Page 1

Instruction manual

Chamber machine P100

MCB01

Serial number:

.........................................................

Service address: Manufacturer:

MULTIVAC

Sepp Haggenmüller GmbH & Co. KG

Bahnhofstraße 4

D-87787 Wolfertschwenden, Germany

Tel.: 0049 8334 601 0

www.multivac.com

Date: 11.06.2014

The reproduction, distribution and utilization of this document as well as the communication of its contents to others without express authorization is

prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

Language: English (EN) - Original operating manual

Order number: P100-P-WO-0005663.3-EN-ER

Page 2

Contents

Contents

Important information on the manual ....................................................................................... 5

Machine documentation ...................................................................................................... 5

Changes not covered in the manual.................................................................................... 5

Symbols used...................................................................................................................... 6

1 Safety.................................................................................................................................. 8

1.1 General safety instructions......................................................................................... 8

1.1.1 Target group................................................................................................... 8

1.1.2 Unauthorised modifications and manufacture of spare parts....................... 10

1.2 EC Conformity.......................................................................................................... 11

1.3 Intended use ............................................................................................................ 11

1.3.1 Electromagnetic compatibility (EMC) ........................................................... 12

1.3.2 Non-ionising radiation .................................................................................. 12

1.4 Reasonably foreseeable incorrect use..................................................................... 12

1.5 Warning against incorrect use.................................................................................. 12

1.6 Residual risks........................................................................................................... 13

1.7 Obligations of the operating company...................................................................... 13

1.7.1 Creating the operating directive................................................................... 13

1.7.2 Monitoring obligation.................................................................................... 13

1.7.3 Making the selection of personnel................................................................ 14

1.7.4 Training the personnel ................................................................................. 14

1.7.5 Providing personal protective equipment ..................................................... 14

1.7.6 Avoiding hazards.......................................................................................... 14

1.7.7 Providing the installation location................................................................. 14

1.7.8 Provide power supply................................................................................... 14

1.7.9 Observe the requirements for the gas supply.............................................. 15

1.7.10 Avoiding hygiene risks ................................................................................. 16

1.7.11 Checking the packs...................................................................................... 17

1.7.12 Pump protection function ............................................................................. 18

1.7.13 Testing pressure equipment......................................................................... 18

1.8 Danger zones........................................................................................................... 18

1.8.1 Chamber lid.................................................................................................. 20

1.8.2 Vacuum pump.............................................................................................. 20

1.8.3 Electrical system.......................................................................................... 20

2 11.06.2014

Page 3

Contents

1.9

Safety devices.......................................................................................................... 20

1.10 Machine labelling ..................................................................................................... 20

2 Description....................................................................................................................... 22

2.1 Construction of the machine .................................................................................... 22

2.2 Control terminal........................................................................................................ 23

2.3 Display ..................................................................................................................... 24

2.4 Process sequence.................................................................................................... 25

2.5 Times which have to be set...................................................................................... 26

2.6 Technical specifications ........................................................................................... 27

3 Start-up............................................................................................................................. 30

3.1 Setting up the machine and putting it into operation ................................................ 30

4 Operation ......................................................................................................................... 39

4.1 Opening and closing the chamber lid....................................................................... 39

4.2 Switching on the machine ........................................................................................ 40

4.3 Switching off the machine ........................................................................................ 40

4.4 Setting the times ...................................................................................................... 41

4.5 Packing products...................................................................................................... 41

4.6 Aborting evacuation ................................................................................................. 44

4.7 Aborting packaging procedure ................................................................................. 44

4.8 Working with recipes ................................................................................................ 44

4.8.1 Load recipe .................................................................................................. 44

4.8.2 Save recipe.................................................................................................. 45

4.9 Perform pump protection function ............................................................................ 45

5 Adjustment work and setup ........................................................................................... 46

5.1 Insert and remove the sloping insert ........................................................................ 46

6 Cleaning ........................................................................................................................... 47

6.1 Notes on cleaning .................................................................................................... 47

6.1.1 Instructions for creating company cleaning guidelines................................. 47

6.1.2 Instructions for maintaining the machine's value ......................................... 48

6.1.3 Instructions on the handling of cleansers..................................................... 49

6.1.4 Instructions on the handling of disinfectants ................................................ 49

6.1.5 Instructions on the handling of anti-corrosion agents and lubricants ........... 50

6.1.6 Instructions on the handling of cleaning devices.......................................... 50

6.2 Cleaning recommendations ..................................................................................... 50

6.3 Care products table.................................................................................................. 54

7 Maintenance.....................................................................................................................56

7.1 Maintenance schedule ............................................................................................. 56

7.2 Service recommendation ......................................................................................... 57

7.2.1 Vacuum pump - Perform the pump protection function................................ 57

7.2.2 Entire machine - Visual inspection............................................................... 57

7.2.3 Entire machine - Alkaline cleaning and disinfection..................................... 58

7.2.4 Entire machine - Perform a wipe test........................................................... 58

7.2.5 Entire machine - Acidic cleaning and disinfection ........................................ 58

11.06.2014 3

Page 4

Contents

7.2.6

Connections - Visual inspection................................................................... 58

7.2.7 Vacuum pump - Checking oil level, topping up ............................................ 58

7.2.8 Vacuum pump - Oil change.......................................................................... 59

7.2.9 Vacuum pump - Exchanging the air de-oiling element................................. 59

7.2.10 Entire machine - Check the age................................................................... 59

7.3 Replace the sealing bar ........................................................................................... 59

7.3.1 Remove the sealing bar............................................................................... 59

7.3.2 Install the sealing bar ................................................................................... 60

7.4 Repair counter-pressure bar .................................................................................... 60

7.5 Open and close the housing .................................................................................... 63

7.5.1 Open housing............................................................................................... 63

7.5.2 Close housing .............................................................................................. 66

7.6 Change the oil in the vacuum pump......................................................................... 67

7.6.1 Drain oil........................................................................................................ 67

7.6.2 Filling the vacuum pump with oil. ................................................................. 68

7.7 Change the air de-oiling element ............................................................................. 70

7.8 Change chamber lid gasket ..................................................................................... 72

7.9 Check the chamber for leaks ................................................................................... 73

8 Troubleshooting .............................................................................................................. 75

8.1 Faults with diagnostic message ............................................................................... 75

8.2 Faults without diagnostic message ......................................................................... 75

9 Shutdown, transport, storage ........................................................................................ 78

9.1 Shutting down the machine...................................................................................... 78

9.2 Transporting the machine ........................................................................................ 78

9.2.1 Transporting the machine ............................................................................ 78

9.3 Storing the machine ................................................................................................. 79

10 Disposal ........................................................................................................................... 80

10.1 Disposing of the machine......................................................................................... 80

10.2 Dispose of operating materials................................................................................. 80

10.2.1 Disposing of oil and grease.......................................................................... 80

10.2.2 Disposing of packaging materials ................................................................ 81

10.2.3 Dispose of chemicals ................................................................................... 81

11 Spare parts....................................................................................................................... 83

MULTIVAC branch offices........................................................................................................ 85

4 11.06.2014

Page 5

Important information on the manual

Important information on the manual

Read the manual carefully before you begin working with the machine.

• This manual is an integral component of the unit. Keep the manual

for future reference.

• Do not work with the machine until you have read through the

manual and completely understood its contents.

• Please contact MULTIVAC as soon as possible if there is something you do not understand in the manual! Your comments will

help us to further improve the manual.

• Do not start up the machine if there are any visible defects!

• Only trained persons are permitted to install, operate and service

the machine. The operating company is responsible for the qualifications and training of operating personnel.

• If you sell, transfer ownership or lend the machine to others, you

must provide the manual along with it!

For reasons of clarity, some illustrations show the machine without

the prescribed safety devices. Operating the machine without the

safety devices is prohibited.

WARNING

Injury hazard!

Altered, damaged, defective or incorrectly applied or missing safety

devices will render the danger zones unprotected.

Unprotected danger zones can cause serious or even fatal injuries.

¾ Do NOT alter the safety devices.

¾ Use only MULTIVAC spare parts and accessories.

Before switching on the machine each time:

¾ Check that all safety guards close completely and prevent

reaching into the danger zones.

¾ Check that only those safety devices are used which are suit-

able for the machine equipment.

¾ Check that all safety devices are functional and in a technically

flawless condition.

Machine documentation

• Instruction manual.

• EU Declaration of Conformity

Info

The complete scope of delivery is listed in the order confirmation.

Changes not covered in the manual

Continuous development is the foundation for ensuring that our machines are technically advanced and of high quality. For this reason,

11.06.2014 5

Page 6

Important information on the manual

Changes not covered in the manual

you may discover slight deviations between the specifications in the

manual and your machine. We also cannot rule out errors. The specifications, figures and descriptions in this manual do not constitute a

legal contract between the manufacturer and customer.

Symbols used

Warnings draw your attention to hazards. Warnings are displayed in

the following form:

Danger from electrical shock!

Used to indicate that serious danger of electrical shock is imminent.

DANGER

DANGER

Ignoring this danger can cause serious or even fatal injuries.

¾ Observe the notices for avoiding danger.

Immediate danger!

Used to indicate that serious danger is imminent.

Ignoring this danger can cause serious or even fatal injuries.

¾ Observe the notices for avoiding danger.

Dangerous situations!

Used to indicate dangerous situations.

WARNING

Non-observance can cause serious or even fatal injuries.

¾ Observe the notices for avoiding danger.

Potentially dangerous situations!

Used to indicate potentially dangerous situations.

CAUTION

Ignoring this danger can cause injuries.

¾ Observe the notices for avoiding danger.

NOTICE Danger of material damage!

Used to indicate potentially dangerous situations.

Ignoring these situations can cause material damage.

¾ Observe the notices for avoiding danger.

Information that contributes to a better understanding of how the machine functions is shown in the following form:

Info

Indicates information on special features deserving your attention.

Instructions to follow are displayed in the following form:

6 11.06.2014

¾ Press key A.

¾ Release screw B.

Page 7

Important information on the manual

Symbols used

¾ Press key C.

• Enumerated items are marked with bullet points.

– Dashes are used to mark sub-items of enumerated lists or se-

quences of steps to be taken.

11.06.2014 7

Page 8

Safety

1 Safety

1.1 General safety instructions

The machine incorporates the latest technological principles. Nevertheless, potential hazards for persons, the machine and other materials cannot be entirely excluded.

• Before you start up the machine, read through the instruction

manual and follow the instructions contained therein.

• Keep the instruction manual near the machine for future reference.

• Observe the safety and accident prevention regulations valid in

your country.

1.1.1 Target group

The persons, who work with or at the machine, must have as a minimum requirement the following capabilities, knowledge and competence:

• The persons are authorized by the company operating the machine to carry out those tasks, which they perform with or at the

machine.

• The persons are at least 14 years old.

• The persons know the danger zones of the machine and the accident prevention regulations.

• The persons know how they should behave in an emergency

situation.

• The persons have been given instruction about the machine and

are familiar with the handling of it.

• The persons have read and understood the operating directive.

• The persons have read and understood the instruction manual of

the machine.

• The persons have been informed about the possible hygiene risks.

The persons, who put the machine into service, or adjust and set it up,

or who are responsible for maintenance work and eliminating faults,

must have the following capabilities, knowledge and competence:

• Due to their professional training, knowledge and experience, as

well as their familiarity with the relevant regulations, the persons

are able to assess the tasks assigned to them and to recognize

potential hazards.

• The persons can read and interpret technical texts and technical

drawings or plans.

• The persons are familiar with the handling of computer-controlled

machines.

• The persons can install components and modules for technically

complex systems.

8 11.06.2014

Page 9

Safety

General safety instructions

• The persons can ensure that the machine remains capable of operation.

• The persons can perform maintenance work and inspections.

The persons, who carry out work on electrical components, must

have as a minimum requirement the following capabilities, knowledge

and competence:

• Due to their professional training, knowledge and experience, as

well as their familiarity with the relevant regulations, the persons

are able to assess the tasks assigned to them and to recognize

potential hazards.

• The persons have been trained as qualified electricians and are

able to prove this.

• The persons have up-to-date knowledge and experience in the

electrical area, and they have actively practised these skills in recent years.

The persons, who carry out work on gas supplies, must have as a

minimum requirement the following capabilities, knowledge and competence:

• Due to their professional training, knowledge and experience, as

well as their familiarity with the relevant regulations, the persons

are able to assess the tasks assigned to them and to recognize

potential hazards.

• The persons have been trained in handling gas supplies and are

able to prove this.

• The persons have up-to-date knowledge and experience in gas

supplies, and they have actively practised these skills in recent

years.

Injury hazard!

Operating the machine in a negligent and inattentive manner is very

WARNING

dangerous.

Negligent handling, inattentiveness and a disorderly work area can

cause serious injuries.

¾ Do NOT operate the machine if you are tired or under the influ-

ence of alcohol or medication.

¾ Work attentively and with care.

¾ Wear personal protective equipment.

¾ Keep the work area clean and orderly.

¾ Only carry out work for which training has been given.

11.06.2014 9

Page 10

Safety

General safety instructions

NOTICE Danger of material damage!

Improper use of the machine can damage it.

Damage can cause faults in the machine, which in turn can result in

reject packs.

¾ Do NOT overload the machine.

¾ Clean and service the machine on a regular basis.

¾ Check if the machine is in full working order prior to starting

work.

¾ Do NOT start the machine if you notice defects, damage or a

change in the operating behaviour of the machine.

¾ Have faults and damage repaired immediately by an authorised

technician.

¾ Repairs and service work should only be carried out by an

authorised technician.

1.1.2 Unauthorised modifications and manufacture of

spare parts

WARNING

Genuine MULTIVAC spare parts and accessories provide the highest

level of safety for personnel. Parts and equipment from other manufacturers have not been tested by MULTIVAC and are therefore not

approved. The use of such components can alter the properties of the

machine and thereby impair safe operation.

Injury hazard!

It is very dangerous to use third-party parts.

The use of third-party parts endangers safe operation and can

cause serious injuries.

¾ Do NOT perform any unauthorised modifications or conver-

sions.

¾ Do NOT modify or remove any protective or safety devices.

¾ Use only MULTIVAC spare parts and accessories.

The manufacturer disclaims any liability for damage caused by the

use of third-party parts or unauthorised modifications.

Fig. 1: Pro Original

The lubricants recommended by MULTIVAC are ideally matched to

the individual modules of the machine.

10 11.06.2014

Page 11

Safety

General safety instructions

NOTICE Danger of material damage!

The use of unsuitable lubricants can increase the wear of the machine and lead to corrosion of the transport chains.

This can damage the machine.

¾ Only use recommended lubricants for the transport chains.

1.2 EC Conformity

In the design and construction of packaging lines, packaging machines or auxiliary packaging machines, the following regulations

have been observed:

• EC Machinery Directive 2006/42/EC.

• EC Electromagnetic Compatibility Directive 2004/108/EEC (exception: industrial trucks such as lift trucks and die changing trolleys).

• Regulation 1935/2004/EC on materials and articles intended to

come into contact with food.

The safety objectives of the EC Low Voltage Directive 2006/95/EC

are complied with in accordance with point 1.5.1 of Annex I to the EC

Machinery Directive 2006/42/EC (exception: industrial trucks such as

lift trucks and die changing trolleys).

Agent authorised to compile the relevant technical documentation

according to Directive 2006/42/EC:

MULTIVAC Sepp Haggenmüller GmbH & Co. KG

Department of Technical Services

Bahnhofstraße 4

87787 Wolfertschwenden, Germany

Manufacturer:

MULTIVAC Sepp Haggenmüller GmbH & Co. KG

Bahnhofstraße 4

87787 Wolfertschwenden, Germany

Managing Director:

H.-J. Boekstegers

1.3 Intended use

The machine is a piece of technical equipment to be used exclusively

as a working appliance. The machine may only be operated by persons older than 14 years of age.

Use the machine only to pack products in pre-made film pouches.

The film pouches are closed with a seal seam.

For specifications, see Technical specifications.

11.06.2014 11

Page 12

Safety

Intended use

Any other use is considered improper and can endanger persons, the

product and the machine.

1.3.1 Electromagnetic compatibility (EMC)

The machine has been designed for use in residential, business and

industrial areas (without a separate power substation, it can be connected directly to the public mains). Operation can be impaired when

used in an industrial environment.

1.3.2 Non-ionising radiation

The machine produces unintended non-ionising radiation. This is only

emitted by electrical operating equipment as a function of its inherent

technical nature. e.g. from electric motors, high voltage wires, magnetic coils. There are moreover no strong permanent magnets built

into the machine. Any effect on active implants can therefore be excluded with a high degree of probability as long as a safety distance

of 30 cm is maintained between the implant and the field source. Active implants can be: heart pacemakers, defibrillators etc.

1.4 Reasonably foreseeable incorrect use

The following work methods are not in accordance with regulations

and therefore are prohibited:

• Operating in an atmosphere capable of explosion.

• Inserting or packing of highly flammable, combustible or explosionprone products.

• Packing of dust-forming or powder-forming material.

• Use of the chamber lid as a storage, working or cutting surface.

• Cleaning of the chamber lid with cleaning agents which have an

abrasive effect (e.g. abrasive household liquid cleaner, scouring

pads, steel wool etc).

• Aseptic packing of products.

Info

Misuse will exclude any liability on behalf of the manufacturer. In

such a case, the operating company is solely responsible.

1.5 Warning against incorrect use

• Incorrect operation

For example: sealing times that are too short or too long and therefore result in improperly sealed packs which in turn damage the

product.

• Neglecting the following work tasks:

– Inspections.

– Cleaning work.

– Maintenance work.

12 11.06.2014

Page 13

Safety

Warning against incorrect use

• Use of third-party parts, i.e. parts that are not MULTIVAC spare

parts.

• Operation under prohibited ambient conditions.

1.6 Residual risks

The safety instructions in this manual serve as guidelines for trained

operating personnel in safe working practice with the machine. The

manufacturer cannot however foresee all possible product-related

hazards. This is why the safety instructions and warnings on the machine and in this manual cannot be considered exhaustive. The operating company and operating personnel remain ultimately responsible

for safety.

1.7 Obligations of the operating company

1.7.1 Creating the operating directive

The machine and operating materials are a potential source of hazards. The operating company is obliged to draw up an operating directive. The operating directive regulates the handling of hazardous

machines or operating materials, as well as laying down rules for behaviour in the case of an emergency. The required information can be

found in the following documents:

• The EC directives for worker protection.

• National legislation.

• Accident prevention regulations.

• The machine instruction manual.

1.7.2 Monitoring obligation

The operating company is obliged to continuously monitor the condition of the entire machine, for example:

• Visible defects or damage.

• Changes in the operating behaviour.

• Age of the machine.

The operating company is obliged to ensure, that the machine is no

longer operated when it is older than 19 years. The correct functioning of the safety functions for the electronic components can no

longer be guaranteed after this age. The year of manufacture on the

type plate of the machine serves as the starting point for assessing

the age. In order to be able to operate the machine after this, the operating company must commission the manufacturer to check the

safety functions of the machine.

Info

Do NOT start up the machine, if there are visible defects or if the

machine is older than 19 years.

11.06.2014 13

Page 14

Safety

Obligations of the operating company

1.7.3 Making the selection of personnel

The operating company has to choose the personnel according to the

tasks to be carried out, see Section 1.1.1 "T

ating company has to order and authorise the personnel for the tasks

to be carried out.

Info

Trainees or other persons receiving instructions may only operate

the unit under the constant supervision of an experienced technician.

1.7.4 Training the personnel

The operating company is responsible for ensuring, that the personnel is trained and instructed in accordance with the tasks, which have

been assigned to them. The following measures can for example contribute to the training and instruction:

• Provide an operating directive, which is comprehensible to the

personnel.

• Instruct personnel on how to handle the machine correctly.

• Make the machine instruction manual accessible to the personnel.

If necessary, order an instruction manual from the manufacturer in

the appropriate official language.

• Inform the personnel about measures for avoiding hygiene risks.

• MULTIVAC offers appropriate training courses.

ARGET GROUP". The oper-

1.7.5 Providing personal protective equipment

The operating company must ensure that the operators wear the required personal protective equipment (foot protection, head gear,

gloves, etc.) in accordance with the national directives which apply. In

Europe the directive 89/656/EEC specifies the minimum mandatory

requirements for the use of personal protective equipment.

1.7.6 Avoiding hazards

The operating company must check, whether there are special hazards during operation, e.g. through hazardous fumes. The operating

company must undertake measures to avoid or limit the hazards.

1.7.7 Providing the installation location

The operating company is obliged to provide a suitable installation

location for the machine. The requirements for the installation location

can be obtained from the manufacturer.

1.7.8 Provide power supply

Connect the machine to the mains electricity at an always easily accessible place. In the case of an emergency the machine must be

capable of being disconnected immediately from the mains electricity.

14 11.06.2014

Page 15

Connection via residual

current protective

device

Connection to IT

Safety

Obligations of the operating company

The power supply must be equipped as follows:

• Overcurrent protective device according to IEC 60204-1: 2005.

• Mains power breaker according to IEC 60204-1: 2005.

If the machine is to be operated via a residual current protective device, a residual current protective device which is sensitive to all types

of current should be used.

Info

In exceptional cases, the leakage current can be so high that an

isolating transformer needs to be installed between the power supply and the machine.

network

General requirements

The machine cannot be connected directly to an IT network.

The IT network must be converted to a TN-S network by an isolating

transformer. The machine is connected to the TN-S network.

1.7.9 Observe the requirements for the gas supply

Info

Compliance with the following requirements is mandatory and is

one of the operating company's imperative obligations!

• The operating company is obliged to connect the gas supply in a

way that poses no danger to employees or third parties.

• The operating company is obliged to create an instruction manual

with all safety-related information for the following phases in the

service life of the machine:

– Starting up.

– Operation and conduct in the event of unusual occurrences.

– Servicing during operation.

– Shutdown.

– Rectification of faults.

• All parts of the gas supply and its equipment, which come into contact with oxidizing acting gases, are to be kept free of oil and

grease.

• The operating company must ensure that the input and operating

pressures given in the Technical specifications are adhered to and

not exceeded.

11.06.2014 15

Page 16

Safety

Obligations of the operating company

Personnel qualifications

Only qualified persons with the corresponding required training, experience and reliability may perform work on the gas supply.

Structural requirements

• The operating company is obliged to install a pressure reducer and

safety valve in the gas supply line to the machine.

• The operating company is obliged to connect the machine to the

gas supply with a lockable ball valve.

When the ball valve is closed, the supply of gas to the machine is

interrupted.

• It must be ensured that the input pressure at the machine does not

exceed that given in the Technical specifications, e.g. through the

fitting of an overpressure valve.

• The pressure relief capacity of the safety valve must be dimensioned for the maximum possible throughput of the pressure reducer.

• In the case of a release of pressure, the gas must be diverted to

non-hazardous areas.

WARNING

1.7.10 Avoiding hygiene risks

A high standard of hygiene is achieved through design, choice of materials and workmanship.

It is imperative that this high level of hygiene be maintained by every

operating company. Particularly where food or sterile medical products are being packed, the currently valid hygiene standards must be

strictly observed. The person charged by the operating company with

safety and/or hygiene must clarify, which regulations apply to the

product to be packed, and the person must then implement these

regulations.

The manufacturer assumes no liability whatsoever for any warranty

claims and damage claims of any kind resulting from insufficient hygiene and insufficient cleaning.

Health hazard!

Insufficient or sporadic cleaning can promote the growth of microorganisms which can change unfavourably the product that is to be

packed.

This can severely damage the health of people, especially of the

consumers.

Among other measures the following are definitely required:

¾ Create a company cleaning guideline.

¾ Perform cleaning regularly.

¾ Check the effectiveness of cleaning procedures on a regular

basis.

¾ Follow instructions in the chapter 'Cleaning'.

16 11.06.2014

Page 17

CAUTION

Testing procedure

Obligations of the operating company

1.7.11 Checking the packs

Health hazard!

Faulty or damaged packs (reject packs) can have far-reaching consequences, for example, spoiled products.

Spoiled products can pose a health hazard.

¾ Check packs on a regular basis during running operation.

¾ Do NOT put faulty or damaged packs (reject packs) into circula-

tion.

Info

It is the operating company's duty to determine the overall testing

procedure.

Depending on the film pouch and the demands placed on the packs,

various types of testing procedures are available, e.g.:

• Check seal seam width.

• Visual inspection: Asses the pack optically.

• Storage test: Store a good pack for a defined period and then reinspect.

• Stacking test: Stack good packs on top of each other for a defined

period and then re-inspect.

• Check the seal seam strength with a tensile testing machine.

• Low-pressure test (for vacuum packs).

• Measurement residual oxygen (for gas-flushed packs).

The following faults can result in a pack not being airtight:

• A leaky seal seam. Possible reasons:

– The inside of the packaging material is contaminated by product

in the seal seam area.

– The sealing time is too short.

• Damage to the pack caused e.g. by sharp-edged products.

Safety

Time of inspection

• After machine start-up.

• When a defined time interval was reached during running operation.

• When the pack size was changed.

• When other types of films or other film thicknesses are being used.

• When spare parts or wearing parts were built in.

• After faults to the machine were eliminated.

• After changes to the machine settings.

11.06.2014 17

Page 18

Safety

Obligations of the operating company

1.7.12 Pump protection function

The vacuum pump in the machine runs for a set time when the

chamber lid has been closed. During this time any undesired liquid in

the oil of the vacuum pump evaporates. This increases the lifespan of

the vacuum pump. When packaging moist or liquid products, the operating company is obliged to perform this function at least once a

day at the end of a working day. The manufacturer assumes no liability whatsoever for any warranty claims and damage claims of any

kind that result from the insufficient performance of this function.

NOTICE Danger of material damage!

Penetration by foreign matter (e.g. liquids, product residue, foreign

bodies) will damage the vacuum pump.

Damage can cause faults in the machine, which in turn can result in

reject packs.

¾ Cancel the evacuation process immediately if foreign matter is

sucked in.

¾ Change the oil in the vacuum pump.

1.7.13 Testing pressure equipment

The operating company is responsible for observing the countryspecific test intervals for pressure equipment. This test is to be performed by qualified persons.

1.8 Danger zones

Be particularly aware of the following danger zones:

18 11.06.2014

Page 19

Safety

Danger zones

WARNING

Fig. 2: Danger zones

1

Chamber lid

2

Vacuum pump.

3

Electrical system

Injury hazard!

Altered, damaged, defective or incorrectly applied or missing safety

devices will render the danger zones unprotected.

Unprotected danger zones can cause serious or even fatal injuries.

¾ Do NOT alter the safety devices.

¾ Use only MULTIVAC spare parts and accessories.

Before switching on the machine each time:

¾ Check that all safety guards close completely and prevent

reaching into the danger zones.

¾ Check that only those safety devices are used which are suit-

able for the machine equipment.

¾ Check that all safety devices are functional and in a technically

flawless condition.

11.06.2014 19

Page 20

Safety

Danger zones

CAUTION

WARNING

1.8.1 Chamber lid

Danger of crushing!

The gas strut is unhooked by opening the chamber lid completely.

The chamber lid can therefore fall down unimpeded.

Reaching in between the housing and the falling chamber lid can

lead to crushing injuries.

¾ Close the chamber lid by hand and do NOT let it fall down.

1.8.2 Vacuum pump

Burn hazard!

The surface of the vacuum pump can reach temperatures of over

70 °C during operation.

Touching the vacuum pump can lead to burns.

Before performing any work on the vacuum pump:

¾ Allow the vacuum pump to cool down.

¾ Wear personal protective equipment.

DANGER

1.8.3 Electrical system

Dangerous voltage!

Inside are electrically charged components.

Touching electrically charged components can cause serious or

even fatal injuries.

¾ Before opening the housing, disconnect the machine from the

mains electricity.

¾ Only qualified electricians are permitted to work on electrically

charged components.

¾ Do NOT touch damaged electrical cables but have them re-

placed immediately by a qualified electrician.

¾ If any electrical cables are damaged, stop the machine immedi-

ately.

1.9 Safety devices

The housing is a safety guard and prevents the reaching into danger

zones. The closed housing must be secured with the screws before

the machine can be operated.

1.10 Machine labelling

Safety and information labels have been attached to the machine.

• Do NOT remove these labels.

• Make sure all labels are intact and legible.

20 11.06.2014

Page 21

Safety

Machine labelling

• If necessary, clean the labels with soap and water.

– Do NOT clean the labels with solvents.

• Replace damaged, scratched or illegible labels with new ones.

Info

Labels can be obtained from the manufacturer.

Fig. 3: Safety labels and information labels

Posi-

Sign

tion

Fig. 4:

I

SO manda-

tory sign:

Read the

instruction

manual

Fig. 5: ANSI mandatory sign: Read

the instruction manual (English /

French)

Fig. 7: ANSI mandatory sign: Read

the instruction manual (English / Chi-

nese)

Fig. 6: ANSI mandatory sign: Read

the instruction manual (English / Span-

ish)

11.06.2014 21

Page 22

Description

2 Description

2.1 Construction of the machine

Fig. 8: Construction of the machine

1

Sealing bar

2

Counter-pressure bar

3

Chamber lid

4

Chamber lid gasket

5

Chamber

6

Oil sight glass

7

Power supply connection

8

Control terminal

9

Filling plates and sloping insert with support angle

22 11.06.2014

Page 23

Description

Control terminal

2.2 Control terminal

Fig. 9: Control terminal

1

<Machine control On/Off> key

2

<Evacuation> key

3

<Gas flushing> key

4

Pressure display

5

Display

6

<Arrow> key

7

Keys <1> to <3>

8

<Arrow> key

9

<Sealing> key

10

<Stop> key.

11

<Pump protection> key

<Machine control

On/Off>

• Switch machine control on and off

• Abort the packaging procedure at any time

(e.g. the film pouch has slipped out of position or the packaging procedure was

started with the incorrect recipe).

• Abort pump protection function.

<Evacuation> key Call up evacuation time.

<Gas flushing> key No function

Pressure display Shows the pressure difference between the

chamber and the outside environment.

Example: if the indicator is at -0.6 bar, this

corresponds to a pressure difference of 600

mbar between the chamber and the outside

environment.

11.06.2014 23

Page 24

Description

Control terminal

Display

• Display process data.

• Display settings.

• Display diagnostic messages.

<Arrow key> Increase values.

Keys <1> to <3> Load and save recipes.

<Arrow key> Decrease values.

<Sealing> key Call up sealing time.

<Stop> key.

<Pump protection> Activate pump protection function see Section

• Abort evacuation and then seal (e.g. if liquid products begin to boil).

• Deactivate pump protection function

4.9 "P

ERFORM PUMP PROTECTION FUNCTION"

2.3 Display

Fig. 10: Display

1

Numeric display

2

Icon for pump protection

3

Recipe display

4

Display of the unit

5

Function display

24 11.06.2014

Page 25

Description

Display

Numeric display

• During the packaging procedure: display of

the remaining time of the current process.

• With chamber lid opened: display of the

times currently set.

Icon for pump protec-

tion

• Icon is not displayed: pump protection

function is inactive.

• Icon flashes: pump protection function is

running.

• Symbol is displayed continuously: pump

protection function is activated and can be

started by pressing the chamber lid shut.

Recipe display Shows the currently loaded recipe. If the cur-

rent settings have not yet been saved as a

recipe, no number is displayed.

Display of the unit

• Unit 's' is displayed: the time in the display

is shown in seconds.

• There is no unit displayed: the time in the

display is shown in minutes.

Function display The function display shows the active proc-

esses for the packaging procedure and the

progress within the packaging procedure. The

individual processes are depicted as symbols.

Meaning when the chamber lid is open:

• Symbol is not displayed: the process is

bypassed during the packaging procedure.

• Icon flashes: the time which is called up

can be set with the arrow keys.

• Symbol is displayed continuously: the

process is performed during the packaging

procedure.

Meaning during the packaging procedure:

• Icon is not displayed: the process has

been performed or bypassed.

• Icon flashes: the process is just being performed.

• Icon is continuously displayed: the process

has not yet been performed.

2.4 Process sequence

The film pouches are filled and laid in the chamber. When the chamber is closed, the following procedures run automatically:

11.06.2014 25

Page 26

Description

Process sequence

Evacuation Evacuation if chamber and film pouches.

Sealing

• Compressed air is admitted to the sealing

diaphragm. The sealing diaphragm expands, pressing the sealing bar against the

counter-pressure bar.

• The film pouch is sealed.

• The sealing bar and seal seam cool off.

• The sealing diaphragm is ventilated, the

sealing diaphragm slackens.

• The chamber is ventilated.

• The chamber lid opens automatically if it is

not locked

2.5 Times which have to be set

Times must be set for evacuation and sealing. The times depend on

the product and the film pouch used. A pressure difference of at least

-0.35 bar is required during the evacuation process, so that the

chamber lid remains closed. A pressure difference of at least -0.35

bar is also required before the sealing process, so that the film

pouches can be sealed. The pressure difference can be read at the

pressure display on the machine control.

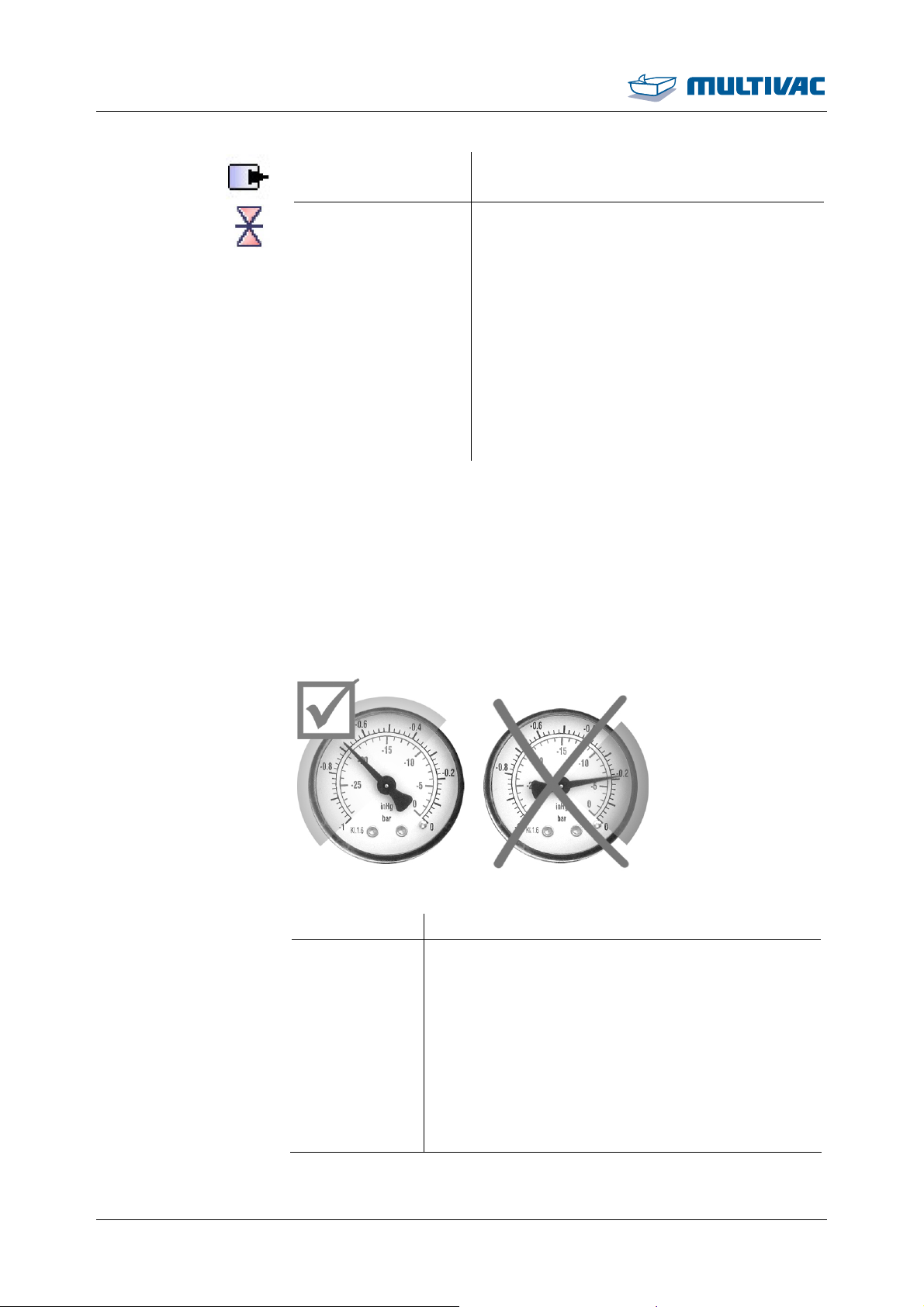

Fig. 11: Areas on the pressure display

Time Explanation

Evacuation time Air is suctioned out of the chamber and the film

pouches during this time. The longer the evacuation time, the better the vacuum and the quality of

the seal. Too long an evacuation time can damage

sensitive products (e.g. raw or pre-cooked pasta,

cooked vegetables). In the case of liquid products,

the evacuation process should be stopped with the

<Stop> key shortly before the product begins to

boil.

Recommended value: at least 3 s

26 11.06.2014

Page 27

Description

Times which have to be set

Time Explanation

Sealing time The film pouch is sealed during this time. The seal-

ing time depends on the material and thickness of

the film pouch.

Recommended value: 1.3 s to 1.5 s

2.6 Technical specifications

Power supply connection

Mains voltage 230 V/50 Hz 110 V/60 Hz

Phases 1/N/PE AC

Nominal power 0.3 kW

Nominal current 5 A 9 A

Maximum mains fuse 16 A 20 A

Maximum short-

5 kA

circuit current

Protection type IP54

Dimensions

Height (a) with open chamber lid 500 mm

Height (a) with closed chamber

275 mm

lid

Width (b) 380 mm

Depth (c) 385 mm

Operating height approx. 250 mm

Effective chamber size (W/H/D) 290 mm/90 mm/205 mm

Sealing length 205 mm

Weight approx. 24 kg

11.06.2014 27

Page 28

Description

Technical specifications

Dimensions

Fig. 12: Dimensions

Installation conditions and ambient conditions

Ambient temperature +2 °C to +40 °C

Storage temperature -25 °C to +80 °C

Relative air humidity during op-

90 % non-condensing

eration or storage of the machine, max.

Inclination of the machine during

15 °

transport, max.

Requirements for the location of

the machine.

• Level surface.

• Sufficient load bearing capacity.

• Free of damage.

Minimum distance on all sides of

100 mm

the machine

Vacuum pump

Vacuum pump 4 m3/h

Achievable final pressure approx. 2 mbar

28 11.06.2014

Page 29

Description

Technical specifications

Noise exposure at the workplace

Based on Machinery Directive

(2006/42/EC)

Measuring instrument Sound level meter, IEC 61672- 1,

class 1, fault limit +/-1,1 dB

Condition of the machine New condition with optimum set-

tings at the time of delivery.

A-weighted emission soundpressure level at the workplace

(DIN ISO 11204, accuracy

L

pA

class 3)

A

0,7 m

1,55 m

A

0,5 m

Fig. 13: Noise exposure measuring point

<70 dB

Info

The measured values of the noise data have been adjusted to take

extraneous and ambient noises into account.

Higher measured values may be produced as a result of the following:

• Highly sound-reflecting rooms.

• Modified settings.

• Wear.

11.06.2014 29

Page 30

Start-up

DANGER

3 Start-up

3.1 Setting up the machine and putting it into

operation

Danger of explosion!

Operating the machine in a potentially explosive atmosphere can

result in explosion due to hot machine parts.

Explosions can cause serious injuries or even death.

¾ Do NOT use the machine in rooms that are exposed to explo-

sion hazards.

¾ Prepare a firm, level site for the machine.

– The site should be at least twice the size of the machine's foot-

print (so that for example the housing can be opened).

– To ensure adequate space for cooling, there must be a clear

distance of at least 100 mm on all sides of the machine.

¾ Ensure that there is adequate access to the connections.

¾ Have the power supply of the machine fitted by a qualified electri-

cian with a suitable mains fuse in accordance with IEC 602041:2005. See the machine type plate or technical specifications for

the dimensions of the mains fuse.

Injury hazard!

The machine is heavy.

WARNING

Carrying the machine can cause injuries.

¾ Have a second person assist you.

¾ Lift the machine carefully out of the box and place it on the pre-

pared site.

30 11.06.2014

Page 31

Start-up

Setting up the machine and putting it into operation

¾ Position the machine on the site in such a way that the sealing bar

is on the right side.

¾ Open the chamber lid. Open the chamber lid more than half way

so that it remains open.

– The chamber lid remains open in the middle position.

¾ Take all the objects out of the chamber apart from the sealing bar.

11.06.2014 31

Page 32

Start-up

Setting up the machine and putting it into operation

¾ Close the chamber lid. So that the chamber lid remains closed,

first open it as far as the limit stop and then close it.

¾ Unscrew the two screws which attach the housing. Turn these

screws anticlockwise.

32 11.06.2014

Page 33

Start-up

Setting up the machine and putting it into operation

¾ Lay a soft underlayer beside the machine.

¾ Ensure that the machine is not connected to the mains electricity.

¾ Open the housing completely.

11.06.2014 33

Page 34

Start-up

Setting up the machine and putting it into operation

¾ Unscrew the screw plug. Turn the screw plug anticlockwise.

¾ Fill the vacuum pump with supplied oil, until there is a small air

bubble at the top of the oil sight glass.

– There should be a small air bubble at the top of the oil sight

glass.

34 11.06.2014

Page 35

Start-up

Setting up the machine and putting it into operation

¾ Check the oil level on the oil sight glass.

¾ If too much oil has been filled into the vacuum pump, drain off ex-

cess oil.

¾ Position the machine such that a liquid container can be held

under the oil sight glass.

¾ Hold the liquid container (e.g. an empty oil bottle) under the

drain opening.

11.06.2014 35

Page 36

Start-up

Setting up the machine and putting it into operation

¾ Unscrew the screw plug. To do so, turn the screw plug anti-

clockwise.

¾ Only fill in so much oil until there is a small air bubble at the top

in the oil sight glass.

¾ Screw the screw plug tightly in the drain opening. To do so,

turn the screw plug clockwise.

¾ Wipe off and remove any oil from the machine.

¾ Check the oil level on the oil sight glass.

¾ Turn the screw plug in the fill opening and screw it tight. Turn the

screw plug clockwise.

36 11.06.2014

Page 37

Start-up

Setting up the machine and putting it into operation

¾ Wipe off any spilt oil

¾ Close the housing. Ensure that there are no cables between the

housing and the base plate.

¾ Tighten the two screws which attach the housing. Turn these

screws clockwise.

– The housing is closed and tight.

¾ Check the mains voltage on the type plate and compare it with the

voltage of the mains electricity.

¾ If the values match, connect the machine to the mains electricity

at a place which is always easily accessible.

11.06.2014 37

Page 38

Start-up

Setting up the machine and putting it into operation

¾ Remove all the protective film.

¾ Clean the machine, see Section 6 "CLEANING"

38 11.06.2014

Page 39

Operation

4 Operation

4.1 Opening and closing the chamber lid

¾ Open the chamber lid more than half way so that it remains open.

– The chamber lid remains open in the middle position.

¾ So that the chamber lid remains closed, first open it as far as the

limit stop and then close it.

11.06.2014 39

Page 40

Operation

Opening and closing the chamber lid

¾ To start the machine after it has been switched on, firmly press

the opened chamber lid shut against the resistance by pressing

the middle of its front edge.

– The chamber is closed when the chamber lid is completely

shut.

– The vacuum pump runs.

– If the chamber lid is properly pressed shut, the pressure display

shows a pressure difference.

– The chamber lid opens automatically after the packaging pro-

cedure.

4.2 Switching on the machine

¾ Before switching on the machine for the first time fill the vacuum

pump with oil, see Section 7 "MAINTENANCE".

¾ If present, open the stop-cock for the gas supply.

¾ Connect the machine to the mains electricity in a place which is

always easily accessible.

¾ Press the <Machine control On/Off> key.

– The machine control performs a self-test.

– The software version of the machine control briefly appears in

the display.

– The machine is ready for operation.

4.3 Switching off the machine

¾ If necessary, perform the pump protection function, see Section

¾ To switch off the display immediately, press the <Machine con-

40 11.06.2014

¾ Press the <Machine control On/Off> key.

– The "pump protection" icon flashes in the display.

4.9 "PERFORM PUMP PROTECTION FUNCTION".

trol on/off> key again.

Info

The display goes out automatically after 10 s without input or without closing the chamber lid.

¾ Close the chamber lid. So that the chamber lid remains closed,

first open it as far as the limit stop and then close it.

Page 41

Operation

Switching off the machine

¾ Close the stop-cock for the gas supply, if part of the machine.

¾ If required disconnect the machine from the mains electricity.

4.4 Setting the times

¾ To set the evacuation time, press the <Evacuation> key.

¾ To set the sealing time, press the <Sealing> key.

¾ To change the value slowly, press the <arrow key> briefly.

¾ To change the value quickly, hold the <arrow key> pressed

¾ Press the key for the desired function.

– The icon of the function flashes in the display.

¾ Using the <arrow> keys, set the desired value.

– The value is adopted.

down.

Info

If the value for the sealing time is set to 0, the function is switched

off and the icon for the function is not shown in the display.

¾ Press the key of the function again.

– The icon of the function is shown continuously in the display.

4.5 Packing products

¾ Open the chamber lid. Open the chamber lid more than half way

so that it remains open.

– The chamber lid remains open in the middle position.

¾ If necessary, use filling plates.

– The pouch neck should be located at the centre of the pouch

height x.

¾ Use the sloping insert for packaging liquids, see Section 5.1 "IN-

SERT AND REMOVE THE SLOPING INSERT ".

– Liquid cannot escape from the film pouch.

11.06.2014 41

Page 42

Operation

Packing products

¾ Switch on the machine.

¾ Set the times.

Health hazard!

Insufficient or sporadic cleaning can promote the growth of micro-

WARNING

organisms which can contaminate the product.

This can pose serious health hazards for consumers.

¾ Disinfect your hands should they come into contact with any

machine part other than the operating elements.

¾ Do NOT lay the product on the machine.

¾ Observe the company cleaning guidelines.

¾ Follow instructions in the chapter 'Cleaning'.

¾ Fill the film pouch.

Info

The products should be as cool as possible for a good pack result.

The optimum temperature for the packaging procedure is approx. 5

°C to 10 °C.

¾ Insert film pouch.

– The opening of the film pouch should extend 2 to 3 cm beyond

the sealing device.

¾ Pull the pouch neck flat on the sealing bar.

– The pouch neck lies on the sealing bar without creases.

42 11.06.2014

Page 43

Operation

Packing products

NOTICE Danger of material damage!

Penetration by foreign matter (e.g. liquids, product residue, foreign

bodies) will damage the vacuum pump.

Damage can cause faults in the machine, which in turn can result in

reject packs.

¾ Cancel the evacuation process immediately if foreign matter is

sucked in.

¾ Change the oil in the vacuum pump.

¾ To start the machine after it has been switched on, firmly press

the opened chamber lid shut against the resistance by pressing

the middle of its front edge.

– The processes in the machine run automatically.

– The chamber lid opens automatically after the packaging pro-

cedure.

¾ Detach the pouch neck.

¾ Check the pack.

Info

Visually inspect the packs on a regular basis while the machine is

running. Depending on product and pack it may be necessary to

carry out additional and considerably more complex test procedures. This is the responsibility of the operating company, see Section 1.7.11 "C

¾ If necessary, adapt the times to the product.

¾ Save recipe, see Section 4.8.2 "SAVE RECIPE".

HECKING THE PACKS".

11.06.2014 43

Page 44

Operation

Aborting evacuation

4.6 Aborting evacuation

Info

Vacuum lowers the boiling point of liquids. This means that liquid

products can boil during the evacuation process. The boiling product contaminates the film pouch in the area of the seal seam and

the film pouch can therefore no longer be sealed.

¾ If the product begins to boil during the evacuation process, abort

the evacuation process with the <Stop> key.

– With machines without inert gas: the film pouch is sealed. The

chamber lid then opens automatically.

– With machines with inert gas: the film pouch is gas flushed and

sealed. The chamber lid then opens automatically.

4.7 Aborting packaging procedure

Info

The packaging procedure can be aborted at any time (e.g. the film

pouch has slipped out of position or the packaging procedure was

started with the incorrect recipe).

¾ To abort the packaging procedure, press the <Machine control

On/Off> key.

– The display goes dark.

– The chamber is ventilated.

– The chamber lid opens automatically.

– The product is not packaged.

4.8 Working with recipes

4.8.1 Load recipe

¾ Press the desired key briefly <1> to <3>.

– The recipe number appears in the display.

– The selected recipe is loaded.

Info

If the settings are changed after a recipe has been loaded, the recipe number goes out in the display.

44 11.06.2014

Page 45

Operation

Working with recipes

4.8.2 Save recipe

¾ Hold the desired key <1> to <3> pressed down for 5 s.

– The recipe number flashes in the display and is then displayed

continuously.

– A recipe which is already saved is overwritten.

– The current values are stored in the selected recipe.

4.9 Perform pump protection function

¾ Press the <Pump protection> key.

– The "pump protection" icons appears in the display.

– The duration of the pump protection function is displayed in

minutes.

– The pump protection function is activated.

¾ To deactivate the pump protection function, press the <Stop> key

again.

– The "pump protection" icon goes out.

– The pump protection function is deactivated.

¾ To start the machine after it has been switched on, firmly press

the opened chamber lid shut against the resistance by pressing

the middle of its front edge.

– The pump protection function starts.

– The "pump protection" icon flashes.

– The vacuum pump runs for 20 minutes.

– The chamber lid opens automatically.

– The display goes dark.

¾ To abort the pump protection function, press the <Machine control

On/Off> key, while the vacuum pump is running.

– The chamber lid opens automatically.

– The display goes dark.

11.06.2014 45

Page 46

Adjustment work and setup

5 Adjustment work and setup

5.1 Insert and remove the sloping insert

¾ If necessary, use filling plates for the desired incline.

¾ Hook the sloping insert on the sealing bar.

¾ Attach the support angle to the sloping insert at the required posi-

tion.

¾ If the sloping insert is no longer needed, remove it, along with the

support angle, from the chamber.

46 11.06.2014

Page 47

Cleaning

6 Cleaning

The objective of the cleaning work is to avoid risks to hygiene. If the

cleaning is insufficient or not performed properly, this may result in

the contamination of the products and to health hazards for end consumers. In addition, the machine may be damaged.

Info

Optional equipment for aiding the cleaning can be retrofitted for

various machine types. For further information, contact our sales

and service departments.

6.1 Notes on cleaning

6.1.1 Instructions for creating company cleaning guidelines

The company operating the machine is under an obligation to create

company cleaning guidelines. These cleaning instructions must be

matched to the particular needs of the operating company (type of

product, environment, sector etc).

The following points should be contained in the company cleaning

guidelines:

• Required cleaning intervals.

• Care products to be used. For care products, refer to the "Care

products table".

• Using the proper dosage of care products.

• Persons in charge of cleaning.

• The individual working stages for hygienic cleaning of the machine,

taking into consideration the following points:

– Safety instructions.

– Instructions for maintaining the machine's value.

– Instructions on the handling of cleansers.

– Instructions on the handling of disinfectants.

– Instructions on the handling of anti-corrosion agents and lubri-

cants.

– Instructions on the handling of cleaning devices.

– Recommendations for the course of the daily cleaning.

– Recommendations for the course of the intensive cleaning.

– Qualifications of the cleaning personnel. Assign only suitably

qualified and instructed personnel. Information on qualification

and training can be obtained from MULTIVAC Service.

• First aid measures.

11.06.2014 47

Page 48

Cleaning

Notes on cleaning

Incorrect use of care

products

6.1.2 Instructions for maintaining the machine's value

Regular and proper care helps to maintain the machine's value. The

best protection against harmful influences is to clean and disinfect the

machine on a regular basis. The longer product residue and other

aggressive deposits remain on the machine, the more harmful their

corrosive effects will be. On the other hand, care products can also

cause damage if they are used incorrectly.

• After every cleaning of the machine or its surroundings (for exam-

ple the floor or adjacent machines), always thoroughly remove any

care product residue from the machine with water of drinking quality. This prevents corrosion.

• Do NOT use any care products for the cleaning of the machine or

its surroundings, which contain chlorine or which are highly acidic

or alkaline. These create strong vapours and cause corrosion.

• Do NOT shorten the cleaning intervals for the mildly acidic clean-

ing and disinfection. All acidic cleansers are corrosive and they

can cause embrittlement and premature aging of plastics.

• Where components are made of aluminium, it is NOT permitted to

use tools which scratch metal, or to use harsh cleansers or cleaning devices which have an abrasive effect. These damage the

anodised layer. The components can then corrode. Residues of

cleansers and other aggressive deposits must be removed immediately.

• Do NOT use care products, which contain solvents, for compo-

nents made of plastic. These can cause embrittlement and premature aging of plastics.

• Dosage and application time of the care products, as well as the

correct temperature of the mixing water, must be observed. The

manufacturers also provide information on the maximum permissible dosages which apply in the food area.

• If used incorrectly, care products can damage components made

of rubber or plastic. Before applying care products, please take

time to read the instructions and warnings provided by the manufacturer.

Parameters for pre-

rinsing water and post-

rinsing water

The following points must be observed in order to prevent damage to

the machine:

• Do NOT rinse with a steam jet or high-pressure cleaner . Only use

low pressure between 4 bar and 6 bar (58 psi to 88 psi).

• Use a flat fan nozzle with a 5 ° to 15 ° inclination and an approx.

3/16 " nozzle opening.

48 11.06.2014

Page 49

Cleaning

Notes on cleaning

• The temperature of the water must NOT exceed 60 °C (140 °F).

• Only rinse off with water of drinking quality.

6.1.3 Instructions on the handling of cleansers

Chemical burn hazard!

Cleansers are caustic. Caustic effects are NOT noticed immedi-

WARNING

ately.

Contact with the skin can cause burns.

¾ Wear the prescribed personal protective equipment when han-

dling cleansers.

¾ Observe the manufacturer's instructions.

• For type of cleanser, refer to the "Care products table".

• Always follow the instructions for use from the cleanser manufac-

turer.

• The quantity of cleanser is not the decisive factor for successful

cleaning.

– Applying amounts in excess of the proper dosage does not im-

prove or accelerate cleaning efficiency, but only hinders the required rinsing off of the cleanser.

• Dried cleanser residues make cleaning more difficult and pro-

longed.

– Even the smallest residues can inhibit the effect of the disinfec-

tion.

– Check by measuring the pH factor of the post-rinsing water.

• Regular checks of cleaning (i.e. by contact tests) reduce the risk of

product contamination.

• Insufficient cleaning cannot be compensated for by doubling the

concentration of the disinfectants.

6.1.4 Instructions on the handling of disinfectants

Incorrect use of disinfectant can contaminate the product with chemicals or decrease the effectiveness of disinfection. This can pose serious health hazards for consumers.

• Always follow the instructions for use from the disinfectant manu-

facturer.

• Only rinse or wipe off after disinfection, if this is required by the

disinfectant manufacturer.

• Always observe the applicable hygiene regulations.

11.06.2014 49

Page 50

Cleaning

Notes on cleaning

6.1.5 Instructions on the handling of anti-corrosion

agents and lubricants

Excess lubricants can accumulate at lubrication points. Excess

grease has no lubricating function; however, it can breed microorganisms and contaminate the product.

• For type of anti-corrosion agent, refer to "Care products table".

• Always follow the instructions for use from the manufacturer of the

anti-corrosion agent or lubricant.

• Check the lubricating points regularly for the accumulation of lubri-

cants and remove excess lubricant.

• Only use H1 or FDA-approved lubricants and anti-corrosion agents.

• Regular checking of the microbiological shelf life of the anti-

corrosion agent and lubricant helps to reduce the risk of product

contamination.

6.1.6 Instructions on the handling of cleaning devices

• The cleaning devices will become germ hot spots if they are not

cleaned often enough. This can cause cross contamination, which

will damage the product. Use only plastic brushes and brooms.

Clean the cleaning devices daily and apply disinfectant afterwards.

• The exhaust air emitted and agitated by the vacuum cleaner must

comply with the prescribed limit values for the packaging environment. Accordingly, the appropriate filter elements must be used in

the vacuum cleaner.

6.2 Cleaning recommendations

Info

• Always clean the machine from top to bottom.

¾ Open the chamber lid. Open the chamber lid more than half way

so that it remains open.

– The chamber lid remains open in the middle position.

¾ Remove all products from the chamber.

¾ Switch off the machine.

¾ Disconnect the machine from the mains electricity.

¾ Cover the mains plug with waterproof plastic bags.

¾ Allow the machine and sealing bar to cool down.

¾ Store empty, new film pouches outside the room in a clean, dry

place during the cleaning procedure.

50 11.06.2014

Page 51

Cleaning

Cleaning recommendations

¾ Remove all waste (e.g. product scraps, film trim) on or around the

machine.

¾ Remove the following components:

– Sloping insert with with support angle.

– Filling plate.

– Sealing bar, see Section 7.3.1 "REMOVE THE SEALING BAR".

¾ Check chamber lid gasket for dirt or contamination.

¾ If there is dirt or contamination, remove the chamber lid gasket

from the groove.

¾ Take the removed components to a separate room suitable for

wet cleaning

¾ Clean dismantled components manually with cleaning solution.

¾ Only clean the Teflon tape of the sealing bar manually with a

soft cloth or a soft brush.

¾ Wait until the contact time has elapsed (see instructions of

cleanser manufacturer).

¾ Wipe with new cloth and water of drinking quality.

¾ Inspect for dirt and cleanser residues.

¾ If necessary, perform another manual cleaning and wipe it off.

¾ Disinfect the removed components with disinfectant.

¾ Wait until the contact time has elapsed (see instructions of disin-

fectant manufacturer).

11.06.2014 51

Page 52

Cleaning

Cleaning recommendations

¾ If necessary, wipe off the components with a new cloth and water

of drinking quality; see instructions of the disinfectant manufacturer.

¾ Clean the floor with a rubber wiper.

¾ Dispose of the waste properly.

¾ Apply cleanser to the floor in the low-pressure foaming procedure.

¾ Wait until the contact time has elapsed (see instructions of

cleanser manufacturer).

¾ Rinse off the floor with water of drinking quality.

¾ Manually clean the entire machine, including the table, with clean-

ing solution.

¾ Only clean the chamber lid manually with a soft cloth or a soft

brush.

¾ Wait until the contact time has elapsed (see instructions of

cleanser manufacturer).

¾ Wipe with new cloth and water of drinking quality.

¾ Inspect the entire machine and the floor for dirt and cleanser resi-

dues.

¾ If necessary, clean and wipe off again.

¾ Disinfect the entire machine, including the table, with disinfectant.

¾ Close the chamber lid. So that the chamber lid remains closed,

first open it as far as the limit stop and then close it.

¾ Use a hand-held spray lance to apply disinfectant to the floor.

¾ Wait until the contact time has elapsed (see instructions of disin-

fectant manufacturer).

¾ If necessary, rinse the floor with water of drinking quality; see in-

structions of the disinfectant manufacturer.

¾ Open the chamber lid. Open the chamber lid more than half way

so that it remains open.

– The chamber lid remains open in the middle position.

¾ If necessary, wipe off the machine with a new cloth and water of

drinking quality; see instructions of the disinfectant manufacturer.

¾ Remove the plastic bag from the mains plug.

¾ Dispose of plastic bags properly. For reasons of hygiene, never

reuse bags

52 11.06.2014

Page 53

Cleaning

Cleaning recommendations

¾ Attach the following components:

– Sealing bar, see Section 7.3.2 "INSTALL THE SEALING BAR".

– Filling plate.

– Sloping insert with with support angle.

¾ Install the chamber lid gasket.