mundoclima H6M, MUEX-18-H6.2, MUEX-14-H6.2, MUEX-27-H6.3, MUEX-28-H6.4 Owner's Manual

...

MULTI INVERTER SERIE H6M

Installation and owner's

manual

www.mundoclima.com

Thank you very much for purchasing our products.

Please read this manual carefully before installing

and using the unit.

CL20440 to CL20457

English

CONTENT

INSTALLATION MANUAL ............................................................................................ 3

Safety precautions ........................................................................................................ 4

Indoor unit installation ................................................................................................... 5

Outdoor unit installation ................................................................................................ 6

Refrigerant pipe connection .......................................................................................... 8

Electrical installation .....................................................................................................10

Drain joint installation ...................................................................................................12

Start up and performance testing .................................................................................12

Function of automatic wiring/piping correction .............................................................13

OWNERS MANUAL .................................................................................................... 14

Safety precautions .......................................................................................................15

Description and operating instructions .........................................................................16

Care and maintenance ................................................................................................ 20

Troubleshooting ........................................................................................................... 22

Disposal ....................................................................................................................... 24

REMOTE CONTROLLER ............................................................................................ 25

IMPORTANT

Thank you for selectiong super quality Air Conditiones. To ensure satisfactory operation for many ears to come,

this manual should be read carefully before the installation and before using the air conditioner. After reading,

store it a safe place. Please refer to the manual for questions on use or in the event that any irregularities occur.

This Air Conditioner should be used for hosehold use.

This unit must be installed by a professional according RD 795/2010, RD 1027/2007 and RD 238/2013.

WARNING

The power supply must be SINGLE-PHASE (one phase (L) and one neutral (N)) with his grounded power (GND)

and his manual switch. Any breach of these specifications involve a breach of the warranty conditions provided by

the manufacturer.

NOTE

In line with the company's policy of continual product improvement, the aesthetic and dimensional characteristics,

technical data and accessories of this appliance may be changed without notice.

ATTENTION

Read this manual carefully before installind or operating you new air conditioning unit. Make sure to save this

manual for future reference.

2

INSTALLATION MANUAL

Before using your air conditioner, please read

this manual carefully and keep it for future reference..

INVERTER SPLIT-TYPE

ROOM AIR CONDITIONER

The design and specifications are subject to

change without prior notice for

product improvement. Consult with the sales

agency or manufacturer for details.

Read This Manual:

Inside you will find many helpful hints on how to use and

maintain your air conditioner properly.

Just a little preventative care on your part can save you

a great deal of time and money over the life of your air

conditioner.

You'll find manyanswers to common problems in the

chart of troubleshooting tips. If you review the chart of

Troubleshooting Tips first, you may not need to call for

service.

3

SAFETY PRECAUTIONS

1. Safety precautions

Read the follow SAFETY PRECAUTIONS carefully before installation.

Electrical work must be installed by a l ic en se d el ectrician. Be sure to use the correct rating

of the power plug and main circu it f or t he m od el t o be i ns ta lled.

Incorrect installation due to igno ri ng o f th e in st ru ction will cause harm or damage.

The seriousness is classified by the following indications.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to property.

The items to be followed are classified by the symbols:

Symbol with background white denotes item that is PROHIBITED from doing.

WARNING

1) Engage dealer or specialist for installation. If installation done by the user is defective, it will cause water

leakage, electrical shock fire.

2) Install according to this installation instructions strictly. If installation is defective, it will cause water

leakage, electrical shock fire.

3) Use the attached accessories parts and specified parts for installation. otherwise, it will cause the set to fall,

water leakage, electrical shock fire.

4) Install at a strong and firm location which is able to withstand the set s weight. If the strength is not enough

or installation is not properly done, the set will drop and cause injury.

5) For electrical work, follow the local national wiring standard, regulation and this installation instructions. An

independent circuit and single outlet must be used. If electrical circuit capacity is not enough or defect found

in electrical work, it will cause electrical shock fire.

6) Use the specified cable and connect tightly and clamp the cable so that no external force will be acted on

the terminal. If connection or fixing is not perfect, it will cause heat-up or fire at the connection.

7) Wiring routing must be properly arranged so that control board cover is fixed properly. If control board cover

is not fixed perfectly, it will cause heat-up at connection point of terminal, fire or electrical shock.

8) When carrying out piping connection, take care not to let air substances other than the specified

refrigerant go into refrigeration cycle. Otherwise, it will cause lower capacity, abnormal high pressure

in the refrigeration cycle, explosion and injury.

9) Do not modify the length of the power supply cord or use of extension cord, and do not share the

single outlet with other electrical appliances. Otherwise, it will cause fire or electrical shock.

,

CAUTION

1) This equipment must be earthed and installed with earth leakage current breaker. It may cause electrical

shock if grounding is not perfect.

2) Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and

accumulates at surrounding of the unit, it may cause fire.

3) Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water

may enter the room and damage the furniture.

4

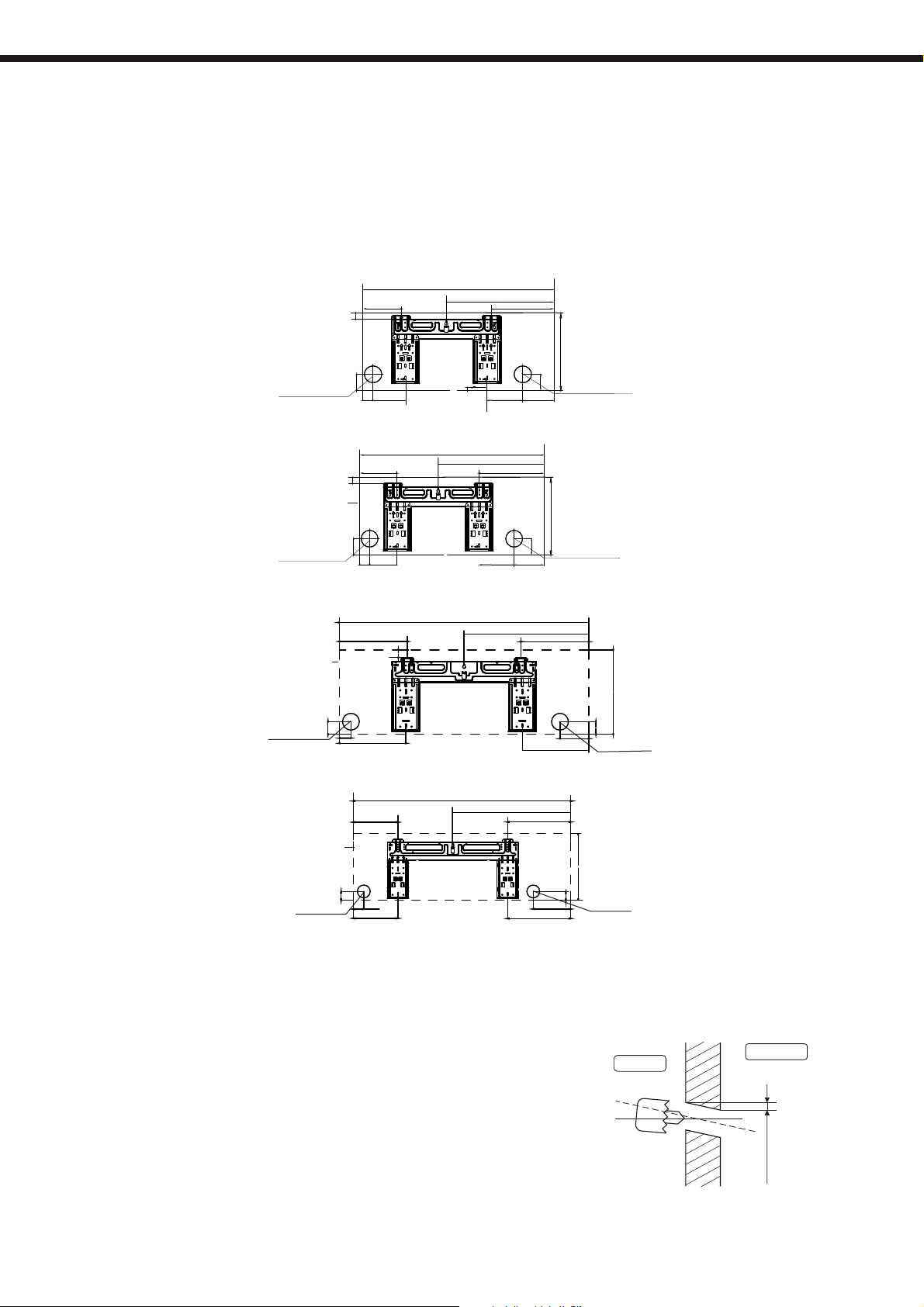

INDOOR UNIT INSTALLATION

2. Indoor unit installation

Fit the installation plate

1)

Fit the installation plate horizontally on structural parts of the wall with spaces

arround the installation plate.

2)

If the wall is made of brick, concrete or like, drill five or eight 5mm diameter holes

in the wall. Insert Clip anchor for appropiates mounting screws.

Dimensiones

unidad interior

Agujero lado

izquierdo 65 mm

Dimensiones

unidad interior

Agujero lado

izquierdo 65 mm

Dimensiones

unidad interior

Agujero lado

izquierdo 65 mm

128 mm

27 mm

63 mm

107 mm 137 mm

39 mm

MUPR-09-H6M

163 mm

27 mm

53 mm

128 mm 112 mm

48 mm

39 mm

262.2 mm

29.2 mm

44 mm

256.6 mm

MUPR-12-H6M

717 mm

805 mm

964 mm

412 mm

11mm(0.43in)

427.9 mm

MUPR-18-H6M

237 mm

224.6 mm

113 mm

481.6 mm

117 mm

53 mm

262 mm

256.6 mm

302 mm

Agujero lado derecho

63 mm

65 mm

302 mm

Agujero lado

derecho

65 mm

48 mm

111 mm

Agujero lado

derecho 65mm

325 mm

Dimensiones

unidad interior

Agujero lado

izquierdo 65 mm

45 mm

227.8 mm

53.7 mm

227.8 mm

1106 mm

MUPR-24-H6M

598.4 mm

Drill a hole in the w all

1. Determine hole positions according to left and right

side of the installation plate. The hole center is obtained

by measuring the distance as shown in the diagram above.

2. Dirll the piping plate hole with φ65mm hole-core drill.

3. Drill the piping hole at either the right or the left and the

hole should be slightly slanted to the outdoor side.

4. Always take steps to protect the pipe when drilling metal

grid, metal plate or the like.

5

319.5 mm

189.4 mm

319.5 mm

45 mm

342 mm

Agujero

lado derecho 65 mm

Wall

Outdoor

Indoor

5-7mm

INDOOR AND OUTDOOR UNIT INSTALLATION

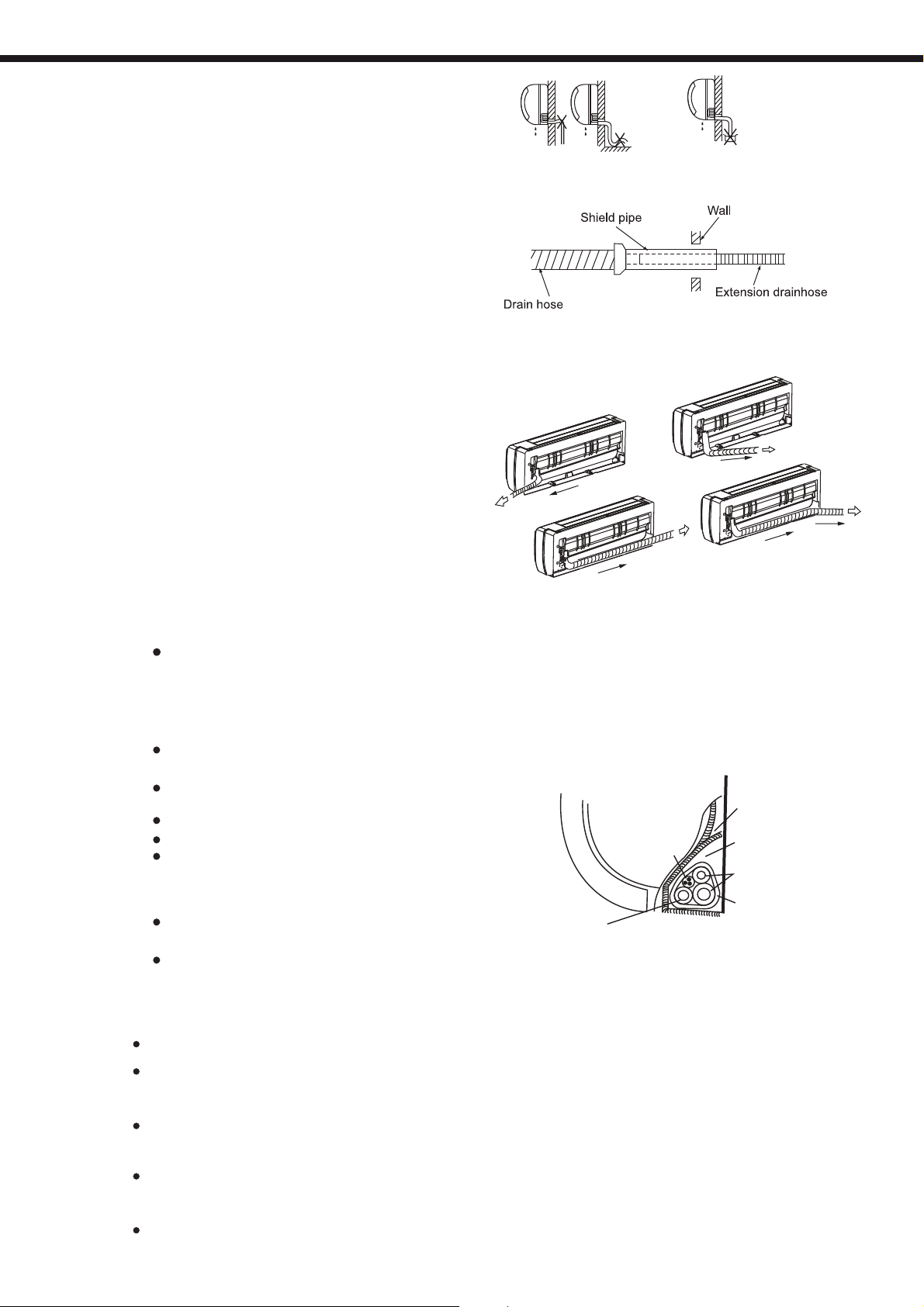

Connective pipe and drainage installation

1. Run the drain hose sloping downward.

Do not install the drain hose as

illustrated in Fig.7.

2. When connecting extension drain hose,

insulate the connecting part of extension

drain hose with a shield pipe, do not let

the drain hose slack.

Connective pipe installation

1. For the left-hand and right-hand piping,

remove the pipe cover from the side

panel.

2. For the rear-right-hand and rear-left-hand

piping, install the piping as shown in Fig.10.

3. Fix the end of the connective pipe. (Refer

to Tightening Connection in REFRIGERANT

PIPING CONNECTION)

Piping and w rapping

Bundle the tubing, connecting cable, and drain

hose with tape securely, evenly as shown in

Fig.11.

Because the condensed water from rear of the

indoor unit is gathered in ponding box and is

piped out of room. Do not put anything else in

the box.

Do not block water flow by a rise.

Right-hand piping

Left-hand piping

Fig.9

Do not put the end of

drain hose into water.

Fig.8

Rear-right piping

Rear-left piping

Fig.10

Caution

Connect the indoor uni t fi rs t, t he n th e

outdoor unit.

Do not allow the piping to let out fro m

the back of the indoor unit.

Be careful not to let the drain hose sla ck .

Heat insulated both of the aux il ia ry p ip ing.

Be sure that the drain hose is loc at ed a t

the lowest side of the bundl e. L oc at in g

at the upper side can cause drain pa n

to overflow inside the unit.

Never intercross nor i nt er tw is t th e po we r

wire with any other wiring .

Run the drain hose sloped do wn wa rd t o

drain out the condensed wa te r sm oo th ly.

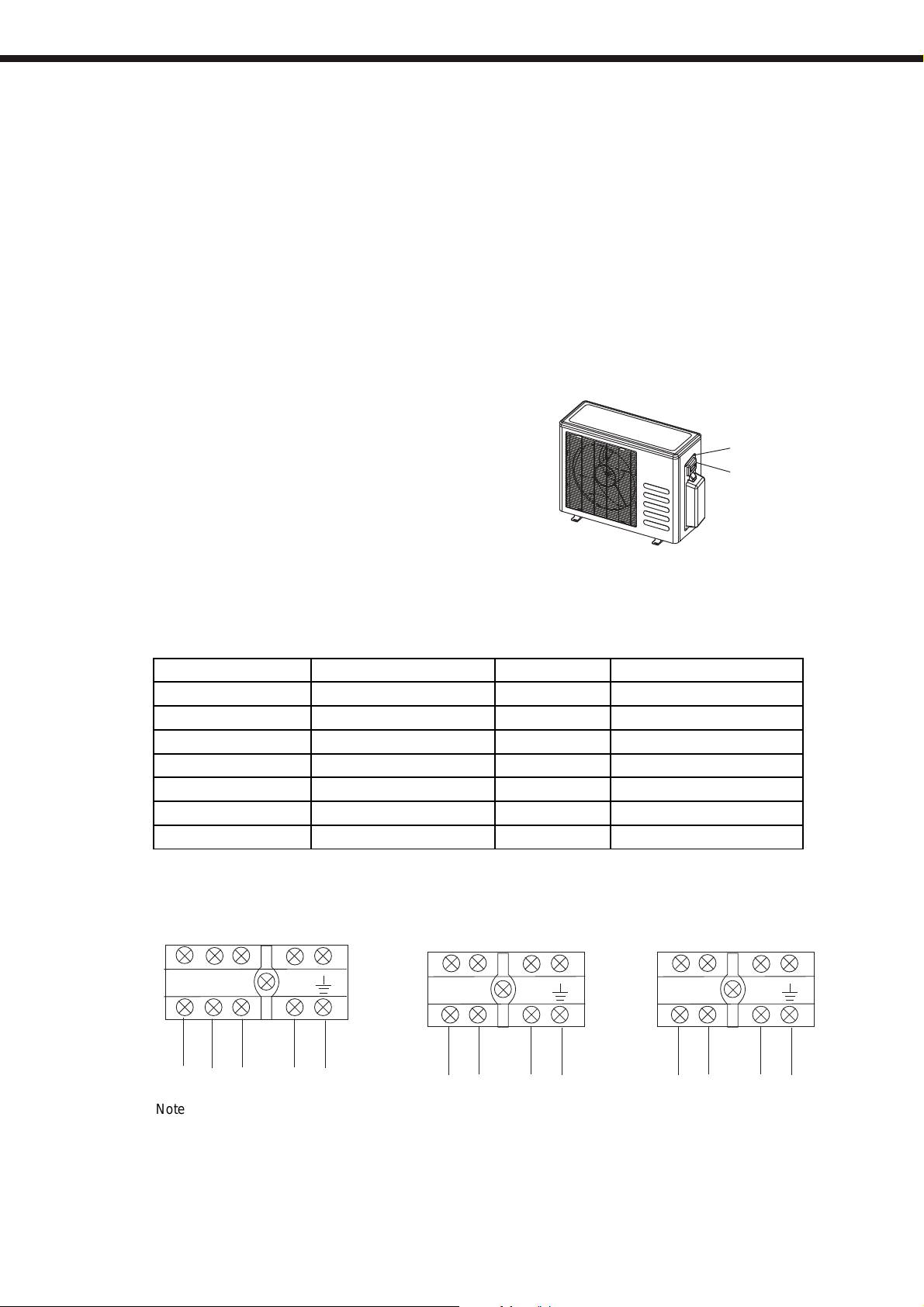

3. Outdoor unit installation

Install the outdoor unit on a rigid base to

Determine the air outlet direction where the

the installation place is exposed to strong wind

properly by putting the unit lengthwise along the

Specially in windy area, install the unit to prevent

installation, the installation bracket should

installation bracket diagram.

The installation wall should be solid brick,

actions to reinforce, damping supporting should

wall, bracket and the air conditioner should be

Be sure there is no obstacle which block

prevent increasing noise level and vibration.

Indoor unit

Connective

cable

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Ponding box

Pipe room

Connective

pipe

Wrapping belt

Drain hose

Fig.11

discharged air is not blocked. In the case that

such as a seaside, make sure the fan operating

wall or using a dust or shield plates.

the admission of wind. If need suspending

accord with technique requirement in the

concrete or the same intensity construction, or

be taken. The connection between bracket and

firm, stable and reliable.

radiating air.

6

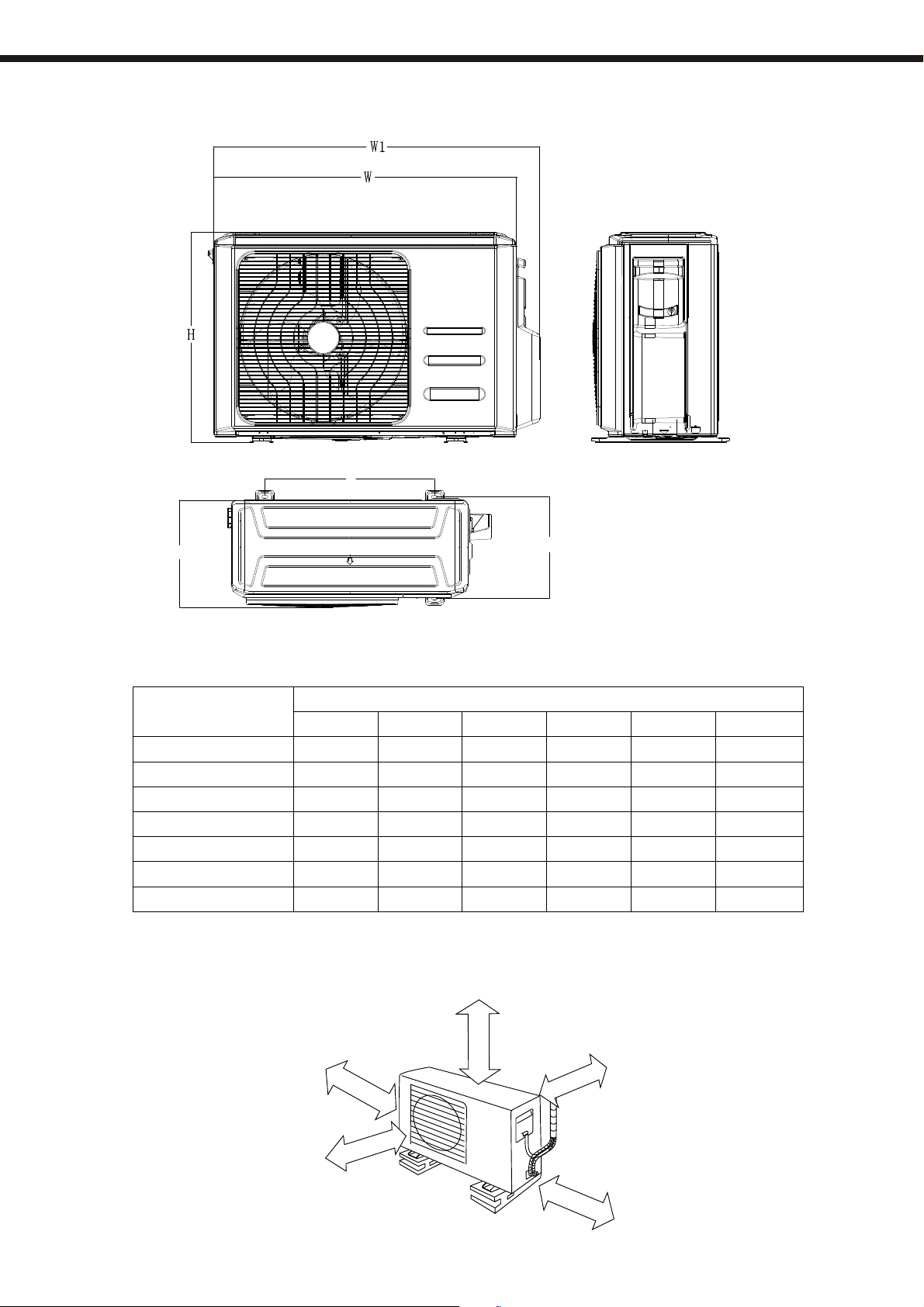

Dimensions

OUTDOOR UNIT INSTALLATION

A

D

Model

W D H W1 A B

MUEX-14-H6.2 800 333 554 860 514 340

MUEX-18-H6.2 800 333 554 860 514 340

MUEX-21-H6.3 845 363 702 923 540 350

MUEX-27-H6.3 845 363 702 923 540 350

MUEX-28-H6.4 946 410 810 1034 673 403

MUEX-36-H6.4 946 410 810 1034 673 403

MUEX-42-H6.5 946 410 810 1034 673 403

B

Space for installation and maintenance

Unit: mm

> 60 cm

> 30 cm

> 30 cm

> 200 cm

> 60 cm

7

REFRIGERANT PIPE CONNECTION

30

45

60

75

25

30

35

35

15

15

15

15

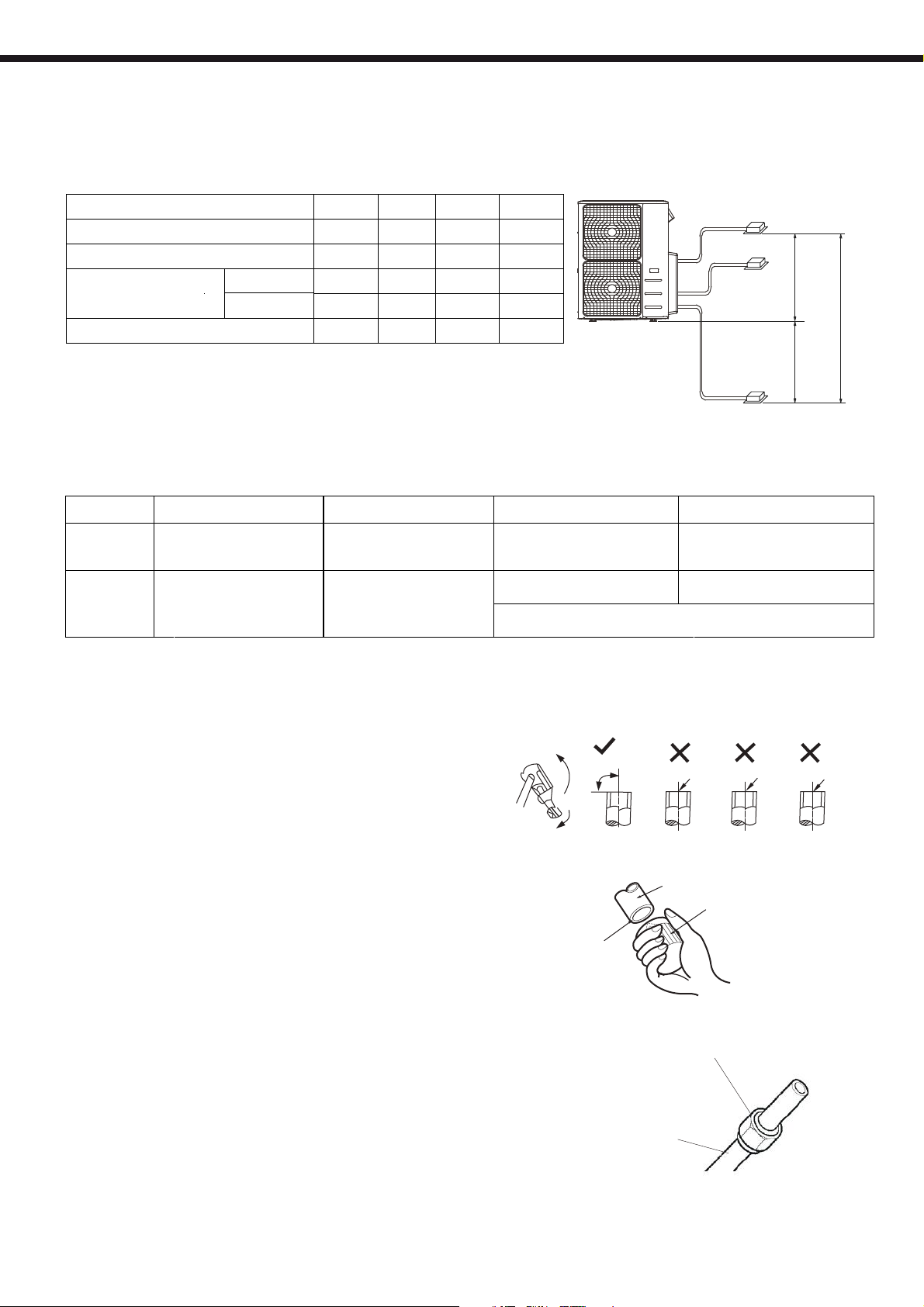

4. Refrigerant pipe connection

Before installing, make sure that the height difference, the length of refrigerant pipe and number of bends

between indoor and outdoor units, meet the following specifications.

UNIT

Max. Length for al l roo ms (m)

Max. Length for on e ind oor u nit (m)

Max. height diff ere nt be twe en

indoor and outdoor un it (m)

Max. height diff ere nt be twe en in doo r uni ts (m)

OU higher than IU

OU lower than IU

Additional charge (R410A)

2 x 1 (H6.2)

3 x 1 (H6.3)

15 15 15 15

10 10 10 10

4 x 1 (H6.4)

5 x 1 (H6.5)

Outdoor unit

Indoor unit

Indoor unit

Indoor unit

Max. height difference

15m

10m

15m

UNIT

Charged until

Additional

charge

(g)

2 x 1 (H6.2)

15m

(Total Liquid Length 1/4")

Total Liquid Length 1/4":

15 x (Total length - 15)

(Total Liquid Length 1/4")

3 x 1 (H6.3)

22,5m

Total Liquid Length 1/4":

15 x (Total length - 22,5)

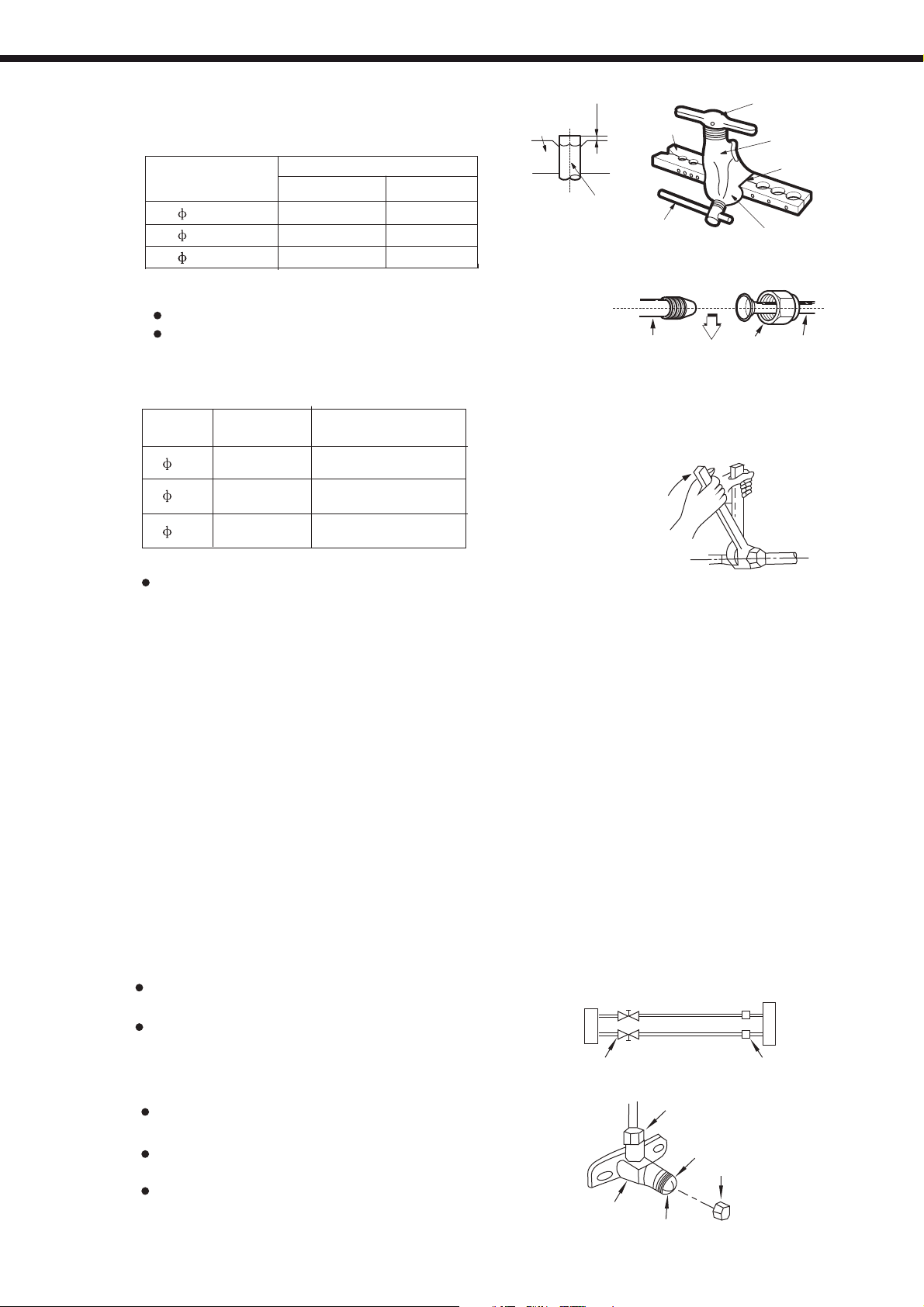

1. Flaring work

Main cause for refrigerant leakage

is due to defect in the flaring work.

Carry out correct flaring work

using the following procedure:

A: Cut the pipes and the cable.

1. Use the piping kit accessory or pipes

purchased locally.

2. Measure the distance between the indoor

and the outdoor unit.

3. Cut the pipes a little longer than the

measured distance.

4. Cut the cable 1.5m longer than the pipe

length.

4 x 1 (H6.4)

30m (Total Liquid Length 1/4")

7,5m (Total Liquid Length 3/8")

Total Liquid Length 1/4":

15 x (Total length - 30) 15 x (Total length - 37,5)

Total Liquid Length 3/8":

30 x (total length - 7,5)

。

90

Point down

37,5m (Total Liquid Length 1/4")

7,5m (Total Liquid Length 3/8")

Total Liquid Length 1/4":

Oblique

Fig.5 4

Pipe

Reamer

Fig.5 5

5 x 1 (H6.5)

Roughness

Burr

B: Burr removal

Flare nut

1. Completely remove all bur rs f ro m th e cu t

cross section of pipe/tube.

2. Put the end of the copper tube/pipe i n a

downward direction as you re mo ve b ur rs i n

order to avoid dropping bu rr s in to t he t ub in g.

Copper tube

C: Putting nut on

Remove flare nuts attached to indoor a nd

Fig.5 6

outdoor unit, then put them on pipe/tube

having completed burr remo va l. (n ot p os si ble

to put them on after flaring work)

8

REFRIGERANT PIPE CONNECTION

D: Flaring work

Firmly hold copper pip e in a d ie i n th e

dimension shown in the table b el ow.

Outer diam.

(mm)

A(mm)

Max.

6.35 1.3

9.53

12.7

12.7

1.6 1.0

1.8

1.8

Tightening connection

Align the center of the pipes.

Sufficiently tighten the flare

nut with fingers, and then tighten

it with a spanner and torque wrench

as shown in Fig.58 & 59

Outer

diam.

6.35

9.52

12.7

Tightening

torque(N.cm)

1500

(153kgf.cm)

2500

(255kgf.cm)

3500

(357kgf.cm)

Additional tightening

torque(N.cm)

1600

(163kgf.cm)

2600

(265kgf.cm)

3600

(367kgf.cm)

Caution

Excessive torque can break nut

depending on installation conditions.

Min.

0.7

1.0

1.0

Bar

"A"

Copper pipe

Clamp handle

Indoor unit tubing Flare nut Pipings

Handle

Bar

Yoke

Cone

Red arrow mark

Fig.5 7

Fig.5 8

Fig.5 9

Air purging

Air and moisture in the refrig er an t sy st em h av e undesirable effects as indicated below:

● Pressure in the system rises.

● Operating current rises.

● Cooling or heating efficiency drops.

● Moisture in the refrigerant circ ui t ma y fr ee ze a nd b lock capillary tubing.

● Water may lead to corrosion of parts in the refrigeration system.

Therefore, the indoor unit and tub in g be tw ee n th e in door and outdoor unit must be leak tested

and evacuated to remove an y no nc on de nsables and moisture from the system.

Air purging w ith vacuum pump

●

Preparation

Check that each tube(both liqu id a nd g as s id e tu be s) between the indoor and outdoor units

have been properly con ne ct ed a nd a ll w iring for the test run has been completed. Remove

the service valve caps fro m bo th t he g as a nd t he l iq uid side on the outdoor unit. Note that

both the liquid and the gas side ser vi ce v al ve s on the outdoor unit are kept closed at this

stage.

●

Pipe length and refriger an t am ou nt :

When relocate the unit to another place,

perform evacuation using vacuum pump.

Make sure the refrigerant added into the air

conditioner is liquid form in any case.

Outdoor

unit

Packed valve

Refrigerant

A

B

Gas side

Liquid side

Half union

Indoor

unit

C

D

Fig.6 5

Caution in handling the pack ed valve

Open the valve stem until it hits against the

stopper. Do not try to open it further.

Securely tighten the valve stem cap with a

spanner or the like.

Valve stem cap tightening torque (See

Tightening torque table in previous page ).

Valve body

Flare nut

Stopper

Valve stem

Cap

Fig.6 6

9

ELECTRICAL INSTALLATION

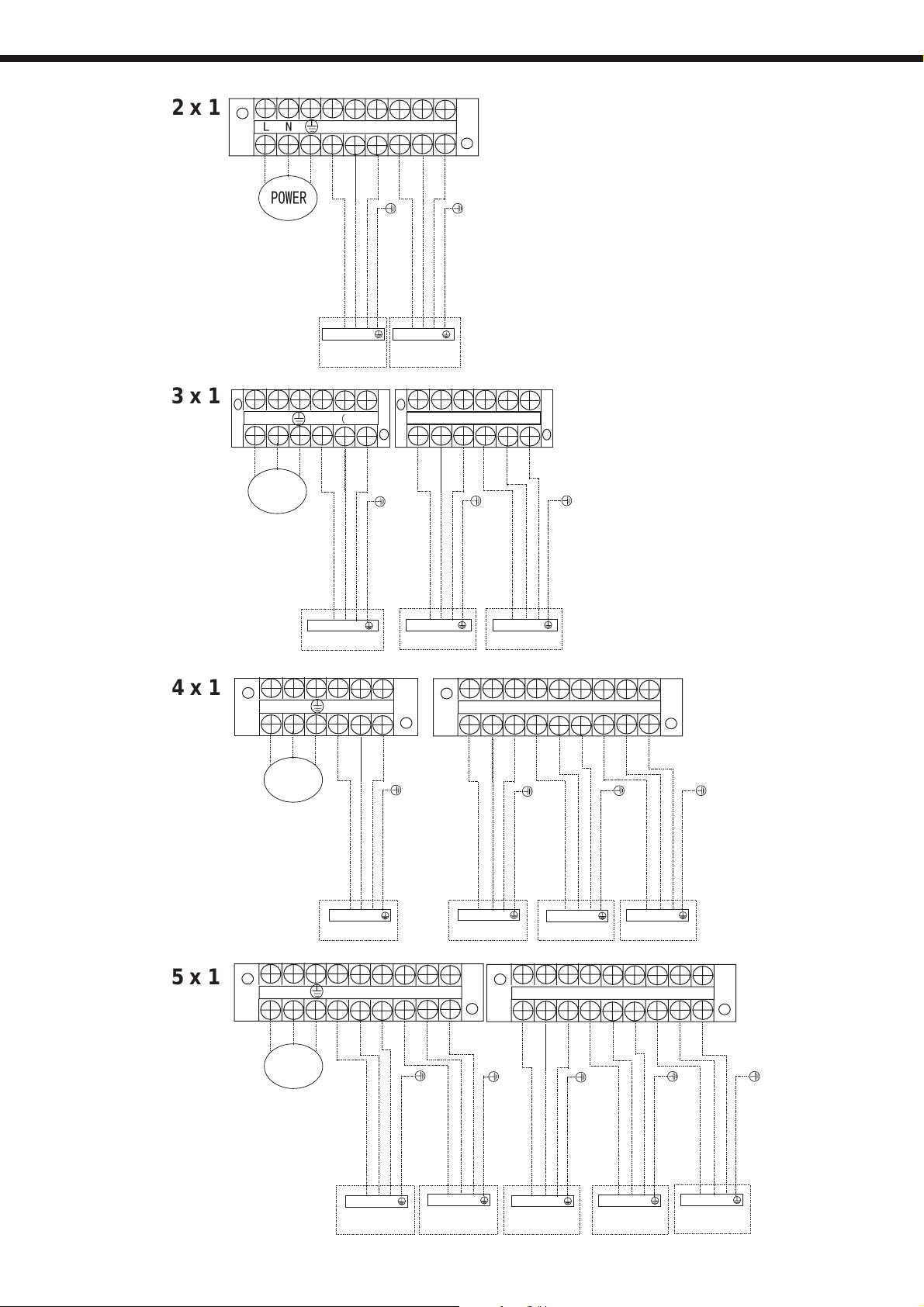

5. Electrical installation

Safety standards

- The supply voltage must be within a range of 90% to 110% of nominal value.

- The thermal circuit breaker and breaker should be 1.5 times the nominal consumption.

- All installation and wiring must comply with local and national average and the installation should

be performed by qualified personnel.

- The minimum section of wiring should be as follows according to consumption.

Connect the cable to the outdoor unit

1. Remove the electrical control board cover

from the outdoor unit by loosening the screw

as shown in figure.

2. Connect the connective cables to the

terminals as identified with their respective

matched numbers on the terminal block of

indoor and outdoor units.

3. Secure the cable onto the control board with

the cord clamp.

4. To prevent the ingress of water, from a loop

of the connective cable as illustrated in the

installation diagram of indoor and outdoor

units.

5. Insulate unused cords (conductors) with

PVC-tape.Process them so they do not

touch any electrical or metal parts.

Screw

Cover

Model ICP

MUEX-14-H6.2

MUEX-18-H6.2

MUEX-21-H6.3

MUEX-27-H6.3

MUEX-28-H6.4

MUEX-36-H6.4

MUEX-42-H6.5

Pow er W ire

2 x 2,5 + T mm

2 x 2,5 + T mm

2 x 4 + T mm

2 x 4 + T mm

2 x 4 + T mm

2 x 6 + T mm

2 x 6 + T mm

2

2

2

2

2

2

2

Indoor unit connection

a) Wall mounted MUPR-H6M

W

Empty

Note:

The wall mounted indoor unit has terminal , that can not be connected.

2(N)

1(L)

L N S T

S

b) Duct MUCR-H6M

L(L1)

N(2)

L N S T

W

Differential sw itch

16 A 2P 30mA

16 A 2P 30mA

20 A 2P 30mA

20 A 2P 30mA

20 A 2P 30mA

25 A 2P 30mA

25 A 2P 30mA

c) Cassette MUCSR-H6M

L

S

N

L N S T

S

10

2 x 1

MUEX-14-H6.2

MUEX-18-H6.2

ELECTRICAL INSTALLATION

L(A)

N

L

N(A)

S(A)

L(B)

N(B)

S(B)

3 x 1

MUEX-21-H6.3

MUEX-27-H6.3

POWER

N

L

POWER

W 1(L) 2(N) S W 1(L) 2(N) S

TO A TO B

L(A)

N(A)

S(A)

W 1(L) 2(N) S

TO A

L(C)

S(B)

L(B)

W 1(L) 2(N) S

N(B)

N(C)

W 1(L) 2(N) S

TO B TO C

S(C)

4 x 1

5 x 1

MUEX-28-H6.4

MUEX-36-H6.4

MUEX-42-H6.5

N

L

POWER

N

L

POWER

L(A)

W 1(L) 2(N) S

TO A

L(A)

N(A)

N(A)

S(A)

S(A)

L(B)

N(B)

S(B)

L(B)

W 1(L) 2(N) S

TO B

N(B)

S(B)

L(C)

L(C)

N(C)

N(C)

W 1(L) 2(N) S

TO C

S(C)

S(C)

L(D)

L(D)

N(D)

N(D)

S(D)

S(D)

W 1(L) 2(N) S

TO D

L(E)

N(E)

S(E)

W 1(L) 2(N) S

TO A

W 1(L) 2(N) S

TO B

11

W 1(L) 2(N) S

TO C

W 1(L) 2(N) S

TO D

W 1(L) 2(N) S

TO E

DRAIN JOINT and

START UP AND PERFORMANCE TESTING

6 . Drain joint installation

Fit the seal into the drain joint, then insert the

drain joint into the base pan hole of outdoor unit,

rotate 90 to securely assemble them.

。

Connecting the drain joint with an extension drain

hose (Locally purchased), in case of the water

draining off the outdoor unit during the heating

mode.

NOTE: The drain joint differ from appl ia nc e

to appliance.

7. Start up and performance testing

Prior check s

Seal

(1)

Drain joint

(2)

Base pan hole of

outdoor unit

Seal

Drain pipe

-

Measure the voltage supply and make sure it is within the specified range.

-

Testing must be performed in all modes of operation.

-

To operate in cool mode, press the ON/OFF button of the remote controller to place the unit in

cooling mode and select a temperature below room temperature.

-

To operate in heat mode, press the ON/OFF button of the remote controller to place the unit in

heating mode and select a temperature above room temperature.

-

You can also check the manual button. This is used when you do not have the remote controller and

and is located under the front panel.

12

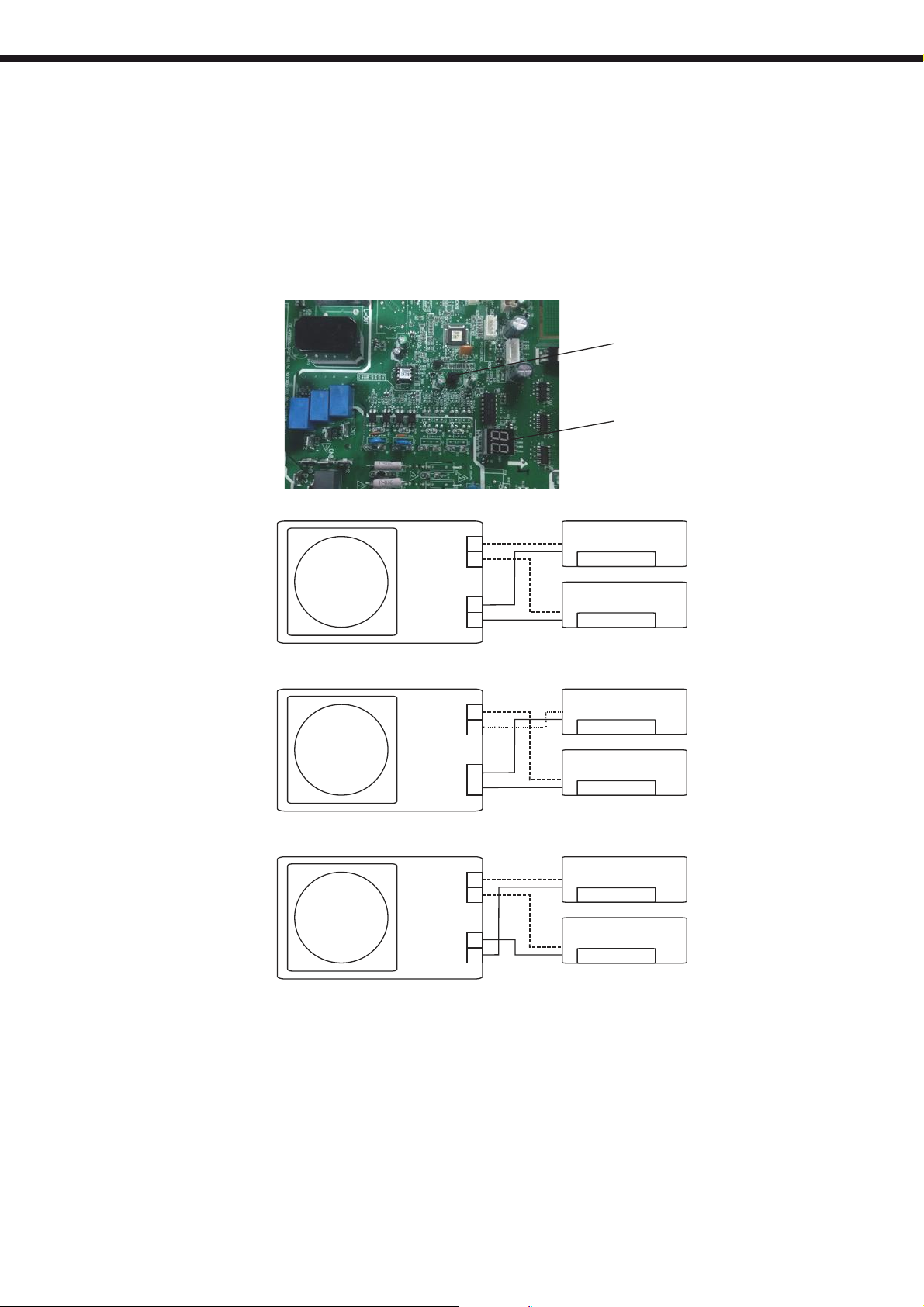

AUTOMATIC WIRING/PIPING CORRECTION

8. Function of automatic wiring/piping correction

Automatic Wiring/Piping Correction Function:

More recent models now feature automatic correction of wiring/piping errors. Press the "check

switch" on the outdoor unit PCB board for 5 seconds until the LED displays "CE”, indicating that this

function is working, Approximately 5-10 minutes after the switch is pressed, the "CE" disappears,

meaning that the wiring/piping error is corrected and all wiring/piping is properly connected.

Check switch

LED display

Correct wiring

Terminal

block

Liquid/

Gas pipe

Outdoor unit

Incorrect wiring

B

A

Indoor unit B

B

A

Indoor unit A

Terminal

block

Liquid/

Gas pipe

Outdoor unit

Incorrect wiring

Terminal

block

Liquid/

Gas pipe

Outdoor unit

B

A

Indoor unit B

B

A

Indoor unit A

B

A

Indoor unit B

B

A

Indoor unit A

How To Activate This Function:

1. Check that outside temperature is above 5℃.

(This function does not work when outside temperature is not above 5℃)

2. Check that the stop valves of the liquid pipe and gas pipe are open.

3. Turn on the breaker and wait at least 2 minutes.

4. Press the check switch on the outdoor PCB board unit LED display "CE".

13

OWNER´S MANUAL

Before using your air conditioner, please read

this manual carefully and keep it for future reference..

INVERTER SPLIT-TYPE

ROOM AIR CONDITIONER

The design and specifications are subject to

change without prior notice for

product improvement. Consult with the sales

agency or manufacturer for details.

Read This Manual:

Inside you will find many helpful hints on how to use and

maintain your air conditioner properly.

Just a little preventative care on your part can save you

a great deal of time and money over the life of your air

conditioner.

You'll find manyanswers to common problems in the

chart of troubleshooting tips. If you review the chart of

Troubleshooting Tips first, you may not need to call for

service.

14

SAFETY PRECAUTIONS

1. Safety precautions

Read the follow SAFETY PRECAUTIONS carefully before installation.

Electrical work must be installed by a l ic en se d el ectrician. Be sure to use the correct rating

of the power plug and main circu it f or t he m od el t o be i ns ta lled.

Incorrect installation due to igno ri ng o f th e in st ru ction will cause harm or damage.

The seriousness is classified by the following indications.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to property.

The items to be followed are classified by the symbols:

Symbol with background white denotes item that is PROHIBITED from doing.

WARNING

1) Engage dealer or specialist for installation. If installation done by the user is defective, it will cause water

leakage, electrical shock fire.

2) Install according to this installation instructions strictly. If installation is defective, it will cause water

leakage, electrical shock fire.

3) Use the attached accessories parts and specified parts for installation. otherwise, it will cause the set to fall,

water leakage, electrical shock fire.

4) Install at a strong and firm location which is able to withstand the set s weight. If the strength is not enough

or installation is not properly done, the set will drop and cause injury.

5) For electrical work, follow the local national wiring standard, regulation and this installation instructions. An

independent circuit and single outlet must be used. If electrical circuit capacity is not enough or defect found

in electrical work, it will cause electrical shock fire.

6) Use the specified cable and connect tightly and clamp the cable so that no external force will be acted on

the terminal. If connection or fixing is not perfect, it will cause heat-up or fire at the connection.

7) Wiring routing must be properly arranged so that control board cover is fixed properly. If control board cover

is not fixed perfectly, it will cause heat-up at connection point of terminal, fire or electrical shock.

8) When carrying out piping connection, take care not to let air substances other than the specified

refrigerant go into refrigeration cycle. Otherwise, it will cause lower capacity, abnormal high pressure

in the refrigeration cycle, explosion and injury.

9) Do not modify the length of the power supply cord or use of extension cord, and do not share the

single outlet with other electrical appliances. Otherwise, it will cause fire or electrical shock.

,

CAUTION

1) This equipment must be earthed and installed with earth leakage current breaker. It may cause electrical

shock if grounding is not perfect.

2) Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and

accumulates at surrounding of the unit, it may cause fire.

3) Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water

may enter the room and damage the furniture.

15

Loading...

Loading...