Page 1

HEAT TRANSFER PRODUCTS, INC.

120 BRALEY RD., E. FREETOWN, MA 02717

Installing, Operating & Maintaining

MUNCHKIN HIGH EFFICIENCY HEATER

with the “925” Controller

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch: do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

WARNING

This manual must only be used by a qualified heating installer / service

technician. Failure to comply could result in severe personal injury, death or

substantial property damage. It is also important to keep these Instructions

with the appliance.

MH27745

CONTROLS

Page 2

USING THIS MANUAL

2

DANGER

Indicates a condition or hazard which

will

cause severe personal injury, death

or major property damage.

SPECIAL ATTENTION BOXES

Throughout this manual you will see these

special attention boxes similar to this one,

which are intended to supplement the

instructions and make special notice of

potential hazards. These categories mean, in

the judgement of Heat Transfer Products, Inc.:

WARNING

Indicates a condition or hazard which

may

cause severe personal injury,

death or major property damage.

WARNINGS

• THIS UNIT IS FOR CATEGORY IV VENTING - 2 PIPE ONLY. THIS IS A SEALED

COMBUSTION APPLIANCE.

• THIS HEATER INSTALLATION MUST CONFORM TO THE LATEST EDITION OF THE

“NATIONAL FUEL GAS CODE” ANSI Z223.1 NEPA 54 AND OR CAN/CGA B149

INSTALLATION CODES. STATE AND LOCAL CODES MIGHT ALSO APPLY TO

INSTALLATION.

• WHERE REQUIRED BY THE AUTHORITY HAVING JURISDICTION, THE

INSTALLATION MUST CONFORM TO THE STANDARDS FOR CONTROLS AND

SAFETY DEVICES FOR AUTOMATICALLY FIRED HEATERS, ANSI/ASME HEATER

AND PRESSURE VESSEL CODE, Section IV, ALONG WITH CSD1.

• THE HEATER, GAS PIPING, WATER PIPING, VENTING AND ELECTRICAL MUST BE

INSTALLED BY TRAINED & QUALIFIED PERSONNEL FAMILIAR WITH

INSTALLATION PRACTICES, LOCAL CODE, LICENSING REQUIREMENTS.

• IF THE INFORMATION IN THESE INSTRUCTIONS ARE NOT FOLLOWED EXACTLY,

A FIRE OR EXPLOSION MAY RESULT; CAUSING PROPERTY DAMAGE, PERSONAL

INJURY, OR DEATH.

• DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE;

• THE USE OF A LOW WATER CUT-OFF DEVICE MAY BE REQUIRED BY STATE OR

LOCAL CODES IF THE MUNCHKIN IS INSTALLED ABOVE RADIATION LEVELS.

CAUTION

Indicates a condition or hazard which

will or can cause minor personal injury

or property damage.

USING THIS MANUAL

Page 3

TABLE OF CONTENTS

3

TABLE OF CONTENTS

PART 1 . . . . . . . . . . . . . . . . . . . . .4 thru 7

GENERAL INFORMATION

A How It Operates . . . . . . . . . . . . . . . . .4

B Munchkin Ratings and Dimensions . . .4

C Pre-installation Requirements . . . . . . .7

D Pressure Relief Valve . . . . . . . . . . . . . .7

PART 2 . . . . . . . . . . . . . . . . . . . . .8 thru 9

ELECTRICAL

A Electrical Connection . . . . . . . . . . . . . .8

PART 3 . . . . . . . . . . . . . . . . . . .10 thru 12

GAS CONNECTION

A Gas Connection . . . . . . . . . . . . . . . . .10

B Gas Piping . . . . . . . . . . . . . . . . . . . . .10

C Gas Table . . . . . . . . . . . . . . . . . . . . . .10

PART 4 . . . . . . . . . . . . . . . . . . .13 thru 21

VENTING

A Approved Venting Materials . . . . . . .13

B Venting the Munchkin in

2” or 3” Plastic Pipe . . . . . . . . . . . . .14

C Longer Vent Runs . . . . . . . . . . . . . . .16

D Heater Removal from a

Common Vent System . . . . . . . . . . .17

E Condensate Requirements . . . . . . . .21

PART 5 . . . . . . . . . . . . . . . . . . .22 thru 34

PIPING

A Hydronic piping with

Circulators or Zone Valves . . . . . . . .22

B Circulator Sizing . . . . . . . . . . . . . . . .23

C Fill and Purge Heating System . . . . .24

D Piping Illustrations . . . . . . . . . . . . . . .25

PART 6 . . . . . . . . . . . . . . . . . . .35 thru 37

START UP PROCEDURES

A Items to be checked before

lighting the Munchkin . . . . . . . . . . . .35

B Lighting Instructions . . . . . . . . . . . . .35

C Operating Instructions . . . . . . . . . . . .36

D Adjusting the Temperature

on the Munchkin Display . . . . . . . . . .36

E Status Menu . . . . . . . . . . . . . . . . . . .37

F To Turn Off Gas to Appliance . . . . . .37

PART 7 . . . . . . . . . . . . . . . . . . .38 thru 41

SERVICING

A Sequence of operation . . . . . . . . . . .38

B Munchkin Temporary

Fault Condition . . . . . . . . . . . . . . . . .38

C Munchkin Fault Requiring

Manual Reset . . . . . . . . . . . . . . . . . .39

PART 8 . . . . . . . . . . . . . . . . . . .42 thru 46

MAINTENANCE

A Maintenance Procedures . . . . . . . . . .42

B Before Each Heating Season . . . . . . .42

C Condensate Cleaning Instructions . . .42

D Combustion Chamber

Coil Cleaning Instructions . . . . . . . . .43

E Munchkin Controller . . . . . . . . . . . . .44

F Components Diagrams . . . . . . . .45–46

Page 4

GENERAL INFORMATION

4

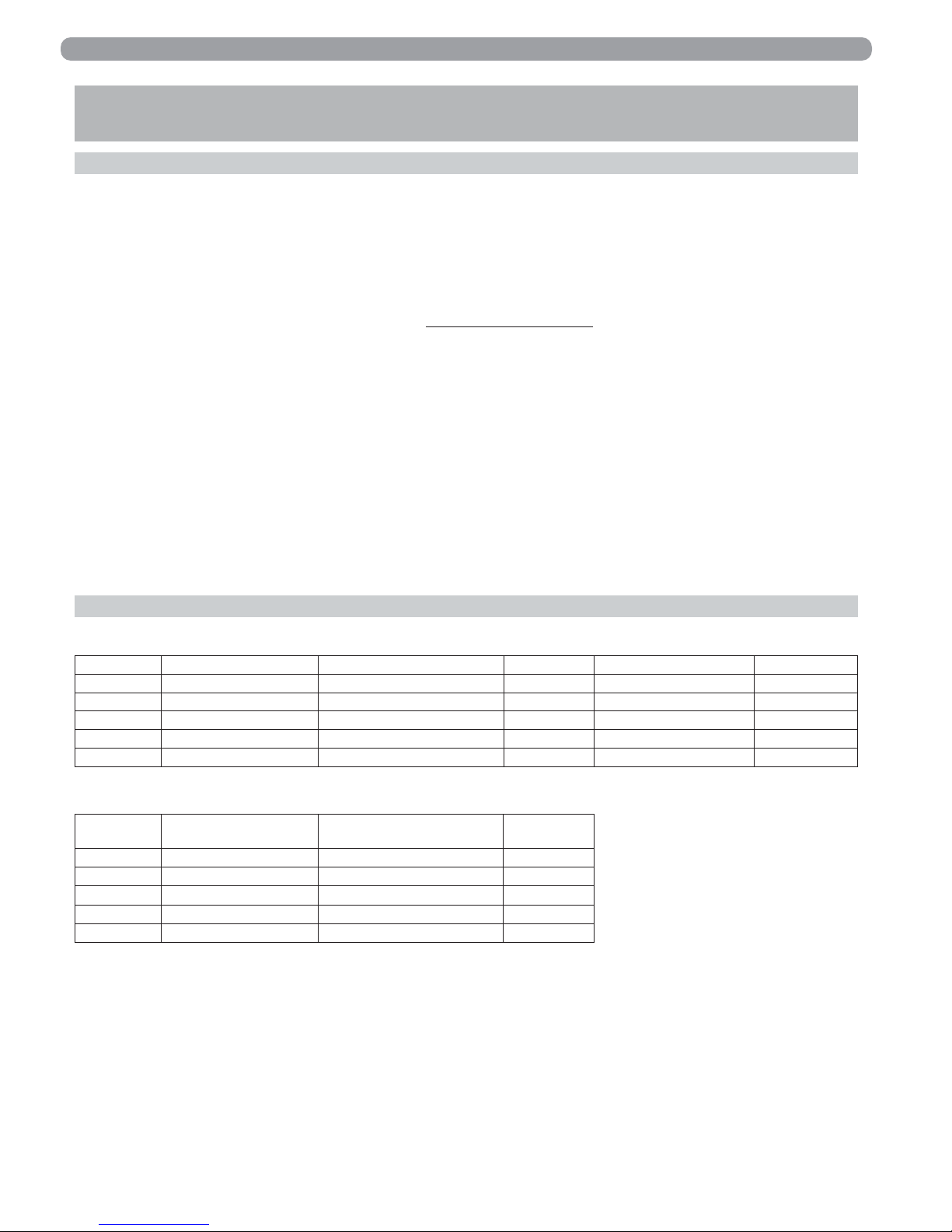

B. MUNCHKIN RATINGS AND DIMENSIONS

PERFORMANCE RATINGS

CONNECTION SIZES

PART 1. GENERAL INFORMATION

A. HOW IT OPERATES

When the room thermostat calls for heat, the Munchkin control board will start the circulator and start

to monitor the return temperature of the system before the heater will begin to heat the water. Once

the controller has sensed a drop in the return water temperature below the temperature set point

minus the differential set point, the heater will start to heat the water. This eliminates the Munchkin

starting every time the thermostat calls for heat. This feature keeps the system from short cycling.

Once the system has sensed the temperature difference, the Munchkin will activate the blower motor

for 5 seconds to pre-purge the system before starting the Munchkin

. The Munchkin controller will now

start to modulate the pre-mix burner based on analyzing the return temperature, supply water

temperature and the set point temperature. By compiling this information, the controller utilizes an

algorithm to fully adjust the firing rate while maintaining the desired output temperature. The pre-mix

burner fan has a direct drive current low-voltage motor with a pulse relay counting. This system allows

precise control over the fan speed and combustion air volumes. Coupled with the Honeywell gas valve

and the Venturi system which are set to provide a one-to-one ratio of precisely measured volumes of

fuel to air, an accurate and instant burner output is achieved. This keeps the Munchkin running at the

highest efficiency.

When the thermostat is satisfied, the Munchkin will then go through a 4 second post-purge cycle before

shutting off. Every Munchkin heater is equipped with a display which will read the outlet temperature of

the heater and then will illuminate a green light showing flame on. If a problem occurs, the front indicator

light will turn red and the display will read a fault code; see Part 7, Section B/C, pages 38 and 39.

ledoMnoitaludoMtupnIgnitaeHEODEUFAthgieWgnippihSRBI

M05T000,05ot000,81000,64ot000,61%29.sbl85000,04

M08T000,08ot000,91000,47ot000,71%29.sbl85000,46

M08000,08ot000,72000,47ot000,52%29.sbl57000,46

M041000,041ot000,64000,921ot000,34%29.sbl101000,211

M991000,991ot000,66000,381ot000,16%29.sbl111000,951

ledoM

M05TTPN"4/1"4/3"2

M08TTPN"4/1"4/3"2

M08TPN"4/1"4/3"3

M041TPN"4/1"4/3"3

M991TPN"4/1"4/3"3

nruteR/ylppuS

noitcennoCeziSnoitcennoCsaG.aiDtneV

Page 5

GENERAL INFORMATION

5

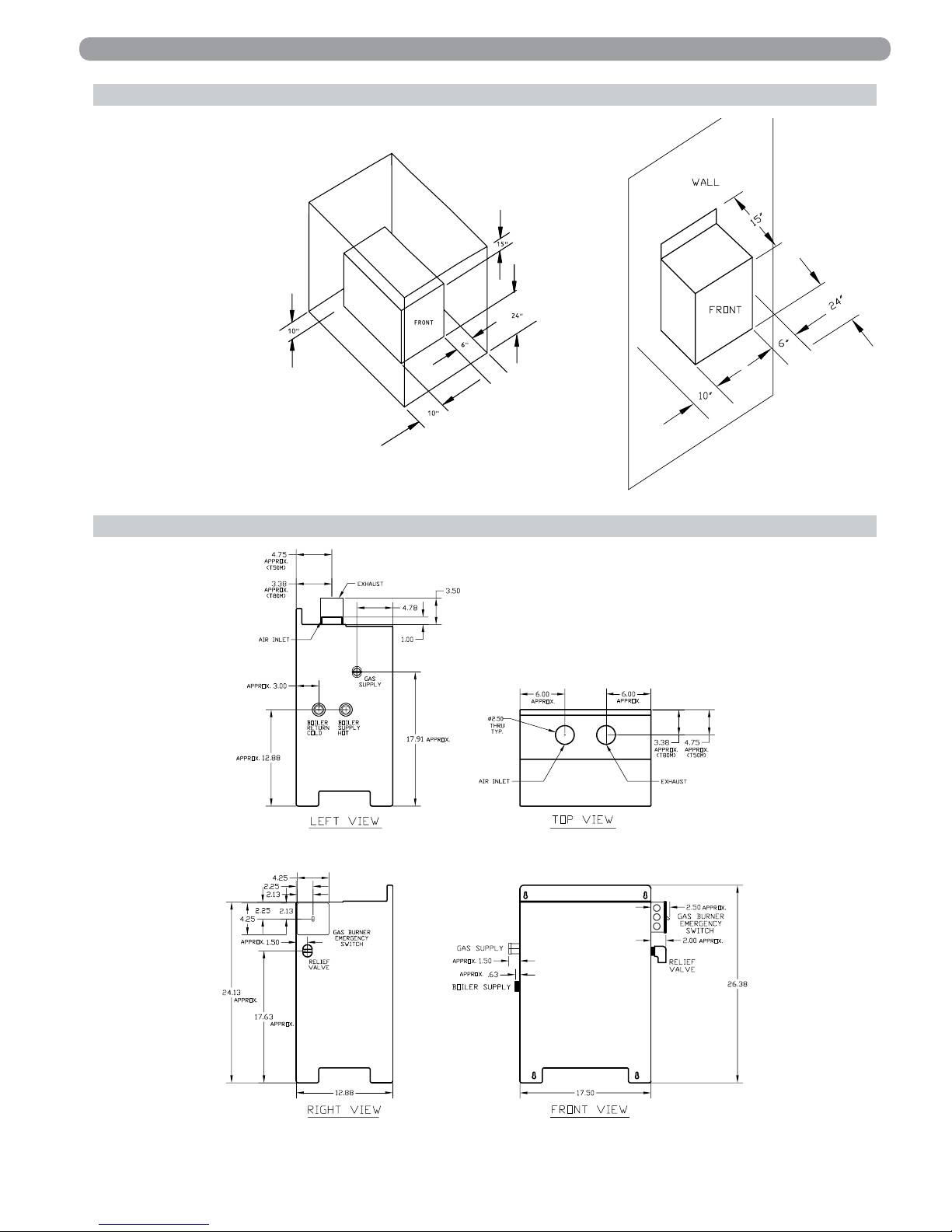

Figure 1-1

(NOTE: The

Munchkin is rated

at zero clearance

to combustibles.)

Figure 1-3

T50M/T80M

80M/140M/199M T50M/T80M

DIMENSIONS

RECOMMENDED SERVICE CLEARANCES

Figure 1-2

Page 6

GENERAL INFORMATION

6

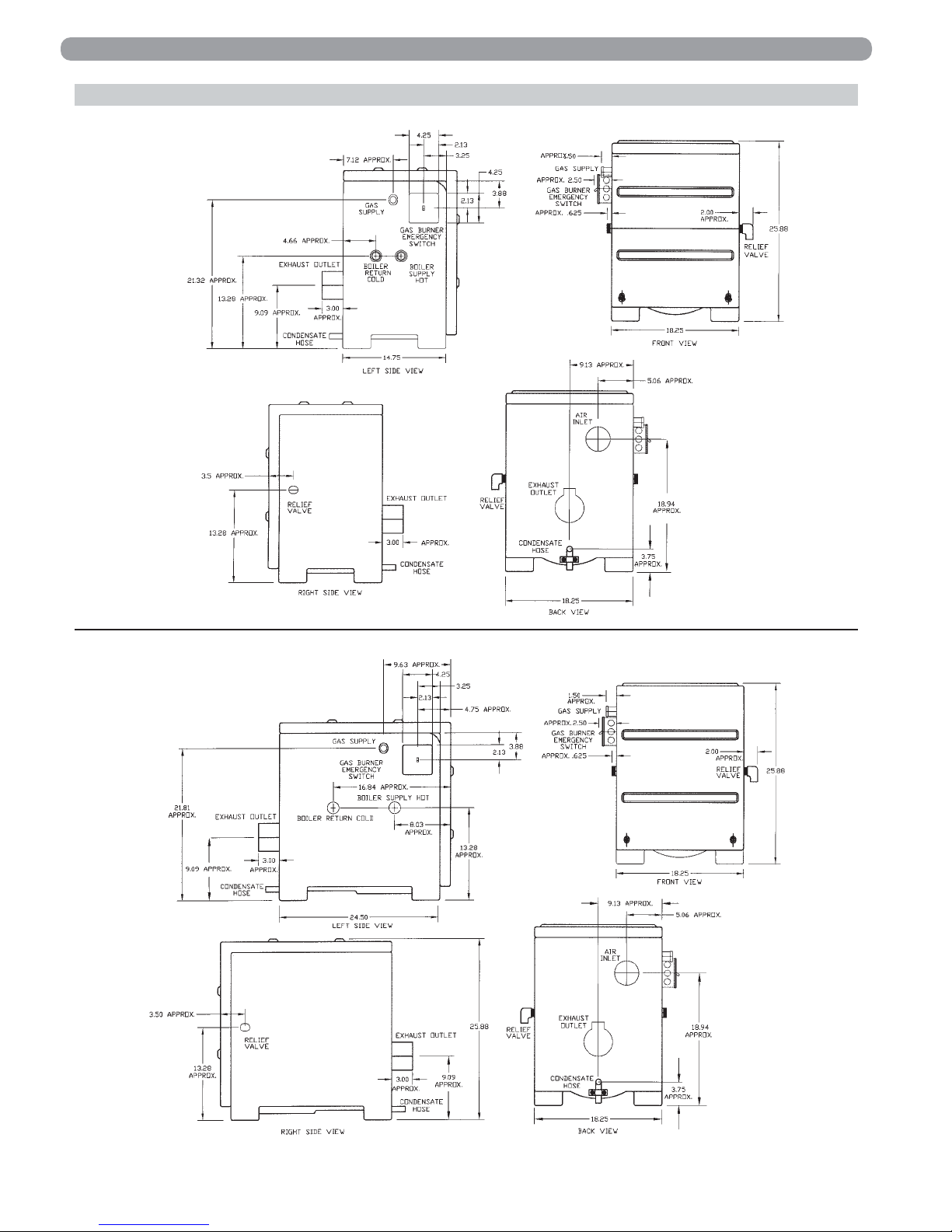

DIMENSIONS

80M

140M/199M

Figure 1-4

Figure 1-5

Page 7

7

GENERAL INFORMATION

C. PRE-INSTALLATION REQUIREMENTS

The Munchkin is designed for installation on non-rated flooring, in alcoves, basements, utility rooms,

and closet but never a bedroom closet. Choose a location for your Munchkin, centralized to the piping

system, along with consideration for Electrical (Part 2, Page 8), Gas Connection (Part 3, Page 10) and

Venting (Part 4, Page 13).

If the Munchkin is set up for liquefied petroleum (LP) gas, some geographic areas follow the Uniform

Mechanical Code, section 304.6, “Liquefied petroleum gas burning appliances shall not be installed in

a pit, basement or similar location where heavier-than-air gas might collect. Appliances so fueled, shall

not be installed in a below grade under-floor space or basement unless such location is provided with

an approved means for removal of unburned gas.”

WARNING

The Munchkin is certified as an indoor appliance. Do not install the Munchkin

outdoors or locate where it will be exposed to freezing temperature. This includes all

related piping and components. If the Munchkin is subjected to flood water or

submersed in water, the Munchkin must be replaced.

NOTICE

Service clearance of the Munchkin: See Section 1, Figures 1-1 and 1-2.

NOTICE

Condensation removal: This is a condensing high efficiency appliance, therefore

condensation removal must be addressed to avoid damage to surrounding area or

appliance. See Part (4) Section E for Condensate Requirements (pg. 21).

WARNING

D. PRESSURE RELIEF VALVE

A pressure relief valve is installed into the front right side manifold. We recommend a WATTS ¾"

M 335 MI valve or equivalent and meets the requirements of ANSI/ASME Heater and Pressure

Vessel Code, Section IV or CSA B51; Heater, Pressure Vessel and Piping Code as applicable for

heating heaters. A ¾" pipe must be directed to a floor drain or suitable location within 6" of a drain

or floor. Protect from freezing, do not plug or cap pressure relief valve. Serious explosion causing

property damage and or loss of life could result. Under no circumstances should the relief valve

be eliminated, capped or plugged.

Page 8

8

ELECTRICAL

PART 2. ELECTRICAL

A. ELECTRICAL CONNECTION

The electrical connection for the Munchkin is on the left hand side of the unit. There is a ½” knockout

location for an electrical connection for both the incoming power and the central heating circulator

connection. All electrical wiring must be performed by a qualified licensed electrician in accordance

with National Electrical Code ANSI/NEPA to and/or the Canadian Electrical Code, Part 1 CSA C22.1, or

to the applicable codes and standards. For your convenience, we have labeled all the wires that need

to be connected to operate the Munchkin.

The electrical requirements are for standard 120 volts, 60 Hz 15 Amp service. This unit is wired with

#18 awg and fused for no more than 15 Amps.

There are two ground points in the electrical compartment that must be connected to the building

ground system. Connect the building ground to the green ground screw and the green ground wire

inside electrical box provided.

The Incoming Power Supply is connected to the Black (Hot) and the White (Neutral).The Munchkin

Control board is polarity sensitive. If the polarity is reversed, the Munchkin control will not sense a

flame and lock out the system. The Orange and Brown wire are provided to the supply of 120 volts to

the Central Heating Circulator. Connect the Orange (Hot) and the Brown (Neutral) directly to the Central

Heating Circulator.

Connect the gray wires to your heating thermostat (TT) connection. Your thermostat heat anticipator

setting is .056 amp.

CAUTION

Electrical wiring on the Incoming Power and Central Heating Circulator shall be

connected directly to the intended connection source and not be connected together

inside the electric box provided. An Electrical Short will result and the Control board

will have to be replaced! If Electrical Requirements of the Central Heating Circulator

exceeds 4 amps (or 3 amps on HA models only) please follow the wiring diagrams on

Page 9, Figures 2-1, 2-2 and 2-3.

DANGER

IT IS EXTREMELY IMPORTANT THAT THIS UNIT BE PROPERLY GROUNDED!

DANGER

IT IS VERY IMPORTANT THAT THE BUILDING GROUND IS INSPECTED BY A

QUALIFIED ELECTRICIAN PRIOR TO MAKING THIS CONNECTION!

DANGER

The Orange wire for the Central Heating Circulator is Switched Hot and must have a

wire nut if not connected to the Central Heating Circulator. Failure to follow this

instruction will result in a short, and the Control Board will have to be replaced.

Page 9

9

ELECTRICAL

It is important that the electrical power is not turned on at this time. Double check all connections and then

turn the power on. The display that is provided with the Munchkin should now be reading the outlet

temperature. Note: see Part 6/Startup Procedure section in the manual to change the temperature setting

or run the heater.

NOTICE

Do not power zone valves directly from the heater transformer. Doing so will greatly

reduce the life of the transformer. Use a separate transformer sized to handle the total

electric load of all zone valves.

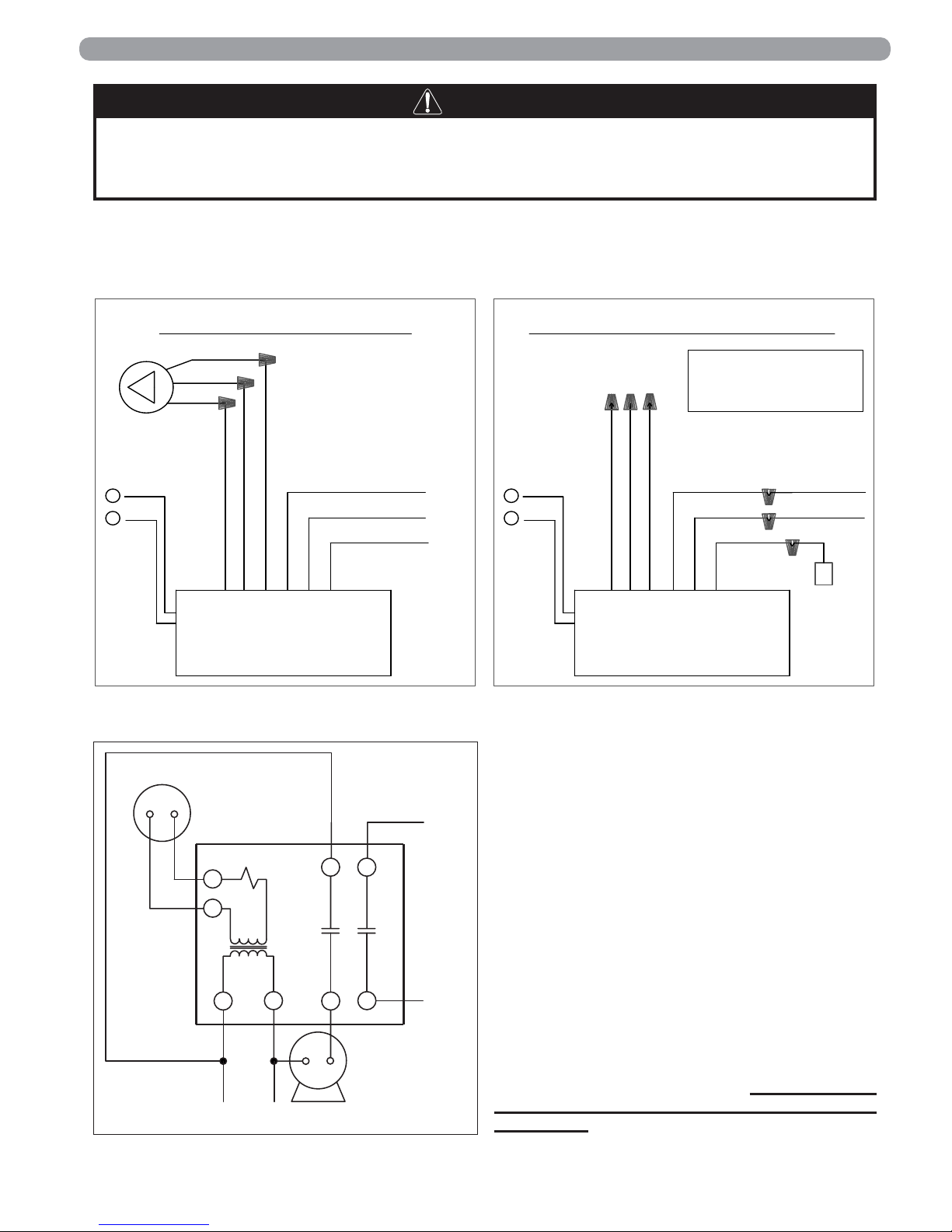

Figure 2-1: Connection Wiring Directly to

Central Heating Circulator

Figure 2-2: Connection Wiring without Wiring

Central Heating Circulator

Note to Electrical Contractor: The orange

wire is 120 Volt/4 Amp maximum for central

heating circulator only. Loads greater than 4

amps or 3 amps for HA models only will blow the

fuse on the board. The brown wire is the neutral wire for the central heating pump only.

Figure 2-3: For circulator amp loads greater

than 4 amps (3 amps for “HA” models) use the

wiring diagram shown at left. The brown and

orange wires will not be used in this

application.

5

T

1

2

3

6

4

T

1K1 1K2

BOILER

"TT"

GRAY

ZONE

CIRCULATOR

120 VOLT

L1 HOT (BLACK)

GRAY

BOILER

"TT"

THERMOSTAT

ZONE

R845A

SWITCHING

RELAY ZONE

1K1

L2 NEUTRAL

(WHITE)

DIAGRAM "A"

WIRING DIAGRAM CONNECTING TO CIRCULATOR

GREEN (GROUND)

WHITE (NEUTRAL)

BLACK

NORMALLY OPEN

THERMOSTAT

CONNECTION

GRAY

T

GRAY

T

BROWN (NEUTRAL)

ORANGE (HOT)

GREEN (GROUND)

(NEUTRAL)

ELECTRICAL

SWITCH JUNCTION BOX

120V 60 HZ

WHITE

(GROUND)

GREEN

BLACK

(HOT)

DIAGRAM "B"

WIRING DIAGRAM WITHOUT CONNECTION TO CIRCULATOR

IMPORTANT NOTE:

N

BE CERTAIN THAT THE ORANGE

WIRE IS SECURELY CAPED.

GREEN

ORANGE

NORMALLY OPEN

THERMOSTAT

CONNECTION

GRAY

T

GRAY

T

BROW

ORANGE (HOT)

BROWN (NEUTRAL)

SWITCH JUNCTION BOX

120V 60 HZ

FAILURE TO DO SO COULD

RESULT IN INJURY OR FIRE

AND COULD DAMAGE THE CONTROL.

WHITE

(NEUTRAL)

GREEN (GROUND)

GREEN

(GROUND)

ELECTRICAL

BLACK

(HOT)

GROUND

BUS

Page 10

10

GAS CONNECTION

PART 3. GAS CONNECTION

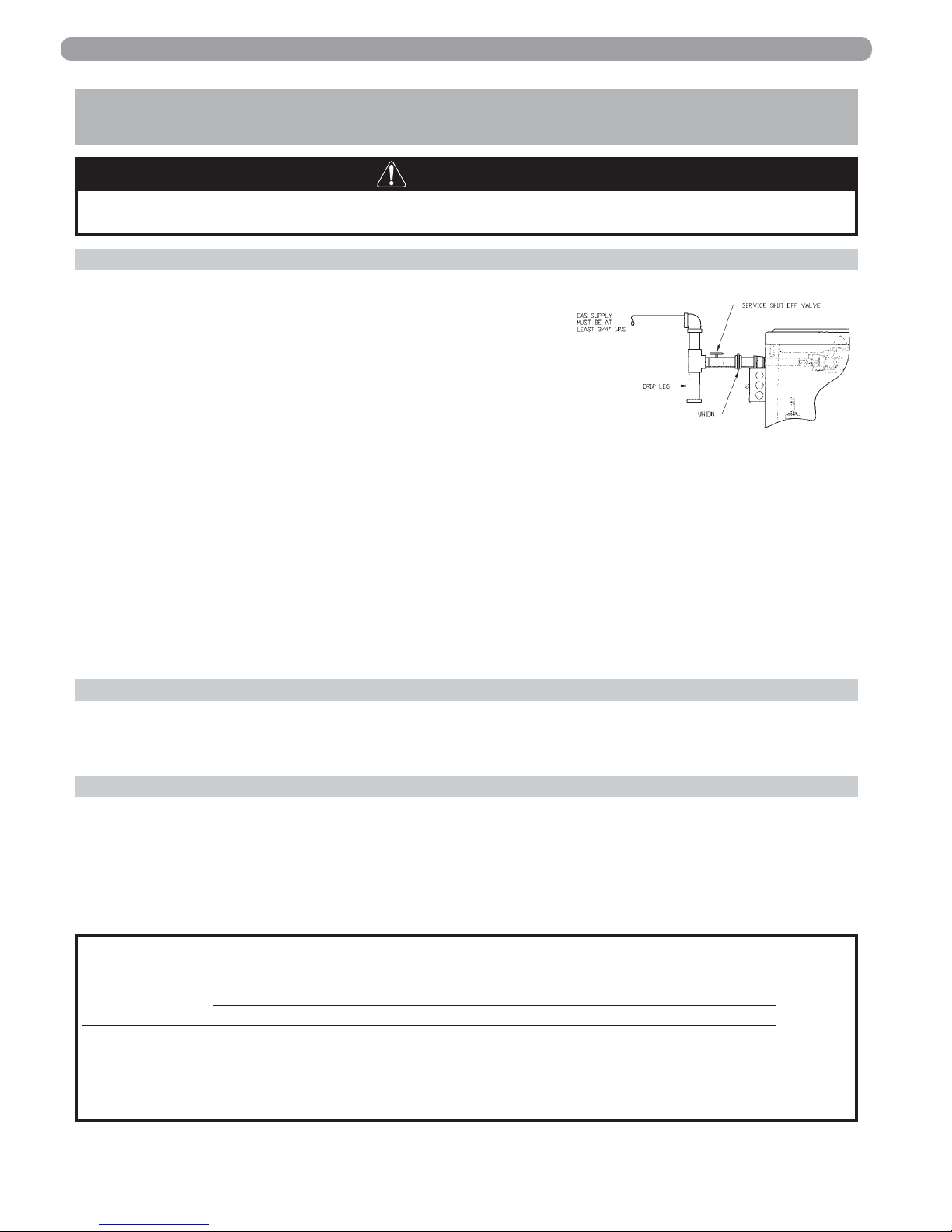

A. GAS CONNECTION

The gas supply shall have a maximum inlet pressure of less

than 14" water column (350 mm), ½ pound pressure (3.4 kPa),

and a minimum of 7" water column. The entire piping system,

gas meter and regulator must be sized properly to prevent

pressure drop greater than 0.5" as stated in the National Fuel Gas

Code. This information is listed on the rating plate. It is very

important that you are connected to the type of gas as noted on the

rating plate. "LP" for liquefied petroleum, propane gas or, "Nat" natural or

city gas. All gas connections must be approved by the local gas supplier, or utility in addition to the

governing authority, prior to turning the gas supply on. The nipple provided is ½" and it is mandatory

that a ¾" to ½" reducing coupling (provided) is used, threaded into the branch of a ¾" tee, and a drip

leg fabricated, as per the National Fuel Gas code. You must ensure that the entire gas line to the

connection at the Munchkin is no smaller than ¾". Once all the inspections have been performed, the

piping must be leak tested. If the leak test requirement is a higher test pressure than the maximum inlet

pressure, you must isolate the Munchkin from the gas line. In order to do this, you must shut the gas

off using factory and field-installed gas cocks (following the lighting instructions in Part 6 Section B.)

This will prevent high pressure. Failure to do so may damage the gas valve. In the event the gas valve

is exposed to a pressure greater than ½ PSI, 14" water column, the gas valve must be replaced. Never

use an open flame (match, lighter, etc.) to check gas connections.

B. GAS PIPING

1. Run the gas supply line in accordance with all applicable codes.

2. Locate and install manual shutoff valves in accordance with state and local requirements.

C. GAS TABLE

Refer to Table (1) to size the supply piping to minimize pressure drop between meter or regulator

and unit.

Maximum Capacity of Pipe in Cubic Feet of Gas per Hour for Gas Pressures of 0.5 psi or Less and a

Pressure Drop of 0.3 Inch water Column

(TABLE 1) (Based on a 0.60 Specific Gravity Gas)

Nominal

Iron Pipe Internal Length of Pipe (Feet)

Size Diameter

(inches) (inches) 10 20 30 40 50 60 70 80 90 100 125 150 175 200.

3/4 .824 278 190 152 130 115 105 96 90 84 79 72 64 59 55} BTU'S

1 1.049 520 350 285 245 215 195 180 170 160 150 130 120 110 100} PER

1 1/4 1.380 1,050 730 590 500 440 400 370 350 320 305 275 250 225 210} HOUR

1 1/2 1.610 1,600 1,100 890 760 670 610 560 530 490 460 410 380 350 320} X 1,000

WARNING

Failure to follow all precautions could result in fire, explosion or death!

Page 11

11

GAS CONNECTION

It is recommended that a soapy solution be used to detect leaks. Bubbles will appear on the pipe to

indicate a leak is present. The gas piping must be sized for the proper flow and length of pipe, to avoid

pressure drop. Both the gas meter and the gas regulator must be properly sized for the total gas load.

If you experience a pressure drop greater than 1" WC, the meter, regulator or gas line is undersized or

in need of service. You can attach a manometer to the incoming gas drip leg, by removing the cap and

installing the manometer. The gas pressure must remain between 7" and 14" during stand-by (static)

mode and while in operating (dynamic) mode. If an in-line regulator is used, it must be a minimum

of 10 feet from the Munchkin. It is very important that the gas line is properly purged by the gas

supplier or utility. Failure to properly purge the lines or improper line sizing, will result in ignition

failure. This problem is especially noticeable in NEW LP installations and also in empty tank situations.

This can also occur when a utility company shuts off service to an area to provide maintenance to their

lines. This gas valve must not be replaced with a conventional gas valve under any circumstances. As

an additional safety feature, this gas valve has a flanged connection to the Venturi and blower.

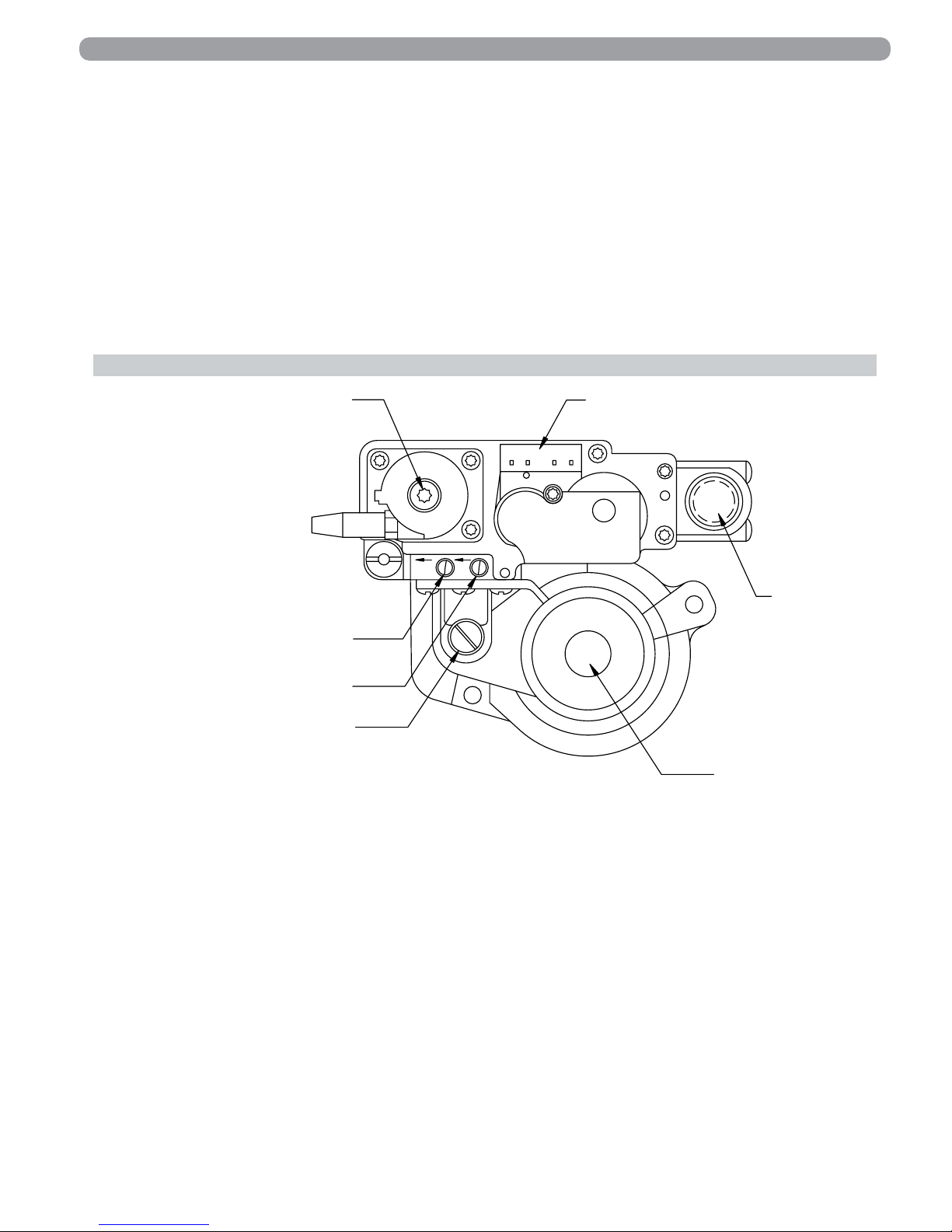

MUNCHKIN GAS VALVE

Fig. 3-1

DO NOT REMOVE THIS SCREW

OR ATTEMPT TO MAKE

ANY ADJUSTMENT TO THIS SCREW.

OUTLET PRESSURE TAP

INLET PRESSURE TAP

THROTTLE ADJUSTMENT SCREW.

NOTE: IF FOR ANY REASON THE SCREW IS

ADJUSTED, A "COMBUSTION ANALYZER"

MUST BE USED TO ENSURE SAFE AND

PROPER OPERATION. TURNING THE SCREW

CLOCKWISE DECREASES YOUR GAS FLOW

WHICH WILL LOWER THE CO/CO2 % LEVELS.

TURNING THE SCREW COUNTER-CLOCKWISE

INCREASES YOUR GAS FLOW WHICH WILL

RAISE THE CO/CO2 % LEVELS.

OUT

MIN

24 VOLT DC ELECTRICAL CONNECTION

V1

V2

1/2" NPT

GAS INLET

AIR INLET, KEEP FREE

OF DEBRIS

Page 12

12

GENERAL INFORMATION

WARNING

Failure to follow all precautions could result in fire, explosion or death!

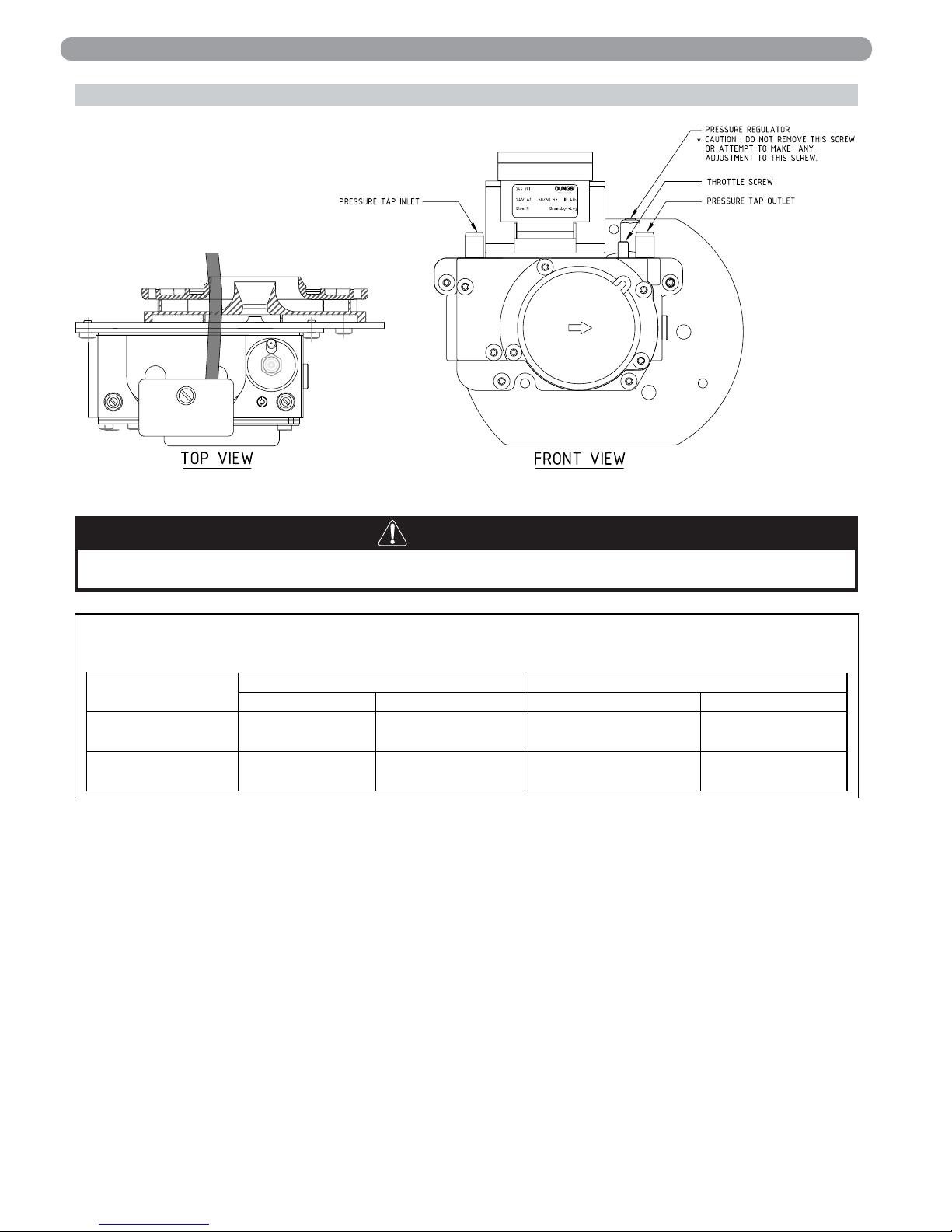

Fig. 3-3

Fig. 3-2

T50M/T80M GAS VALVE

COMBUSTION SETTINGS

HIGH FIRING RATES and LOW FIRING RATES ON ALL MODELS

Natural Gas Propane LP

high

Carbon CO ppm

Monoxide

Carbon CO

Dioxide

2%

low high

0-20 ppm

8-1/2 % - 9-1/2 %

80 ppm - 135 ppm

8-1/2 %- 9-1/2 %

low

0-20 ppm 80 -150 ppm

9-1/2 %- 10-1/2 % 9-1/2 %- 10-1/2 %

Page 13

13

VENTING

PART 4. VENTING

A. APPROVED VENTING MATERIALS

Exhaust V

ent and Extensions

in Plastic 2", 3" and 4" Pipe Schedule 40 or 80.

1. Non Foam Core PVC Pipe

2. Non Foam Core CPVC Pipe

3. Non Foam Core ABS Pipe

Vent Piping must conform to following

1. PVC Non Foam Core Pipe (Polyvinyl Chloride) to ASTM D-1784 Class 12454-B, Formerly designated Type 1, Grade 1.

2. CPVC (Chlorinated Polyvinyl Chloride) Class 23447-B, Formerly designated Type IV, Grade 1 conforming to ASTM D-1784.

3. ABS (Acrylonitrile-Butadiene-Styrene) Class 3-2-2-2-2 conforming to ASTM D3965.

The Munchkin is a direct vent appliance. The Munchkin is listed as a Category

IV Condensing Appliance. (The Munchkin Venting is rated at Zero Clearance

to combustibles.)

Note: For Concrete construction or to meet certain fire codes, exhaust and inlet piping at the wall

penetration to the Munchkin must be CPVC Schedule 40 or 80 to meet local fire codes. The balance

from the penetrated wall to the outside, may be PVC Schedule 40 or 80.

Inlet Air V

ent

Use the same material as used for exhaust in either 2", 3" or 4" Plastic Pipe. Cellular Foam Core Pipe

may be used for the inlet only, NEVER ON EXHAUST PIPING!

DANGER

It is extremely important to follow these venting instructions carefully. Failure to do

so can cause severe personal injury, death or substantial property damage.

DANGER

Foam Core Pipe is not to be used in connecting the exhaust pipe.

WARNING

This vent system will operate with a positive pressure in the vent pipe. Do not

connect vent connectors serving appliances by natural draft into any portion of

mechanical draft systems operating under positive pressure.

Page 14

14

VENTING

B. VENTING THE MUNCHKIN

The inlet pipe on the back of the cabinet should be 3" PVC schedule 40. It is very important that you

plan the location properly to eliminate long pipe runs and excessive fittings. Inlet pipe size must not

be reduced. Do not combine the inlet air with any other inlet pipe including an inlet to an additional

similar appliance. The joints must be properly cleaned, primed and cemented. The piping must also

be properly supported as per Local and National Standard Plumbing Codes. It is important that the

piping must be clean and free from burrs, debris, ragged ends and particles of PVC.

Exhaust piping should be sloped back to the connection on the Munchkin, at least ¼" per foot to

remove additional condensate that forms within the pipe. The total combined length of pipe (intake

piping plus exhaust piping added together) including elbow allowances intake and exhaust (each

elbow = 5' of pipe) should not exceed 85'. The combined vent length should not be less than a combined length of 6' plus two 90 degree elbows. Choose your vent termination locations carefully. You

must also make certain that exhaust gas does not re-circulate back into the intake pipe. You must

place them in an open area and follow the following guidelines.

1) Never vent into a walkway, patio area, alley or otherwise public area less than 7' from the

ground. (See the following detail references Fig. A.10.8 in the National Fuel Gas Code 2002

“Exit Terminals of Mechanical Draft and Direct-Venting Systems”.)

2) Never vent over or under a window or over a doorway where the exhaust plume or condensation liquid will cause obtrusive or dangerous conditions. (Or refer to National Fuel Gas

Code, CAN B149)

3) Never install a heat saver or similar product to capture waste heat from exhaust.

4) Always have a vent location at least 1' above maximum snow level.

5) Always have vent 1' above ground level, away from shrubs and bushes.

6) Follow local gas codes in your region or refer to National Fuel Gas Code, Can B149.

7) Always have at least 3' from an inside corner of outside walls.

8) Maintain at least 4' clearance to electric, gas meters, windows, exhaust fans, chimneys, inlets

or mechanical vents.

9) Very Important! The inlet air connection must be connected to outside air and should be

located no closer than 8" to the exhaust and no further than 36".

10) Always place screens in all openings in intake and exhaust to prevent foreign matter from

entering the Munchkin.

11) The vent intake and exhaust must be properly cleaned and glued for a pressure tight joint.

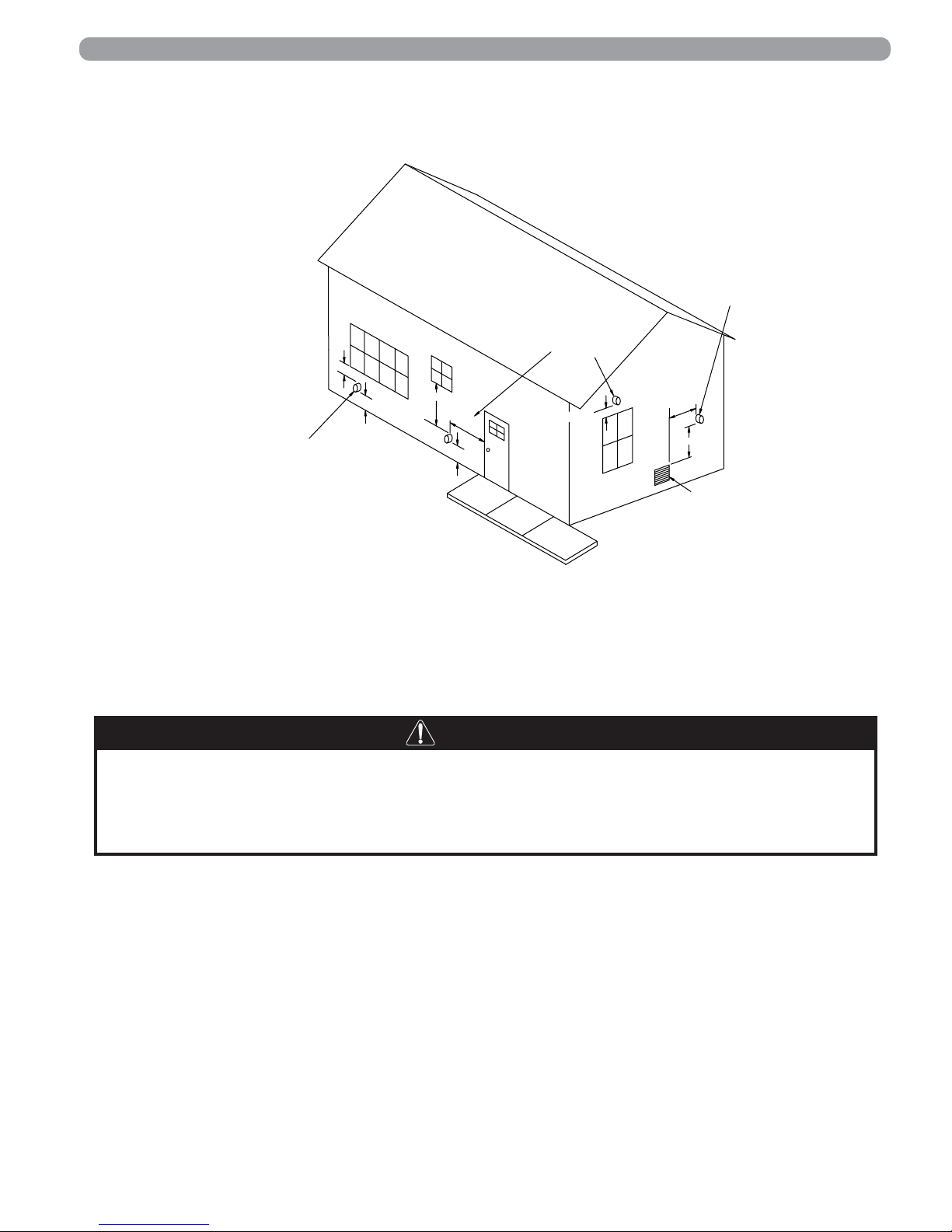

Several methods for venting the Munchkin can be found in Figures 4-1 thru 4-6, this section

pages 18 and 20. Use these layouts as guidelines: certain site conditions such as multiple

DANGER

It is extremely important to follow these venting instructions exactly. Failure to do so

can cause severe personal injury, death or substantial property damage.

NOTICE

The following are code restrictions for the location of the flue gas vent terminal.

Compliance to these requirements doesn’t insure a satisfactory installation; good

common sense must also be applied. It is important to make sure that exhaust gases

are not recirculated into the inlet air of the Munchkin.

Page 15

15

roof lines/pitches may require venting modifications (consult factory). The air inlet must be a

minimum of 1' vertically above the maximum snow level. It is very important that there are

no other vents, chimneys or air inlets in any direction for at least 4'.

All venting must be properly supported. The Munchkin is not intended to support any venting

whatsoever. All piping, glue, solvents, cleaners, fittings and components, must conform to ASTM

(American Society for Testing and Materials), and ANSI (American National Standards Institute). It is

recommended that you use one of the optional vent kits specifically designed for Munchkin installations, available from Heat Transfer Products, Inc. (KGAVT0601CVT [3 in.], KGAVT0501CVT [2 in.] or

V1000). NOTE: When using the KGAVT601CVT KIT, REMOVE THE 2 SCREENS FROM THE PROVIDED INLET TEE AND INSTALL THEM IN THE INLET SOCKET AND OUTLET SOCKET (Y TEE CONNECTION) OF THE KIT PRIOR TO INSTALLING THE SCHEDULE 40 PIPE AND GLUING.

*Note: The V1000 when used for the T50 or T80 will require a transition piece from 2" to 3".

VENTING

CAUTION

Flue Gas will condense as it exits the vent termination. This condensate can freeze on

exterior building surfaces which may cause discoloration of these surfaces.

Consideration should be given to the plume of condensation that exits the exhaust

which may affect the cosmetic appearance of the building.

echanical

M

ent

raft v

d

al

in

rm

te

(see 10.8.1)*

raft

ical d

echan

M

al

in

12 in.m

vent term

(see 10.8.2)*

inimum

Less

than 10 ft.

3 ft.minimum

Forced air

inlet

rade

G

C

12 in.minimum

Direct vent terminal clearance

Minimum clearance, C

Input (Btu/hr)

10,000 or less

10,001 to 50,000

Over 50,000

(see 10.8.3)*

For SI units: 1 ft = 0.305 m; 1 in. = 25.4 mm;

1 Btu/hr = 0.293 W

Clearance (in.)

6

9

12

inim

4 ft.m

12 in.minimum

um

4 ft.

minimum

EXIT TERMINALS OF MECHANICAL DRAFT

AND DIRECT-VENT VENTING SYSTEM

* REFERENCE: THE NATIONAL FUEL GAS CODE

2002 EDITION

Page 16

16

VENTING

Friction Loss Equivalent in Piping and Fittings

Fittings or Piping Equivalent Feet

90 degree elbow = 5

45 degree elbow = 3

Coupling = 0

air inlet tee = 0

Plastic Pipe = 1

concentric vent kit = 3

V1000 vent kit = 0

Example: Installation requires the following material for both inlet and exhaust piping for the

Munchkin

Required: 4 Pcs. (2" or 3") 90 degree elbow (4 x 5 = 20 Equivalent Feet) = 20 Equivalent Feet

Required: 20' of (2" or 3") Plastic PVC Pipe (20 x 1 = 20 Equivalent Feet) = 20 Equivalent Feet

Total Friction Loss in Equivalent Feet (20 + 20 = 40 Equivalent Feet) = 40 Equivalent Feet

C. LONGER VENT RUNS

The connection of the air inlet and exhaust vent at the heater must remain at the standard vent size

from the unit (2" for the T50/T80) (3" for the 80M/140M/199M). If a transition is required, it must occur

at a minimum of 5 feet from the unit for both intake and exhaust and no greater than 15 feet. Then

transition to the next size pipe. See the friction loss equivalent table to apply longer vent runs. The

overall extended combined length of pipe on the inlet and exhaust must not exceed 125 equivalent

feet total.

Example: Installation requires the following material for both the inlet and exhaust piping when

extending the vent run for the Munchkin.

3" Vented Appliance

2 Pcs. – 3" 90 degree elbow (2 x 5 = 10 Equivalent Feet) = 10 Equivalent Feet

20' of 3" Plastic PVC Pipe (20 x 1 = 20 Equivalent Feet) = 20 Equivalent Feet

Total of 3" Equivalent Piping with Fittings = 30 Equivalent Feet

Transitioning to 4" Venting

6 Pcs. – 4" 90 degree elbows (6 x 3 = 18 Equivalent Feet) = 18 Equivalent Feet

4 Pcs. – 4" 45 degree elbows (4 x 1 = 4 Equivalent Feet) = 4 Equivalent Feet

40' of 4" Plastic PVC Pipe (40 x 1 = 40 Equivalent Feet) = 40 Equivalent Feet

Total of 4" Equivalent Piping with Fittings = 62 Equivalent Feet

Total Friction Loss in Equivalent Feet for both 3" and 4"

(30 + 62 = 92 Equivalent Feet) = 92 Equivalent Feet

NOTICE

Do not exceed the 85 foot maximum requirement (intake plus exhaust piping added

together) including fitting allowance.

WARNING

Transitioning from 2" to 3" or 3" to 4" should be done in the Vertical position to avoid

condensation blockage. If done in the horizontal position check to make sure

condensation blockage will not occur.

Page 17

17

D. HEATER REMOVAL FROM A COMMON VENT SYSTEM

At the time of removal of an existing heater, the following steps shall be followed with each appliance remaining connected to the common venting system placed in operation, while the other appliances remaining connected to common venting system are not operating.

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and horizontal pitch to determine if there

is blockage, leakage, corrosion or other deficiencies that could cause an unsafe condition.

3. If practical, close all building doors, windows and all doors between the space in which the

appliance remains connected to the common venting system located and other spaces in the

building. Turn on clothes dryers and any appliances not connected to the common venting

system. Turn on any exhaust fans, such as range hoods and bathroom exhausts, at maximum

speed. Do not operate a summer exhaust fan. Close all fireplace dampers.

4. Place in operation the appliance being inspected. Follow the lighting instructions. Adjust the

thermostat so the appliance will operate continuously.

5. Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use

the flame of a match or candle or smoke from a cigarette.

6. After it has been determined that each appliance remaining connected to common venting

system properly vents when tested as outlined, return doors, windows, exhaust fans, fireplace dampers and any other gas burning appliance to their previous condition of use.

7. Any improper operation of the common venting system should be corrected so the installation conforms with the National Fuel Gas Code, ANSI Z223.1. When resizing any portion of

the common venting system, the common venting system should be resized to approach the

minimum size as determined using the appropriate tables in Appendix G in the National Fuel

Gas Code , ANSI Z 223.1

DANGER

The Munchkin is not intended to be common vented with any other

existing appliance!

Page 18

18

VENTING

**IMPORTANT NOTE: All vent pipes must be

glued, properly supported and the exhaust must

be pitched a minimum of a ¼" per foot back to

the heater (to allow drainage of condensate).

Figure 4-1

**IMPORTANT NOTE: All vent pipes must be glued, properly supported and the exhaust must be pitched a minimum of a ¼" per foot back to the heater (to allow drainage

of condensate).

Figure 4-2

DIAGRAMS FOR SIDEWALL VENTING

Page 19

VENTING

19

**IMPORTANT NOTE: All vent pipes must be glued, properly supported and the exhaust must be pitched a

minimum of a ¼" per foot back to the heater (to allow drainage of condensate).

Figure 4-3

**IMPORTANT NOTE: All vent pipes must be glued, properly supported and the exhaust must be pitched a

minimum of a ¼" per foot back to the heater (to allow drainage of condensate).

Figure 4-4

Page 20

VENTING

20

**IMPORTANT NOTE: All vent pipes must be glued,

properly supported, and the exhaust must be pitched

a minimum of a ¼" per foot back to the heater (to

allow drainage of condensate).

Figure 4-5

**IMPORTANT NOTE: All vent pipes must be glued,

properly supported, and the exhaust must be pitched

a minimum of a ¼" per foot back to the heater (to

allow drainage of condensate).

Figure 4-6

DIAGRAMS FOR VERTICAL VENTING

Page 21

21

VENTING

E. CONDENSATE REQUIREMENTS

This is a condensing high efficiency appliance, therefore this unit has a condensate removal system.

Condensate is nothing more than water vapor, derived from the combustion products, similar to an

automobile when it is initially started. This condensate does have a low PH and should be treated

with a condensate filter. This filter contains either lime crystals or marble crystals, which will

neutralize the condensate. The outlet of the filter is sized for 5/8" ID (Inside diameter) plastic tubing.

It is very important that the condensate line is sloped away from and down to a suitable inside drain,

if the condensate outlet on the Munchkin is lower than the drain, you must use a condensate

removal pump. A condensate filter and a condensate pump kit are available from Heat Transfer

Products, Inc. It is also very important that the condensate line is not exposed to freezing

temperatures, or any other type of blockage. Plastic tubing should be the only material used for the

condensate line. Steel, brass, copper or others will be subject to corrosion and deterioration. A

second vent may be necessary to prevent condensate line vacuum lock if a long horizontal run is

used. Also, an increase to 1" tubing may be necessary.

Page 22

22

PIPING

PART 5. PIPING

A. HYDRONIC PIPING WITH CIRCULATORS OR ZONE VALVES

The Munchkin is designed to function in a closed loop 15 PSI System. To assure you that you have

adequate pressure in the system, we have installed in the outlet manifold, a pressure switch that will

not let the Munchkin operate without a minimum of 10 PSI water pressure. This assures you that if the

system does have leak, the Munchkin will lock out (PRO on the display) before it damages the Stainless

Steel Heat Exchanger. We have also included a Temperature and Pressure gauge which should be

located on the Munchkin outlet to monitor the system pressure and outlet temperature from the

Munchkin. It is important to note that the Munchkin has a minimal amount of pressure drop and must

be figured in when sizing the circulators. Each Munchkin installation must have an Air Elimination

device which will remove air from the system. Install the Munchkin so the gas ignition system

components are protected from water (dripping, spraying, etc.) during appliance operation for basic

service of circulator replacement, valves and other. Observe minimum 1” clearance around all uninsulated hot water pipes when openings around pipes are not protected by non-combustible

materials. On a Munchkin installed above radiation level, some states and local codes require a low

water cut off device at the time of installation. If the Munchkin supplies hot water to heating coils in air

handler units, flow control valves or other devices must be installed to prevent gravity circulation of

heater water in the coils during the cooling cycle. Chilled Water Medium must be piped in parallel with

the heater. Freeze Protection for new or existing systems must use glycol that is specially formulated

for this purpose. It includes inhibitors, which prevent the glycol from attacking the metallic system

components. Make certain that the system fluid is checked for the correct glycol concentration and

inhibitor level. The system should be tested at least once a year and as recommend by the producer

of the glycol solution. Allowance should be made for the expansion of the glycol solution in the system

piping. Example 50% by volume solution expands 4.8% in volume for the temperature increase from

32 F to 180 F, while water expands 3% with the same temperature rise.

Basic steps are listed below, with Illustration, which will guide you through the installation of the

Munchkin.

1. Connect the system return marked “Heater In”, make sure to install with pipe sealant compound. Threaded connections are 1 ¼” NPT Brass nipples located on the left hand side of

unit.

2. Connect the system supply marked “Heater Out”, make sure to install with pipe sealant compound. Threaded connections are 1 ¼” NPT Brass nipples located on the left hand side of the

unit.

3. Install Purge and Balance Valve or shut off valve and drain on system return to purge air out

of each zone.

4. Install a Back Flow preventor on the Cold Feed Make-Up Water line.

5. Install a Pressure Reducing Valve on the Cold Feed Make-Up Water line, (15 PSI nominal on

the system return). Check Temperature and Pressure Gauge which should read minimum

pressure of 12 PSI.

6. Install a circulator on system supply. Make sure the circulator is properly sized for the system

and friction loss.

7. Install an Expansion Tank on the system supply. Consult the tank manufacturer’s instruction

for specific information relating to tank installation. Size the expansion tank for the required

system volume and capacity.

CAUTION

The Munchkin should not be operated as a potable Hot Water Heater. It should not be

used as a direct Hot Water Heating Device.

Page 23

23

PIPING

8. Install an Air Elimination Device on the system supply.

9. Install a drain valve at the lowest point of the system. Note: The Munchkin can not be drained

completely of water without purging the unit with an air pressure 15 PSI.

10. The Safety Relief Valve is installed at the factory located on the right hand side of Munchkin.

Pipe the discharge of safety relief valve to prevent injury in the event of pressure relief. Pipe

the discharge to a drain. Provide piping that is the same size as the safety relief valve outlet.

Never block the outlet of safety relief valve.

11. In compliance with ASME CSD-1, a low water cut-off device should be properly connected in

the field, both electrically and mechanically.

See the piping illustrations included in this section, pages 25–34, Figs. 5-3 to 5-11 for suggested

guidelines in piping the Munchkin heater with either zone valves or circulator pumps.

*Please note that these illustrations are meant to show system piping concept only, the installer

is responsible for all equipment and detailing required by local codes.

B. CIRCULATOR SIZING

The Munchkin Heat Exchanger does have pressure drop which must be considered in your system

design. Refer to the graph below for pressure drop through the Munchkin Heat Exchanger.

Figure 5-1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

Friction in Feet of Head

4

3

2

1

0

123456789101112131415161718192021

Flow in Gallons per Minute

MUNCHKIN 50M MUNCHKIN 80M

MUNCHKIN 140M MUNCHKIN 199M

* THE RECOMMENDED CIRCULATORS ARE BASED ON 1 GPM PER 10,000 BTU/HR W/20

BOILER TACO P/N GRUNDFOS P/N

50M/80M 007 * 15-42 F SPD-2

140M 0010 * 26-64 F

199M 0011 * 26-96 F

Page 24

24

PIPING

C. FILL AND PURGE HEATING SYSTEM

• Attach the hose to balance and purge hose connector or drain valve and run hose to nearest drain

• Close the other side of the balance and purge valve or the shut off valve after the drain.

• Open first zone balance and purge or drain valve to let water flow out the hose. If zone

valves are used, open the valves one at a time manually. (Note: please check valve manufacturer’s instruction prior to opening valves manually, so as not to damage the valve.)

• Manually operate fill valve regulator. When water runs out of the hose, while it’s connected to the balance and purge valve or drain you will see a steady stream or water (with no

bubbles). Close balance and purge valve or drain to stop the water from flowing.

Disconnect the hose and connect it to next zone to be purged.

• Repeat this procedure for additional zones (one at time).

Upon completion, make sure that the fill valve is in automatic position and each zone balance and

purge or shut off is in an open position and zone valves are positioned for automatic operation.

1. Glycol in hydronic applications which is specially formulated for this purpose includes

inhibitors which prevent the glycol from attacking metallic system components. Make certain

that the system fluid is checked for the correct glycol concentration and inhibitor level.

2. The glycol solution should be tested at least once a year and as recommended by the glycol

manufacturer.

3. Anti-freeze solutions expand more than water. For example a 50% by volume solution

expands 4.8% in volume for a temperature increase from 32° F to 180° F, while water expands

3% with the same temperature rise. Allowances must be made for this expansion in the system design.

4. A 30% mixture of glycol will result in a BTU output loss of 15% with a 5% increase in head

against system circulator.

5. A 50% mixture of glycol will result in a BTU output loss of 30% with a 50% increase in head

against system circulator.

CAUTION

For installation that incorporates standing Iron Radiation and systems with manual

vents at the high points. Follow above section and starting with the nearest manual

air vent, open vent until water flows out, then close vent. Repeat procedure, working

your way toward furthest air vent. It may be necessary to install a basket strainer in

an older system where larger amounts of sediment may be present. Annual cleaning

of the strainer may be necessary.

WARNING

Use only inhibited propylene glycol solutions which are specially formulated for

hydronic systems. Ethylene glycol is toxic and can attack gaskets and seals used in

hydronic systems.

Page 25

25

PIPING

D. PIPING ILLUSTRATIONS

Fig. 5-2

Piping Symbol Legend

circulator

(w/ isolation flanges)

circulator w/

integral flow check

gate valve

globe valve

ball valve

swing-check valve

flow-check valve

spring-loaded check valve

hose bib / boiler drain

TRV (straight)

pressure reducing valve

diff. pressure bypass

3-way thermostatic

Munchkin heater

pressure gauge

4-way motorized

mixing valve

3-way motorized

mixing valve

pressure relief valve

P&T relief valve

backflow preventer

TRV angle

circuit setter

manual 3-way valve

zone valve

air separator

diaphragm-type

expansion tank

float -type

air vent

union

temperature / pressure

T/P

radiant manifold

gauge

heat exchanger

Super Stor

indirect DHW tank

Page 26

26

PIPING

Fig. 5-3

Standard Munchkin heater

Traditional piping (zoning with valves)

Space heating mode

zone valves

make-up water

P1

purging

valves

V1

OFF

Drawing 1A

flow

bypass

valve

anti-scald

mixing valve

T/P

Munchkin heater

NOTES:

1. This drawing is meant to show system piping concept only.

Installer is responsible for all equipment & detailing required by local codes.

2. Adjust flow bypass valve for the following minimum boiler flow rates in any operating mode:

Munchkin model T50M: 3 gpm

Munchkin model T80M: 3 gpm

Munchkin model 80M: 3 gpm

Munchkin model 140M: 5 gpm

Munchkin model 199M: 7 gpm

3. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

The minimum pipe size for connecting a Munchkin heater is 1.25 inches.

4.

5. All pumps are shown with isolation flanges. The alternative is standard flanges with full port ball valves.

6. The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119

Install a minimum of 12 diameters of straight pipe upstream of all circulators.

7.

8. A purging valve may be used in lieu of the ball valve / hose bib combination shown.

Super Stor

indirect DHW tank

F.

˚

Page 27

27

PIPING

Fig. 5-4

Standard Munchkin heater

Traditional piping (zoning with valves)

Domestic water heating mode

zone valves

make-up water

P1

purging

valves

OFF

V1

OFF

OFF

anti-scald

mixing valve

Drawing 1B

OFF

flow

bypass

valve

T/P

NOTES:

1. This drawing is meant to show system piping concept only.

Installer is responsible for all equipment & detailing required by local codes.

2. Adjust flow bypass valve for the following minimum boiler flow rates in any operating mode:

Munchkin model T50M: 3 gpm

Munchkin model T80M: 3 gpm

Munchkin model 80M: 3 gpm

Munchkin model 140M: 5 gpm

Munchkin model 199M: 7 gpm

3. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

4. The minimum pipe size for connecting a Munchkin heater is 1.25 inches.

All pumps are shown with isolation flanges. The alternative is standard flanges with full port ball valves.

5.

6. The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119

Install a minimum of 12 diameters of straight pipe upstream of all circulators.

7.

8. A purging valve may be used in lieu of the ball valve / hose bib combination shown.

Munchkin heater

Super Stor

indirect DHW tank

F.

˚

Page 28

28

PIPING

Fig. 5-5

Standard Munchkin heater

Traditional piping (zoning with circulators)

Space heating Mode

space heating zone circuit

make-up water

closely

spaced

tees

Drawing 1C

zone

circulators

zone

purging

valves

P1

T/P

Munchkin heater

NOTES:

This drawing is meant to show system piping concept only.

1.

Installer is responsible for all equipment & detailing required by local codes.

2. All closely spaced tees shall be within 4 pipe diameter center to center spacing.

A minimum of 6 pipe diameters of straight pipe shall be installed upstream and

3.

downstream of all closely spaced tees.

The ninimum pipe size for connecting a Super Stor water heater is 1 inch.

4.

5. The minimum pipe size for connecting a Munchkin heater shall be 1.25 inches.

All pumps are shown with isolation flanges. The alternative is standard flanges

6.

with full port ball valves for isolation.

The anti-scald mixing valve shown on the domestic water heater is optional.

7.

8. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

A purging valve may be used in lieu of the ball valve / hose bib combination shown.

9.

P2

indirect DHW tank

Super Stor

Page 29

29

PIPING

Fig. 5-6

Standard Munchkin heater

Preferred piping (zoning with circulators)

Domestic water heating Mode

space heating zone circuit

make-up water

closely

spaced

tees

purging

valves

P1

P2

Drawing 1D

zone

circulators

anti-scald

mixing valve

T/P

NOTES:

This drawing is meant to show system piping concept only.

1.

Installer is responsible for all equipment & detailing required by local codes.

All closely spaced tees shall be within 4 pipe diameter center to center spacing.

2.

3. A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream

of all closely spaced tees.

4. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

The minimum pipe size for connecting a Munchkin heater shall be 1.25 inches.

5.

6. All pumps are shown with isolation flanges. The alternative is standard flanges with full port ball valves.

7.

8. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

9.

The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119

A purging valve may be used in lieu of the ball valve / hose bib combination shown.

Munchkin heater

Super Stor

indirect DHW tank

F.

˚

Page 30

30

PIPING

Fig. 5-7

Standard Munchkin heater

Preferred piping (zoning with valves)

Space heating mode

zone valves

make-up water

P2

closely

spaced

tees

purging

valves

V1

Drawing 2A

differential

pressure

bypass

valve

anti-scald

mixing valve

P1

T/P

Munchkin heater

Super Stor

indirect DHW tank

NOTES:

1. This drawing is meant to show system piping concept only.

Installer is responsible for all equipment & detailing required by local codes.

2. Adjust differential pressure bypass valve to eliminate any flow velocity noise when zone with highest pressure

drop operates by itself.

3. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

The minimum pipe size for connecting a Munchkin heater is 1.25 inches.

4.

5. All pumps are shown with isolation flanges. The alternative is standard flanges with full port ball valves.

The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119

6.

7. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

8. A purging valve may be used in lieu of the ball valve / hose bib combination shown.

A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream

9.

of all closely spaced tees.

F.

˚

Page 31

31

PIPING

Fig. 5-8

Standard Munchkin heater

Preferred piping (zoning with valves)

Domestic water heating mode

zone valves

make-up water

P2

closely

spaced

tees

purging

valves

OFF

V1

OFF

OFF

anti-scald

mixing valve

Drawing 2B

OFF

differential

pressure

bypass

valve

P1

T/P

Munchkin heater

Super Stor

indirect DHW tank

NOTES:

1. This drawing is meant to show system piping concept only.

Installer is responsible for all equipment & detailing required by local codes.

2. Adjust differential pressure bypass valve to eliminate any flow velocity noise when zone with highest pressure

drop operates by itself.

3. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

The minimum pipe size for connecting a Munchkin heater is 1.25 inches.

4.

5. All pumps are shown with isolation flanges. The alternative is standard flanges with full port ball valves.

6.

7. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

8.

9.

The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119

A purging valve may be used in lieu of the ball valve / hose bib combination shown.

A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream

of all closely spaced tees.

F.

˚

Page 32

32

PIPING

Fig. 5-9

Standard Munchkin heater

Preferred piping (zoning with circulators)

Space heating mode

space heating zone circuit

make-up water

closely

spaced

tees

purging

valves

P2

Drawing 2C

zone

circulators

anti-scald

mixing valve

P1

T/P

Munchkin heater

Super Stor

indirect DHW tank

NOTES:

This drawing is meant to show system piping concept only.

1.

Installer is responsible for all equipment & detailing required by local codes.

All closely spaced tees shall be within 4 pipe diameter center to center spacing.

2.

3. A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream

of all closely spaced tees.

4. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

The minimum pipe size for connecting a Munchkin heater shall be 1.25 inches.

5.

6. All pumps are shown with isolation flanges. The alternative is standard flanges with full port ball valves.

7. The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119

Install a minimum of 12 diameters of straight pipe upstream of all circulators.

8.

9. A purging valve may be used in lieu of the ball valve / hose bib combination shown.

F.

˚

Page 33

33

PIPING

Fig. 5-10

Standard Munchkin heater

Preferred piping (zoning with circulators)

Domestic water heating mode

space heating zone circuit

make-up water

closely

closely

spaced

spaced

tees

tees

purging

valves

P2

Drawing 2D

zone

circulators

anti-scald

mixing valve

P1

T/P

Munchkin heater

Super Stor

indirect DHW tank

NOTES:

This drawing is meant to show system piping concept only.

1.

Installer is responsible for all equipment & detailing required by local codes.

All closely spaced tees shall be within 4 pipe diameter center to center spacing.

2.

3. A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream

of all closely spaced tees.

4. The minimum pipe size for connecting a Super Stor water heater is 1 inch.

The minimum pipe size for connecting a Munchkin heater shall be 1.25 inches.

5.

6. All pumps are shown with isolation flanges. The alternative is standard flanges with full port ball valves.

The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119

7.

8. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

A purging valve may be used in lieu of the ball valve / hose bib combination shown.

9.

F.

˚

Page 34

34

PIPING

Fig. 5-11

Standard Munchkin heater

Preferred piping

(multiple heaters / zoning with circulators)

Space heating mode

space heating zone circuit

make-up water

closely

spaced

tees

purging

valves

Drawing 2E

zone

circulators

anti-scald

mixing valve

P2

PB1

T/P

Munchkin heater

PB2

T/P

Munchkin heater

Super Stor

indirect DHW tank

NOTES:

This drawing is meant to show system piping concept only.

1.

Installer is responsible for all equipment & detailing required by local codes.

2. All closely spaced tees shall be within 4 pipe diameter center to center spacing.

A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream

3.

of all closely spaced tees.

The minimum pipe size for connecting a Super Stor water heater is 1 inch.

4.

5. The minimum pipe size for connecting a Munchkin heater shall be 1.25 inches.

All pumps are shown with isolation flanges. The alternative is standard flanges with full port ball valves.

6.

7. The anti-scald mixing valve is recommended if the DHW temperature is set above the factory setting of 119

Install a minimum of 12 diameters of straight pipe upstream of all circulators.

8.

9. A purging valve may be used in lieu of the ball valve / hose bib combination shown.

F.

˚

Page 35

35

START-UP PROCEDURES

PART 6. START-UP PROCEDURES

A. ITEMS TO BE CHECKED BEFORE LIGHTING THE MUNCHKIN

It is recommended that you read the General Information Section (Part 1) to get a better understanding how the Munchkin operates before you start the unit.

1. Make sure that you follow the Lighting instruction before running the Munchkin.

2. Make sure the unit has a minimum water supply pressure of 10 PSI or a fault code of PrO will

appear in the display. While this Fault code is on the display the unit will not operate unit until

the water pressure is brought above 10 PSI. This Fault code is caused by the Water pressure

switch being open for more than 5 seconds which is an indication your system pressure is

below 10 PSI. Increase the water pressure in the system until the pressure gauge reads 10psi.

This code will disappear once the Water Pressure switch is closed, which will allow you to

start the Munchkin.

3. Check to see if all the electrical connections are on securely. Also, make sure the clear plastic hose is connected to the outlet of the combustion blower outlet and connected back to

the Air Switch.

4. Make sure that the Gas is turned on inside the cabinet and outside of the Munchkin.

5. Double check the temperature setting (Note: The Munchkin is factory set at 180 degrees)

6. Make sure the unit is properly grounded and the electrical wiring meets the requirements of

the electrical section (Part 2, Page 8).

7. Turn on the power to the Munchkin. The Temperature of the Munchkin Outlet will appear in

the display provided. If a fault code appears, correct the fault before operating. Make sure that

the room thermostat is connected and turn the room thermostat up above room temperature

to start the combustion blower fan to run the Munchkin. The Munchkin will now run its prepurge cycle, then begin running, which will be indicated by the Green light illuminating under

“Flame On” in your display.

B. LIGHTING INSTRUCTIONS

FOR YOUR OWN SAFETY READ BEFORE OPERATING

1. This appliance does not have pilot. It is equipped with an ignition device which automatically lights the burner. Do not try to light the burner by hand.

2. BEFORE OPERATING smell all around the appliance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas suppliers'

instructions.

• If you cannot reach your gas supplier, call the fire department.

3. Turn on gas shutoff valve (located inside of the Heater) so that the handle is aligned with the

gas pipe. If the handle will not turn by hand, don't try to repair it, call a qualified service technician. Force or attempted repair may result in a fire or explosion.

WARNING

If you do not follow these instructions exactly, a fire or explosion may

result, causing property damage, personal injury or loss of life.

Page 36

36

START-UP PROCEDURES

4. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any

gas control which has been under water.

5. The Munchkin Heater shall be installed so the gas ignition system components are protected

from water (dripping, spraying, rain, etc.) during appliance operation and service (circulator

replacement, condensate trap, control replacement, etc.)

C. OPERATING INSTRUCTIONS

1. STOP! Read the safety information in Part 6, Page 35.

2. Set the thermostat to the lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device which automatically lights the burner. Do

not try to light the burner by hand.

5. Remove front cover.

6. Turn gas shutoff valve clockwise to “off ”. The handle will be vertical, do not force it.

7. Wait five (5) minutes to clear out any gas. If you then smell gas, STOP! Follow Part 6, Section

B/Lighting Instructions in the safety information. If you don't smell gas, go to the next step.

8. Turn the gas shutoff valve counter clockwise to “on”. The handle will be horizontal.

9. Replace the Front Cover.

10. Turn on all electric power to appliance.

11. Set the thermostat to the desired setting.

12. If the appliance will not operate, follow the instructions “To Turn Off Gas To Appliance”

Section E pg. 33 and call your service technician or gas supplier.

D. ADJUSTING THE TEMPERATURE ON THE MUNCHKIN DISPLAY:

1. Before you can change the temperature from the factory setting of 180 degrees. You must make

sure that none of the thermostats are calling for heat. The Munchkin controller will not memorize a

program setting while in a heating cycle. To adjust the temperature to the Munchkin simply press in

the S3/Program key for three seconds until you see a flashing (C) then an alternate value of (180)

.

This number is the factory set point of the unit, which is 180 degrees. To change the temperature,

simply push either the S1/– or S2/+ on the display. The S1/– button will decrease the tempera-

ture while the S2/+ will increase the temperature of the Munchkin. The temperature of the

Munchkin can be set as low as 50 Degrees and as high 203 Degrees. These ranges are your maximum and minimum ranges of the Munchkin. In addition to changing the temperature you are also

allowed to change three more settings in this model (1. Munchkin differential – 2. Indirect setting

(Vision System Only) – 3. Celsius to Farenheit measurement. Simply press in the S3/Program key

to get to next value, the Munchkin differential setting will appear in the display ch and alternating

value of 30. This allows the installer to adjust the activation of the burner based on the differential

temperature setting of the Munchkin. The burner will not start until the outlet water temperature

reaches a temperature that is equal to the temperature setting for the Munchkin, minus the differential EX: The Munchkin is set to heat at 180° F degrees and the differential is set at 20° F. The burner will not start until the outlet temperature of the system falls below 159° F degrees (180° – 20° F =

160° F). To adjust, press either S1/– (Decrease Value) or S2/+ (Increase Value) Ranges 5° F to 30°

F. Press the S3/Program key again and you will see the Indirect Setting de and an alternative value

of 119 (Vision Systems Only) To adjust, press either S1/– (Decrease Value) or S2/+ (Increase Value).

The final adjustment in this mode is the Farenheit to Celcius measurement. Press the S3/Program

key again and you will see t and alternating value of F

. To change value press the S1/– or S2/+ to

choose the correct measurement.

Page 37

37

E. STATUS MENU

Installers are also able to check the current status of the Munchkin parameters by pressing S4/RESET

key for 3 seconds. Once activated, the display will show d1 alternating value of the actual outlet temperature. Actual values are displayed for each function. To view the next value simply press the S/4

key to go to the next displayed value. Listed below are the values which can be displayed. These values cannot be changed. To exit this menu, simply press S3/Program key to resume normal operation.

Function Value

d1/ Actual Temperature from outlet sensor

d2/ Actual Temperature from inlet sensor

d3/ If using a standard mechanical control, the control will display 1 for closed 0 for open

If the sensor is connected to the SuperStor Indirect Fired Water Heater it will measure

the actual temperature. (Vision only.)

d4/ Not used

d5/ Actual Temperature from the outdoor sensor. (Vision only.)

d6/ Actual Fan speed multiplied by 10 (Example: If fan speed displayed is

410 RPM x 10 = 4100 actual fan speed)

d7/ Actual Ionization current read from Flame Rectification probe

d8/ Actual Status of the Central Heating Circulator Off = 0 , On = 1 . (Vision only.)

d9/ Actual Status of the Indirect Fired Circulator Off = 0 , On = 1 . (Vision only.)

d10/ Actual Status bus communication co = connected, no = not connected

F. TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to be performed.

3. Remove the front cover.

4. Turn gas shutoff valve clockwise to "off". Handle will be vertical. Do not force.

5. Install front cover.

START-UP PROCEDURES

DANGER

Water temperature over 125 degrees F. can cause severe burns

instantly, or death from scalds. Children, disabled, and elderly

are at highest risk of being scalded. See instruction manual

before setting temperature at water heater. Feel water before

bathing or showering! Temperature limiting valves are available.

Fig. 6-1

GAS VALVE SHUT OFF

80M / 140M / 199M

T50 / T80

GAS VALVE SHUT OFF

Page 38

38

PART 7. SERVICING

A. SEQUENCE OF OPERATION

1. When power is first applied to the control, the control display will read the outlet temperature. The control will initially run through a self-diagnostic routine and then go into its operating mode. If there is no call for heat, the System will go into an idle state.

2. If the thermostat is calling for heat, the control will apply power to the circulator pump. If the

control determines the water temperature is below the programmed set point value minus

the switching differential, the control will initiate a heating cycle.

3. The control then performs selected system diagnostic checks. If all checks are successfully

passed, a pre-purge cycle is initiated (the blower will be on maximum speed).

4. When the pre-purge period is complete, power is applied to the spark ignitor for approximately 6 seconds. Approximately 2 seconds later, we verify flame. If a flame is not verified

during the trial-for-ignition, the gas valve is immediately closed and the control will return to

step. After three trials, if a flame is not verified, the control will go into a lockout mode. If a

flame is confirmed, the control enters the heating mode. The fire rate will be based on the

proprietary algorithm.

5. When water temperature reaches the temperature set point value plus 10 degrees F (or if the

thermostat call-for-heat is satisfied), the gas valve is closed and the control enters a postpurge state (the blower will be on maximum speed). NOTE: If the thermostat is still calling

for heat, the circulator pump will continue to run until the thermostat call for heat is satisfied.

6. When the post-purge is complete, the control enters an idle state while continuing to monitor temperature and the state of other system devices. If a call-for-heat is received, the control will automatically return to step 2 in sequence and repeat the entire operating cycle.

During the idle state and heat state, if the control detects an improper operating state from external

devices, such as the high-limit switch, the red light on the control will illuminate an error code will

appear in the display.

B. MUNCHKIN TEMPORARY FAULT CONDITION

A Temporary Fault Condition may occur in the installation of the Munchkin. This condition may lead

to a lock out condition of the controller, which will need to be manually reset through the S4/Reset

button. These temporary codes will help the installer correct the problem before going into a lock

out condition, which will require a manual reset. Example: A temporary fault-code of E15 indicates

that the Air Pressure Switch is open when the fan is in the pre-purge function, when it should be

closed. This could occur if the clear hose, which is connected to the outlet of the fan is disconnected. This can be corrected by re-connecting the hose. Listed below are the Temporary Fault Codes.

E00 This code will appear if there is an overshoot of the high limit. The Temporary Fault Code will

be displayed only 50 seconds.

E13 This code will appear if the expected fan speed is lower then 70%. This will show on the dis-

play 10 seconds after the fan has started. The Temporary Fault code will only be displayed an

additional 50 seconds before going into lock out mode (F13).

Remedy – Check wiring to assure that the Fan is connected correctly.

E14 This code will appear if the expected fan speed is higher then 130%. This will show on the

display 10 seconds after fan is started. The Temporary Fault Code will only be displayed an

additional 50 seconds before going into lock mode (F14).

Remedy – Check wiring to assure that the Fan is connected correctly.

E15 This code will appear if the Air Pressure Switch is open when the fan is switched on in the

SERVICING

Page 39

39

SERVICING

pre-purge or post purge cycle. This code will only appear 10 seconds after the fan starts. The

Temporary fault will only be displayed an additional 50 seconds before going into lock mode

(F15).

Remedy – Check the hose connection from switch to fan. Check to see if the inlet is

blocked. Check the air pressure switch contact. Adjust the switch, turn center screw

counter clockwise in ¼ turn increments until the switch clicks into closed position. Also

check to see if the fan is functional.

E16 This code will appear if the Air Pressure Switch is closed when the fan is switched on in the

pre-purge or post purge state. This code will only appear 10 seconds after the fan has started. The Temporary fault will only be displayed an additional 50 seconds before going into

lock mode (F16).

Remedy – Check the Air pressure switch for a possible adjustment. Adjust switch, turn

center screw clockwise in ¼ turn increments until the switch clicks into open position.

PR0 This code will appear if the Water Pressure Switch is open for more than 5 seconds. The unit

will not be allowed to operate while this code is on the display.

Remedy – Check the water pressure in the system. Make sure the pressure is at least 10

PSI. Check all electrical connections to the switch. If the switch still does not close, try

adjusting the switch with a screw driver and turn screw in center of the switch counterclockwise to close switch. If the switch still does not close with a minimum supply pressure

of 10 PSI, then replace the switch.

C. MUNCHKIN FAULT REQUIRING MANUAL RESET

When a fault condition occurs or is sensed on the Munchkin controller or in the appliance, the controller goes into a lockout state. When in LOCKOUT state, the red led light will illuminate and a fault

code will be presented in the display. To reset the lockout condition, simply push the S4/Reset to

bring the control out of its lockout state. If the problem is not corrected, the Munchkin will repeat the

fault until the condition is corrected. Once corrected, the display will resume its supply temperature

setting. Listed below are the Fault Codes and the remedies to correct the fault.

F00 Safety Limit ECO – This code appears if the Safety Limit ECO opens. The ECO will normally

open if it senses a temperature greater than 225 degrees.

Remedy – Let the unit cool down and push the reset button (S4). Determine if there is

water flow through the heater. Manually reset the unit by pushing the S4/reset button. If

the lockout continues, replace the switch to correct the problem.

F01 Safety Limit Flue – This code appears if the Safety Limit Flue senses a temperature higher

than 210 degrees.

Remedy – Push the red button down on the Flue sensor, then push the reset button on the

display. If you experience another F01 lock out code, replace the flue sensor, then try again.

Check to see that condensation line is not frozen. Manually reset by pushing the S4/reset

button. If this problem persists, call factory for further assistance.

F02 Interrupted or Shorted Supply Thermister – This code appears if the Supply thermister

located on the Munchkin Outlet manifold has been interrupted or shorted.

Remedy – Check the wiring connection and connectors on the thermister. If the unit locks

out again, replace the Supply Thermister. Manually reset the unit by pushing the S4/reset

button

F03 Interrupted or Shorted Return Thermister – This code appears if the Return thermister

located on the Munchkin Outlet manifold has been Interrupted or shorted.

Remedy – Check the wiring connection and connectors on the thermister. If the connection

is okay, hit reset S4/Reset . If the unit locks out again, replace the Return Thermister.

F05 Supply Temperature is to High – This code appears if the Supply temperature sensor

goes above 230 degrees.

Remedy – Let the Munchkin cool down, then manually push the reset button and see if the

Page 40

40

temperature increases to above 230 degrees. Determine if you have water flow or if the

thermostat is continuously energized and correct the problem. Manually reset by pushing

the S4/reset button.

F06 Return temperature is too High – This code comes if the return water temperature goes

above 230 degrees,

Remedy – Let the Munchkin cool down then manually push the reset button and see if the

temperature on the return increases to above 230 degrees. Check piping and determine the