Munro Irrigation User Manual

We’re For Irrigation.

Introduction to Munro

Munro is your irrigation pumping partner. As manufacturers and innovators of irrigation pumping products for 50 plus

years, Munro understands the irrigation market and has the unique ability and desire to serve the irrigation industry

better than any other pump company.

We’re different. Really.

If you’ve done business with some of our competitors, you know that they are not focused on helping irrigation wholesalers provide resources and excellent service to their customers. That’s why we’re different. We WANT to partner with

irrigation wholesalers and distributors. We can help you build your pump category to improve your bottom line!

Our products are better.

Our pumps are engineered to work better for longer. Our centrifugals offer performance to horsepower that is jaw

dropping. Our submersibles outlast our competition and are better built at very competitive prices. Our pump controls

are industry leaders. Our pump stations are recognized as innovative problem solvers, nationwide. We consider ease

of installation, energy consumption, and difficult conditions to make our products more flexible and easier to use. But

enough about us – if you’re not sure which pump you need, our handy resources and expert team will help you identify

the best equipment for your geography and application.

We’ve got what you need.

Our customers are always commenting on the breadth of pumping equipment we offer. We understand irrigation so

we know which accessories you need for different applications. Need hose or fittings? We’re one of the largest suppliers in the Western United States. Need valves, strainers or gauges? We’ve got those too. And our expanded line of

submersibles and specialty pumps means you can rely on Munro for all your pumping needs.

We’re easy to do business with.

With next day or two-day delivery to many regions, favorable terms and inventory to keep you rolling, we make it easy

to do business with us. Our team understands that you need your orders on-time and complete. We communicate with

you every step of the way. We also actively seek out your feedback on our products, people and processes; plus we

innovate to meet your needs.

INTRODUCTION

Munro Pump

created their

own line of

lawn pumps.

1985

The Munro

Smart Box was

created.

Munro Supply

expanded hose as-

Munro Systems

opened to expand focus and

capabilities on

custom pump

stations.

1986 1999 2003 2008 2009 2011 2012 2013 2014

Munro Supply

expanded their

offerings of

hose and other

industrial goods

to serve mining,

oil and gas and

other industries.

Munro Supply

expands to

include crimping

capabilities for

hydraulic and

industrial hose.

Munro Pump presents

the Complete PRO I,

the first complete

homeowner-ready

pumping package.

sembly capabilities

again to become

one of the largest

hose assembly

houses in the Rocky

Mountain region.

Munro Systems

adds state-of-theart test facility.

Munro Pump presents

the Complete PRO II, a

professional solution

to the age-old issue

of disparate components and Christmas

tree retrofits.

Munro Valve &

Fitting brings to

market grooved

fittings and

specialty valves.

I

Introduction

INTRODUCTION

Table of Contents

CENTRIFUGAL SUBMERSIBLE SPECIALTY PUMPS CONTROLS PACKAGED SYSTEMS

HOSE

FITTINGS & FLANGES VALVES INDUSTRIAL GOODS RESOURCES

Centrifugal

Irrigation & Booster ..................................................................................................... 1

LP ..............................................................................................................2-10

Turf ..........................................................................................................11-13

Complete PRO ll ....................................................................................... 15-18

Universal PRO Enclosure ........................................................................... 19,20

Submersible

Water Feature ........................................................................................................... 23

RP ............................................................................................................ 24-30

POND ...................................................................................................... 31,32

Dewatering ............................................................................................................... 33

FS ............................................................................................................34-39

FSR .......................................................................................................... 40,41

FSL........................................................................................................... 42,43

Residential Dewatering .............................................................................. 44,45

Sump ....................................................................................................................... 46

Sump Series.............................................................................................. 47,48

FSE .......................................................................................................... 49,50

Sewage & Effluent ..................................................................................................... 51

FSE .......................................................................................................... 52,53

FSA Vortex ................................................................................................ 54,55

FSA Stainless ............................................................................................ 56,57

FSG ......................................................................................................... 58,59

Well Pumps ..............................................................................................................60

Multistage Bottom Suction ......................................................................... 61,62

Deep Well ................................................................................................63-67

Well Pump Accessories ..............................................................................68,69

Well Pump Sleeve/Stands ...............................................................................70

Specialty Pumps ................................................................................................................ 71

Controls

StartBox ...............................................................................................................73-75

Liquid Level Control Box ............................................................................................ 76

SmartBox ............................................................................................................. 77-79

Pressure Start Control ................................................................................................ 80

TimeBox ................................................................................................................... 81

BrainBox .............................................................................................................82-84

DamBox .............................................................................................................. 85,86

Control Panels .....................................................................................................87,88

Custom Boxes ...................................................................................................... 89-93

Control Accessories ............................................................................................ 94-100

Packaged Systems

Complete PRO ll .............................................................................................. 102-105

VFD ....................................................................................................................... 106

Simplicity ......................................................................................................... 107,108

Stand Alone ..................................................................................................... 109,110

Custom Prefabricated Stations .......................................................................... 111,112

www.munropump.com II

Introduction

Table of Contents

Hose

Hose ...............................................................................................................113-122

Clamps ........................................................................................................... 123,124

Fittings & Flanges

Fittings ............................................................................................................126-142

Flanges .................................................................................................................. 143

HDPE .............................................................................................................. 144,145

Grooved Fittings ..............................................................................................146-156

Valves

Cam ............................................................................................................... 158,159

Butterfly ........................................................................................................... 160,161

Foot ................................................................................................................162-164

Gate ...................................................................................................................... 165

Ball ........................................................................................................................ 166

Check .............................................................................................................167-169

Float ...................................................................................................................... 170

Flow Control ........................................................................................................... 171

Air Evacuating ........................................................................................................ 171

Unloader ................................................................................................................ 172

Relief ...................................................................................................................... 172

Industrial Goods

Strainers .......................................................................................................... 173-175

Gauges .................................................................................................................. 176

Pump Stands .......................................................................................................... 177

Pressure Tanks ........................................................................................................177

Industrial Goods ..................................................................................................... 178

Freeze Defeat .......................................................................................................... 179

Resources

Typical Applications .......................................................................................... 182,183

Pump Data Worksheets ....................................................................................184-186

Hose Selection Worksheet ........................................................................................187

Pump Station Request for Quote .............................................................................. 188

Control Workseets ..............................................................................................93,189

Charts & Tables

Pump Controls Selection .........................................................................190-195

Friction Loss ...........................................................................................196,197

Wire Size ............................................................................................... 198,199

Capacities of Steel Pipe ................................................................................. 199

Conversion Tables ..................................................................................200-202

Measuring Tools ............................................................................................ 203

Glossaries .......................................................................................................204-219

Installation Guides ........................................................................................... 220-227

M95 HDPE Coupling .............................................................................. 220,221

M97 Transition Coupling ........................................................................ 222,223

M7705 Flexible Coupling ....................................................................... 224,225

Cut Groove Spec Sheets ................................................................................ 226

Roll Groove Spec Sheets ................................................................................ 227

Troubleshooting ...............................................................................................228-241

Winterization ................................................................................................ 241

Warranty ................................................................................................................242

Index .........................................................................................................................243-246

INTRODUCTIONCENTRIFUGALSUBMERSIBLESPECIALTY PUMPSCONTROLSPACKAGED SYSTEMS

HOSE

FITTINGS & FLANGESVALVESINDUSTRIAL GOODSRESOURCES

III

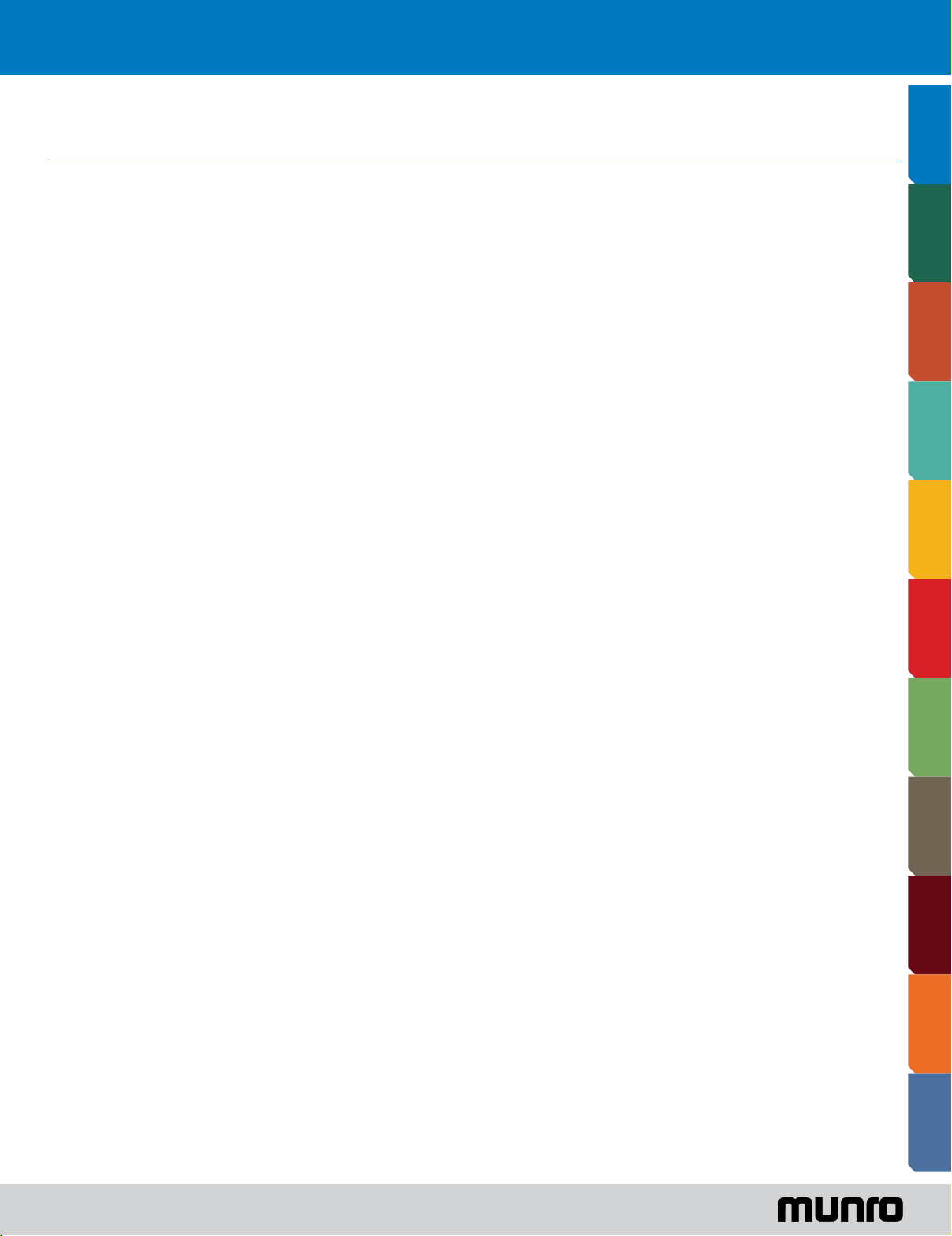

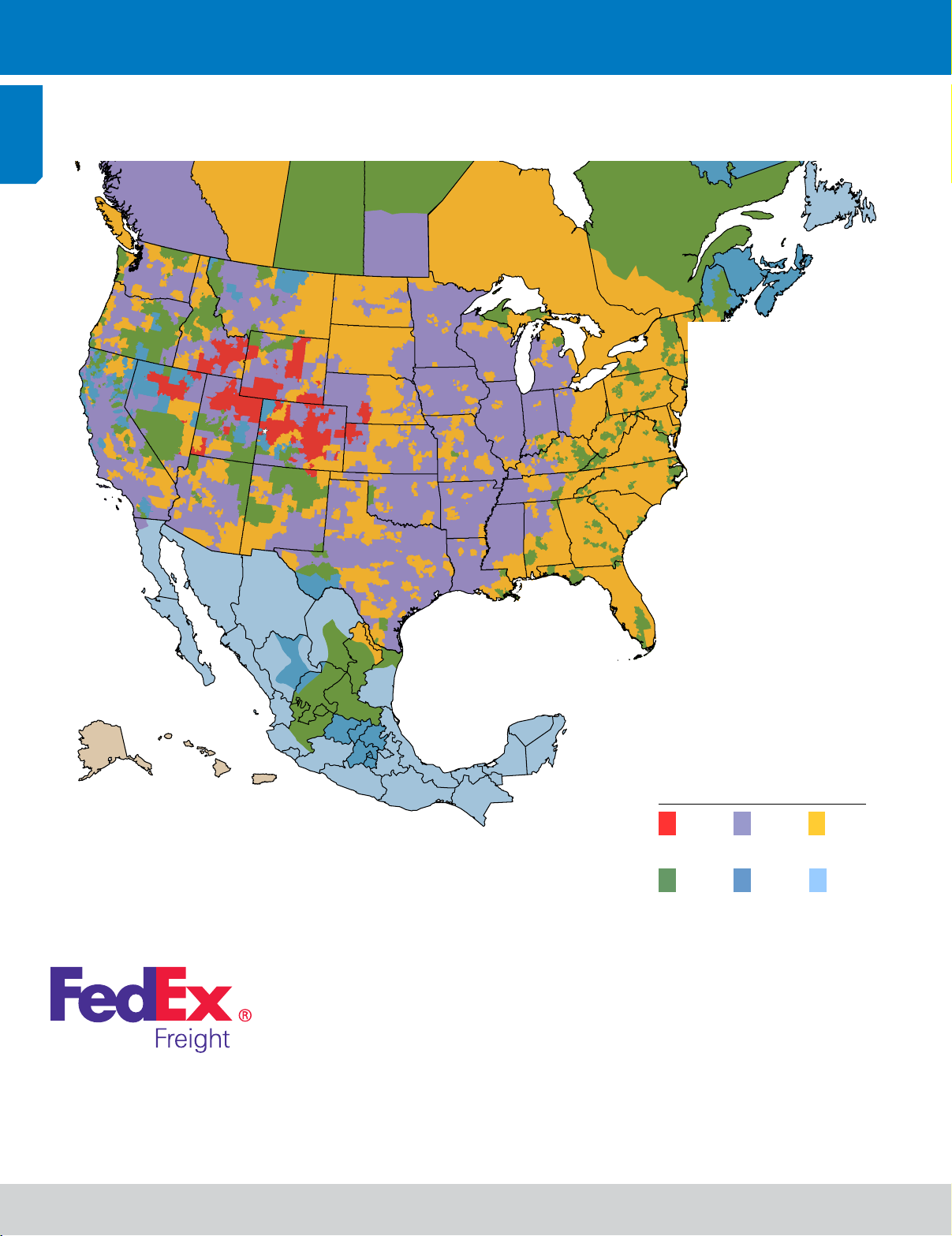

Freight Map

INTRODUCTION

NF

BC

WA

OR

NV

CA

BJ

AB

ID

UT

AZ

SO

SK

MT

WY

CO

NM

CI

MB

ND

MN

SD

NE

KS

TX

IA

MO

OK

AR

ON

QC

ME

VT

WI

MI

PA

OH

IN

IL

TN

AL

MS

LA

WV

KY

GA

VA

NC

SC

FL

NH

NY

MA

CT

RI

NJ

MD

DE

PE

NB

NS

BS

SI

NA

AK

HI

PR

CU

DG

ZT

JA

CL

NL

TM

SL

AG

GJ

QA

HG

EM

MH

GR

VZ

TL

DF

MR

PU

OA

TA

CH

YC

QR

CP

Service Standards

1 Day 2 Days 3 Days

4 Days 5 Days 6+ Days

Estimated freight times when Fedex Priority is used - shipping from Grand Junction, CO.

Weather is uncontrollable variable.

As of 9/19/18 fedex.com

www.munropump.com IV

Turf Irrigation Centrifugal Pumps

ABOUT CENTRIFUGAL PUMPS

How does a centrifugal pump work?

Using a rotating impeller, a centrifugal pump draws liquid into the center of the impeller

and then slings it out again, which increases the speed of the liquid and creates pressure

to move the liquid through pipe or hose.

Benefits and Applications

Centrifugal pumps are flexible and have many uses. A centrifugal pump can handle

muddy or dirty liquids and high temperatures. These pumps are most commonly

used to move or increase pressure (boost) of liquid through a pipe or hose system and

can be found in irrigation, water treatment, and even manufacturing environments.

Irrigation professionals use Munro pumps to draw water from lakes, ponds, cisterns,

shallow wells and more. In addition, they are commonly applied to increase operating

pressure (boost) in pressurized systems including domestic city water.

MUNRO PUMPS ARE EXCEPTIONAL

Outstanding performance to horsepower

Check out our curves. Our pumps outperform common competitor units, time after time.

Time-proven design re-engineered for maximum performance and longevity

With over 50 years experience in designing centrifugal pumps, the engineers at Munro studied the common failure points of

competing units and meticulously addressed each with high-grade materials and intelligent design. We refuse to settle.

Built tough in every component

A cast iron body and diffuser, standard on all sizes, mean these pumps are built to last.

Upgraded products without upgraded cost

A brass impeller and silicon carbide seal are standard for our full line, instead of pricey special-order upgrades.

CENTRIFUGAL

Easiest to install and maintain

Two priming ports, a sensor port and dual chamber drains makes maintenance quick and simple.

Did You Know?

The first centrifugal pump was developed in 1475 – that’s what we

call proven technology!

Pick-A-Pump

170 LP3005B/LP1502B LP3005B 73.69

160 LP3005B/LP1502B LP3005B/LP1502B LP3005B LP3005B 69.26

150 LP3005B/LP1502B LP3005B LP3005B/LP1502B LP3005B LP3005B LP3005B 64.93

140 LP300B LP300B LP300B LP1502B LP3005B LP3005B LP3005B 60.60

130 LP200B LP200B LP300B LP300B LP1502B/LP300B LP3005B LP3005B LP3005B 56.27

120 LP200B LP200B LP200B LP300B LP1502B/LP300B LP300B LP3005B LP3005B LP3005B 51.94

110 LP150B LP200B LP200B LP200B LP300B/LP200B LP300B LP300B LP3005B LP3005B LP3005B 47.61

100 LP100B LP150B LP150B LP200B LP200B LP200B LP300B LP300B LP3005B LP3005B LP3005B 43.29

90 LP075B LP100B LP100B LP150B LP200B LP200B LP300B LP300B LP300B LP3005B LP3005B 38.96

80 LP075B LP075B LP100B LP150B LP150B LP200B LP200B LP300B LP300B LP3005B LP3005B 34.63

70 LP075B LP075B LP075B LP100B LP150B LP200B LP200B LP200B LP300B LP300B LP3005B 30.30

TOTAL HEAD IN FEET

60 LP075B LP075B LP075B LP075B LP100B LP150B LP200B LP200B LP300B LP300B LP3005B 25.97

50 LP075B LP075B LP075B LP075B LP075B LP100B LP200B LP200B LP200B LP300B LP3005B 21.64

For larger flows or higher pressure than depicted, consult pump professional.

20 30 40 50 60 70 80 90 100 110 120

GALLONS PER MINUTE

PSI

1

Turf Irrigation Centrifugal Pumps

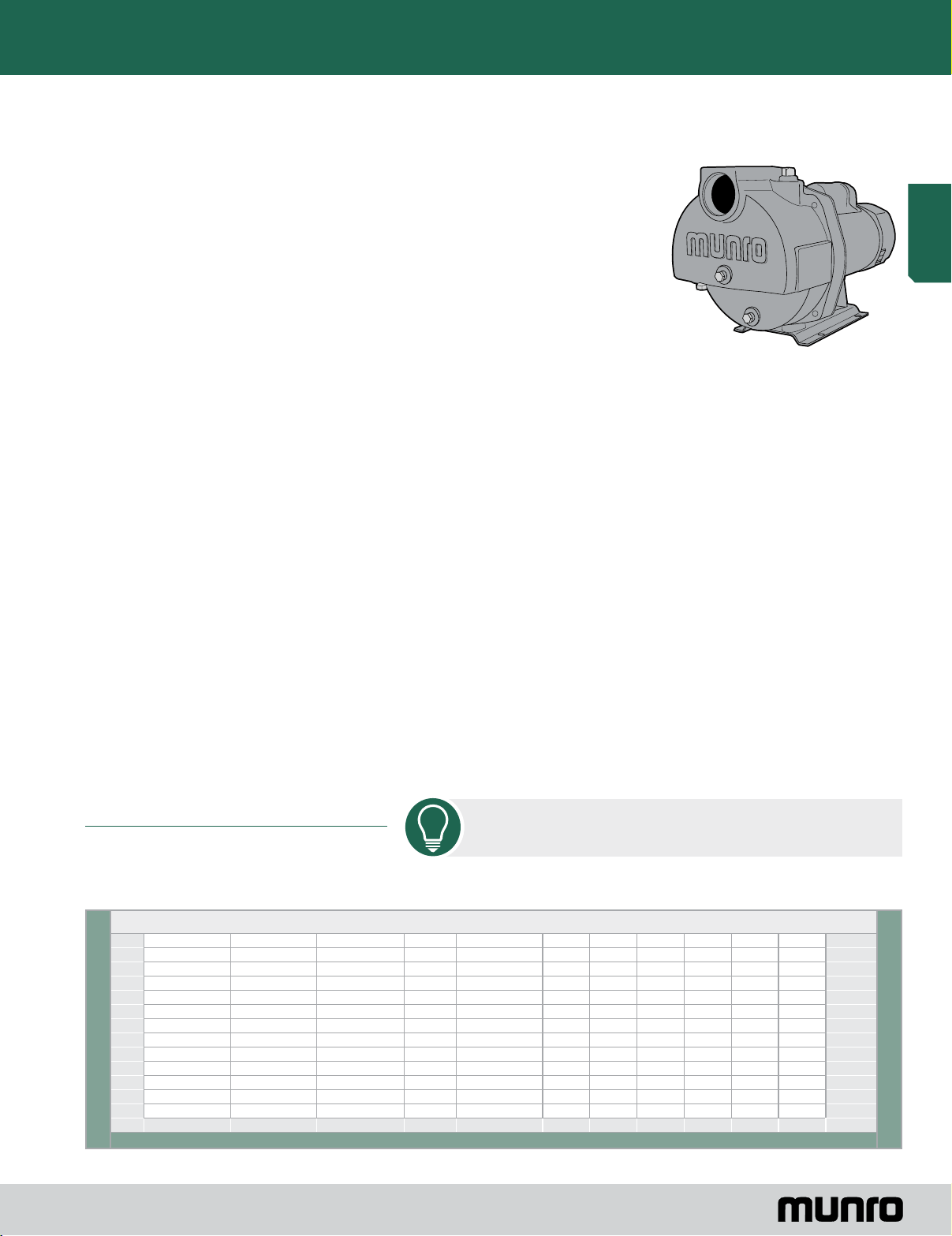

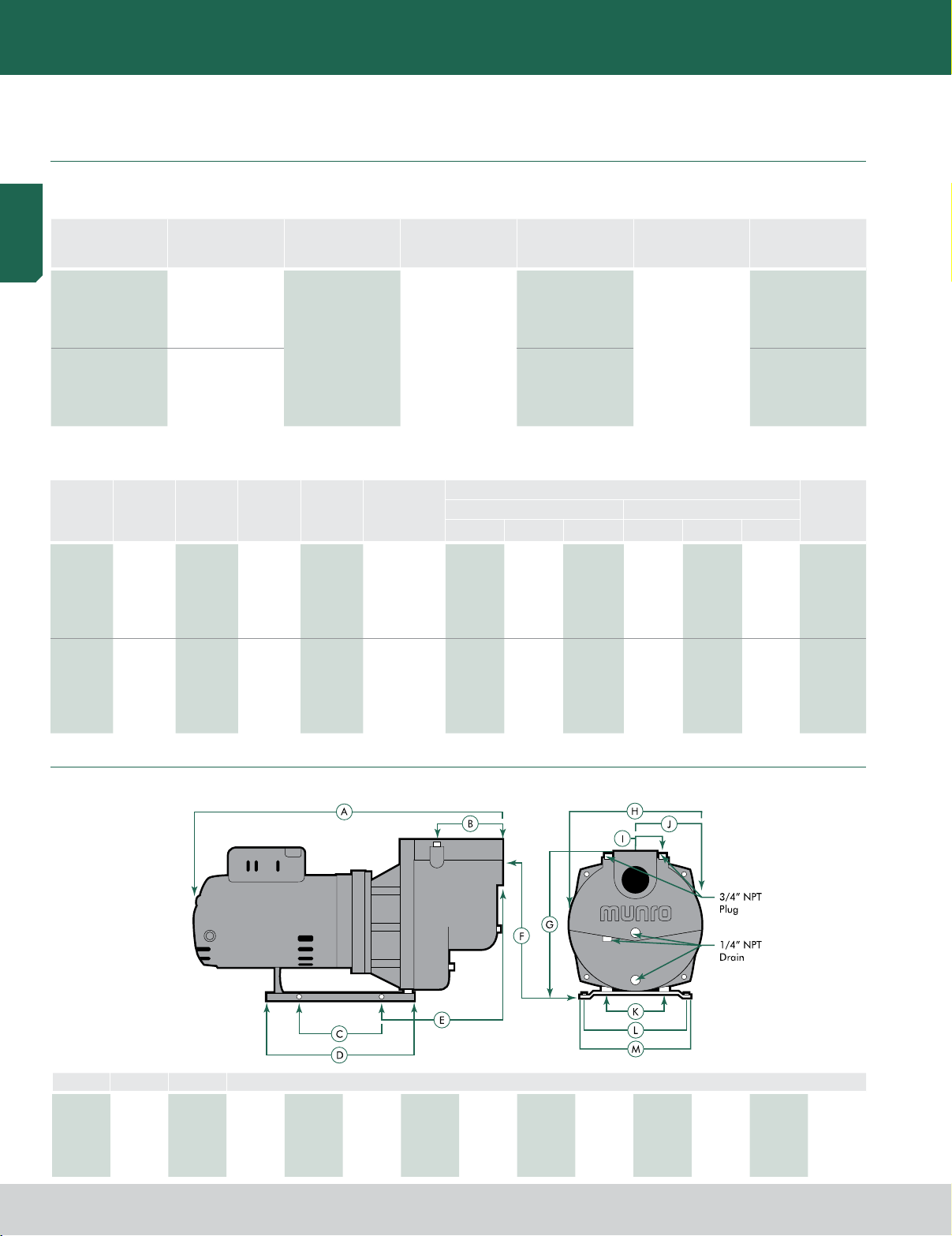

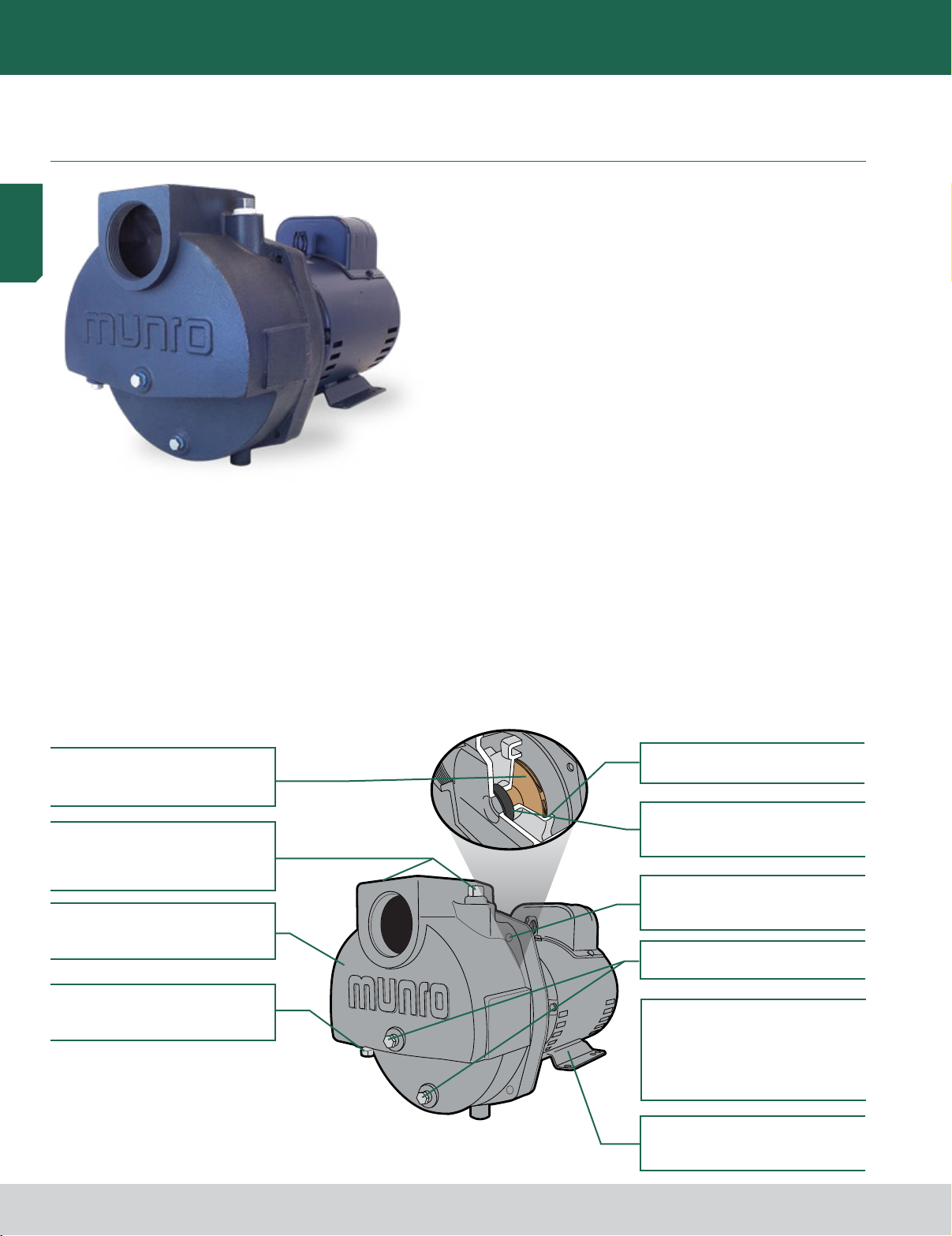

Munro LP Series ¾hp - 3hp

CENTRIFUGAL

Designed specifically for turf irrigation, this self-priming pump

provides outstanding performance to horsepower ratio. Our LP Series

is truly heavy duty, offering standard high-end features that our

competitors only offer as pricey add-ons. Professionals trust the LP

Series to deliver trouble-free performance.

• Brass impeller – durable and low maintenance with the

longest life in its class

• Stainless steel wear ring – eliminates impeller friction due to

rust build-up

• Cast iron body and internal components – heavy duty for

long-term performance and reliability

COMMON APPLICATIONS

• Residential turf irrigation: Drawing water from ponds, lakes,

streams, cisterns and shallow wells

• Booster: Boost domestic water pressure for use in irrigation

• Water transfer

ADVANTAGES

Durable and long lasting – While many centrifugal turf irrigation pumps are made out of plastic, which wears and warps, our

cast iron construction and brass impeller mean that our self-priming pumps are built to stand the test of time, even in more unusual

or difficult environments. Testing in tough conditions shows Munro LP series pumps last up to four times as long as typical

competitors products.

Industry leading performance to horsepower – The proof is in our curves. In many cases a lower horsepower Munro LP

pump will meet the same GPM performance that you’d expect to see only in higher horsepower pumps. With greater starting torque

and an efficient run cycle, our pumps truly lead the pack.

Easy to install and maintain – With two priming ports and a durable steel base plate, installing a Munro LP Series is a snap.

When it’s time to maintain or winterize the pump, you’ll love our two drain plugs. A stainless steel wear ring reduces oxidation and

friction, minimizing wear and repairs. If you do have to service the pump, stainless steel bolts and a dry-socket design provide

easy access.

BRASS IMPELLER – Longest life in its

class. Offers greatest durability and

reduces costly maintenance vs.

traditional plastic impellers.

BUILT-IN PRIMING & DRAIN PORTS –

Added start-up and maintenance

convenience, with stainless steel plugs

and no extra parts to buy.

CAST IRON CONSTRUCTION –

Designed for long term performance,

season after season. No plastic case to

warp or crack.

SENSOR PORT – Allows temperature

monitoring to avoid costly

maintenance issues.

SILICON CARBIDE/CARBON SEAL –

Proven tough, this seal is an industrial

standard for challenging applications,

including higher temperatures and

more abrasive conditions.

www.munropump.com 2

CAST IRON DIFFUSER – Assures

durability for the life of the pump.

STAINLESS STEEL WEAR RING –

Reduces springtime oxidation and

impeller friction.

STAINLESS STEEL BOLTS – No more

“busting knuckles” to remove bolts

during maintenance.

THERMALLY PROTECTED MOTOR – Shut

down protection protects motor from

damage due to over amping.

STEEL BASE PLATE – Easiest, most stable

mounting. Provides four handy

bolt holes.

Munro LP Series ¾hp - 3hp

Turf Irrigation Centrifugal Pumps

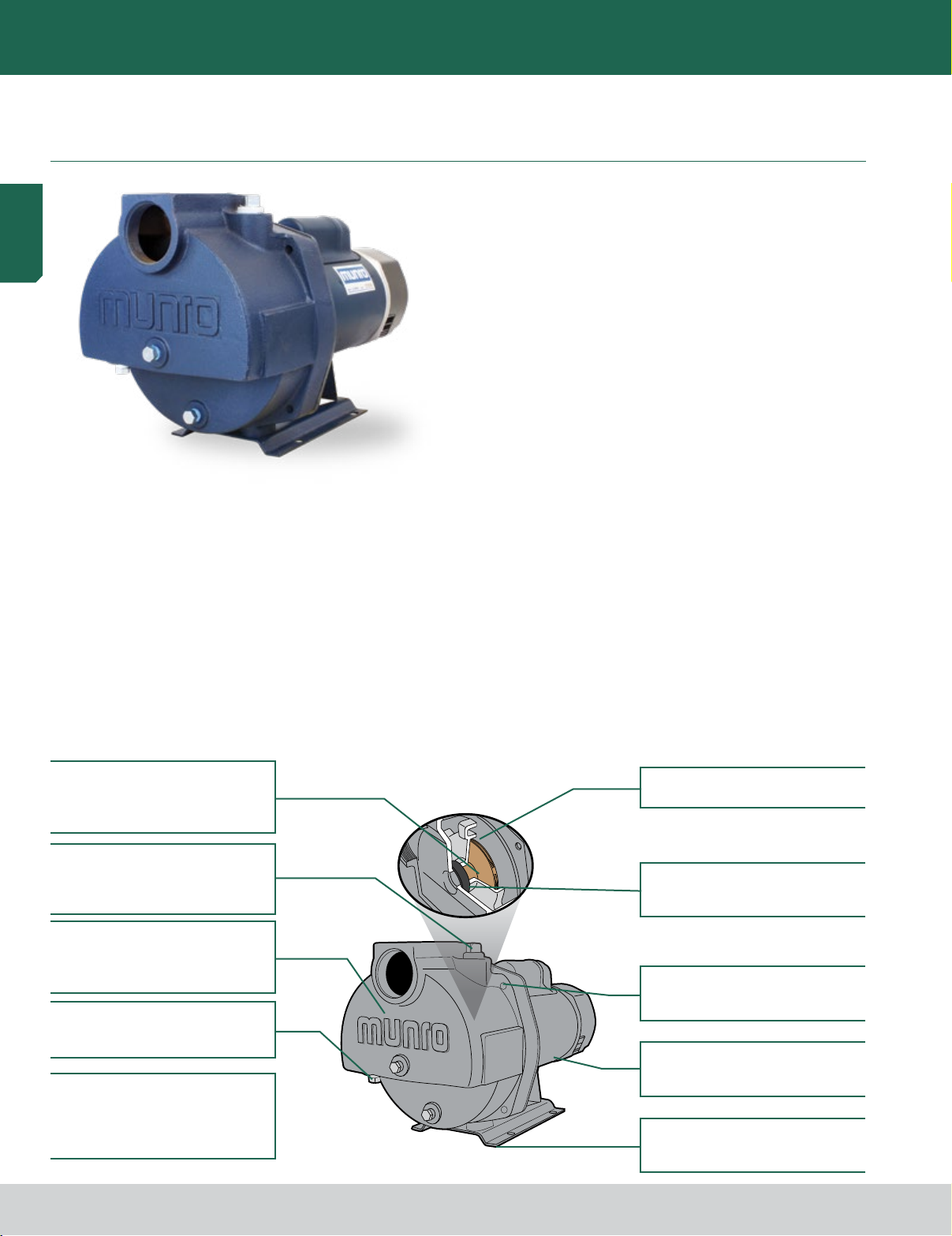

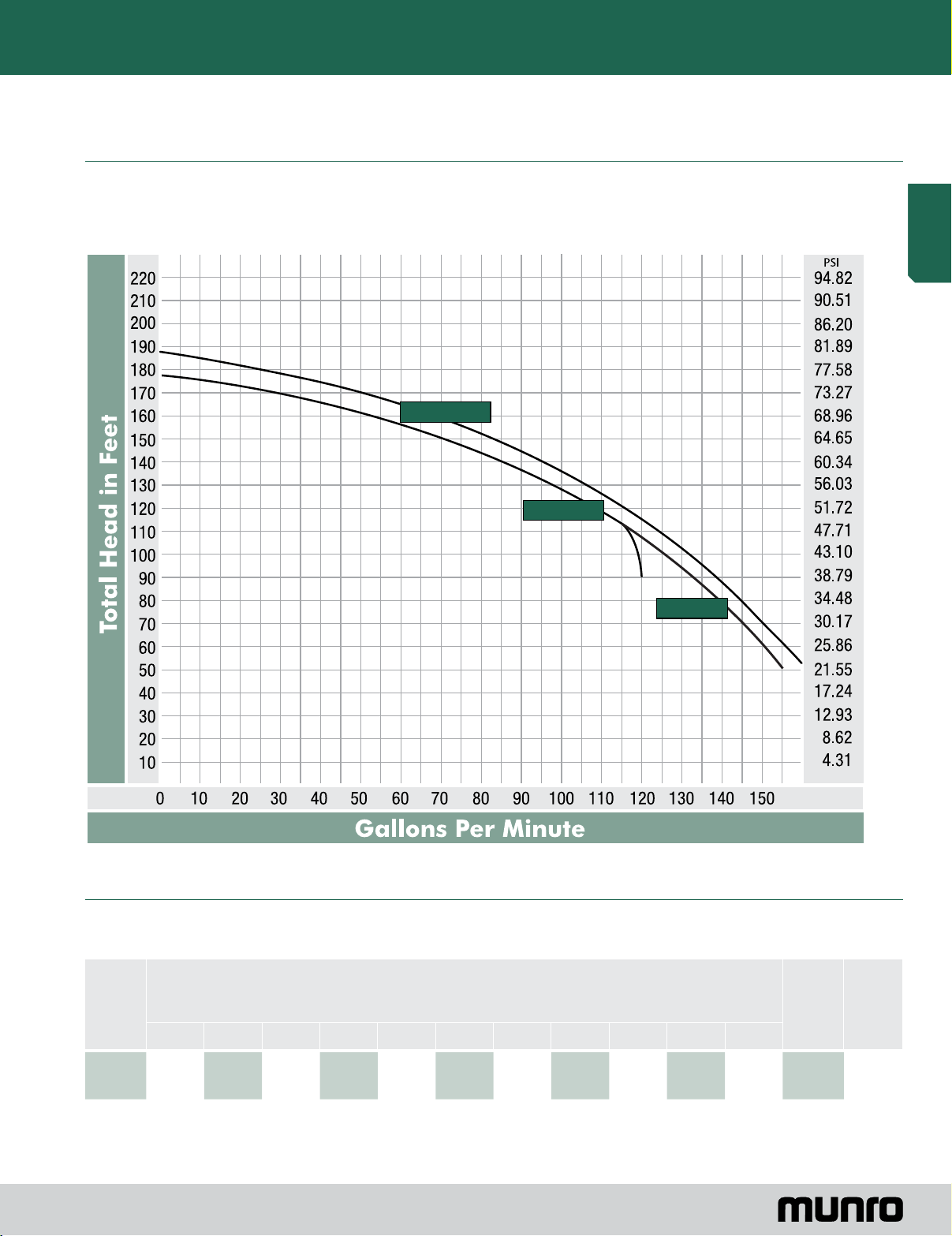

Curves

HORSEPOWER RANGE: 3/4 - 5

Curve includes LP 1502 (p.5) & LP3005 (p.8) for reference

CENTRIFUGAL

Did You Know?

Protect your pump using Munro’s SmartBox Pump Control.

See p.77-79 for details.

Performance

Capacity – U.S. Gallons per Minute

HP

20 25 30 35 40 45 50 55 60

3/4 63 53 43 33 25 45 LP075B

1 73 65 57 47 35 18 47 LP100B

1-1/2 75 70 68 60 48 35 49 LP150B

2 102 98 92 82 74 61 52 40 60 LP200B

3 115 114 112 105 100 88 72 56 30 61 LP300B

Suction lift varies, depending upon elevation (altitude) and water temperatures. Max lift is 15 feet at 5000 feet elevation. Maximum case pressure is 150 PSI.

Discharge Pressure (PSI) at 5’ Suction Lift

Shut Off

Pressure

psi

3

Model

Number

Turf Irrigation Centrifugal Pumps

Munro LP Series ¾hp - 3hp

Specifications – Pump

CENTRIFUGAL

Approx Ship

HP Phase Discharge Suction

3/4

1 72 LP100B

1-1/2 1 72 LP150B

2 80 LP200B

3 94 LP300B

3/4 57 LP075B3

1 62 LP100B3

1-1/2 3 68 LP150B3

2 70 LP200B3

3 76 LP300B3

1-1/2” 2”

Weight

lbs

66

Max

Liquid

Temperature

180˚

Model Number

LP075B

Specifications – Motor

Motor

HP Phase Voltage Hz RPM

3/4

1 16.6 8.5 8.3 LP100B

1-1/2 23 12.5 11.5 LP150B

2 208/230 13 12 LP200B

3 230 18 17 LP300B

3/4

1 -- 3.6 1.8 LP100B3

1-1/2 5.4 5.2 2.6 LP150B3

2 6.8 6.6 3.3 LP200B3

3 -- 9.2 4.6 LP300B3

1

3

115/208-

230

208-

230/460

60 3450 208/230V

60 3450 208/230V

For amperage ratings consult motor nameplate. Specications subject to change without notice.

Voltage

(Factory)

Connected

115 V 208V 230V 208V 230V 460V

11.6 5.8 5.8 LP075B

Service Factor Motor Amps

Single Phase Three Phase

2.6 2.8 1.4 LP075B3

Model

Number

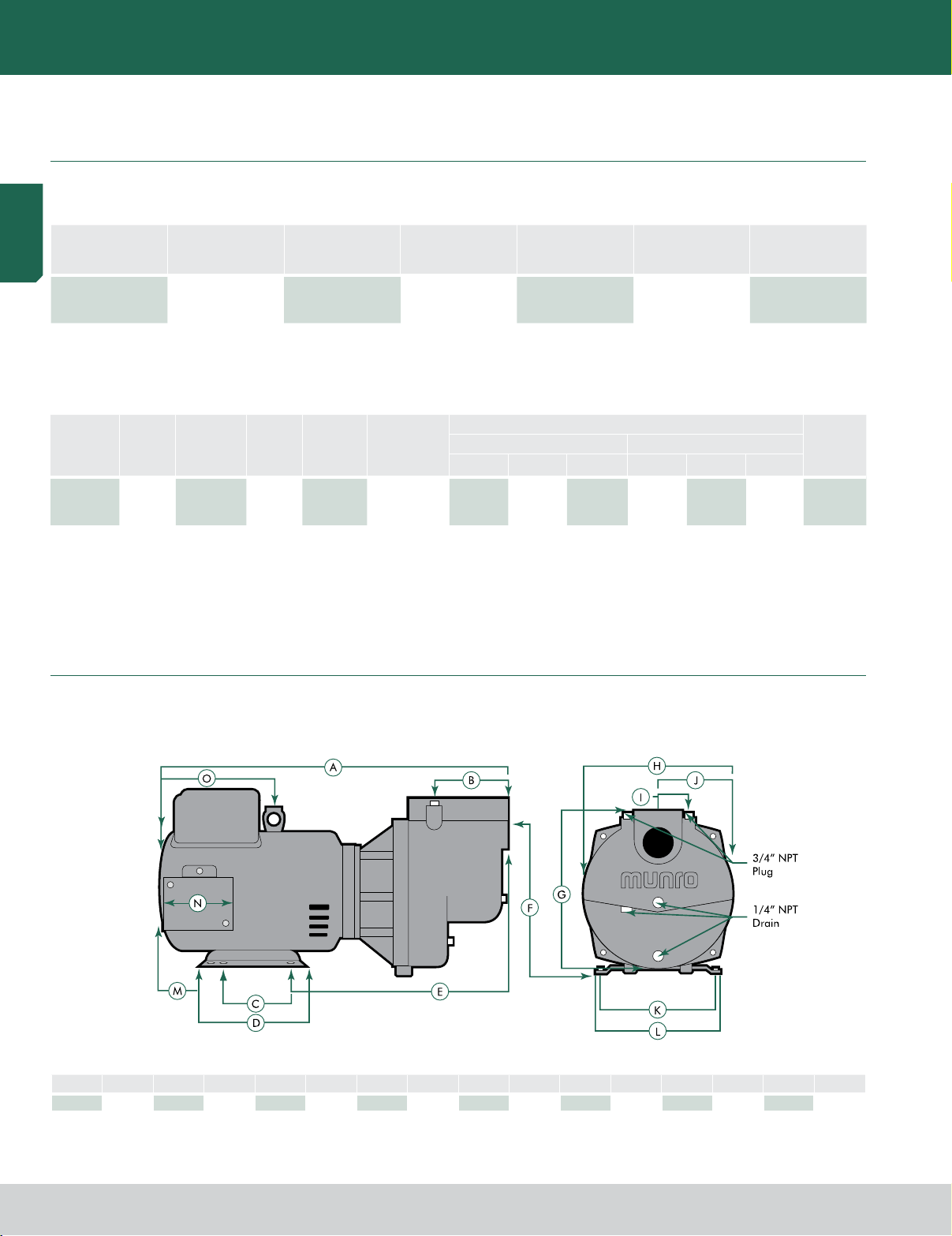

Dimensions

HP A

3/4 19 3/4” 3 5/8” 4 1/4” 8 1/2” 7 1/2” 9 1/2” 10 7/8” 9 1/2” 2 3/8” 4 3/4” 2 5/8” 5 1/4” 6”

1 19 3/4” 3 5/8” 4 1/4” 8 1/2” 7 1/2” 9 1/2” 10 7/8” 9 1/2” 2 3/8” 4 3/4” 2 5/8” 5 1/4” 6”

1 1/2 19 3/4” 3 5/8” 4 1/4” 8 1/2” 7 1/2” 9 1/2” 10 7/8” 9 1/2” 2 3/8” 4 3/4” 2 5/8” 5 1/4” 6”

2 18 3/4” 3 5/8” 4 1/4” 8 1/2” 7 1/2” 9 1/2” 10 7/8” 9 1/2” 2 3/8” 4 3/4” 2 5/8” 5 1/4” 6”

3 20 1/2” 3 5/8” 4 1/4” 8 1/2” 7 1/2” 9 1/2” 10 7/8” 9 1/2” 2 3/8” 4 3/4” 2 5/8” 5 1/4” 6”

B C

D E F G H I J K L M

www.munropump.com 4

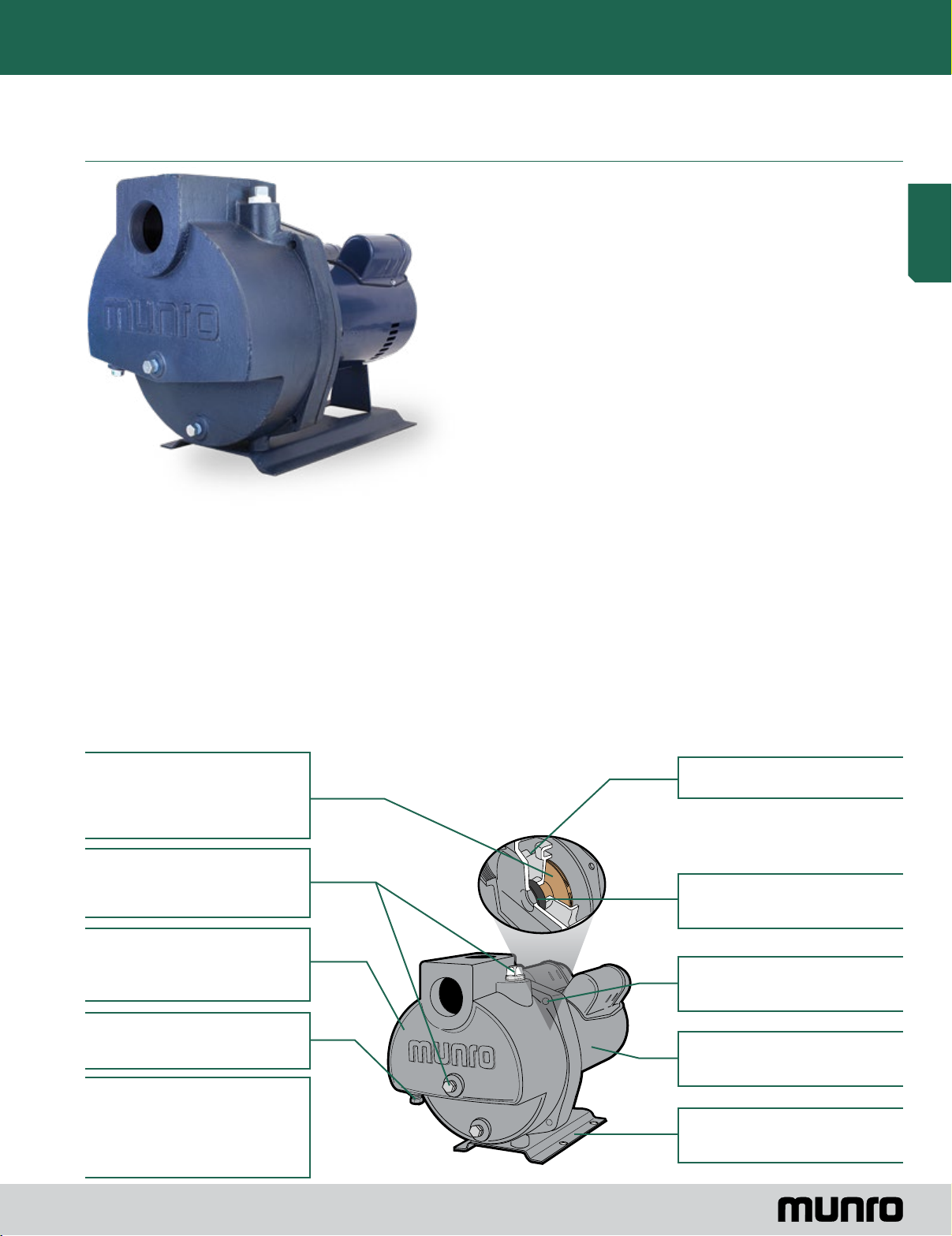

Munro LP 1502 - 2.5hp

Turf Irrigation Centrifugal Pumps

This very unique pump offers multi-stage performance with

single-stage simplicity. The Munro LP 1502 self-priming centrifugal

pump provides higher operating pressure like a multi-stage pump

without the additional maintenance concerns multiple impellers

present. Built for maximum durability and longevity.

• Brass impeller – tough and long lasting, one brass impeller

means you’ll see less maintenance than with other pumps that offer

similar performance

• Stainless steel wear ring – eliminates impeller friction due to

rust build up

• Heavy-duty motor – lasts longer and provides application flexibility

COMMON APPLICATIONS

• Residential clean water turf irrigation: Small to mid-size community

or commercial turf irrigation

• High-pressure booster

• Water transfer

CENTRIFUGAL

ADVANTAGES

Multi-stage performance with single-stage simplicity – This self-priming pump is truly unique and in a class by itself,

delivering almost 60 gpm at 60 psi. The high-pressure capabilities of this pump can be compared to other brand’s multi-stage or

5hp pumps.

Durable and long lasting – Before the LP 1502, only a multi-stage pump could achieve this performance to horsepower ratio.

However, additional impellers require a longer shaft, which puts more load on the motor bearing and creates maintenance issues,

including misalignment and wear. Keeping the shaft short makes the pump more stable and durable. Add to this our cast iron

construction and brass impeller and it’s clear that this is a pump made to stand the test of time, even in more unusual or

difficult environments.

Easy to install and maintain – Two priming ports make the Munro LP 1502 easy to install and two drain plugs make

winterization a snap. A stainless steel wear ring reduces oxidation and friction, minimizing wear and repairs. If you should have to

service the pump, stainless steel bolts and dry-socket design provide easy access.

SINGLE BRASS IMPELLER – Longest life

in its class. A single solid brass impeller

offers greatest durability vs. multiple

impeller units. Lower cost to operate

and maintain over the life of the pump.

BUILT-IN PRIMING & DRAIN PORTS –

Added start-up and maintenance

convenience, with stainless steel plugs,

no extra parts to buy.

CAST IRON CONSTRUCTION –

Designed for long term performance,

season after season. No plastic case to

warp or crack.

CAST IRON DIFFUSER – Assures

durability for the life of the pump.

STAINLESS STEEL WEAR RING –

Reduces springtime oxidation and

impeller friction.

STAINLESS STEEL BOLTS – No more

“busting knuckles” to remove bolts

during maintenance.

SENSOR PORT – Allows temperature

monitoring to avoid costly

maintenance issues.

CERAMIC CARBON WITH BUNA

RUBBER – Proven tough, this seal is an

industrial standard for challenging

applications, including higher

temperatures and more

abrasive conditions.

THERMALLY PROTECTED MOTOR – Shut

down protection protects motor from

damage due to over amping.

STEEL BASE PLATE – Easiest, most stable

mounting. Provides four handy

bolt holes.

5

Turf Irrigation Centrifugal Pumps

Munro LP 1502 - 2.5hp

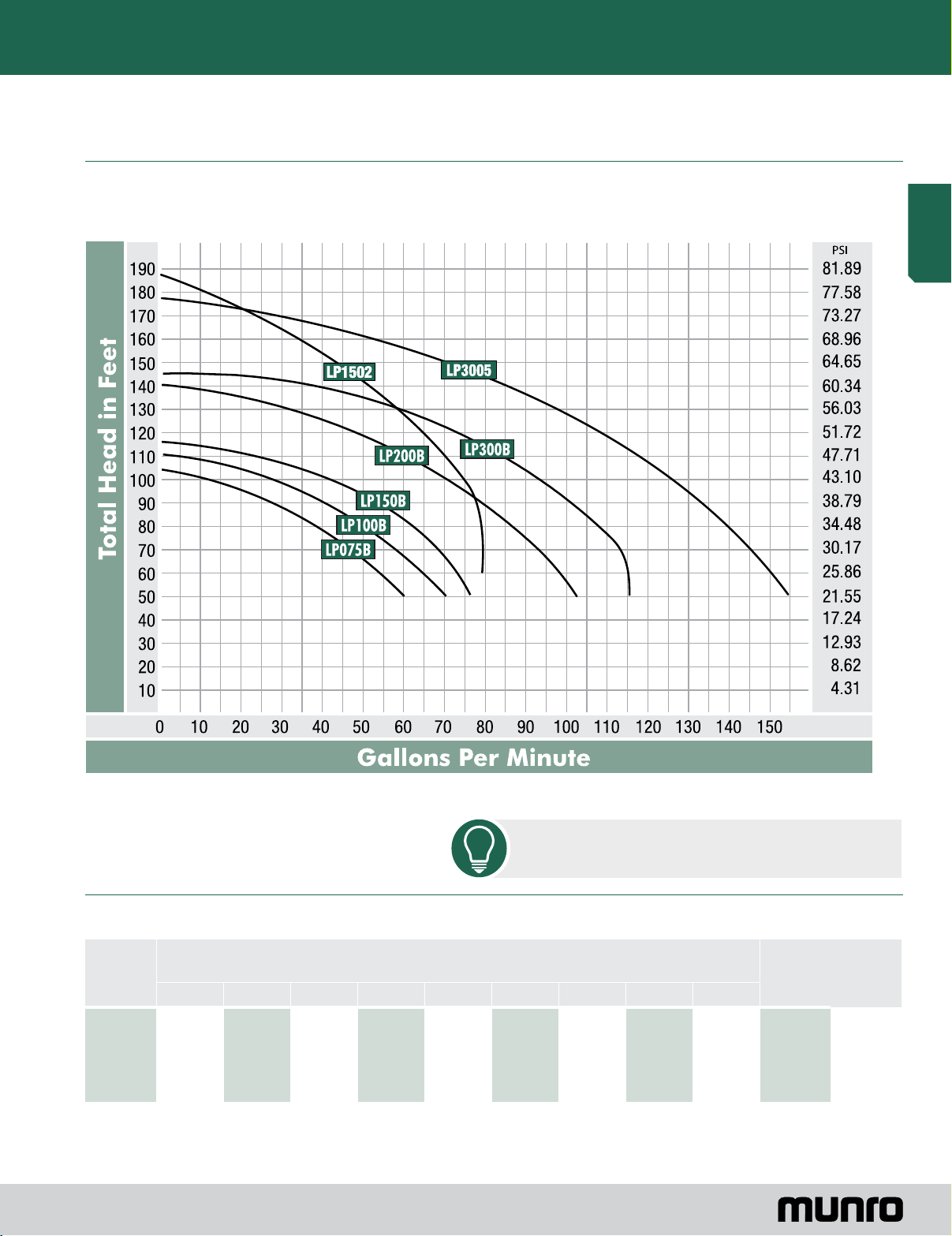

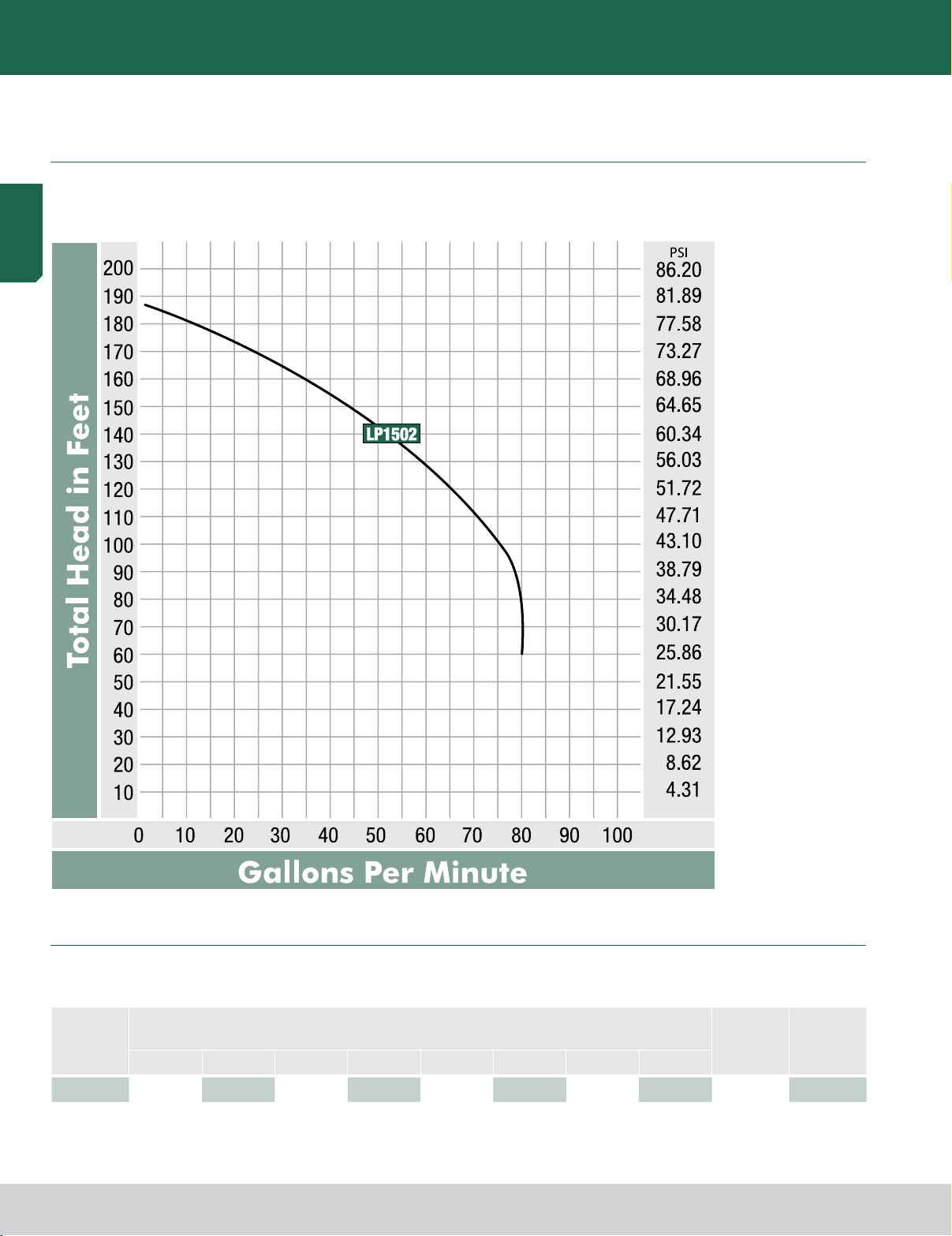

Curves

CENTRIFUGAL

HORSEPOWER RANGE: 2.5

Performance

HP

20 30 40 50 60 70 80 90

2.5 -- -- 75 67 56 38 0 0 80 LP1502B

Suction lift varies, depending upon elevation (altitude) and water temperatures. Max lift is 15 feet at 5000 feet elevation. Maximum case pressure is 100 PSI.

Discharge Pressure (PSI) at 5’ Suction Lift

U.S. Gallons per Minute

Shut Off

Pressure

psi

www.munropump.com 6

Model

Number

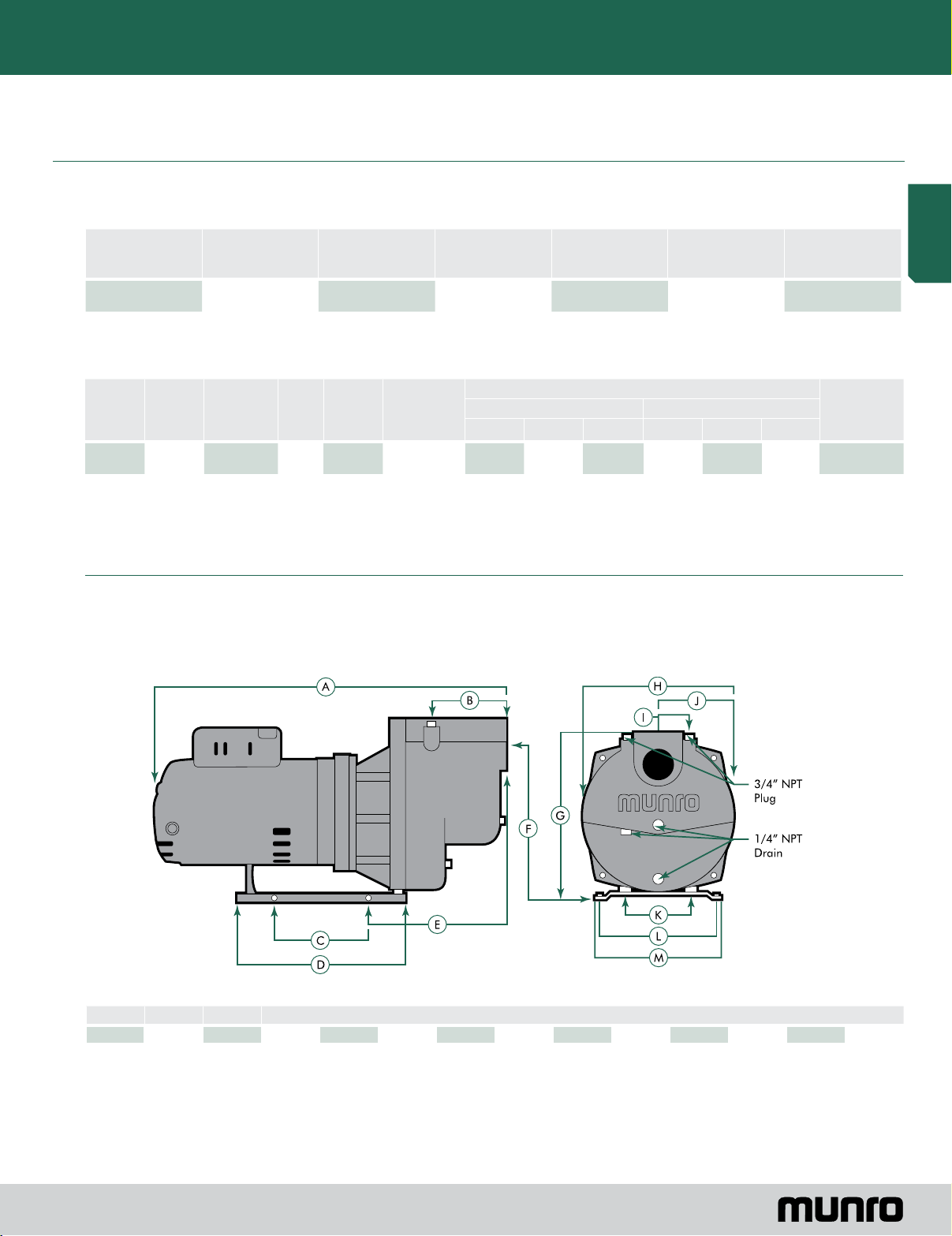

Munro LP 1502 - 2.5hp

Specifications – Pump

Turf Irrigation Centrifugal Pumps

Approx Ship

HP Phase Discharge Suction

2.5 1

2.5 3 105 LP1502B3

1-1/2” 2”

Weight

lbs

116

Max

Liquid

Temperature

180˚

Model Number

LP1502B

Specifications – Motor

Motor

HP Phase Voltage Hz RPM

2.5 1 208/230

2.5 3 208/230/460 -- -- -- -- 5.6 2.8 LP1502B3

60 3450 208/230

For amperage ratings consult motor nameplate. Specications subject to change without notice.

Voltage

(Factory)

Connected

115 V 208V 230V 208V 230V 460V

-- 15.7 16 -- -- --

Service Factor Motor Amps

Single Phase Three Phase

Dimensions

CENTRIFUGAL

Model

Number

LP1502B

HP A

2.5 20” 4 1/4” 7.95” 14” 9 1/4” 11 1/4” 13 1/2” 11 1/2” 3” 5 3/4” 4” 7” 8”

B C

D E F G H I J K L M

7

Turf Irrigation Centrifugal Pumps

Munro LP 3005 Series 5hp

CENTRIFUGAL

Perfect for mid-size turf applications like athletic fields or small

pasture land, this 5 horsepower pump provides professionalgrade performance, easy maintenance, and long life. Built

with components proven to perform, this pump is a

heavy-duty workhorse.

• Brass impeller – durable and low maintenance with the

longest life in its class

• Ceramic carbon with buna rubber seal – proven

toughness stands up to less than ideal situations

• Heavy-duty motor – lasts longer and provides

application flexibility

COMMON APPLICATIONS

• Turf irrigation: Residential, community or commercial

turf irrigation

• High-pressure booster

• Water transfer

ADVANTAGES

Industry leading performance to horsepower – The proof is in our curves. Compared to other 5 horsepower pumps, the Munro

LP 3005 has much stronger performance. With high starting torque and an efficient run cycle, our pumps truly lead the pack.

Durable and long lasting – At this horsepower rating, performance requirements lead most pump manufacturers to use

heavy-duty materials similar to those that come standard on all of our models. But look closely... we’re building the toughest pumps

around. Our cast iron construction and brass impeller mean that our self-priming pumps are built to stand the test of time, even in

more unusual or difficult environments.

Easy to install and maintain – With two priming ports and a durable steel base plate, installing a Munro LP 3005 is a snap.

When it’s time to maintain or winterize the pump, you’ll love our two drain plugs. A stainless steel wear ring reduces oxidation and

friction, minimizing wear and repairs. If you do have to service the pump, stainless steel bolts provide easy access.

BRASS IMPELLER – Longest life in its

class. Offers great durability and

reduces costly maintenance.

BUILT-IN PRIMING & DRAIN PORTS –

Added start-up and maintenance

convenience, with stainless steel plugs,

no extra parts to buy.

CAST IRON CONSTRUCTION –

Designed for long term performance,

season after season.

SENSOR PORT – Allows temperature

monitoring to avoid costly

maintenance issues.

www.munropump.com 8

CAST IRON DIFFUSER – Designed for

long-term irrigation performance.

STAINLESS STEEL WEAR RING –

Reduces springtime oxidation and

impeller friction.

STAINLESS STEEL BOLTS – No more

“busting knuckles” to remove bolts

during maintenance.

STAINLESS STEEL PLUGS –

Easy removal for winterization.

CERAMIC CARBON WITH BUNA

RUBBER – Proven tough, this seal is an

industrial standard for challenging

applications, including higher

temperatures and more

abrasive conditions.

STEEL BASE PLATE – Easiest, most stable

mounting. Provides four handy

mounting holes.

Munro LP 3005 Series 5hp

LP3005B3B

LP3005B3

LP3005B

Curves

HORSEPOWER RANGE: 5

PHASE: 1

Turf Irrigation Centrifugal Pumps

CENTRIFUGAL

CENTRIFUGAL

Performance

HP

20 25 30 35 40 45 50 55 60 65 70

5

-- -- 145 137 132 123 110 98 85 67 47 75 LP3005B

-- -- -- -- -- 120 110 98 85 67 47 75 LP3005B3

-- 160 154 145 135 130 116 107 95 84 63 78 LP3005B3B

Suction lift varies, depending upon elevation (altitude) and water temperatures. Max lift is 15 feet at 5000 feet elevation. Maximum case pressure is 100 PSI.

Capacity – U.S. Gallons per Minute

Discharge Pressure (PSI) at 5’ Suction Lift

9

Shut Off

Pressure

psi

Model

Number

Turf Irrigation Centrifugal Pumps

Munro LP 3005 Series 5hp

Specifications – Pump

CENTRIFUGAL

Approx Ship

HP Phase Discharge Suction

5 1

5 3 121 LP3005B3

5 3 135 LP3005B3B

3” 3”

Weight

lbs

151

Max

Liquid

Temperature

180˚

Model Number

LP3005B

Specifications – Motor

Motor

HP Phase Voltage Hz RPM

5 1 208/230

5 3 208-230/460 -- -- -- -- 14 7 LP3005B3

*5 3 230/460 3450 230V/460V -- -- -- 17.2 8.6 LP3005B3B

For amperage ratings consult motor nameplate. Specications subject to change without notice.

*Phase Conversion Compatible

60

3450 230V

Voltage

(Factory)

Connected

115 V 208V 230V 208V 230V 460V

-- 27 24.5 -- -- --

Service Factor Motor Amps

Single Phase Three Phase

Model

Number

LP3005B

Dimensions

HP A

5 21 3/4” 4” 4 1/2” 6 1/2” 13 1/2” 9 1/2” 12 5/8” 11” 3 1/8” 5 5/8” 7 1/2” 8 1/2” 2 1/2” 4 1/4” 7 1/2”

B C

D E F G H I J K L M N O

www.munropump.com 10

Turf Irrigation Centrifugal Pumps

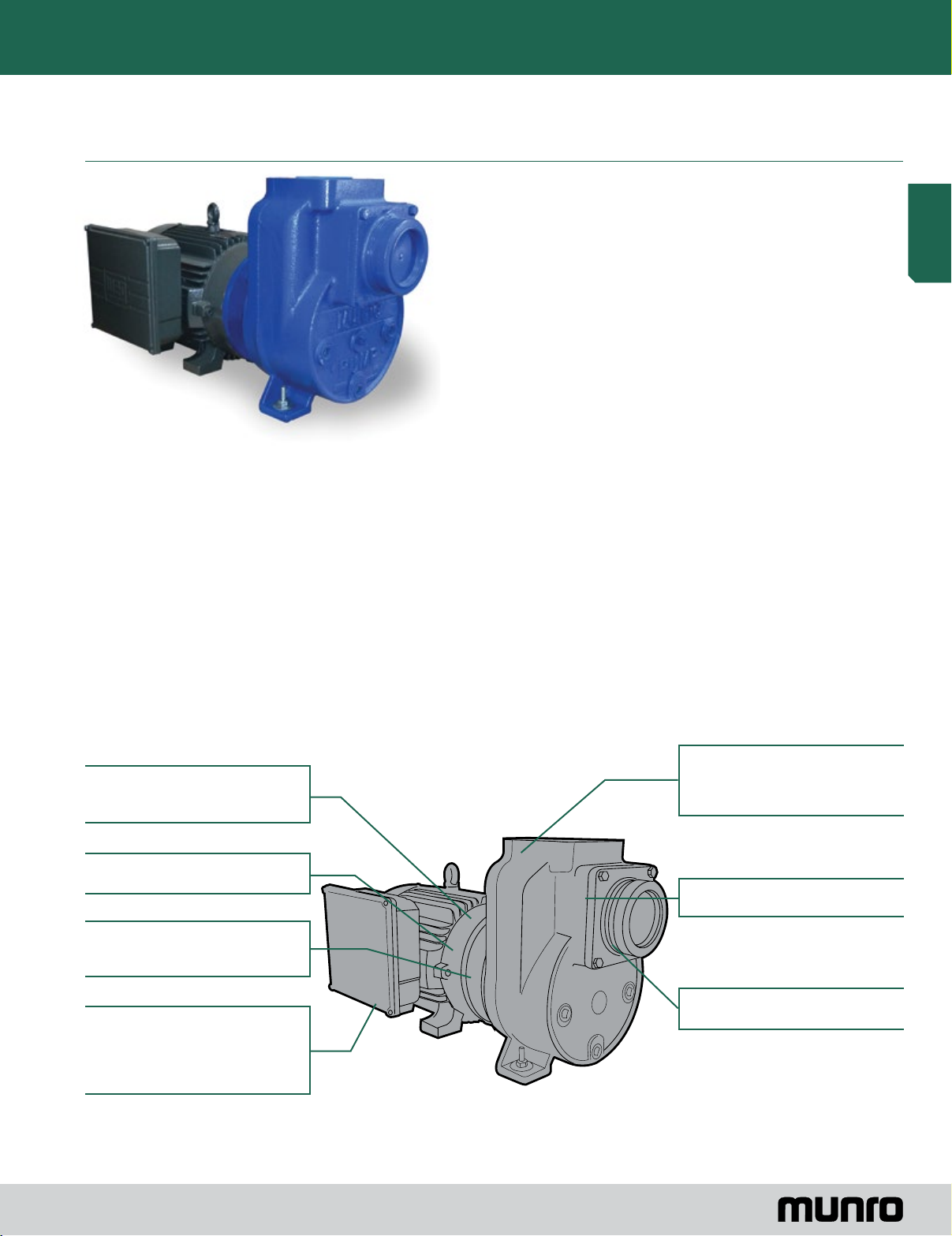

Munro MU Series High and Medium Head 7 1/2 - 20hp

These pumps are ideally suited to turf irrigation applications where

greater flows and higher heads are required.

• Bronze impeller – the enclosed, single piece design is balanced

and trimmed for specific operation

• Mechanical shaft seal – proven toughness stands up to less

than ideal situations

• Heavy-duty motor – lasts longer and provides

application flexibility

COMMON APPLICATIONS

• Turf irrigation: Residential, mid-size community or commercial

• Booster

• Water transfer

ADVANTAGES

Versatile – These pumps can be used for a wide variety of applications, including irrigation, draining barges and tank cars, and

dewatering mines or underground storage facilities. Homeowners use them for sprinkler systems and swimming pools. When it

comes to moving water from one place to another, there’s no end to the jobs that a self-priming pump can handle!

Quick start-up – Because these pumps are self-priming, there is no additional work required to get the pump ready to operate.

Just install, fill and go!

CENTRIFUGAL

CENTRIFUGAL

ENCLOSED BRONZE IMPELLER – Single

piece design, balanced and trimmed for

a specific operating range.

BRONZE SHAFT SLEEVE – Dissipates

effects of shaft torque

CARBON CERAMIC MECHANICAL

SHAFT SEAL – Reduces maintenance

problems.

NEMA JM MOTOR – Provides a short

shaft overhand and reduces axial strain

on the motor bearings. Continuous,

open drip proof motors are standard

but other motor options are available.

CAST IRON CASE – With built-in drain

and priming plugs, the extra large

priming chamber offers fast, trouble

free priming.

BOLT ON SUCTION FLANGE –

Allows for 3” or 4” NPT connection

BUILT IN CHECK VALVE – Prevents

siphoning and need for re-priming.

11

Turf Irrigation Centrifugal Pumps

Munro MU Series High and Medium Head 7 1/2 - 20hp

Curves Curves

CENTRIFUGAL

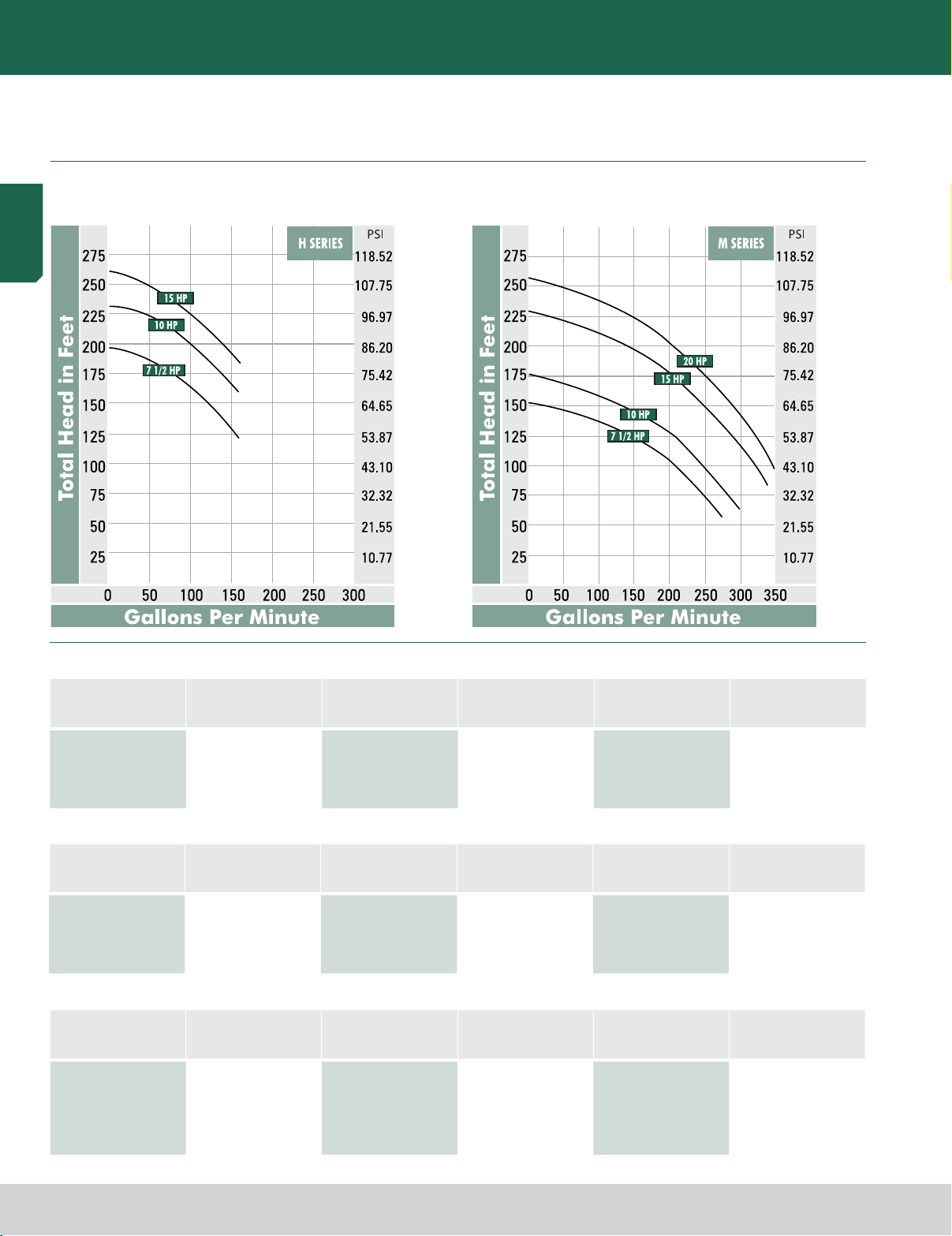

HORSEPOWER RANGE: 7 1/2 – 15 HORSEPOWER RANGE: 7 1/2 – 20

Specifications – Pump – H Series

HP Suction Discharge

7.5

7.5 174 MU75HT

10 229 100˚ MU10HS

10 197 MU10HT

15 210 MU15HT

3” 3”

Specifications – Motor – H Series

HP Phase Volts Run Amps

7.5 1 230

7.5 3 208/230/460 21/19.4/9.7 MU75HT

10 1 230 47 100˚ MU10HS

10 3 208/230/460 28/25/12.5 MU10HT

15 3 208/230/460 42/38/19 MU15HT

Specifications – Pump – M Series

HP Suction Discharge

7.5

7.5 174 MU75MT

10 229 MU10MS

10 197 MU10MT

15 210 MU15MT

20 241 MU20MT

Maximum case pressure is 120 PSI.

4” 3”

Approx Ship

Weight

lbs

225 MU75HS

37 MU75HS

Approx Ship

Weight

lbs

225

Max

Liquid

Temperature

Max

Liquid

Temperature

Max

Liquid

Temperature

100˚

Model Number

Model Number

Model Number

MU75MS

www.munropump.com 12

Turf Irrigation Centrifugal Pumps

Munro MU Series High and Medium Head 7 1/2 - 20hp

Specifications – Motor – M Series

HP Phase Volts Run Amps Model Number

7.5 1 230

7.5 3 208/230/460 21/19.4/9.7 MU75MT

10 1 230 47 MU10MS

10 3 208/230/460 28/25/12.5 MU10MT

15 3 208/230/460 42/38/19 MU15MT

20 3 208/230/460 52.6/47/23.5 MU20MT

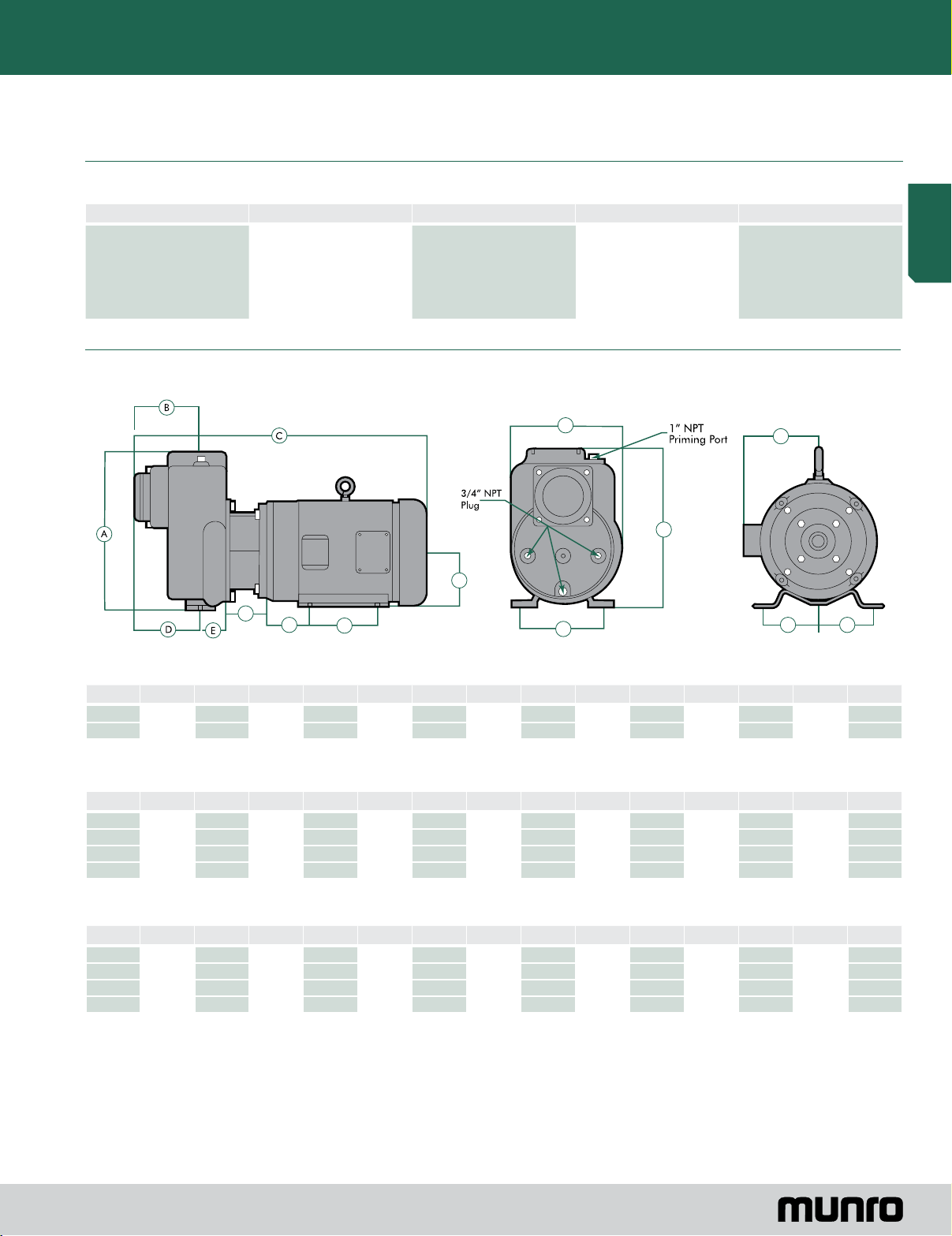

Dimensions

37 MU75MS

CENTRIFUGAL

CENTRIFUGAL

J

L

I

F

G

H

K

M

Single Phase

HP A

7.5 15 1/4" 8 3/4" 26 5/8" 6 1/8" 2 3/4" 2 7/8" 3 1/2" 5 1/2" 5 1/4" 10 9/16" 7 15/16" 15 5/32" 9 5/16" 4 1/4"

10 15 1/4" 8 3/4" 27 1/4" 6 1/8" 2 3/4" 2 7/8" 3 1/2” 7" 5 1/4" 10 9/16" 7 15/16" 15 5/32" 9 5/16" 4 1/4"

B C

D E F G H I J K L M N

Three Phase

HP A

7.5 15 1/4" 8 3/4" 23 1/2" 6 1/8" 2 3/4" 2 7/8" 2 3/4" 4 1/2" 4 1/2" 10 9/16" 7 15/16" 15 5/32" 8 3/32" 3 3/4"

10 15 1/4" 8 3/4" 25 5/8" 6 1/8" 2 3/4" 2 7/8" 3 1/2" 5 1/2" 5 1/4" 10 9/16" 7 15/16" 15 5/32" 9 5/16" 4 1/4"

15 15 1/4" 8 3/4" 27 1/4" 6 1/8" 2 3/4" 2 7/8" 3 1/2" 7" 5 1/4" 10 9/16" 7 15/16" 15 5/32" 9 5/16" 4 1/4"

20 15 1/4" 8 3/4" 29 1/2" 6 1/8" 2 3/4" 2 5/8" 4 1/4" 8 1/4" 7" 10 9/16" 7 15/16" 15 5/32" 11" 5"

B C

D E F G H I J K L M N

NN

Three Phase TEFC

HP A

7.5 15 1/4" 8 3/4" 30 13/16" 6 1/8" 2 3/4" 2 7/8" 2 3/4" 4 1/2" 4 1/2" 10 9/16" 7 15/16" 15 5/32" 8 3/32" 3 3/4"

10 15 1/4" 8 3/4" 35 1/4" 6 1/8" 2 3/4" 2 7/8" 3 1/2" 7" 5 1/4" 10 9/16" 7 15/16" 15 5/32" 9 5/16" 4 1/4"

15 15 1/4" 8 3/4" 35 1/4" 6 1/8" 2 3/4" 2 7/8" 3 1/2" 7" 5 1/4" 10 9/16" 7 15/16" 15 5/32" 9 5/16" 4 1/4"

20 15 1/4" 8 3/4" 42" 6 1/8" 2 3/4" 2 5/8" 4 1/4" 10" 7" 10 9/16" 7 15/16" 15 5/32" 11" 5"

B C

D E F G H I J K L M N

13

Turf Irrigation Centrifugal Pumps

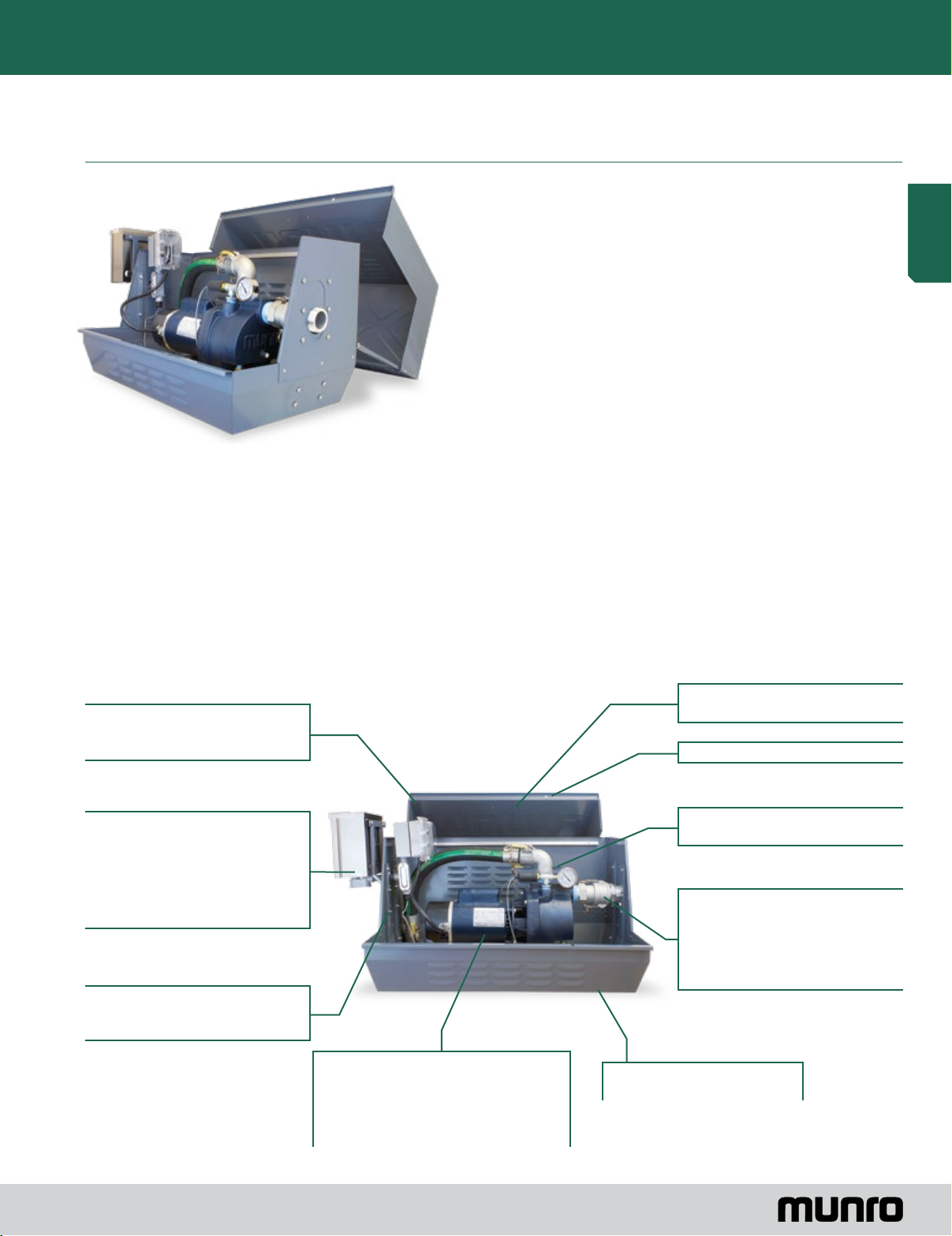

Introducing the Complete PRO ll Series & Universal PRO Enclosure

CENTRIFUGAL

Complete PRO ll

Complete PRO ll 5HP

with enclosure

Complete PRO ll 5HP

Skid Mount

Visit munropump.com/completevideo

to see just how EASY irrigation pump installation can be!

Universal PRO Enclosure

www.munropump.com 14

Turf Irrigation Centrifugal Pumps

Munro Complete PRO II

The Munro Complete PRO II is a revolutionary complete pump package

that includes a professional-grade pump, the highest quality pump

control with built-in pump protection, and simplified plumbing

connections – all housed in a unique enclosure designed specifically for

a pump. With this complete solution, the days of purchasing and

assembling numerous components and housing them in a makeshift

enclosure are over.

Munro has incorporated best-in-class pump control with state-of-theart pump protection features for the highest level of reliability and

performance. With durable materials and advanced engineering, this

long-lasting, quality product will be one that distributors and contractors

will be confident in recommending to installers and end-users.

ADVANTAGES

• Easiest system to select & specify – With only one product to buy or specify, you have everything you need for a complete

pumping system.

• Highest quality components – Just like all of Munro’s products, the Complete PRO II is made with high-quality materials for

a long, trouble-free service life.

• Fast and easy installation – This product ships complete, with everything you need to quickly adapt to any existing piping or

electrical. All you have to do is hook it up and plug it in – it’s really that easy!

CENTRIFUGAL

CENTRIFUGAL

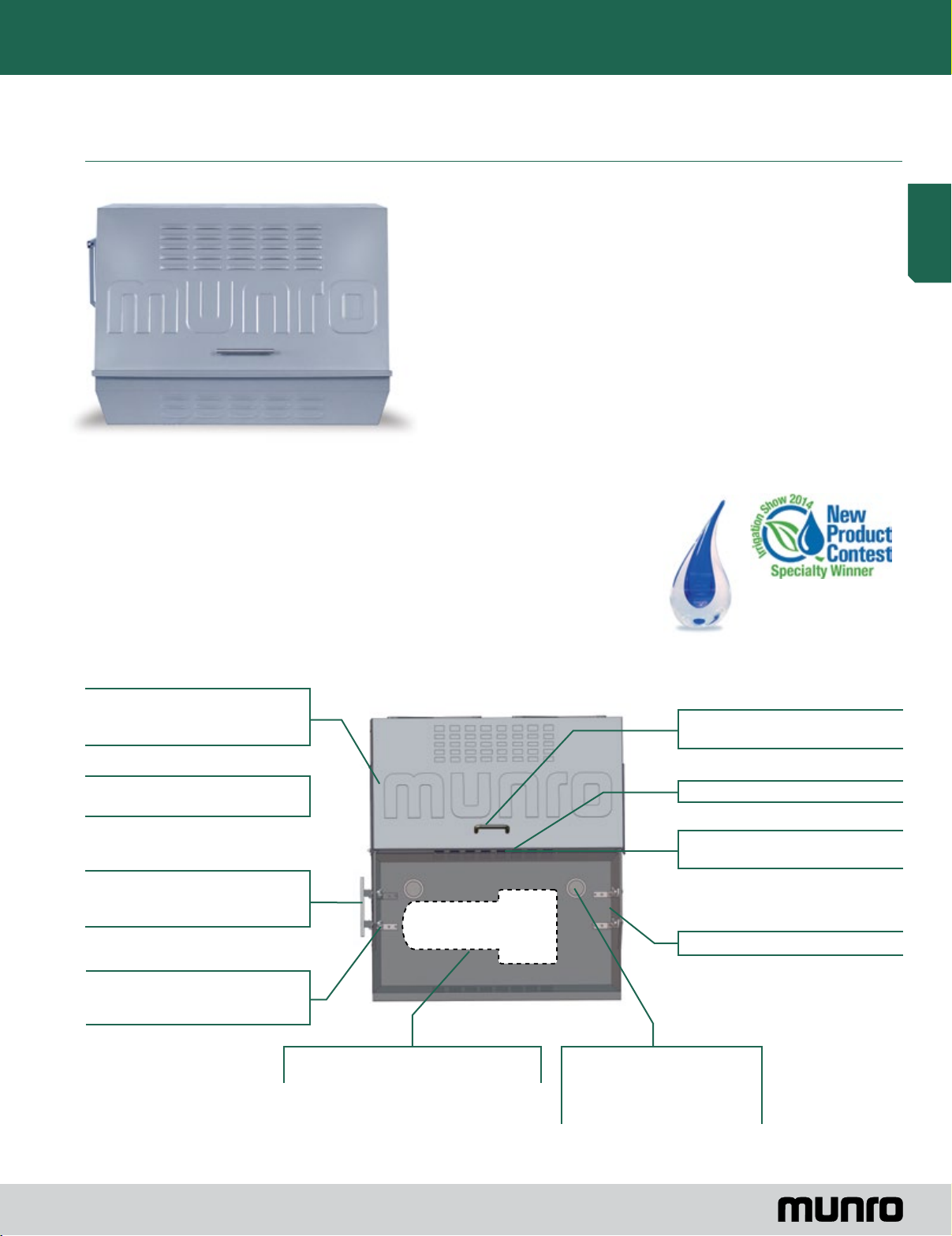

ENCLOSURE – Powder-coated stainless

steel offers durable, non-corrosive

housing to stand up to the elements.

PUMP CONTROL – SmartBox housed

in UL-50 Type 3R enclosures features

reduced amperage compatible and

thermal protection. Or choose from the

full range of Munro pump controls,

including StartBox, SmartBox

and BrainBox.

UNIVERSAL DESIGN – Interchangeable

side panels allow for pump to face left

or right.

PUMP – Our LP Series centrifugal pumps are

durable and long lasting with industryleading performance to horsepower. Offered

in 3/4 - 3 hp, all sizes come with top-of-theline components that are only available as

costly upgrades on other pumps.

HANDLE – Stainless steel handle for

easy accessibility.

SECURITY – Lockable.

SELF COOLING – Vented for air flow to

keep the pump cool.

FITTINGS AND ACCESSORIES – From

our one-of-a kind Munster fitting to the

long-lasting hose and electrical components included, the Munro Complete

PRO II is complete with everything

you need.

DISCHARGE – Discharge holes are

knock-outs for easy installation.

15

Turf Irrigation Centrifugal Pumps

Munro Complete PRO II

Curves

CENTRIFUGAL

HORSEPOWER RANGE: 3/4 - 3

HORSEPOWER RANGE: 2.5

Specifications

HP Phase

Complete PRO ll – SmartBox MPLC242W22TS

3/4

1 110 CP100B

1 1/2 120 CP150B

2

3 230 143 CP300B

3/4

1 121 CP100B3

1 1/2 117 CP150B3

2 128 CP200B3

3 137 CP300B3

2.5 1 208/230 168 CP1502B

2.5 3 208/230 163 CP1502B3

Contact Munro for other control or voltage options.

Lead times vary for specialty or custom options.

Must specify line voltage for 3 phase.

All measurements are approximate and are subject to change.

1

3 208-230

Standard

Voltage

208-230

208-230

Discharge

1 1/2” 2” 23 1/4” 36” 19 1/2” SmartBox

Suction

Height Length Depth

Dimensions

Control

Approx Ship

Weight

lbs

109 CP075B

128 CP200B

115 CP075B3

Model

Number

Did You Know?

Complete PROs are available with BrainBox or

Pressure Start controls?

Contact Munro – 800.942.4270

www.munropump.com 16

Munro Complete PRO II 5HP

Turf Irrigation Centrifugal Pumps

A Better, COMPLETE Solution

With or without enclosure.

This rugged, complete pump system simplifies

installation and can be customized for your application.

The skid-only version is perfect for indoor installations,

while the powder-coated marine grade aluminum

enclosure will stand up to outdoor elements.

ADVANTAGES

• Easiest system to select & specify – One

professional package includes pump, smart controls

and enclosure.

• Highest quality components – High quality

materials for a clean, durable installation to be

proud of.

• Fast and easy installation – Comes complete. No

parts to forget, no need for shortcuts. No fuss,

no errors.

CENTRIFUGAL

CENTRIFUGAL

PUMP CONTROL – Choose from the

full range of Munro pump controls,

including StartBoxes, SmartBoxes, and

BrainBoxes, housed in their own UL-50

Type 3R enclosures and including

features such as thermal protection,

safe 24v out and run-dry protection.

ENCLOSURE OR SKID – Powder-coated

marine-grade aluminum offers durable

housing or base to stand up to

the elements. Made to order.

Did You Know?

Munro offers a variety of adapters to link a

grooved coupling to your irrigation system. For

steel pipe, groove x weld or groove x thread are

great options. For PVC systems, grooved x

spigot, groove x thread and other PVC adapters

are available. See fitting and flange section

on p. 125

SECURITY – Lockable.

FITTINGS AND ACCESSORIES – From

our rugged pipe and grooved couplings

to the long-lasting electrical components

included, the Munro Complete PRO II is

complete with everything you need.

PUMP – Our LP Series 5 hp centrifugal

pumps are durable and long lasting

with industry-leading performance

to horsepower.

SELF COOLING – Vented for air flow to

keep the pump cool.

17

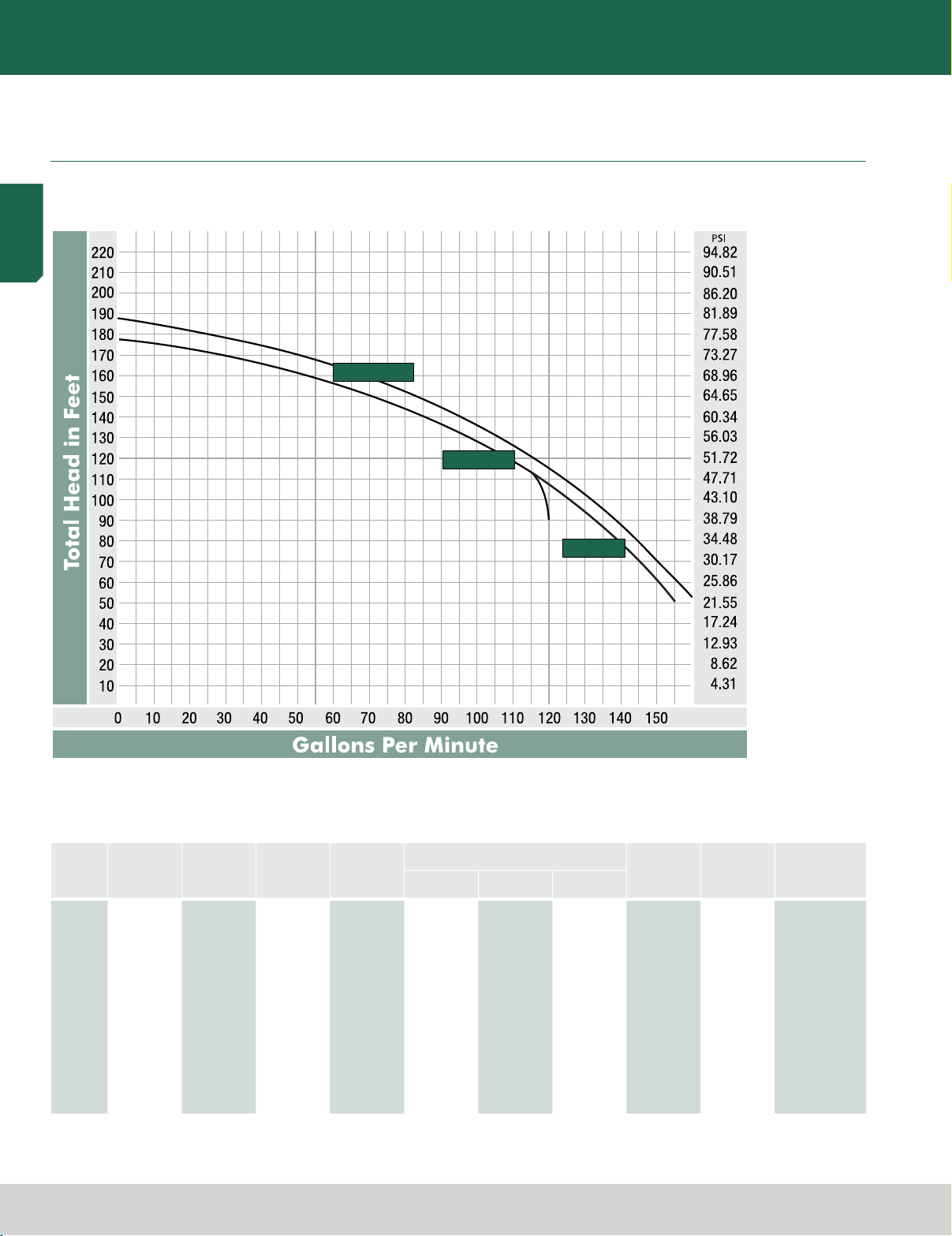

Turf Irrigation Centrifugal Pumps

Munro Complete PRO II 5HP

Curves

CENTRIFUGAL

HORSEPOWER RANGE: 5

CP3005B3B

CP3005B3

Specifications

HP Phase Voltage**

1 208-230

3 208-230 X CP3005B3

5

1 208-230 X CP3005B-SKID

NOTE: Curve includes LP1502 (pg.5) for reference

Discharge

3” 3” 35.5” 44” 22”

Suction

Height Length Depth

Dimensions

CP3005B

Enclosure

X CP3005B

Skid

Mounted

Model

Number*

3 208-230 X CP3005B3-SKID

3 230 X CP3005B3B-SKID

*Model numbers shown are for Complete PRO II – 5hp with standard SmartBox MPLC2452WTS. Contact Munro for other control or voltage options.

** For 208V, contact factory for special accommodations.

All measurements are approximate and are subject to change, without notice.

www.munropump.com 18

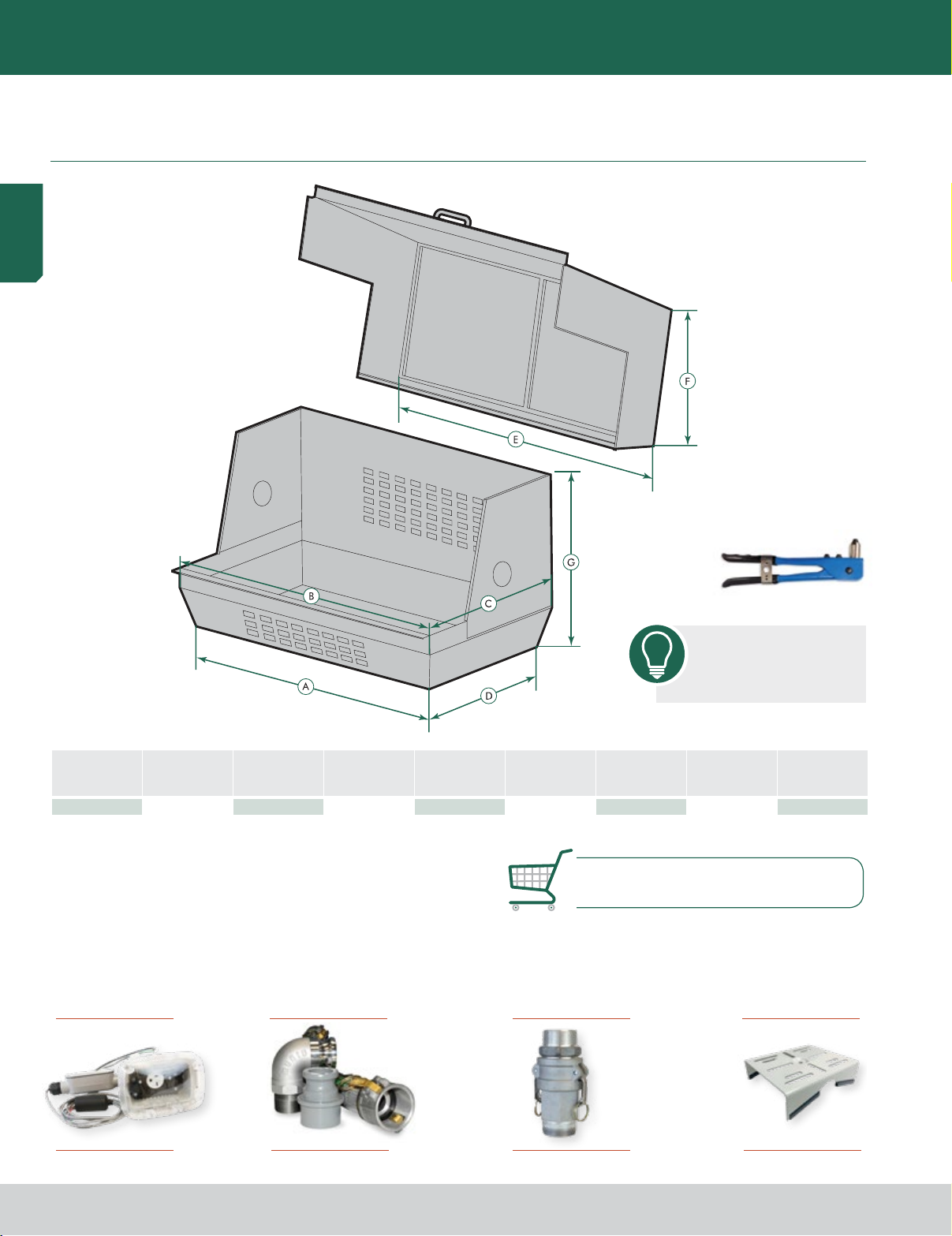

Munro Universal PRO Enclosure

Munro’s Universal PRO Enclosure is designed specifically for a pump. The

powder-coated stainless steel enclosure includes inlet and outlet ventilation

points, mounting for a pump control box, and security features to keep your

investment safe.

ADVANTAGES

• Easy – Order the enclosure separately or include all the fittings you

need. Assembly is simple with the hand-held rivet gun.

• Professional – With a Universal PRO Enclosure, your pump installation

looks professional and is protected. This enclosure is built to last.

• Better – Durable, adaptable, and easy to assemble and use. With the

Universal PRO Enclosure, you finally have a better way to house a pump,

at a great price!

Turf Irrigation Centrifugal Pumps

CENTRIFUGAL

CENTRIFUGAL

ENCLOSURE – Powder-coated stainless

steel offers durable, non-corrosive

housing to stand up to the elements.

Stainless steel rivets and hand-held rivet

gun included for easy assembly.

PUMP CONTROL MOUNTING –

Designed to fit a wide range of pump

control panels.

UNIVERSAL DESIGN – Interchangeable

side panels allow for pump to face left

or right.

PUMP – Universal design will fit a wide-range

of irrigation pumps.

HANDLE – Stainless steel handle for

easy accessibility.

SECURITY – Lockable.

SELF COOLING – Vented for air flow to

keep the pump cool.

(insert your pump here)

ADJUSTABLE – Height adjustable intake.

DISCHARGE – Discharge holes are

knock-outs for easy installation.

Provides an anchor in high wind,

additional security and a

clean look.

19

Turf Irrigation Centrifugal Pumps

Munro Universal PRO Enclosure

Dimensions

CENTRIFUGAL

Suction and

electrical panel

adjustment height:

7 3/4” - 13 1/2”

Munro Rivet Gun Included!

Did You Know?

Centrifugal pumps need

airflow to cool the motor

for optimal longevity.

A

29 3/8” 31 1/2” 17 3/4” 15 3/4” 31 1/2” 13 3/4” 17 1/2” 50 ENCP2

Optional Kits & Assemblies

B C

(Order separately)

D E F G

Get everything you need!

For other fitting options, see pages 125–156.

Approx Ship

Weight

lbs

Model

Number

Pump Electrical Kit

See page 100

Centrifugal Pump

Discharge Kit

See page 116

www.munropump.com 20

Centrifugal Pump

Suction Assembly

See page 130

Centrifugal Pump

Stand

See page 177

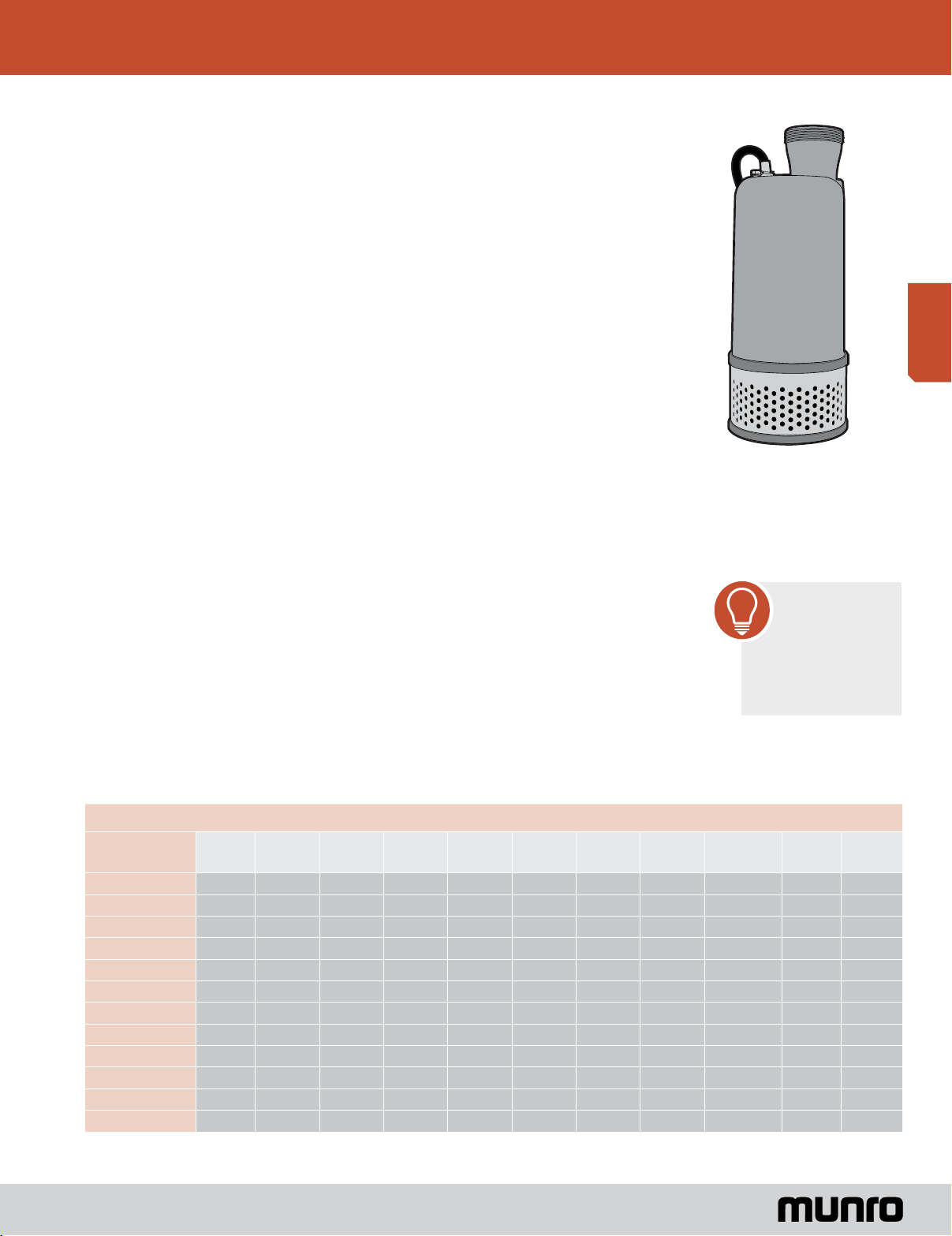

Submersible Pumps

ABOUT SUBMERSIBLE PUMPS

How does a submersible pump work?

A submersible pump is designed to run while located within the fluid being pumped.

The fluid is accelerated by a spinning impeller to create pressure and move the

liquid up through pipe or hose.

Benefits and Applications

Submersible pumps run very efficiently, are virtually noiseless, and require minimal

maintenance. Top discharge designed submersibles often cool the motor by flowing

the fluid past the motor housing. This cooling process allows the pump to run long

hours with little or no shutdown period. Submersible pumps have many uses

including water features, water transfer, industrial settings, sump, effluent and

sewage transfer.

MUNRO PUMPS ARE EXCEPTIONAL

Continuous duty design

We take continuous duty style submersibles a step further by using high-quality components such as abrasion-resistant

double mechanical shaft seals and motors built for long life. Our designs keep the motor cool and your pump in

service – day after day.

SUBMERSIBLE

CENTRIFUGAL

A pump for every job

Whether you need to create a waterfall, pump out a basement, or move sewage –

Munro’s got it! We have a full line of submersibles and can help you find the

perfect pump for your job.

Advanced engineering for efficiency and flexibility

We are pump experts who don’t settle for the same-old, same-old. We’ve improved

standard industry designs to bring you products that are more efficient and versatile.

Many of our submersibles draw lower amps than others on the market, which means

they cost less to run. We use high quality components and thoughtful designs to give

you more flexibility and versatility.

= Acceptable for Application –

ü

= Recommended for Use

üü

Choosing the Right Pump for the Right Application

Bottom

Suction

SUMP FSA

üü üü üü

Irrigation

Water Features

Dewatering

Water Transfer

Industrial

Sump

Effluent

Grey water

Sewage

Marine

Trash

Flood Control

RP FS POND FSR FSL

ü ü üü

üü üü üü üü üü üü

ü üü üü üü üü üü

ü üü üü üü üü ü üü

ü üü üü üü üü ü ü ü üü

ü ü ü ü üü üü üü

ü üü üü üü üü ü üü üü üü üü

ü üü üü üü üü ü ü üü üü üü üü

ü ü ü ü ü ü ü üü

ü üü üü üü

ü ü ü

Did You Know?

Use a Munro

Liquid Level Pump

Control to extend

pump life and increase

efficiency. See p.76 for

details.

FSA

Survivor

FSG FSE

21

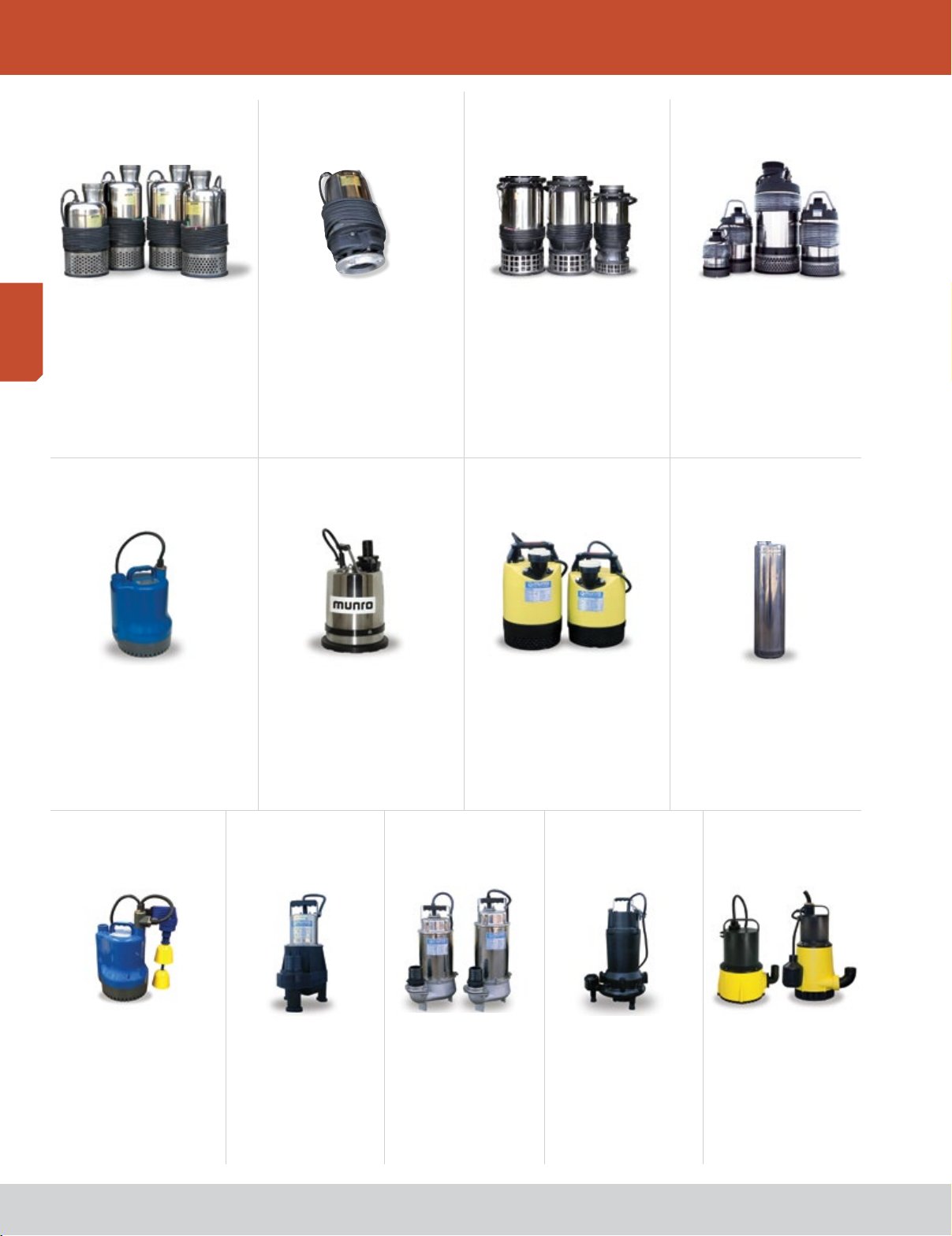

Choosing the Right Submersible Pump

Munro RP Series

1/2hp – 5hp

Features semi-open impeller Features aluminum bronze impeller

SUBMERSIBLE

Recommended for: river and

waterfall style decorative

water features, both interior

and exterior

Other uses: water transfer,

wastewater, flood irrigation

Munro POND Series

1/7hp – 1/3hp

Munro RP Amphibious

Series 2hp – 5hp

Recommended for: river and

flooded irrigation, water

features

Other uses: water transfer,

wastewater, booster

Munro FS R Series

Munro RP Large Volume

7.5hp – 20 hp

Recommended for: river and

waterfall style water features

Other uses: large volume water

transfer, flood control,

extraction of water, flood

irrigation, tail water recycling

Munro FS L Series

1/2hp – 1hp

Munro FS Series

1/3 hp – 30 hp

Features high-chrome wear-resistant impeller

Recommended for: river and

waterfall style decorative water

features, both interior and

exterior, dewatering water with

some abrasives

Other uses: water transfer,

wastewater, flood irrigation

Munro 5” Multistage

Bottom Suction

Submersible Pumps

Recommended for: water

features, dewatering,

utility, sump

Other uses: hot tub drainage,

pools, pool covers, cooling

water for machinery

Munro SUMP Series

1/7hp – 1/3hp

Recommended for:

sump, dewatering, utility

Other uses: hot tub

drainage, pools, water

features pool covers,

cooling water

for machinery

Recommended for: dewatering

to within 1/8” depth

Other uses: water features,

water transfer

Munro FS A

Sewage Pumps

1/3hp – 3/4hp

Recommended for:

sewage

Other uses: effluent

Recommended for: pondless

and waterfall style

water features

Other uses: construction

dewatering, utility, manholes

Munro FS A

Industrial

Survivor Sewage

Pumps 1hp – 2hp

Recommended for:

commercial sewage

Other uses: residential

sewage

Munro FS G

Sewage Grinder

Pumps 2hp

Recommended for:

sewage

Other uses: effluent

Recommended for: irrigation,

shallow wells, rain collection

tanks, grey water

Other uses: dewatering,

fountains, pressure boosting

domestic non-potable water

Munro FS E

1/3hp – 3/4hp Sump

& Effluent Pumps

Recommended for:

sump, effluent

Other uses: utility,

dewatering

* Unless otherwise noted Munro submersible pumps not intended for drinking water applications.

www.munropump.com 22

Submersible Water Feature Pumps

Submersible Water Feature Pumps

How does a submersible water feature pump work?

The pump is the most important aspect of any water feature. Whether you are creating melodic raindrops, a rushing river, or a

dramatic spillway, selecting the right pump will provide the perfect water volume to make the project a success.

As with any construction project, a properly working water feature is dependent on high-quality components. Well-made long-lasting pumps, like Munro builds, will decrease annoying maintenance issues and cost less to run over the long term. Many features

require continuous operation to maintain water turnover and minimize algae. Choosing a pump that is designed for long life operation is essential.

Choosing a pump for a water feature

1. Style of feature – There are many different types of water features, such as ponds, river/streams, falls, etc., and each

require different features and capabilities.

2. Height of feature – How high will you need to move the water from the water source to the discharge point?

3. Width of waterway and depth of water desired over any spillways – Look for a pump that can create the desired

volume of water – too much or too little can make a big difference in the feel of the feature. Many features are designed to

provide pleasant ambient sound which can require a higher-volume pump.

4. Turnover rate – Cycling the water through a filter will keep it cleaner and healthier. Choose a pump with a gallons per hour

(gph) rate high enough to cycle the total volume of your water feature through quickly enough to meet your desired turnover rate.

For example, a 1,000 gallon water feature may need a pump that can cycle through at least 500 gph to ensure the total volume

is turned over once every two hours, 12 times per 24 hours.

5. Fish in the water feature – You’ll want to ensure that the pump is safe for the fish. You may also want to consider a higher

turnover rate to keep the feature clean.

SUBMERSIBLE

CENTRIFUGAL

Depth in Inches

1

1 1/4

1 1/2

1 3/4

2

2 1/4

2 1/2

2 3/4

3

Calculating GPH Required for Water Features

Length (L) of Weir in Feet

1 3 5

2125 6450 10790 2165

2970 9025 15025 3025

3895 11820 19770 3970

4860 14400 24900 5015

5910 18120 30360 6120

7020 21660 36300 7320

8170 25320 42360 8580

9420 29100 48900 9900

10670 33120 55560 10020

Additional GPH for

Each Ft. Over 5 Ft.

23

Submersible Water Feature Pumps

Munro RP Series 1/2hp - 5hp

SUBMERSIBLE

Designed for continuous duty water features, the Munro RP Series

pumps offer high flow to horsepower ratios with low amp draw

for a lower operating cost. The RP series pumps work vertically or

horizontally for maximum flexibility. The option to mount the

pump horizontally can provide special advantages in concealing

the pump within complex decorative water features.

• Abrasion-resistant mechanical shaft seal – protects the

motor for longer life

• Enclosed channel impeller – increases efficiency and

lowers operating cost

• Stainless steel outer case – durable and low

maintenance

COMMON APPLICATIONS

Recommended for: river and waterfall style decorative water

features, both interior and exterior

Other uses: non-potable water transfer, wastewater, flood irrigation

ADVANTAGES

Continuous duty design – These pumps are made to run! Our design takes the flow path across the motor housing to whisk

away the heat generated by the motor. A cool motor means a longer life.

Low cost to own – When pumps are in continuous use, the energy use and cost can really add up! Our pumps use lower amps

than our competitors, which saves power and money.

Industry leading performance to horsepower – High gallon output sets this pump apart from the crowd.

THREADED NPT DISCHARGE – Easy

transition to a hose or pipe.

STAINLESS STEEL CASE – Stands up to

the elements.

DOUBLE MECHANICAL SHAFT SEAL –

Abrasion-resistant, providing maximum

motor protection with added oil reserve.

CHROME STEEL IMPELLER – Provides

increased efficiency and performance in

2-5 HP models.

OPEN VEIN IMPELLER – Offers wide

open performance for high volume in

1/2 and 1 HP models.

The upper seal is carbon/ceramic and

the lower seal is silicon/silicon.

THERMALLY PROTECTED MOTOR – Shut

down protection protects motor from

damage due to over amping.

SACRIFICIAL ANODE PROTECTION –

Slows damaging oxidation of the pump.

RP35 and RP41 only.

Did You Know?

Submersible pumps used to feed centrifugal pumps need to exceed

the centrifugal pump GPM output.

www.munropump.com 24

STRAINER INLET – For added flexibility

and durability, passes between .31” to

.5” solids.

Loading...

Loading...