0

Operating Instructions

Automatic Wedge Welder

Wedge It LE

MUNSCH Kunststoff-Schweißtechnik GmbH

Im Staudchen • D-56235 Ransbach-Baumbach

Phone: +49 (0) 2623 898-80

Fax: +49 (0) 2623 898-85

mailto: munsch@munsch.de

http://www.munsch.de

Firmensitz/Registered Office: Im Staudchen, D-56235 Ransbach-Baumbach

Registergericht/Registration Court: Amtsgericht Montabaur, HRB 3959

Geschäftsführer/Managing Director: Stefan Munsch

1

Contents

Technical data:..............................................................................................................1

Safety ............................................................................................................................1

Product Description.......................................................................................................3

Control...........................................................................................................................4

Function ........................................................................................................................4

Preparation of Unit ........................................................................................................6

Welding Procedure ......................................................................................................8

Service and Repair 11

Warranty and Conformity 12

Note: These operating instructions must always be available to the

machine operators. Make sure to read them carefully before placing

the unit in service.

Very important!

Switch off the heating wedge whenever the unit is out of service for

prolonged periods.

This will prevent heating up of the machine due to radiating heat.

Otherwise some machine components may develop high surface

temperatures.

Additional cooling of the heating wedge is not allowed. (water, chilling

agents or similar)

Technical data:

Voltage V

230

Frequency HZ

50

Heating capacity W

1350

Motor rating (brushless) W

60

Temperature °C

Max. 450

Max. travel speed m/min

8

Max. welding pressure N

1200

Weight kg

13

Dimensions LxWxH mm

410x220x330

Materials

PE-HD, PE-LD, PE-C,PP, PVC( with steel

wedge)

Material thicknesses mm

0.5-2.5

14

EU Conformity Declaration

MUNSCH Kunststoff – Schweißtechnik GmbH

Im Staudchen

D 56235 Ransbach - Baumbach

hereby declare on their own behalf that the industrial unit to which this declaration refers

conforms to the standards, codes and regulations listed below. Any modifications

made to the unit(s) without prior consultation with MUNSCH Kunststoff –

Schweißtechnik GmbH will void this declaration.

Description of unit:

A

utomatic wedge welder Wedge-It LE

EU Directives:

98/37/EG

89/336/EWG

73/23/EWG

Harmonized standards:

DIN EN ISO 12100-1

DIN EN ISO 12100-2

EN 55014-1

EN 55014-2

The unit must not be placed into service unless all necessary safety precautions

are in place and the occupational health and safety requirements are satisfied.

Ransbach-Baumbach, 01 February 2007

________________________

Dipl.-Ing. Stefan Munsch

Managing Director

13

Service and Repair

Repairs shall be carried out exclusively by MUNSCH Kunststoff-Schweißtechnik

GmbH. Any warranties for units which are no longer in the original condition shall be

expressly excluded. The units may not be modified and/or changed in any way

whatsoever. Any liability for damage resulting from improper use or normal wear and

tear of the units shall be excluded.

Welder type

Serial number

Date Operating hours Type of repair Carried out by:

2

3

Safety

Danger to life when opening the unit due to exposure to live

components. Disconnect the power supply (all poles) before opening

the unit. A damaged connecting cable may cause fatal electrical shock.

The rated voltage indicated on the unit type tag must match the mains

voltage. If required, check with your electric utility.

Improper use of the welding unit poses a fire and explosion hazard,

especially when working in the vicinity of flammable materials and

explosive gases.

Not suitable for use in explosion hazard areas!!!

Risk of burns!!!

Do not touch the heating wedge when hot. Always allow unit to cool

down.

Protection Class I equipment

Connect the unit only to power outlets equipped with a protective

conductor. Each interruption of the protective conductor presents a

hazard. Only use extension cables with the correct conductor crosssection and a protective conductor.

FI

FI switch required for personal protection.

Unit may only be operated under observation. Heat may propagate to

flammable materials outside the range of vision.

Protect the unit from moisture and direct rainfall!

12

Important Note

When the unit is out of operation (between two welding operations, during

breaks or on the shelf), tilt it towards the front to prevent it from rolling away

and avoid damage caused by the hot wedge.

Do not deposit the unit sideways (see above). Risk of damage of the

power supply cable.

11

Now, the welding process has been started.

Once the unit reaches the last few centimetres of the weld seam, disengage the nip

pressure lever (1) and move the heating wedge (4) to its starting position.

Press the “Motor Stop“ button to turn off the motor (page 4) When restarting the

machine, it will continue with the same travel speed unless the potentiometer has

been readjusted.

Test the weld seam (tensile test, proper fusion). Correct the travel speed and/or

temperature, if necessary.

Attention!!

Never allow the machine to run with the nip rollers

locked in place and no material in the machine. This

will destroy the nip rollers and the wedge assembly.

4

Product Description

1 - Nip pressure lever

2 - Wedge adjustment disk (adjustable and engaging)

3 - Spring element

4 - Heating wedge

5 - Upper contour roller

6 - Lower contour roller

7 - Nip pressure cam (labelled with sheet thicknesses)

8 - Main switch

9 - Heater switch

10 - Motor panel with speed display and Start/Stop button

11 - Display for setting and checking the heating element temperature

12 - Potentiometer to increase (clockwise) or reduce (counter-clockwise) the

travel speed.

5

Control

Temperature

Speed

10

Operation of the nip pressure lever (1) as

shown in the illustration on the left will

cause the nip pressure cam (7) to turn and

the upper nip roller to pinch down on the

sheet.

The nip pressure cam is labelled with the

respective sheet thicknesses (2.5, 2.0. 1.5.

1.0, 0.5). Pull down the nip pressure lever

until the respective sheet thickness appears

in horizontal position at the bottom of the

cam. The contact force is generated by a

spring, so that no further adjustments will

be needed.

Pull out the T-handle (2) and rotate the

toggle in counter-clockwise direction until

it engages in the bottom position. This will

cause the heating wedge to be positioned

between the nip rollers.

Attention!!

The contact area between the nip pressure cam (7) and the support plate mu st be lubricated daily

and/or before each welding operation ( see illustration above). This will help pre vent wear

and reduce the effort needed to operate the nip pressure lever.

9

Welding Procedure

The exact welding parameters are determined by producing a test weld.

Make sure to check the unit for damage prior to each welding operation.

Check the nip rollers and the heating wedge for fouling and residues.

The sheets to be welded must be clean. This applies to both the overlap area and the

areas between the two sheets and below and above the sheets.

Operate main switch (8) to turn on the unit. The motor display (10) will light up.

Operate switch (9) to activate heating current supply. The heater display will light up.

Set the desired heating wedge temperature using the temperature preset

pushbuttons “Up” and “Down” (page 4).

Position the unit in the overlap area between the two sheets to be welded.

Press the “Motor Start“ button to start the motor (page 4) The travel speed will be

displayed in m/min in Display (10). To change the speed, use potentiometer (12)

(clockwise Æ faster, counter-clockwise – slower)

Attention!!

Never leave the unit unattended and never lay it

down for prolonged periods with the heating current

activated.

This will cause unnecessary heat development and

ultimately damage to the machine components.

6

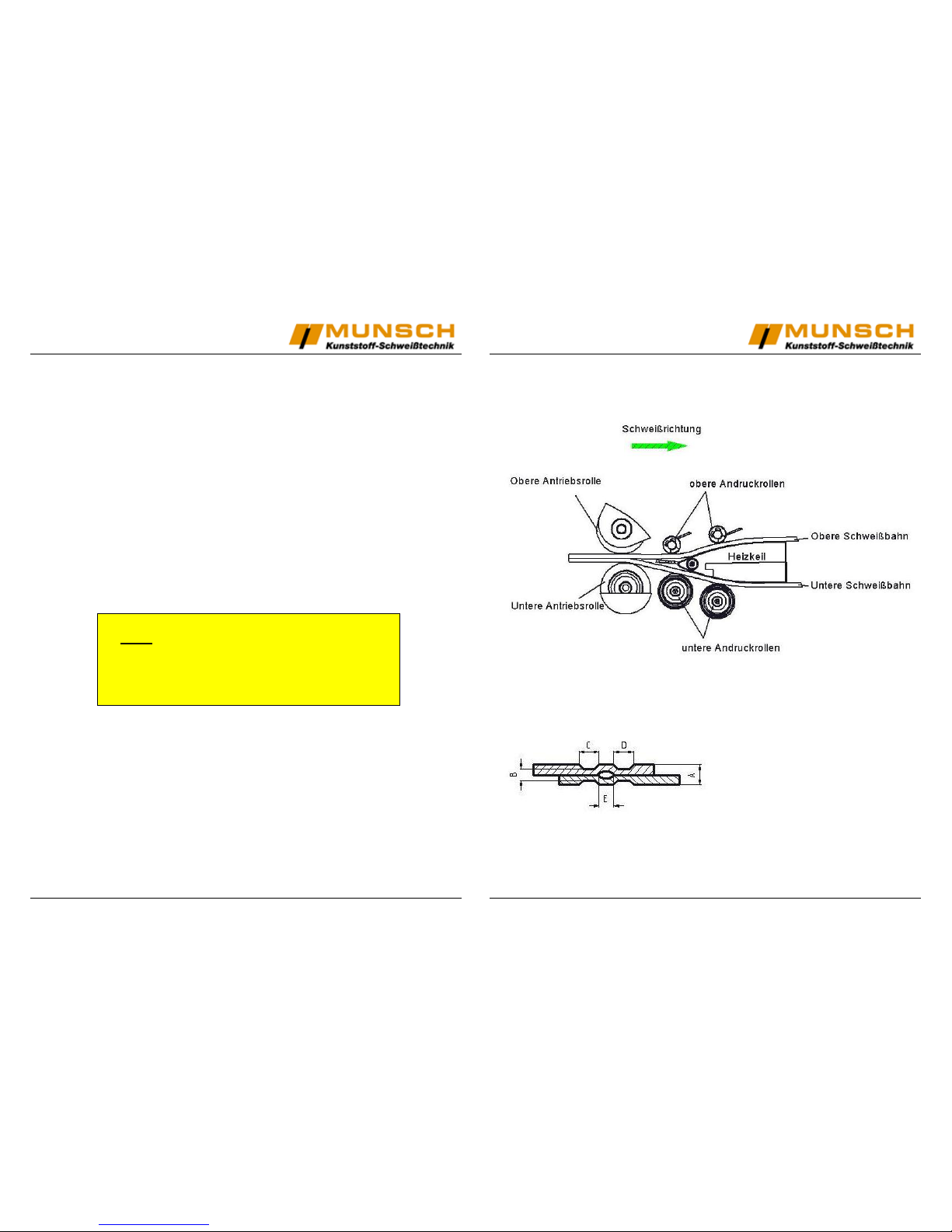

Function

Heating wedge drive system

Overlap weld with air channel

The Wedge It LE produces an

overlap seam with a width of 50 mm

(including air channel) at an overlap

of approx. 130 mm.

A: Sheet thickness

B Thickness of weld seam

C: Part seam 1

D: Part seam 2

E: Air channel

7

Preparation of Unit

The dimension “E“ (wedge position between nip rollers) can be adjusted.

Proceed as follows:

Loosen the two locking screws (A) on the

adjustment disk.

Unlock toggle ( C ) by pulling the T-handle

(B) and rotate toggle (C) counterclockwise until it engages in the bottom

position.

Rotate adjustment disk (D) to adjust the

rear position of the heating wedge

(dimension E). After that, re-tighten the

two locking screws (A).

The angle of inclination of the wedge can

be corrected using the two screws (F).

8

The lower contour rollers (G) can be

adjusted for optimum contact of the sheet

with the wedge. For this purpose, loosen the

hex screws (SW10) on the rear and turn

contour roller (I), which is mounted on

eccentric cams, using an Allan key (SW3).

When the correct clearance between the

contour roller and the heating wedge is

reached, retighten the hex screw.

When operating the unit with power supply from a generator set,

make sure that the generating capacity is sufficient.

Loading...

Loading...