Munsch Wedge It PLUS Operating Instructions Manual

Serien-Nr.:

Typenschild klein

Operating instructions

Automatic Wedge Welder

Wedge It PLUS

1/20 Ausgabe 01.2017/Rev.00 MUNSCH Kunststoff-Schweißtechnik GmbH

MUNSCH Kunststoff-Schweißtechnik GmbH

Im Staudchen D-56235 Ransbach-Baumbach

Tel.: +49 (0) 2623 898-80

Fax: +49 (0) 2623 898-85

E-Mail: info-kst@munsch.de

http://munschwelding.com

Firmensitz/Registered Office: Im Staudchen, D-56235 Ransbach-Baumbach

Registergericht/Registration Court: Amtsgericht Montabaur, HRB 3959

Geschäftsführer/Managing Director: Stefan Munsch

Introduction

Wedge It Plus, manufactured by MUNSCH Kunststoff-Schweißtechnik GmbH, is a selfpropelled, heat/pressure fusion machine, used for the seaming of thermoplastic geomembranes

and related materials.

Although this unit was designed for use in the field, it can be used in-house as well.

CAUTION

This machine is an electro-mechanical device with moving parts capable of exerting powerful force. Care

should be taken to prevent the accidental engagement of clothing, hair or personal extremities with any

moving parts.

MUNSCH Kunststoff-Schweißtechnik GmbH Ausgabe 01.2017/Rev.00 2/20

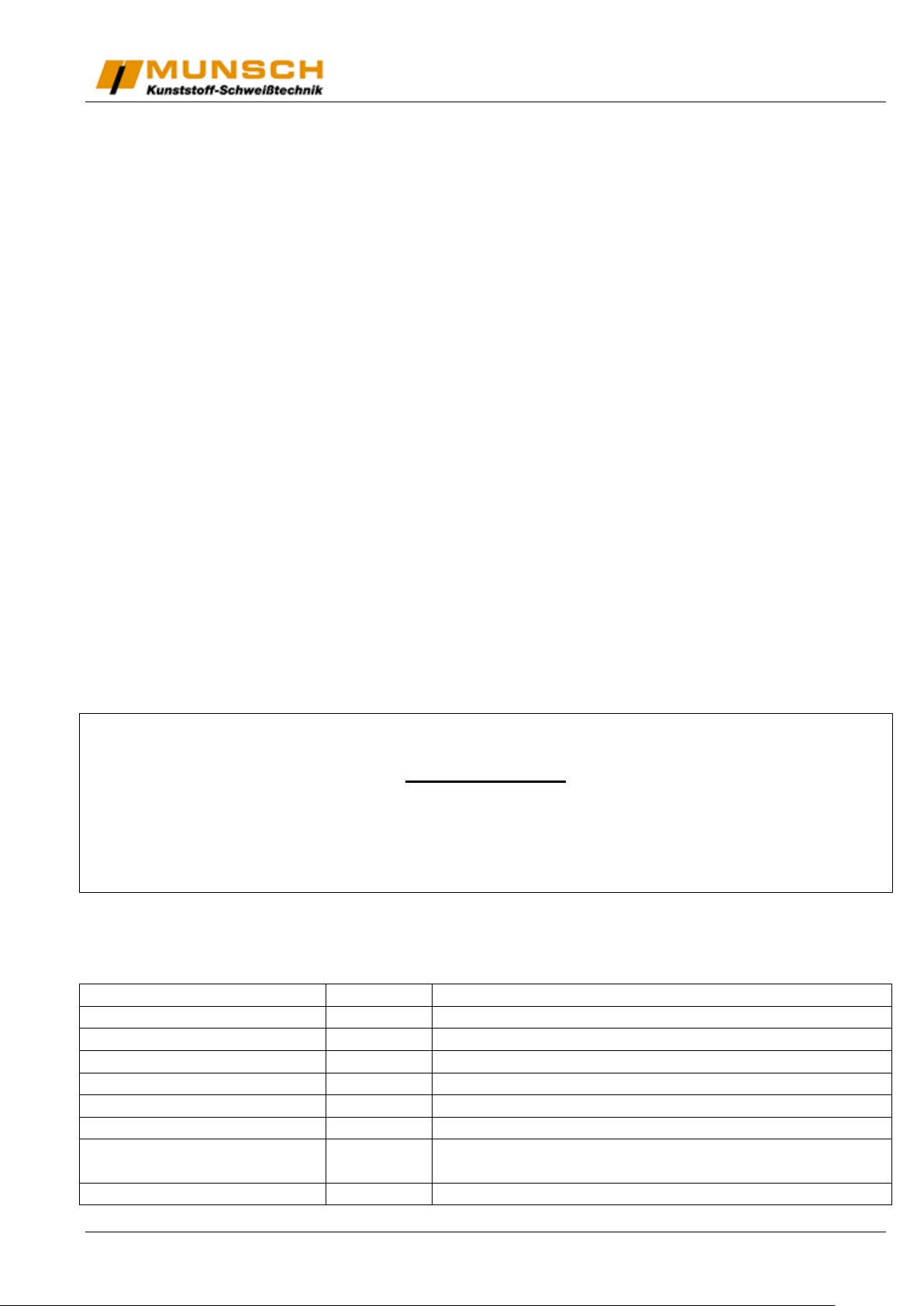

Voltage

V

110/220

Frequency

HZ

50/60

Capacity

W

2000

Temperature

°C

Max. 450, infinitely variable

Max. travel speed

m/min

6.5, infinitely variable

Dimensions LxWxH

mm

406x279x267

Weight

kg

38.5

Materials

PE-HD (20-120),PP, Hypalon,

PVC (with stainless steel wedge), …

Material thicknesses

mm

0.5-2.5

Contents

Technical data: .............................................................................................................................................................. 3

Safety ............................................................................................................................................................................. 4

Identification ................................................................................................................................................................... 5

Key electrical controls ................................................................................................................................................ 5

Key mechanical components and functions .............................................................................................................. 5

Set-Up Procedure ...................................................................................................................................................... 7

Suggested set-up for HDPE material ......................................................................................................................... 8

Basic welding operation ............................................................................................................................................. 9

Executing a weld ........................................................................................................................................................ 9

Removing the Wedge-It at the end of the seam ...................................................................................................... 10

Welding procedure summary ................................................................................................................................... 10

Welding parameters – HDPE and LLDPE ............................................................................................................... 11

Maintenance ............................................................................................................................................................. 12

Lubricating gears, sprockets and chains.................................................................................................................. 13

Removing and reinstalling hot wedge assembly ...................................................................................................... 15

Re-Setting timing of rack & pinion wedge movement .............................................................................................. 16

Temperature alignment ............................................................................................................................................ 16

General information .................................................................................................................................................. 17

Key internal electronic components ..................................................................................................................... 17

Main spare part list ............................................................................................................................................... 18

Changing operating voltage of Wedge-It .............................................................................................................. 19

Troubleshooting chart .............................................................................................................................................. 19

EC-Declaration of Conformity by the Manufacturer ..................................................................................................... 20

Note: These operating instructions must always be available to the machine operators.

Make sure to read them carefully before placing the unit in service.

Very important!

Switch off the heating wedge whenever the unit is out of service for prolonged periods.

This will prevent heating up of the machine due to radiating heat. Otherwise some machine

components may develop high surface temperatures.

Additional cooling of the heating wedge is not allowed

(water, chilling agents or similar)

3/20 Ausgabe 01.2017/Rev.00 MUNSCH Kunststoff-Schweißtechnik GmbH

Technical data:

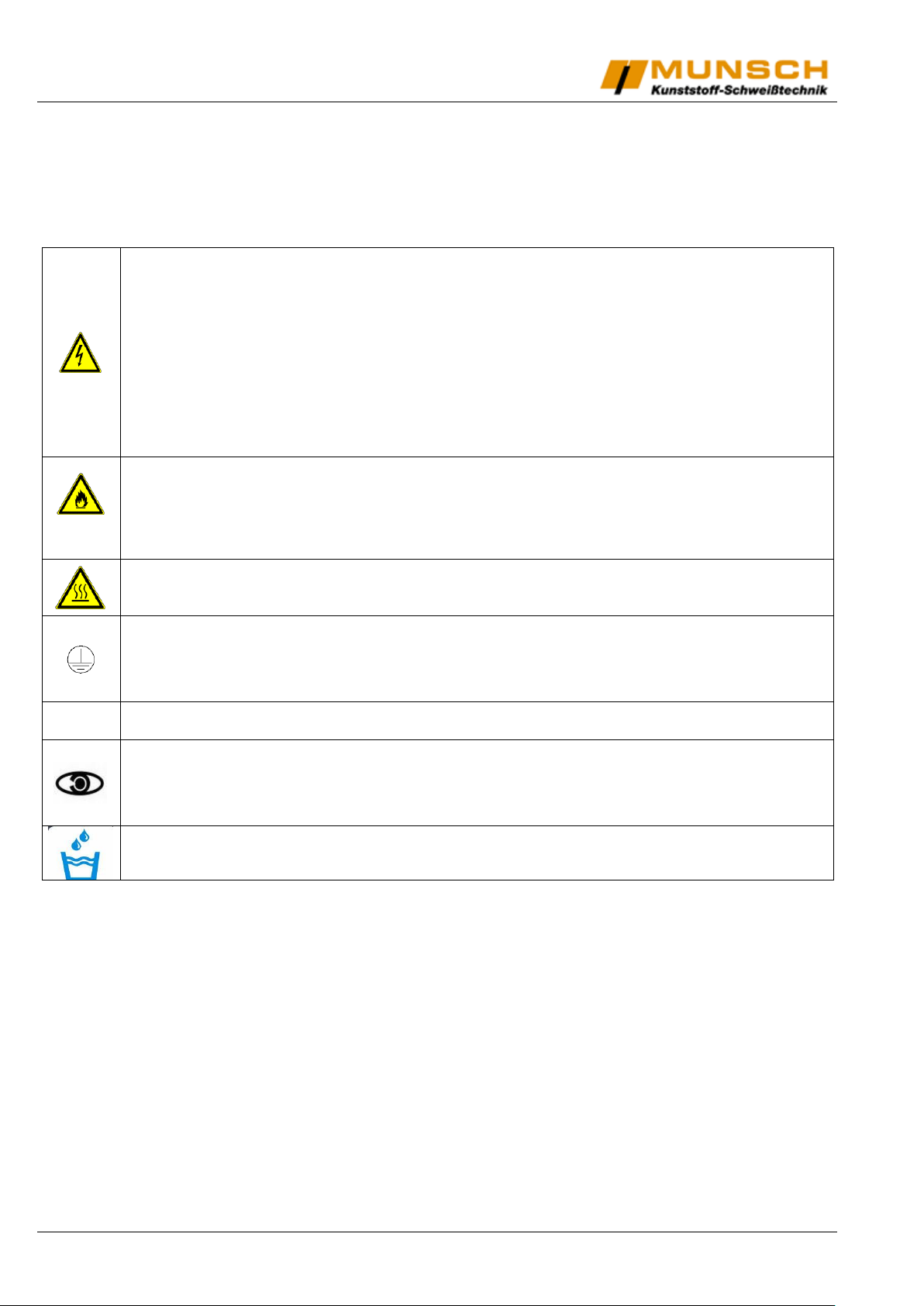

Danger to life when opening the unit due to exposure to live components. Disconnect the power supply (all poles) before opening the unit. A damaged connecting

cable may cause fatal electrical shock. The rated voltage indicated on the unit type

tag must match the mains voltage. If required, check with your electric utility.

Improper use of the welding unit poses a fire and explosion hazard, especially when

working in the vicinity of flammable materials and explosive gases.

Not suitable for use in explosion hazard areas!!!

Risk of burns!!!

Do not touch the heating wedge when hot. Always allow unit to cool down.

Protection Class I equipment

Connect the unit only to power outlets equipped with a protective conductor. Each

interruption of the protective conductor presents a hazard. Only use extension cables with the correct conductor cross-section and a protective conductor.

FI

FI switch required for personal protection.

Unit may only be operated under observation. Heat may propagate to flammable

materials outside the range of vision.

Protect the unit from moisture and direct rainfall!

Safety

MUNSCH Kunststoff-Schweißtechnik GmbH Ausgabe 01.2017/Rev.00 4/20

Motor

Speed

Control

On/Off

Switch

(Motor)

Speed Readout

Temperature Control

Heating

Element

Indicator

Lights

On/Off Switch

(Temperature)

Nip Pressure

Cam Lever

Lock-in Plate

Wedge Movement Handle

Retract Plunger

Lower Nip

Roller

Upper Nip

Roller

Nip Pressure

Cam

Identification

Key electrical controls

Fig.1

Key mechanical components and functions

Fig. 2

5/20 Ausgabe 01.2017/Rev.00 MUNSCH Kunststoff-Schweißtechnik GmbH

Wedge

Upper Contour

Roller Assy

Upper Contour

Roller Adjustment

Lower Contour

Roller Adjustment

Cover

Wedge Up/Down

Centering Adjustment

Drop Out Plate

Lower Contour

Roller Assy

Fig. 3

Fig. 4

MUNSCH Kunststoff-Schweißtechnik GmbH Ausgabe 01.2017/Rev.00 6/20

Loading...

Loading...