Standard Chemical Pump

Operating manual NPC series

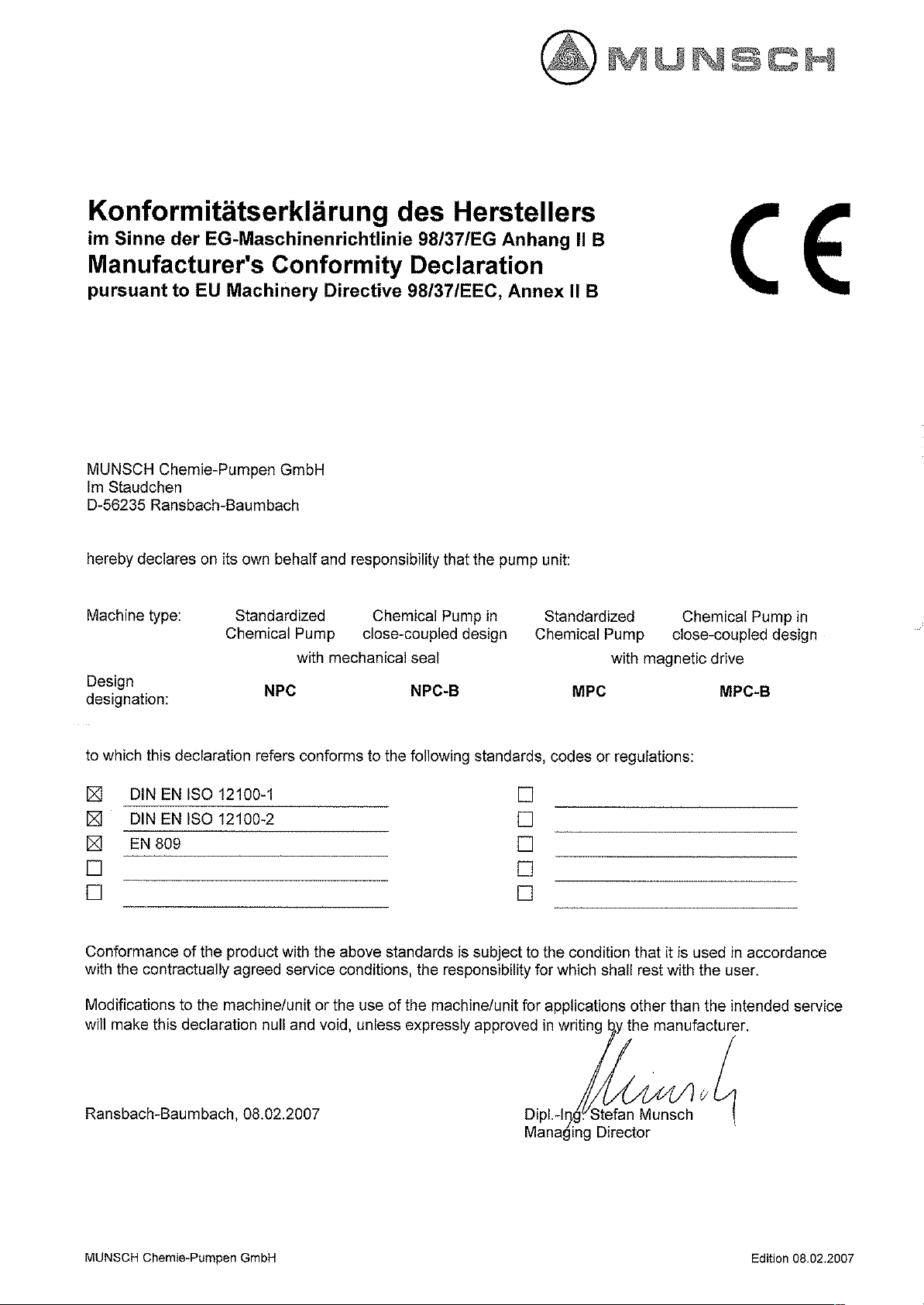

Version BA-2005.07

Print-Nr. 02

VM-Nr. EN

Munsch Chemie-Pumpen GmbH

Im Staudchen

56235 Ransbach-Baumbach

Germany

Phone: +49 (0) 26 23-8 98-90

Fax: +49 (0) 26 23-8 98-95

E-mail: munsch@munsch.de

Internet: http://www.munsch.de

Technical alterations reserved.

Table of contents

Table of contents

1 About this document ............................... 6

1.1 Target groups ................................. 6

1.2 Other applicable documents . .. . .. . .. .. . .. . . 6

1.3 Warning labels and symbols ................ 7

1.4 Technical terms ............................... 7

2 Security ... ........................................... 8

2.1 Intended use ........ .......................... 8

2.2 General safety instructions .................. 8

2.2.1 Product safety ......... ....................... 8

2.2.2 Duties of the operating company . . . .. . .. . .. 9

2.2.3 Duties of the operating personnel . . .. .. . .. . . 9

2.3 Special hazards ............ .................. 9

2.3.1 Explosion hazard area ..................... .. 9

2.3.2 Hazardous pumped media . .. . . .. . .. . .. .. . .. 9

3 Layout and function ................................ 10

3.1 Labels ............ ............................. 10

3.1.1 Type plate ........................... .......... 10

3.1.2 ATEX plate ....................... ............. 10

3.1.3 Pump type code . .. . . . .. . .. . .. .. . .. . .. .. . .. . .. 10

3.2 Layout ............... .......................... 11

3.3 Shaft seals ............... ..................... 11

3.3.1 Mechanical seals ........ ..................... 11

3.4 Auxiliary operating systems ................. 12

3.4.1 Sealing systems ....................... ....... 12

4 Transport, storage and disposal .................. 13

4.1 Transport .................... .................. 13

4.1.1 Unpacking and inspection on delivery .. . .. . 13

4.1.2 Lifting .. ........................................ 13

4.2 Preservation ..................... ............. 14

4.3 Storage ................................ ....... 14

4.4 Disposal ............................. .......... 14

5 Setup and connection ............................ .. 15

5.1 Preparing the setup ................... ....... 15

5.1.1 Checking the ambient conditions . ... .. .. . .. 15

5.1.2 Preparing the setup site ..................... 15

5.1.3 Preparing the foundation and setup

surface ........................................ 15

5.1.4 Installing the heat insulation .. .. . .. .. . ... .. .. 15

5.2 Setup with foundation ........... ............. 16

5.2.1 Setting the pum p aggregate on the

foundation .... ................................ 16

5.2.2 Fastening the pump aggregate .. . .. . ... . .. . 16

5.3 Setup without foundation ..... ............... 17

5.4 Mounting the moto

5.5 Planning the piping .... ....................... 17

5.5.1 Avoid contamination of the piping . . .. . .. .. . . 17

5.5.2 Specifying supports and flange

connections . . .. . ... . .. . .. . .. .. . .. . .. .. . ... . .. . 17

r ..........................

17

5.5.3 Specifying nominal widths ................... 18

5.5.4 Specifying pipe lengths .................. .... 18

5.5.5 Optimizin g cross-section and direction

changes ....................................... 18

5.5.6 Arranging for safety and control devices

(recommended) .............................. 18

5.6 Connecting the pipes ........................ 18

5.6.1 Installing auxiliary pipes ................... .. 18

5.6.2 Installing the suction pipe . . ... . .. . .. . . .. . .. . . 18

5.6.3 Installing the pressure pipe . .. . ... . .. . ... .. .. 18

5.6.4 Inspection for stress-free pipe

connections . . .. . ... . .. . .. . .. .. . .. . .. .. . ... . .. . 19

5.6.5 Inspecting the support foot for

distortion .................... .................. 19

5.7 Electrical connection ......................... 19

5.7.1 Connecting the motor ........................ 19

5.7.2 Checking the direction of rotation .. . .. . . .. . . 19

5.8 Fine alignment of the coupling . ... . .. . .. . . .. 20

5.9 Aligning the motor .......... .................. 20

5.9.1 Aligning the motor using sets of shims . .. . . 20

6Operation ............................................ 21

6.1 Preparations for the initial start-up .. .. . . . .. . 21

6.1.1 Identifying the pump type ....... ............. 21

6.1.2 Lubricating the bearings ..................... 21

6.1.3 Preparing auxiliary operating syste ms (if

available) ........ ............................. 21

6.1.4 Filling and bleeding .......................... 21

6.2 Start up ....................................... 22

6.2.1 Switching on .................................. 22

6.2.2 Switching off .................................. 22

6.3 Shut-down ..................... ............... 23

6.4 Start-up following a shutdown period .. . .. . . 23

6.5 Running the stand-by pump .. ............... 23

7 Maintenance . ........................................ 24

7.1 Inspections . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. 24

7.2 Maintenance ........ .......................... 24

7.2.1 Roller bearings with grease lubrication ... . . 24

7.2.2 Roller bearings with oil lubrication . . . .. . .. . . 25

7.2.3 Stationary seal rings .. ....................... 25

7.3 Disassembling . . .. . .. . . .. . .. . .. .. . .. . .. .. . .. . . 25

7.3.1 Returning the pump to the manufac-

turer ................................. .......... 26

7.3.2 Preparations for disassembl ing . . ... . .. . .. . . 26

7.3.3 Loosening connectors (if available) . .. . .. . .. 2 7

7.3.4 Extract ing the volute casing . ... . .. . .. . . .. . .. 27

7.3.5 Disassemblin g the impeller .. .. . ... . .. . .. . . .. 27

7.3.6 Disassemblin g a casing cover with

MUNSCH-REA-C mechanical seal .. . .. .. . . 28

7.3.7 Disassemblin g the atmosphere-side

stationary seal ring ........................... 28

7.3.8 Disassemblin g the bearing bracket . ... . .. . . 29

7.3.9 Disassemblin g the pump shaft . ... . .. . .. . . .. 29

7.4 Assembli

ng ...... .............................

30

2 NPC series BA-2005.07 EN – 02

7.4.1 Preparations for assembling . ... . .. . ... .. .. . 30

7.4.2 Fitting the pump shaft ........ ................ 30

7.4.3 Fitting the bearing bracket . .. . .. . . .. . .. . .. .. . 30

7.4.4 Fitting the casing cover . . .. . ... . .. . .. . .. .. . .. 30

7.4.5 Fitting the pump into the installation . .. . . .. . 30

7.5 Ordering replacement parts ................. 30

8 Disturbance recovery ........... ................... 31

9 Appendix ....... ...................................... 34

9.1 Sectional drawings ........................... 34

9.1.1 Part numbers and designations ............. 34

9.1.2 Overview sect ional drawing . .. . ... . .. . ... .. . 36

9.1.3 Variants .................................. ..... 36

9.2 Technical specifications ................. ..... 40

9.2.1 Ambient conditions ..... ...................... 40

9.2.2 Paramet ers for auxiliary operating

systems ............................ ........... 40

9.2.3 Noise pressure level .. . ... . .. . .. . . .. . .. . .. .. . 40

9.2.4 Tightening torques ........................... 41

9.2.5 Lubricants . . .. . .. .. . ... .. .. . ... .. .. . ... .. .. . ... 42

9.2.6 Detergents .................................... 42

9.2.7 Socket loads according to ISO 5199 .. . . .. . 42

9.3 Replacement parts for 2 years of continuous

operation according to DIN 24296 .. . .. . .. .. 43

Table of contents

EN – 02 BA-2005.07 NPC series 3

Table of contents

List of figures

Fig. 1 Type plate (example) .................... .... 10

Fig. 2 ATEX plate (example) ................. ....... 10

Fig. 3 Pump type code (example) . . .. . ... . .. . .. . .. . 10

Fig. 4 Layout NPC ......................... .......... 11

Fig. 5 Double mechanical seal with quench

(operating principle) ................ .......... 12

Fig. 6 Double mechanical seal with foreign blocking

(operating principle) ................ .......... 12

Fig. 7 Fastening the lifting gear to the pump

aggregate ..................................... 13

Fig. 8 Fastening the lifting gear to the pump . . .. . . 13

Fig. 11 Setup without foundation ..... ............... 17

Fig. 12 Straight pipe lengths upstream and down-

stream of the pump (recommended) . .. . ... 18

Fig. 16 Oil level in sight glass .............. .......... 21

Fig. 17 Loosening the flushing connector or supply

connectors REA-C/D .. . ... . .. . .. . .. .. . ... .. .. 27

Fig. 18 Extracting the volute casing .. . ... . .. . ... . .. . 27

Fig. 19 Disassembling the impeller . . . . .. . .. . .. .. . .. . 27

Fig. 20 Disassembling a casing cover with

MUNSCH-REA-C mechanical seal .. . .. .. . . 28

Fig. 21 Disassembling MUNSCH-REA-D stationary

seal ring ................ ....................... 28

Fig. 22 Disassembling the bearing bracket (grease

lubrication, L16A, L18B, L20A) .. . .. . .. .. . .. . 29

Fig. 23 Disassembling the pump shaft (no lifetime

lubrication) .................................... 29

Fig. 24 Disassembling the pump shaft (with lifetime

lubrication) .................................... 29

Fig. 25 Fitting the casing cover .................. .... 30

Fig. 26 NPC – overview sectional drawing . ... . .. . . 36

Fig. 27 NPC – casing foot .......... .................. 36

Fig. 28 Emptying (optional) .......................... 36

Fig. 29 MUNSCH-REA-C single mechanical

seal ....................... ..................... 37

Fig. 30 MUNSCH-REA-C/D double mechanical

seal ....................... ..................... 37

Fig. 31 Stationary seal ring holder (o

mechanical seal) ............................. 37

Fig. 32 Shutdown/continuous flushing (flushing of

pump interior) ............ ..................... 37

Fig. 33 Single mechanical seal with spring chamber

flushing (supply connectors) . .. . .. . .. .. . .. . . 37

Fig. 34 MUNSCH-REA-C/

tors ............ ................................ 38

Fig. 35 Casing cover (split) ................ .......... 38

D supply connec-

nly for double

Fig. 36 Bearing bracket L16A (grease-lubricated

bearing) ....................................... 38

Fig. 37 Bearing bracket L16A (grease-lubricated

bearing, lifetime lubrication) ................. 38

Fig. 38 Bearing bracket L16A (oil-lubricated

bearing) ....................................... 39

Fig. 39 Bearing bracket L18B (grease-lubricated

bearing) ....................................... 39

Fig. 40 Bearing bracket L18B (oil-lubricated

bearing) ....................................... 39

Fig. 41 Blocking – pressure of sealing medium . . ... 40

Fig. 42 Socket loads at the pump ... . .. . .. . .. .. . .. . . 42

4 NPC series BA-2005.07 EN – 02

List of tables

Tab. 1 Target groups and their duties . .. .. . ... .. .. . 6

Tab. 2 Other applicable documents and their

purpose ....................................... 6

Tab. 3 Warning labels and consequences of

disregarding them .................... ........ 7

Tab. 4 Symbols and their meaning ................. 7

Tab. 5 Technical terms and their meaning .. . .. . .. . 7

Tab. 6 Quenching – variants and characteris-

tics ............... .............................. 12

Tab. 7 Foreign blocking – variants and

characteristics ............................. ... 12

Tab. 8 Action to be taken for pump shutdowns . ... . 23

Tab. 9 Measures depending on pumped medium

behavior ....................... ................ 23

Tab. 10 Actions to be taken after prolon ged shutdow n

periods ....... ................................. 23

Tab. 11 Actions for return ........................ ..... 26

Tab. 12 Fault/number assignment .. . .. . .. .. . .. . .. .. . 31

Tab. 13 Troubleshooting list .......................... 33

Tab. 14 Designations of components listed with part

numbers ................................. ..... 35

Tab. 15 Ambient conditions ................ ........... 40

Tab. 16 Operating parameters for sealing medium in

open flow system ....... ...................... 40

Tab. 17 Noise pressure level . .. . .. .. . ... . .. . .. . .. .. . . 40

Tab. 18 Steel/cast pairing . .. . .. .. . .. . .. .. . .. . . .. . .. . .. 41

Tab. 19 Socket head cap screw 914.1 - steel/steel

pairing ......................................... 41

Tab. 20 Lubricating greases .......................... 42

Tab. 21 Minimum amounts for grease lubrica-

tion ............................................ 42

Tab. 22 Lubricating oils ............................... 42

Tab. 23 Minimum amounts for oil lubrication . . .. . ... 42

Tab. 24 Detergents ... ................................. 42

Tab. 25 Socket loads – forces .. ... .. .. . ... .. .. . ... .. . 42

Tab. 26 Socket loads – torques . . . .. . .. . .. .. . .. . .. .. . 42

Tab. 27 Replacement parts for 2 years' continuous

operation ..... ................................. 43

Table of contents

EN – 02 BA-2005.07 NPC series 5

About this document

1 About this document

This manual

• is part of the pump

• applies to the pump series mentioned above

• describes safe and appropriate operation during all operating phases

1.1 Target groups

Target group Duty

Operating company Keep this manual available at the site of operation of the

installation, including for later use.

Ensure that personnel read and follow the instructions in this

manual and the other applicable documents, especially all safety

information and warnings.

Observe any additional rules and regulation referring to the

installation.

Qualified personnel, fitter Read, observe and follow this manual and the other applicable

documents, especially all safety information and warnings.

Tab. 1 Target groups and their duties

1.2 Other applicable documents

Document Purpose

ATEX additional instructions

Order data sheet Technical specifications, conditions of operation

Setup drawing Setup dimensions, connection dimensions, etc.

Technical description

Sectional drawing Sectional drawing, parts numbers, component designations

Supplier documentation Technical documentation for parts supplied by subcontractors

Replacement parts list

Safety certificate Returning the pump to the manufacturer

Tab. 2 Other applicable documents and their purpose

Operation in explosion hazard areas

Technical specifications, operating limits

Ordering replacement parts

6 NPC series BA-2005.07 EN – 02

1.3 Warning labels and symbols

About this document

Warning label Risk level

Immediate acute risk Death, grievous bodily harm

DANGER

Potential acute risk Death, grievous bodily harm

WARNING

Potential hazardous situation Minor bodily harm

CAUTION

Potential hazardous situation Material damage

CAUTION

Tab. 3 Warning labels and consequences of disregarding them

Symbol

1. , 2. , ...

→

Meaning

Safety warning sign

Take note of all information highlighted by the safety warning sign

and follow the respective instructions to avoid injury or death.

Safety instruction

Step-by-step safety instructions

Precondition

Cross reference

Information, hint

Consequences of disregard

Tab. 4 Symbols and their meaning

1.4 Technical terms

Ter m Me a n ing

Sealing medium Medium for locking or quenching of shaft seals

Auxiliary operating systems

Tab. 5 Technical terms and their meaning

Systems for operating the pump

EN – 02 BA-2005.07 NPC series 7

Security

2 Security

The manufacturer does not accept any liability for events

resulting from disregard of the entire documentation.

2.1 Intended use

• Only use the pump for pumping the agreed pumped media

(→ Order data sheet).

• Adhere to operating limits and size-dependent minimum

flow rate.

• Avoid dry running:

Initial damage such as destruction of mechanical seal and

plastic parts within only a few seconds.

– Make certain that the pump is never put into operation

and never operated without a pumped medium.

• To avoid cavitation:

– Fully open the suction-side armature and do not use

for adjusting the flow rate.

– Do not open the pressure-side armature beyond the

agreed operating point.

• To avoid overheating:

– Do not operate the pump while the pressure-side arma-

ture is closed.

– Observe the minimum flow rate (→ Order data sheet).

• To avoid damage to the motor:

– Do not open the pressure-side armature beyond the

agreed operating point.

– Observe the allowed number of motor swi tch-ons per

hour (→ Manufacturer's specifications).

• Consult with the manufacturer about any other use of the

pump.

2.2 General safety instructions

Take note of the following instructions before carrying out

any work.

2.2.1 Product safe ty

The pump has been constructed according to up-to-date technology and established technical safety rules. Nevertheless,

operation of the pump can involve risks to life and health of the

user or of third parties, or risks of damaging the pump and other

property.

• Operate the pump only if it is in perfect technical condition,

according to its intended use, in awareness of safety and

risks and in adherence to the instructions in this manual.

• Keep this manual and all other applicable documents complete, legible and accessible to personnel at all times.

• Refrain from any procedures and actions that would

expose personnel or third parties to any risk.

• Should there be any safety-relevant fault, deactivate the

pump immediately and have the fault corrected by appropriate personnel.

• In addition to the entire documentation for the product,

always comply with statutory or other safety and accident-prevention rules and with the applicable standards

and guidelines in the country where the pump is operated.

Prevention of self-evident misuse (examples)

• Observe the operating limits of the pump regarding operating temperature, pressure, flow rate and speed (→ Order

data sheet).

• The power uptake of the pump will increase with increasing

density of the pumped medium. To avoid any overload for

the pump, the coupling and the motor, do not exceed the

allowable density (→ Order data sheet).

A lower density is allowed. Adapt auxiliary system s accordingly.

• Adhere to limits on solids content and grit size when pumping solids-carrying fluids (→ Order data sheet, technical

description).

• When using auxiliary operating systems, en sure that

there is a continuous supply of the appropriate operating

medium.

8 NPC series BA-2005.07 EN – 02

Security

2.2.2 Duties of the operating company

Safety-conscious operating

• Operate the pump only if it is in perfect technical condition,

according to its intended use, in awareness of safety and

risks and in adherence to the instructions in this manual.

• Ensure that the following safety aspects are observed and

monitored:

– adherence to intended use

– statutory or other safety and accident-prevention rules

– safety regulations governing the handling of hazardous

substances

– applicable standards and guidelines in the country

where the pump is operated

• Make protective equipment available.

Qualified personnel

• Make certain that all personnel tasked with work on the

pump have read and understood this manual and all other

applicable documents, especially the safety, maintenance

and repair instructions, before they begin the job.

• Organize responsibilities, who is in charge of any specific

duty and how personnel is supervised.

• Ensure that all work is carried out by specialist technicians

only:

– fitting, repair and maintenance work

– work on the pump electrical system

• Make certain that trainee personnel is supervised by a specialist technician when performing tasks on the pump.

Safety installations

• Provide the following safety installations and verify their

integrity:

– for hot and moving parts: device-side contact protec-

tion on the pump

– in case of potential electrostatic charging: appropriate

grounding

2.2.3 Duties of the operating personnel

• Observe and keep legible all directions given on the pump,

e.g. the arrow indicating the direction of rotation and the

markings for fluid connections.

• Do not remove the contact protection f or hot, cold and moving parts during operation.

• Use protective equipment if necessary.

• Carry out work on the pump only while the pump is not

running.

• Isolate the motor from its supply voltage and keep it locked

in that state while carrying out any fitting or maintenance

work.

• Mount the safety installations on the pump according to

instructions after completion of work on the pump.

2.3 Special hazards

2.3.1 Explosion hazard area

• (→ ATEX additional instructions).

2.3.2 Hazardous pumped media

• Observe the safety regulations for the handling of hazardous substances when working with hazardous pumped

media (e.g. hot, flammable, poison ous or potentially harmful).

• Use protective equipment when carrying out any work on

the pump.

Warranty

• Obtain the manufacturer's approval prior to carrying out

any modification, repair or alterations during the warranty

period.

• Only use original parts or parts that have been approved

by the manufacturer.

EN – 02 BA-2005.07 NPC series 9

Layout and function

3 Layout and function

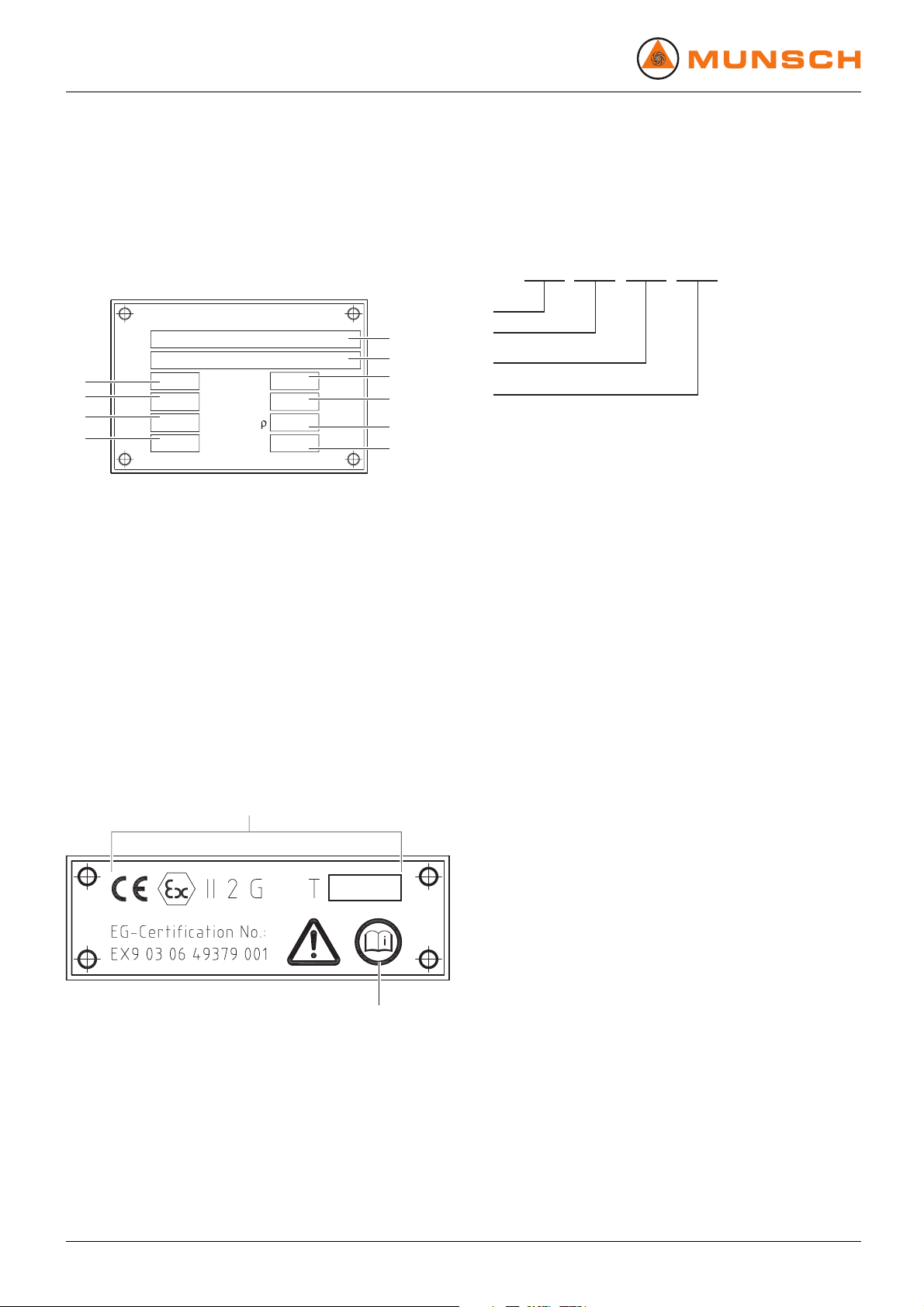

3.1 Labels

3.1.1 Type plate

MUNSCH Chemie-Pumpen GmbH

Typ

type

W.-Nr.

serial-no.

10

Lfrd.

impeller

9

8

7

Fig. 1 Type plate (example)

1Pumptype

2 Serial number

3 Construction year

4 Total differential head

5 Density

6Torque

7 Speed

8 Power consumption

9Flowrate

10 Impeller di ameter

D-56235 Ransbach-Baumbach

3

Q

P

n

m /h

kW

min

-1

Baujahr

year

3.1.3 Pump type code

NPC

50 - -32 200

1

1

2

3

H

M

m

kg/dm

Nm

4

3

5

6

2

3

4

Fig. 3 Pump type code (example)

1 Pump series

2 Suction flange DN [mm]

3 Pressure flange DN [mm]

4 Impeller nominal diameter [mm]

3.1.2 ATEX plate

1

Fig. 2 ATEX plate (example)

1 Explosion protection mark

2 Reference to ATEX additional instructions

2

10 NPC series BA-2005.07 EN – 02

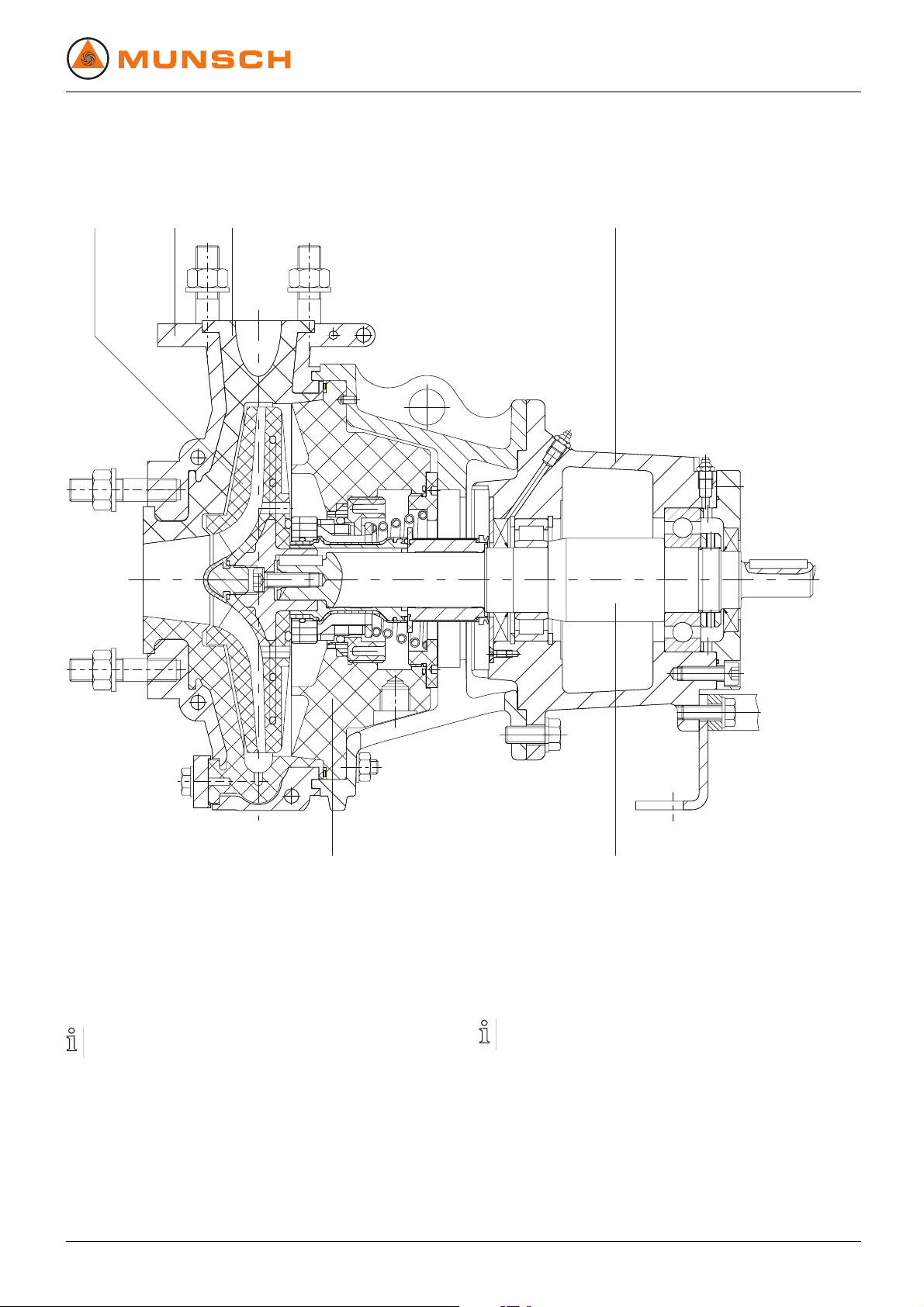

3.2 Layout

Layout and function

1

2 3 4

56

Fig. 4 Layout NPC

1 Impeller

2 Casing armour plating

3.3 Shaft seals

Only one of the following shaft seals can be used.

EN – 02 BA-2005.07 NPC series 11

3 Volute casing

4 Bearing bracket

5 Pump shaft

6 Casing cover

3.3.1 Mechanical seals

Mechanical seals will always show some functional drip

leakage.

• Single mechanical seal

• Double mechanical seal with quench

• Double mechanical seal with foreig

n blocking

Layout and function

3.4 Auxiliary operating systems

3.4.1 Sealing sy stems

Only one of the following sealing systems can be used.

Quenching

1 2

3

Fig. 5 Double mechanical seal with quench

(operating principle)

1 Pumped medium

2 Sealing medium (unpressurized)

3 Double mechanical seal

With quenching, the pressure of the pumped medium exceed s

the pressure of the sealing medium. The sealing friction surfaces of the product-side seal are lubricated by the pumped

medium.

Application examples:

• pumped media that crystallize in air, cau sing long-term

damage to the seal

• prevention of odors

• seal cooling

Varia nt

Open system

Closed system

Tab. 6 Quenching – variants and characteristics

Sealing medium

characteristics

• supplied and drained

continuously

• unpressurized

• circulates in a closed

cycle

• unpressurized

Blocking

1 2

3

Fig. 6 Double mechanical seal with foreign blocking

(operating principle)

1 Pumped medium

2 Sealing medium (pressurized)

3 Double mechanical seal

With foreign blocking, the pressure of the sealing m edium

exceeds the pressure of the pumped medium. The sealing

friction surfaces are lubricated by the sealing medium.

Application examples:

• pumped media that crystallize or carry solids, causing longterm damage to the seal

• toxic pumped media

• pumped media presenting an environmental hazard

Varia nt

Open flow system

Closed flow system

Tab. 7 Foreign blocking – variants and characteristics

Sealing medium

characteristics

• supplied and drained

continuously

• pressurized

• circulates in a closed

cycle

• pressurized

12 NPC series BA-2005.07 EN – 02

4 Transport, storage and disposal

Transport, storage and disposal

4.1 Transport

Weight specifications (→ Individual order documentation).

4.1.1 Unpacking and inspection on delivery

1. Unpack the pump/aggregate on delivery and inspect for

transport damage.

2. Report any transport damage to the manufacturer without

delay.

3. Dispose of packaging material according to local regulations.

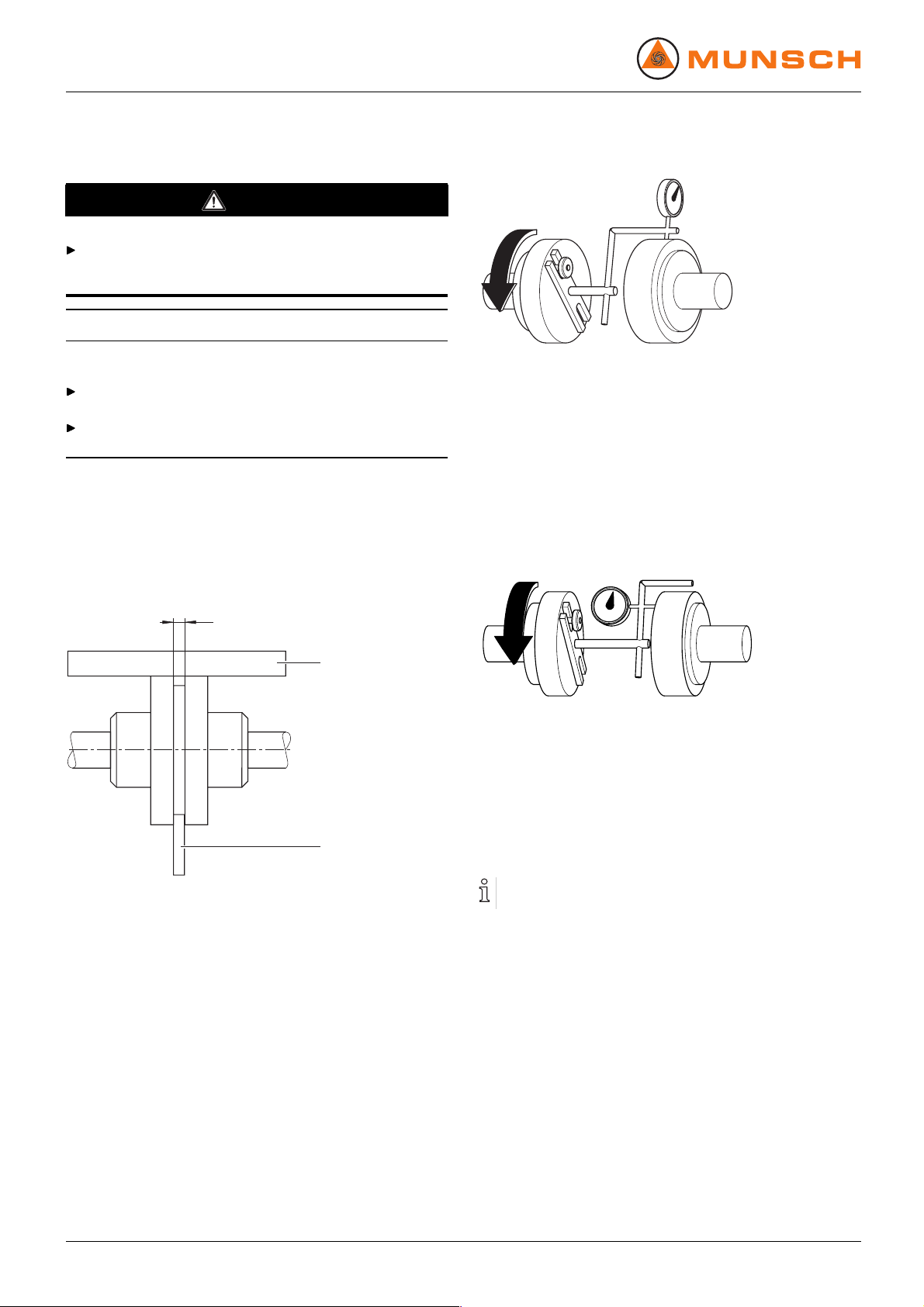

4.1.2 Lifting

DANGER

Death or crushing of limbs caused by falling loads!

Use lifting gear appropriate for the total weight to be transported.

Fasten the lifting gear as shown in the illustrations below.

Do not stand under suspended loads.

Fig. 7 Fastening the lifting gear to the pump aggregate

Fig. 8 Fastening the lifting gear to the pump

Lift the pump/aggregate appropriately.

EN – 02 BA-2005.07 NPC series 13

Transport, storage and disposal

4.2 Preservation

No preservation required.

Do not preserve the pump.

4.3 Storage

CAUTION

Material damage due to inappropriate storage!

Store the pump appropriately.

1. Seal all openings with blind flanges, blind plugs or plastic

covers.

2. For mode ls with oil-lubricated bearings and downtimes in

excess of one year:

– Dismount any existing reservoir

– Dismount any existing oil level controller

– Seal the tap hole

– Fill the bearing bracket with oil, up to the brim

– Seal the bleeding hole

3. Make certain that the storage room meets the following

conditions:

–dry

– frost-free

– vibration-free

4. Turn shaft once a month.

5. Make certain that the shaft and the bearing change their

rotational position in the process.

4.4 Disposal

Plastic parts can be contaminated by poisonous or radioactivepumpedmediatosuchanextentthatcleaningwill

be insufficient.

WARNING

Risk of poisoning and environmental damage caused by

pumped medium or oil!

Use protective equipment when carrying out any work on

the pump.

Prior to disposal of the pump:

– Collect pumped medium and oil or grease running out

and dispose of the pumped medium according to local

regulations.

– Neutralize residues of pumped medium in the pump.

Dismount plastic parts and dispose of the parts according

to local regulations.

Dispose of pump according to local regulations.

14 NPC series BA-2005.07 EN – 02

5 Setup and connection

Setup and connection

For pumps in explosion hazard areas (→ ATEX additional

instructions).

CAUTION

Material damage caused by dirt!

Do not remove tra nsport locks until imm ediately before setting up the pump.

Do not remove covers and transport and sealing covers

until immediately before connecting the piping to the pum p.

5.1 Preparing the setup

5.1.1 Checking the ambient conditions

1. Make certain that the required ambient conditions are fulfilled (→ 9.2.1 Ambient conditions, Page 40).

2. For setup sites > 1000 m above sea l evel, consult with the

manufacturer.

5.1.2 Preparing the setup site

Make certain that the setup site meets the following conditions:

– pump is freely accessible from all sides

– sufficient space for installation/removal of the pipes

and for maintenance and repair work, especially for the

removal and installation of the pump and the motor

– pump not exposed to external vibrations (damage to

bearings)

– frost protection

5.1.4 Installing the heat insulation

Only necessary to maintain the temperature of the pumped

medium.

CAUTION

Material damage caused by overheating!

Only install the heat insulation on the volute casing.

Install the heat insulation appropriately.

5.1.3 Preparing the foundation and setup surface

Setup options:

– with concrete foundation

– with steel foundation frame

– without foundation

Make certain that the foundation and setup surface meet

the following conditions:

– level surface

– clean (no oil, dust or other impurities)

– foundation and surface can support the weight of the

pump aggregate and all operating forces

– safe stand of the pump aggregate ensured

– for concrete foundation: Standard concrete of strength

class B 25

EN – 02 BA-2005.07 NPC series 15

Setup and connection

5.2 Setup with foundation

CAUTION

Material damage due to base plate distortion!

Set and fasten the base plate on the foundation as

described in the following.

5.2.1 Setting the pump aggregate on the foundation

✔ Implements, tools and materials:

– foundation bolts (→ Setup drawing)

– steel washers

– mortar grout, non-shrinking

– spirit level

1. Lift the pump aggregate (→ 4.1 Transport, Page 13).

2. Working from below, hang the foundation bolts in the fixation holes of the base plate.

Observe the manufacturer's instruction when using chemical anchors.

3. Set down the pump a ggregate on the foundation. When

doing this, sink the foundation bolts into the prepared

anchoring holes.

5.2.2 Fastening the pump aggregate

Filling out the base plate with mortar grout will improve the

damping behavior.

1. Fill the anchoring holes with mortar grout.

2. Once t he mortar grout has set, screw on the base

plate at three points with the specified tightening torque

(→ 9.2.4 Tightening torques, Page 41).

3. Before tightening the remaining bolts, compensate any

unevenness of the fixation surface, using metal shims next

to each bolt.

4. To inspect the pump aggregate for distortions, using a hair

ruler:

1

32 1 2

Fig. 9 Setup with foundation

4. Use steel washers to align the pum p aggregate to height

and system measures as described in the following:

– Position 1 steel washer (2) each left and right of each

foundation bolt (1).

– If the distance between anchoring holes is > 750 mm,

position additional steel washer (3) centrally at each

side of the base plate.

5. Make certain that the base plate and the steel washers are

in full surface contact.

6. Use machine spirit level to check that the allowable height

deviation (1 mm/m) lengthwise and crosswise is not

exceeded.

7. Repeat procedure until the base plate is correctly aligned.

Fig. 10 Checking for di stortions

– Measure in two planes at an angle of 90° to each other

on the circumference of the coupling.

– Measure the light gap at the outer diameter with hair

ruler (1):

Position the hair ruler across both halves of the coupling.

If there are major deviations, loosen the fixation at the

base plate and correct the distortion by inserting more

shims.

– Fill the base plate with molding material if applicable.

Knock on the base plate to ensure that no cavities are

created in the process.

Couplings with a spacer piece (Dismountable coupling) can

also be inspected with a dial gauge.

16 NPC series BA-2005.07 EN – 02

Setup and connection

5.3 Setup without foundation

✔ Implements, tools and materials:

–Wrench

– Spirit level

1

1

1

2

1

3

4

Fig. 11 Setup without foundation

1. Lift the pump aggregate (→ 4.1.2 Lifting, Page 13).

2. Mount the four leveling feet (1) as shown in the figure.

3. Set down the pump aggregate on the setup surface.

4. Adjust the height of the base plate using leveling feet (1)

as shown above:

– Use wrench to hold the hexagon at leveling foot (4).

– Slacken hexagon nut (2).

– Adjust height by turning hexagon nut (3).

– Tighten hexagon nut (2) (→ 9.2.4 Tightening torques,

Page 41).

– Use machine spirit level to check that the allowable

height deviation (1 mm/m) lengthwise and crosswise

is not exceeded.

– Repeat procedure until the base plate is aligned cor-

rectly.

5.4 Mounting the motor

Only necessary if the pump aggregate is assembled at he

setup site.

CAUTION

Material damage caused by knocks and blows!

Do not cant the coupling halves when pushing on the motor.

Do not knock or hit any component of the pump.

1. Apply a very thin film of molybdenum sulfite (e.g. Molykote)

on the pump and motor shaft ends.

2. Insert keys.

3. Without a mounting device: Remove rubber buffers and

heat coupling halves to approx. 100 °C.

4. Slide on the pump-side and motor-side coupling halves

until the shaft end and the coupling center are flush with

each other. Keep to the specified distance between the

coupling halves (→ Assembly instructions for the coupling).

5. Tighten the threaded pins at both coupling halves.

6. Use suitable m etal shims at the motor to adjust the motor

shaft end to the height of the pump shaft end.

7. Turn in the motor screws, but do not tighten them yet

(→ 5.9 Aligning the motor, Page 20).

5.5 Planning the pipi ng

5.5.1 Avoid contamination of the piping

CAUTION

Material damage due to impurities in the pump!

Make certain that no impurities can get into the pump.

1. Clean all piping components and armatures prior to assembly.

2. Ensure that no flange gaskets are protruding inwards.

3. Remove blind flanges, plugs, protective foils and/or protective paints on flanges.

5.5.2 Specifying supports and flange connections

CAUTION

Material damage due to excessive forces and torque from

piping on the pump!

Do not exceed allowable limits (→ 9.2.7 Socket loads

according to ISO 5199, Page 42).

1. Calculate pipe forces and take into account every possible

operating condition:

– cold/warm

– empty/full

– unpressurized/pressurized

– position shifts of flanges

2. Ensure that pipe supports have permanent low-friction

properties and will not seize up through corrosion.

EN – 02 BA-2005.07 NPC series 17

Setup and connection

5.5.3 Specifying nominal widths

Keep flow resistance in pipes as low as possible.

1. Specify suction pipe nominal width ≥ suction flange nominal

width.

2. Specify pressure pipe nominal width ≥ pressure flange

nominal width.

5.5.4 Specifying pipe lengths

D

C

A

Fig. 12 Straight pipe lengths upstream and downstream

of the pump (recommended)

A>5xDNs

B DNs

C DNd

D>5xDNd

Observe recommended minimum parameters when installing the pump.

Suction side: Shorter pipes are allowable but can restrict

hydraulic performance data.

Pressure side: Shorter pipes are allowable but can lead to

increased operating noise.

5.5.5 Optimizing cross-section an d direction changes

1. Avoid radii of curvature smaller than 1.5 times the nominal

pipe width.

2. Avoid abrupt changes of cross-section along the piping

system.

B

5.5.6 Arranging for safety and control devices (recommended)

Avoiding contamination

1. Integrate filter into the suction pipe.

2. To monitor contamination, mount a differential pressure

gage with a contact manometer.

Avoiding reverse running

1. Install a check valve between the pressure socket and the

gate valve to ensure that the medium will not flow back

whenthepumpisswitchedoff.

2. To allow bleeding, provide a bleeding connection between

the pressure socket and the check valve.

Providing for isolating and shut-off devices for the pipes

For maintenance and repair work.

Provide for shut-off devices in the suction and pressure

pipes.

Allowing the measurement of the operating conditions

1. Provide for manometers for pressure measurements in

suction and pressure pipes.

2. Provide for motor-side torque m easurement.

3. Provide for pump-side temperature measurement.

5.6 Connecting the pipes

5.6.1 Installing auxiliary pipes

Follow manufacturers' specifications of any existing auxiliary operating system.

1. Install auxiliary piping to auxiliary unions, ensuring stress-

free and sealed connections (→ Setup drawing).

2. To avoid air enclosures: run pipes with a continuous slope

up to the pump.

5.6.2 Installing the suction pipe

1. Remove transport and sealing covers at the pump.

2. To avoid air enclosures: run pipes with a continuous slope

up to the pump.

3. Ensure that no gaskets are protruding inwards.

4. For suction operation: Install a foot valve in the suction line

to prevent the pump and suction pipe from running empty

during downtime.

5.6.3 Installing the pressure pipe

1. Remove transport and sealing covers at the pump.

2. Mount the pressure pipe.

3. Ensure that no gaskets are protruding inwards.

18 NPC series BA-2005.07 EN – 02

Setup and connection

5.6.4 Inspection for stress-free pipe connections

✔ Piping complete and cooled down

1. Separate the connecting flanges of the pipes from the

pump.

2. Check that pipes are freely moveable in all directions within

the range of expected expansions:

– nominal width < 150 mm : by hand

– nominal width > 150 mm : with short lever

3. Make certain that the flange surfaces are parallel.

4. Reconnect the connecting flanges of the pipes at the pump.

5.6.5 Inspecting the support foot for distortion

1. Loosen the bolts connecting the support foot to the base

plate.

2. If the support foot moves, compensate distortion:

– lateral shift: by means of slotted holes

– height shift: by means of metal shims

3. Tighten the support foot bolts in t he base plate, making certain that the bearing bracket is not distorted in the process.

5.7 Electrical connection

DANGER

Risk of death through electric shock!

Have all electrical work carried out by qualified electricians

only.

5.7.2 Checking the direction of rotation

DANGER

Risk of death due to rotating parts!

Use protective equipment when carrying out any work on

the pump.

Secure the key against being thrown off during the rotation

direction check.

Keep adequate distance to rotating parts.

CAUTION

Material damage caused by running dry and wrong direction of rotation!

Decouple the motor from the pump.

1. Switch motor on and immediately off again.

2. Check that the direction of rotation of the motor corresponds to the rotational direction arrow on the pump.

3. If the direction of rotation is different: swap two phases.

4. Couple the motor to the pump.

DANGER

Risk of death due to rotating parts!

Isolate the motor from its supply voltage and keep it locked

in that state while carrying out any fitting or maintenance

work.

5.7.1 Connecting the motor

Follow the instructions of the motor manufacturer.

1. Connect the motor according to the connection diagram.

2. Make certain to prevent hazards due to electric energy.

3. Install an EMERGENCY OFF switch.

EN – 02 BA-2005.07 NPC series 19

Setup and connection

5.8 Fine al ignment of the coupling

DANGER

Risk of death due to rotating parts!

Isolate the motor from its supply voltage and keep it locked

in that state while carrying out any fitting or maintenance

work.

CAUTION

Material damage due to incorrect alignment of the coupling!

If there is any height, lateral or angle misalignment, align

the motor exactly with the pump.

For detailed information and special couplings: (→ Manufacturers instructions).

Inspecting the coupling alignment

✔ Implements, tools and materials:

– feeler gage

– hair ruler

– dial gage (can be used for coupling with a spacer piece)

– other suitable tools, e.g. laser alignment instrument

Fig. 14 Inspecting for lateral and height misalignment

4. Inspect for lateral and height misalignments using the dial

gage:

– Carry out the measurement as shown in the figure.

– If there is any lateral or height misalignment, align the

motor (→ 5.9 Aligning the motor, Page 20).

Allowable axial or radial deviation, measured on the

coupling front or coupling circumference, respectively:

<0.05mm

A

1

2

Fig. 13 Inspecting the coupling alignment

1. Measure in two planes at an angle of 90° to each other on

the circumference of the coupling.

2. Measure the light gap to the outer diameter with hair ruler

(1):

– Position the hair ruler across both halves of the cou-

pling.

– If there is a light gap at the outer diameter, align the

motor (→ 5.9 Aligning the motor, Page 20).

3. Measure the gap using feeler gage (2):

– Allowable gap (→ Setup drawing).

– Use the feeler gage for measuring gap width (A)

between the coupling halves.

– If the gap width is outside the allowable range, align

the motor (→ 5.9 Aligning the motor, Page 20).

Fig. 15 Inspecting for angle misalignment

5. Inspect for angle misalignment using the dial gage:

– Carry out the measurement as shown in the figure.

– If there is any angle misalignment: align the motor.

5.9 Aligning the motor

Alignment options:

– using sets of shims

5.9.1 Aligning the motor using sets of shims

1. Align the motor so that the coupling halves are exactly flush

with each other. Underlay with compensation shims where

necessary.

2. Check the alignment.

3. Repeat alignment procedure if there is still a height misalignment.

4. Tighten the motor screws.

20 NPC series BA-2005.07 EN – 02

6 Operation

Operation

For pumps in explosion hazard areas (→ ATEX additional

instructions).

6.1 Preparations for the initial start-up

6.1.1 Identifying the pump type

Identify the pump type (→ Order data sheet).

Pump types vary e.g. with regard to bearing lubrication,

bearing bracket size, type of shaft sealing and auxiliary

operating systems.

6.1.2 Lubricating the bearings

Pumps with grease-lubricated roller bearings are ready for

operation as delivered.

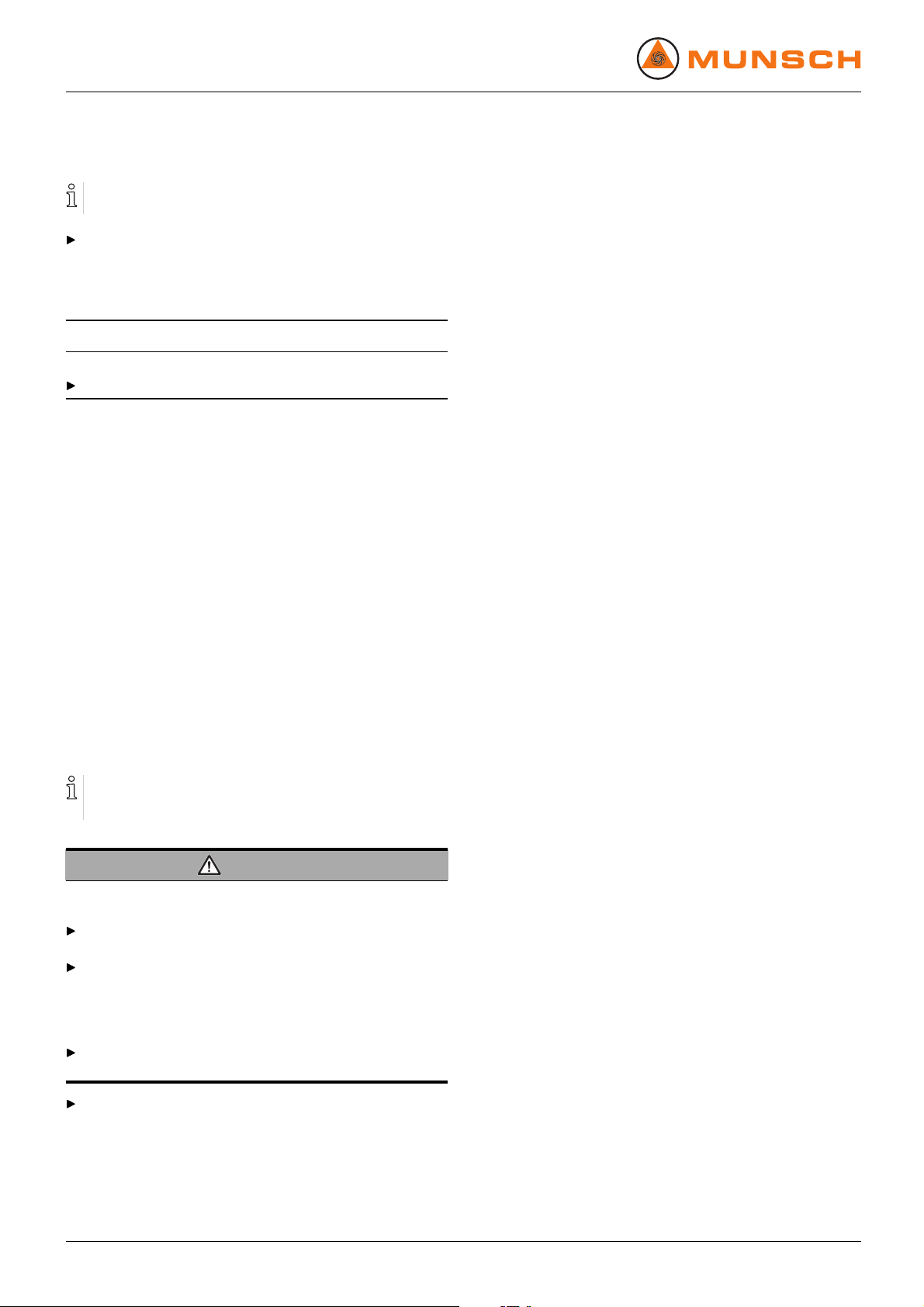

Filling the bearing bracket with lubrication oil

Only for pumps with oil-lubricated roller bearings.

1

6.1.3 Preparing auxiliary operating systems

(if available)

The manufacturer does not accept any liability for damage

arising from the installation or use of a third-party or unapproved auxiliary operating system.

Sealing systems

1. Verify that the sealing medium is suitable for mixing with

the pumped medium.

2. Identify the sealing system (→ Order data sheet)

(→ 3.4.1 Sealing systems, Page 12).

3. Install the sealing system (→ Manufacturer's instructions).

4. Make certain that the parameters required for the installed

sealing system are met (→ 9.2.2 Parameters for auxiliary

operating systems, Page 40).

6.1.4 Filling and bleeding

✔ Auxiliary operating systems are ready for operation

WARNING

Risk of injury and poisoning due to hazardous pumped

media!

Safely collect any emerging pumped medium and dispose

of it in accordance with environmental rules and requirements.

2

Fig. 16 Oil level in sight glass

1 Minimum oil level ⅓ full

2 Maximum oil level ½ full

1. Be certain to use the corre ct type and at least the minimum amount of lubrication oil for filling the bearing bracket

(→ 9.2.5 Lubricants, Page 42).

2. Open the oil filler plug.

3. Fill bearing bracket with lubrication oil until the oil level is

within the specified limits in the sight glass.

4. Screw in the oil filling plug with its gasket.

5. Check the oil level in the sight glass and adjust if necessary.

CAUTION

Material damage caused by dry running!

Make certain that the pump is properly filled.

1. Fill the pump and the suction pipe with pumped medium.

2. Open the suctio n-side armature.

3. Open the pressure-sid e armature.

4. If available: open auxil iary operating systems and check

the flow rate.

5. Verify that all pipe connections are sealed.

EN – 02 BA-2005.07 NPC series 21

Operation

6.2 Start up

6.2.1 Switching on

✔ The pump is correctly set up and connected

✔ The motor is correctly set up and connected

✔ The motor is exactly align ed with the pump

✔ All connections are stress-free and seal ed

✔ Any existing auxiliary operating systems are ready for oper-

ation

✔ All safety installations have been insta lled and tested for

integrity

✔ The pump has been correctly prepared, filled and bled

DANGER

Risk of injury due to running pump!

Do not touch the running pump.

Do not carry out any work on the running pump.

Allow the pump to cool down completely before commenc-

ing any work on it.

DANGER

Risk of injury and poisoning caused by pumped medium

spraying out!

Use protective equipment when carrying out any work on

the pump.

5. For pumps with hot pumped media, make certain that temperature changes do not exceed 50 °C/h.

6. After the first stresses caused by pressure and operating

temperature, check that the pump is not leaking.

7. For hot pumped media, briefly switch off the pump at operating temperature, check the alignment of the coupling and

realign the motor if necessary (→ 5.8 Fine alignment of the

coupling, Page 20).

6.2.2 Switching off

✔ The pressure-side armature is closed (recommended)

WARNING

Risk of injury caused by hot pump parts!

Use protective equipment when carrying out any work on

the pump.

1. Switch off the motor. Maintain the following functions if

applicable:

– for double mechanical seals: block pressure until the

pump is unpressurized

2. Check all connecting bolts and tighten if necessary.

CAUTION

Material damage caused by dry running!

Make certain that the pump is properly filled.

CAUTION

Risk of cavitation when throttling down the suction flow

rate!

Fully open the suction-side armat ure, do not use for adjusting the flow rate.

Do not open the pressure-side armature beyond the operating point.

CAUTION

Material damage caused by overheating!

Do not operate the pump while the pressure-side armature

is closed.

Observe the minimum flow rate (→ Order data sheet).

1. Open the suction- side armature.

2. Close the pressure-side armature.

3. Switch on the motor and check for smooth running.

4. Once the motor has reached its nominal speed, slowly

open the pressure-side armature until the operating point

is reached.

22 NPC series BA-2005.07 EN – 02

Operation

6.3 Shut-down

WARNING

Risk of injury and poisoning due to hazardous pumped

media!

Safely collect any emerging pumped medium and dispose

of it in accordance with environmental rules and requirements.

Carry out the following measures when the pump is shut

down:

Pump is Action

shut down for

a prolonged

period

emptied

disassembled

put into storage Follow storage instructions

Tab. 8 Action to be taken for pump shutdowns

Behavior

of pumped

medium

solids sediment Flush the

solidifies/

freezes,

non-corrosive

solidifies/

freezes,

corrosive

remains liquid,

non-corrosive

remains liquid,

corrosive

Tab. 9 Measures depending on pumped

medium behavior

Carry out measures depending

on the pumped medium

(→ Table 9 Measures

depending on pumped medium

behavior, Page 23).

Close suction-side and

pressure-side armatures.

Isolate the motor from its power

supply and secure against

unauthorized switch-on.

(→ 4.3 Storage, Page 14).

Duration of shutdown (depending

on process)

short long

Flush the

pump.

Heat up or

empty the

pump and

containers.

Heat up or

empty the

pump and

containers.

––

–

pump.

Empty the

pump and

containers.

Empty the

pump and

containers.

Preserve the

pump and

containers.

Empty the

pump and

containers.

Preserve the

pump and

containers.

6.4 Start-up following a shutdown period

1. For shutdowns > 1 year, take the following actions before

restarting the pump:

Shutdown period

>1year For oil-lubricated bearings:

>2years Replace elastomer seals

Tab. 10 Actions to be taken after prolonged

shutdown periods

2. Carry out all steps as for the initial start-up (→ 6.2 Start up,

Page 22).

Action

carry out oil change.

For variants with roller

bearings without lifetime

lubrication: relubricate.

(O-rings, shaft sealing rings).

Replace roller bearings.

6.5 Running the stand-by pump

✔ Thestand-bypumpisfilledandbled

Run the stand-by pump at least once a week.

1. Completely ope n the suction-side armature.

2. Open the pressure-side armature to an extent that the

stand-by pump reaches its operating temperature and is

heated through evenly (→ 6.2.1 Switching on, Page 22).

EN – 02 BA-2005.07 NPC series 23

Maintenance

7 Maintenance

For pumps in explosion hazard areas (→ ATEX additional

instructions).

Trained service technicians are available for fitting and

repair jobs. Present a pumped medium certificate (DIN

safety data sheet or safety certificate) when requesting

service.

7.1 Inspections

The inspection intervals depend on the operational strain

on the pump.

DANGER

Risk of injury due to running pump!

Do not touch the running pump.

Do not carry out any work on the running pump.

WARNING

Risk of injury and poisoning due to hazardous pumped

media!

Use protective equipment when carrying out any work on

the pump.

1. Check at appropriate intervals:

– compliance with minimum flow rate

– roller bearing temperatures < 70 °C

– normal operating conditions unchanged

– top up oil if necessary

– coupling alignment and condition of elastic elements

2. For trouble-free operation, always ensure the following:

– no dry running

– no leaks

– no cavitation

– suction-side gate valves open

– unobstructed and clean filters

– sufficient supply pressure

– no unusual running noises and vibrations

– no excessive leakage at the shaft seal

– proper functioning of auxiliary operating systems

7.2 Maintenance

Service life of the roller bearings for operation within the

allowable operating regime: > 2 years

Intermittent operation, high temperatures, low viscosity and

aggressive ambient and process conditions reduce the service life of roller bearings.

Stationary seal rings are subject to natural wear, which

strongly depends on the actual operating conditions.

Therefore, general statements regarding their service life

cannot be made.

DANGER

Risk of injury due to running pump!

Do not touch the running pump.

Do not carry out any work on the running pump.

Isolate the motor from its supply voltage and keep it locked

in that state while carrying out any fitting or maintenance

work.

DANGER

Risk of death through electric shock!

Have all electrical work carried out by qualified electricians

only.

WARNING

Risk of injury and poisoning due to hazardous or hot

pumped media!

Use protective equipment when carrying out any work on

the pump.

Allow the pump to cool down completely before commencing any work.

Make certain that the pump is unpressurized.

Empty the pump, safely collect the pumped medium and

dispose of the medium in accordance with environmental

rules and requirements.

7.2.1 Roller beari ngs with grease lubrication

1. As a precaution, replace roller bearings with lifetime lubrication every 2 years (recommended).

2. Relubricate roller bearings that can be relubricated:

– after every 3000 hours of operation

– (→ 9.2.5 Lubricants, Page 42).

24 NPC series BA-2005.07 EN – 02

Maintenance

7.2.2 Roller bearings with oil lubrication

1. Carry out lubricating oil change:

– after the first 300 hours of operation

– after every 5000 hours of operation or at least once a

year

2. For o il changes, remove the screwed plug at the bearing

bracket and drain the lubrication oil at operating temperature into a suitable container.

3. Reinsert the screwed plug and top up lubricating oil

(→ 6.1.2 Lubricating the bearings, Page 21).

7.2.3 Stationary seal rings

Mechanical seal will always show some functional dripleakage (→ Manufacturer's instructions).

Double mechanical seal with quench: any drastic rise of the

quench system level indicates a major leak at the productside mechanical seal.

Double mechanical seal ring with foreign blocking: any

drastic pressure drop in the blocking system (loss of

lubricating fluid) indicates a major leak at the product-side

mechanical seal.

If there is a major leak: replace the mechani cal seal with its

auxiliary seals and check the integrity of auxiliary operating

systems.

7.3 Disassembling

DANGER

Risk of injury due to running pump!

Do not touch the running pump.

Do not carry out any work on the running pump.

Isolate the motor from its supply voltage and keep it locked

in that state while carrying out any fitting or maintenance

work.

DANGER

Risk of death through electric shock!

Have all electrical work carried out by qualified electricians

only.

WARNING

Risk of injury and poisoning due to hazardous or h ot

pumped media!

Use protective equipment when carrying out any work on

the pump.

Allow the pump to cool down completely before commencing any work.

Make certain that the pump is unpressurized.

Empty the pump, safely collect the pumped medium and

dispose of the medium in accordance with environmental

rules and requirements.

EN – 02 BA-2005.07 NPC series 25

Maintenance

7.3.1 Returning the pump to the manufacturer

✔ Pump is unpressurized

✔ Pump is completely empty

✔ Electrical connections are isolated and the motor is

secured against switch-on

✔ Pump has cooled down

✔ Coupling shield is dismounted

✔ For couplings with a spacer piece: spacer piece is removed

✔ Auxiliary operating syst ems are shut down, unpressurized

and emptied

✔ Manometer connections, manometer and fixtures are dis-

mounted

1. Always enclose a truthfully completed safety certificate

when returning pumps or components to the manufacturer.

Order a safety certificate from the manufacturer if required.

2. Take necessary measures, depending o n the required

repair work, as listed in the table below for returning the

pump to the manufacturer.

Repair carried out

at customer's

premises

Action for return

Return the defective

component to the

manufacturer.

at manufacturer's

premises

Flush the pump and

decontaminate if hazardous

media were pumped.

Return the complete pump

(not disassembled) to the

manufacturer.

at manufacturer's

premises for

warranty repairs

For hazardous pumped

media only: flush and

decontaminate the pump.

Return the complete pump

(not disassembled) to the

manufacturer.

Tab. 11 Actions for return

7.3.2 Preparations for disassembling

✔ Pump is unpressurized

✔ Pump is completely empty, flushed and decontaminated

✔ Electrical connections are isolated and the motor is

secured against switch-on

✔ Pump has cooled down

✔ Coupling shield is dismounted

✔ For couplings with a spacer piece: spacer piece is removed

✔ Auxiliary operating syst ems are shut down, unpressurized

and emptied

✔ Manometer connections, manometer and fixtures are dis-

mounted

The pumps are constructed in process architecture as standard. The slide-in unit can be dismounted witho ut removing

the volute casing and piping.

If a coupling with a spacer piece is used, the motor can

remain mounted on the base plate.

1. For disassembling take note of the following:

– Precisely mark the assembly orientation and position

of all components before disassembly.

– Dismount components concentrically without canting.

– Disassemble the pump (→ Sectional drawing).

2. Loosen the fixation bolts of support foot 183 and casing

feet 187.

3. Lift the pump out of the installation (→ 4.1.2 Lifting,

Page 13).

26 NPC series BA-2005.07 EN – 02

Maintenance

7.3.3 Loosening connectors (if available)

Flushing connector or supply connectors REA-C/D

710.2/.3

412.70/.8

925

718

412.70/.8

710.1

Fig. 17 Loosening the flushing connector or supply

connectors REA-C/D

1. Loosen lock nut 925.

2. Screw in socket 718 clockwise with a few turns.

3. Loosen and unscrew pipes Skt12 710.1/.2/.3.

4. Unscrew socket 718.

5. Remove O-rings 412.70/.8 from pipes 710.1/.2/.3.

7.3.4 Extracting the volute casing

155+

102

Fig. 18 Extracting the volute casing

1. Loosen the casing nuts.

2. Loosen and extract casing armour plating 155 and volute

casing 102 by screwing in the two ejector screws.

7.3.5 Disassembling the impeller

Connector for spring chamber flushing

Loosen and unscrew fittings 738.

412.74

230

938

412.4

906

Fig. 19 Disassembling the impeller

1. Loosen and remove impeller screw 906 and O-ring 412.4

using circlip pliers.

2. Unscrew socket head ca p screw with SCHN ORR spring

washer 938.

3. Extract impeller 230.

4. Remove O-ring 412.74 from impeller.

EN – 02 BA-2005.07 NPC series 27

Maintenance

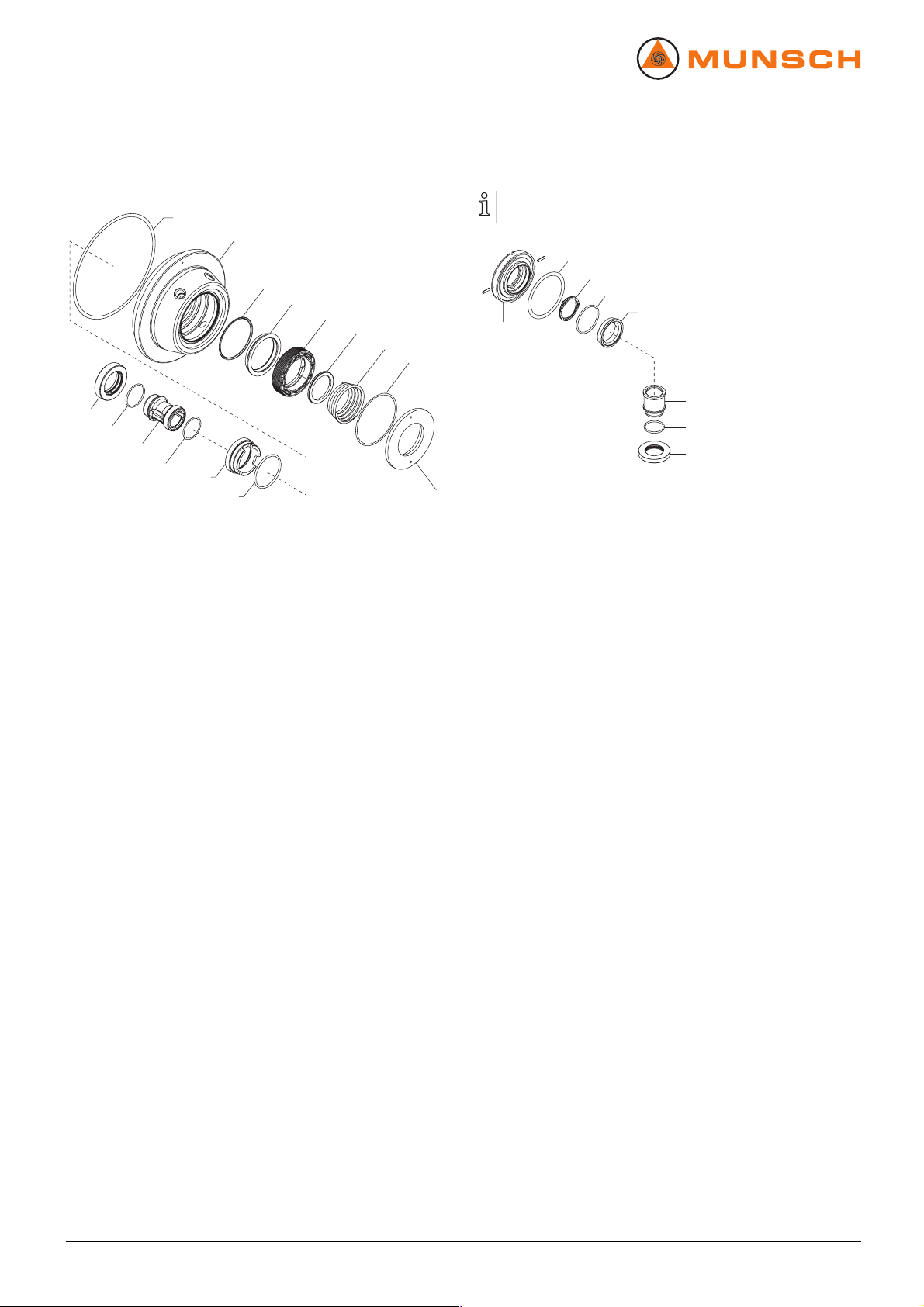

7.3.6 Disassembling a casing cover with

MUNSCH-REA-C mechanical seal

400.10

161

412.3

474.1

473

474.2

477

412.6

472

412.61

523.6

412.5

475

412.2

Fig. 20 Disassembling a casing cover with

MUNSCH-REA-C mechanical seal

1. Extract rotating seal ring 472 with shaft sleeve 523.6 from

pump shaft 211. Free the rotating seal ring from the shaft

sleeve.

2. Remove casing cover 161 and put it down with seal cover

471 facing down.

3. Remove gasket 400.10 from casing cover 161 and replace

gasket if necessary.

4. Extract stationary seal ring 475.

5. Turn the casing cover upside down.

6. Loosen and un screw seal cover 471 using an adjustable

pin wrench.

7. Remove spring 477 and thrust ring 474.2.

8. Unscrew stat ionary seal ring holder 473 using the special

tool.

9. Remove thrust ring 474.1.

10. Remove and replace O-rings 412.61, 412.5, 412.2, 412.6,

412.3.

471

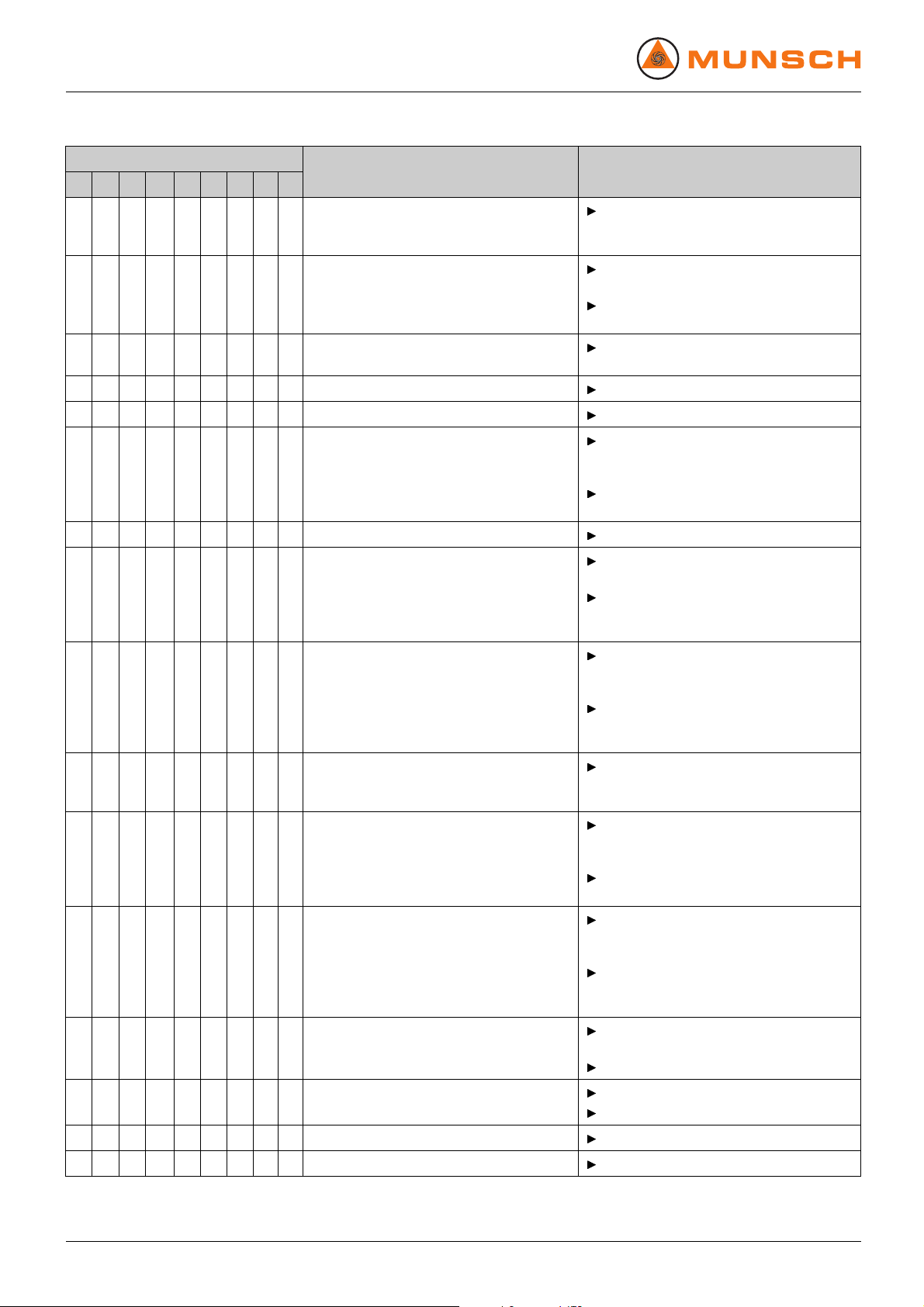

7.3.7 Disassembling the atmosphere-side stationary seal ring

Only for MUNSCH-REA-C/D double mechanical seal.

412.9

477.2

412.45

475.2

473.2

523.5

412.52

472.2

Fig. 21 Disassembling MUNSCH-REA-D station-

ary seal ring

1. Remove rotating seal ring 472.2 and shaft sleeve 523.5.

2. Remove stationary seal ring holder 473.2.

3. Extract stationary seal ring 475.2 from the stationary seal

ring holder.

4. Remove spring 477.2.

5. Remove and replace O-rings 412.52, 412.45, 412.9.

28 NPC series BA-2005.07 EN – 02

Maintenance

7.3.8 Disassembling the beari ng bracket

✔ Intermediate lantern 146 disassembled.

937

360.4

421.1

636.2

636.1

330

412.12

421.2

360

914.3

901.3183

Fig. 22 Disassembling the be aring bracket (grease

lubrication, L16A, L18B, L20A)

1. To dismount support foot 183: Loosen hexagon head bolts

901.3.

2. Unscrew grease nipples 636.1 and 636.2 if applicable.

3. Loosen countersunk screws 937 and remove bearing cover

360.4.

4. Unscrew socket head cap screws 914.3 and extract bearing cover 360.

5. Remove radial shaft seal ring 421.2 and O-ring 412.12 from

bearing cover 360.

6. Remove radial shaft seal rings 421.1 from bearing bracket

330.

7.3.9 Disassembling the pump shaft

With roller bearings without lifetime lubrication

322

940.1

932.1

(322)

932.1

211

940.2

321

923

Fig. 23 Disassembling the pump shaft (no

lifetime lubrication)

1. Press out pump shaft 211 with radial ball bearing 321 from

bearing bracket 330 towards the motor end.

2. Remove bearing nut 923.

3. Extract radial ball bearing 321 and inner ball race (322) of

radial roller bearing 322 from pump shaft 211.

4. Remove circlip 932.1.

5. Press out radial roller bearing 322 from bearing bracket 330

and remove second circlip 932.1.

With lifetime-lubricated roller bearings

321.6

940.1

211

932.1

940.2

321

923

Fig. 24 Disassembling the pump shaft (with

lifetime lubrication)

1. Remove circlip 932.1.

2. Press out pump shaft 211 with radial ball bearings 321 and

321.6 from bearin g bracket 330.

3. Remove bearing nut 923.

4. Extract radial ball bearings 321 and 321.6 from pump shaft

211.

With labyrinth rings

(→ Additional instructions).

EN – 02 BA-2005.07 NPC series 29

Maintenance

7.4 Assembling

7.4.1 Preparations for assembling

1. For assembling take note of the following:

– Replace worn components w ith authentic replacement

parts.

– Replace gaskets, insert new gaskets so that they can-

not rotate.

– Observe specified tightening torque (→ 9.2.4 Tighten-

ing torques, Page 41).

– Refit components concentrically without canting

according to the prepared orientation and position

markings.

2. Clean all components (→ 9.2.6 Detergents, Page 42). Do

not remove the prepared markings.

3. Assemble the pump (→ S ectional drawing).

Assembly is carried out in reverse order of disassembly.

The following sections only describe particular aspects to

be observed when assembling the product.

7.4.2 Fitting the pump shaft

With roller bearings without lifetime lubrication

1. Heat up inner ball race of radial roller bearing 322 and press

it onto pump shaft 211.

2. Heat up radial ball bearing 321 and press it onto pump shaft

211.

3. Cool down radial ball bearing 321 and grease it if it is

grease-lubricated.

4. Screw bearing nut 923 onto pump shaft 211.

5. Screw in threaded pins with 1 drop of LOCTITE 243 in bearing nut 923 and apply color markings to the threaded pins.

6. Insert circlip 932.1 in bearing bracket 330.

7. Press in radial roller bearing 322 and grease it if it is greaselubricated.

8. Insert circlip 932.1.

9. Press pump shaft 211 into bearing bracket 330.

10. For bearing bracket L18B (→ Figure Bearing bracket L18B

(grease-lubricated bearing), Page 39).

With lifetime-lubricated roller bearings

1. Heat up radial ball bearings 321 and 321.6 and press them

onto pump shaft 211.

2. Screw bearing nut 923 onto pump shaft 211.

3. Screw in threaded pins with 1 drop of LOCTITE 243 in bearing nut 923 and apply color markings to the threaded pins.

4. Insert circlip 932.1 in bearing bracket 330.

5. Press pump shaft 211 into bearing bracket 330.

7.4.3 Fitting the bearing bracket

1. Insert radial shaft seal ring 421.2 and O-ring 412.12 into

bearing cover 360.

2. Screw on bearing cover 360 with socket head cap screw

914.3.

3. Insert radial shaft seal ring 421.1 in bearing bracket 330.

4. Screw on bearing cover 360.4 with socket head cap screws

937.

7.4.4 Fitting the casing cover

560

146 161

Fig. 25 Fitting the casing cover

Fit casing cover 161 into intermediate lantern 146.

7.4.5 Fitting the pump into the installation

(→ 5 Setup and connection, Page 15).

7.5 Ordering replacement parts

For trouble-free replacement in case of any fault we recommend keeping a complete slide-in units or replacement

pumps available on site.

The application guidelines according to DIN 24296 recommend provisioning for two years of continuous use

(→ 9.3 Replacement parts for 2 years of continuous operation according to DIN 24296, Page 43).

Have the following information ready to hand for ordering

replacement parts (→ Type plate):

– short designation of the pump

– serial number

– construction year

– part number

– designation

– quantity

30 NPC series BA-2005.07 EN – 02

8 Disturbance recovery

For faults which do not appear in the following table or faults

that cannot be traced back to the suggested causes, please

consult with the manufacturer.

Possible faults are identified by a fault number in the below

table. This number points to the respective cause and remedy

in the troubleshooting list.

Fault Number

Pump not pumping 1

Pumping rate insufficient

Pumping rate excessive 3

Pumping pressure insufficient

Pumping pressure excessive

Pump running roughly 6

Roller bearing temperatures too high

Pump leaking 8

Motor power uptake excessive 9

Tab. 12 Fault/number assignment

2

4

5

7

Disturbance recovery

Fault number

12 3456

––– –––––

X

–

XX–X

–

X

–

X

X

XX–X

XX–X

–

–

X

–

X

––– –––––

–

X

––––X–––

––––X–––

–

X

–––––

X

–

–

X

–

X

–

–

–

X

7

–––

X

–––

X

–––

X

–––

X

–––

X

–––

X

89

Cause

Supply/suction line and/or pressure line

closed by armature

Supply/suction pipe not fully opened

Supply/suction pipe, pump or suction

screen blocked or encrusted

Supply/suction pipe cross-section too

narrow

Transport and sealing cover still in place Remove transport and sealing cover.

Differential head excessive: NPSH

larger than NPSH

Supply/suction pipe and pump not bled

properly or not filled up completely

Supply/suction line contains air enclosures

Air sucked in

Excessive amount of gas: pump cavitated

Pumped medium temperature too high:

pump cavitated

installation

pump

Remedy

Open the armature.

Open the armature.

Clean supply/suction pipes, pump or

suction screen.

Increase cross-section.

Remove encrustations from suction

pipe.

Open the armature completely.

Disassemble pump and inspect for

dry-running damage.

Increase supply pressure.

Consult with manufacturer.

Fill up pump and/or piping completely

and bleed them.

Mount armature for bleeding.

Correct the piping layout.

Seal the source of malfunction.

Consult with manufacturer.

Increase supply pressure.

Lower the temperature.

Inquire with manufacturer.

EN – 02 BA-2005.07 NPC series 31

Disturbance recovery

Fault number

12 3456

–

–

–

XX

XX–X

XX–X

–

––

–

X

–

X

––

X

––

–

X

XX–X

––––

X

–––––

X

XX

XX

–

–––––

–

X

7

–––

–––

–––

X

XX

––

89

––

––X––X––

––X–

––X–

––X–

XX–X

–

–

X

X

–– –– –

––––

X

XXX–X Motor speed excessively high

XX

–

–

––

–––

X

–––

X

XX–X

–––– ––X–

Cause

X

Viscosity or density of the pumped

medium outside the specification range

for the pump

Geodetic differential head and/or pipe flow

resistance too high

Pressure-side armature not opened

sufficiently

Pressure pipe blocked

Pump running the wrong direction

Motor speed insufficient

Pump components worn

X Pressure-side armature opened too wide

X

Geodetic differential head, pipe flow

resistance and/or other resistance lower

than specified

Viscosity lower than expected

X Impeller diameter too large

Impeller out of balance or clocked

Hydraulic components of the pump dirty,

clotted or encrusted

Roller bearing in bearing bracket defective

X

Roller bearing in motor defective

Remedy

Consult with manufacturer.

Remove sediments in pump and/or

pressure pipe.

Install larger impeller and consult with

manufacturer.

Open the pressure-side armature.

Clean the pressure pipe.

Swap any two phases at the motor.

Compare required motor speed with

specification on pump type plate.

Replace motor if necessary.

Increase motor speed with speed

control if available.

Replace worn pump components.

Throttle down at pressure-side

armature.

Mill down the impeller. Consult with

manufacturer and adjust impeller

diameter.

Throttle down flow rate at pressure-side

armature. Observe the minimum flow

rate limit.

Mill down the impeller. Consult with

manufacturer and adjust impeller

diameter.

Mill down the impeller. Consult with

manufacturer and adjust impeller

diameter.

Compare required motor speed with

specification on pump type plate.

Replace motor if necessary.

Reduce motor speed with speed control

if available.

Throttle down flow rate at pressure-side

armature. Observe the minimum flow

rate limit.

Mill down the impeller. Consult with

manufacturer and adjust impeller

diameter.

Disassemble pump and inspect for

dry-running damage.

Clean the impeller.

Disassemble pump.

Clean the components.

Replace roller bearing.

Replace roller bearing.

32 NPC series BA-2005.07 EN – 02

Disturbance recovery

Fault number

12 3456

7

89

–––– ––X––

–––– –––X–

–––– –––X–

–––– –––X–

–––– –––X–

–– –– –

–– –– –

XXXXPumpdistorted

XX

––

–– –– –X–––

–

–

X

–

X

X

––

Tab. 13 Troubleshooting list

Cause

Lubricant: too much, too little or unsuitable

Connecting screw or bolts not tightened

correctly

Stationary seal ring worn

Casing seal defective

Shaft sleeve is infiltrated

Coupling not properly aligned

Coupling packets worn

X Motor running on 2 phases

Remedy

Reduce, top up or replace lubricant.

Tighten connecting screws and bolts.

Replace stationary seal ring.

Replace casing seal.

Replace shaft sleeve and/or O-rings.

Check pipe connections and pump

fixation.

Check coupling alignment.

Check support foot fixation.

Align coupling.

Replace coupling packets and realign.

Check fuse and replace it if necessary.

Check cable connections and

insulation.

EN – 02 BA-2005.07 NPC series 33

Appendix

9 Appendix

9.1 Sectional drawings

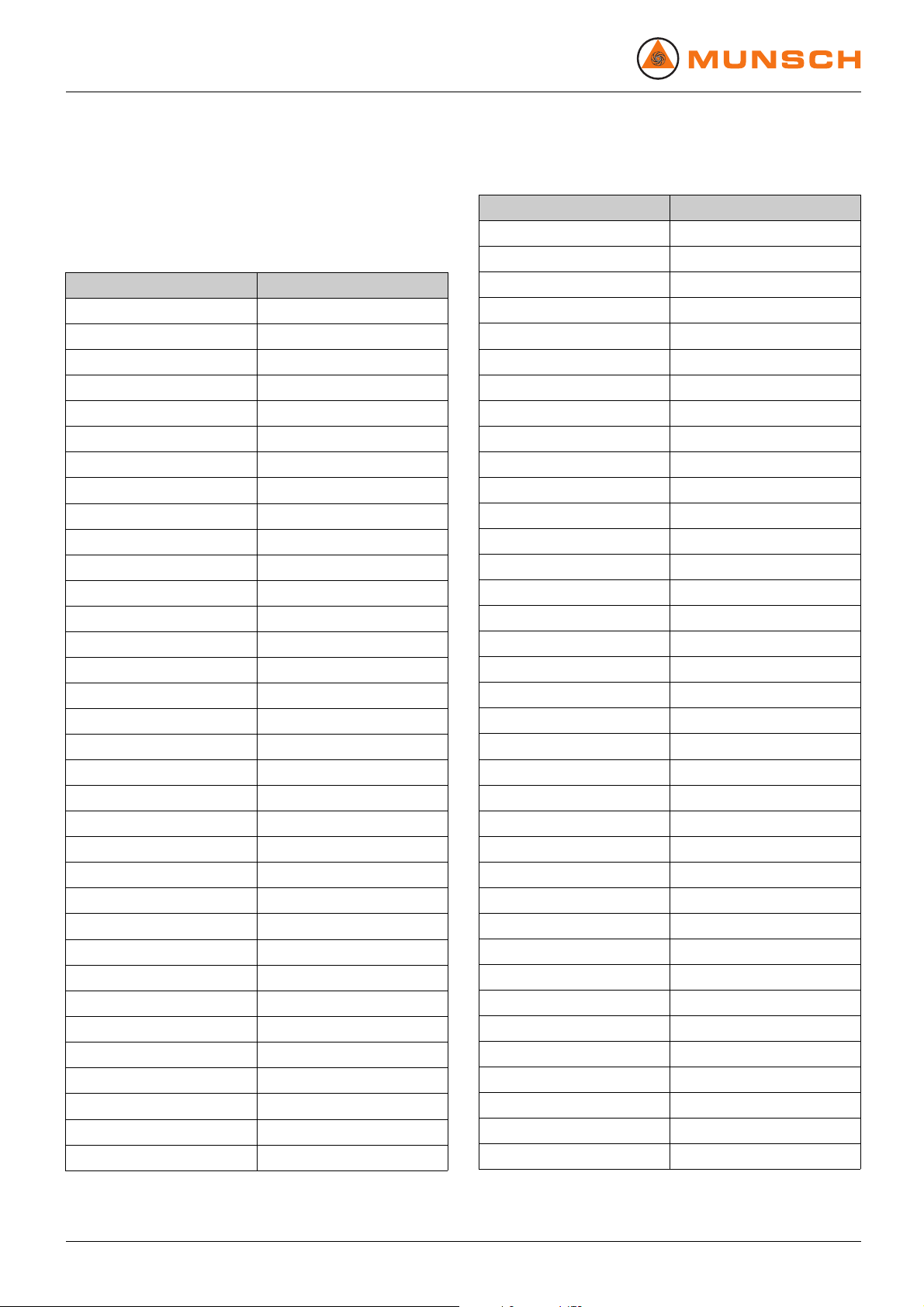

9.1.1 Part numbers a nd designations

Part no. Designation

102 Volute casing

122 Blind cover

132 Intermediate piece

146 Intermediate lantern

155

161

161.2

161.3

167

183

187

211

230 Impeller

321 Radial ball bearing

321.5 Radial ball bearing

321.6 Radial ball bearing

322 Radial roller bearing

330 Bearing bracket

360 Bearing cover

360.4 Bearing cover

400.1

400.10

400.2

400.3

412.10

412.12

412.18

412.2

412.3

412.4

412.45

412.5

412.52

412.6

Casing armour plating

Casing cover

Casing cover

Casing cover

Cover insert

Support foot

Casing foot

Pump shaft

Gasket

Gasket

Gasket

Gasket

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

Part no. Designation

412.61

412.70

412.74

412.76

412.8

412.82

412.84

412.9

421.1

421.2

423.1 Labyrinth ring

423.2 Labyrinth ring

471

472 Rotating seal ring

472.2 Rotating seal ring

473

473.2

474.1 Thrust ring

474.2 Thrust ring

475

475.2

477

477.2

500 Ring

523.5

523.6

554.1 Washer

554.14 Washer

554.15 Washer

554.18 Washer

554.19 Washer

554.20 Washer

554.26 Washer

554.3 Washer

560 Pin

560.2 Pin

560.5 Pin

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

Radial shaft seal ring

Radial shaft seal ring

Seal cover

Stationary seal ring holder

Stationary seal ring holder

Stationary seal ring

Stationary seal ring

Spring