mundoclima UE-MUCSR-12-H8, UE-MUSTR-18-H8, MUCSR-12-H8, MUCR-12-H8, UE-MUCSR-18-H8 Service Manual

...

SUPER INVERTER H8

Service manual

MUCSR-H8

MUSTR-H8

MUCR-H8

MUCOR-H8

www.mundoclima.com

Thank you very much for purchasing our products.

Please read this manual carefully before installing

and using the unit.

CL20260 to CL20288

CL20395

English

Contents

Part 1 General Information .................................................................................................... 1

Part 2 Indoor Units ................................................................................................................. 5

Part 3 Outdoor Units ............................................................................................................ 94

Part 4 Installation ............................................................................................................... 108

Part 5 Electrical Control System ....................................................................................... 140

※The specifications, designs, and information in this book are subject to change without notice for

product improvement.

Contents i

General Information

Part 1

General Information

1. Model Lists ........................................................................................... 2

2. External Appearance ........................................................................... 3

2.1 Indoor Units ............................................................................................................... 3

2.2 Outdoor Units ............................................................................................................ 4

General Information 1

Model Lists

1. Model Lists

1.1 Indoor Units

R410A (capacity multiplied by 1000Btu/h)

Type Function 12 18 24 30 36 48 60

Super slim cassette Cooling and heating ● ● ● ● ●

Duct Cooling and heating ● ● ● ● ● ● ●

Ceiling-floor Cooling and heating ● ● ● ● ● ●

Four-way

cassette(compact)

Floor standing Cooling and heating

1.2 Outdoor Units

Universal Outdoor unit Model

UE –

MUCR-12-H8 /

MUCSR-12-H8

UE –

MUCR-18-H8 /

MUCSR-18-H8 /

MUSTR-18-H8

UE –

MUCR-24-H8 /

MUCSR-24-H8 /

MUSTR-24-H8

UE –

MUCR-30-H8 /

MUCSR-30-H8 /

MUSTR-30-H8

UE –

MUCR-36-H8

/ MUCSR-36-H8

/ MUSTR-36-H8

UE - MUCR-48-H8 / MUCSR-48-H8 /

MUSTR-48-H8

UE –

MUCR-48-H8T /

MUCSR-48-H8T /

MUSTR-48-H8T

UE –

MUCR-60-H8T /

MUCSR-60-H8T /

MUSTR-60-H8T

Cooling and heating ● ●

Compressor

type

Rotary GMCC

Rotary GMCC

Rotary GMCC

Rotary GMCC

Rotary GMCC

Rotary GMCC

Rotary GMCC

Rotary GMCC

Compressor

Brand

●

Matched indoor units

MUCR-12-H8

MUCSR-12-H8

MUCSR-18-H8

MUCR-18-H8

MUSTR-18-H8

MUCSR-24-H8

MUCR-24-H8

MUSTR-24-H8

MUCSR-30-H8

MUSTR-30-H8

MUCR-30-H8

MUCSR-36-H8

MUCR-36-H8

MUSTR-36-H8

MUCSR-48-H8 /

MUCSR-48-H8T

MUSTR-48-H8 /

MUSTR-48-H8T

MUCR-48-H8 / MUCR-48-H8T

MUCOR-60-H8T

MUCSR-60-H8 /

MUCSR-60-H8T

MUCR-60-H8 / MUCR-60-H8T

MUSTR-60-H8 /

MUSTR-60-H8T

General Information 2

External Appearance

2. External Appearance

2.1 Indoor Units

Super slim cassette

Duct

Ceiling-Floor

Floor standing

Compact Four-way cassette

General Information 3

External Appearance

2.2 Outdoor Units

Single fan outdoor unit (Models 12 to 36)

Double fan outdoor unit (Models 48 to 60)

General Information 4

Indoor Units

Part 2

Indoor Units

MUCSR-H8 (24 to 60) Cassette Type ……………………6

MUCR-H8 Duct Type ………………………..…………… ..46

MUSTR-H8 Ceiling & Floor Type ....................................... 49

MUCSR-H8 (12 to 12) Cassette Type (Compact) ............. 68

MUCOR-H8 Floor standing Type ...................................... 82

Indoor Units 5

MUCSR-H8 (24 to 60) Cassette Type

MUCSR-H8 (24 to 60) Cassette Type

1. Features ........................................................................... 7

2. Dimensions .................................................................... 10

3. Service Space ................................................................ 11

4. Wiring Diagrams ............................................................ 12

5. Air Velocity Distributions (Reference Data) ................. 18

6. Electric Characteristics ................................................. 21

7. Sound Levels ................................................................. 22

8. Accessories .................................................................... 23

9. The Specification of Power ........................................... 24

10. Field Wiring .................................................................. 25

Indoor Units 6

Features

1. Features

1.1 Overview

Compact design, super slim body size, less space requiring in installation

Each louver can be separately controlled, more comfort air blowing is possible.

Auto-lifting panel design, more convenient to clean and maintain the filter. (optional)

1.2 Fresh air intake function

Fresh air fulfills air quality more healthy and comfortable.

Ventilation motor is optional to increase the effect of fresh air.

1.3 Optional ionizer generator

Ionizer generator is optional to get refreshing air to your room.

Ionizer can be switched on or off by remote controller.

When pressing the Clean Air button on the remote controller, Ionizer will work and the indicator light on

display board will shine.

Ionizer generator

connector

Ventilation motor

connector

Indoor Units 7

Features

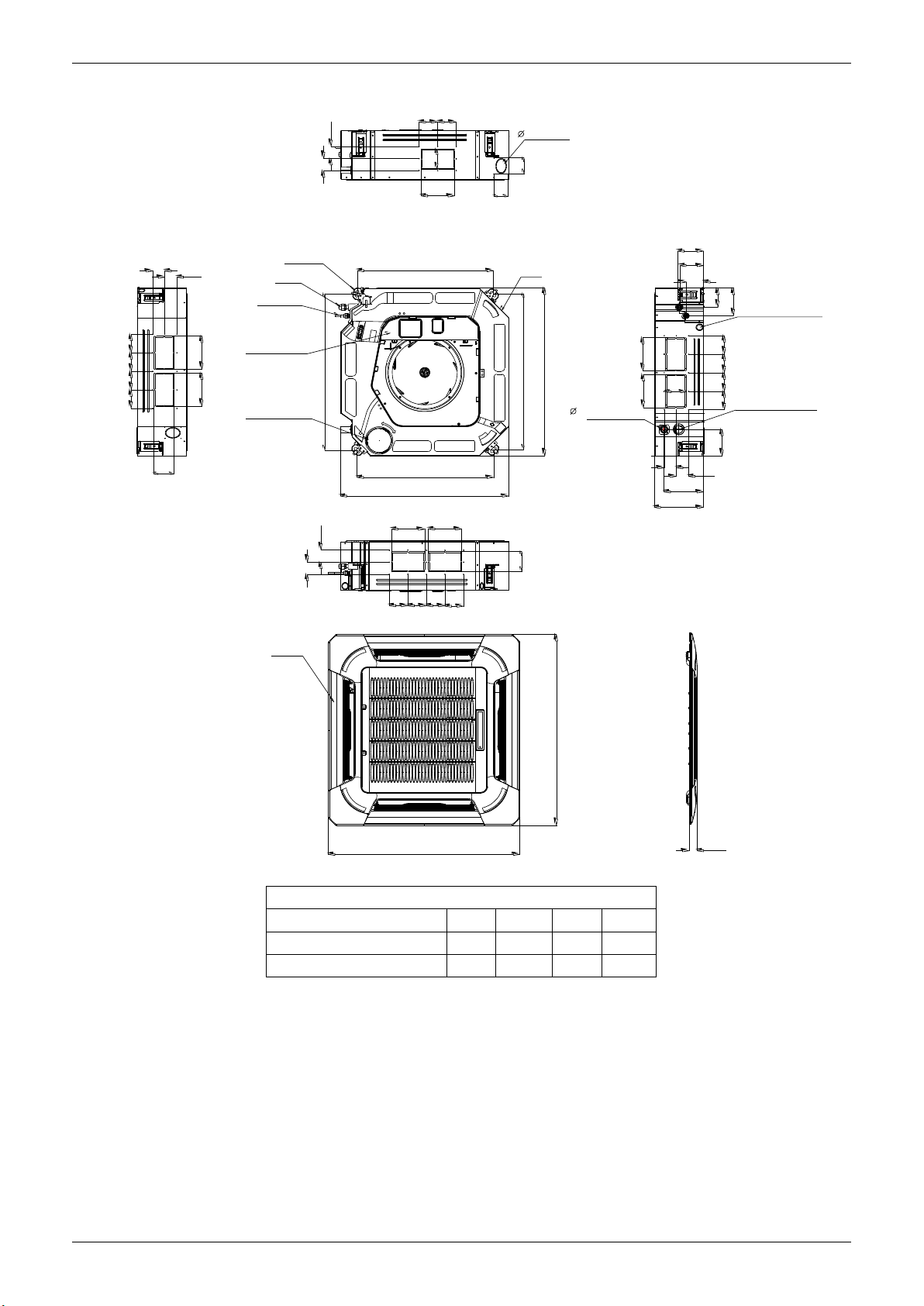

1.4 Built-in draining pump

Due to the improvement of structure, more convenient to repair or replace the draining pump.

Built-in draining pump to make sure condensed water drain out reliably.

Draining Pump

1.5 Terminals for alarm lamp and long-distance on-off controller connection are

standard

Reserve terminals for the connection of alarm lamp and long-distance on-off controller, more human

control.

Indoor Units 8

Alarm lamp

Long-distance on-off controller

Features

1.6 Twins Combination (18k-30k)

The units can be installed as Twin systems: one outdoor unit can connect with two indoor units. The

indoor units can be combined in any of the different available ratings.

Indoor Units 9

Dimensions

2. Dimensions

D

D

92 92

B

A

75

Fresh air intake

80

80

D

D

92

9292

92

A

A

B

4-install hanger

Gas side

Liquid side

E-parts box

Service hole for

draining pump

Panel

780

D

D

A

92 92

680

680

840

Body

780

840

32

Drain hole

A

B

92

92

136

126

91

90

Wiring connection port

135

A

B

A

D

196

92929292

Test mouth &

132

D

C

Test cover

950

950

Unit: mm

Model(kBtu/h) A B C D

24~36 160 95 245 60

48~60 160 95 287 60

55

Indoor Units 10

780(Hook-location)

880(Ceiling hole)

>2500mm

outlet intle t outlet

ground

Chart 1

No te:

880mm

Hook

B

Panel

Chart 2

Body

Bolt M6X12

180 00-24000Btu/h(R 22) Serie s A 26 0mm

36000-48000Btu/h(R 22) Series A 330mm

≥

≥

No te:

180 00- 24000B tu/ h(R 22) S eri es B= 240mm

3 60 00- 48000B tu /h(R 22) Series B= 310mm

Service Space

3. Service Space

>1000mm

>1000mm

>1000mm

>1000mm

Indoor Units 11

Wiring Diagrams

4. Wiring Diagrams

CODE:16022500000803

FUNCTION OF SWITCH

FOR CCM UNIT ADDRESS

SWITCH

0

1

ON

F

2

E

S2

3

D

4

C

5

+

B

6

A

7

9

8

STATE

MODE

STATE

VALUE

0~15

0

F

E

D

C

B

A

9

8

32~47

SWIT CH

ON

SWIT CH

ON

1 2

1

ON

2

3

4

5

6

7

1 2

FOR AUT O-RES TART SE TTING

ON

REME MBER

FOR TE MP.COMP ENSATIO N

ON

1 2

6

S1

ADDRESS

Facto ry

Setti ng

S2

+

S1

ADDRESS

Facto ry

Setti ng

SW3

Fac tory

Set ting

SW6

Fac tory

Set ting

Anti-cold air

SW1

FAN MOTOR STOP-TEM

ON

24

1 2

Factory setting

ON

15

1 2

ON

8

1 2

Acc ordin g

ON

to th e

EEP ROM

1 2

set ting

This symbol indicates the - - - -

the actual element is optional,

shape shall prevail.

ON

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

1 2

16~31

ON

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

1 2

48~63

ON

NO_R EMEMB ER

ON

1 2

4

ON

ON

1 2

1 2

E fun ction

2

SWIT CH

SW2

ON

STATE

MODE

Fac tory

Set ting

SWIT CH

SW5

ON

STATE

MODE

NO SLAV E

Fac tory

Set ting

SWITCHENC1

NUMBER

4

5

6

7

8

9

A

FOR FAN M OTER CO NTROL

THEN NO P OWER RE QUEST .

ON

FAN OF F

FOR MA IN-SL AVE SETTI NG

ON

ON

ON

1 2

1 2

MAIN

MAIN

1 2

MAIN

(FOR POWER)

POWER

4000W-5300W£2.0HP£

5400W-7100W£2.5HP£

7500W-9000W £3.2HP£

9100W-10500W£4.0HP£

12000W-14000W(5.0HP)

14500W-16000W(6.0HP)

Reactor

ON

FAN ON

ON

1 2

SLAV E

/

Inn er Driv er

DC Mo tor

M

Y/G

RED

RED

TO SWING

BOARD

M

3

CN3

DC MO TOR

CN1

DRI VER MOD LE

Out er Driv er DC Mot or

Rem ote

Con trol

Ala rm

Out put

XS2

XP2

TO GO-UP-AND

-DOWN BOARD

5

CN1 3

JR6

XS2

XP2

MAGNETIC RING

5

CN1 5

ON - OF F

JR6

CN2 3

ALA RM

CN3 3

CN16

CN66

CN3

CN55

E Y X

To CCM

Com m.Bus

CN4 0

CN13

CN1 0(CN1 0A)

INDOO R UNIT

MAINB OARD

CN2

Q E P

CN1

S1

S2

RED (BROW N)

MAGNETIC RING

To OUTD OOR

Com m.Bus

L

CN5

BLU E(BLA CK)

N

CN14

CN8

4

CN7

CN6

Y/G

10

4

P1

P4

KJR-120C / WF-60A1

CON TROLL ER

XS9

XS10

M

NEW FAN

2

M

PUM P

DIS PLAY

BOA RD

OUTER PIPE TEMP.

BLA CK

WHI TE

WATER LEVEL SWITCH

Y/G

TO WI RE

XP9

XP10

KJR-12B / KJR-29B

5

CON TROLL ER

MIDDLE PIPE TEMP.

ROOM TEMP.

SWING

MOTOR

SWING

MOTOR

TO WI RE

T2B

T2

T1

Indoor Units 12

Wiring Diagrams

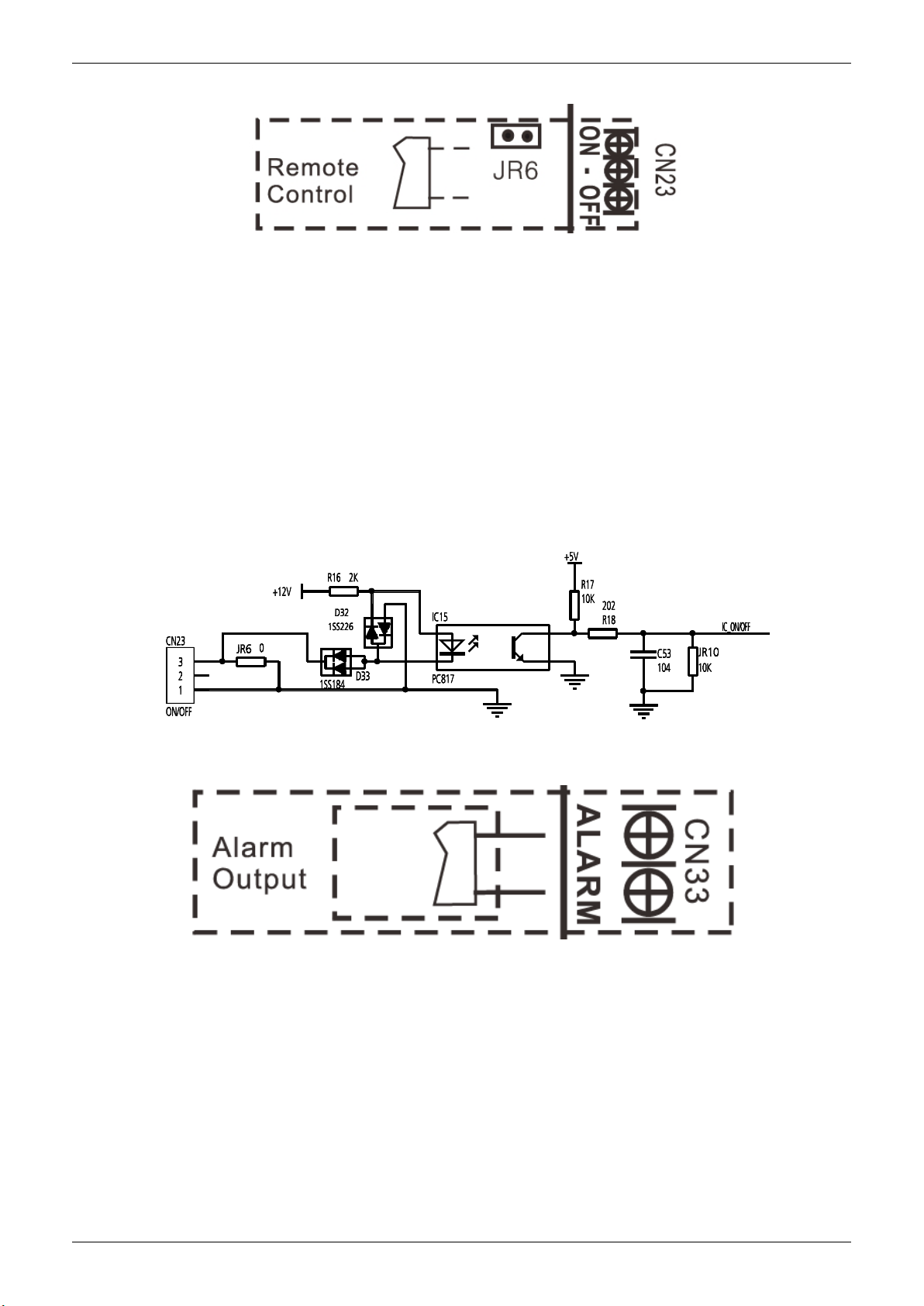

4.1 Some connectors introduce:

A For remote control (ON-OFF) terminal port CN23 and short connector of JR6

1. Remove the short connector of JR6 when you use ON-OFF function;

2. When remote switch off (OPEN), the unit would be off;

3. When remote switch on (CLOSE), the unit would be on;

4. When close/open the remote switch, the unit would be responded the demand within 2

seconds;

5. When the remote switch on. You can use remote controller/wire controller to select the mode

what you want; when the remote switch off, the unit would not respond the demand from remote

controller/wire controller.

When the remote switch off, but the remote controller/wire controller are on, CP code would be

shown on the display board.

6. The voltage of the port is 12V DC, design Max. current is 5mA.

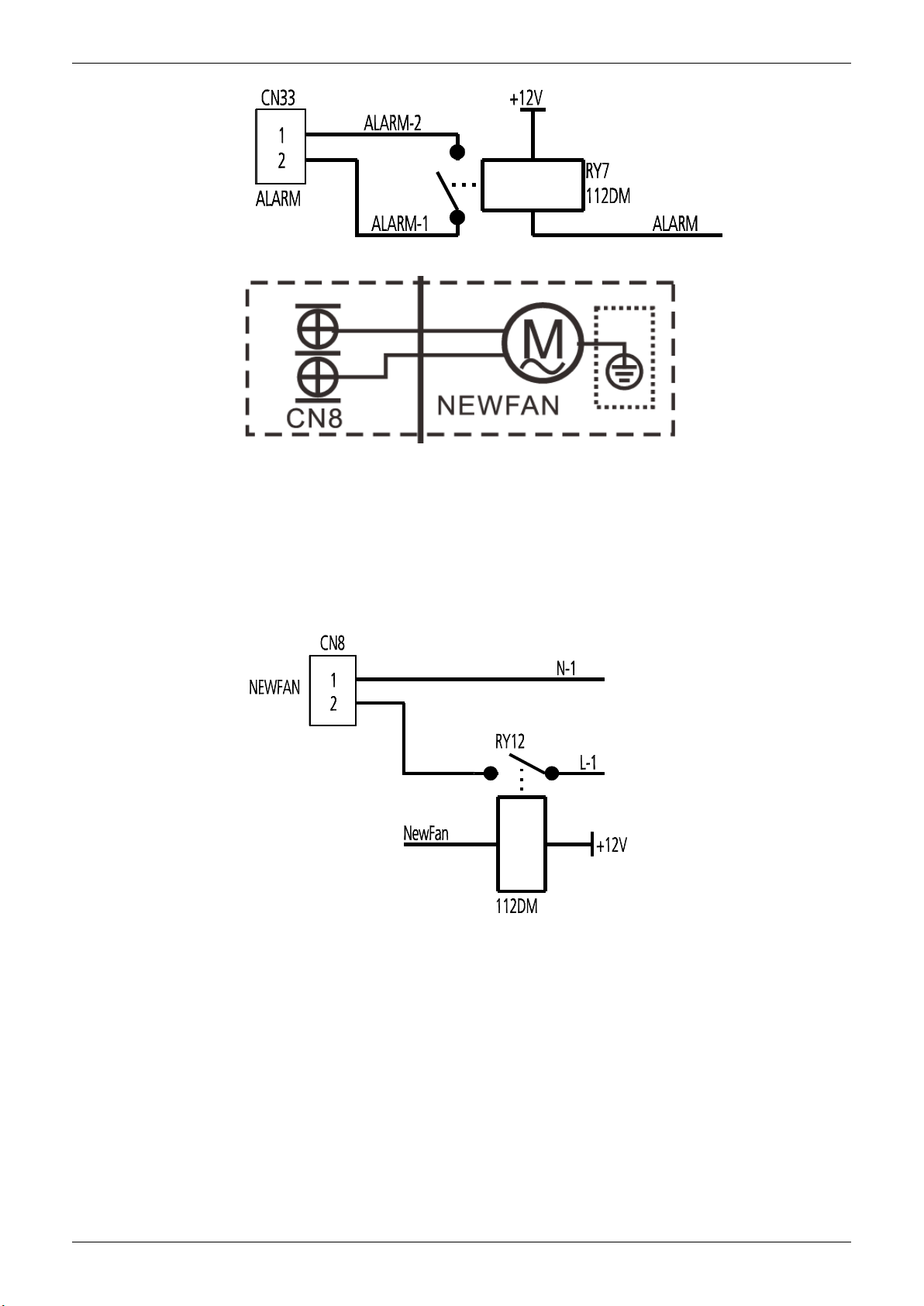

B For ALARM terminal port CN33

1. Provide the terminal port to connect ALARM, but no voltage of the terminal port , the power

from the ALARM system (not from the unit )

2. Although design voltage can support higher voltage, but we strongly ask you connect the

power less than 24V, current less than 0.5A

3. When the unit occurs the problem, the relay would be closed, then ALARM works

Indoor Units 13

Wiring Diagrams

C. For new fresh motor terminal port CN8

1. Connect the fan motor to the port, no need care L/N of the motor;

2. The output voltage is the power supply;

3. The fresh motor cannot excess 200W or 1A, follow the smaller one;

4. The new fresh motor will be worked when the indoor fan motor work ;when the indoor fan

motor stops, the new fresh motor would be stopped;

5. When the unit enter force cooling mode or capacity testing mode, the fresh motor isn’t work.

Indoor Units 14

Wiring Diagrams

4.2

Micro-Switch Introduce:

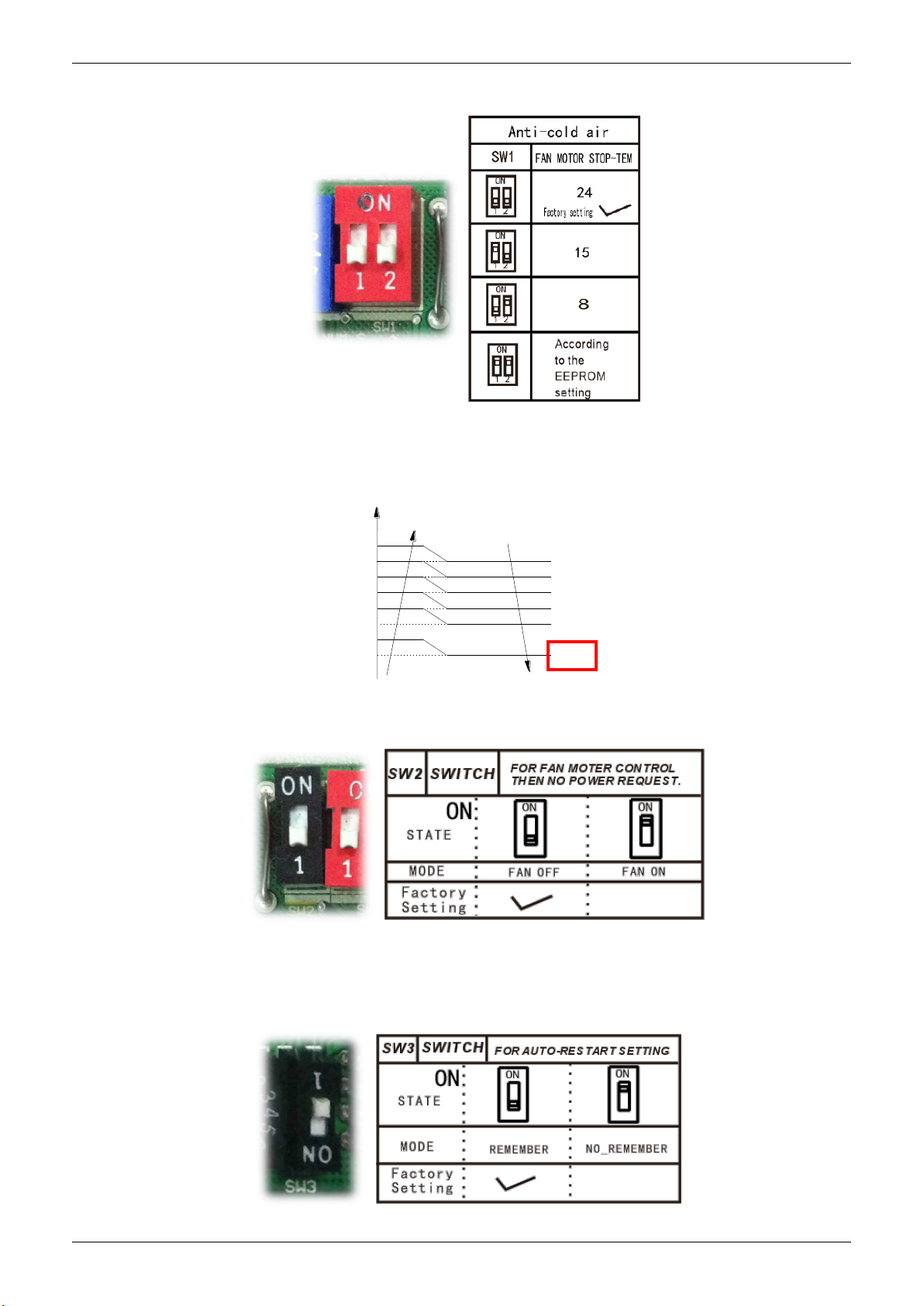

A. Micro-switch SW1 is for selection of indoor fan stop temperature (TEL0) when it is in anti-cold

wind action in heating mode.

Range: 24oC, 15oC, 8 oC, according to EEROM setting (reserved for special customizing).

T2

TEL0+16

TEL0+14

TEL0+12

TEL0+10

TEL0+8

TEL0+6

Setting fan speed

H

M+

M

L

Super slow

Fan off

TEL0+12

TEL0+10

TEL0+8

TEL0+6

TEL0+4

TEL0

B.Micro-switch SW2 is for selection of indoor FAN ACTION if room temperature reaches the

setponit and the compressor stops.

Range: OFF (in 127s), Keep running.

Indoor Units 15

Wiring Diagrams

C.Micro-switch SW3 is for selection of auto-restart function.

Range: Active, inactive

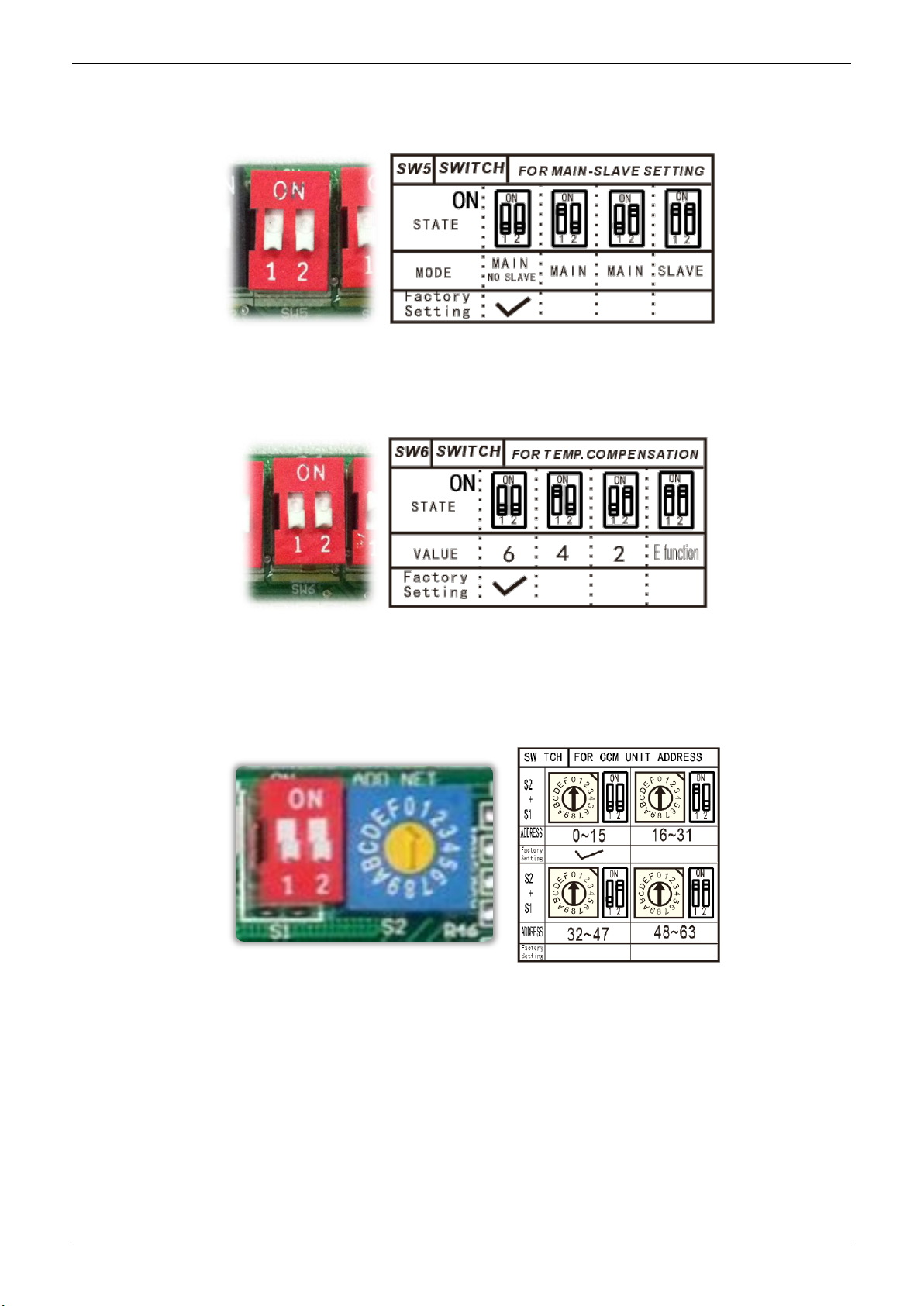

D. Micro-switch SW5 is for setting the master or slave unit when the unit is in twin connection.

Range: Master no slave (Normal 1 drive 1 connection), Master (2 positions without difference),

Slave

E.Micro-switch SW6 is for selection of temperature compensation in heating mode. This helps

to reduce the real temperature difference between ceiling and floor so that the unit could run

properly. If the height of installation is lower, smaller value could be chosen.

Range: 6oC, 4oC, 2oC, E function (reserved for special customizing)

F.Micro-switch S1 and dial-switch S2 are for address setting when you want to control this unit

by a central controller.

Range: 00-63

Indoor Units 16

Wiring Diagrams

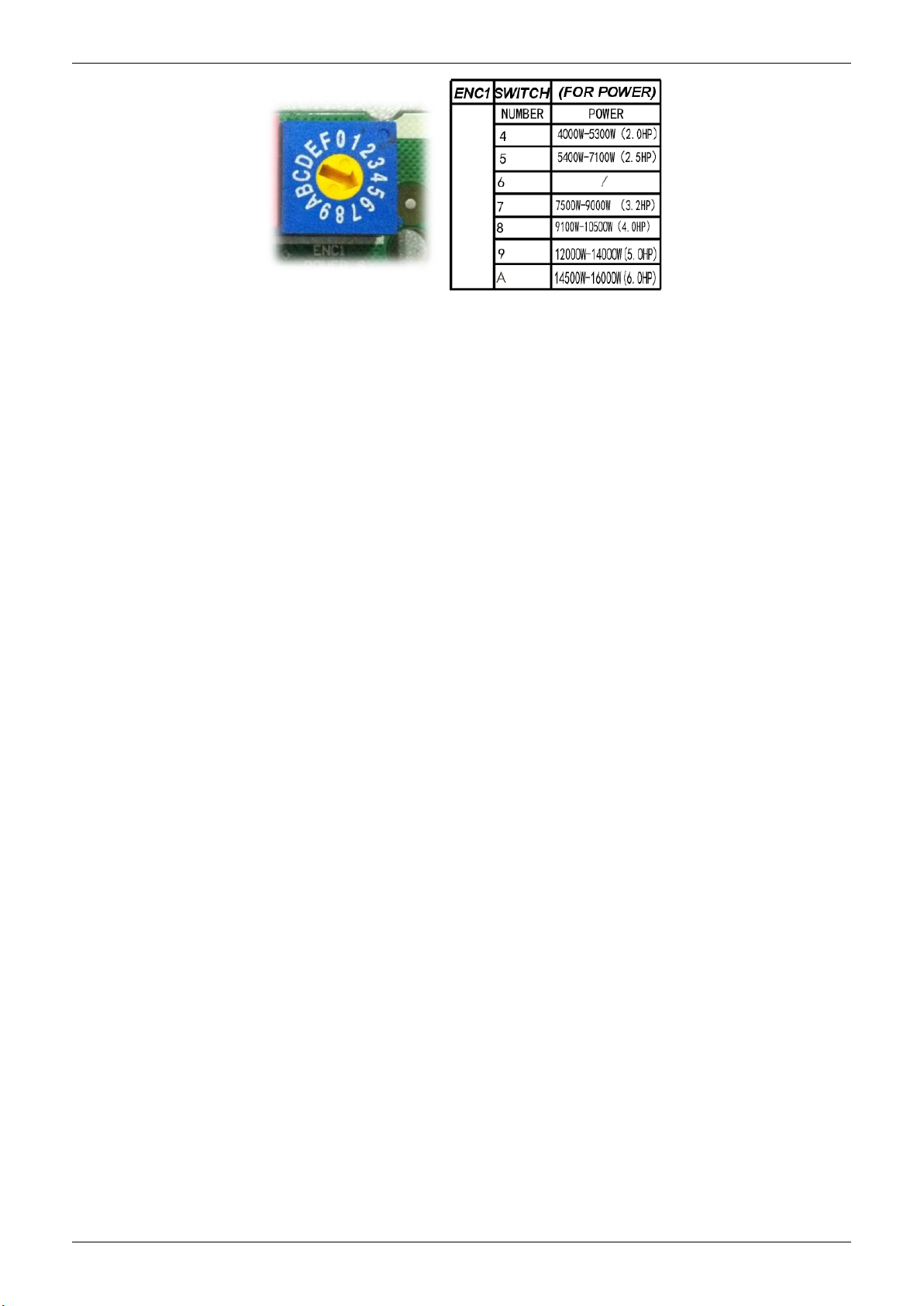

G. Dial-switch ENC1: The indoor PCB is universal designed for whole series units from 18K to

55K. This ENC1 setting will tell the main program what size the unit is.

NOTE: Usually there is glue on it because the switch position cannot be changed at random

unless you want to use this PCB as a spare part to use in another unit. Then you have to select

the right position to match the size of the unit.

Indoor Units 17

Air Velocity Distributions (Reference Data)

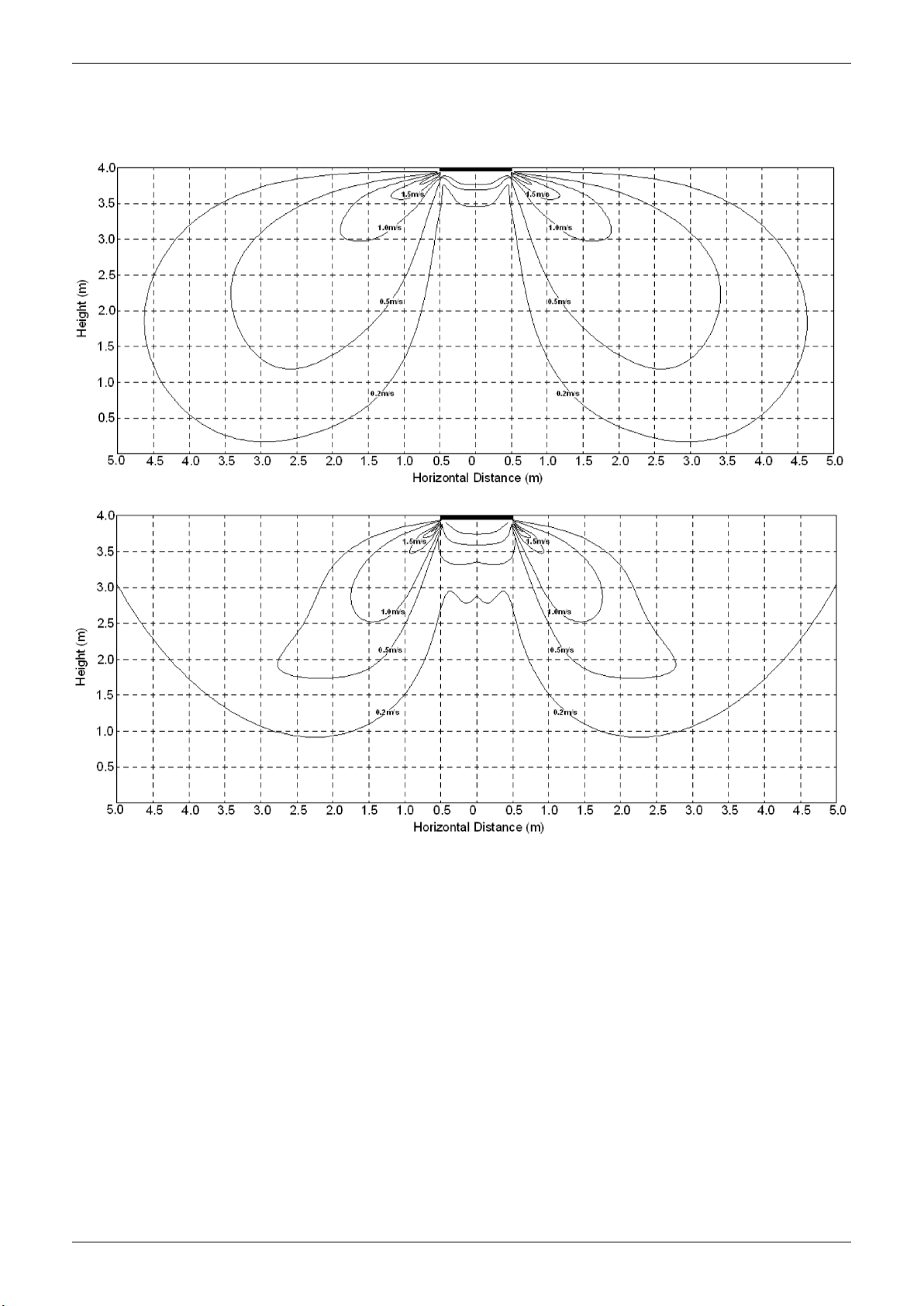

5. Air Velocity Distributions (Reference Data)

24K:

Cooling:

Heating:

Indoor Units 18

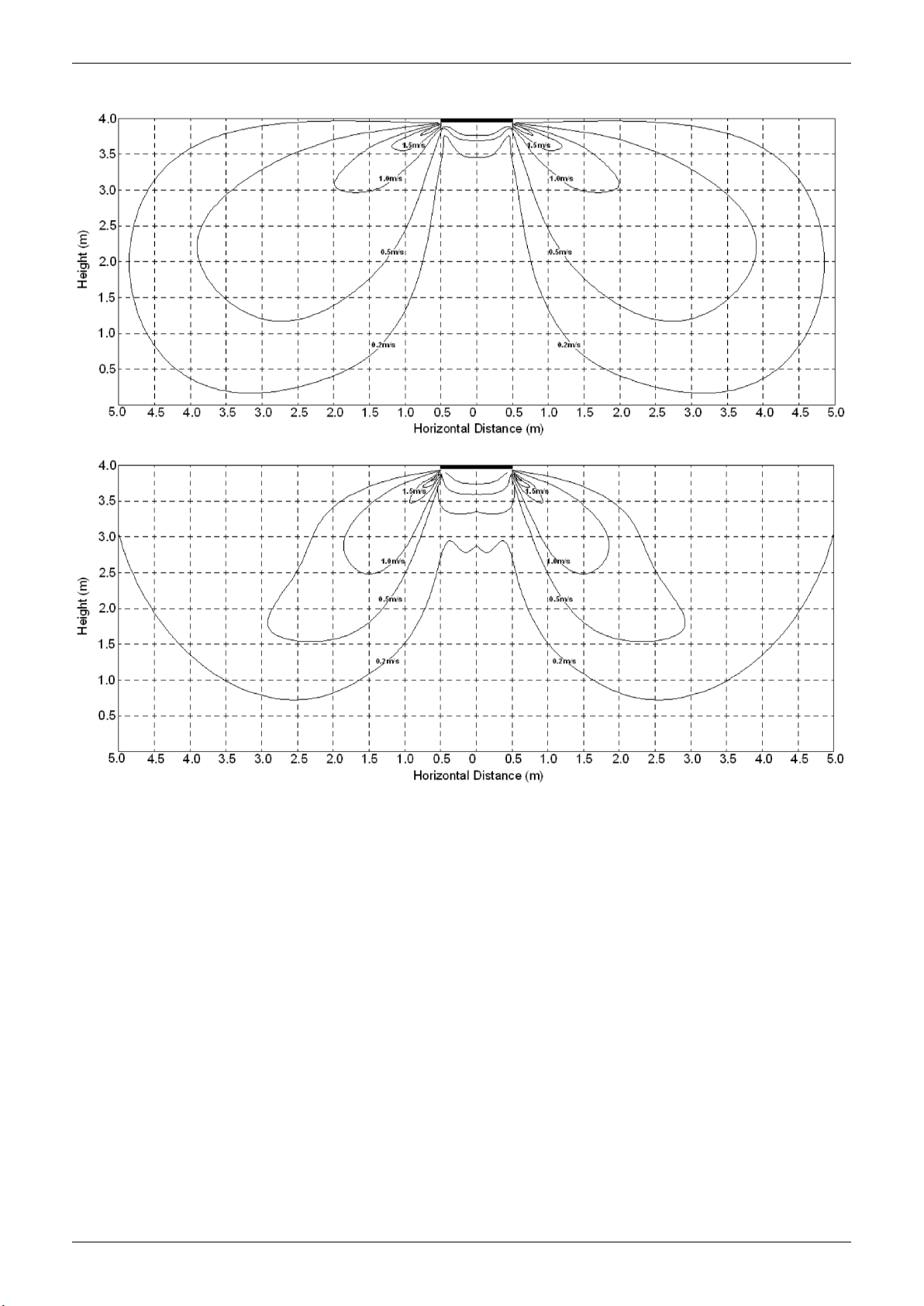

Air Velocity Distributions (Reference Data)

30-36K:

Cooling:

Heating:

Indoor Units 19

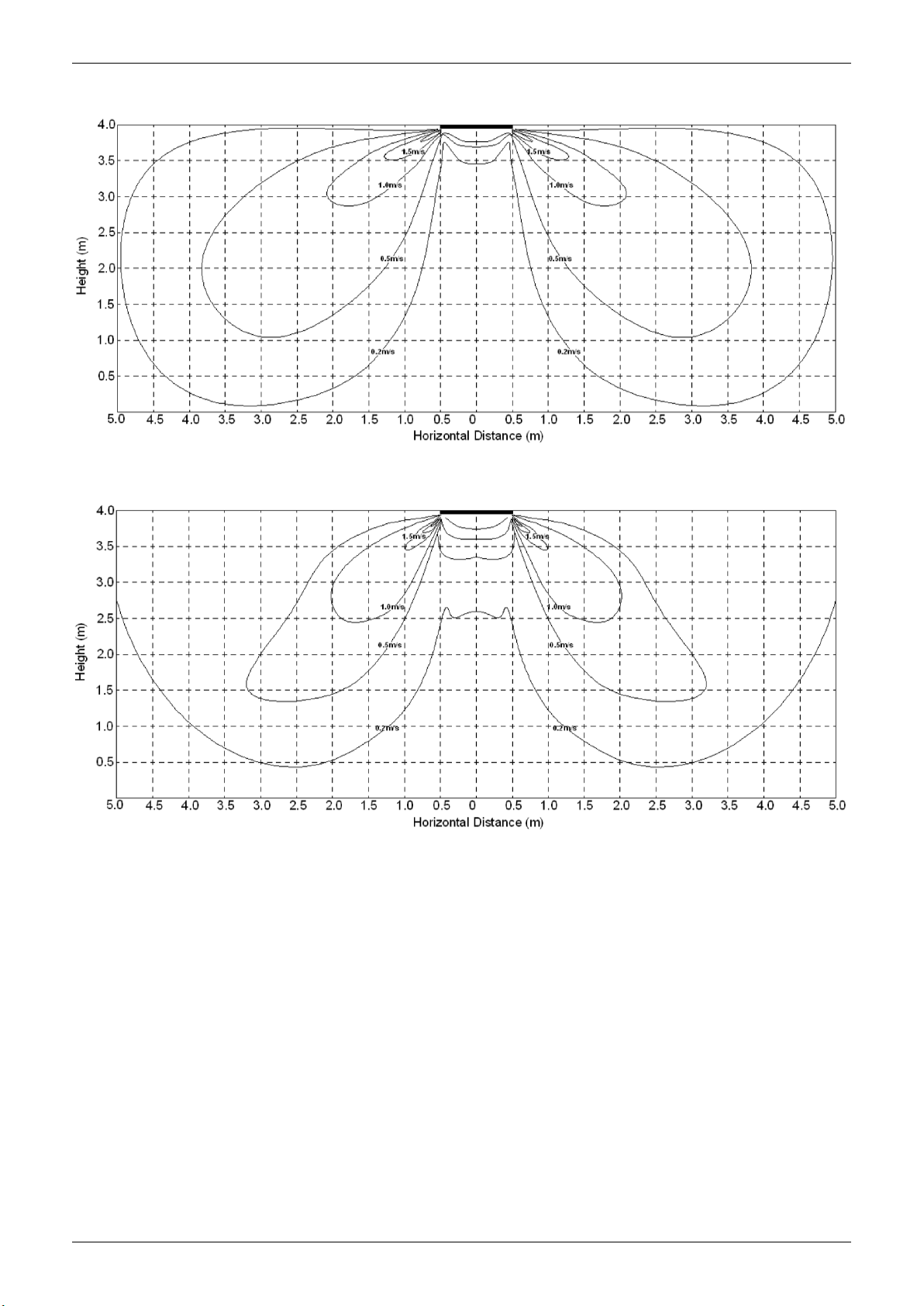

Air Velocity Distributions (Reference Data)

48-60K:

Cooling:

Heating:

Indoor Units 20

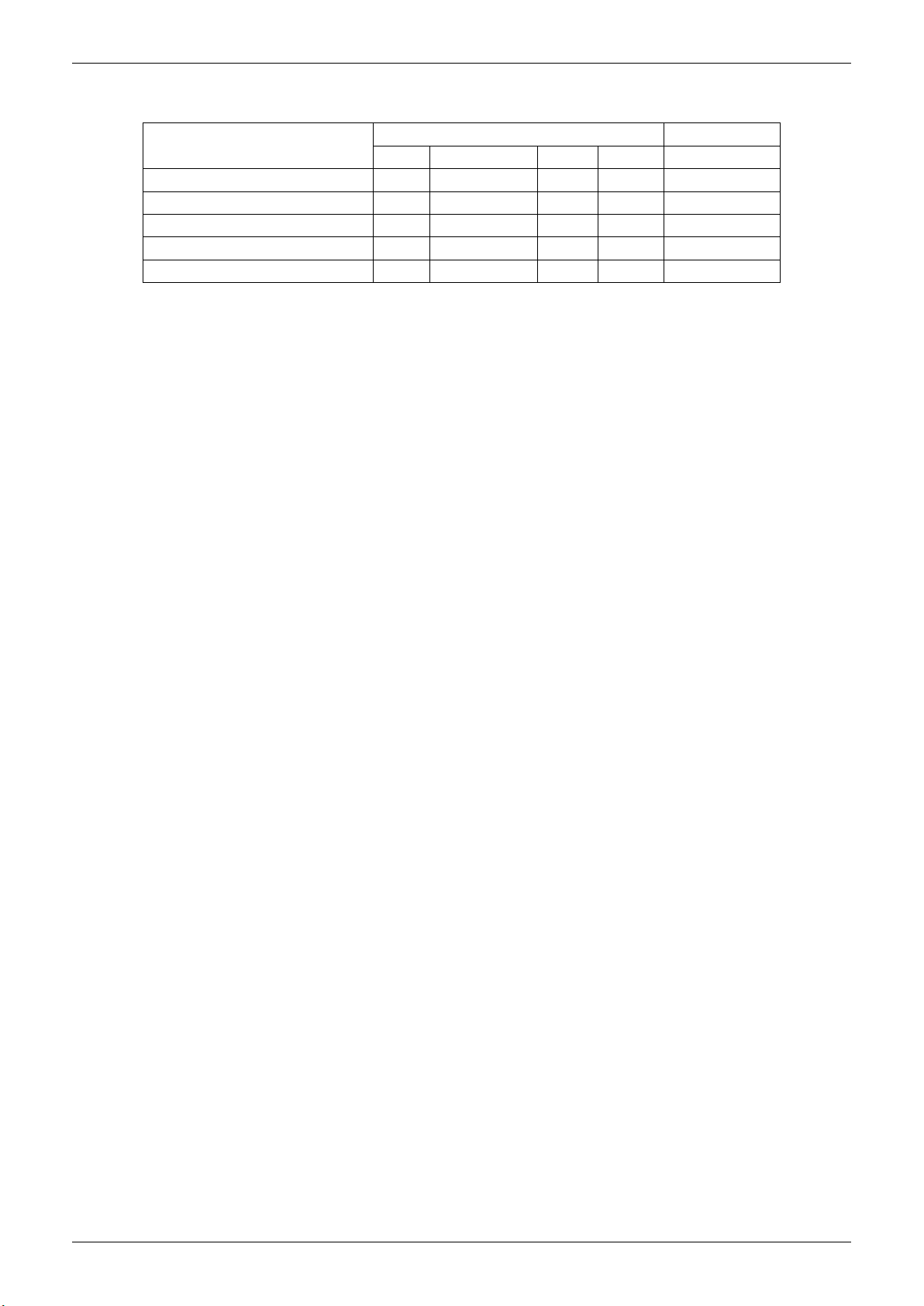

Electric Characteristics

6. Electric Characteristics

Model

MUCSR-24-H8 50 220-240V 198V 254V /

MUCSR-30-H8

MUCSR-36-H8 50 220-240V 198V 254V /

MUCSR-48-H8 / MUCSR-48-H8T 50 220-240V 198V 254V /

MUCSR-60-H8 / MUCSR-60-H8T 50 220-240V 198V 254V /

Hz Voltage Min Max MFA

50 220-240V 198V 254V /

Indoor Unit Power Supply

Notes:

MFA: Max. Fuse Amps. (A)

Indoor Units 21

Sound Levels

7. Sound Levels

1.4m

Microphone

MUCSR-24-H8

MUCSR-30-H8

MUCSR-36-H8

MUCSR-48-H8 /

MUCSR-48-H8T

MUCSR-60-H8 /

MUCSR-60-H8T

Model Noise Power dB(A)

62 46 42 39

65 53 48 44

65 56 52 48

65 55 51 48

69 52 49 46

Noise level dB(A)

H M L

Indoor Units 22

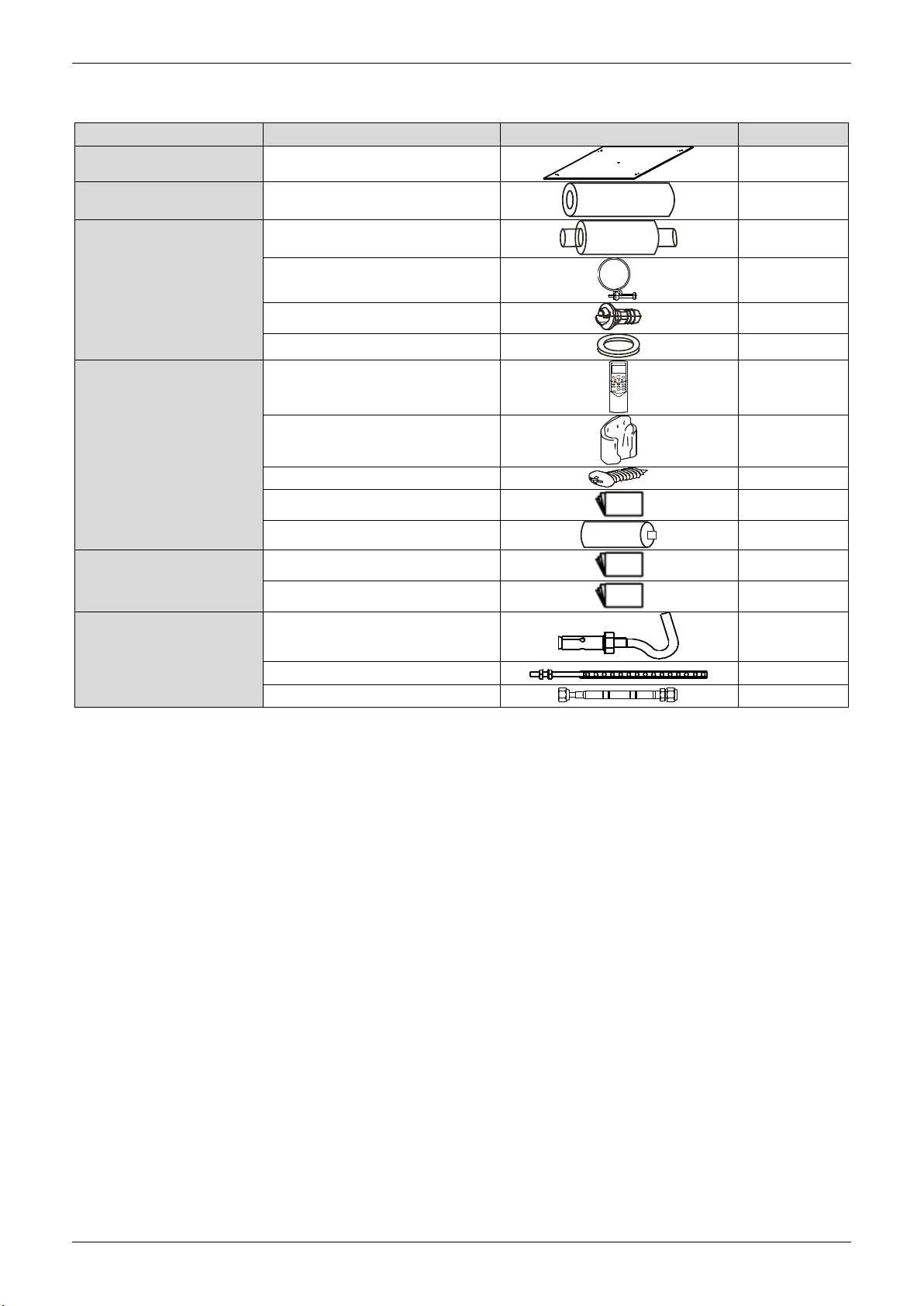

Accessories

8. Accessories

Name Shape Quantity

Installation Fittings

Tubing & Fittings

Drainpipe Fittings

Remote controller & Its

Frame(The product you

have might not be

provided the following

accessories)

Others

Installation paper board

Soundproof / insulation sheath

Out-let pipe sheath

Out-let pipe clasp

Drain joint

Seal ring

Remote controller & Its Frame

Remote controller holder

Mounting screw(ST2.9×10-C-H)

Remote controller manual

Alkaline dry batteries (AM4)

Owner's manual

Installation manual

1

1

1

1

1

1

1

1

2

1

2

1

1

Installation accessory

(The product you have

might not be provided the

following accessories

Expansible hook

Installation hook

Orifice

4

4

1

Indoor Units 23

The Specification of Power

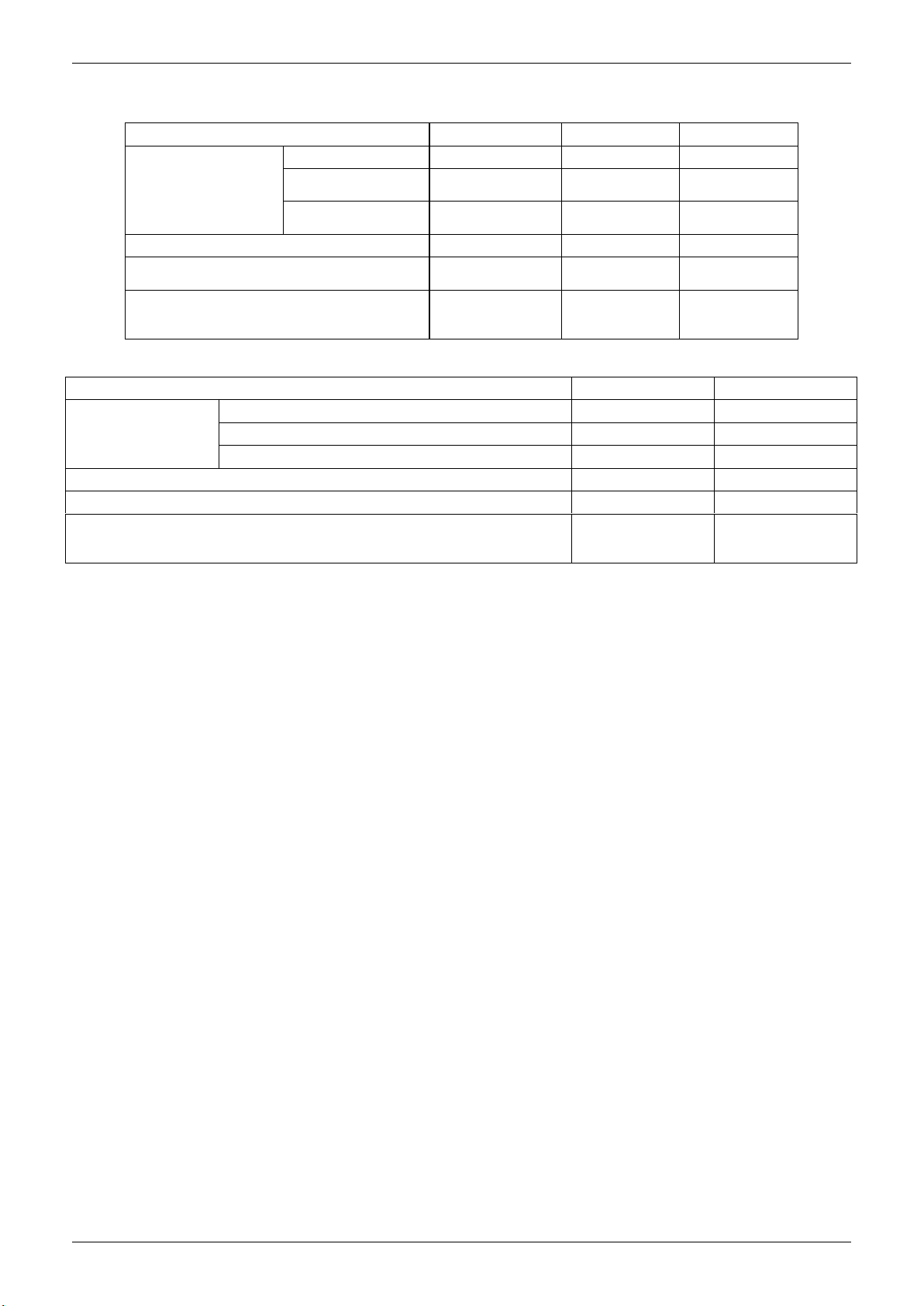

9. The Specification of Power

Model(Btu/h) 24000 30000 36000

Phase 1-phase 1-phase 1-phase

POWER

CIRCUIT BREAKER/Fuse (A) 30/20 40/30 40/30

Indoor/Outdoor Connecting Wiring

(Weak Electric Signal) (mm2)

Indoor/Outdoor Connecting Wiring

(Strong Electric Signal) (mm2)

Frequency and

Voltage

POWER WIRING

(mm2)

Model(Btu/h) 48000 48000~60000

Phase 1-phase 3-phase

POWER

Circuit Breaker/Fuse(A) 40/35 30/25

Indoor/Outdoor Connecting Wiring(Weak Electric Signal) (mm2) 2×0.2 2×0.2

Indoor/Outdoor Connecting Wiring(Strong Electric Signal) (mm2)

Frequency and Voltage 220-240V, 50Hz 380-415V, 50Hz

Power Wiring (mm2) 3×4.0 5×2.5

220-240V, 50Hz 220-240V, 50Hz 220-240V, 50Hz

3×2.5 3×2.5 3×4.0

2×0.2 2×0.2 2×0.2

3×1.0(3x2.5 with

auxiliary electric

heater)

3×1.0(3x2.5

with auxiliary

electric heater)

3×1.0(3x2.5 with

auxiliary electric

heater)

3×1.0(3x2.5

with auxiliary

electric heater)

3×1.0(3x2.5 with

auxiliary electric

heater)

Indoor Units 24

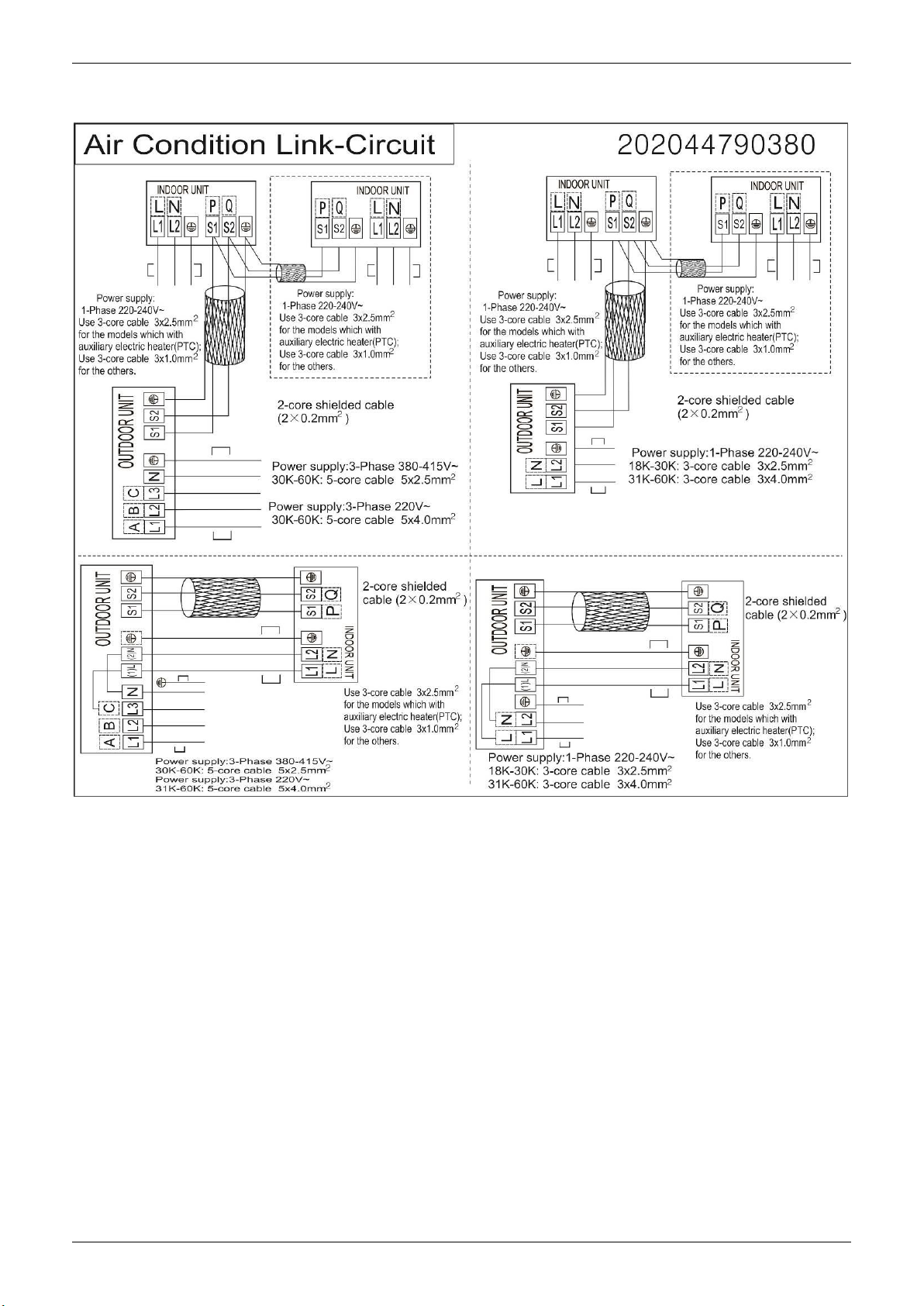

Field Wiring

10. Field Wiring

Indoor Units 25

MUCR-H8 Duct Type

MUCR-H8 Duct Type

1. Features .......................................................................... 27

2. Dimensions .................................................................... 30

3. Service Space ................................................................ 31

4. Wiring Diagrams ............................................................ 32

5. Static Pressure ............................................................... 38

6. Electric Characteristics ................................................. 44

7. Sound Levels ................................................................. 45

8. Accessories .................................................................... 46

9. The Specification of Power ........................................... 47

10. Field Wiring .................................................................. 48

Indoor Units 26

Features

1. Features

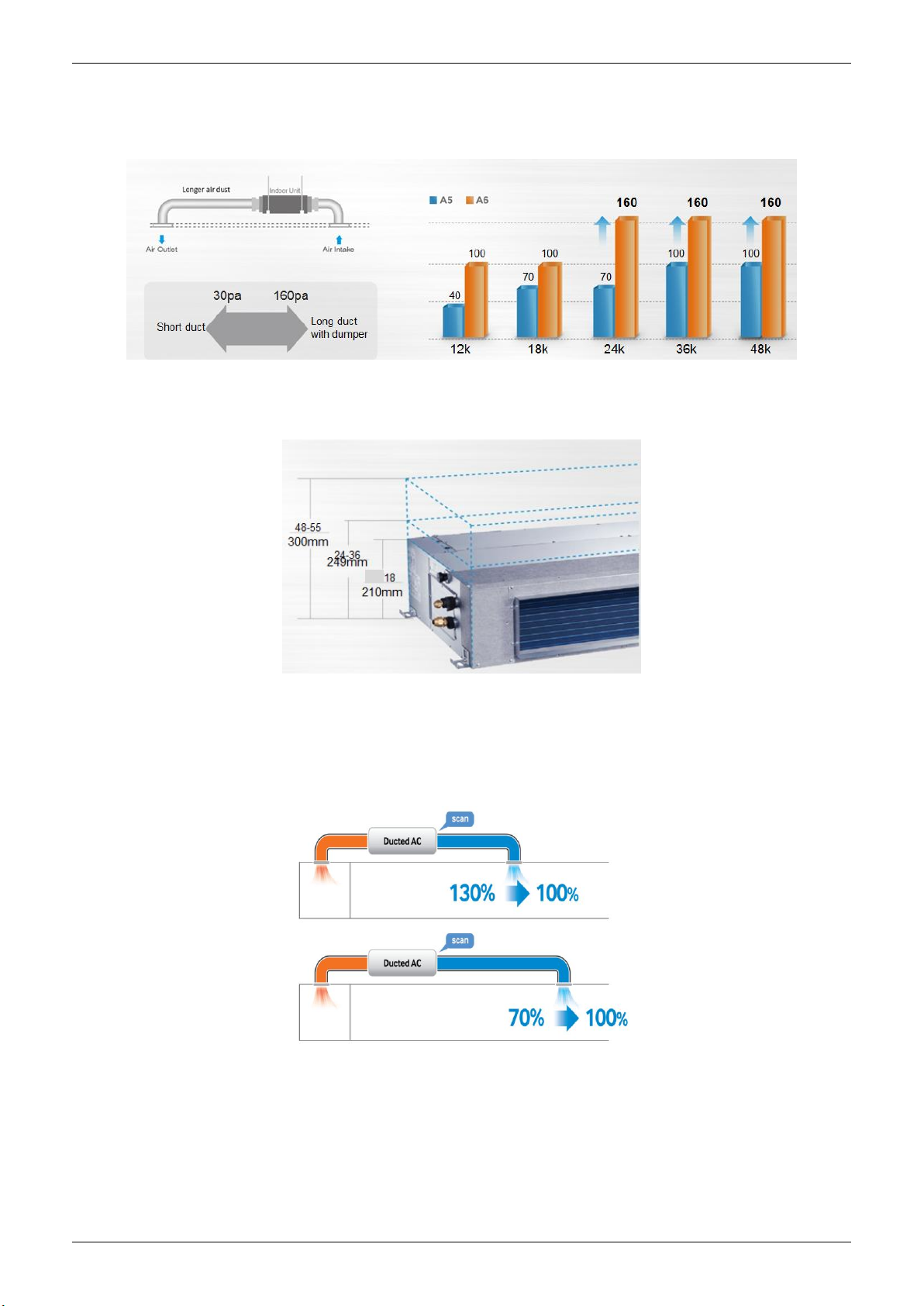

1.1 Higher Static Pressure

As a ducted air conditioner with medium static pressure, it has the widest static pressure range.

The maximum static pressure reaches 160 Pa

1.2 Slim Design

The industry lowest height is designed to be fitted into tight roof spaces.

*18K unit - 210mm,24K/36K unit - 249mm,48K unit -300mm

1.3 Constant air volume control

For ordinary duct, when the static pressure exceeds the expected range, it is fairly difficult even for an

experienced installer to calculate and adjust the air volume precisely.

With constant air volume control technology, the duct will automatically adjusts to perfect static pressure

and keep constant air volume.

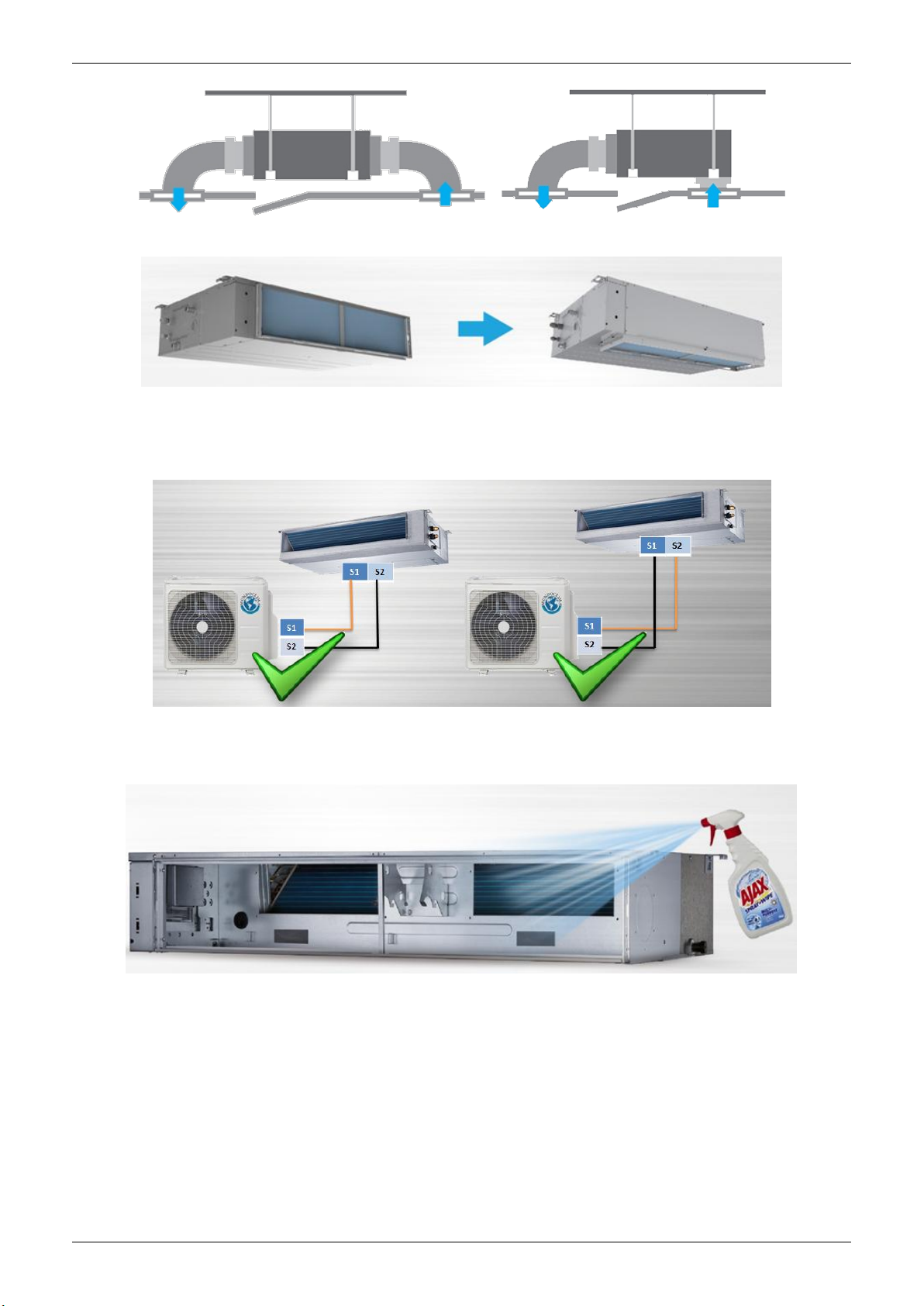

1.4 Flexible Air Intake Way (Bottom side or Rear side)

The frame size of air inlet in rear and bottom is the same. It’s very easy to switch to match different

application.

Indoor Units 27

Features

Air intake from rear (Standard)

Air intake from bottom (Optional)

1.5 Communication wire connection

MUCR-H8 uses two wires without polarity connection way, which almost has no mistake during the

installation.

1.6 Easy Clean

With a larger window design, once the motor and the blower wheels have been detached, heat

exchanger and water receiver tray in behind can be seen very clearly. Dust can be easily removed from

the inside by vacuum

Indoor Units 28

Loading...

Loading...