355x368x130mm

3.5 kgs

225 - 300pcs

70-120PSI (4.9-8.3bar)

1/4’’ N.P.T.

45-90mm

MI CN-90mm

Thank you very much for purchasing our MI CN-90mm Pneumatic Coilnailer

COILNAILER

MI CN-90mm

- 2 -

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using pne umatic to ols, bas ic safety pre cautions Should al ways

be followed to reduce the risk of personal injury Including the following :

READ AND FOLLOW ALL INSTRUCTIONS.

There are certain applications for which this tool was designed. we strongly

recommends that this tool NOT be modified and /or used for any application other

than for which it was designed. If you have any questions relative to its application,

please contact with your seller.

1. KEEP WORKING AREA CLEAN.

Cluttered areas invite injuries.

2. DON'T ALLOW CHILDREN AT THE

WORKING AREA.

Don't let them handle the

tool.

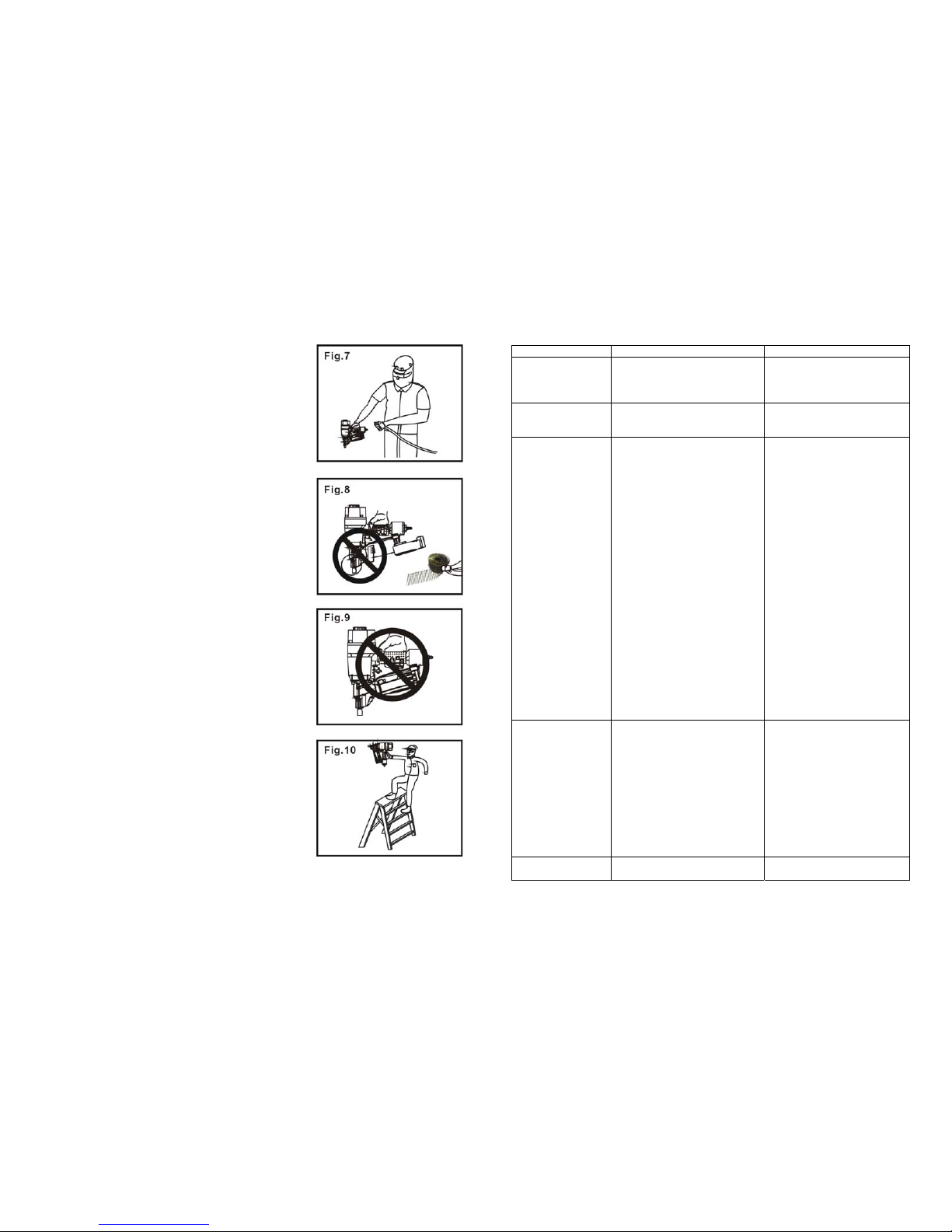

3. USE SAFETY GLASSES.

To prevent eye

injuries, the tool operator and all persons in the

working area must wear safety glasses with

permanently attached, rigid, plastic side shields.

These safety glasses must conform to ANSI Z87.1

requirements (approved glasses have “Z87” printed

or stamped on them).

4 . USE EAR PROTECTION.

The working area

may be exposed to high noise levels that can lead to

hearing damage.

5. DRESS SAFELY.

Protective gloves and nonskid

footwear or safety shoes are recommended when

working with and operating this tool. Don't wear

loose clothing or jewelry. They can get caught in

moving parts. Also, wear a protective hair covering

to prevent long hair from getting caught in the tool.

6. ONLY USE CLEAN, DRY AND

REGULATED

compressed air at 70 to 120 PSI (5

to 8.3 BAR).

PARTS LIST

1 HCN086

Screw

52 HCN135

Washer

2 HCN087

Bushin

g

53 HCN136

Safe Sleeve

3 HCN088

Exhaust Cover

54 HCN137

O-rin

g

6.4x1.8

4 HCN089

Seal

55 HCN138

Washer

5 HCN090

Muffler

56 HCN139

O-rin

g

20.3x2.5

6 HCN001

Screw

57 HCN140

O-rin

g

20.3x1.5

7 HCN091

S

p

ring Washer 6

58 HCN141

Valve Guide

8 HCN092

C

y

linder C a

p

59 HCN041

O-rin

g

9.5x1.9

9 HCN093

Gaske

t

60 HCN142

O-rin

g

10.3x1.9

10 HCN094

S

p

rin

g

61 HCN143

Trigg

er Valve Seat

11 HCN095

Valve Sea

t

62 HCN044

O-rin

g

12.8x1.9

12 HCN096

O-rin

g

48.8x2.5

63 HCN144

Sprin

g

13 HCN097

Valve

64 HCN145

O-rin

g

5.5x1.5

14 HCN098

O-rin

g

67x3

65 HCN146

Trigg

er Valve Stem

15 HCN099

Collar

66 HCN147

Tirgg

er Valve Guide

16 HCN100

C

y

linder Seal

67 HCN148

Spring Pin 3x26

17 HCN101

O-rin

g

57.46x3.53

68 HCN149

Trigg

er Sprin

g

18 HCN102

Piston Assembl

y

69 HCN150

Rotatin

g

Shaft Bushin

g

19 HCN103

C

y

linder

70 HCN151

Locking Washer 3

20 HCN083

O-rin

g

65.4x2.5

71 HCN152

Trigg

er Assembl

y

21 HCN104

Restrictive Plate

72 HCN153

Steel Ball

22 HCN105

O-rin

g

101.91x3.53

73 HCN154

Sprin

g

23 HCN106

Bum

p

er A

74 HCN155

Rotating Shaft Pin

24 HCN107

Bum

p

er B

75 HCN156

Locking Washer 28

25 HCN108

Bod

y

76 HCN157

Cover

26 HCN109

O-rin

g

62.3x1.8

77 HCN158

Piston Bumper

27 HCN110

Nut

78 HCN159

S

p

rin

g

28 HCN111

Washer

79 HCN160

O-rin

g

24.3x2.8

29 HCN112

O-rin

g

8.3x1.8

80 HCN161

Spring Pin 4x12

30 HCN113

Protector

81 HCN162

Piston

31 HCN114

S

p

ring Washer

82 HCN163

O-ring 12.3x1.9

32 HCN115

Screw

83 HCN164

Feed Hook Sea

t

33 HCN116

Nose

84 HCN165

Feed Hook Pin

34 HCN117

Washer

85 HCN166

S

p

rin

g

35 HCN118

Pin

86 HCN167

Feed Hook

36 HCN119

Handwheel Assembl

y

87 HCN168

Screw

37 HCN120

S

p

rin

g

88 HCN169

Pin

38 HCN121

Feed Hook Pin

89 HCN170

Lower Nail Housin

g

39 HCN122

Sto

pp

ed Hook

90 HCN171

Nut

40 HCN123

S

p

rin

g

91 HCN172

Ad

j

usting Stem

41 HCN124

Latch

92 HCN173

S

p

ring Pin 2.5x17

42 HCN125

Safe Guide

93 HCN174

Ad

j

uster Plate

43 HCN126

S

p

ring Pin 3x28

94 HCN175

Sprin

g

44 HCN127

S

p

rin

g

95 HCN176

Ad

j

uster Nu

t

45 HCN128

Screw

96 HCN177

U

pp

er Nail Houshin

g

46 HCN129

Safe Bra c k et

97 HCN178

Washer

47 HCN130

Screw

98 HCN179

Screw

48 HCN131

S

p

rin

g

99 HCN180

Soft Gri

p

Sleeve

49 HCN132

Ad

j

usting Button

100 HCN181

End C a

p

50 HCN133

Ad

j

usting Stem

101HCN085Air Plu

g

51 HCN134

Bracke

t

- 3 -

EXPLODED VIEW DRA WING

7. NEVER USE OXYGEN, CARBON

DIOXIDE, combustible gases or any other

bottled gas as a power source for this tool.

8. DO NOT CONNECT TOOL to pressure

that potentially exceeds 120 PSI (8.3 BAR).

9. ONLY USE AIR HOSE THAT IS

RATED for 150% of the maximum system

pressure. Please try to usea 3/8” ID hose con

nect in nailer with compressor.

10.DON'T OPERATE TO NEAR ANY

COMBUSTIBLE, or any other explosive

material. Don't operate the tool where it is

easy producing corrosion, rust or in a having

heavy powder environment.

11 DISONNECT TOOL FROM AIR

SUPLY HOSE before doing tool

maintenance , clearing a jammed fastener,

leaving work area, moving tool to another

location, or handing the tool to another

person..

12. ONLY DISCONNECT THE QUICK

CONNECTOR with the connector of the

body tail portion air inlet, no compressed

air can be guaranteed when disconnecting. If

operation is not correct, the tool can Remain

charged with air after being disconnected and

still be able to drive a fastener, causing

personal injury.

13. REPLACE PARTS AND ACCESSORIES. Only allow use same repla cement parts

while servicing. Approved accessories and replacement parts are available.

- 4 -

14. BEFORE USING TOOL, carefully check if

there is any part damaged to obtain ideal results. Do

not use the tool if the tool has any air leaks,

uncompleted, damaged parts and needs repairing.

15. NEVER USE TOOL if safety, trigger or spring is

inoperable, missing or damaged. Do not alter or

remove safety, trigger or springs Make daily

inspections for free movement of trigger and safety

mechanism.

16.ONLY USE PARTS AND FASTENERS

recommended by us.

17. CONNECT TOOL TO AIR SUPPLY BEFORE

loading fasteners to prevent fastener from being fired

during connection. The tool driving mechanism

may cycle when tool is connected to the air supply.

When not in use remove all fasteners from the nail

housing.

18. ALWAYS ASSUME THE TOOL CONTAINS

FASTENERS. Keep the tool pointed away from

yourself and others at all times. No horseplay. Respect

the tool as a working implement.

19. DO NOT LOAD FASTENERS with trigger or

safety depressed to prevent unintentional firing of a

fastener.

20. REMOVE FINGER FROM TRIGGER when

not driving fasteners. Never carry tool with finger on

trigger: tool will fire a fastener if safety is bumped

while trigger is depressed.

21. DON'T OVER REACH. Keep proper footing

and balance at all times when using or handling the

tool.

22. FIRE FASTENERS INTO WORK SURFACE

ONLY: NEVER into materials too hard to penetrate.

PROBLEM CAUSE SOLUTION

Failure to start tool. 1. Tool dry, lacks lubrication.

2. The spring in the cylinder cap is

damaged.

3. Valve sticks with cylinder cap.

1. Use pneumatic tool oil

2.Replace the spring in the

cylinder cap.

3.Disassemble/check/lubricate

Blade driving fasteners

too deeply

1. Safe bracket poison is not correct.

2. Air pressure is too high.

1. Rotate knob of the adjuster to

move safe bracket down.

2. Decrease air pressure.

Skipping

fasteners/ feeding

intermittently

1. Having foreign matters between the

small piston and small cylinder.

2. O-ring on the small piston is worn

and damaged.

3. Tool dry and lacks lubrication.

4. The spring on the small piston is

damaged.

5. Air pressure is lower.

6. Connecting screw of nose and body

is loose.

7. Stopped hook can't stop the

fasteners.

8. Bent fasteners.

9. Wrong size fasteners.

10. Gasket is damaged.

11.Dry small piston

12. Small piston bumper is worn and

damaged.

13. Feed hook is binding.

14. Nail length is not correct with

loading space of nail housing.

15. Weld wires in nail coilare broken.

1. Disassemble/ clean/lubricate.

2.Check/replaceO-ring/ lubricate

3. Use pneumatic ic tool oil.

4. Replace small piston the spring.

5. Increase the air pressure, but don't

exceed 120 PSI (8.3 bar).

6. Tighten al l screws.

7.Replace taper spring of the

stopped hook.

8. Use recommended fasteners.

9.Use recommended fasteners

10. Replace gasket/t tighten screw.

11. Open nai l housing, place several

drops of pneumatic tool oil into end

cover hole of the small piston.

12.Replace bumper and lubricate

small piston.

13. Clean feed hook and torsion

spring.

14.Adjust adjusting nut at the nail

housing tail portion according to the

recommended nail length to make

arrow on the nail housing tail point

to correct direction.

15. Stop using.

Runs slowly or has

power loss

1. Tool dry, lacks lubricate ion

2. The spring in the cylinder cap is

damaged.

3. Having foreign matters between

piston assembly and cylinder.

4. Have not assembled the cylinder to

home posit ion.

5. O-ring on the valve is dry after

disassembly.

6. Air pressure is too low.

7.Driver is worn (sort)

8. Inner diameter of hose is small.

1. Use pneumatic tool oil.

2. Replace the spring in the cylinder

cap.

3. Disassemble/clean/lubricate.

4. Reassemble after disassembling.

5.Reassemble after lubricating

6. Increase the air pressure, but don't

exceed 120 PSI (8.3 bar).

7. Replace piston assembly.

8. Use bigger inner diameter of the

hose.

Fasteners are jammed 1. Fasteners are wrong size.

2. Weld wires in nail coil are broken.

1. Use recommended fasteners.

2. Stop using.

- 5 -

Keep all screws tight. Loose screws can cause personal injury or damage tool.

Check if there are worn and damaged parts. If any, please replace immediately.

If tool is used without an in-line oiler: place 5 or 6 drops of air tool oil into the

air inlet of the tool at the beginning of each workday.

SERVICE AND REPAIR

All quality tools eventually require servicing of replacement parts due to wear

from normal use. Some user serviceable components are described in the

TROUBLESHOOTING Sect ion. All repairs made by local agencies are fully

guaranteed against defective material and workmanship. We cannot guarantee

repairs made or attempted by anyone other than these agencies.

Should you have any questions about your tool , please contact with seller at any

time. In any communications, please give all information shown on the

nameplate of your tool (model number, type, serial number, etc.)

TROUBLESHOOTING

CAUTION: Disconnect tool from air supply before perform i ng

any service procedure.

PROBLEM CAUSE SOLUTION

Air leaking at trigger

area

1. O-ring in trigger valve stem is worn

and damaged.

2. O-ring in trigger valve head is worn

and damaged.

3. Having foreign matters.

1.Check/replaceO-ring/lubricate.

2.Check/replaceO-ring/ lubricate

3.Clean the tool/lubricate

Air leaking at the body

lower portion and nose

1. Screw is loose at connecting port ion of

the nose and body.

2. O-ring is damaged between body and

nose.

3. Bumper is damaged.

4.Having foreign matters at the contacting

p

ortion of the bumper and body.

1.Tighten screw/recheck

2.Check/replaceO-ring/ lubricate

3. Replace the bumper.

4. Disassemble and clean

Air leaking at the upper

portion and nose body

1. Screw is loose at the connecting port

ion of the cylinder and body.

2. O-ring is damaged.

3. Gasket is damaged.

1. Tighten the screw and

recheck.

2. Check/replace0-ring/ lubricate

3. Replace the gasket.

23. GRIP TOOL FIRMLY TO MAINTAIN

CONTROL

while allowing tool to recoil away

from work surface as fastener is driven. If safety

bracket is allowed to contact work surface again

before trigger is released, an unwanted fastener will

be fired.

24. DO NOT DRIVE FASTENERS on top

of other fasteners, or with the tool at too steep

an angle: the fasteners can ricochet causing

personal injury.

25 .DO NOT DRIVE FASTENERS CLOSE

to the edge of the work piece. The work piece

is likely to split allowing the fastener to fly

free or ricochet causing personal injury.

26. KEEP ALERT. Watch what you are

doing. Use common sense. Do not operate any

tool when you are tired.

27. KEEP HANDS AND BODY PARTS

away from area shown in Fig. 13 to avoid

injury.

28. THIS TOOL IS EQUIPPED WITH

ADJUSTER that can adjust driving depth.

When adjusting the driving depth, first

disconnect from air supply and rotate the knob

of the adjuster by hand until it is satisfactory.

29. WHEN NOT IN USE, tool should be

cleaned and put back into the packing box.

For safety, keep out of reach of children.

EMPLOYER’S RESPONSIBILITIES

Employer must enforce compliance with the safety warnings and all other

instructions contained in this manual. Keep t his manual available for use by all

people assigned to use this tool. For personal safety and proper operation of this

tool, read and follow all of these instructions carefully.

- 6 -

PACKING LIST

DESCRIPTION Q'ty

MI CN-90MM Roofing coil nailer

1

S6 Hex Key

1

S5 Hex Key

1

S4 Hex Key

1

S3 Hex Key

1

Air Tool Oil

1

Safety glasses

1

Operating instructions

1

TECHNICALPARAMETER

CHARACTERISTIC VALUE

Compressed Air pressure 70-120PSI (4.9-8.3bar)

Outline Dimension (L× H ×W) 13.9"× 5"×14.1” (355× 130 ×368mm)

Nail Length Range 1 ¾ "-3 9/16"

Tool Weight 7.7 Ibs (3.5Kg)

Air Inlet 1/4 " NPT

Air Consumption 0.17ft 3 /cycle at 100psi(at pressure

6.9bar, 4.77litre/cycle)

3. Driving depth will be increased or decreased by rotating the depth of

drive knob or adjuster (A) f ig. 19. Test fire fastener and check depth. If

the nail is driven too deep, rotate the adjuster clockwise to make the safe

bracket push downward. Wh er eas , ro tat e the adj ust er co unt erclockwise to

make the safe bracket push upward. Repeat this step to achieve desired

results (See Fig. 20).

CLEARING A JAMMED FASTENER

1.

CAUTION: Disconnect tool from air

supply.

2. Open latch, rotate lower housing and

remove the nails of the lower housing.

3. Use a slender, soft steel r od to drive the

drive blade to its uppermost position. Use

needle nose pliers to remove the jammed

fastener (see Fig.21).

4. Follow instructions in PREPARING THE TOOL BEFORE DRIVING to

reload fasteners.

MAINTENANCE

CLEAN AND INSPECT DAILY

CAUTION: Disconnect tool from air supply before cleaning and inspection.

Correct all problems before operating.

Check the filter of the compressor weekly and switch off manual valve to drain

water and contaminations out. Wipe the tool clean. Do not soak tool with

cleaning solutions. Such solutions can damage internal parts. The exposed

portion of the small piston rod and feed hook must be kept clean.

Inspect trigger and safety mechanism to assure system is complete and functional : no loose or missing parts, no binding or sticking parts shall be found..

- 7 -

2..Dual-action firing: One method is to put the drive guide on the working surface,

lightly push the tool toward the working surface until the safety bracket is

depressed, then depress the trigger assembly to drive the asteners. Due to the

rebounding of the nailer, the safety bracket will be depressed again, causing a double

hit . The tool will then fire two nails in the same time or one fire, one blank.

Another method is to depress the trigger assembly, then, repeatedly impact the safety

bracket. The tool can repeatedly drive the fasteners. The tool will drive one fastener

when the safety bracket is impacted one time. This method is working in the

non-accurate position so using this method w ill increase work efficiency.

1. Original factory setting is single sequential trigger mode.

2. Read and understand operating manual before changing the trigger mode.

Improper use may result in serious injury.

3. Manufacturer assumes no responsibil ity for any injuries and loss caused by any

improper use of this tool.

CAUTION: Remove finger from trigger when not driving fasteners. Never carry

tool with finger on trigger: tool will fire a fastener if safety is bumped.

Keep tool pointed in a safe direction at all times

Never attempt to drive a fastener into material that is too hard, or at too steep an

angle, or near the edge of the workpiece. The fastener can ricochet causing personal

injury.

Disconnect tool from air supply before performing maintenance, cl earing a jammed

fastener, leaving working area, moving tool to another location, or handing the tool

to another person.

Clean and inspect tool daily. Carefully check for proper operation of trigger and

safety mechanism. Do not use the tool unless both the trigger and the safety

mechanism are functional, or if the tool is leaking air or needs any other repair .

FASTENER SPECIFICATIONS

Only use recommended fasteners. They may be screw, ring and smooth fasteners

OPERAT ING INSTRUCTIONS

FOREWORD

MI CN-90MM is a light duty, coil fed, pneumatic nailer, using compressed air as a

power source. It is designed to instal l2˝-3-1/2˝or0.1˝-0.131˝ diameter nails of

various lengths. It is widely used for connection of frame and connection of frame

and felt. The tool has a magnesium alloy body and cylinder cap is of light and

provides high specific strength and rigidity.

POWER SOURCE

This tool is designed to operate on clean, dry, compressed air at regulated pressures

between 70 and 120 PSI (4.9 and8.3bar). The preferred syst em would include a filter

(C) Fig.2, a pressure regulator (A) Fig.2, and automatic oiler (B) Fig.2 located as

close to the tool as possible (within15 feet is ideal).

All compressed air contains moisture an d other conta minates that are d etrimental to

internal components of the tool. An air-line fi l ter will remove most of these

contaminates and significantly prolong the life of the tool. If an in-line oiler is not

available: place five or six drops of oil into the tool’s air inlet at the beginning of

each workday .

Only disconnect quick connector being connected with the connector of the body tail

portion air inlet , no compressed air can be guaranteed when disconnecting.

CAUTION: All line components (hoses, connectors, filters, regulators,etc.) must

meet 150% of the maximum system pressure. Please try to use a hose of ID 3/8”

- 8 -

connecting nailer with compressor.

Do not connect this tool to a system with maximum potential. Only disconnect the

quick connector with the body tai l portion of the air inlet.

No compressed air can be guaranteed when disconnecti ng.

Disconnect tool from air supply before performing maintenance, cl earing a jammed

fastener, leaving work area, moving tool to another location, or handing the tool to

another person.

PREPARING THE TOOL BEFORE DRIVING

1. After reading and understanding this entire manual, connect tool to air supply.

CAUTION: Keep tool pointed away from yourself and others at all times .

Always connect tool to air supply before loading fasteners.

Do not load fasteners with trigger or safety depres sed.

Always wear Z87 approved safety glasses, and hearing protection when preparing or

operating the tool.

Never use a tool that leaks air or needs repair.

2. Depress handle (See A Fig. 14) and open latch.

3. Rotate adjusting nut to adjust the lower housing (see B Fig. 15) according to

desired nail length. The highest posi tion is used for 2" , th e center position used for

2-

3/16 ", 2-3/8 ", 2- 9/16",2-3/4 ",2-31/32 " , 3-5/32 " and 3-11/32 " and the lowest position

used for 3-

9/16 " nails.

4. Rotate to the side of the body. Place a coil of nails over the Lower Nail Housing.

Uncoil enough nails to reach the Feed Hook and pl ace the second nail b etween the

teeth on the Feed Hook.

5. Close the latch (see Fig. 17).

6. Adjust directional exhaust deflector (see Fig. 18) , so that the exhaust air blast will

be directed away from the operator. Grasp the deflector and rotate it to the desired

position for the current application.

USING THE TOOL

Complete all steps of PREPARING THE TOOL befor e using the tool.

This tool can be fired in two different ways:

This tool can be fired using either trigger fire (single sequential) or bump fire or

(contact actuation).

Trigger firing (single sequential): Turn the rotating shaft so the tail of the

rotating shaft is up (see fig. 18A).

When safety bracket is pressed against the work splace, push the trigger

repeatedly, and the nails can be shot continuously.

Dual-action (bump fire): Turn the rotating shaft so the tail of rotating shaft is

down (see Fig. 19A).

1. Trigger firing: Put the nose on the working surface, lightly push the tool

toward the working surface until the safety bracket is depressed, then, depress

the trigger to drive the fasteners. This “trigger fire” method provides the most

accurate fastener placement. In this method, the safety bracket can be adjust

downwards with knob to avoid striking two nails at one time.

Loading...

Loading...