)40879690-0

mgd@munters.de

www.munters.de

Tel:+390183521377

marketing@munters.it

www.munters.it

Tel:+31172433231

vochtbeheersing@munters.nl

www.munters.nl

Tel.:+48583053517

dh@munters.pl

www.munters.com.pl

Tel:+34916400902

marketing@munters.es

www.munters.es

Tel:+4686266300

avfuktning@munters.se

www.munters.se

Tel:+41523438886

info.dh@munters.ch

www.munters.ch

Tel:+441480432243

info@munters.co.uk

www.munters.co.uk

AUSTRALIA

BRAZIL

CANADA

CHINA

INDIA

JAPAN

KOREA

190TEN-1098-D1404ContactMunters44

Tel:+61288431588

dh.info@munters.com.au

Tel:+551150540150

www.munters.com.br

Tel:+1-800-843-5360

dhinfo@munters.com

Tel:+861080418000

marketing@munters.cn

Tel:+912066818900

info@munters.in

Tel:+81359700021

mkk@munters.jp

Tel:+8227618701

munters@munters.kr

MEXICO

SINGAPORE

SOUTHAFRICA

TURKEY

UAE(Dubai)

USA

Tel:+527222704029

munters@munters.com.mx

Tel:+6567446828

singapore@muntersasia.com

Tel:+27119972000

info@munters.co.za

Tel:+902165481444

info@muntersform.com

Tel:+97148813026

middle.east@munters.com

Tel:+1-800-843-5360

dhinfo@munters.com

Page 48

www.munters.com

Loading...

Loading...