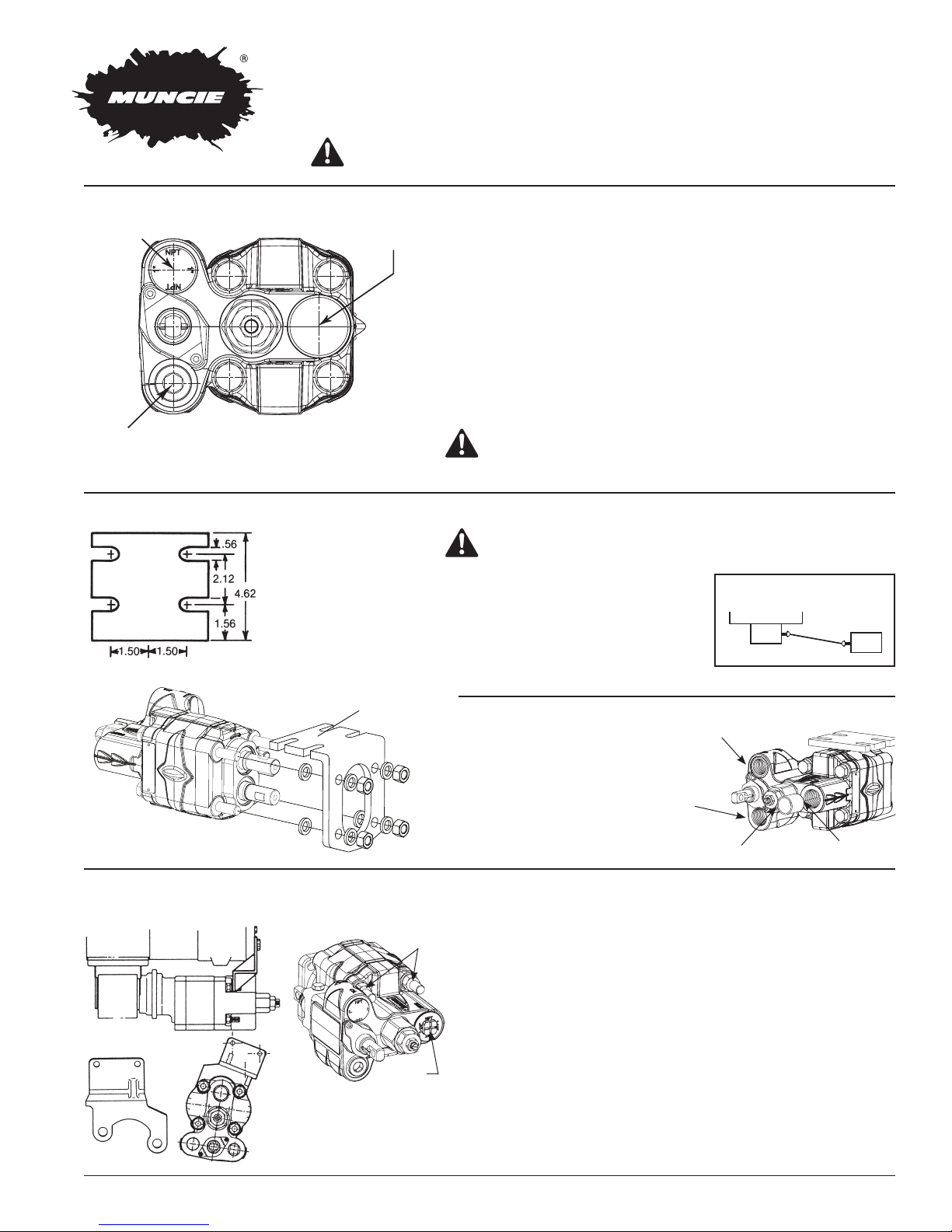

E/EH SERIES DUMP PUMPS

E-SERIES PORTS

1-1/2" N.P.T. (EH)

INSTALLATION INSTRUCTIONS

Product designed for dump body applications only.

DANGER:

PLUMBING INSTRUCTIONS

1" N.P.T. (E/EH)

CYLINDER

1-1/4" N.P.T. (EH)

1" N.P.T. (E)

RETURN

1-1/4" N.P.T. (E)

(INLET)

MODELS:

E – 23, 27

EH – 23, 27

MOUNTING INSTRUCTIONS – REMOTE MOUNT

Twin shafted remote mount

pumps require optional

B1235

mounting bracket No.

B1235.

Remove nuts and spacers.

Slide bracket over bolts,

replace washers and tighten

nuts. This procedure does

not open the pump.

Never work on a raised dump bed without proper body props and supports.

Do not use Teflon Tape as a thread sealant. The use of Teflon Tape

will void all warranties expressed or implied for this product.

Always use suction hose (SAE-100R4) on pump inlet.

Three line hook-up requires conversion sleeve No. AA-1257

(AA-1257-2 for the EH) in inlet port. Always route third line so it is

below the oil level at all times.

Two line hook-up has return port plugged and NO sleeve.

Port sizes are different between the E and EH. See drawing at left.

SPECIAL NOTE: For long term product life and improved pump per-

formance always use a three line hook-up. The two line system will

reduce product life. A two line system operated for extended running

times will result in excessive heat build up and subsequent damage.

CAUTION: The relief valve is pre-set at 2000 PSI ± 5%

Adjustable to (but do not exceed) 2500 PSI

WARNING: The rotating shaft between PTO and pump

should be shielded with appropriate guard.

Driveline angles should not exceed 12°.

Maximum speed for solid shafting is

1000 RPM. Consult driveline manufacturer for specifications. Pump and PTO

shafts must be parallel within 1.5°.

TOP VIEW

Transmission

PTO

PUMP

Part No. B1235A

MOUNTING INSTRUCTIONS – DIRECT MOUNT

EXAMPLES OF BRACKET CONSTRUCTION

STUDS

INLET

CONVERSION SLEEVE INSTALLATION

To convert to 3-line operation

install sleeve in inlet port. Remove

pipe plug from tank return port.

E: Part No. AA1257, EH: Part No. AA1257-2

Direct mount pumps are provided with extended studs and extra nuts

for support of pump. A bracket attached to two or more transmission

bolts is required. The bracket design should assure that there is no

stress or force exerted on the pump or PTO shaft. If vertical supports

are greater than 20° off of perpendicular with the transmission main

shaft then a reinforced “Z” bracket must be used. Reinforce horizontal members to prohibit flexing at bend or weld.

Attach the bracket at the pump bolt closest to the center of gravity

of the pump. Consult Muncie PTO Owner’s Manual for special recommendations.

Always apply anti-seize grease to shaft splines before installing into

PTO if not done by the manufacturer. Reapply annually or sooner for

severe use. PTOs with greasable shaft splines are available. Contact

Muncie Power Products for additional information.

TO CYL.

TO TANK

INLET

PULL OUT CABLES (NEUTRAL SAFETY STOP)

This clevis hole is part of a neutral stop device and is provided for

RECOMMENDED

1”

those applications using a “pull-out” cable. This device allows the

cable to move the spool from the raise position to the neutral position, only. As shock loading is possible, it is essential that a spring

be incorporated in the pull-out cable hook-up. Failure to do so could

result in breakage of the neutral stop device and could lead to injury.

We recommend that the cable be fully enclosed and directly in line

with the valve spool. Use spring part No. PS-1233V.

NOT

RECOMMENDED

NOTE: Never use a pull-out cable on an air shift pump as exact

spool position cannot be adequately controlled. Instead use

1436A-1 safety limit dump valve on raise side of air cylinder.

LEVER CONTROLS

WARNING: If valve is to be shifted by lever and rod linkage type control, the installer is responsible for fitting

the lever with a neutral locking device to prevent the accidental shifting of the valve spool and accidental

raising of the dump body. Muncie offers a complete line of in-cab consoles and controls as listed below.

Lever control rods must be attached to the spool on the front side of pump. Lever control rods cannot be attached

to the spool on the rear side due to the neutral safety stop components. On direct mount units, accessibility to the

spool eye can be improved by ordering kit No. EHK-DR (Discard unused parts).

OTHER CONTROLS DIMENSIONS IN INCHES

3.8

3.0

5.2

1.6 Typ.

4.1

1.6 Typ.

3.0

3.8

4/8/13

5.2

3.8

4.9

3.1

4.1

3.0

12

4/8/13

4.9

3.1

7.7

5.2

3.8

12

7.7

TYPE A TYPE B TYPE C, D, H TYPE E, F, G

10.0

4.3 4.3

7.0 Ref.

12.0

ASC2-**

Consoles offer within

the industry the largest

variety of dump body

feathering controls

(six models w/wo

automatic PTO kick

out and various detent

positions) with multiple

console choices for

customizing with user

accessories.

See Muncie brochure

number MP04-01 for

complete details.

Member of the Interpump Group

IN05-05 (Rev. 04-17)

800-367-7867 • Fax 765-284-6991 • info@munciepower.com • www.munciepower.com

201 East Jackson Street • Muncie, Indiana 47305

Specications are subject to change without notice. Visit www.munciepower.com

for warranties and literature. All rights reserved. © Muncie Power Products, Inc. (2010)

12.0

para mayores detalles.

Muncie número MP04-01

Consulte el folleto de

los accesorios del usuario.

se realizan a medida según

opciones de consola que

mecánico) con múltiples

posiciones de freno

7.0 Ref.

PTO y diferentes

sin dispositivo automático

volteo (seis modelos con o

controles para unidades de

más amplia variedad de

dentro de la industria la

Las consolas ofrecen

ASC2-**

10.0

IN05-05S (Rev. 04-17)

Las especicaciones están sujetas a cambios sin previo aviso. Visita www.munciepower.com

para las garantías y la literatura. Todos los derechos reservados. © Muncie Power Products, Inc. (2012)

Miembro de Interpump Hydraulics Group

800-367-7867 • Fax 765-284-6991 • info@munciepower.com • www.munciepower.com

Oficinas generales y centro de distribución • 201 East Jackson Street • Muncie, Indiana 47305

TIPO A TIPO B TIPO C, D, H TIPO E, F, G

5.2

4/8/13

3.8

1.6 Typ.

3.0

4.1

4.3 4.3

1.6 Typ.

3.0

3.8

4/8/13

3.0

12

3.8

7.7

4.1

5.2

3.1

4.9

12

3.8

5.2

7.7

3.1

4.9

OTROS CONTROLES LAS DIMENSIONES SE EXPRESAN EN PULGADAS

descarte no utilizadas).

de montaje directo, la accesibilidad a la anilla del carrete puede mejorarse mediante el pedido del equipo Nº EHK-DR (Piezas de

palanca no pueden sujetarse al carrete en la parte trasera debido a los componentes de parada de seguridad neutral. En las unidades

Los vástagos de control de la palanca deben estar sujetos al carrete en la parte frontal de la bomba. Los vástagos de control de la

cabina, tal como se enumera a continuación.

válvula y la elevación del cuerpo de volteo. Muncie ofrece una línea completa de consolas y controles incorporados a la

responsable de ajustar la palanca con un dispositivo de bloqueo neutral para evitar la activación accidental del carrete de la

ADVERTENCIA: Si se activará la válvula mediante una palanca y un control de tipo de conexión de vástago, el instalador es

CONTROLES DE PALANCA

cilindro neumático.

válvula de descarga con límite de seguridad 1436A-1 en el lado de elevación del

OBSERVACIÓN: para bombas con activación neumática de carrete. Utilice la

la pieza de resorte Nº PS-1233V.

aislamiento adecuado y directamente en línea con el carrete de la válvula. Utilice

de retorno a neutro y se instale. Recomendamos que el cable cuente con

mismo. El incumplimiento de este paso puede resultar en la rotura del dispositivo

debe utilizar un resorte para ensamblar al dispositivo para evitar la fractura del

activación de una posición de levante a una posición neutral, únicamente. Se

1”

a posición de neutro. Este dispositivo permite que el cable mueva el carrete de

Este orificio de la horquilla forma parte de un dispositivo de retorno de bomba

RECOMENDADOS

NO

RECOMENDADOS

ENSAMBLE DE CABLE A CARRETE DE ACTIVACIÓN PARA RETORNO A POSICIÓN DE NEUTRO

Power Products.

1" N.P

CILINDR

1-1/4" N.P

1" N.P

RETORNO

eje engrasables. Para mayor información, comuníquese con Muncie

extremos. Se encuentran disponibles dispositivos PTO con ranuras de

fabricante. Vuelva a aplicarla en forma anual o antes, en caso de usos

de instalarlo en el PTO, en caso de que no haya sido realizado por el

Siempre aplique grasa anti-agarrotamiento a las ranuras del eje antes

especiales.

Manual del Propietario de PTO Muncie para obtener recomendaciones

pernos de la transmisión con soporte en una sola pieza. Consulte el

Sujete el soporte a los dos pernos superiores de la bomba y a dos

arqueamiento o soldadura.

Refuerce los miembros horizontales para evitar la flexión durante el

el eje de transmisión principal, se debe utilizar un soporte “Z” reforzado.

PTO. Si los soportes verticales superan los 20º de perpendicularidad con

asegurar que no haya tensión o presión ejercida en la bomba o el eje

sujetado a dos o más pernos de transmisión. El diseño del soporte debe

y tuercas adicionales para el soporte de la bomba. Se requiere un soporte

Las bombas de montaje directo están equipadas con pernos extendidos

ALIMENTACIÓN

PERNOS EXTENDIDOS

EJEMPLOS DE CONSTRUCCIÓN DE SOPORTES

INSTRUCCIONES DE INSTALACIÓN: MONTAJE DIRECTO

BOMBA

ALIMENTACIÓN

AL CILINDRO

PTO

Transmisión

VISTA SUPERIOS

VISTA LATERAL

E: Pieza Nº AA1257, EH: Pieza Nº AA1257-2

HACIA EL TANQUE

SAE1 00R4 al tanque.

conexión y manguera SAE 100R1 o

tapón del puerto de retorno e instale

el puerto de alimentación. Retire el

2 a tres líneas, instale el buje en

Para convertir a una operación de

INSTALACIÓN DEL BUJE DE CONVERSIÓN

paralelos a menos 1.5°.

las especificaciones. Los ejes de la bomba y toma de fuerza deben ser

fabricante del sistema de transmisión para

máxima 1000 RPM eje sólido. Consulte al

no deben superar los 12°. Velocidad

cada caso en particular. Los ángulos

requiere de un diseño específico para

La utilización de un eje remoto cardán

protección adecuada.

transferencia de potencia) y la bomba debe cubrirse con una

ADVERTENCIA: El eje cardan entre el PTO (Dispositivo de

PSI + o - 5% Ajustable a 2500 PSI (sin exceder este límite)

PRECAUCIÓN: La válvula de alivio se calibra de fábrica a 2000

prolongados generará un aumento de calor y daño posterior.

El sistema de dos líneas operado durante períodos de ejecución

tres líneas. El sistema de dos líneas reducirá la vida útil del producto.

mejorar el rendimiento de la bomba siempre utilice una conexión de

• OBSERVACIÓN ESPECIAL: Para prolongar la vida útil del producto y

esquema de la izquierda.

• El tamaño de los puertos varía entre las series E y EH. Véase el

y no incluye el buje para sistema de tres líneas.

• La conexión de dos líneas tiene el puerto de retorno al tanque sellado

retorno al tanque quede en la parte inferior respecto al puerto al cilindro.

Siempre instale la bomba de volteo de tal forma que el puerto de

Nº AA-1257 (AA-1257-2 para la serie EH) en el puerto de alimentación.

• El sistema de tres líneas requiere para la serie E un buje de conversión

de la bomba.

• Siempre utilice una manguera (SAE-100R4) en el puerto de alimentación

implícitas de este producto.

hidráulicas. La utilización de teflón anulará todas las garantías expresas e

• No utilice teflón liquido o en cinta como sellador para conexiones

Pieza Nº B1235A

bomba.

procedimiento no abre la

ajuste las tuercas. Este

reemplace las arandelas y

soporte sobre los pernos,

espaciadores. Deslice el

Retire las tuercas y los

B1235

.T. (E)

.T. (EH)

O

.T. (E/EH)

EH – 23, 27

E – 23, 27

MODELOS:

(ENTRADA)

(ALIMENTACIÓN)

1-1/4" N.P.T. (E)

1-1/2" N.P.T. (EH)

montaje adicional, Nº B1235.

requieren un soporte de

remoto con doble eje

Las bombas de montaje

HIDRÁULICAS Y MANGUERAS

Aseg

ú

rese de colocar soportes fisicos adecuados para el cuerpo de volteo.

PELIGRO: Nunca trabaje en una unidad con el cuerpo de volteo elevado.

INSTRUCCIONES DE INSTALACIÓN: MONTAJE REMOTO

INSTRUCCIONES PARA INSTALACIÓN DE CONEXIONES

Producto diseñado para aplicaciones de volteo únicamente.

INSTRUCCIONES DE INSTALACIÓN

BOMBAS DE VOLTEO SERIE E/EH

Loading...

Loading...