Page 1

AC-2000

3G

Manual for use and maintenance

AC-2000 3G

Climate Controller

Ag/MIS/Um/Gb-2792-01/21 Rev 1.0

P/N: 117336

Page 2

AC-2000 3G

Manual for use and maintenance

Revision: N.1.0 of 01/2021

Product Software: 9.19

This manual for use and maintenance is an integral part of the apparatus together with the attached

technical documentation.

This document is destined for the user of the apparatus: it may not be reproduced in whole or in part,

committed to computer memory as a file or delivered to third parties without the prior authorization of

the assembler of the system.

Munters reserves the right to effect modifications to the apparatus in accordance with technical and

legal developments.

© Munters AB, 2018 2

Page 3

Index

Chapter page

1

INTRODUCTION -------------------------------------------------------------------------------------------------------------------------------------- 3

1.1 Disclaimer

1.2 Introduction

1.3 Notes

2

INTRODUCTION TO THE AC-2000 3G ------------------------------------------------------------------------------------------- 4

2.1 Keypad

2.2 Hot Screens

2.3 Standard Display

2.4 Main Menu Icons

2.5 Cold Start

3

CONTROL MENU ------------------------------------------------------------------------------------------------------------------------------------ 9

3.1 Temperature Curve

3.1.1 Temperature Curve Help | Set Definitions

3.1.2 Radiant Heaters Help | Set Definitions

3.1.3 Cycle Heaters | Set Definitions

3.1.4 Variable Heater Help | Set Definitions

3.1.5 Variable Floor Heater | Set Definitions

3.2 Introduction to Humidity, Ammonia, and CO2 Treatment

3.3 Humidity Treatment

3.3.1 Humidity Treatment Help | Set Definitions

3.4 CO2 Treatment

3.4.1

3.5 Min/Max Level

3.5.1 By Day and By Soft Days Curve

3.5.2 By Time

3.5.3 Day Soft Min.

3.5.4 By Weight

3.6 Static Pressure

3.6.1 Disabling the Static Pressure Sensor

3.6.2 Static Pressure Help | Set Definitions

3.6.3 Multi Stage Tunnel Curtains

3.7 Control Mode

3.8 System Parameters

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------

.....................................................................

...........................................................................

..........................................................................................

...........................................................................

...........................................................................

--------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------

.....................................................................

--------------------------------------------------------------------------------------------------------------------------------------------------------

CO2 Treatment Help | Set Definitions

--------------------------------------------------------------------------------------------------------------------------------------------------------

........................................................................................................................................

............................................................................................................................

...................................................................................................................................

-----------------------------------------------------------------------------------------------------------------------------------------------------------

.................................................................................................

-----------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------

............................................................................

........................................................................................

.................................................................................

...............................................................................

10

11

12

13

16

17

17

18

19

20

20

21

21

22

22

27

27

28

28

29

29

3

3

3

4

5

6

7

8

9

© Munters AB, 2018 3

Page 4

3.9 Ammonia Treatment

----------------------------------------------------------------------------------------------------------------------------------------------

3.9.1 Ammonia Treatment Help | Set Definitions

....................................................................

30

31

4

DEVICE MENU --------------------------------------------------------------------------------------------------------------------------------------- 32

4.1 Levels of Ventilation

4.1.1 Levels of Ventilation Help | Set Definitions

4.1.2 Wind Chill

4.2 Variable Speed Fan Levels

4.3 Vent & Curtain Levels

4.3.1 Vent & Curtain Levels Help | Set Definitions

4.4 Stir Fan Levels

4.5 Stir Fan Program

4.5.1 Stir Fan Program Help | Set Definitions

4.6 Cool Pad

----------------------------------------------------------------------------------------------------------------------------------------------------------------------

4.6.1 Cool Pad Help | Set Definitions

4.7 Foggers

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

4.7.1 Foggers Help | Set Definitions

4.8 Light

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

4.8.1 Light Help | Set Definitions

4.9 Water & Feed

4.9.1 Water and Feed Help | Set Definitions

4.10 Extra Systems

4.11 Water on Demand

4.11.1 Relay Control

4.11.2 Sensor Control

-----------------------------------------------------------------------------------------------------------------------------------------------

....................................................................

...................................................................................................................................

--------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------

.................................................................

------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------

..........................................................................

.........................................................................................

...........................................................................................

..................................................................................................

-----------------------------------------------------------------------------------------------------------------------------------------------------------

..........................................................................

------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------

.............................................................................................................................

..........................................................................................................................

33

34

35

35

36

37

37

38

39

40

41

42

42

43

44

45

46

47

47

48

48

5

MANAGE MENU ---------------------------------------------------------------------------------------------------------------------------------- 50

5.1 Inventory

5.2 Feed Inventory

5.2.1 Feed Inventory Help | Set Definitions

5.3 Time & Date

5.4 Growth Day & Flock

5.5 Alarm Setting

5.5.1 Alarm Setting Help | Set Definitions

5.6 Alarm Reset

5.7 Password

6

SCALE MENU ----------------------------------------------------------------------------------------------------------------------------------------- 57

6.1 Scale Layout

6.2 General Settings

6.2.1 General Settings Help | Set Definitions

6.3 Bird Scale Setting

----------------------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------

..............................................................................

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------

.................................................................................

----------------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------

..........................................................................

----------------------------------------------------------------------------------------------------------------------------------------------------

50

51

51

51

52

52

54

56

56

57

57

58

58

© Munters AB, 2018 4

Page 5

6.3.1 Bird Scale Setting, Version 9.18 and Below

6.3.2 Bird Scale Setting, Version 9.19

6.4 Bird Curve/Bird Weight

--------------------------------------------------------------------------------------------------------------------------------------

6.4.1 Bird Curve, Version 9.18 and Below

6.4.2 Bird Weight, Version 9.19

6.5 History

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------

...................................................................................................

6.5.1 History, Version 9.18 and Below

6.5.2 History, Version 9.19

6.6 Feed Conversion

6.7 Test

6.8 Calibration

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------

.............................................................................................................

.................................................................

........................................................................................

...............................................................................

.......................................................................................

58

59

59

60

60

61

61

62

63

63

63

7

HISTORY MENU ------------------------------------------------------------------------------------------------------------------------------------ 65

7.1 Temperature

7.2 Humidity

7.3 CO2

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

7.4 Water

7.5 Feed

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

7.6 Mortality

7.7 Heaters

7.8 Radiant Heaters

7.9 Alarms

7.10 Table of Events

7.11 History View

8

TEST MENU --------------------------------------------------------------------------------------------------------------------------------------------- 68

8.1 Relays

8.2 Alarm

8.3 Analog Sensors

8.4 Digital Sensors

8.5 Analog Output

8.6 Static Pressure

8.7 Communication

---------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------

65

65

65

66

66

66

66

67

67

67

67

68

68

69

69

69

70

70

9

SERVICE MENU ------------------------------------------------------------------------------------------------------------------------------------- 71

9.1 Temperature Calibration

9.2 Humidity Calibration

9.3 CO2 Sensor Calibration

9.4 Static Pressure Calibration

9.5 Light Sensor Calibration

9.6 Feed Calibration

------------------------------------------------------------------------------------------------------------------------------------------------------

9.7 Water Calibration

© Munters AB, 2018 5

-------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------

71

72

72

73

74

74

75

Page 6

9.8 Ventilation Potentiometer Calibration

9.9 Save Settings to SD Card

9.10 Read from SD Card

9.10.1 Load Settings Report

9.11 WOD Calibration

---------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------

...............................................................................................................

9.11.1 WOD Calibration Help | Set Definitions

---------------------------------------------------------------------------------------------------------

........................................................................

75

76

77

77

78

78

10 INSTALL MENU -------------------------------------------------------------------------------------------------------------------------------------- 79

10.1 Setup

10.1.1 Static Pressure Unit Definition

10.2 Relay Layout

10.2.1 Supported Relays

10.2.2 Relay Layout – Help | Set Definitions

10.3 Analog Sensors

10.4 Digital Sensors

10.5 Analog Output

10.6 Vent/Curtain Setup

10.6.1 Using Time to Calibrate

10.6.2 Using a Potentiometer to Calibrate

10.6.3 Vent/Curtain Help | Set Definitions

10.7 Temperature Definition

10.8 Fan Air Capacity

10.9 House Dimensions

10.10 Communication

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

..............................................................................................

--------------------------------------------------------------------------------------------------------------------------------------------------------------

.....................................................................................................................

..............................................................................

--------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------

.........................................................................................................

...................................................................................

..................................................................................

----------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------

79

80

80

80

81

81

82

83

83

83

84

84

85

86

86

87

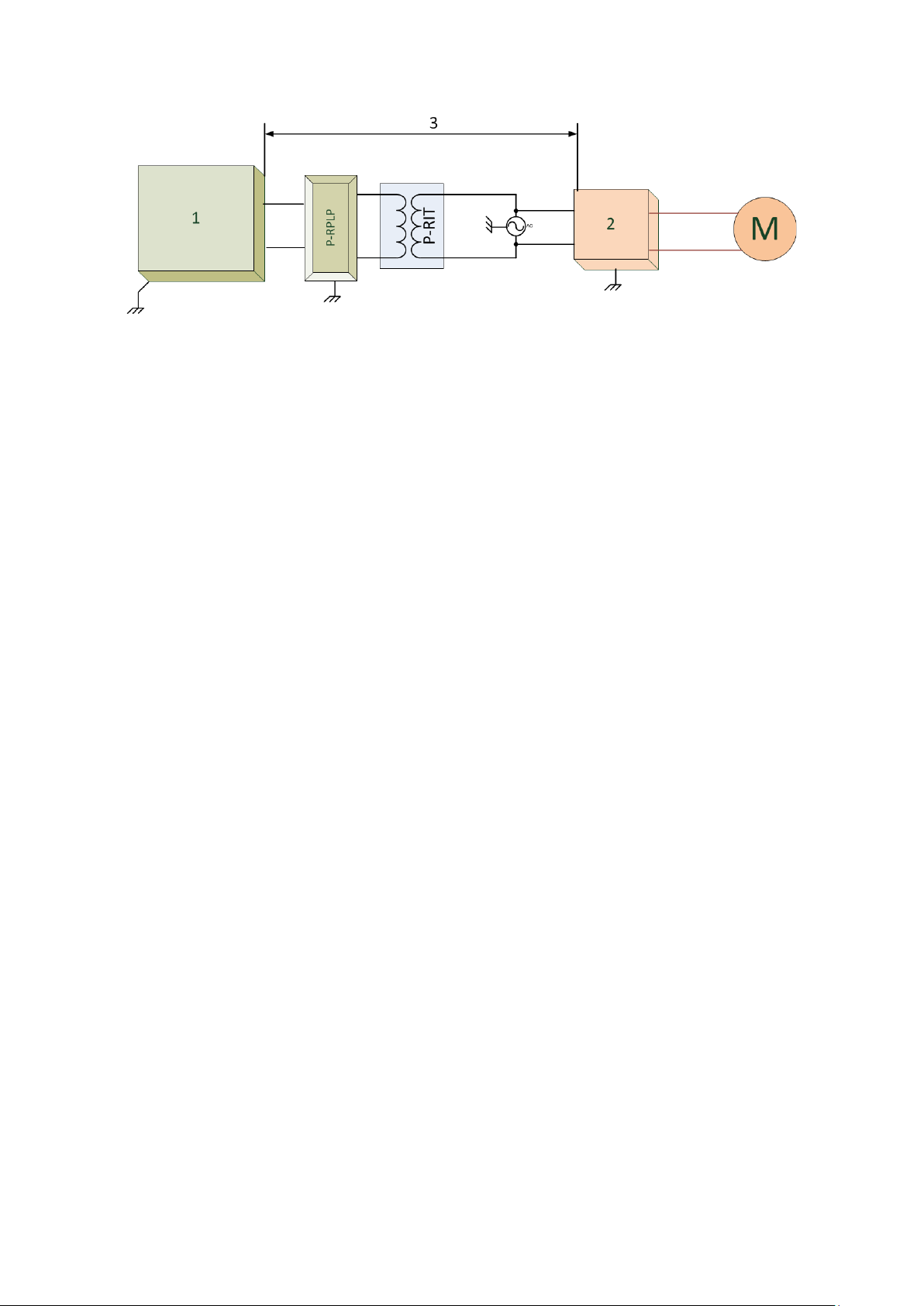

11 TECHNICAL SPECIFICATIONS --------------------------------------------------------------------------------------------------------- 88

12 INSTALLATION --------------------------------------------------------------------------------------------------------------------------------------- 89

12.1 Precautions

12.1.1 Grounding

12.1.2 Filtering

12.1.3 Checking the Battery Level

12.1.4 Frequency Inverters

12.2 Mounting the Unit

12.3 AC-2000 3G Wiring

12.3.1 Board Layout

12.3.2 Relays

12.3.3 High Voltage Wiring (Relays)

12.3.4 Terminal Setup

12.4 Communication Card

12.4.1 Wiring

12.4.2 Communication Card Grounding

-----------------------------------------------------------------------------------------------------------------------------------------------------------------

..................................................................................................................................

........................................................................................................................................

...................................................................................................

.................................................................................................................

---------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------

.............................................................................................................................

...........................................................................................................................................

.............................................................................................

..........................................................................................................................

-------------------------------------------------------------------------------------------------------------------------------------------

..........................................................................................................................................

...................................................................................

101

89

89

89

89

89

90

91

91

92

93

94

98

99

© Munters AB, 2018 6

Page 7

12.4.3 Termination and 5V Setup

.................................................................................................

101

13 APPENDIX A: DATA OUTPUT ---------------------------------------------------------------------------------------------------------- 104

14 APPENDIX B: INSTALLING A CO2 SENSOR AND SECOND HUMIDITY SENSOR ---- 107

14.1 Humidity Sensor

14.2 CO2 Sensor

----------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------

108

108

15 APPENDIX C: AC-2000 3G PANEL MOUNT ---------------------------------------------------------------------------- 110

15.1 Metal Assembly Precautions

15.2 Panels

15.3 Panel Dimensions

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------

15.4 Connecting the Metal Panels

15.4.1 Precautions

..............................................................................................................................

15.4.2 Panel Mount Cable Connections

-------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

....................................................................................

110

110

111

111

111

112

16 APPENDIX D: ELECTRICAL GROUNDING FOR CONTROLLERS ---------------------------------------- 113

16.1 Ground Rods

16.2 Ground Wire

16.3 Ground Clamps

16.4 What Should Be Grounded?

----------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

113

114

114

114

17 WARRANTY ------------------------------------------------------------------------------------------------------------------------------------------ 115

© Munters AB, 2018 7

Page 8

1 Introduction

1.1 Disclaimer

Munters reserves the right to make alterations to specifications, quantities, dimensions etc. for production

or other reasons, subsequent to publication. The information contained herein has been prepared by

qualified experts within Munters. While we believe the information is accurate and complete, we make no

warranty or representation for any particular purposes. The information is offered in good faith and with

the understanding that any use of the units or accessories in breach of the directions and warnings in this

document is at the sole discretion and risk of the user.

1.2 Introduction

Congratulations on your excellent choice of purchasing an AC-2000 3G!

In order to realize the full benefit from this product it is important that it is installed, commissioned and

operated correctly. Before installation or using the controller, this manual should be studied carefully. It is

also recommended that it is kept safely for future reference. The manual is intended as a reference for

installation, commissioning and day-to-day operation of the Munters Controllers.

1.3 Notes

Date of release: July 2010

Munters cannot guarantee to inform users about the changes or to distribute new manuals to them.

All rights reserved. No part of this manual may be reproduced in any manner whatsoever without the

expressed written permission of Munters. The contents of this manual are subject to change without notice.

© Munters AB, 2021 3

Page 9

2 Introduction to the AC-2000 3G

This document describes the AC-2000 3G Precision Mode operation.

Computerized Electronic Controllers such as the AC-2000 3G advance the producer’s ability to grow

high quality eggs by accurately controlling the environment. Instead of struggling with individual

thermostats for heat zones and ventilation, AC-2000 3G brings them all together into one convenient

place with great accuracy. The AC-2000 3G optimizes and precisely applies your equipment and energy

sources to most benefit from the accuracy of your computer and sensors.

The AC-2000 3G coordinates your ventilation equipment in precise levels of ventilation to provide the

optimal fresh air balanced with heating costs. The light and feed clocks provide additional channels for

greater capability. Besides advanced Cooling Pad methods, you benefit from superior stir fan programs

to recover ceiling heat and other features. Precision Mode’s additional features enable you to improve

your profitability significantly.

AC-2000 3G provides a variety of management and history utilities. You can choose from simple

overviews, or fully detailed

by the minute

records of minimum, maximum and average temperatures for

each individual sensor. The unique Table of Events records the moment of every significant action taken

by the AC-2000 3G and, optionally, its operator.

•

Keypad, page 4

•

Hot Screens, page 5

•

Standard Display, page 6

•

Main Menu Icons, page 7

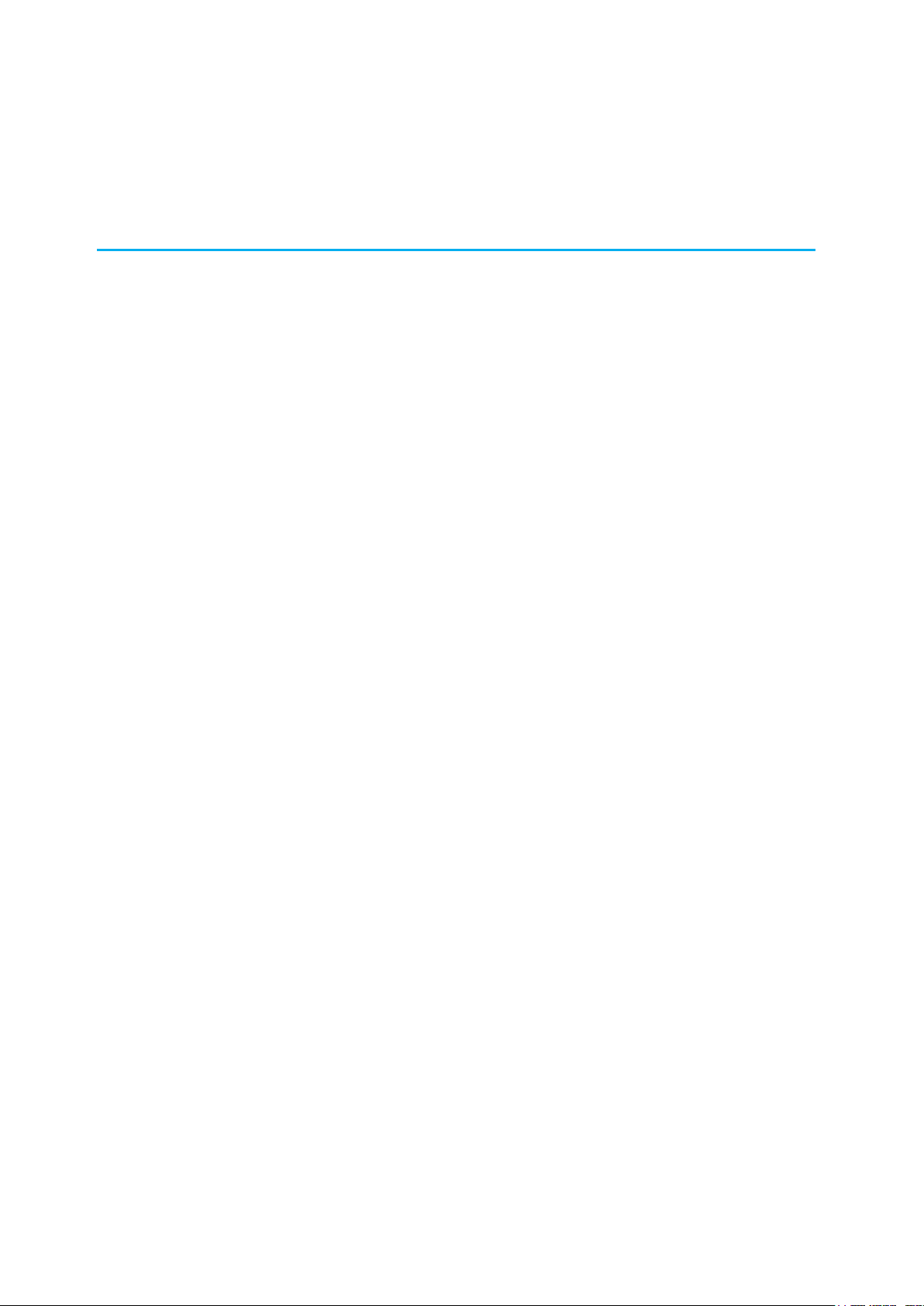

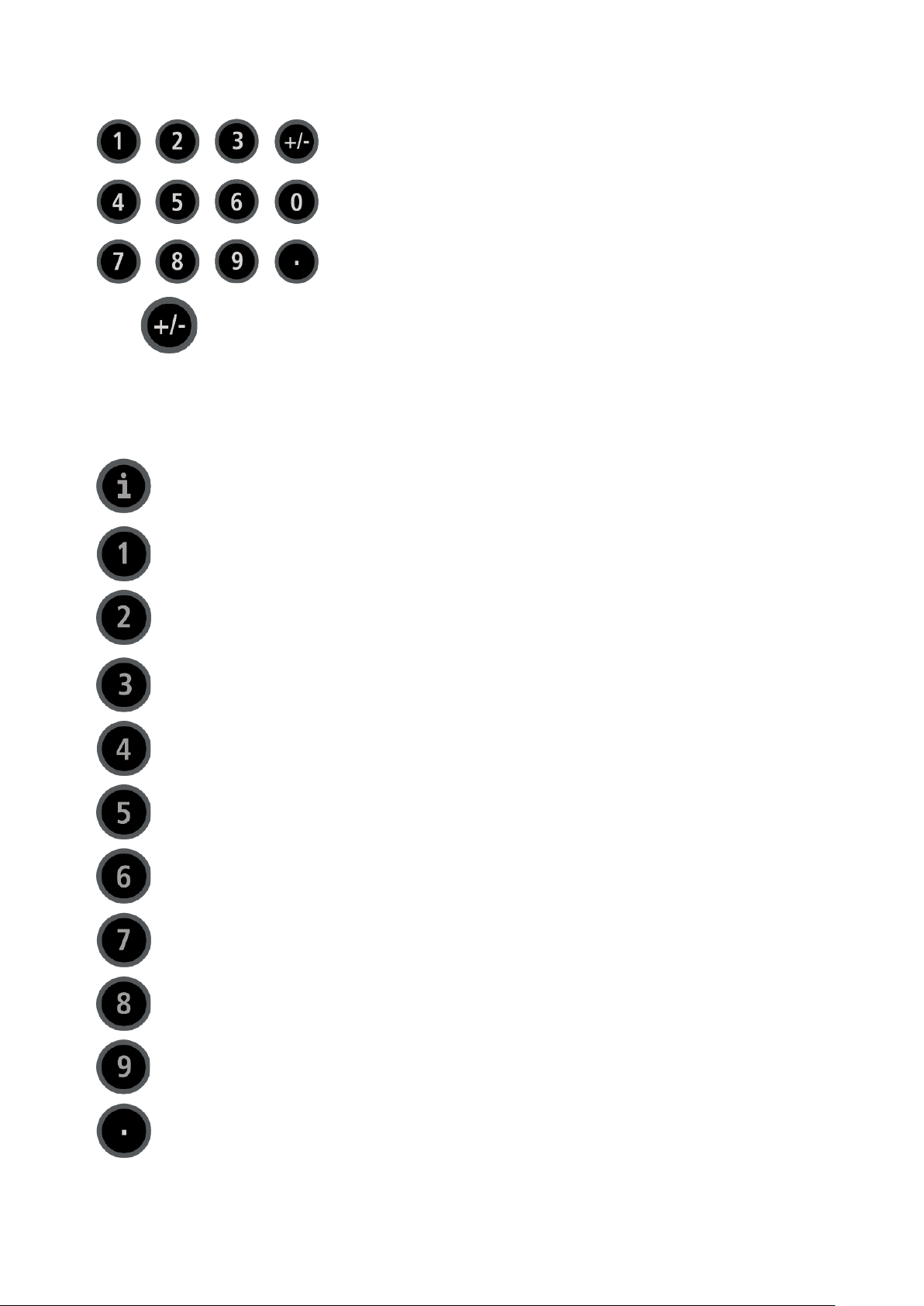

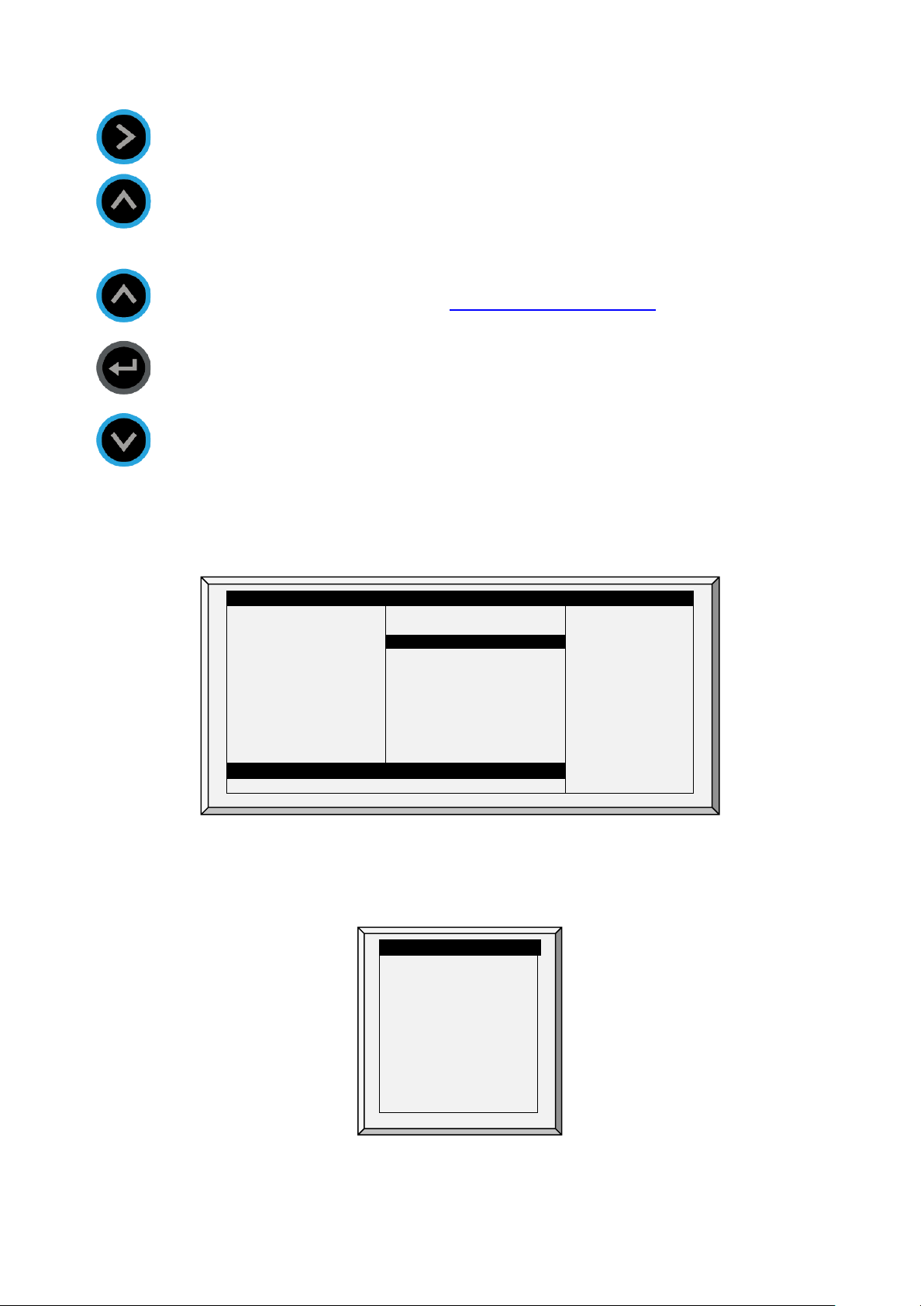

2.1 Keypad

Enter main menu, also acts as "ESC" or "Back" key

Access help screens and graphs

Erase typing mistakes

Enter menus, values, open windows

Scroll up, down, left and right

© Munters AB, 2021 4

Page 10

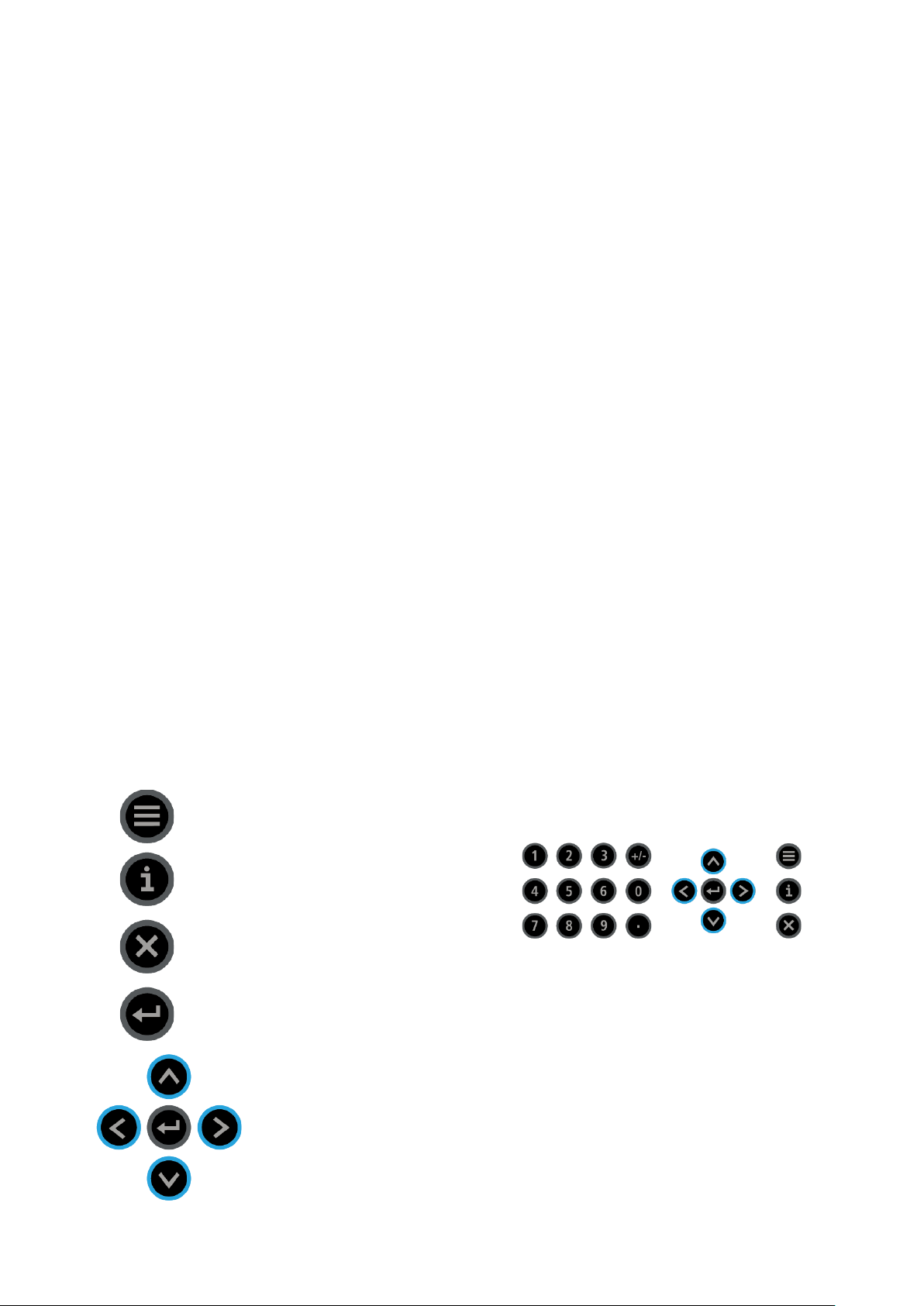

Enter values, select options and make selections

Toggle between positive and negative values and mark check boxes.

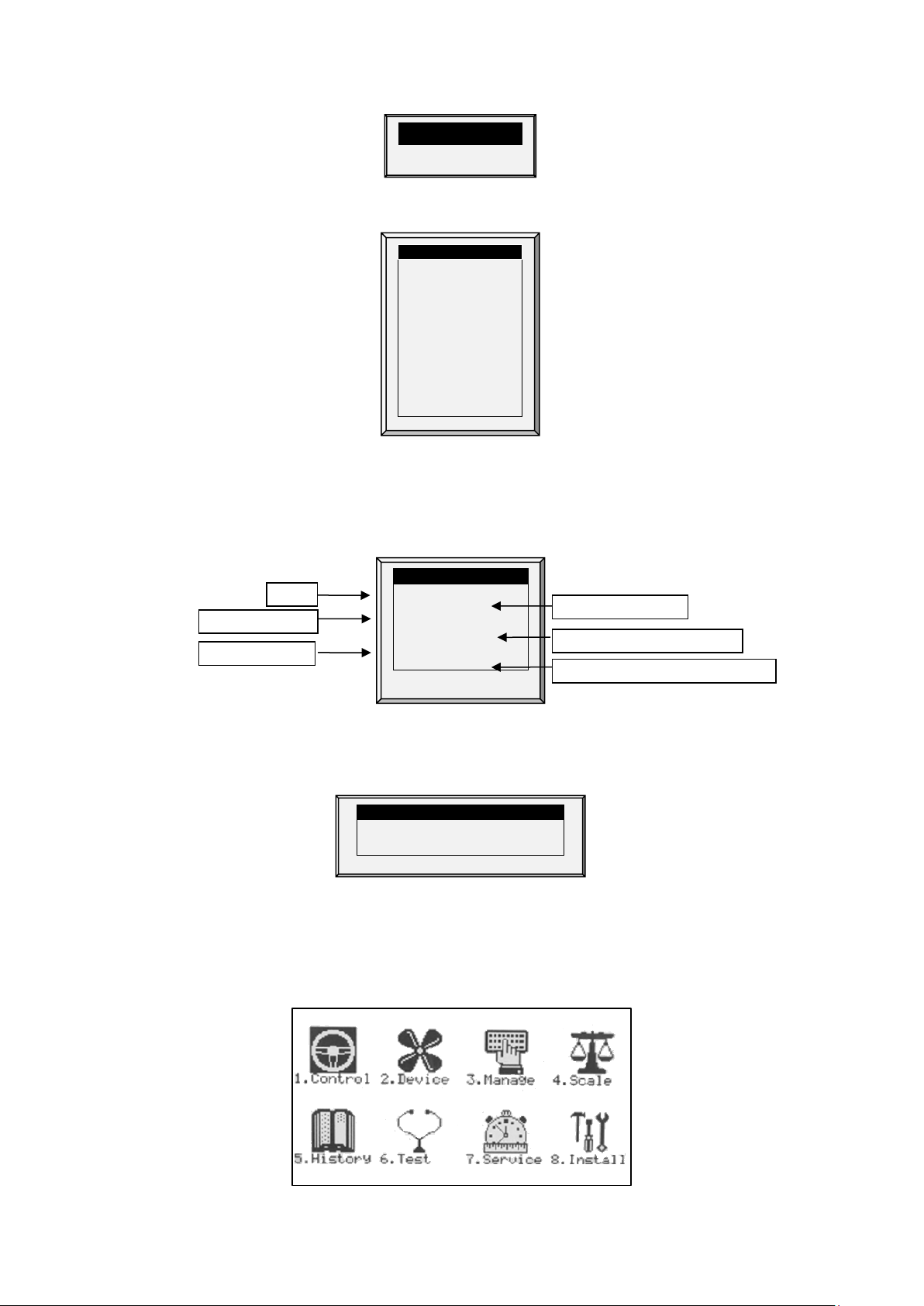

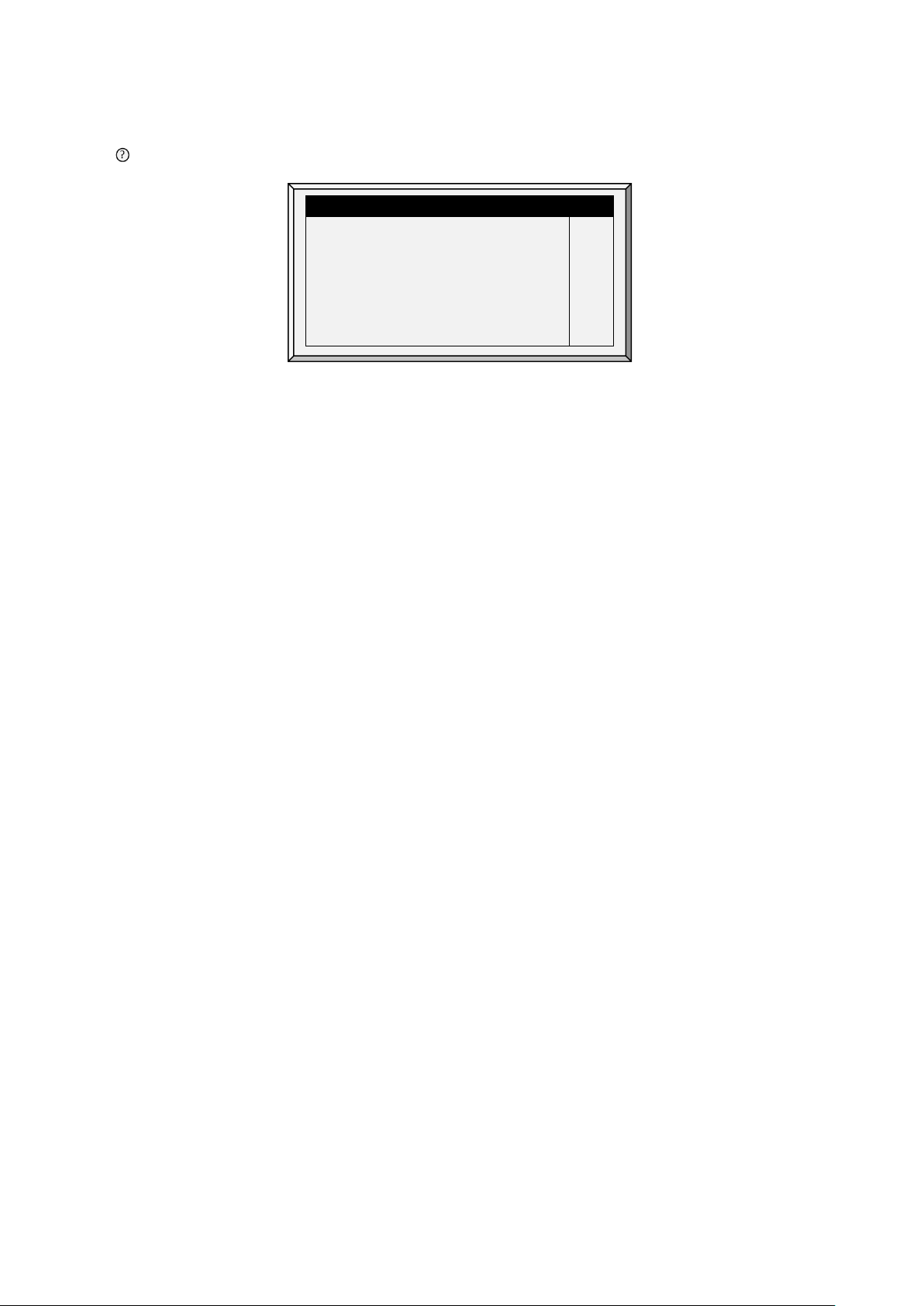

2.2 Hot Screens

Many of the keys serve as shortcuts. Here are the main ones:

Software version

Return to standard main screen

Temperature, Humidity Status, and Wind Chill Temperature

NOTE If two humidity sensors are installed, Hot Screen 2 displays their average.

Curve status

Curtain tunnel, vent, and attic opening positions

Bird scale status

Light status

Analog output status

Temperature sensors

Feed bin status

Scan through Hot Screens for five seconds each

© Munters AB, 2021 5

Page 11

Stir fans status

Increase/ decrease offset from temperature setting from the standard display only

SENSORS

AV. TEMP.

ACTI VE

Temp1

37.9°

27.5°

Heat 1 Temp2

16.2°

Heat. Hi

1

Temp3

28.2°

STATUS

Tun. Fan

E. Tmp1

28.8°

08:53:06

Exh. Fan

E. Tmp2

28.4°

Day: 5

Stir

Press.

23

Set:

25.0

Cool P.

Out T.

23.9°

Level:

3

Fogger

Hum. In

58.7%

Min.

Vent

Curt. 1

100%

Hum. Out

61.9%

FanOff:

176

Curt. 2

100%

Weight

0.000

Curt. 3

0%

Weights

0 Curt. 4

0%

4 MESSAGES

Ext. Sys

(2) Low Feed At Bin 2

Alarm SENSORS

Temp1

37.9°

Temp2

16.2°

Temp3

28.2°

E. Tmp1

28.8°

E. Tmp2

28.4°

Press.

23

Out T.

23.9°

Hum. In

58.7%

Hum. Out

61.9%

Weight

0.000

Weights

0

Air Status (refer to Weight Hot Screen, page 26 for details on this screen)

(hold both keys) – defined in the T

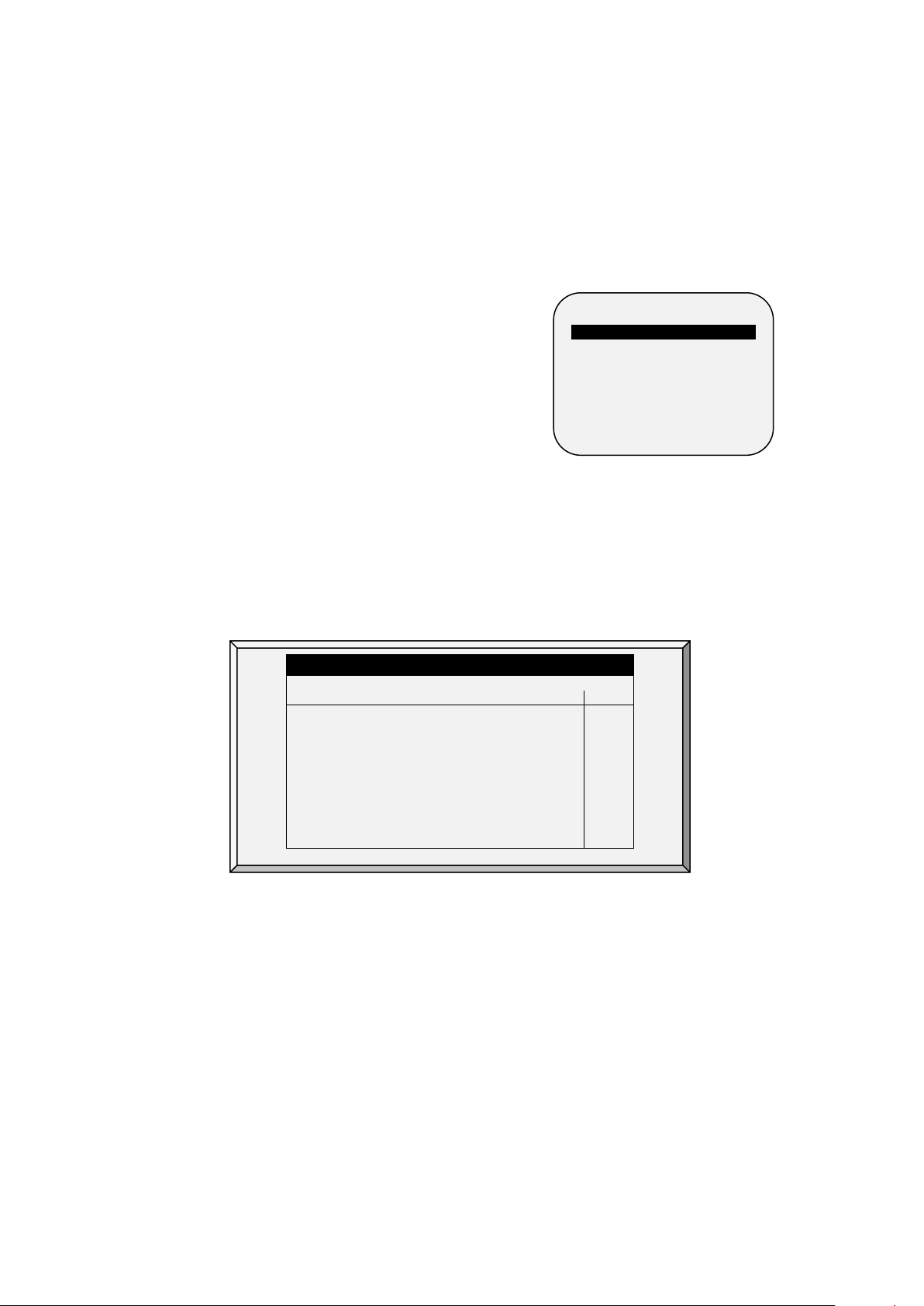

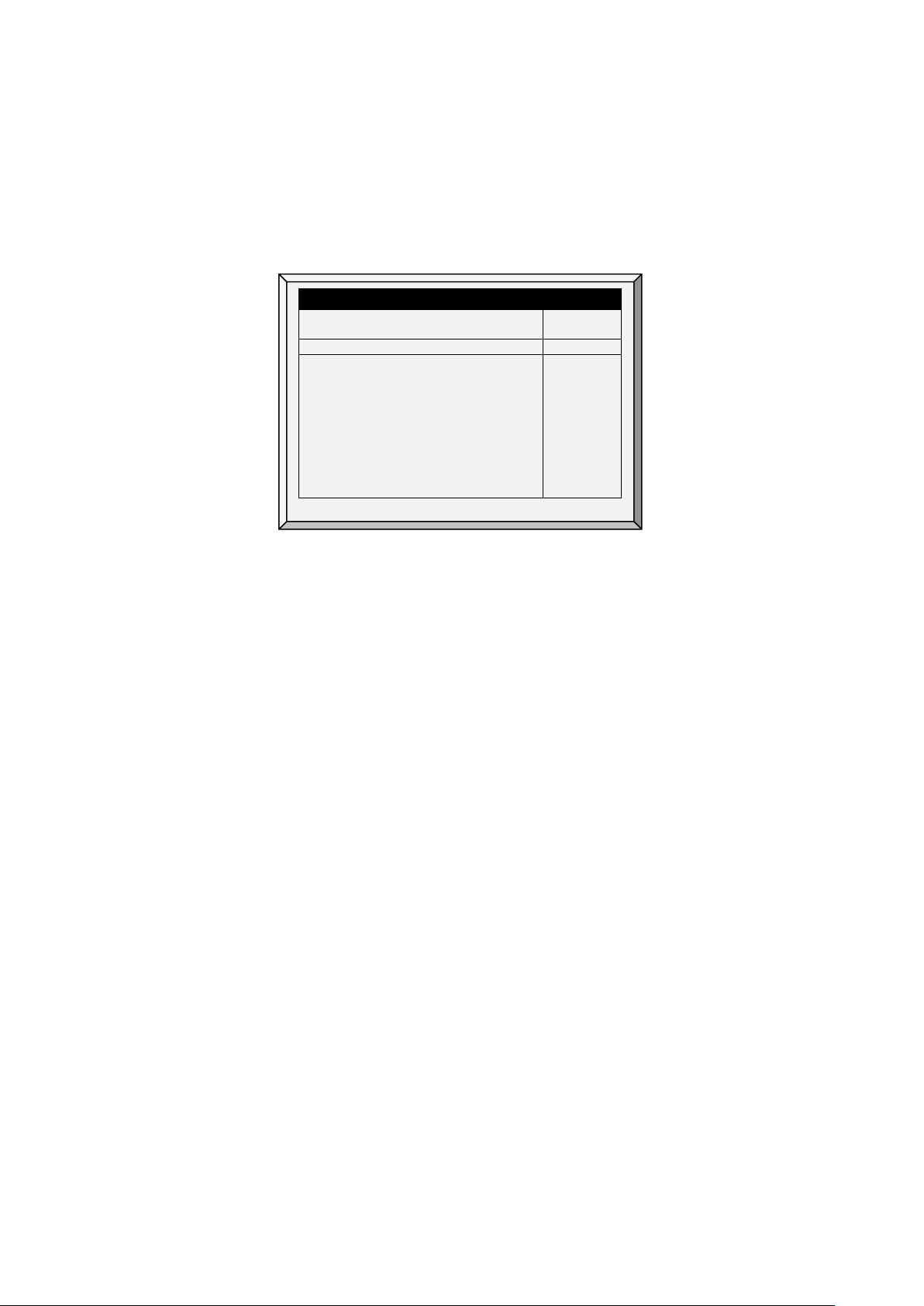

2.3 Standard Display

The main screen consists of the following parts.

EMPERATURE CURVE HELP | SET

1. Sensors: Displays individual sensor readings. Temperature sensors marked with dark squares

form the current average temperature.

o

Filled square: Indicates the sensor participates in the average calculation.

o

Empty square: Indicates the sensor does not participate in the average calculation.

Go to Table 1: Sensor Readings page 104, to view all the possible sensors.

2. Av. Temp: Reports the current average temperature. This example is in Celsius, but yours may be

in Fahrenheit.

© Munters AB, 2021 6

Page 12

27.5°

ACTI VE

Heat 1 Heat. Hi

1

Tun. Fan

Exh. Fan

Stir

Cool P.

Fogger

Curt. 1

100%

Curt. 2

100%

Curt. 3

0%

Curt. 4

0%

STATUS

08:53:06

Day: 5

Set:

25.0

Level:

3

Min.

Vent

FanOff:

176 4 MESSAGES

(2) Low Feed At Bin 2

Te

Time

Controller State

Growth day

Current level of ventilation

Time until

Av. Temp

3. Active: Displays the output relay list. The filled black boxes indicate active outputs. Controller

also informs the position of inlets and curtains, as well as the number of operating heaters or fans.

Go to Table 2: Output List (Active), page 104 to view all the available readings (ACTIVE).

The ACTIVE screen shows rectangular markers by the outputs. Filled rectangles indicate operating

outputs; empty rectangles indicate outputs that are off.

4. Status: Provides important general information such as the time and ventilation mode.

mp set to

cycle ends operation

Go to Table 1: Sensor Readings, page 104 to view all the available readings.

5. Messages: Displays important messages/alarms. The title bar displays the number of important

messages, and if there are several messages, they each appear in turn.

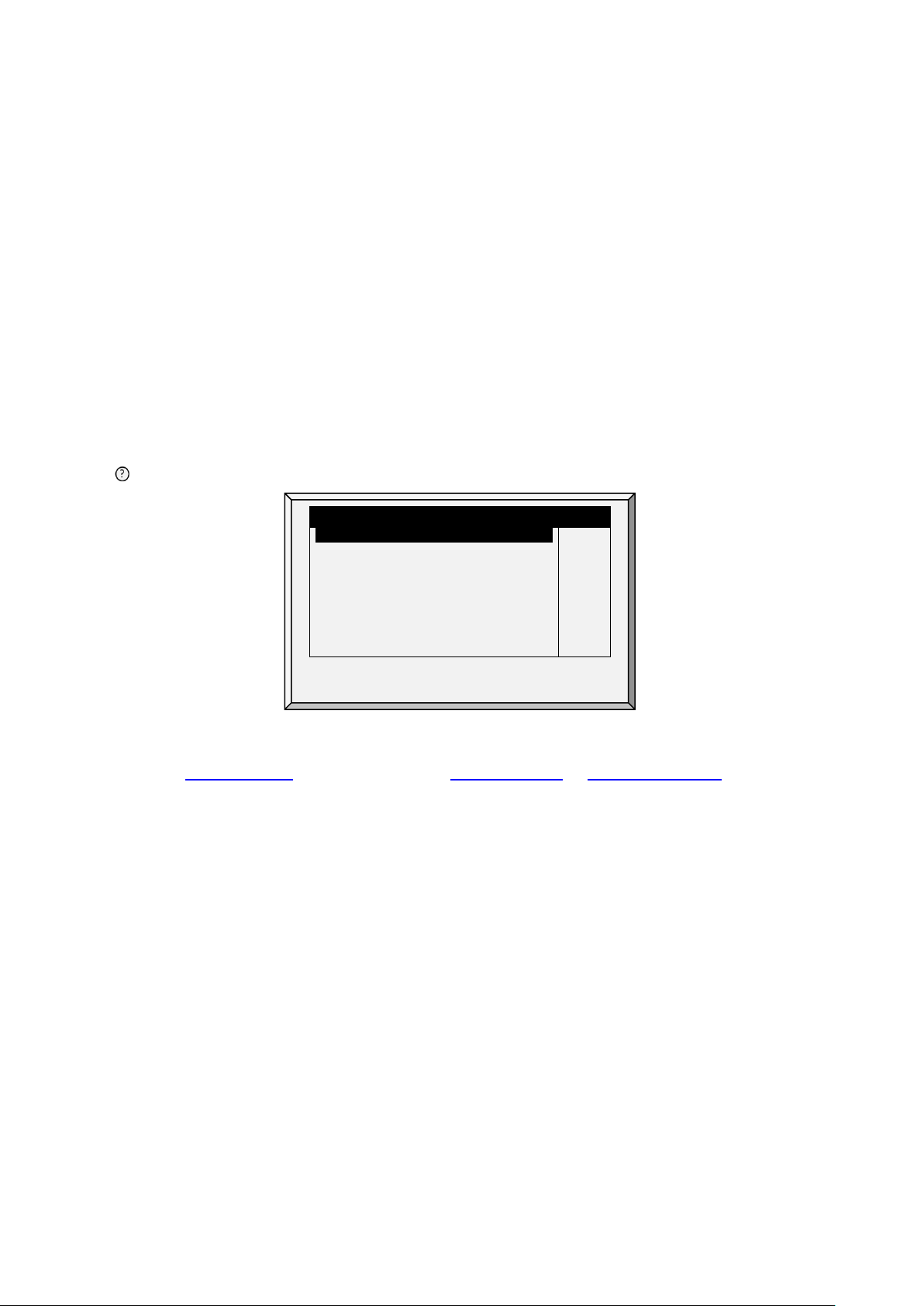

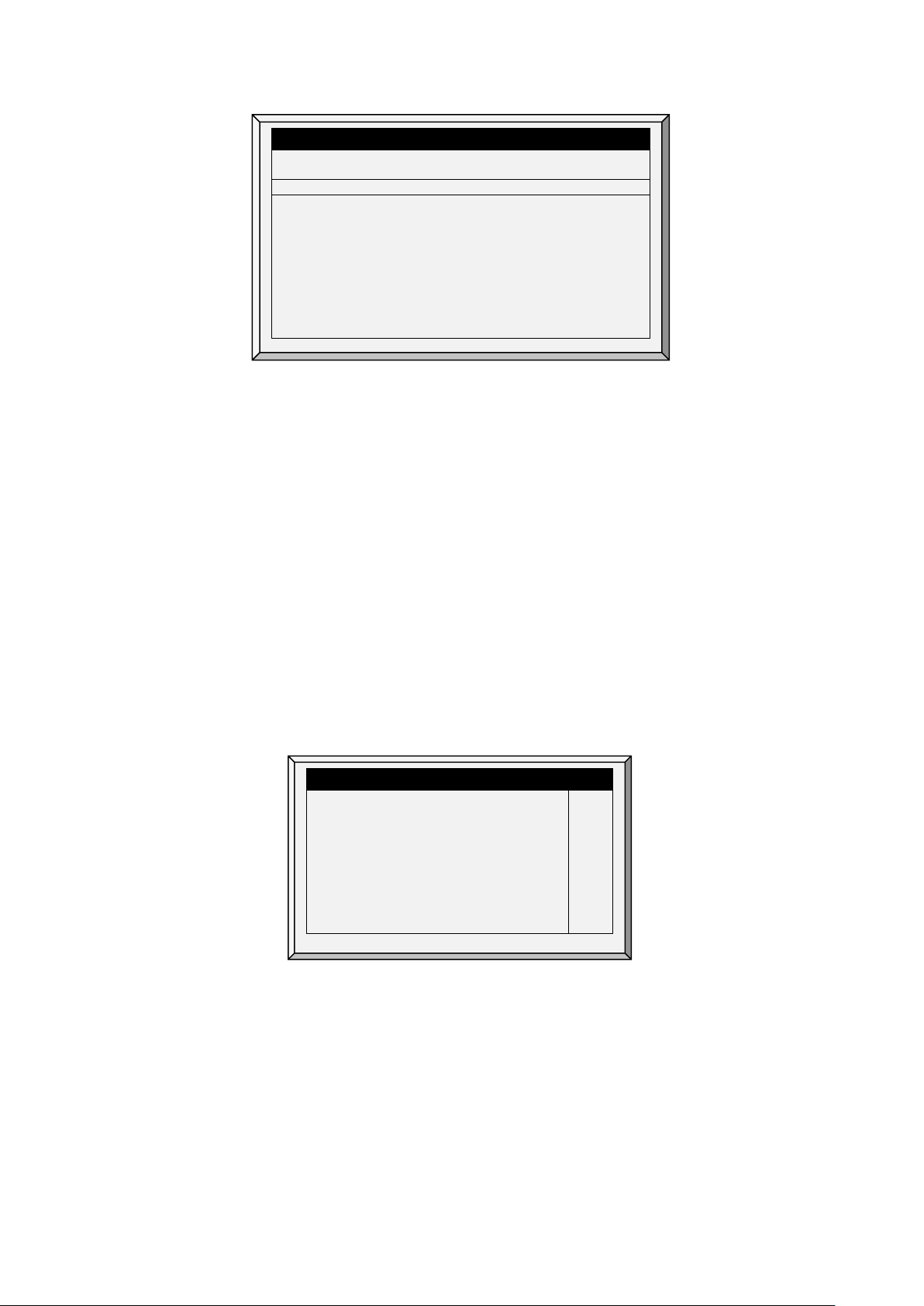

2.4 Main Menu Icons

1. To enter the Main Menu screen, press Menu.

2. To select an option, press Enter.

© Munters AB, 2021 7

1. Control temperature, humidity, ventilation, static pressure and system parameters.

Page 13

2. Define equipment settings

3. Manage inventory, livestock, and alarm/password settings.

4. Set, calibrate and test bird scales.

5. View history of all controller functions.

6. Test to see switches, relays, communication, and alarms are functioning properly.

7. Calibrate temperature, humidity, ventilation, static pressure, feed, water, read/save to plug.

8. Install sensors, devices, communication, etc.

2.5 Cold Start

To perform a cold start:

1. Disconnect the power cable from the power source.

2. Reapply power while pressing Delete. The Cold Start screen appears.

3. Select Yes.

© Munters AB, 2021 8

Page 14

Temperature Curve, page 9

CONTROL

8. AMMONIA TREATMENT

Day

Target

Heat

Tunnel

Alarm

Low

High

T.Hi

1

48

89.0

68.0

89.0

66.0

100.0

73.0

84.0

60.0

102.0

83.0

103

103

3 Control menu

The following sections detail the following functions:

•

•

Introduction to Humidity,

Ammonia, and CO2 Treatment,

page 17

•

CO2 Treatment, page 19

•

Min/Max Level, page 20

•

Static Pressure, page 27

•

Control Mode, page 28

•

System Parameters, page 29

•

Ammonia Treatment, page 30

1. TEMPERATURE CURVE

2. HUMIDITY TREATMENT

3. CO2 TREATMENT

4. MIN/MAX LEVEL

5. STATIC PRESSURE

6. CONTROL MODE

7. SYSTEM PARAMETERS

3.1 Temperature Curve

This screen sets the temperature targets according to the bird age.

TEMPERATURE CURVE

2

1. In

Install > Analog Sensors

of sensors as temperature sensors. When using more than one sensor, AC-2000 3G begins

treatments based on the average.

2. In

Install > Relays Layout

3. If required, go to

4. In

Install > Temperature Definition

devices. If a zone does not have an assigned sensors, calculations are based on the current

average temperature.

5. In

Control > Temperature Curve

o

Set up to 20 lines, 999 growth days. When a curve is not required, enter temperatures in

the first line only.

89.0

3

87.0

7

84.0

15

82.0

21

79.0

28

76.0

35

72.0

42

70.0

(refer to Analog Sensors, page 81), designate the required number

, define the required number of relays as Heaters.

Service > Temperature Calibration

89.0

87.0

83.0

81.0

78.0

74.0

70.0

68.0

99.0

97.0

91.0

89.0

86.0

81.0

77.0

75.0

84.0

82.0

80.0

78.0

75.0

71.0

67.0

63.0

, calibrate the sensors.

, assign specific sensors brood setups, heater zones, and

, define the required target temperature curve

102.0

95.0

95.0

93.0

90.0

87.0

84.0

83.0

103

103

103

103

103

103

103

103

© Munters AB, 2021 9

Define: Day: Sets growth day. You can program negative growth days up to -7 for

pre-warming. To enter a negative growth day, type the day number followed by

the +/- key.

Page 15

TEMPERATURE CURVE

Non Brood Area Diff. From Heat

-3.0

6. In

Manage > Alarm Setting

7. If required set the:

o

o

o

o

o

Target: Set the desired temperature.

Heat: Set the temperature to stop heat.

Tunnel: Set the temperature for tunnel ventilation to begin.

Alarm Low & High: Set average temperature alarm limits. See Manage | Alarm

Settings for zone alarm settings.

, set the Sensor Alarms (page 52).

Temperature Curve Help | Set Definitions, page 10

Radiant Heaters Help | Set Definitions, page 11

Cycle Heaters | Set Definitions, page 12

Variable Heater Help | Set Definitions, page 13

Variable Floor Heater | Set Definitions, page 16

3.1.1 T

EMPERATURE CURVE HELP | SET DEFINITIONS

While viewing the Temperature Curve menu: Press HELP, select

SYSTEM PARAMETERS

Temperature Curve Offset

Set Temp. Change Reminder (Diff)

Target Temp. Band

Heater Temp. Band

Cool Down Factor (%)

Cool Down Fast Response (Deg.)

Min Vent Below Heat Temp By:

•

Temperature Curve Offset: Adjusts all temperature curves by this amount. You can use this to

temporarily adjust all temperatures up or down for special circumstances. The curve appears in

the Status Window, and you can use the ENTER and Up or ENTER and Down hot key

combinations to change the offset.

•

Set Temperature Change Reminder (Diff): Sets the change in set temperature that triggers a

reminder for you to set backup thermostats. Often producers forget to set backup thermostats as

their birds grow from baby chicks to market age, so the AC-2000 3G reminds you. When you

press Enter to acknowledge the reminder, the AC-2000 3G logs it in the Table of Events.

•

Target Temperature Band: The size of the target temperature zone. This "Happy Zone” is

between Target Temperature and (Target Temperature + Band).

•

Heater Temperature Band: Heaters turn on at ‘Band’ degrees below Heat, and turn off at the

Heat Temperature.

SET

, and press

0.0

3.0

1.5

1.0

15

3.0

ZONE

ENTER.

NOTE Heaters operate at minimum level only; however, Radiant Heaters can operate at any

temperature or level below Tunnel.

•

Cool Down Factor (%): Minimum percentage correction towards target during each increase

ventilation level delay. If average temperature does not improve by this amount, the AC-2000

3G increases ventilation by one level.

Cool Down Fast Response (Deg.): Set a limit to the maximum degrees per minute of cooling.

•

If Average Temperature drops more than this in one minute, the AC-2000 3G decreases

© Munters AB, 2021 10

ventilation one level to avoid overshooting.

Page 16

TEMPERATURE CURVE

Radiant Ignition Time (sec)

NOTE Avoid making this parameter too small or the normal temperature variation caused by timer fans

reduces the ventilation level.

•

Min Vent Below Heat Temp By: Tells controller to go directly to Min Level in some cases.

Select from the following choices:

o

None: Operate by the normal level decrease time delay rule.

o

Zone: Go directly to minimum level if any active temperature sensor reaches heat

temperature.

o

Avg.: Go directly to minimum level if the average temperature reaches heat temperature.

•

Non Brood Area Diff. From Heat: Set differential temperature for non-brood heaters. You

normally use this to set temperatures in unoccupied areas.

NOTE When set at -99° F the heaters are effectively disabled, since it will probably never go to 99º F

below the heater temperature. Putting this parameter at 0º sets the non-brood areas to the

heater temperature.

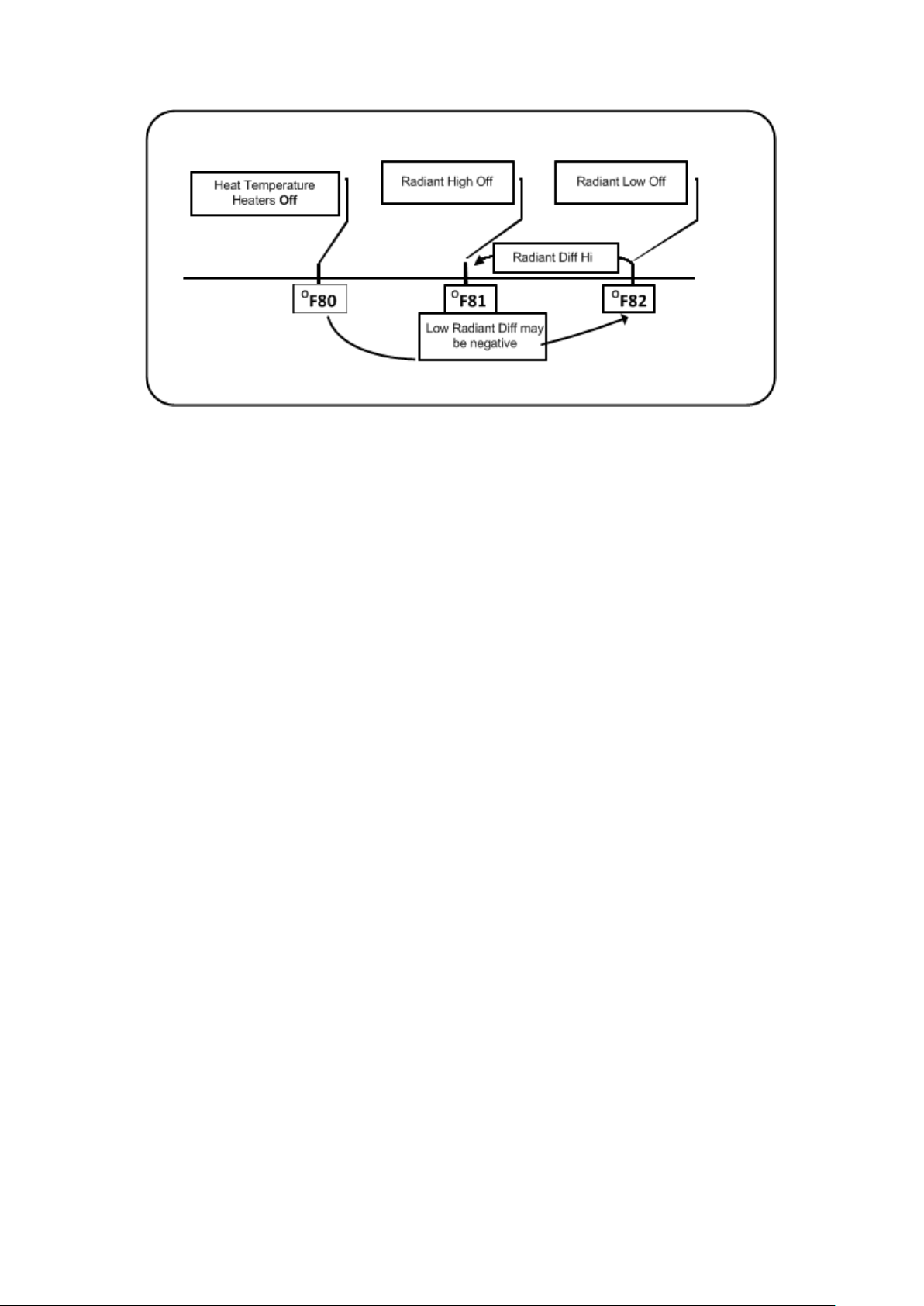

3.1.2 R

ADIANT HEATERS HELP | SET DEFINITIONS

To configure the radiant heaters:

1. In

Installation > Relay Layout

page 80).

2. Configure the following parameters:

o

Radiant Low – Differential from Heat Set: Set degree of difference from Heat for LOW

Radiant Heaters to begin working. This differential can be positive or negative. (default:

2.0)

o

Radiant High – Differential (Below Low Set): Set number of degrees below Radiant

Low Heaters for HIGH Radiant Heaters to begin working (default: 1.0). To ensure

proper heater ignition, Radiant High Heaters remain on for the Radiant Ignition Time

along with the Radiant Low Heaters.

o

Radiant Ignition Time (sec): Set number of seconds to power radiant ignition (default:

30).

SYSTEM PARAMETERS

0.0

3.0

1.5

1.0

15

3.0

ZONE

-3.0

0.0

1.0

30

Temperature Curve Offset

Set Temp. Change Reminder (Diff)

Target Temp. Band

Heater Temp. Band

Cool Down Factor (%)

Cool Down Fast Response (Deg.)

Min Vent Below Heat Temp By:

Non Brood Area Diff. From Heat

RADI ANT HE ATERS

Rad. Low –Diff from Heat Set

Rad. High –Diff (Below Low Set)

define at least one relay as a radiant heater (Relay Layout,

The Heater Temperature Band applies to radiant heaters as well. For example, if the Heat

Temperature is 80º F and the Heater Temperature Band is 1º F, heaters turn on at 79º F and off at

80º F. If the Radiant Low Differential is 2.0º F, radiant heaters turn off at 82º F, and on 1º F below

that (81º F). However, a Radiant High Heater turns on regardless of its temperature setting for the

Radiant Ignition Time whenever the corresponding Radiant Low Heater turns on. This feature

ensures proper flame ignition.

© Munters AB, 2021 11

Page 17

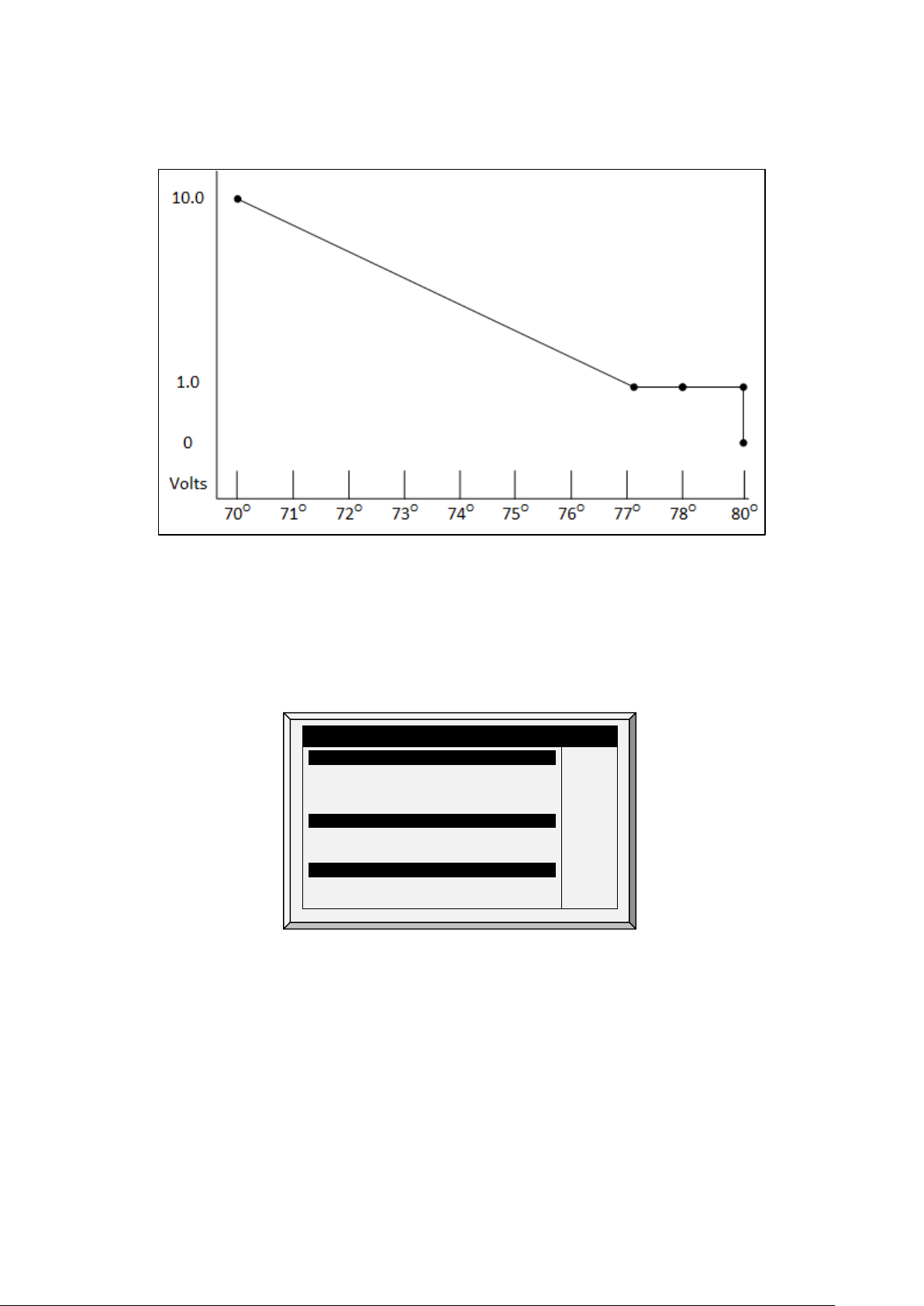

Figure 1: Radiant Heater Differentials

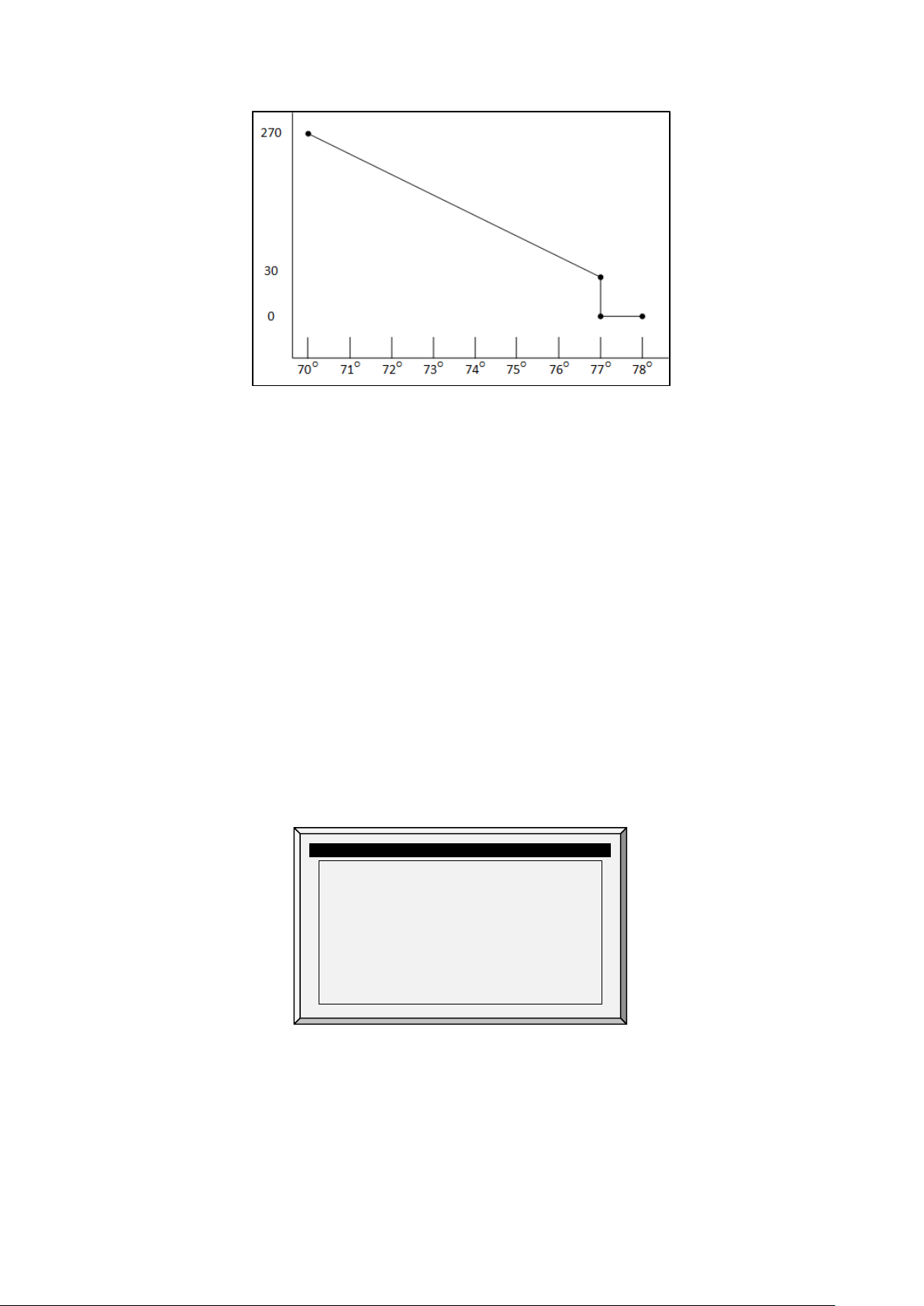

3.1.3 C

YCLE HEATERS | SET DEFINITIONS

Heat Cycle means providing heat in conjunction with the ventilation system during minimum ventilation

cycles, using heaters and fans connected to relays. When enabled, heaters operate during the fans’

cycle off time (as defined in the Levels of Ventilation Cycle Timer On and Off parameters). How does it

work?

Between the Heat Temperature and the differential temperature, heaters do not operate. When the

temperature goes below the Heat Off temperature minus the Low Heat Differential:

•

Heaters begin to operate when the exhaust or tunnel fans are off. Heaters operate for the

Minimum On Time.

•

If the temperature continues to drop, heaters operate for longer periods of time, up to the

Maximum On Time (defined in Levels of Ventilation).

•

AC-2000 3G automatically generates a curve.

In this example:

•

Temperature Curve Heat Off is 78°.

•

Low Heat Differential is 1°.

•

High Heat Differential is 8°.

•

Minimum On time is 30 seconds.

•

Cycle Off time is 270 seconds.

© Munters AB, 2021 12

Page 18

Output

Function

Min

V.Out

Max

V. Out

1

Var. Heater 1

1.0

10.0 2 Var. Heater 2

1.0

10.0

1. Define the required number of heater and exhaust and/or tunnel relays (Relay Layout, page 80).

2. In Control > Control Mode, set the Heater Cycle to Yes.

3. In Control > Temperature Curve > Help, scroll to Cycle Heater.

4. Define:

o

Low Heat Differential: The differential below the Heat Off temperature, at which heating

begins and runs for the minimum amount of time.

o

High Heat Differential: The differential below the Heat Off temperature, at which heating

runs for the maximum amount of time

o

Minimum ON Time: Minimum heating time when the exhaust or tunnel fans are off.

3.1.4 V

ARIABLE HEATER HELP | SET DEFINITIONS

The AC-2000 3G Controller enables configuring up to two variable heaters. The heater output changes

according to the output of a 0 – 10 VDC device.

To configure the variable heaters:

1. In

Installation > Analog Output

configure:

a. up to two analog outputs as variable heaters

b. the minimum and maximum voltage output for each heater

ANALOG OUTPUT

Out No.

2. In

Control > Control Mode > Analog Heat Mode

•

Linear Heat

•

Proportional Heat

•

Linear Valve

, define the mode.

Refer to Control Mode, page 29 for details.

3. In Control > Temperature Curve > Help, define the parameters for each mode.

© Munters AB, 2021 13

Page 19

RADI ANT HE ATERS

8.0

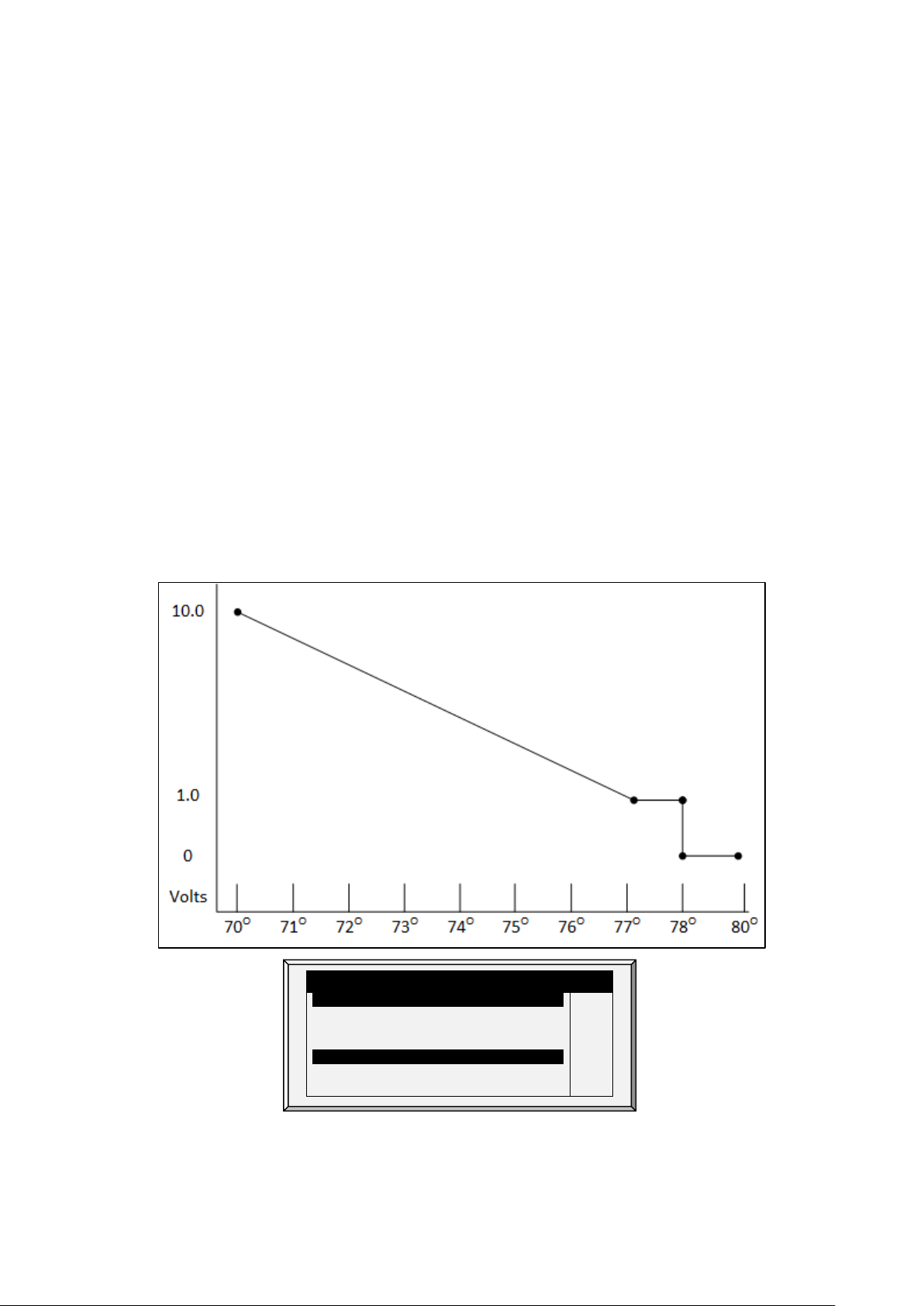

3.1.4.1 Linear Heat

When Linear Mode is enabled:

•

Between the Heat Temperature and the Target temperature, heaters do not operate (meaning,

the output voltage is 0).

•

Between the Heat Temperature and the Low Difference Below Heat, heaters operate at the

minimum voltage output.

•

If the temperature continues to drop, the voltage output increases until it reaches the maximum

voltage output at the High Difference below Heat.

In this example:

•

Target Temperature is 80°

•

Temperature Curve Heat Off is 78°.

•

Low Heat Differential is 1°.

•

High Heat Differential is 8°.

o

If the temperature is between 77° to 78°, the output voltage is the minimum voltage

defined in Installation > Analog Output (1 volt in this example).

o

If the temperature continues to drop, the output voltage increases until it reaches the

maximum voltage defined in Installation > Analog Output. Output increases or

decreases to keep the temperature within the Target Temperature and Heat Off band.

•

Define the parameters:

o

Low Difference Below Heat: Temperature difference between the Heat Off parameter

at which the variable heater begins to function.

SYSTEM PARAMETERS

Rad. Low –Diff from Heat Set

Rad. High –Diff (Below Low Set)

Radiant Ignition Time (sec)

VARIABL E HEATER

Low Diff Below Heat

High Diff Below Heat

0.0

1.0

30

1.0

© Munters AB, 2021 14

Page 20

RADI ANT HE ATERS

15

RADI ANT HE ATERS

8.0

o

High Difference Below Heat: Temperature at which the heater begins to operate at

maximum output.

3.1.4.2 Proportional Heat

Proportional Heat works in manner similar to Linear Mode. The difference is that Proportional Heat

features a delay time.

•

When the temperature falls below the user-defined point, the heaters begin operating at their

minimum output.

•

After the response time passes, AC-2000 3G checks the temperature. If it is still below the

defined point, AC-2000 3G increases the voltage by a certain amount (this amount of the

increase cannot be changed).

•

After the response time passes, the process is repeated until heaters operate at their maximum

output.

SYSTEM PARAMETERS

•

Define the parameters.

o

Difference Above Heat to Stop Heater: Differential from target temperature at which

the heater runs at minimal input

o

High Difference Below Heat: High Difference Below Heat: Temperature at which the

heater begins to operate at maximum output

o

Response Time (seconds): Amount of time before the controller begins to change the

ventilation.

3.1.4.3 Linear Valve

Rad. Low –Diff from Heat Set

Rad. High –Diff (Below Low Set)

Radiant Ignition Time (sec)

VARIABL E HEATER

Diff Above Heat to Stop Heater

High Diff Below Heat

Response Time (seconds)

SYSTEM PARAMETERS

Rad. Low –Diff from Heat Set

Rad. High –Diff (Below Low Set)

Radiant Ignition Time (sec)

VARIABL E HEATER

Low Diff Below Heat

High Diff Below Heat

0.0

1.0

30

1.0

8.0

0.0

1.0

30

1.0

Linear Valve enables defining that variable heater input voltage is always equal to or above the minimum

input defined in Installation > Analog Sensors..

When the Analog Heat Mode is defined as having Linear Valve control, there is always a minimal

voltage input. Therefore, if the minimum voltage is 1 volts:

© Munters AB, 2021 15

•

The voltage range is from 1 to 10 volts

o

this corresponds to 10% at 1V and 100% at 10V

Page 21

RADIANT HEATERS

High Diff Below Heat Tmp.

o

interpolation inside the band

•

There is 0% voltage when the target temperature is reached.

•

Define.

o

Difference Above Heat to Stop Heater: Differential from target temperature at which

the heater runs at minimal input

o

High Difference Below Heat: High Difference Below Heat: Temperature at which the

heater begins to operate at maximum output.

3.1.5 V

ARIABLE FLOOR HEATER | SET DEFINITIONS

SYSTEM PARAMETERS

Rad. Low –Diff from Heat Set

Rad. High –Diff (Below Low Set)

Radiant Ignition Time (sec)

VARIABL E HEATER

Low Diff Below Heat Tmp.

High Diff Below Heat Tmp.

VARIABLE FLOOR HEATER

Low Diff Below Heat Tmp.

0.0

1.0

30

0.5

4.5

0.5

4.5

AC-2000 3G Controllers enable configuring up to two variable floor heaters. The output of the heaters

changes as the temperature increases or decreases.

Install at least one analog output card.

To configure the variable floor heaters:

1. In

a. up to two analog outputs as variable heaters

b. the minimum and maximum voltage output for each heater

© Munters AB, 2021 16

Installation > Analog Output

configure:

Page 22

Output

Function

Min

V.Out

Max

V. Out

1

Var. Heater 1

1.0

10.0 2 Var. Heater 2

1.0

10.0

ANALOG OUTPUT

Out No.

2. In

Control > Temperature Curve > Help

, scroll down to Variable Floor Heater.

3. Set the response time (amount of time before the controller begins to change the ventilation).

4. Variable heat parameters are dependent on the mode employed.

o

Linear Heat

o

Proportional Heat

o

Linear Valve

3.2 Introduction to Humidity, Ammonia, and CO2 Treatment

AC-2000 3G provides various options to controlling the humidity, CO2, and ammonia levels.

•

None: No treatment is provided.

•

Level: Ventilation levels increase for a designated amount of time.

•

Tunnel or exhaust fan: A designated fan turns on for a designated amount of time. The amount

of air blown into the house is greater than that provided by an increase in ventilation level.

•

Increase in air / weight: The total amount of air that fans need to provide increases by a user

defined amount. Fan stay on until CO2, humidity, or ammonia levels fall to their defined levels.

This option is only available when using Minimum Ventilation by Weight.

•

Humidity treatment by heat: In cold air situations, heaters can be turned on to lower the

relative humidity.

If there is a contradiction between CO2, humidity, and ammonia treatments:

•

Ammonia treatment has priority over CO2 treatment.

•

C02 treatment has priority over humidity treatment.

•

Increase in air / weight has priority over other treatments.

•

Humidity treatment by heat takes priority over increasing the ventilation.

3.3 Humidity Treatment

Humidity treatment forces an increase in ventilation level when the humidity is too high. It holds the

increase for ‘Duration Seconds’, and checks back after ‘Interval Minutes’ for another increase. After the

duration, the ventilation level comes back down automatically.

© Munters AB, 2021 17

Page 23

Delay

(Min)

Duration

(sec.) 1 70

10

130

7

75 7 150

14

80 5 180

0 0 0

0

0 0 0

0

0 0 0

0

0 0 0

0

0 0 0

0

Humidity Band (%)

5.0

HUMIDITY TREATMENT BY HEATERS

Humidity Treatment by Heaters

Diff to Stop Treatment by Heaters

YES

3.6

HUMIDITY TREATMENT

Day Humidity

1. In

Install > Analog Sensors

(refer to Analog Sensors, page 81), designate up one or two sensors

as indoor humidity sensors (outdoor sensor is for information only). When using more than one

sensor, AC-2000 3G begins treatments based on the average.

2. If required, go to

Service > Humidity Calibration

Calibration, page 72).

3. In

Control > Humidity Treatment

o

Day: Growth day. Can set multiple programs for same day (maximum number of

programs: 20)

o

Humidity: Humidity at which to begin treatment

o

Delay Minute: Amount of time the controller pauses before ventilating

o

Duration Sec.: Number of seconds the controller maintains the increased level of

ventilation

4. Set the Humidity Sensor Alarm (page 55).

3.3.1 H

UMIDITY TREATMENT HELP | SET DEFINITIONS

While viewing the Humidity Treatment menu: Press HELP, select SET, and press ENTER.

Humidity Treatment below Heat

Humidity Treatment By

Outside Temp Treat by Heaters

, and calibrate the sensors (refer to CO2 Sensor

set the parameters as required.

HUMIDITY TREATMENT

YES

Exh 6

-18.0

• Define:

o

Humidity Band (%): Hysteresis band (delay) for Humidity Treatment.

o

Humidity Treatment below Heat: Select YES or NO for allowing Humidity Treatment

when heaters are operating (set in Temperature Curve).

o

Humidity Treatment By: This parameter designates the method used when humidity or

CO2 treatment begins. Normally, this parameter is relevant only when minimum

ventilation is running. When a treatment is required, select one the method to be

employed:

Level: Increases the ventilation level when a treatment is required.

NOTE When employing Ventilation by Weight, the controller increases the cycle time or the level,

depending on the particular settings.

Exhaust: Designate a specific exhaust fan (press a number key to select the fan).

© Munters AB, 2021 18

Page 24

Day

Start

Stop

Delay

Duration

Value

Value

(sec)

(sec)

1

0

3000

0

2500

0

120

0

130

0

Tunnel: Designate a specific tunnel (press a number key to select the fan).

None: Disables the treatment.

To enable the exhaust/tunnel options, in

Output

, designate at least one relay/variable device as a tunnel or exhaust fan.

o

Humidity Treatment by Heaters: This parameter enables using the heaters to lower the

Installation > Relay Outlet

or

Installation > Analog

relative humidity. If enabled, define:

Outside Temp Treat by Heaters: Heaters handle humidity treatment when the

outside temperature is lower than the target temperature by this amount.

Diff to Stop Treatment by Heaters: Heaters cease the humidity treatment if the

inside temperature is lower (or higher) than the target temperature by this amount.

This number can be positive or negative.

Humidity Treatment by Heaters requires designating at least one temperature sensor as an

outside sensor (refer to Temperature Definition, page 85).

NOTE If the heaters are operating because of the interior temperature, Humidity Treatment by Heaters

is disabled.

3.4 CO2 Treatment

CO2 treatment forces an increase in ventilation level when the CO2 level is too high. It holds the increase

for ‘Delay Seconds’, and checks back after ‘Interval Minutes’ for another increase. After the duration, the

ventilation level may come back down automatically. If during treatment, the CO2 level drops below the

Stop Value parameter, the ventilation level automatically returns to that level used before CO2 treatment

was initiated.

1. In

Install > Analog Sensors

sensor.

2. If required, go to

page 81).

3. In

Control > CO2 Treatment

o

Day: Growth day. Can set multiple programs for same day (Max. programs 20)

o

Start Value: CO2 value at which to begin treatment

o

Stop Value: CO2 value at which to end treatment

o

Delay (Sec): Number of seconds the controller pauses before ventilating

o

Duration (Sec): Number of seconds the controller maintains the increased level of

ventilation

CO2 TREATMENT

7

14

0

0

0

0

0

0

2700

2500

0

0

0

0

0

0

2200

2000

0

0

0

0

0

0

(refer to Analog Sensors, page 81), designate one sensor as a CO2

Service > CO2 Calibration

set the parameters as required.

120

90

0

0

0

0

0

0

150

180

0

0

0

0

0

0

, calibrate the sensors (refer to Analog Sensors,

4. Set the CO2 Sensor Alarm (page 55).

© Munters AB, 2021 19

Page 25

CO2 Treatment Below Heat

NO

CO2 Treatment By

Exh 6

CO2 TREATMENT BY HEATERS

CO2 Treatment by Heaters

YES

3.4.1

CO2 T

While viewing the CO2 Treatment menu: Press HELP, select SET, and press ENTER.

REATMENT HELP | SET DEFINITIONS

SYSTEM PARAMETERS

CO2 TREATMENT

Outside Temp Treat by Heaters

Diff to Stop Treatment by Heaters

•

CO2 Treatment below Heat: Select YES or NO to enable CO2 treatment when heaters are

-18.0

3.6

operating (set in Control | Temperature Curve).

•

CO2 Treatment By: This parameter designates the method used when humidity or CO2

treatment begins. Normally, this parameter is relevant only when minimum ventilation is

running. When a treatment is required, select one the method to be employed:

o

Level: Increases the ventilation level when a treatment is required.

NOTE When employing Ventilation by Weight (refer to page 22), the controller increases the cycle

time or the level, depending on the particular settings.

o

Exhaust: Designate a specific exhaust fan (press a number key to select the fan).

o

Tunnel: Designate a specific tunnel (press a number key to select the fan).

o

None: Disables the treatment.

To enable the exhaust/tunnel options, in

Output

, designate a relay/variable device as a tunnel or exhaust fan.

o

CO2 Treatment by Heaters: This parameter enables running the heaters in situations

Installation > Relay Outlet

or

Installation > Analog

where the CO2 level is high. Typically this can happen in cold temperatures when CO2

is produced by the heaters. By increasing the heat in the house, ventilation can then be

increased. If enabled, define:

Outside Temp Treat by Heaters: Heaters handle CO2 treatment when the outside

temperature is lower than the target temperature by this amount.

Diff to Stop Treatment by Heaters: Heaters cease the CO2 treatment if the inside

temperature is lower (or higher) than the target temperature by this amount. This

number can be positive or negative.

CO2 Treatment by Heater requires designating at least one temperature sensor as an

outside sensor (refer to Temperature Definition, page 85).

NOTE If the heaters are operating because of the interior temperature only, CO2 Treatment by Heater

is disabled.

3.5 Min/Max Level

IMPORTANT: Before setting Min/Max levels, go through and set up the Device Settings,

especially the ventilation levels.

Once you have entered the ventilation levels, use Min/Max to select the range of levels to apply to your

situation. Typically, you increase the minimum ventilation level as litter conditions deteriorate and the

© Munters AB, 2021 20

Page 26

Day

Min

Max

1

0

1

0

16

0 MIN/MAX LEVEL

From

Min

Max

06:00

00:00

1

0

6

0

birds require greater amounts of fresh air. You can also restrict the maximum level to prevent excess

airflow on young birds.

Use one of the following methods to set the Min/Max levels:

•

By Day and By Soft Days Curve

•

By Time

•

Day Soft Min.

By Weight

•

Before configuring these parameters, go to

28) to select the required method.

3.5.1 BY D

AY AND BY SOFT DAYS CURVE

•

Day: Set growth day

•

Min: Set the controller's minimum ventilation level

•

Max: Set the controller's maximum ventilation level

o

BY DAYS CURVE generates an incremental increase/decrease between the defined

days.

o

BY DAYS operates according to that day's values until the next defined day is reached.

Control Mode > Min. Max. Level Control

MIN/MAX LEVEL

3

6

10

14

21

35

0

0

2

3

4

5

6

7

0

0

16

16

16

21

21

21

0

0

(page

3.5.2 BY T

© Munters AB, 2021 21

IME

10:00

13:00

18:00

21:00

00:00

00:00

00:00

00:00

•

From: Set time of day (hh:mm) in 24 hour format

•

Min: Set minimum ventilation level for controller

•

Max: Set maximum ventilation level for controller

4

8

6

12

8

15

1

3

0

0

0

0

0

0

0

0

Page 27

Day

Min

Soft

Min

Max

11

SYSTEM PARAMETERS

SOFT MIN/MAX LEVEL

Temp Choice for Soft Min.

ATTIC

3.5.3 D

AY SOFT MIN

•

Day: Set growth day

•

Min Soft: Set minimum ventilation level for when temperature drops below heat temperature

•

Min: Set minimum ventilation level for when temperature is above heat temperature

•

Max: Set maximum ventilation level for controller

.

SOFT MIN/MAX LEVEL

1

3

6

10

14

21

35

0

0

0

1

11

2

11

3

11

4

11

5

11

6

11

7

0

0

0

0

0

0

3.5.3.1 Soft Min/Max Level Help | Set Definitions

While viewing the Soft Min/Max Level menu: Press HELP, select SET, and press ENTER.

16

16

16

16

21

21

21

0

0

0

Diff. Below Heat for Soft Min.

10.0

•

Differential Below Heat for Soft Min: Set the degree of difference from heat temperature (set

in Control | Temperature Curve) to switch minimum level from Min. to Soft Min.

Temp Choice for Soft Min: Select inside/outside/attic temperature to control Minimum Level

•

changes. The minimum level adjusts towards the Soft Min as this temperature falls. Above the

heat temperature, the minimum level is at the Min setting.

As temperature rises, INSIDE and ATTIC stay at lowest ventilation level reached until average

temperature gets to the heat setting, and then changes instantly. With the OUTSIDE selection, the

minimum ventilation level increases gradually as temperature rises to the heat setting. This means inside

and attic soft min vent choices to latch to the lowest level reached as long as the temperature remains

below the heat setting.

3.5.4 BY W

EIGHT

The By Weight option enables controlling the minimum air flow depending on the number of birds, their

weight and the current outside temperature. When using the Weight option, AC-2000 3G takes several

parameters and calculates the air speed, level of ventilation and cycle time needed to supply the required

volume. As opposed to the other ventilation methods, the Weight option is dynamic, with the ventilation

changing according to the current parameters (quantity of air required, weight of birds and number of

birds, outside air temperature). In addition, Ventilation By Weight sends out an alarm if the current

ventilation is below the minimum required level.

To set up the Weight Option:

1. In

Install > Setup

© Munters AB, 2021 22

(page 79) enable Minimum Vent (Power).

Page 28

Day

Min

Level

Air Per Kg/Lb

Max

Level

Cold

Warm

1

350

1

70

0.5

0

1.5

1.7

16

22

2. In

Install > Fan Air Capacity

3. In

Management > Bird Inventory

4. In

Scale> General Setting

5. In

Scale > Bird Curve

6. In

Control > Control Mode

7. In

Control > Min/Max Level

, define the air capacity / hour (page 86).

, define the number of birds.

, select the curve.

, define the growth days and weights as required.

>

Min. Max Level Control

, select Weight.

, set the parameters as required.

SOFT MIN/MAX LEVEL BY WEIGHT (OUT TEMP)

3

6

10

12

15

17

19

21

o

Day: Set growth day

o

Min Level: Set the minimum level of ventilation (refer to Levels of Ventilation, page 33)

o

Air Per Kg/Lb: Volume of air per kilogram/pound per hour per bird.

Cold: Volume of air supplied when the outside temperature goes down to the

Temperature

parameter (see the following section).

Warm: Volume of air supplied when the outside temperature reaches

– Diff Below Heat

1

1

4

4

7

7

7

7

0.5

0.5

1.1

1.1

1.1

1.1

1.1

1.1

1.5

1.5

1.7

1.7

1.7

1.7

1.7

1.7

16

16

16

21

21

21

21

21

(see the following section).

Cold

Warm Temp.

NOTE As the level rises between days (for example between day 6 and day 10 in the screen above),

the air volume rises proportionally each day, once a day. For example, on Day 7, the Cold Air

per Kg/Lb. rises to 0.65; on Day 8, 0.8 and so on.

o

Max Level: Set the maximum level of ventilation (refer to Levels of Ventilation, page 33).

8. In the

Management > Bird Inventory

menu, type the number of birds.

9. In the Help menu, define the parameters as required.

Ventilation by Weight is configured.

• Min/Max Level By Weight Help | Set Definitions, Version 9.18 and Below

• Min/Max Level By Weight Help | Set Definitions Version 9.19

• Weight Hot Screen

© Munters AB, 2021 23

Page 29

SOFT MIN/MAX LEVEL BY WEIGHT

Air Per Weight Curve Mode

2

3.5.4.1 Min/Max Level By Weight Help | Set Definitions, Version 9.18 and Below

While viewing the Min/Max Level by Weight menu: Press HELP, select SET and press ENTER.

SYSTEM PARAMETERS

Warm Temp. – Diff Below Heat

Cold Temperature

Air Change

Fan Cycle Time (sec, 0 – Manual)

Minimum ON Time in Vent Cycl e

Minimum OFF Time Vent Cycle

Air Change by Humidity/CO2 %

•

Warm Temperature – Difference Below Heat: Differential below the heat temperature (refer

2.0

68.0

0.24

600

60

60

20

to Temperature Curve, page 9) that defines outside temperature as Warm in the Soft Min/Max

table. For example, if the Heat Temperature is 78° F, Warm Temp. – Diff Below Heat is 2.0,

than the outside temperature is defined as warm at 76° F.

•

Cold Temperature: Outside temperature (or below) at which Air per Kg/Lb (Cold) capacity

is reached.

When the outside temperature is between the Warm and Cold Temperature, the flow rate is

calculated at a proportional rate.

•

Air Change: As the temperature rises from the Cold Temperature parameter to the Heat

Temperature (or drops from the Heat Temperature to the Cold Temperature parameter), the

minimal air volume rises/falls proportionally. Air Change defines the minimal change in air

temperature that must takes place to cause a change in the air supply.

•

Fan Cycle Time: The total amount of time that the fans operate while operating under Minimum

Ventilation. During this time, the fans supply the required volume of air at the minimum

ventilation level required. AC-2000 3G adjusts the minimum ON time and OFF time as

needed. If the fans cannot supply the required volume at a particular level of ventilation, the

controller automatically adjusts the minimum ventilation level.

o

Minimum ON Time in Vent Cycle: The minimum amount of time that the fans operate

during a cycle. The controller adjusts the actual fan time as needed.

o

Minimum OFF Time in Vent Cycle: The minimum amount of time that the fans do not

operate during a cycle. The controller adjusts the actual fan time as needed.

As the temperature rises, the actual Minimum OFF Time decreases until it reaches the minimum time.

Only then does the Minimum On Time begin to rise.

NOTE If the temperature goes above the Band Temperature, Power Ventilation begins and times are

adjusted accordingly.

•

Air Change By Humidity/CO2/Ammon%: As the humidity, CO2, or ammonia levels rise

above the levels specified in Humidity Treatment, CO2 Treatment, or Ammonia Treatment the

minimal air volume rises proportionally. Air Change By Humidity/CO2/Ammon% defines the

minimal change in in these levels that must take place to cause an increase in the air supply.

•

Air Per Weight Curve Mode: By default, Air per Kilo/Lb has two data points: cold

temperature and warm. If desired, the user can add an additional intermediate (computer

defined) data point which is between the two default points. This point determines the quantity

of air to be distributed when the temperature reaches the midpoint between the cold and warm

© Munters AB, 2021 24

temperatures.

Page 30

SOFT MIN/MAX LEVEL BY WEIGHT (OUT TEMP)

Day

Min

Level

Air Per Kg/Lb

Max

Level

Cold Warm

1

35

1

7

0.5

0

0.9

1.4

1.5

1.7

16

22

SOFT MIN/MAX LEVEL BY WEIGHT

Air Per Weight Curve Mode

3

3

6

10

12

15

17

19

21

1

1

4

4

7

7

7

7

0.5

0.5

1.1

1.1

1.1

1.1

1.1

1.1

0.9

0.9

1.4

1.4

1.4

1.4

1.4

1.4

1.5

1.5

1.7

1.7

1.7

1.7

1.7

1.7

16

16

16

21

21

21

21

21

NOTE In a three point curve, the intermediate value must be between the cold and warm value in each

line.

3.5.4.2 Min/Max Level By Weight Help | Set Definitions Version 9.19

Version 9.19 has an additional parameter, Medium Temp, which enables setting up a more accurate

temperature curve in Air by Weight. By default, the curve is determined by the Air per Kg/Lb Cold and

Warm Temperatures. Medium Temp adds an additional (user-defined) point to the curve.

To add the Medium Temp point:

1. Configure Air by Weight as shown in By Weight, page 22.

2. Go to Control > Min/Max > Help and configure the parameters (refer to Min/Max Level By

Weight Help | Set Definitions, Version 9.18 and Below, page 24 for details).

3. In the Help screen, define the Air per Weight Curve Mode:

•

Using the number pad keys to define the mode as 2 or 3.

o

If set to 2, the Medium Temp parameter is disabled.

o

If set to 3, define the Medium Temp parameter.

SYSTEM PARAMETERS