Munsch MEK-32, MAK-32, MEK-36, MAK-48, MEK-48 Operating Instructions Manual

...

MUNSCH Kunststoff-Schweißtechnik GmbH Issue 12.2009/Rev. 02 Page 1/20

Operating Instructions

Type: MEK-32 / MAK-32 Serial No.: ______________

Article No.: ______________

These operating instructions contain important

information to be observed for hand extruder operation

and maintenance.

It is therefore imperative that they be read and their

contents fully understood by the operators before the

hand extruder is placed in service.

Hand Extruder MEK-32 / MAK-32

Page 2/20 Issue 12.2009/Rev. 02 MUNSCH Kunststoff-Schweißtechnik GmbH

Scope of delivery:

Please check that the delivery is complete.

The delivery comprises:

1 hand extruder 1 extruder stand

1 handle

1 welding shoe, machined

3 preheat nozzles

1 hot air hood

Contents

1 GENERAL......................................................................................................................................................................4

2 SAFETY..........................................................................................................................................................................4

2.1 I

DENTIFICATION OF INFORMATION IN THE OPERATING INSTRUCTIONS

.......................................................................5

2.2 P

ERSONNEL QUALIFICATION AND TRAINING

..............................................................................................................5

2.3 R

ISKS RESULTING FROM NON-OBSERVANCE OF THE SAFETY INSTRUCTIONS

..............................................................5

2.4 S

AFE WORKING PRACTICES

........................................................................................................................................5

2.5 S

AFETY INSTRUCTIONS FOR OPERATOR / OPERATING PERSONNEL

.............................................................................5

2.6 S

AFETY INSTRUCTIONS FOR MAINTENANCE, INSPECTION AND MOUNTING

.................................................................7

2.7 U

NAUTHORIZED MODIFICATIONS AND SPARE PARTS

..................................................................................................7

3 TRANSPORT AND STORAGE ...................................................................................................................................8

3.1 T

RANSPORT

...............................................................................................................................................................8

3.2 S

TORAGE

...................................................................................................................................................................8

3.3 R

ETURN TO MUNSCH

.................................................................................................................................................8

4 PRODUCT DESCRIPTION .........................................................................................................................................8

4.1 A

PPLICATION RANGE

.................................................................................................................................................8

4.2 G

ENERAL

...................................................................................................................................................................8

5 STARTUP AND SHUTOFF..........................................................................................................................................9

5.1 G

ENERAL

...................................................................................................................................................................9

5.2 P

REPARATION

............................................................................................................................................................9

5.3 S

TARTING THE HAND EXTRUDER

.............................................................................................................................10

5.4 W

ELDING WITH THE HAND EXTRUDER

.....................................................................................................................11

5.4.1 Introducing the welding rod............................................................................................................................11

5.4.2 Replacement and aging of welding rod...........................................................................................................11

5.4.3 Welding direction / rate ..................................................................................................................................11

5.4.4 Interruption of work........................................................................................................................................11

5.4.5 Shutoff ............................................................................................................................................................12

5.4.6 Transport/Storage............................................................................................................................................12

5.5 S

ET TEMPERATURES ON TEMPERATURE CONTROLLER

.............................................................................................12

5.5.1 Set temperatures..............................................................................................................................................12

6 MAINTENANCE/INSPECTION ...............................................................................................................................14

6.1 M

AINTENANCE/INSPECTION OF

MEK/MAK

HAND EXTRUDER

................................................................................14

6.2 D

ISMANTLING

..........................................................................................................................................................14

6.2.1 Overview of spare parts/attachments ..............................................................................................................14

7 MALFUNCTIONS, CAUSES AND REMEDIES......................................................................................................16

7.1 T

ROUBLE-SHOOTING

................................................................................................................................................16

7.2 F

AULT DIAGNOSIS

....................................................................................................................................................16

8 TECHNICAL DATA ...................................................................................................................................................18

MEK-32 / MAK-32 Issue 12.2009/Rev. 02 Page 3/20

EG-Konformitätserklärung des Herstellers

nach der EG-Maschinenrichtlinie 2006/42/EG Anhang II, Nr. 1 A

EC-Declaration of Conformity by the Manufacturer

as defined by machinery directive 2006/42/EC, Annex II, No. 1 A

MUNSCH Kunststoff-Schweißtechnik GmbH

Im Staudchen

D-56235 Ransbach-Baumbach

Germany

Mr. Johann Dausenau,

Kunststoffschweißtechnik GmbH,

is authorised to compile the technical documentation.

We hereby declare that the hand extruders

Machine type: Hand extruder Hand extruder

Type designation: MEK-32 MAK-32

are in accordance with all relevant provisions of the EC Machinery Directive.

The following harmonised standards (or parts of these standards) were applied:

DIN EN ISO 12100-1: 2004 DIN EN 13732-1: 2008

DIN EN ISO 12100-2: 2004

In addition, the hand extruders are in accordance with the following EC-directives, standards, codes and

regulations:

EU Low-Voltage Directive 73/23/EC EU EMC Directive 89/336/EC

EN 60204-1 (VDE 0113 Part 1): 2007 DIN EN 55014-1: 2007

EN 61029-1 (VDE 0740 Part 500): 2003 DIN EN 55014-2: 2009

VDE 0701 Part 1: 2008

VDE 0702 Part 1: 2003

This industrial tool complies with the aforesaid standards insofar as it is used at the contractually agreed

conditions. The operator is responsible for this.

In the event of any modifications to the machine/unit or use not as intended, this declaration becomes invalid

unless the manufacturer’s prior written approval has expressly been given.

Ransbach-Baumbach, 29.12.2009 Dipl.-Ing. Stefan Munsch

Managing Director

Hand Extruder MEK-32 / MAK-32

Page 4/20 Issue 12.2009/Rev. 02 MUNSCH Kunststoff-Schweißtechnik GmbH

1 General

These operating instructions must always

be available at the place of use of the hand

extruder.

The objective of these operating instructions is to

support operators in familiarizing themselves with the

hand extruder and in using its functions for the

intended service.

These operating instructions provide important

information for the safe, workmanlike and

economical operation of the hand extruder. Their

observance helps avoid danger, minimize repair

costs and downtimes, enhance reliability, and extend

the service life of the hand extruder.

These operating instructions must be observed by all

persons working with/on the hand extruder. Such

work includes, for instance:

• operation,

• maintenance, inspection and repair

• transport.

The hand extruder may only be mounted, operated

and maintained by trained personnel.

In addition to the operating instructions and the

national and local accident prevention regulations

applicable at the place of use, the acknowledged

technical rules for safe and proper working practices

must be observed.

These operating instructions provide basic

information to be observed for operation and

maintenance. For this reason, it is imperative that

they be read by the specialist personnel/Operator

prior to placing the hand extruder in service and that

they always be available at the place of use.

Apart from the general safety instructions under

section “Safety“, also the special safety instructions

given under the respective sub-sections must be

adhered to.

Non-observance of the safety instructions

may cause hazards to persons and the environment

or damage to the hand extruder.

Moreover, failure to observe the safety instructions

may lead to the forfeiture of any damages.

Non-observance of the safety instructions may in

particular involve the following risks:

• failure of important hand extruder functions,

• hazards to persons due to electrical and

mechanical impacts including risk of burns,

• hazards to the environment due to vapour-phase

hazardous substances,

• risk of fire.

2 Safety

These operating instructions provide basic

information to be observed for operation and

maintenance. For this reason, it is imperative that

they be read by the specialist personnel/Operator

prior to placing the hand extruder in service and that

they always be available at the place of use.

Safe operation of the hand extruder presupposes

that the instructions under section 1 – General – of

these operating instructions are complied with. In no

case must the limit values indicated be violated.

Intact and unaltered hand extruders conform to the

applicable codes and standards and meet all

regulatory limit values regarding EMC

(electromagnetic discharges and interference

immunity). For the country-specific limit values to be

observed, the Operator should consult the local

electric utility. Nevertheless, the hand extruders emit

electromagnetic fields within the acceptable limits.

Electromagnetic fields may interfere with the

operation of vital electronic devices (e.g. cardiac

pacemakers). Persons wearing a cardiac pacemaker

should therefore consult their physician before using

the machine.

In addition to the operating instructions and the

national and local accident prevention regulations

applicable at the place of use, the acknowledged

technical rules for safe and proper working practices

must be observed.

Apart from the general safety instructions under

section “Safety“, also the special safety instructions

given under the respective sub-sections must be

adhered to.

Any working practices posing a safety risk are

prohibited.

MEK-32 / MAK-32 Issue 12.2009/Rev. 02 Page 5/20

2.3 Risks resulting from non-observance of the

safety instructions

Non-observance of the safety instructions may cause

hazards to persons and the environment or damage

to the hand extruder. Moreover, failure to observe

the safety instructions may lead to the forfeiture of

any damages.

Non-observance of the safety instructions may in

particular involve the following risks:

• failure of important hand extruder functions,

• hazards to persons due to electrical and

mechanical impacts including risk of burns,

• hazards to the environment due to vapour-phase

hazardous substances,

• risk of fire.

2.4 Safe working practices

The safety instructions given in these operating

instructions, the applicable national accident

prevention regulations and any existing in-company

work instructions, operating and safety procedures

issued by the Operator must be followed.

2.5 Safety instructions for Operator / operating

personnel

• Before placing the hand extruder in service,

check the mains voltage and frequency against

the data indicated on the type tag. The allowable

tolerances are ± 5 % for voltage and/or ±2 % for

frequency.

• According to VDE 0100 §55, the hand extruder

must be operated via a residual current-operated

circuit breaker or an isolating transformer.

• CAUTION During hand extruder operation (under

load), a voltage of not less than 230 V1) must be

available at the connector of the hand extruder.

• When using an extension cable, make sure to

observe the minimum conductor cross-section.

Use extension cables with protective conductor

only.

Length

[m]

Minimum cross-section

[mm²]

up to 19 4.0 1)

20-50 6.0 1)

2.1 Identification of information in the operating

instructions

In these operating instructions, safety instructions

whose non-observance may cause hazards to

persons are identified with

Hazard symbol according to DIN 4844 – W 9

for general hazards and with

Hazard symbol according to DIN 4844 – W 8

for electrical hazards.

Safety instructions whose non-observance may

cause damage to the hand extruder and its functions

are marked with

CAUTION

Instructions directly indicated on the hand extruder

must be strictly followed and kept in a fully legible

state.

2.2 Personnel qualification and training

The operating, maintenance and inspection

personnel must possess appropriate qualification for

the work to be performed. Functional and technical

responsibilities and supervision of the operating

personnel must be clearly regulated by the Operator.

Where the personnel do not have the necessary

skills and knowledge they must be trained and

instructed (e.g. a DVS basic welder training in

extrusion welding). A detailed instruction into hand

extruder operation will be provided by the

Manufacturer/Supplier on request. Furthermore, the

Operator has to make sure that the contents of the

operating instructions is fully understood by the

operating personnel.

1) for 230 V AC

Hand Extruder MEK-32 / MAK-32

Page 6/20 Issue 12.2009/Rev. 02 MUNSCH Kunststoff-Schweißtechnik GmbH

• Extension cables must be certified for the specific

service conditions (e.g. outdoor service) and

identified accordingly.

Always handle the connecting cable with care.

- Do not kink the connecting cable.

- Do not place any objects on the cable.

- Do not jam or squeeze the connecting cable,

nor pull it over sharp edges.

- Protect the connecting cable from moisture.

• Do not touch the mains connector or

connecting cable with wet hands. Hold the cable

always at the connector when plugging or

unplugging it.

• CAUTION Power generator sets used for power

supply must be designed for the following rated

output:

≥ 4 x rated output of hand extruder

• Never allow the hand extruder to come into

contact with water: Hazard to persons and

equipment, short-circuit risk.

• CAUTION Never operate the hand extruder

without air supply; risk of hand extruder

damage.

When using an external air source, make sure

that the air supply line is adequately

dimensioned.

• CAUTION The supply air must be clean, dry and

free from oil and water.

• The hand extruder must not be used in

explosion hazard areas or flammable

atmospheres.

Make sure that the hand extruder is firmly

positioned during the extrusion welding job.

The connecting cable, welding rod and hose for

external air supply, if applicable, must be freely

movable and must not obstruct the operator or

third parties in their work.

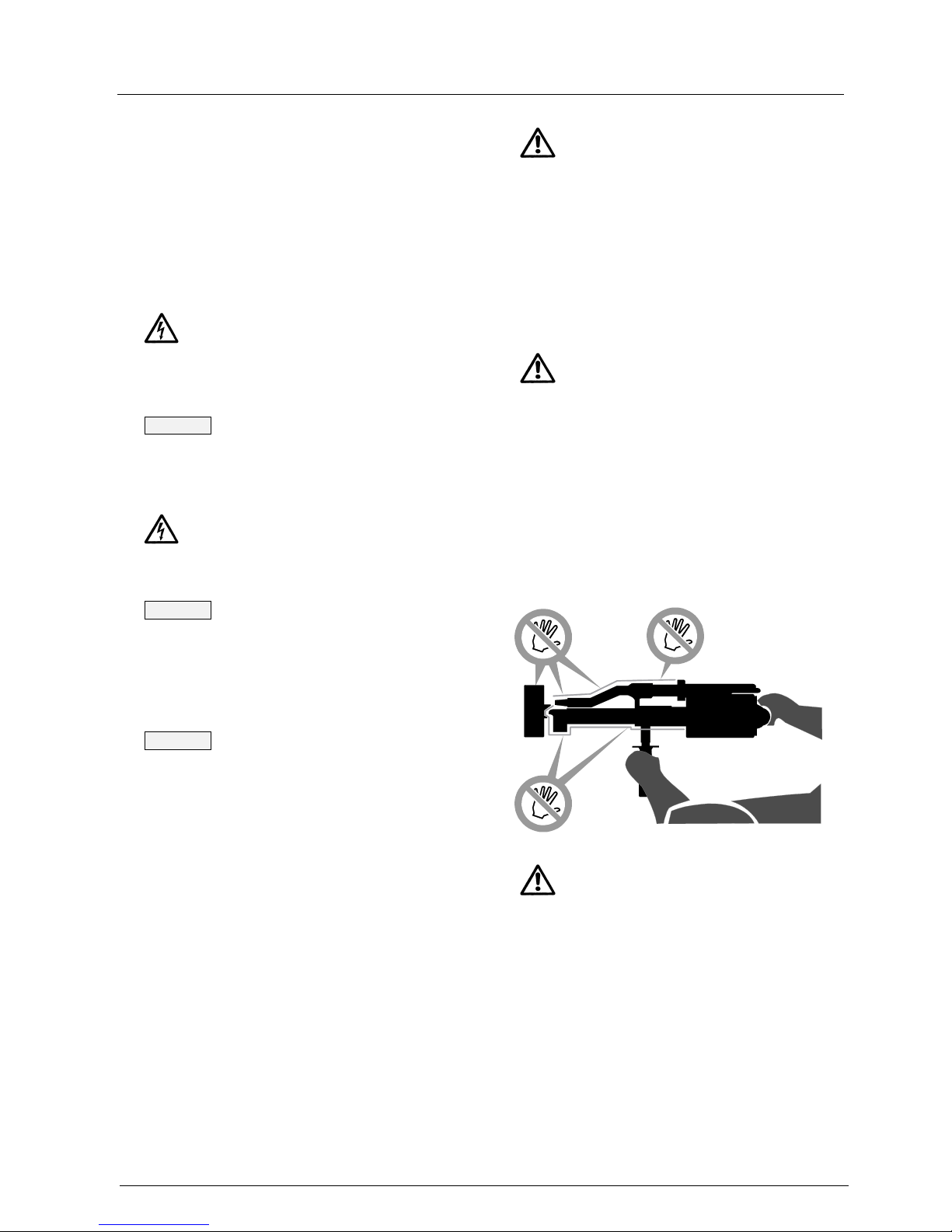

• Hold and touch the hand extruder only on

the handles provided for this purpose.

- Do not touch bare metal parts (including hot

air hood) either with or without gloves. These

parts reach temperatures of up to 350 °C.

- Attachments may be damaged or impaired

in their function if subjected to the full weight

of the hand extruder.

- Bare metal parts must not come into contact

with other items during the work or work

breaks (e.g. cooling).

FIG. D02-0001

• Contact of combustible components

with hot bare metal parts poses a risk of fire!

Do not use synthetic gloves!

D02-0001

Loading...

Loading...