Page 1

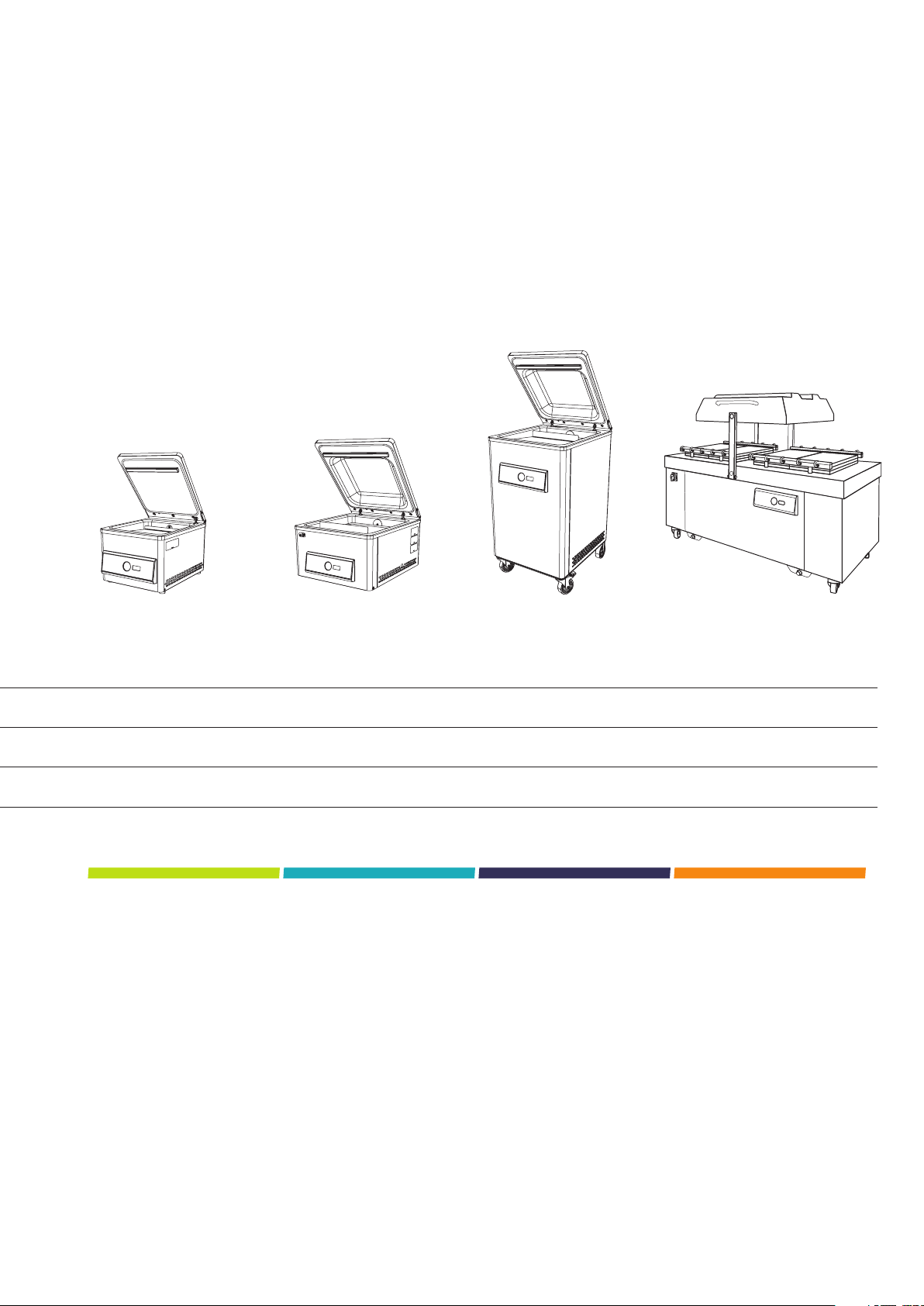

BASELINE P Series

Chamber Machines

Page 2

The BASELINE range professional from top

to bottom

Successful and high quality vacuum packing is simple

with BASELINE chamber machines, because every

BASELINE machine is a genuine MULTIVAC. This

means a long lifespan, high level of reliability and the

best service are guaranteed.

BASELINE product range

Typ e P 100 P 200 P 300 P 400 P 600

Design Table-top machine Table-top machine Table-top machine Free-standing machine Double chamber machine

Usable volume 290 x 205 x 90 mm 305 x 300 x 110 mm 420 x 425 x 170 mm 420 x 425 x 170 mm 600 x 500 x 160 mm

Pump output 4 m³/h 8 m

Even inexperienced personnel are able to pack reliably

and efficiently with a BASELINE machine. BASELINE

chamber machines are therefore the ideal vacuum

packing solution for butchers' shops, restaurants,

hotels, cheese dairies, direct marketing companies and

farm shops. It can also be used for a wide range of

consumer and industrial products.

2

Page 3

3

/h 20 m³/h 60 m³/h 60 m³/h

The P200, P300, P400 and P600 machines are available

with an optional gas flushing system.

We offer a mobile stand as an accessory for table-top

machines.

3

Page 4

BASELINE P 100

Table-top machine

290 x 205 x 90 mm

4

Page 5

5

Page 6

BASELINE P 200

Table-top machine

305 x 300 x 110 mm

6

Page 7

7

Page 8

BASELINE P 300

Table-top machine

420 x 425 x 170 mm

8

Page 9

9

Page 10

BASELINE P 400

Free-standing machine

420 x 425 x 170 mm

10

Page 11

11

Page 12

BASELINE P 600

Double chamber machine

600 x 500 x 160 mm

12

Page 13

13

Page 14

Quality and equipment

for high quality demands

• Housing made of stainless steel

• Transparent, acrylic glass chamber lid

• Double-seam sever sealing

• Plug-in sealing bar

• Sloping insert and filling plates

• Automatic progressive ventilation

• Function for vacuum quick-stop

• Three program memory spaces

14

Page 15

15

Page 16

High quality materials

The housing and vacuum chamber of the BASELINE

chamber machines are manufactured from high quality

stainless steel. The chamber lid is made of robust

acrylic glass (PMMA) or of stainless steel. The materials

used contribute to ease of cleaning and to the long

lifespan of the machine.

Transparent chamber lid

The complete packaging procedure can be monitored

through the acrylic glass chamber lid. The chamber lid

can be opened wide for loading and unloading.

Chamber lid made of stainless steel

The double chamber machines feature a high-quality

chamber lid made of stainless steel. This can be pivoted

without requiring much force.

Three memory spaces for user programs

The evacuation and sealing times for frequently used

applications can be saved on three keys. This includes

the gas flushing time in the case of machines with a gas

flushing unit.

16

Vacuum quick-stop

function

When the quick-stop

button is pressed, the

evacuation and gas

flushing processes are

ended immediately. Use

this function to stop the

evacuation of liquids

when the boiling point has

been reached.

Page 17

Automatic progressive

ventilation

When packing products

with sharp edges such as

pork chops, kebob

skewers or salmon

portions, the film pouch

wraps itself gently around

the contours of the packed

product. This reduces the

risk of puncturing the film

pouch.

Double-seam sever sealing

BASELINE chamber machines seal with a three

millimetre wide primar y seal seam and a one millimetre

wide separation seam. The excess film on the film

pouch can be easily pulled of f at the separation seam

without using tools. The result: cleanly and reliably

sealed film pouches.

Sloping insert

The sloping insert prevents liquids from flowing out of

the film pouch during packing. The film pouch is simply

placed at the required height on the adjustable

magnetic support angle.

Filling plates

The seal seam should be at half the product height for

high-quality packaging. The sealing height can be

adjusted to the product by means of the filling plates.

The filling plates also reduce the chamber volume and

therefore the evacuation time and gas consumption.

17

Page 18

Simple cleaning reliable hygiene

MULTIVAC Hygienic Design™

All BASELINE chamber machines feature the

MULTIVAC Hygienic Design™ and can therefore be

used in production environments where the highest

requirements in cleanliness and hygiene must be

satisfied. The machine is designed for cleaning and

disinfection with fluids. Easy-care materials and smooth

surfaces ensure quick and simple cleaning.

Removable inserts

Access to the vacuum chamber is optimal when the

chamber lid is in the cleaning position. Filling plates,

the sloping insert and the plug-in sealing bar can be

removed with just a few steps and without needing

tools.

Smooth operating display

The smooth, film-covered operating display can be

simply wiped down with a damp cloth.

18

Page 19

Page 20

Long lifespan

We only use long-lasting materials and components

for the BASELINE machine series. Thanks to the

vertical integration of our manufacturing, we can

ensure that their quality is efficiently maintained.

This means that you obtain a reliable machine from

an integrated source - and all that at an attractive

price-performance ratio.

DGUV tested

The BASELINE chamber machines have been tested by

the German Social Accident Insurance (DGUV) are carry

the GS test seal.

20

Page 21

Options

Gas flushing system

The P200, P300, P400 and P600 BASELINE chamber

machines are available with an optional gas flushing

system. The inert gas acts against bacteria by reducing

the oxygen content in the film pouch. Pressuresensitive food is protected by the gas cushion. Tears in

the film pouch due to sharp products are avoided.

Mobile stand made of stainless steel, with pouch shelf

Page 22

Professional

vacuum packing

1 2 3

22

Filling the film pouches

The seal seam must

remain clean on the inside

and outside.

Inserting the film pouches

If the content of the film

pouch is liquid, position

the film pouch using

the sloping insert and

magnetic set square.

Aligning the seal area

Place the open end of

the film pouch over the

sealing bar. The edge

of the pouch must not

be trapped in the

chamber lid.

Page 23

4

5

6

7

Selecting the program

Select one of the three

defined programs, or

enter a sealing time

and vacuuming time

in accordance with

requirements.

Starting the program

The packaging procedure

is star ted by closing the

chamber lid.

Removing the packaging

After vacuuming and

sealing, the chamber lid

opens automatically.

Pulling off the excess

pouch film

Pull off the excess pouch

film at the separation

seam.

23

Page 24

i

Information about the vacuum pouch

Select a pouch size which is suitable for the packaged

product. Make sure when filling the pouch that the

pouch neck remains clean. Use boilable film pouches, if

the content has to be heated up at a later stage. Special

shrink pouches enable excess pouch material to be

shrunk back by dipping in hot water.

Packing liquids

Products containing liquid can be positioned

conveniently with the sloping insert and the magnetic

set square. If the liquid begins to boil (formation of

bubbles), the maximum vacuum has been reached.

End the evacuation process by pressing the vacuum

quick-stop button.

Tips

Modified atmosphere packaging

Inert gas protects the pack content against mechanical

stress and it acts against bacteria through oxygen

deprivation. The chamber machine has to be equipped

with a gas flushing system, and the modified atmosphere must be matched to the pack content.

24

Page 25

Optimum shelf life

Cleanliness

Essential for a long shelf life: Only work with clean hands

or with gloves, on a clean work surfaces and with

residue-free tools.

Freshness

Only use products which are fresh. This is the only way

you will achieve the maximum shelf life, with flavor

retention to the greatest possible extent.

Cold

The colder the product being packaged is, the higher

the vacuum that can be physically achieved and

therefore the longer the shelf life of the product. As

soon as the products have been packed, chill them

again immediately and ensure that the required chill

chain is maintained so that the maximum shelf life is

guaranteed.

25

Page 26

Page 27

Better packaging with MULTIVAC

Founded in 1961, MULTIVAC has developed into a

leading global full-range supplier of packaging

solutions for food, sterile medical products and

a wide variety of industrial items. MULTIVAC offers

an extensive product range to its customers in both

manual production businesses and industrial scale

manufacturing - from chamber machines to integrated

packaging lines. The company currently employs

4,200 employees worldwide in more than 70 locations,

with 1,500 of these in sales and service.

Spare parts and service

In order to obtain genuine spare parts and qualified

service from MULTIVAC, please contact the dealer from

which you bought your BASELINE chamber machine.

27

Page 28

MU LT I VAC

Sepp Haggenmüller GmbH & Co. KG

Bahnhofstr. 4

87787 Wolfertschwenden

Germany

www.multivac-baseline.com

107175731 © MU LTIVAC · 08/14 · Printe d in Germ any on chl orine f ree pa per ·

Subje ct to te chnical cha nges in l ine wit h prod uct de velop ment·

MULTIVAC and B ASELINE are re gist ered t rademarks o f MULTIVAC Sep p Hagge nmüller GmbH & C o. KG

Loading...

Loading...