mundoclima H6M SERIE Service Manual

MULTI INVERTER SERIE H6M

Service manual

www.mundoclima.com

Th

ank you very much for purchasing our products.

Please read this manual carefully before installing

and using the unit.

CL20440 to CL20452

English

CONTENTS

1. General information of Outdoor Units .......................................... 3

2. Features ................................................................ .......................... 4

3. Dimensions ..................................................................................... 5

4. Refrigeration Cycle Diagram ......................................................... 6

5. Wiring diagram ............................................................................... 8

6. Indoor units combination ............................................................ 11

7. Sound Levels ................................................................................ 13

8. Installation Details ........................................................................ 14

8.1 Wrench torque sheet for installation .......................................................................................... 14

8.2 Connecting the cables ............................................................................................................... 14

8.3 Pipe length and the elevation .................................................................................................... 14

8.4 Installation for the first time ........................................................................................................ 15

8.5 Adding the refrigerant after running the system for many years ............................................... 19

8.6 Re-installation while the indoor unit need to be repaired .......................................................... 20

8.7 Re-installation while the outdoor unit need to be repaired ........................................................ 22

9. Electronic control function ........................................................ 24

10. Troubleshooting ........................................................................ 29

3

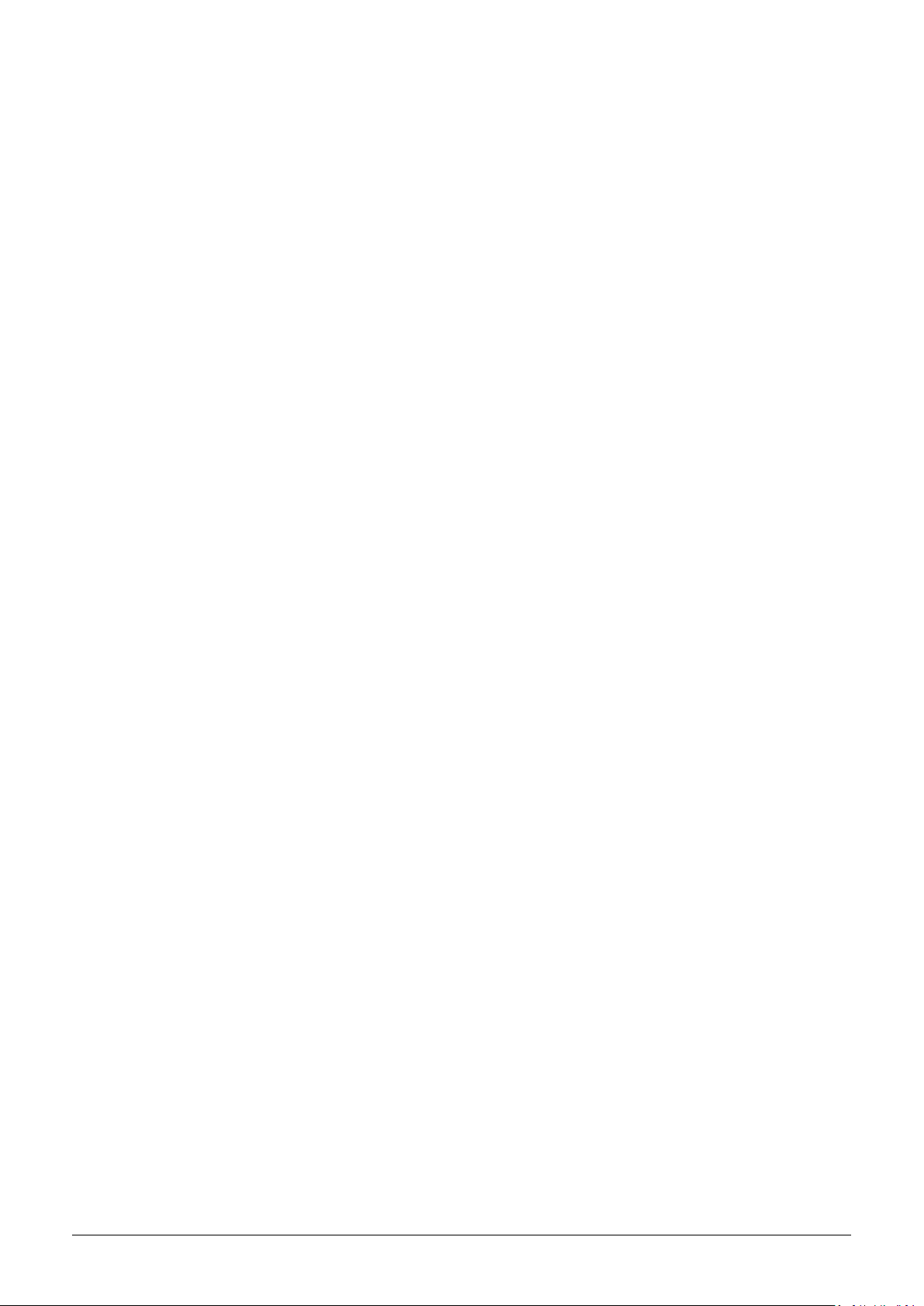

1. General information of Outdoor Units

Model name Dimension (mm) Compressor

MUEX-14-H6.2

MUEX-18-H6.2

MUEX-21-H6.3

MUEX-27-H6.3

MUEX-28-H6.4

MUEX-36-H6.4

MUEX-42-H6.5

800x333x554

800x333x554

845x363x702

845x363x702

946x410x810

946x410x810

946x410x810

ASN108D22UEZ

ASM135D23UFZ

ASM135D23UFZ

ATF235D22UMT

ATF235D22UMT

ATF310D43UMT

ATF310D43UMT

Outdoor unit

Discharge pipe temperature protection

4

2. Features

Power relay control

Low noise air flow system

Hydrophilic aluminum fin

The hydrophilic fin can improve the heating efficiency at operation mode.

4 way valve control

It is only operated in the heating operation mode except defrosting operation.

Anti-rust cabinet

Valve protection cover

It protects the valves and prevents water from dripping.

5

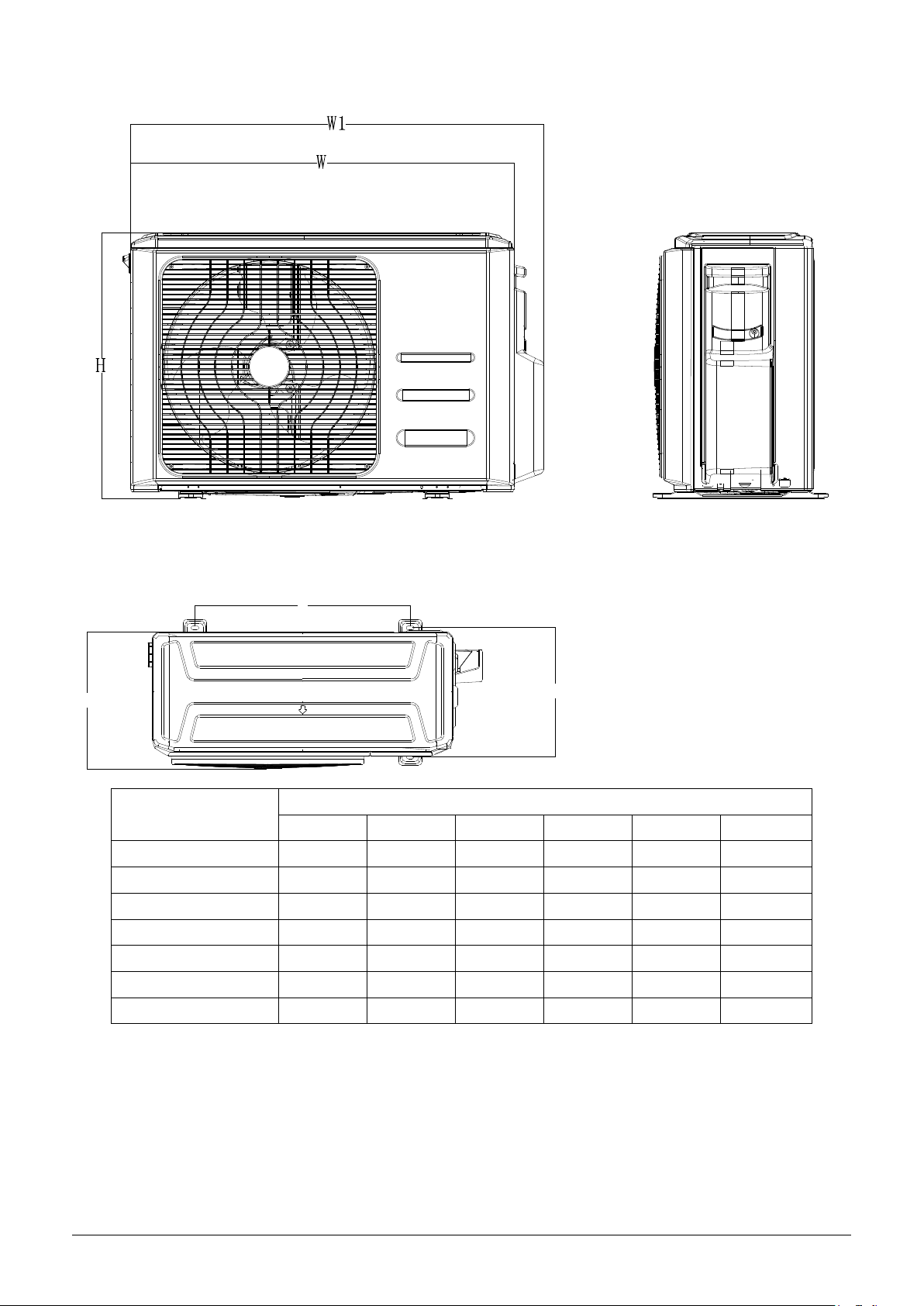

3. Dimensions

A

D

Model

W D H W1 A B

MUEX-14-H6.2 800 333 554 860 514 340

MUEX-18-H6.2 800 333 554 860 514 340

MUEX-21-H6.3 845 363 702 923 540 350

MUEX-27-H6.3 845 363 702 923 540 350

MUEX-28-H6.4 946 410 810 1034 673 403

MUEX-36-H6.4 946 410 810 1034 673 403

MUEX-42-H6.5 946 410 810 1034 673 403

B

Unit: mm

6

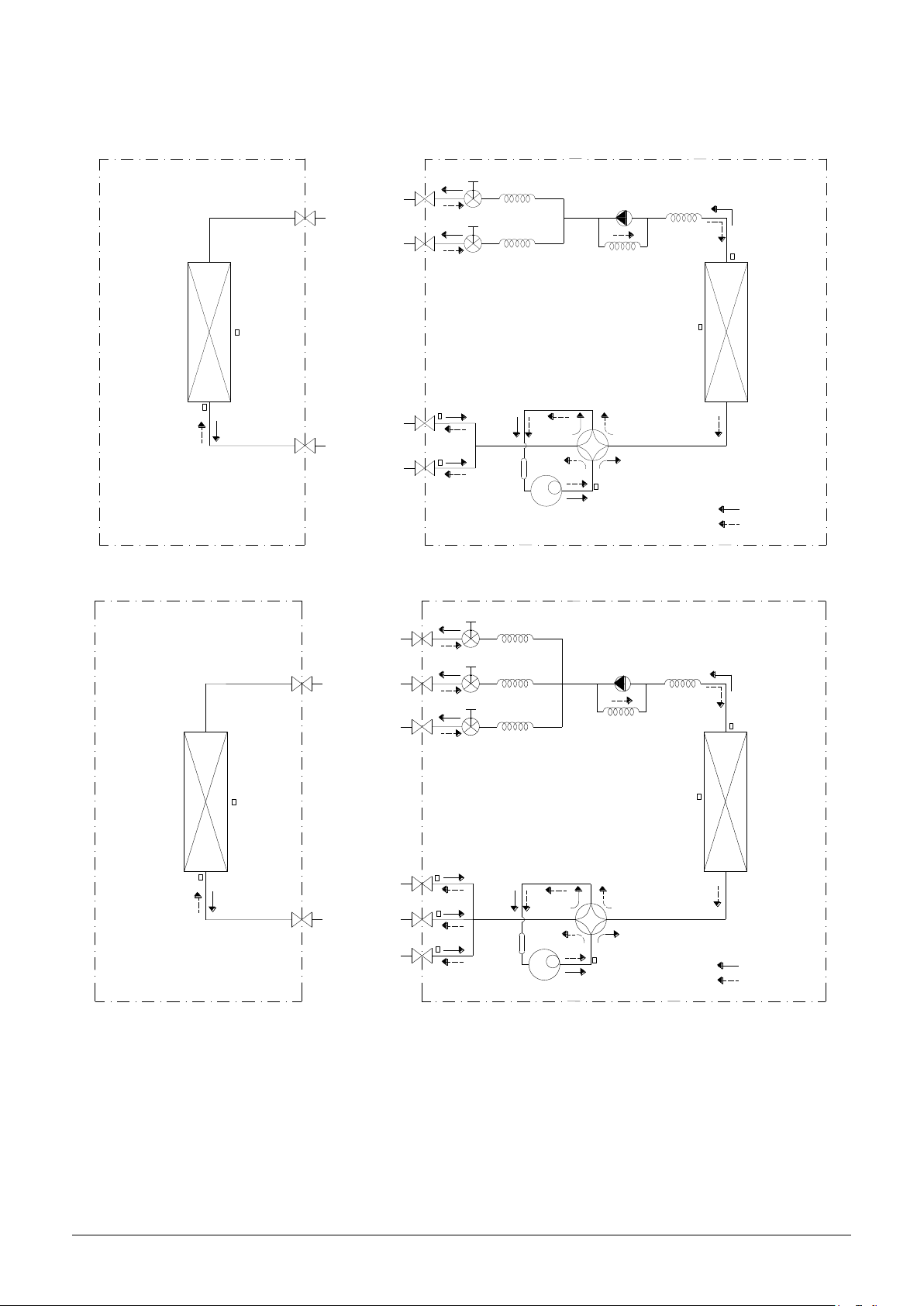

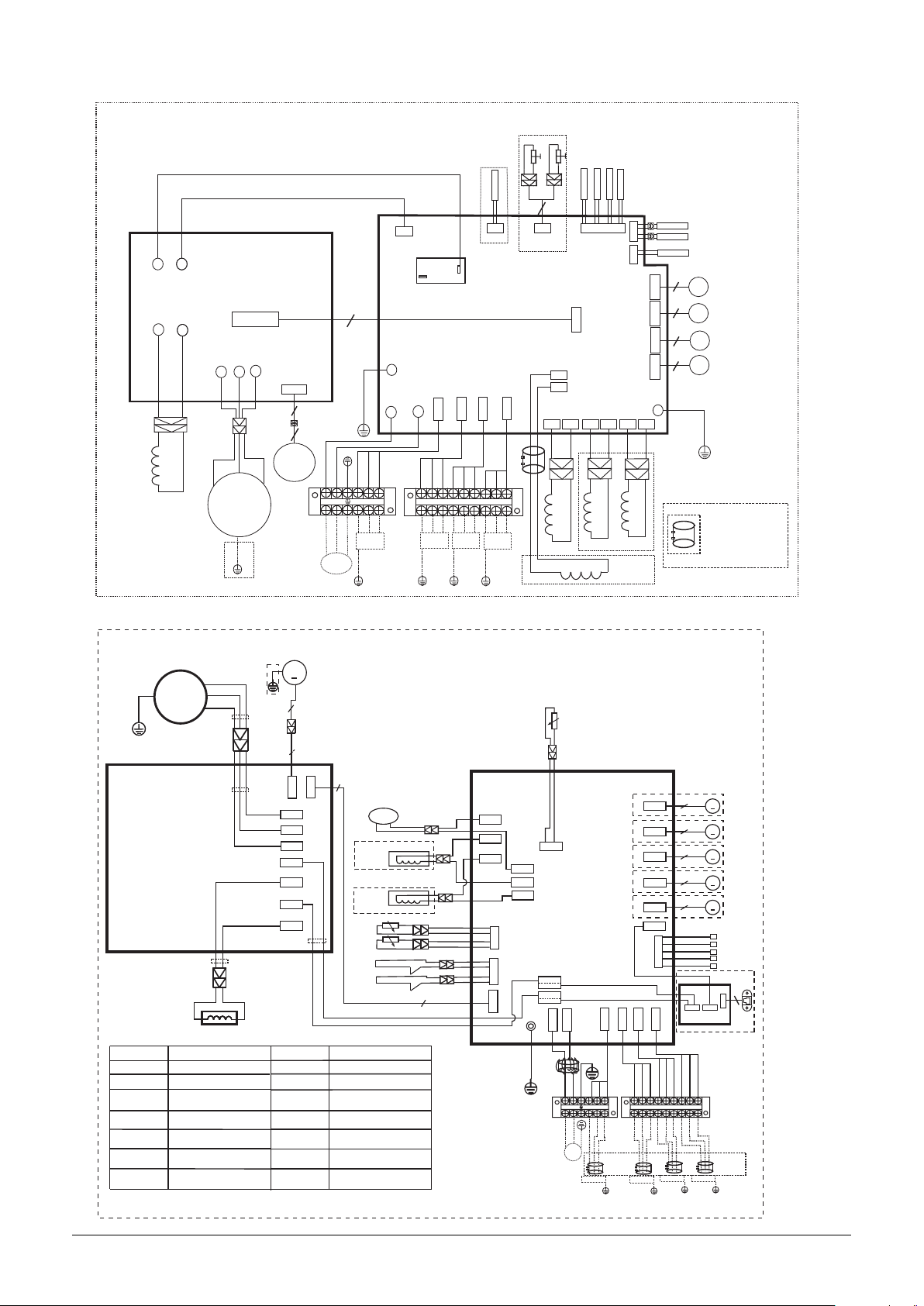

4. Refrigeration Cycle Diagram

4.1 Refrigeration circuit drawing of inverter 1 drive 2 type

INDOOR OUTDOOR

CAPILIAR

EXV

A

CAPILIAR

EXV

B

T2B-

A

Evaporator

temp. sensor outlet

Accumulator

HEAT

EXCHANGE

(EVAPORATOR)

T2

E

vaporator

temp. sensor

middle

T1 Room

temp. sensor

LIQU

ID

VALVE A

LIQU

ID

VALVE B

GAS VALVE A

GAS VALVE B

T2B-B

4.2 Refrigeration circuit drawing of inverter 1 drive 3 type

INDOOR OUTDOOR

CAPILIARY A

V

A

LIQU

ID

VALVE A

EX

Y A

Y B

Compressor

CHECK V

CAPILIARY TUBE

T5 Discharge

temp. sensor

A

4-

WA

LVE

T4 Ambient

temp. sensor

Y VALVE

T3

Condenser

temp. sensor

HEAT

EXCHANGE

(CONDENSER)

COOLING

HEATING

HEAT

EXCHANGE

(EVAPORATOR)

E

vaporator

T2

temp. sensor

middle

T1 Room

temp. sensor

VALVE B

ID

LIQU

LIQUID VALVE C

GAS VALVE A

GAS VALVE B

S

VALVE C

GA

CAPILIARY B

B

V

EX

CAPILIARY C

V

C

EX

A Evaporator

B-

T2

temp. sensor outlet

T2B-B

T2B-C

Accumulator

Compressor

K VALVE

EC

CH

CAPILIARY TUBE

T4 Ambient

temp. sensor

VALVE

Y

4-WA

T5 Discharge

temp. sensor

T3

Condenser

temp. sensor

HEAT

EXCHANGE

(CONDENSER)

COOLING

HEATING

7

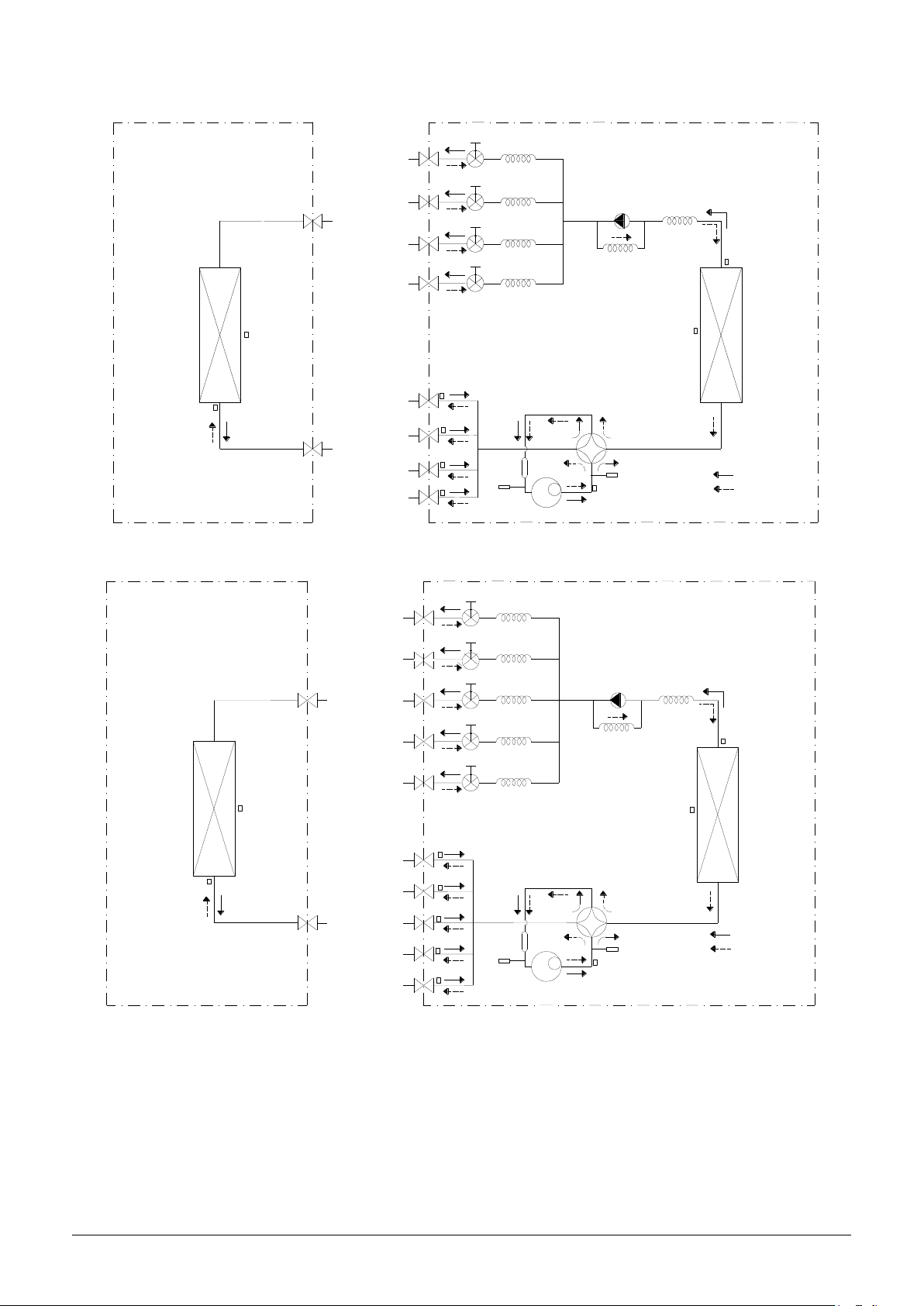

4.3 Refrigeration circuit drawing of inverter 1 drive 4 type

INDOOR OUTDOOR

CA

A

LIQUID V

LIQUID V

LVE A

A

LVE B

LIQUID VALVE C

LIQUID VALVE D

EXV A

EXV B

EXV

EXV

CA

CA

C

CA

D

PIL

IARY A

PIL

IARY B

PILIARY C

PILIARY D

EC

K VALVE

CH

CAPILIARY TUBE

T3

Condense

. sensor

temp

r

HEAT

EXCHANGE

(EVAPORATOR)

Evaporator

2

T

temp. sensor

middle

T1 Room

temp. sensor

GAS VALVE A

GAS VALVE B

V

ALVE C

GAS

V

ALVE D

GAS

T2B-A Evaporator

temp. sensor outlet

T2B-B

T2B-C

T2B-D

Ac

Lo

switch

c

umulator

w pressu

4.4 Refrigeration circuit drawing of inverter 1 drive 5 type

INDOOR OUTDOOR

PILIARY A

CA

EXV

A

CA

B

C

D

E

PILIARY B

CA

PILIARY C

PILIARY D

CA

PILIARY E

CA

EXV

EXV

EXV

EXV

T2B-A Evaporator

temp. sensor outlet

HEAT

EXCHANGE

(EVAPORATOR)

T1 Room

temp. sensor

LIQ

D VALVE A

UI

LIQ

UI

D VALVE B

LIQUID VALVE C

LIQUID VALVE D

LIQUID VALVE E

GAS VALVE A

re

Compressor

T4 Ambient

temp. sensor

W

AY VALVE

4-

gh

pressure

Hi

switch

T5 Discharge

temp. sensor

CH

K VALVE

EC

CAPILIARY TUBE

T4 Ambient

temp. sensor

HEAT

EXCHANGE

(CONDENSER)

COOLING

HEATING

T3

Conden

r

se

temp. sensor

HEAT

EXCHANGE

(CONDENSER)

T2 Evaporator

temp. sensor

middle

GAS VALVE B

GA

S VALVE

GA

S VALVE

GA

VALVE E

S

T2B-B

T2B-C

C

Acc

um

Lo

w pre

switch

ulator

ssure

Com

pres

sor

T2B-D

D

T2B-E

4-

W

AY VALVE

Hig

h pre

switch

T5

arge

Disch

temp. sensor

ssure

CO

NG

OLI

HEATING

8

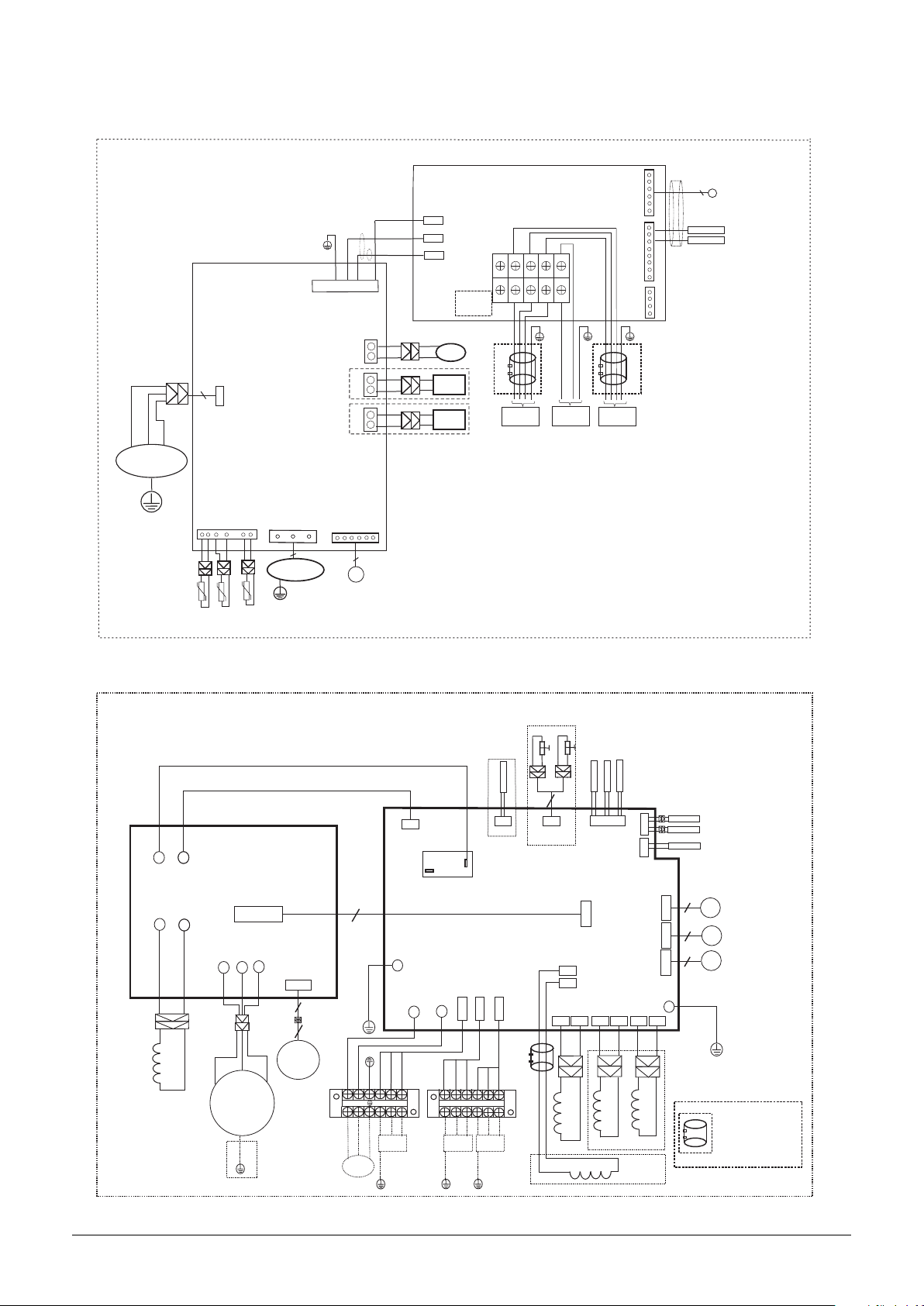

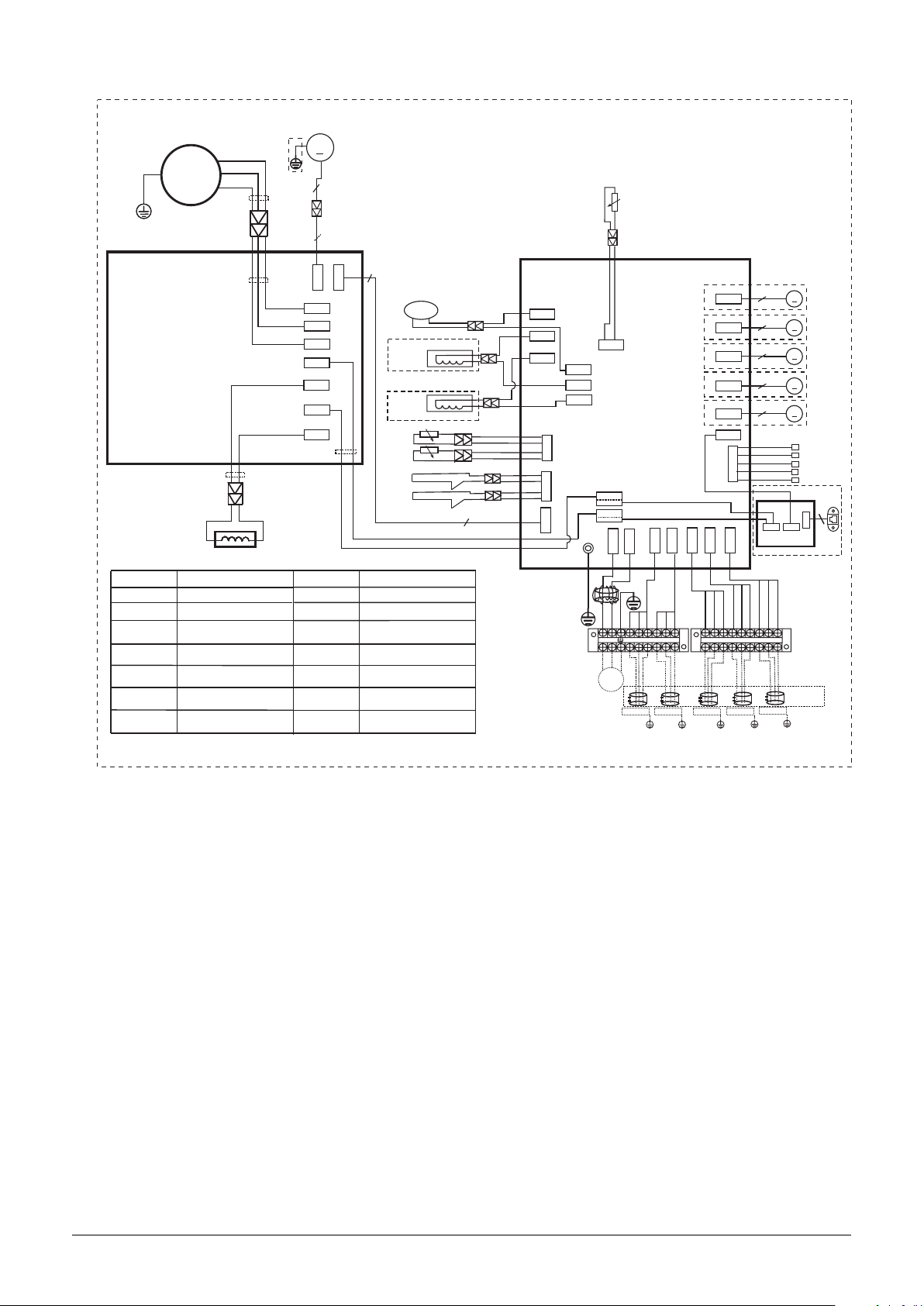

5. Wiring diagram

MUEX-14-H6.2 / MUEX-18-H6.2

BLUE

RED

BLACK

V

W

U

COMPRESSOR

Y/G

DISCHARGE TEMP. SENSOR

CN 50

3

CN 21

CONDENSER TEMP. SENSOR

AMBIENT TEMP. SENSOR

CN 7

3

DC-FAN

Y/G

CN 1A

CN 31

ELECTRONIC

EXPANSION

VALVE

CN 60

CN 17

CN 15

VALVE-B

5/6

BLACK

BLUE

BROWN

OPTIONAL

OPTIONAL

S

N

L

4-WAY

CRANKCASE

HEATER

PAN

HEATER

CN 1-3

CN 1-2

CN 1-1

NOTE:

S(1);S(2)

NO USED

CN 2

S(A)

S(2)

S(1)

S(B)

OPTIONAL

TO B

VALVE-A

CN 4

L(A)

N(A)

N

L(B)

N(B)

L

CN 3

TESTPORT

CN 7

5/6

ELECTRONIC

EXPANSIVE

VALVE

INDOOR PIPE

A

OUT TEMP

B

OPTIONAL

POWER

SUPPLY

TO A

Y/G

MUEX-21-H6.3 / MUEX-27-H6.3

RED(BROWN)

BLUE

CN4

CN2

BLUE

CN5

~

~

IPM BOARD

CN3

BLUE

BLUE

CN1

U

W

V

CN14

BLACK

RED

3

3

16022300001333

16022300000913

C

A

B

LOW PRESSURE PROTECT

RED

YELLOW

4

CN14

LOW/HIGH

MAIN BOARD

P1

P2

WHITE

WHITE

CN20

CN1

4-WAY

CN2

COM(3)

S-A

L-OUT

CN25

S-B

RY2

CN23

CN12

CompTop

S-C

CN29

ON(4)

5

P-1

N-IN

Y/G

L-IN

CN3

CN4

INDOOR PIPE

HIGH PRESSURE PROTECT

OUT TEMP

CN15

CN17

T2B

CN7

VALVE-C

VALVE-B

VALVE-A

HEAT2

CN9

CN22

CN19

CN18

P-2

CN8

CN21

CN6

HEAT1

CN5

OUTDOOR AMBIENT

TEMPERATURE SENSOR

T4

CONDENSER

T3

TEMPERATURE SENSOR

DISCHARGE SENSOR

6

6

6

Y/G

ELECTRONIC

EXPANSIVE

VALVE

ELECTRONIC

EXPANSIVE

VALVE

ELECTRONIC

EXPANSIVE

VALVE

Y/G

W(C)

DC FAN

RED

L

POWER

SUPPLY

BLACK

Y/G

N

L(A)

L(A)

BROWN

N(A)

N(A)

TO A

Y/G

S(A)

S(A)

BLUE

BLACK

BROWN

N(B)

L(B)

TO B

Y/G

BLUE

S(B)

BLACK

BROWN

L(C)

BLUE

N(C)

TO C

Y/G

BLACK

S(C)

4-WAY

HEATER1

OPTIONAL

REACT0R2 R05094A

OPTIONAL

HEATER2

NOT E:Use t he magn etic ri ng

(no t suppl ied, op tiona l part)

to hi tch the c onnec tive ca ble

of in door an d outdo or unit s

aft er inst allat ion. on e magne tic

rin g is used f or one ca ble.

REACTOR

V(S)

U(R)

COMPRESSOR

9

MUEX-28-H6.4

CN4

CN2

BLUE

CN5

~

~

IPM BOARD

CN3

BLUE

BLUE

16022300000803

C

A

D

RED(BROWN)

BLUE

CN29

LOW PRESSURE PROTECT

RED

4

CN14

CN12

CompTop

LOW/HIGH

L-OUT

ON(4)

CN1

U

W

V

CN14

BLACK

RED

3

5

P-1

N-IN

L-IN

Y/G

CN3

CN4

3

S-A

COM(3)

CN25

S-B

RY2

CN23

S-C

CN20

MAIN BOARD

S-D

WHITE

WHITE

CN16

CN1

B

HIGH PRESSURE PROTECT

YELLOW

CN15

T2B

VALVE-D

VALVE-C

CN21

VALVE-B

P1

P2

HEAT1

4-WAY

CN2

CN6

CN9

CN5

INDOOR PIPE

OUT TEMP

CN17

CN7

CN24

CN22

CN19

VALVE-A

CN18

P-2

HEAT2

CN8

OUTDOOR AMBIENT

TEMPERATURE SENSOR

T4

CONDENSER

T3

TEMPERATURE SENSOR

DISCHARGE SENSOR

6

6

6

6

Y/G

ELECTRONIC

EXPANSIVE

VALVE

ELECTRONIC

EXPANSIVE

VALVE

ELECTRONIC

EXPANSIVE

VALVE

ELECTRONIC

EXPANSIVE

VALVE

REACTOR

MUEX-36-H6.4

W

COMP

Y/G

DRIVER BOARD

CODE PART NAME

COMP

CAP1

EEV

FM1

FAN1

HEAT

H-PRO

U

YELLOW

COMPRESSOR

FAN MOTOR CAPACITOR

ELECTRIC EXPANSIVE

VALVE

OUTDOOR DC FAN

OUTDOOR AC FAN

CRANKCASE HEATING

HIGH PRESSURE SWITCH

V(S)

U(R)

COMPRESSOR

BLACK

RED

V

BLUE

L

Y/G

YELLOW

BLACK

RED

BLUE

BLUE

BLUE

W(C)

Y/G

DC FAN

FM1

3

CN1 9

W

V

U

CN5 4

CN5 1

CN5 3

CN5 2

L-PRO

RED

BLACK

L

N

POWER

SUPPLY

3

CN5 5

7

RED

BLACK

PFC INDUCTOR

L

LOW PRESSURE SWITCH

EXHAUST

TP

TEMPERATURE SENSOR

SV

CONDENSER

T3

TEMPERATURE SENSOR

OUTDOOR AMBIENT

T4

TEMPERATURE SENSOR

HEATSINK

TH

TEMPERATURE SENSOR

BROWN

BLUE

Y/G

S(A)

S(A)

N(A)

N(A)

L(A)

L(A)

TO A

Y/G

4-WAY1

SV

BLUE

HEAT_Y

HEAT_D

T3

T4

H-PRO

L-PRO

PART NAMECODE

4-WAY VALVE

BLACK

BLUE

OPTIONAL

OPTIONAL

BROWN

N(B)

L(B)

TO B

Y/G

7

BLUE

BLACK

S(B)

BLUE

BROWN

L(C)

BLACK

BLACK

BLUE

N(C)

TO C

Y/G

BLACK

S(C)

BROWNBROWN

L(D)

TO D

Y/G

CN3

BLUE

CN4

CN1 0

RDE

RDE

N(D)

CN8

CN9

CN7

BLUE

BLACK

S(D)

CN2 2

CN4 0

CN4 4

BLACK

Y/G

4-WAY

REACT0R2 R05094A

TP

CN3 3

MAIN BOARD

CN5

RED

CN6

CN1

CN2

P-1

RED

BLACK

L

N

POWER

SUPPLY

L(A) N(A) S(A)

TO A

HEATER1

OPTIONAL

OPTIONAL

CN3 0

BLUE

BROWN

Y/G

CN2 9

BLACK

HEATER2

5(6 )

CN2 0

A

5(6 )

CN2 1

B

5(6 )

CN1 7

C

5(6 )

CN1 8

D

5(6 )

CN1 9

E

CN1 6

T2B-A B C D E

CN13

CN5

CN2 7

CN2 8

BLUE

BROWN

L(B) N(B) S(B) L(C) N(C) S(C) L(D) N(D) S(D)

TO B

BLACK

BROWN

Y/G

TO C

BLUE

BLACK

BROWN

DR BOARD

BLUE

Y/G

NOT E:Use t he magn etic ri ng

(no t suppl ied, op tiona l part)

to hi tch the c onnec tive ca ble

of in door an d outdo or unit s

aft er inst allat ion. on e magne tic

rin g is used f or one ca ble.

M

M

M

EEV

M

M

INDOOR

PIPE OUT

TEMP A B C D E

OPTIONAL

RJ45

CN2

4

CN1

FOR USER

TO CONNECT

BLACK

OPTIONAL

TO D

Y/G

10

MUEX-42-H6.5

COMP

Y/G

DRIVER BOARD

YELLOW

CODE PART NAME

COMP

H-PRO

FAN MOTOR CAPACITOR

CAP1

EEV

FM1

FAN1

HEAT

HIGH PRESSURE SWITCH

ELECTRIC EXPANSIVE

VALVE

OUTDOOR DC FAN

OUTDOOR AC FAN

CRANKCASE HEATING

BLACK

W

RED

V

BLUE

U

L

COMPRESSOR

BLACK

RED

BLUE

BLUE

BLUE

YELLOW

Y/G

FM1

3

CN1 9

W

V

U

CN5 4

CN5 1

CN5 3

CN5 2

3

L

L-PRO

TP

SV

T3

T4

TH

CN5 5

7

SV

RED

BLACK

PART NAMECODE

PFC INDUCTOR

LOW PRESSURE SWITCH

EXHAUST

TEMPERATURE SENSOR

4-WAY VALVE

CONDENSER

TEMPERATURE SENSOR

OUTDOOR AMBIENT

TEMPERATURE SENSOR

HEATSINK

TEMPERATURE SENSOR

4-WAY1

BLUE

HEAT_Y

HEAT_D

T3

T4

H-PRO

L-PRO

BLUE

OPTIONAL

OPTIONAL

BLACK

BLACK

CN3

BLUE

CN4

CN1 0

RDE

RDE

CN8

CN9

CN7

BLUE

7

TP

CN3 3

CN2 2

CN4 0

CN4 4

MAIN BOARD

BLACK

CN5

RED

CN6

CN1

P-1

Y/G

RED

BLACK

L

N

POWER

CN2

L(A)

TO A

BLUE

BROWN

N(A)

S(A)

CN3 0

BLACK

BROWN

L(B)

N(B)

TO B

Y/G

CN2 8

CN2 9

BLACK

BLUE

L(C) N(C) S(C) L(D) N(D) S(D) L(E) N(E) S(E)

S(B)

TO C

Y/G

A

B

C

D

E

CN2 7

BROWN

CN2 0

CN2 1

CN1 7

CN1 8

CN1 9

CN1 6

BLUE

Y/G

5(6 )

5(6 )

5(6 )

5(6 )

5(6 )

T2B-A B C D E

CN13

CN2 6

BLACK

BLUE

BROWN

BLACK

TO D

Y/G

CN5

DR BOARD

BLACK

BLUE

BROWN

TO E

M

M

M

EEV

M

M

PIPE OUT

TEMP A B C D E

OPTIONAL

CN2

CN1

OPTIONAL

Y/G

INDOOR

RJ45

4

FOR USER

TO CONNECT

11

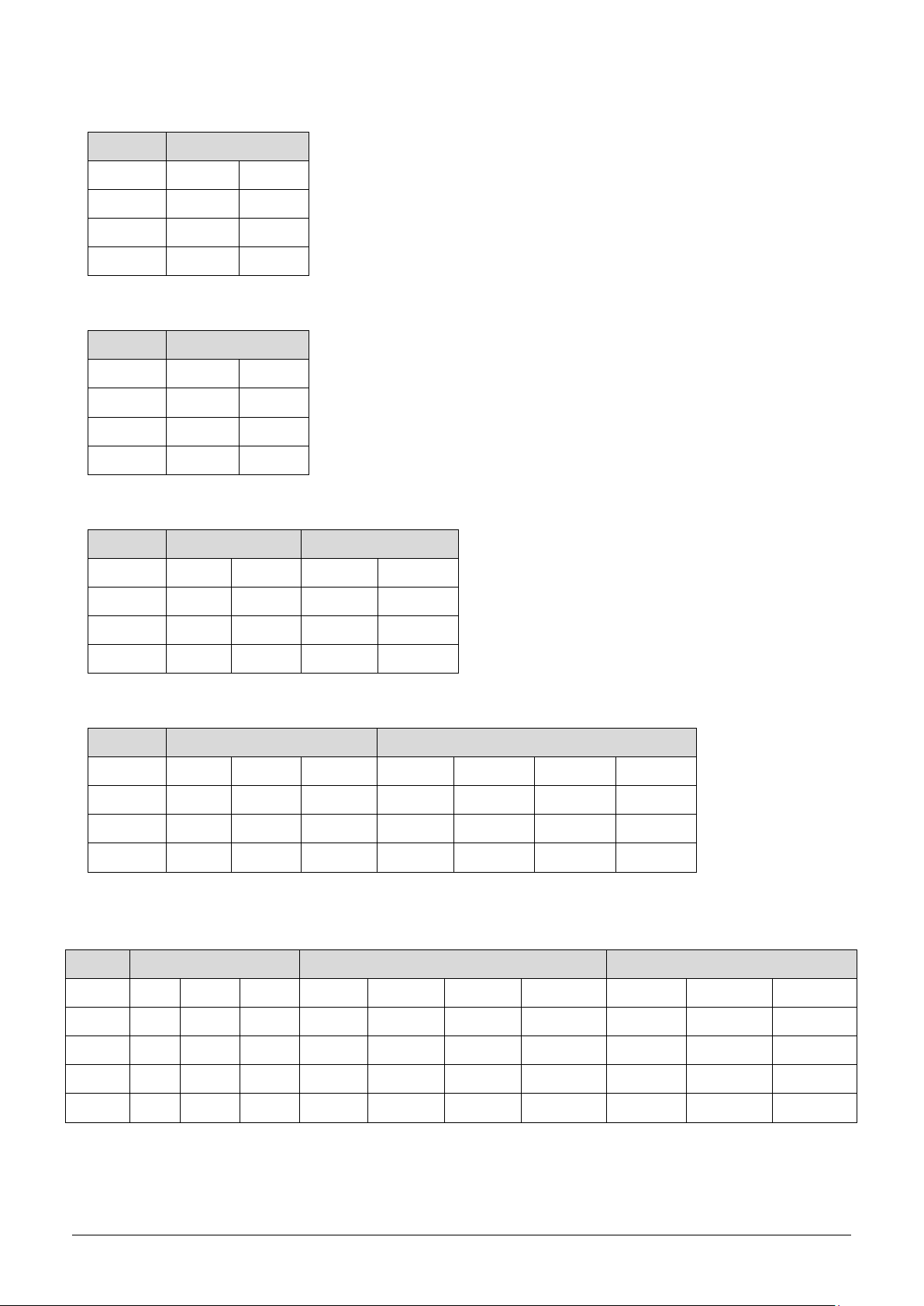

6. Indoor units combination

6.1 Indoor unit combination for MUEX-14-H6.2

One unit Two unit

7 7+7 9+9

9 7+9 9+12

12 7+12

18

6.2 Indoor unit combination for MUEX-18-H6.2

One unit Two unit

7 7+7 9+9

9 7+9 9+12

12 7+12 9+18

18 7+18 12+12

6.3 Indoor unit combination for MUEX-21-H6.3

One unit Two unit Three unit

7 7+7 9+9 7+7+7 7+9+12

9 7+9 9+12 7+7+9 9+9+9

12 7+12 9+18 7+7+12 9+9+12

18 7+18 12+12 7+9+9 7+12+12

6.4 Indoor unit combination for MUEX-27-H6.3

One unit Two unit Three unit

7 7+7 9+9 12+18 7+7+7 7+9+9 7+12+18 9+12+12

9 7+9 9+12 18+18 7+7+9 7+9+12 9+9+9 9+12+18

12 7+12 9+18 7+7+12 7+9+18 9+9+12 12+12+12

18 7+18 12+12 7+7+18 7+12+12 9+9+18

6.5 Indoor unit combination for MUEX-28-H6.4

One unit Two unit Three unit Four unit

7 7+7 9+9 12+18 7+7+7 7+9+9 7+12+18 9+12+18 7+7+7+7 7+7+9+9 7+9+9+12

9 7+9 9+12 12+24 7+7+9 7+9+12 9+9+9 12+12+12 7+7+7+9 7+7+9+12 7+9+12+12

12 7+12 9+18 18+18 7+7+12 7+9+18 9+9+12 12+12+18 7+7+7+12 7+7+9+18 9+9+9+9

18 7+18 12+12 7+7+18 7+9+24 9+9+18 7+7+7+18 7+7+12+12 9+9+9+12

24 7+24 9+24 7+7+24 7+12+12 9+12+12 7+9+9+9

One Unit

Two Unit

Three Unit

7

7+7

9+18

7+7+7

7+9+18

9+9+12

12+12+12

9

7+9

9+24

7+7+9

7+9+24

9+9+18

12+12+18

12

7+12

12+12

7+7+12

7+12+12

9+9+24

12+12+24

18

7+18

12+18

7+7+18

7+12+18

9+12+12

12+18+18

24

7+24

12+24

7+7+24

7+12+24

9+12+18

9+9

18+18

7+9+9

7+18+18

9+12+24

9+12

7+9+12

9+9+9

9+18+18

Four Unit

7+7+7+7

7+7+9+18

7+9+9+12

7+12+12+12

9+9+12+12

7+7+7+9

7+7+9+24

7+9+9+18

7+12+12+18

9+9+12+18

7+7+7+12

7+7+12+12

7+9+9+24

7+12+12+24

9+9+12+24

7+7+7+18

7+7+12+18

7+9+12+12

9+9+9+9

9+12+12+12

7+7+7+24

7+7+12+24

7+9+12+18

9+9+9+12

9+12+12+18

7+7+9+9

7+7+18+18

7+9+12+24

9+9+9+18

12+12+12+12

7+7+9+12

7+9+9+9

7+9+18+18

9+9+9+24

12+12+12+18

Five Unit

7+7+7+7+7

7+7+7+9+18

7+7+9+9+24

7+9+9+12+12

9+9+9+12+12

7+7+7+7+9

7+7+7+9+24

7+7+9+12+18

7+9+9+12+18

9+9+9+12+18

7+7+7+7+12

7+7+7+12+18

7+7+12+12+12

7+9+12+12+12

9+9+12+12+12

7+7+7+7+18

7+7+7+18+18

7+7+12+12+18

7+9+12+12+18

9+12+12+12+12

7+7+7+7+24

7+7+9+9+9

7+9+9+9+9

9+9+9+9+9

9+12+12+12+18

7+7+7+9+9

7+7+9+9+12

7+9+9+9+12

9+9+9+9+12

12+12+12+12+12

7+7+7+9+12

7+7+9+9+18

7+9+9+9+18

9+9+9+9+18

Two unit

Three unit

Four unit

7

7+7

9+18

7+7+7

7+9+18

9+9+12

12+12+12

7+7+7+7

7+7+9+24

7+9+12+12

9+9+12+12

9

7+9

9+24

7+7+9

7+9+24

9+9+18

12+12+18

7+7+7+9

7+7+12+12

7+9+12+18

9+9+12+18

12

7+12

12+12

7+7+12

7+12+12

9+9+24

12+12+24

7+7+7+12

7+7+12+18

7+9+18+18

9+12+12+12

18

7+18

12+18

7+7+18

7+12+18

9+12+12

12+18+18

7+7+7+18

7+7+18+18

7+12+12+12

9+12+12+18

24

7+24

12+24

7+7+24

7+12+24

9+12+18

7+7+7+24

7+9+9+9

7+12+12+18

12+12+12+12

9+9

18+18

7+9+9

7+18+18

9+12+24

7+7+9+9

7+9+9+12

9+9+9+9

12+12+12+18

9+12

7+9+12

9+9+9

9+18+18

7+7+9+12

7+9+9+18

9+9+9+12

7+7+9+18

7+9+9+24

9+9+9+18

12

6.6 Indoor unit combination for MUEX-36-H6.4

6.7 Indoor unit combination for MUEX-42-H6.5

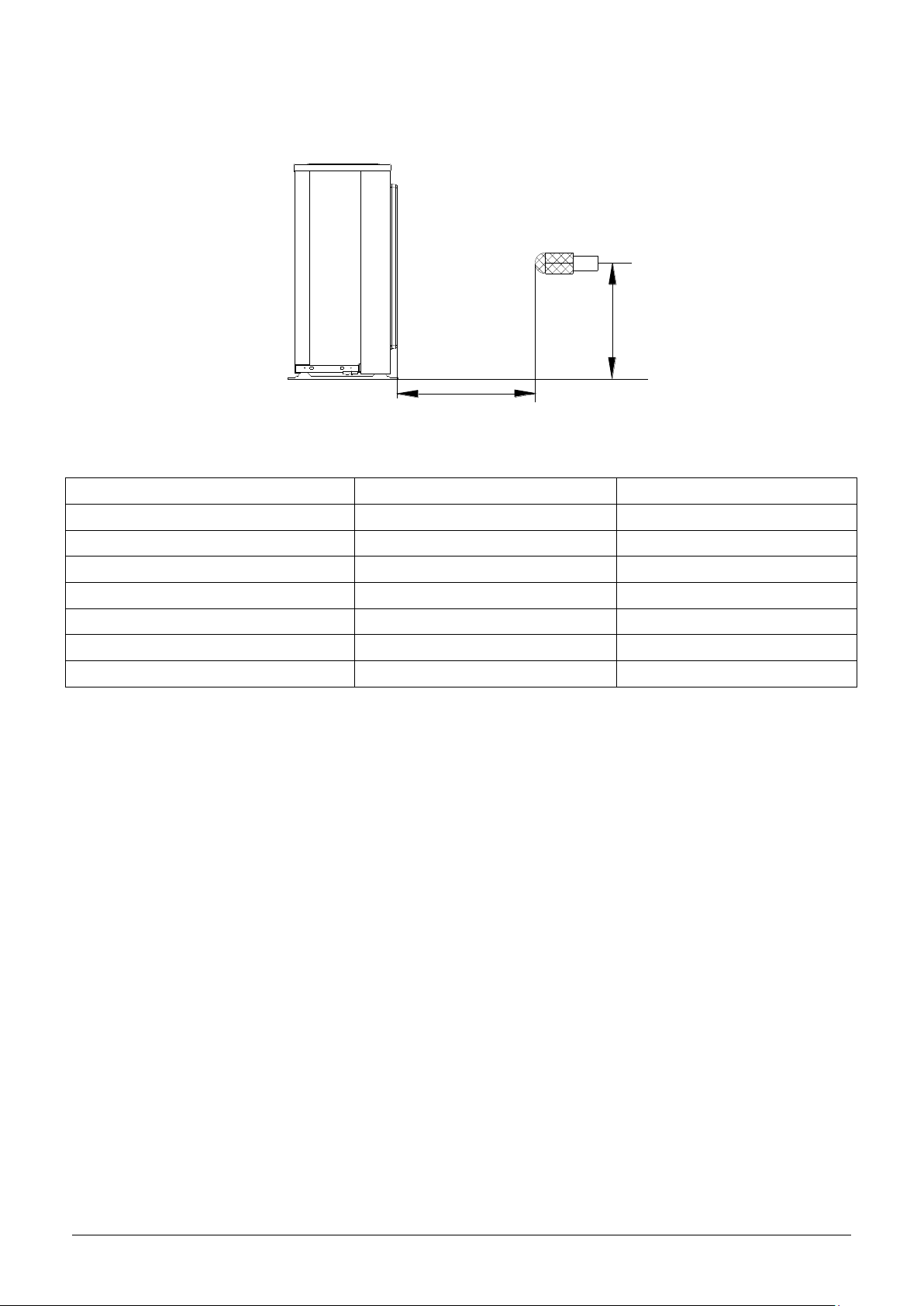

H

1.0m

Outdoor Unit

Microphone

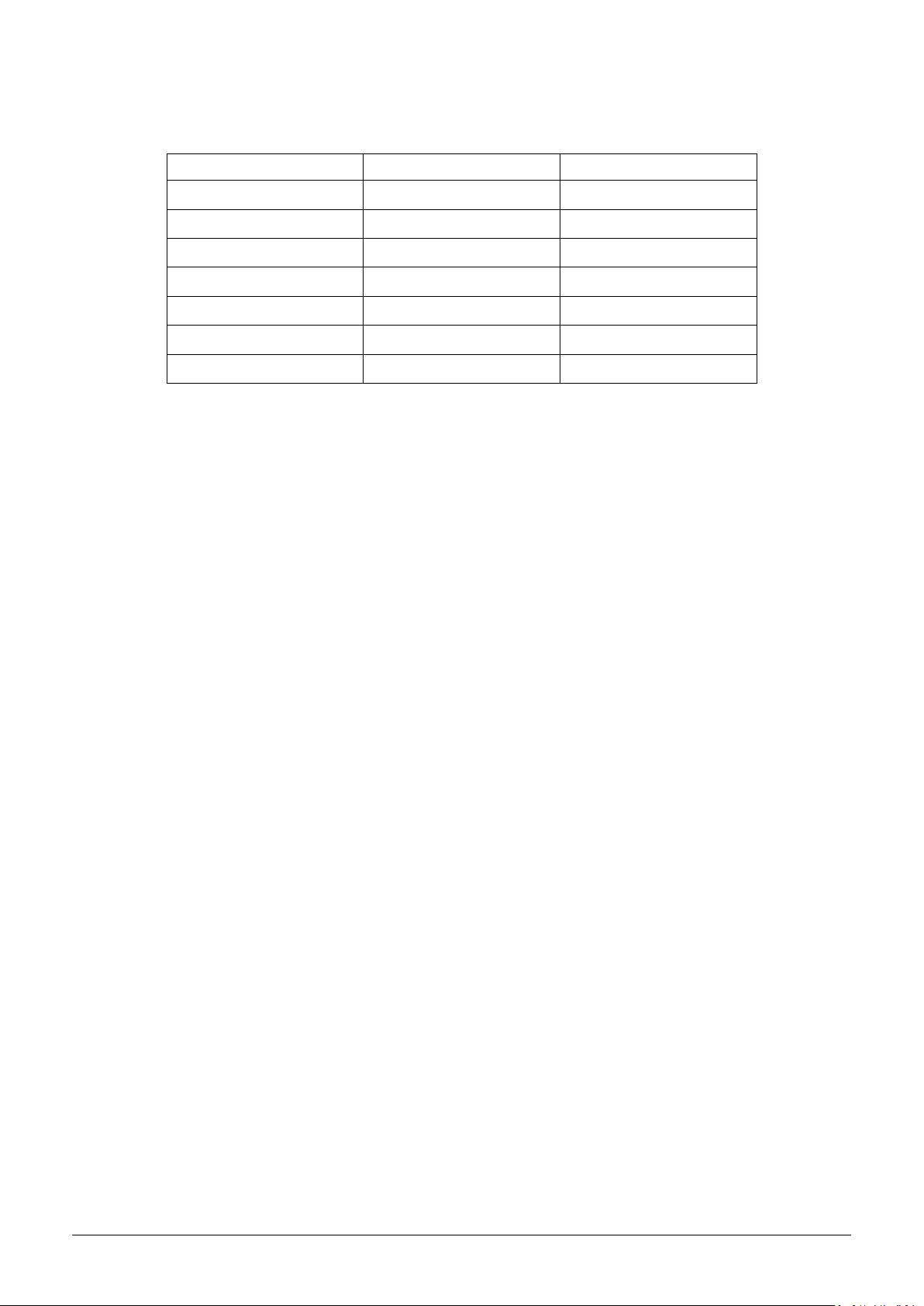

Model

Noise Power dB(A)

Noise level dB(A)

MUEX-14-H6.2

MUEX-18-H6.2

65

56.5

MUEX-21-H6.3

65

57.5

MUEX-27-H6.3

68

59.5

MUEX-28-H6.4

66

60

MUEX-36-H6.4

68

63.5

MUEX-42-H6.5

68

62

13

7. Sound Levels

Note: H= 0.5 × height of outdoor unit

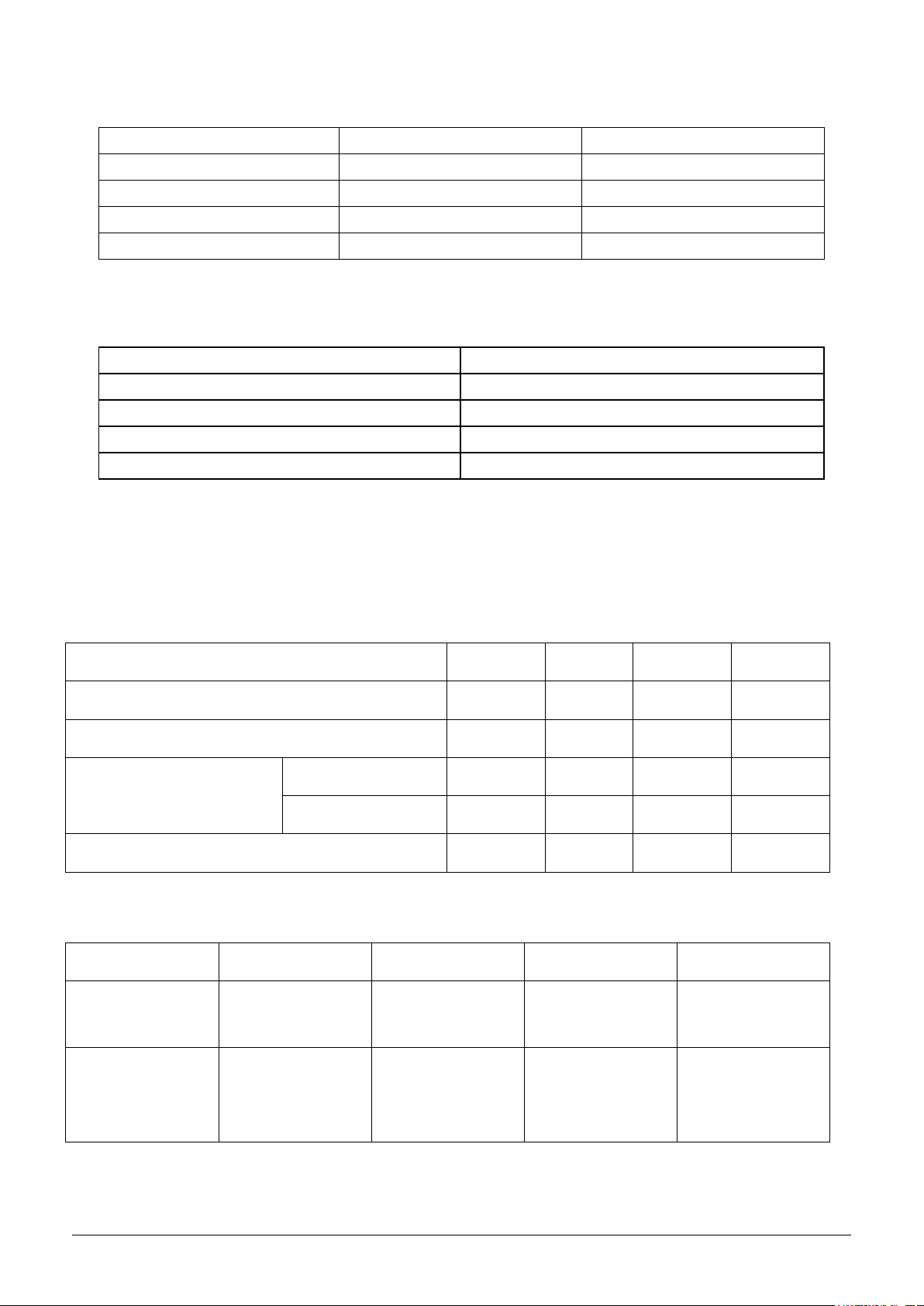

Outside diameter

Torque

Additional tightening torque

mm

N.cm

N.cm

Ф6.35

1500(153kgf.cm)

1600(163kgf.cm)

Ф9.52

2500(255kgf.cm)

2600(265kgf.cm)

Ф12.7

3500(357kgf.cm)

3600(367kgf.cm)

Rated current of appliance

Nominal cross-sectional area (mm²)

>3 and ≤6

0.75

>6 and ≤10

1

>10 and ≤16

1.5

>16 and ≤25

2.5

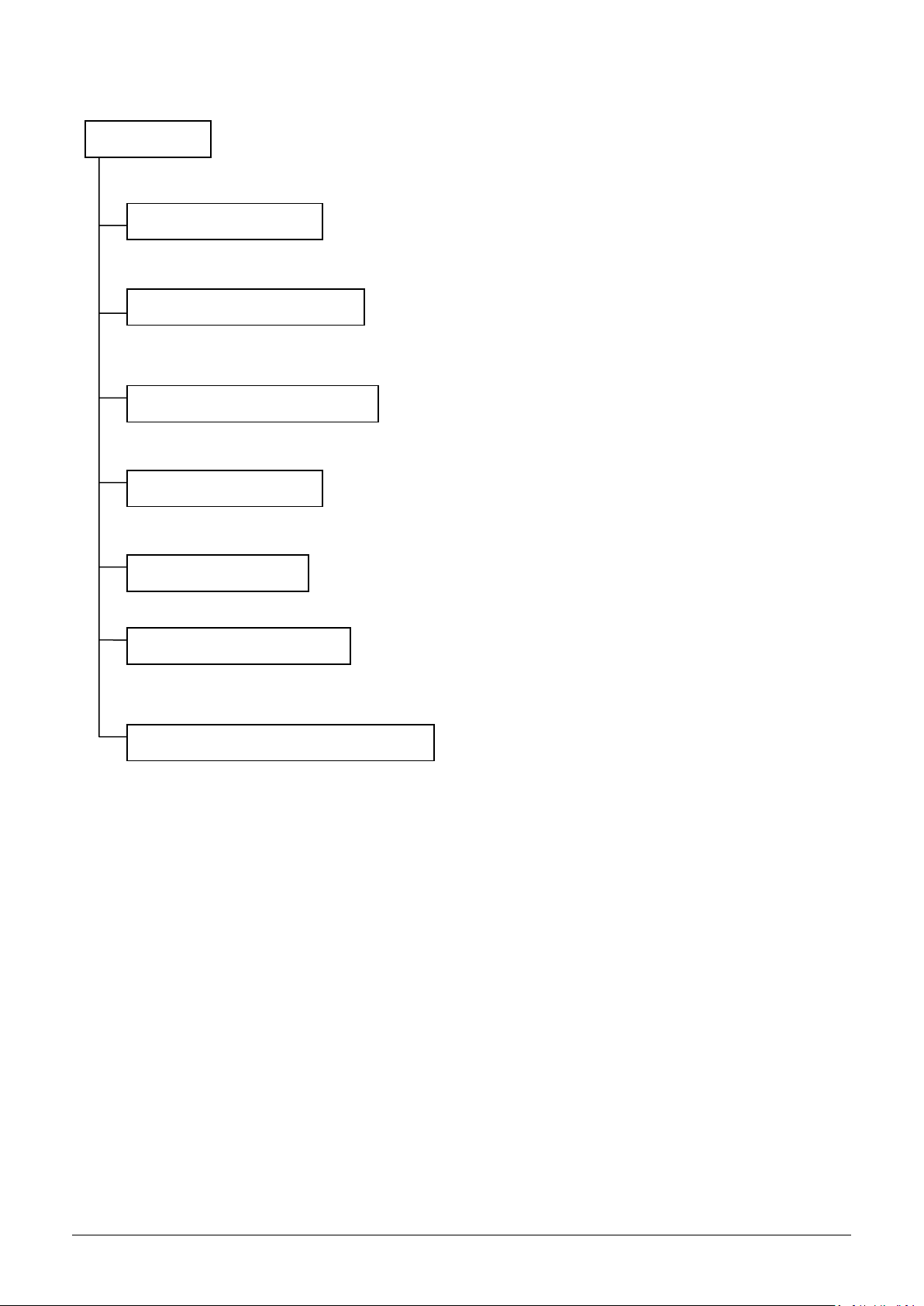

1 drive 2

1 drive 3

1 drive 4

1 drive 5

Max. length for all rooms (m)

30

45

60

75

Max. length for one IU (m)

20

25

30

30

Max. height difference

between IU and OU (m)

OU higher than IU

10

10

10

10

OU lower than IU

15

15

15

15

Max. height difference between IUs (m)

10

10

10

10

1 drive 2

1 drive 3

1 drive 4

1 drive 5

Chargeless pipe

length (m)

10

15

20

25

Additional

refrigerant charge

(g)

15 x (length for all

rooms - 10)

15 x (length for all

rooms - 15)

15 x (length for all

rooms - 20)

15 x (length for all

rooms - 25)

14

8. Installation Details

8.1 Wrench torque sheet for installation

8.2 Connecting the cables

The power cord of connect should be selected according to the following specifications sheet.

The cable size and the current of the fuse or switch are determined by the maximum current indicated on the

nameplate which located on the side panel of the unit. Please refer to the nameplate before selecting the

cable, fuse and switch.

8.3 Pipe length and the elevation

Maximum piping length and height difference

Additional refrigerant charge

Caution:

Indoor unit

Extension pipe diameter (mm/inch)

Model

Pipe diameter (mm/inch)

7K9K12K

Liquid

6.35(1/4)

Liquid

6.35(1/4)

Gas

9.52(3/8)

Gas

9.52(3/8)

18K

Liquid

6.35(1/4)

Liquid

6.35(1/4)

Gas

12.7(1/2)

Gas

12.7(1/2)

24K

Liquid

9.52(3/8)

Liquid

9.52(3/8)

Gas

15.9(5/8)

Gas

15.9(5/8)

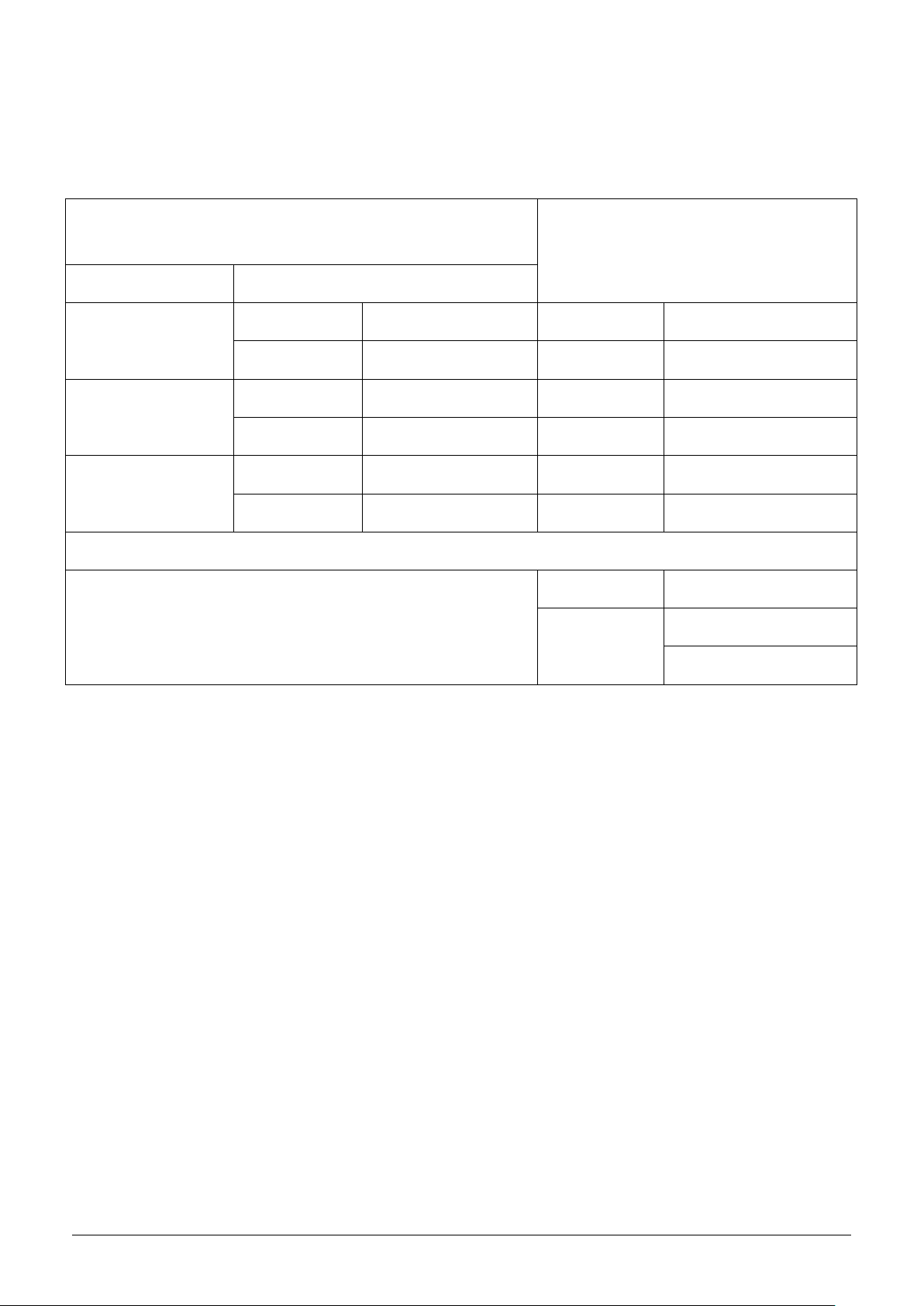

Outdoor unit union diameter (mm/inch)

Indoor unit A/B/C/D/E

Liquid

6.35(1/4)

Gas

9.52(3/8)

12.7(1/2)

15

● Refrigerant pipe diameter is different according to indoor unit to be connected. When using the

extension pipe, refer to the tables below.

● When refrigerant pipe diameter is different from that of outdoor unit union (for 18K indoor unit), additional

transfer connector needs to be used on outdoor unit union.

8.4 Installation for the first time

Air and moisture in the refrigerant system have undesirable effects as below:

● Pressure in the system rises.

● Operating current rises.

● Cooling or heating efficiency drops.

● Moisture in the refrigerant circuit may freeze and block capillary tubing.

● Water may lead to corrosion of parts in the refrigerant system.

Therefore, the indoor units and the pipes between indoor and outdoor units must be leak tested and

evacuated to remove gas and moisture from the system.

Gas leak check (Soap water method):

Apply soap water or a liquid neutral detergent on the indoor unit connections or outdoor unit

connections by a soft brush to check for leakage of the connecting points of the piping. If bubbles come out,

the pipes have leakage.

1. Air purging with vacuum pump

(Indoor unit)

(Liquid side)

(Gas side)

Vacuum

pump

Vacuum

pump

Lo

Hi

Handle Hi

Two-way valve

Close

Manifold valve

Compound meter

Pressure

gauge

-0.1MPa

Handle Lo

Charge hose

Charge hose

(Outdoor unit)

Close

Three-way valve

16

1) Completely tighten the flare nuts of the indoor and outdoor units, confirm that both the 2-way and 3-way

valves are set to the closed position.

2) Connect the charge hose with the push pin of handle lo to the 3-way valves gas service port..

3) Connect the charge hose of handle hi connection to the vacuum pump.

4) Fully open the handle Lo of the manifold valve.

5) Operate the vacuum pump to evacuate.

6) Make evacuation for 30 minutes and check whether the compound meter indicates -0.1Mpa. If

the meter does not indicate -0.1Mpa after pumping 30 minutes, it should be pumped 20 minutes more. If the

pressure can’t achieve -0.1Mpa after pumping 50 minutes, please check if there are some leakage points.

Fully close the handle Lo valve of the manifold valve and stop the operation of the vacuum pump. Confirm

that the gauge needle does not move (approximately 5 minutes after turning off the vacuum pump).

7) Turn the flare nut of the 3-way valves about 45° counterclockwise for 6 or 7seconds after the gas

coming out, then tighten the flare nut again. Make sure the pressure display in the pressure indicator is a

little higher than the atmosphere pressure. Then remove the charge hose from the 3 way valve.

8) Fully open the 2 way valve and 3 way valve and securely tighten the cap of the 3 way valve.

17

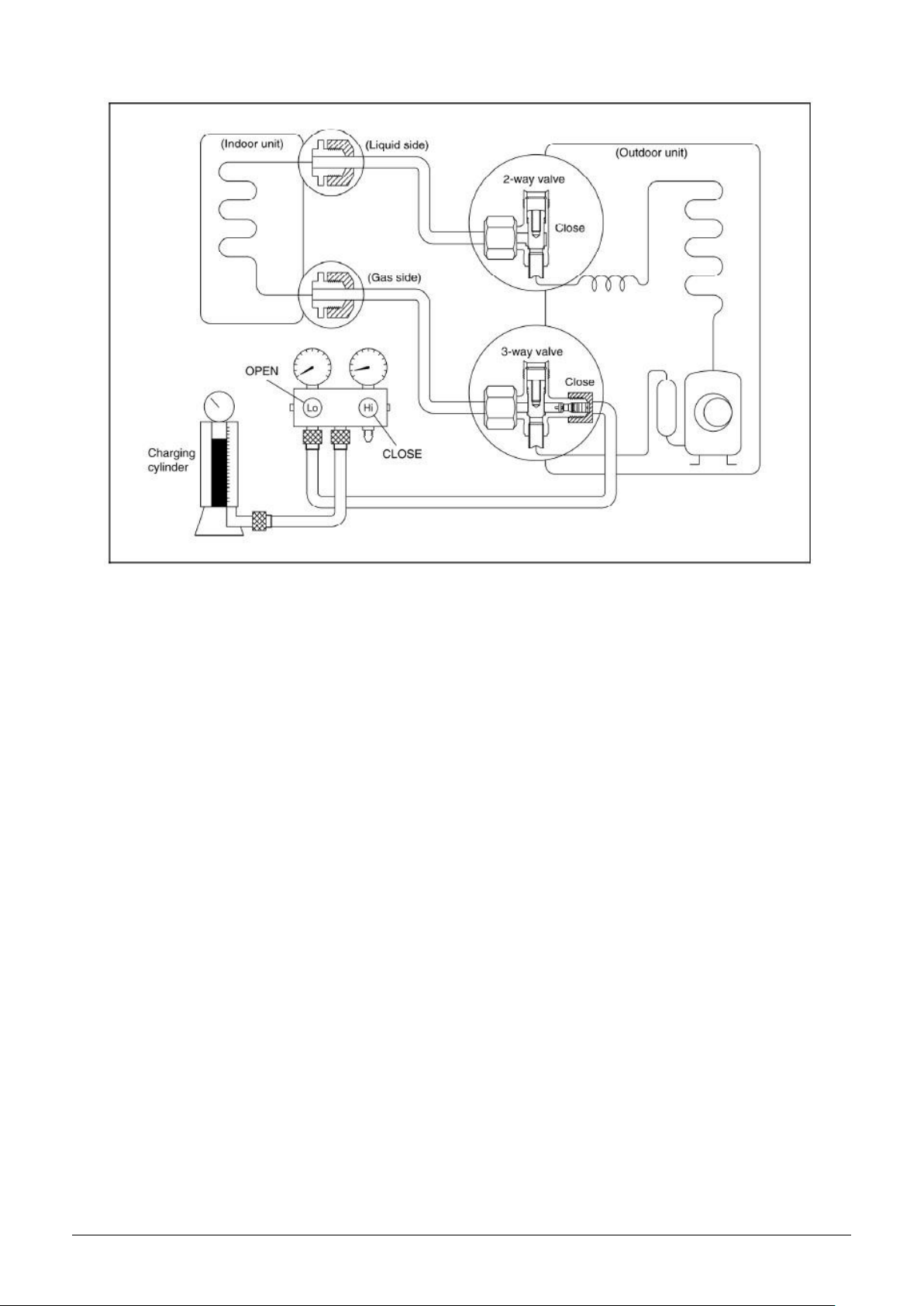

2. Air purging by refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the closed position.

2). Connect the charge set and a charging cylinder to the service port of the 3-way valve.

3). Air purging.

Open the valves on the charging cylinder and the charge set. Purge the air by loosening the flare nut on the

2-way valve approximately 45’ for 3 seconds then closing it for 1 minute; repeat 3 times.

After purging the air, use a torque wrench to tighten the flare nut on the 2-way valve.

4). Check the gas leakage.

Check the flare connections for gas leakage.

5). Discharge the refrigerant.

Close the valve on the charging cylinder and discharge the refrigerant by loosening the flare nut on the

2-way valve approximately 45’ until the gauge indicates 0.3 to 0.5 Mpa.

6). Disconnect the charge set and the charging cylinder, and set the 2-way and 3-way valves to the open

position.

Be sure to use a hexagonal wrench to operate the valve stems.

7). Mount the valve stems nuts and the service port cap.

Be sure to use a torque wrench to tighten the service port cap to a torque 18N·m.

Be sure to check the gas leakage.

Loading...

Loading...