mundoclima CL23380, CL23383, CL23390, CL23394 Installation Manual

MVD

High Pressure Duct MVD DC

Installation manual

www.mundoclima.com

CL23380 to CL23383

English

Installation manual High pressure duct

CONTENTS P

INSTALLATION PRECAUTION...............................................................1

INSTALLATION PLACE.........................................................................1

ACCESSORIES......................................................................................2

INDOOR UNIT INSTALLATION ..............................................................2

INSTALLATION SPACE.......................................................................10

REFRIGERANT PIPE............................................................................10

DUCT DESIGN....................................................................................11

INSTALL THE CONNECTING PIPE.....................................................13

REFRIGERANT PIPE CONNECTION...................................................14

CONNECT THE DRAIN PIPE..............................................................15

WIRING..............................................................................................16

CONTROL...........................................................................................17

TROUBLE SHOOTING.........................................................................20

INSTALL ELECTRICTHROTTLE PART..................................................21

INSTALL BRANCH PIPE.....................................................................21

TEST OPERATION..............................................................................22

1. INSTALLA

To install properly

TION PRECAUTION

, please read this manual at first.

AGE

If the supply cord is damaged, it must be replaced by the

manufacturer or its service agent or a similarly qualified person

in order to avoid a hazard.

An all-pole disconnection switch having a contact separation of

at least 3mm in all poles should be connected in fixed wiring.

The appliance shall be installed in accordance with national

wiring regulations.

The temperature of refrigerant circuit will be high, please keep

the interconnection cable away from the copper tube.

An all-pole disconnection device which has at least 3mm

separation distance in all pole and a residual current

device(RCD) with the rating of above 10mA

in the fixed wiring according to the national rule.

The power cord type designation is H05RN-R/H07RN-F or above.

shall be incorporated

2. INSTALLATION PLACE

Indoor Unit

●

Enough room for installation and maintenance.

●

The ceiling is horizontal and it can afford the weight of the indoor

unit.

The air conditioner must be installed by qualified persons.

When installing the indoor unit or its tubing, please follow this

manual as strictly as possible.

When all the installation work is finished, please turn on the power

only after a thorough check.

No further announcement if there is any change of this manual

caused by product improvement.

NOTE

The installor

and maintain the air-conditioner, as well as remind users to

carefully read and keep both Installation Manual and Owner's

Manual well.

should illustrate to users how to correctly use

CAUTION

DISPOSAL˖Do not dispose this product as unsorted municipal

waste. Collection of such waste separately for special treatment

is necessary.

●

The air inlet and outlet are not impeded and does not af

outdoor air too much.

●

The air flow can reach every part of the room.

●

The connecting pipe and drainpipe can be easily extracted out.

●

There is no direct radiation from heat source.

Outdoor Unit

●

Enough room for installation and maintenance.

●

The air inlet and outlet are not impeded and does not af

outdoor air too much.

●

Dry and well ventilated place.

●

The

supporter is flat and horizontal and can afford the weigh of

outdoor unit, without noise and vibration.

●

The noise and the outlet air will not influence your neighbor.

●

No combustible gas.

●

Place convenient for piping and wiring.

Please keep away from the following places, or malfunction may

●

be caused.(if unavoidable, please consult the professionals):

fected by

fected by

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of esperience and knowledge ,unless they have been

given supervision or instruction concerning use of the appliance

by a person responsible for their safety

Children should be supervised to ensure that they do not play

with the appliance.

Disconnect the power supply before cleaning and maintenance.

The appliance must be installed 2,3m above floor.

The appliance shall not be installed in the laundry.

.

There is mineral oil like the oil of cutting machine.

●

There is much salty air. (Near the coast)

●

There is caustic gas such as sulfuric gas. (Near the hotspring.)

●

Factory where the voltage fluctuate greatly.

In the car or in the cabin.

●

In the kitchen or a place full of oil steam.

●

There is strong electromagnetic wave.

●

1

Installation manual

●

There is combustible gas or materials.

●

There is much evaporating acid or alkaline gas.

●

Other special areas.

●

Notes Before Installation

Select the correct carry-in path.

Move this unit as originally packaged as possible.

●

If the air conditioner is installed on a metal part of the building, it

●

must be electrically insulated according to the relevant standards

to electrical appliances.

●

●

Avoid installing it in a narrow sapce which has a high requirement

to noise.

NOTE

Remark per

For to prevent flicker impressions during the start of the

compressor (technical process), following installation

conditions apply.

●

The power connection for the air conditioner has to be done

at the main power distribution.The distribution has to be of

a low impedance, normally the required impedance reaches

at a 32A fusing point.

●

No other equipment has to be connected with this power

line.

●

For detailed installation acceptance, please refer to your

contract with the power supplier if restrictions do apply for

products like washing machines, air conditioners or

electrical ovens.

For power

●

plate of the product.

EMC Directive 89/336/EEC

details of the air conditioner, refer to the rating

High pressure duct

The following are selectable accessories

Remote controller & Its Frame

Remote controller....................................1

1.

2. Remote controller holder.........................1

3. Mounting screw

(ST2.9x10-C-H)................................ ........2

4. Alkaline dry battery(AM4)

..................................................................2

3

Mounting screw

1

ote

Rem

controller

Cautions on remote controller installation

●

Never throw or beat the controller.

●

Before

installation, operate the remote controller to determine

its location in a reception range.

Keep the remote controller at least 1m apart from the nearest

●

TV set or stereo equipment. (It is necessary to prevent

image disturbances or noise interferences.)

2

Remote controller

ho lder

Fig.3-1

For any question contact your local dealer.

●

3. ACCESSORIES

Table.3-1

Nam

e of

Accessories

Inst

allation manual

Wire controller

Pipe insulation material

Water outlet joint

Clasp

Water connecting pipe

Adhesive tape

for seal

Network matching wire

Copper nut

7.1-16.0

20.0-28.0

7.1-16.0

20.0-28.0

7.1-16.0

20.0-28.0

Q‘t

1

1

2

4

1

1

1

1

1

2

y

1

Outl

ine

(T

his manual)

Usag

e

Wire

control the

air-conditioner

Heat insulation

For drainage

Chucking the joint which

connect the drain hose

and the outlet of indoor

unit

To connect drain pipe

To connect drain pipe

The indoor unit which at

the terminal of

communication system

should connect a

impedance between port

P and port Q

Use for pipe connection

of engineering installation

●

Do not install the remote controller in a place exposed to

direct sunlight or close to a heatingsource, such as a stove.

Note that the positive and negative poles are in right positions

when loading batteries.

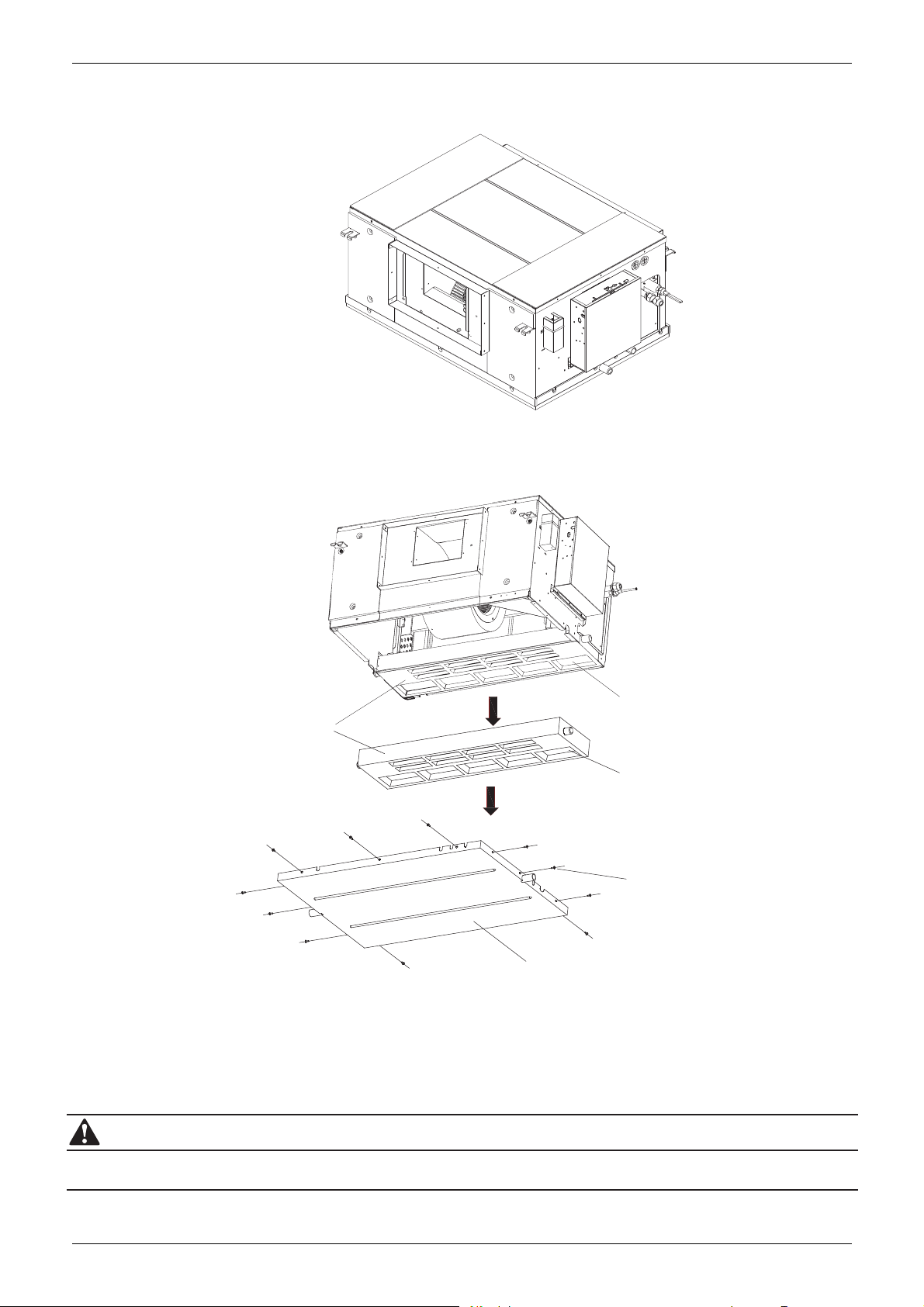

4. INDOOR UNIT INSTALLA

Installing Φ10 Hanging Screw Bolts (4 Bolts)

refer

Please

measurement between the screw bolts.

Please install with screw bolts.

The handling to the ceiling varies from the constructions, consult

the construction personnels for the specific procedures.

The size of the ceiling to be handledDo keep the ceiling flat. Con-

●

solidate the roof beam for possible vibration.

●

Cut off the roof beam.

Strengthen the place cut off, and consolidate the roof beam.

●

Carry out the pipe and line operation in the ceiling after

finishing the installation of the main body. While choosing where

to start the operation, determine the direction of the pipes to be

drawn out. Especially in case there is a ceiling, position the

refrigerant pipes, drain pipes, indoor & outdoor lines to the connection places before hanging up the machine.

The installation of hanging screw bolts.

to the following figure for the distance

TION

2

Installation manual

Wooden construction

Put the square timber traversely over the roof beam, then

install the hanging screw bolts. (Refer to

Timber over the beam

Roof beam

Hanging screw bolt s

New concrete bricks

Inlaying or embedding the screw bolts (Refer to

Ceiling

Fig.4-1

)

Fig.4-1

Fig.4-2)

High pressure duct

Take out the air-in grill.

ĸ

Ĺ

Dismantle the air filter

Clean the air filter (Vacuum cleaner or pure water may be

ĺ

used to clean the air filter. If the dust accumulation is too

heavy , please use soft brush and mild detergent to clean it

and dry out in cool place).

The air-in side should face down when using water.

Ļ

(See Fig.4-7)

ļ

The air-in side should face up when using vacuum cleaner.

(See Fig.4-8)

Blade shape insertion Slide insertion

Fig.4-2

For original concrete bricks

Use embeding screw bold, crock and stick harmness (refer

to

Fig.4-3)

Steel bar

bedding screw bolt

Em

(Pipe hanging and embedding screw bolt)

Fig.4-3

Steel roof beam structre

Install and use directly the supporting angle steel. (refer to

Fig.4-4)

Ha

Hanging bolts

nging screw bolt

Supporting

steel

angle

Fig.4-4

Overhanging the indoor unit

Fig.4-6

Fig.4-7

●

Overhang the

indoor unit onto the hanging screw bolts with

block.

●

Position the indoor unit in a flat level by using the level indicator,

unless it may cause leakage.

Screw nut

washer

Hanging

screw bolt

Overhang part

Fig.4-5

Install the main body

●

Installing the dust proof net and canvas air passage

Open the air-in grill

ķ

Anti-clockwise the

bolts as indicated in follow figure

sketch.Then pull down the air-in grill.

Fig.4-8

●

Pipe Connection

The static

pressure outside the unit is 200Pa , the length of

the air pipe attached is determined by this parameter.

●

The positioning of ceiling hole and indoor unit and hanging

screw bolts

Routine method of installation: the size of installation for indoor

ķ

unit following Fig.4-9

ĸ

Please install with Φ10 hanging screw bolts.

Carry out the pipe and line operation in the ceiling after finishing

Ĺ

the installation of the main body. While choosing where to start

the operation,

determine the direction of the position the

refrigerant pipes, drain pipes, indoor & outdoor lines and linecontrolled lines to the connection places before.

3

Installation manual

The positioning of ceiling hole and indoor unit and hanging screw bolts

routine method of installation: the size of installation for indoor unit following the Fig.4--9 and Fig.4-10

High pressure duct

Unit: mm

7.1~11.2 kW

REFRIGERANT-PIPE FLANED

CONNECTION Φ9.52(3/8)

REFRIGERANT-PIPE FLANED

CONNECTION Φ16(5/8)

952

214

85

420

PLASTIC COVER

CONNECTING POINT OF

DRAIN PIPE

189123

43

61

75

SAFETY DRAIN CONNECTING PIPE

4-12*25 OBLONG SUSPENTION BOLT HOLES

690

642

AIR OUTLET DUCT FLANGE

856

AIR INTAKE

800

4-Φ5HOLES FOR AIR

INTAKE DUCT CONNECTION

AIR OUTLET

86

ELECTRICAL CONTROL BOX

189123

44253155

26

255 33

14~16 kW

REFRIGERANT-PIPE FLANED

CONNECTION Φ9.52(3/8)

REFRIGERANT-PIPE FLANED

CONNECTION Φ16(5/8)

339

Fig.4-9

72265

135 88

82

PLASTIC COVER

68

4-12*25 OBLONG SUSPENTION BOLT HOLES

CONNECTING POINT OF

DRAIN PIPE

189123

43

638

61

75

SAFETY DRAIN CONNECTING PIPE

137

AIR INTAKE DUCT FLANGE

600

AIR OUTLET DUCT FLANGE

65

400

930

29

249

AIR INTAKE

8

114

800

4-Φ5 HOLES FOR AIR

OUTLET DUCT CONNECTION

6-Φ5 HOLES FOR

AIR

DUCT CONNECTION

OUTLET

400

1300

65

Unit: mm

82

15

50

37

15

56

420

270

24

ELECTRICAL

CONTROL

46

90

69

136

14

253

17

BOX

169

15

52

179

28

11

638

691

123

35

125

136

AIR OUTLET

339

82

31

64

1073

82

Fig.4-10

4

Installation manual

High pressure duct

The method of installation: Adopt following method if the air-conditioning’

installtionsite.

7.1~11.2 kW

s size of installationsite is limited and the indoor unit can’t put into the

1

Fig.4-1

ray

Water T

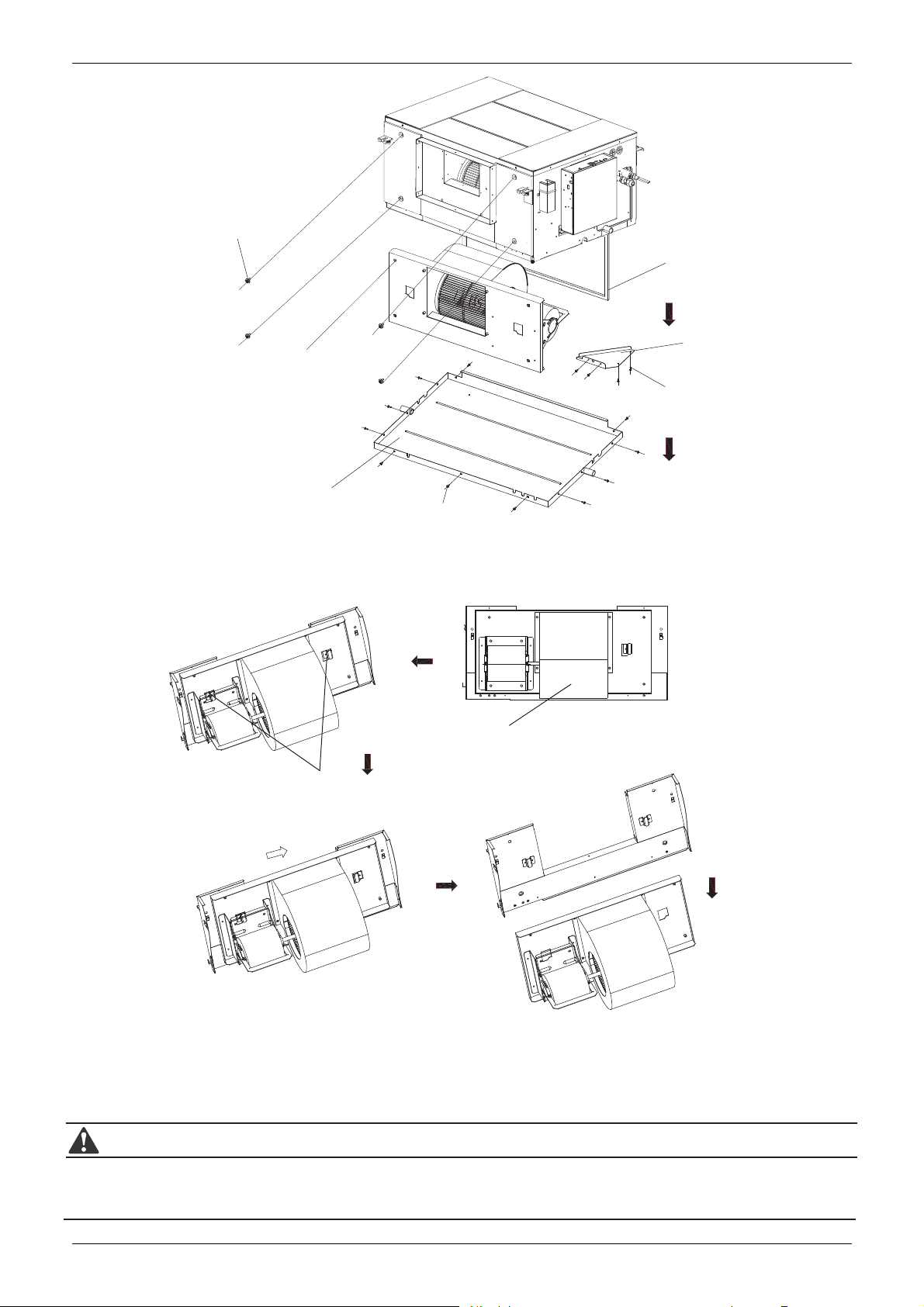

1. The whole unit status show as Fig.4-11

2. Remove the all 1

3. Take off the tray along the direction of the arrow show in Fig.4-12

4. Clean the tray and evaporator.

5. Re-install the unit follow the reverse above orders.

screw

from fixed Safety Drain T

1

, and then take off the tray as figure showed in Fig.5-11.

ray

CAUTION

Safety Drain T

ray

Position A

Position B

11-Screw

Fig.4-12

1. Please shut down the unit and cut off power cable before maintain the motor.

2. Don’t heavy pull the foam tray, when dismounting; otherwise the foam tray would break.

5

Installation manual

Maintenance of motor:

4 Bolts

For fixing the fan assembly

High pressure duct

Filter

Inside of structure

Side view of fan assembly

installation state

Motor Asseembly

Safety Drain Tray

Pothook

11-Screw

For fixing the satety drain tray

Front view of fan assembly installation state

Scroll

Fortified panel

4 Screw

For fixing the reinforced panel

Fig.4-13

Fan assembly should

push horizontally to the

end (about 18mm), and

then take of

1. Refer to Fig.4-13, remove all 1

2. Refer to Fig.4-13, remove all 4 bolts from reinforced panel, and take off the panel.

3. Refer to Fig.4-13, remove all 4 bolts from fan assembly, see Fig.4-14, according to which orders to take off the fan assembly.

4. Refer to Fig.4-14, horizontal pushing the fan assembly, until it cannot not move any further, and then lift up slightly and take down to remove it.

5. After motor maintenance, reinstall the fan assemblies as per the reverse above orders. And connect the motor with electric control box,

as motor with power cable of capacity.

f it.

Move 18mm

Move

The state after fan assembly is taken off

1 bolts from safety drain tray, and take off the safety drain tray.

CAUTION

1. Please shut down the unit and cut off power cable before maintain the motor.

2. Before dismount the fan assembly, you must remove the motor and electric control box, as well as connective wires between

motor and capacity assembly.

3. Fan subassembly is very heavy, please be careful during maintaining, otherwise physical injury would be caused.

6

Fig.4-14

Installation manual

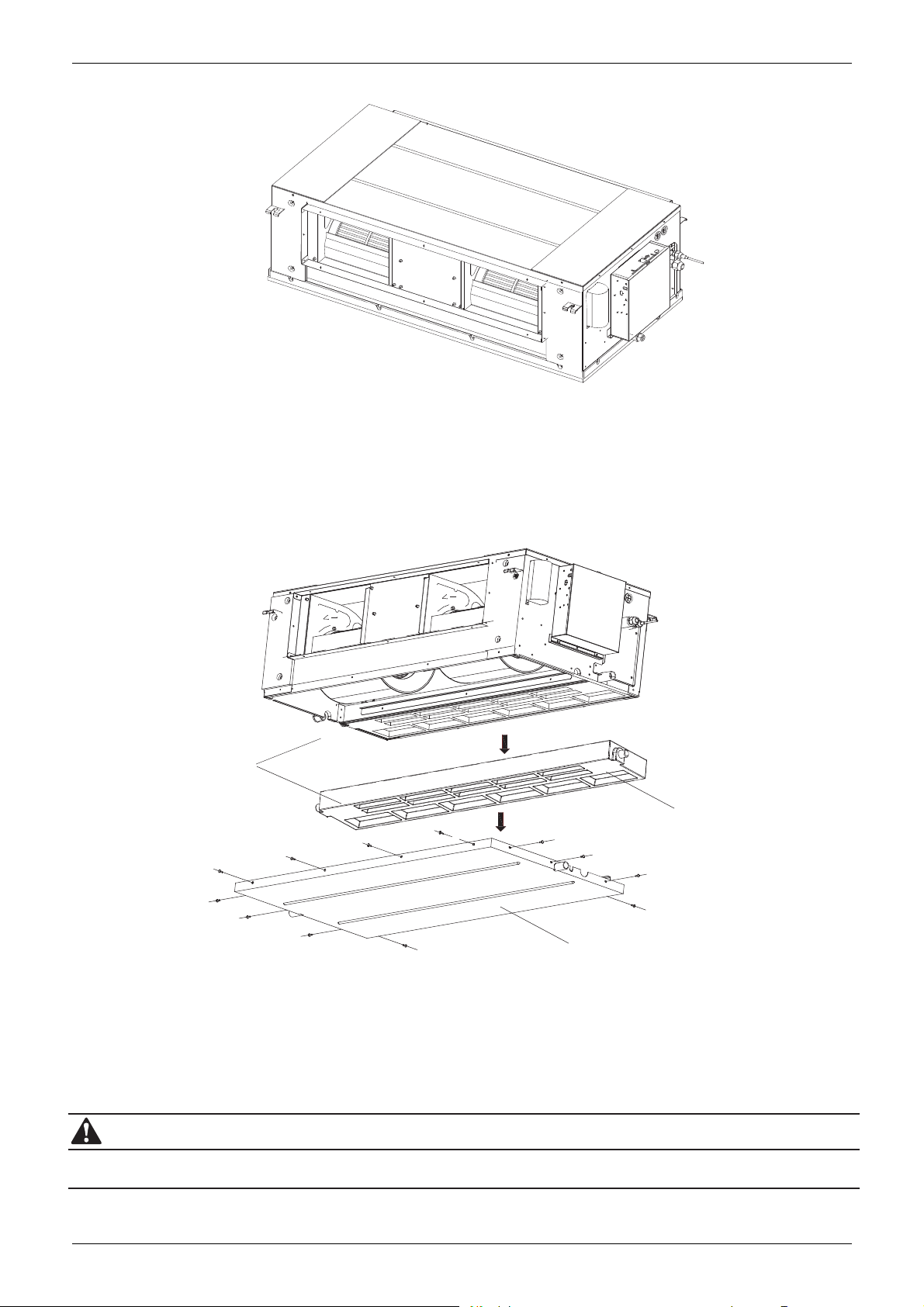

14~16 kW

High pressure duct

g.4-15

Fi

er Tray

Wat

1.

The whole unit status show as Fig.4-15.

2. Remove the all 11

3. Take off the tray along the direction of the arrow show in Fig.4-16.

4. Clean the tray and evaporator.

5. Re-install the unit follow the reverse above orders.

1. Please shut down the unit and cut off power cable before maintain the motor.

2. Don’t heavy pull the foam tray, when dismounting; otherwise the foam tray would break.

scre

f

w

om fixed Safety Drain Tray, and then take off the tray as figure showed in Fig.4-16.

r

CAUT

ION

12 S

For fixing the safety drain tray

Safety Drain Tray

ition A

Pos

Position B

crew

Fi

g.4-16

7

Loading...

Loading...