Multiva Optima T500 Optima T600, Optima T800, Optima T900, Optima T700, Optima T Maintance Manual

...

Optima

Starting from serial nr 05240016

01 / 2016

O

O

O

P

P

P

E

E

E

R

R

R

A

A

A

T

T

T

I

I

I

O

O

O

N

N

N

A

A

A

N

N

N

D

D

D

M

M

M

A

A

A

I

I

I

N

N

N

T

T

T

E

E

E

N

N

N

A

A

A

N

N

N

C

C

C

E

E

E

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

S-TINE HARROWS

Contents

1. FOREWORD ............................................................................................................................................................................ 1

1.1. Intended use of the machine ...................................................................................................................................... 1

1.2. Technical specifications ................................................................................................................................................. 2

1.3. Type plate ........................................................................................................................................................................... 2

2. SAFETY INSTRUCTIONS ...................................................................................................................................................... 3

2.1. Warning symbols ............................................................................................................................................................. 3

2.2. Hitching and unhitching ............................................................................................................................................... 4

2.3. Transport on public roads ............................................................................................................................................ 4

2.4. Using the harrow ............................................................................................................................................................. 5

2.5. Maintenance ...................................................................................................................................................................... 6

3. COMMISSIONING AND BASIC ADJUSTMENTS ........................................................................................................... 7

3.1. Measures before commissioning ............................................................................................................................... 7

3.2. Hitching to tractor ........................................................................................................................................................... 7

3.3. Adjusting hydraulic hoses ............................................................................................................................................ 8

3.4. Side section and front levelling board hydraulics selector valve, Optima T500 - T700 .......................... 8

3.5. Operating principle of the front levelling board and depth adjustment hydraulics .............................. 9

3.6. Synchronizing the cylinders......................................................................................................................................... 9

3.7. Harrow position adjustment..................................................................................................................................... 10

3.8. Basic adjustment of the side sections ................................................................................................................... 10

4. USE AND ADJUSTMENT OF THE HARROW............................................................................................................... 12

4.1. Seedbed preparation .................................................................................................................................................. 12

4.2. Tillage technique .......................................................................................................................................................... 12

4.3. Starting and setting into work position ................................................................................................................ 13

4.4. Transport position ........................................................................................................................................................ 13

4.5. Adjusting working depth ........................................................................................................................................... 14

4.6. Adjusting the depth scale .......................................................................................................................................... 14

4.7. Using the levelling boards ......................................................................................................................................... 15

4.8. Using the rear harrow ................................................................................................................................................. 16

4.9. Using the cage roller .................................................................................................................................................... 17

4.10. Front support wheel ( T1000 – T1500 only) ..................................................................................................... 17

5. MAINTENANCE .................................................................................................................................................................. 18

5.1. Wear parts ....................................................................................................................................................................... 18

5.2. Changing a wheel ......................................................................................................................................................... 18

6. MAINTENANCE PROGRAMME, INSPECTIONS ......................................................................................................... 19

6.1. Bolt tightening torques .............................................................................................................................................. 19

6.2. Tyre pressure .................................................................................................................................................................. 19

6.3. Wheel hub bearing clearance .................................................................................................................................. 20

6.4. Bogie bearing clearance ............................................................................................................................................. 20

6.5. Hydraulics ........................................................................................................................................................................ 20

6.6. Side section locking ..................................................................................................................................................... 21

6.7. Front support wheel bearing clearance ............................................................................................................... 21

6.8. Selector valve operation ............................................................................................................................................ 22

7. MAINTENANCE PROGRAMME, LUBRICATION......................................................................................................... 23

8. STORAGE .............................................................................................................................................................................. 27

9. WARRANTY.......................................................................................................................................................................... 28

Appendix 1. EC DECLARATION OF CONFORMITY ........................................................................................................ 29

Appendix 2. Hydraulic schematic Optima T500............................................................................................................. 30

Appendix 3. Hydraulic schematic Optima T600-700 .................................................................................................... 31

Appendix 4. Hydraulic schematic Optima T800-900 .................................................................................................... 32

Appendix 5. Hydraulic schematic Optima T1000 .......................................................................................................... 33

Appendix 6. Hydraulic schematic Optima T1250 .......................................................................................................... 34

Appendix 7. Hydraulic schematic Optima T1500 .......................................................................................................... 35

Appendix 8. Connection socket according to SFS 2473 .............................................................................................. 37

1

1. FOREWORD

Multiva agricultural machines are manufactured in Finland. The modern production technology,

excellent raw materials and careful manufacturing and finishing utilised in the production of the

machines guarantees a high quality product. Multiva product range includes the following agricultural

machines:

• Trailers

• S-Tine Harrows

• Disc Harrows

• Cultivators

We thank you for choosing and putting your trust on the Multiva S-Tine Harrow. We hope that the

product fulfils you requirements and serves you for a long time. We advise you to carefully go

through these instructions before commissioning the machine. The inspection and maintenance

activities described in these instructions are vitally important for the proper functioning of the machine

and the validity of the warranty.

All instructions, warnings and cautions must be followed without exception. They are given to ensure

the safety of the user and the durability of the machine.

These operation and maintenance instructions apply to Optima range harrows starting from serial

number 05240016.

1.1. Intended use of the machine

Multiva s-tine harrow is designed to perform seedbed preparation of soil, to which primary tillage has

already been carried out, to prepare the soil for seeding. Multiva s-tine harrow produces a smooth

seedbed and a sufficiently fine crumb structure, which are the requirements for even and optimal

growth, economically with a minimum amount of harrowing. The s-tine harrow, with two or three

levelling boards and narrower tine spacing, can also be used for levelling. Never use the s-tine harrow

to perform primary tillage to unprepared soil!

Multiva Optima T is an efficient harrow for various soil types. The spacious frame structure prevents even

extensive amounts of plant residue from causing harrow clogging. The supporting wheels ensure

uniform tillage depth even on soft soil types. Due to the great weight and robustness of the tines of the

harrow, it is also suitable for tilling heavy soil. The tilling power of Optima T models can be increased by

utilising a rear levelling board which is available as an option. The working width can be changed by

using extension parts in models T600 and T800. Extension parts are bolted to the base frame of the stine harrow.

2

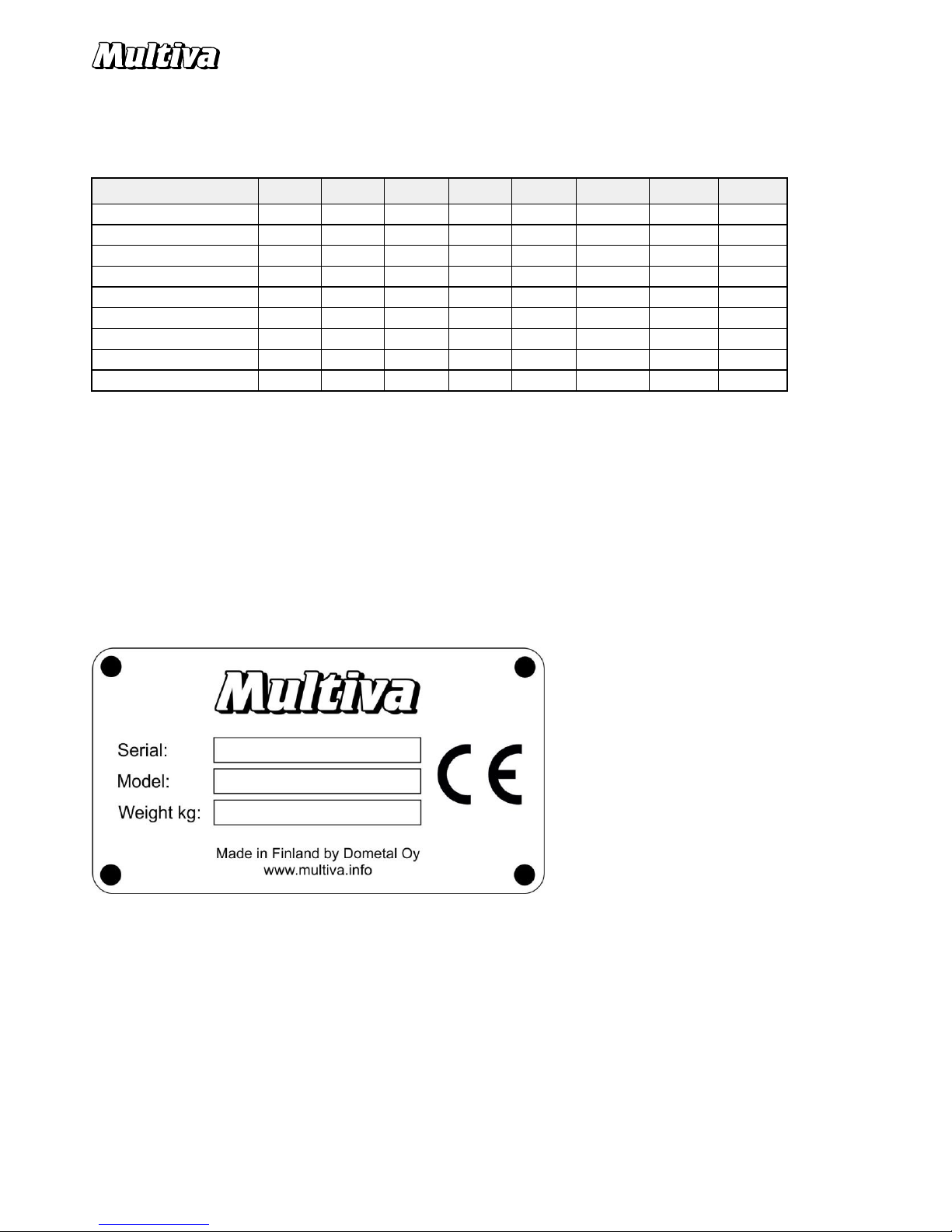

1.2. Technical specifications

With standard equipment

Optima T

T500 T600 T700 T800 T900 T1000

T1250

T1500

Nr of s

-

tines

67 79 91 105 117 129

163 183

Tine spacing mm

75 75 75 75 75 75

75 75

Nr of tine axles

7 7 7 7 7 9 9 9

Working width cm

500 600 700 800 900 1000

1300

1450

Length of the frame

300 300 300 300 300 410

410 410

Transport width cm

300 340 340 340 340 420 420 420

Extension parts

- - 2x0,5m

- 2x0,5m

- - -

Power require

ment hp

80 100 120 140 160 200

260 300

Weight kg

2220

2700

3120

3540

3970

6530

7865

9820

Technical specifications can be found also on the manufacturer's website. Please contact the

manufacturer to acquire information about new products.

Due to ongoing product development, products and specifications discussed herein are subject

to change.

1.3. Type plate

A type plate similar to the one below is attached to the harrow. Please write all the information from the

type plate in this manual. When you are dealing with the supplier of the Multiva machine or a factory

representative, please mention the model and serial number of the machine. This is recommended to

avoid delays and unnecessary misunderstandings.

Fields in the type plate:

Serial = Serial number of the machine

Model = Model of the machine

Weight = Weight of the machine with standard

3

2. SAFETY INSTRUCTIONS

These safety instructions and safety distances must without exception be followed when using the

machine. The machine must be configured according to this manual and this manual must be utilised in

the operation and maintenance of the machine.

Never allow any person to ride the harrow during work or transport!

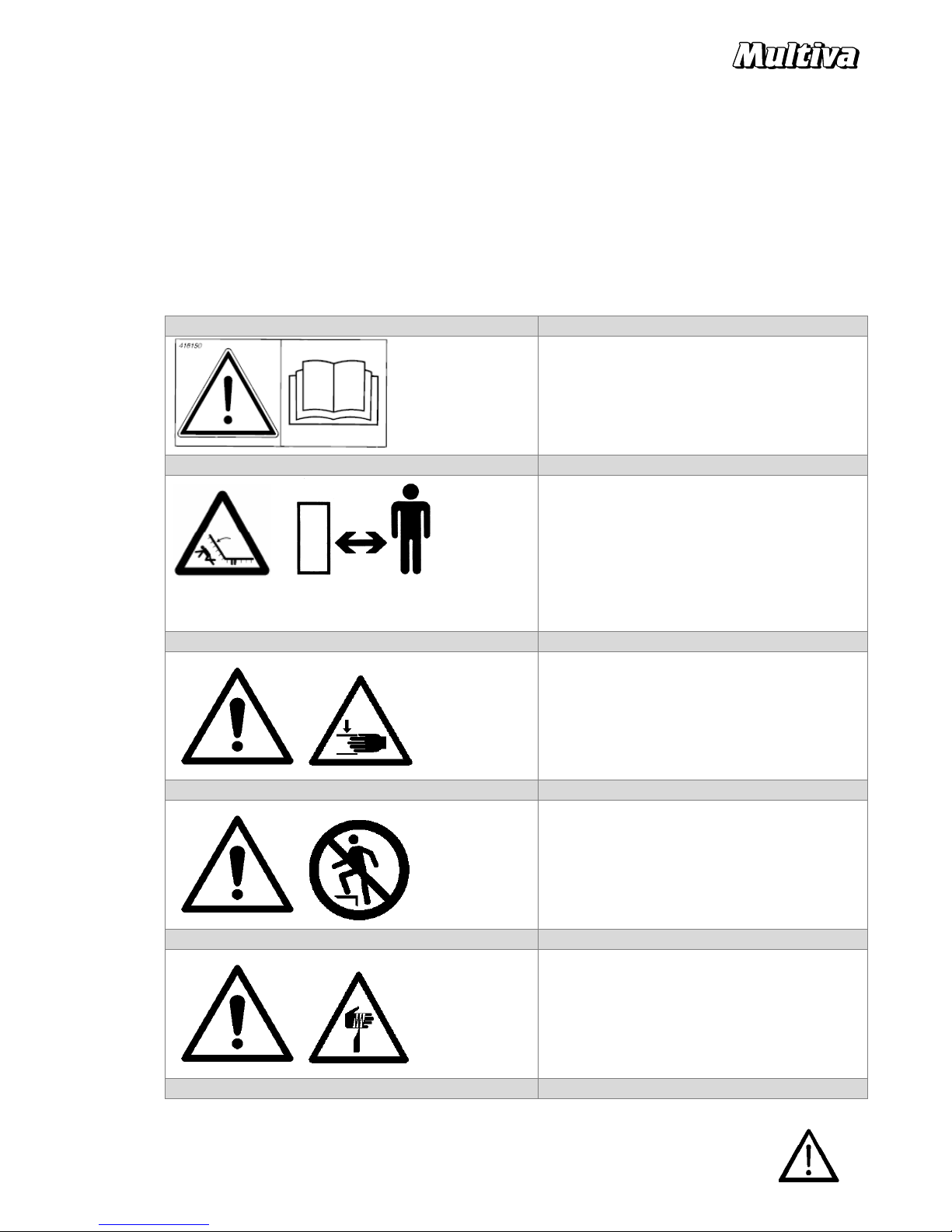

2.1. Warning symbols

Follow the warning labels attached to the harrow pictured below. Do not remove the warning labels on

the machine.

Warning label

Explanation

CAREFULLY READ THE OPERATION

MANUAL AND THE SAFETY INSTRUCTIONS

BEFORE CONNECTING THE MACHINE TO A

TRACTOR!

CRUSHING HAZARD!

IMPACT HAZARD!

Maintain a 10-metre safety distance from the

machine when the side wings are up and

when the machine is in operation.

Do not go under the machine unless it is

mechanically supported.

CRUSHING HAZARD!

There is a danger of crushing in hitching and

unhitching activities. Beware the bruising of

feet, fingers and arms

RISK OF FALLING!

Standing on the machine is not allowed in any

situation.

SHARP EDGES!

There is a risk of injury when using the

machine functions. Maintain a 10 m safety

distance when connecting the machine to the

tractor.

4

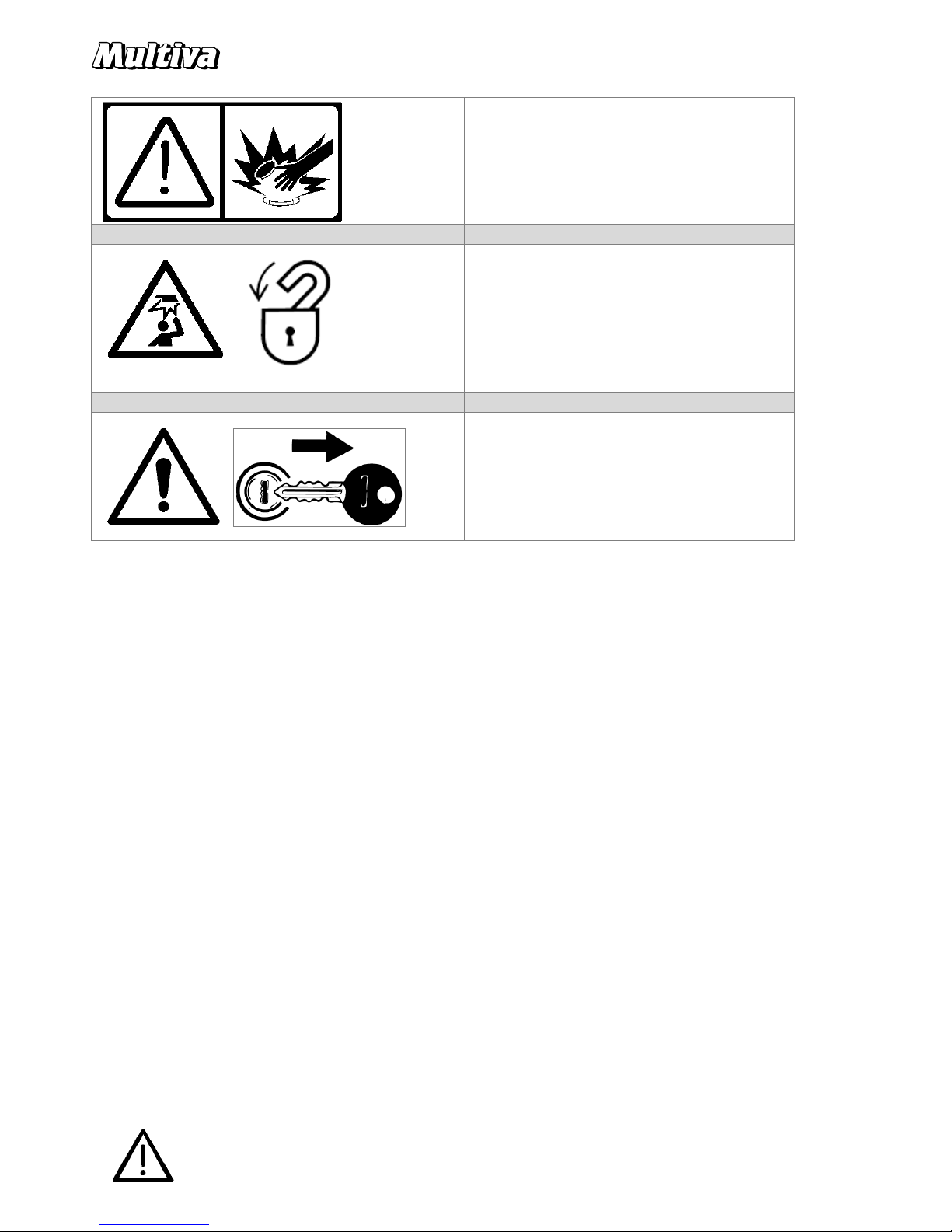

HIGH PRESSURE

HYDRAULIC OIL

!

Escaping hydraulic fluid under pressure can

penetrate the skin causing serious injury!

DANGER!

Proper function of the locking mechanisms

must be checked before any road transport;

Locking of the side wings and the ball valve for

the side wing hydraulics.

NOTE!

Turn off the tractor before making service or

adjustments to the machine.

Make sure that the tractor and machine won’t

move itself. Apply hand brake or wheel

wedges.

2.2. Hitching and unhitching

The harrow can only be hitched to the trailer hitch of the tractor. Follow all safety instructions

concerning the tractor when hitching or unhitching the harrow. There is a danger of crushing in

hitching and unhitching activities. Also beware the bruising of feet, fingers and arms. Do not disconnect

pressurised hydraulic connectors. When the harrow is hitched to the tractor, standing near the harrow,

and particularly its side sections, is forbidden.

2.3. Transport on public roads

When transporting the harrow on a public road, please take care and follow all orders under the Road

Traffic Act and special regulations concerning slow vehicles. Before moving, check the visibility of the

harrow's reflectors and the slow vehicle triangle as well as the functioning and visibility of the tractor's

lights. The reflectors, triangle and tractor lights must be maintained clean, as they affect the traffic

safety of the entire combination. When transporting the harrow, particular attention should be given on

the visibility of the rear turn signals. Always ensure that the harrow is sufficiently clean before transport

on public roads.

As standard, the harrow is fitted with reflectors at the extremities of the harrow to indicate the over

width portion of the towed machine. When driving on public roads, make sure that the lights of the

tractor are also visible from behind the harrow.

The maximum transport speed for the harrow with 300 tyres is 40 km/h and with 340 tyres 50

km/h.

5

1. Transport support pin

2. Spring cotter pin

The harrow has a transport support which prevents the machine lowering down accidentally in case of a

users fault or a sudden leak in the hydraulics. Transport support pin 1 must be set to its hole and locked

with pin 2 before any road transport.

Always before the road transport, make sure that the side wings have locked to the transport position.

Unintended opening of the wings should be prevented by closing the ball valve in the hydraulic hose.

Turn the lever crosswise to the hose. See section 4.4 in this manual.

2.4. Using the harrow

The operator must be familiar with the operation of the harrow and he/she must have the knowledge

and skills to operate the harrow correctly. The operator must study the operating instructions and

follow them.

The condition of the harrow, the tightness of the bolts and the tyre pressures must always be visually

checked before starting work. Never adjust or clean a moving harrow. During work, persons are

forbidden to ride the harrow or stand within the working area (safety distance 5 m). Safety distance

should also be kept while the harrow is not moving when the hydraulics is being used. Pressurised

hydraulic cables can release a deadly liquid spray. The side sections of the harrow can only be raised and

lowered when the harrow is not moving. When raising or lowering the side sections, ensure that no

persons are standing near the harrow. Before transport, ensure that the side sections are set to transport

position and locked. Before commencing working with the harrow, side sections must be fully lowered,

so that the cylinders are fully extended.

The side sections of the harrow should be raised and lowered by keeping the hydraulic pressure

continuously on during the whole movement. Interrupting the movement may disturb the function of a

valve in the system and the side sections will not move at the same time. Sudden change to the balance

may cause the harrow to tip over. This applies in particular 800 – 1500 harrows.

6

2.5. Maintenance

For maintenance, the harrow must be stopped and it must be blocked to stop it from moving.

Maintenance must be carried out on an even and stable surface to prevent the harrow from tipping

over or moving. Note the danger of slipping: Do not step on any part of the machine.

Maintenance-related and other measures should not be carried out when the harrow or one of its parts

is raised and unsupported.

When maintenance is carried out to the harrow, the side blocks must be lowered. In any event, ensure

safe working conditions and sufficient lighting. Turn off the tractor and release the pressure from the

hydraulics before handling any hydraulic hoses or components.

Only use original spare parts in the maintenance of the harrow. Using non-original spare parts will void

the warranty.

7

3. COMMISSIONING AND BASIC ADJUSTMENTS

3.1. Measures before commissioning

The sections of the harrow requiring lubrication have been lubricated at the factory and oil has been

driven to the cylinders during test runs. Still, it is recommended to review the lubrication points before

the first period of usage. Lubrication points are described in section 7 MAINTENACE PROGRAMME,

LUBRICATION.

3.2. Hitching to tractor

Attach the towing eye of the harrow's drawbar to the hydraulic tow hitch of the tractor. Note the safety

distance. Ensure that the hitch of the tractor locks on and that the hitch is not supported by the lifting

device.

Remember that pressurised hoses should never be handled and the hydraulics should be depressurised

before handling.

Hydraulic hoses are marked with colourful collars. Hoses are connected to dual purpose outputs.

Optima T500 - T700 :

The tractor must have 2 dual purpose hydraulic outputs.

The selector valve of the harrow directs the oil to the levelling board cylinders or the opening/closing

cylinders of the side sections depending on the height setting of the harrow. The operation of the

selector valve is described in section 3.4

Optima T800 - T1500

The tractor must have 3 dual purpose hydraulic outputs.

NB! All models: Ensure that the dual purpose valve used for height adjustment is actually set to

function as dual purpose and that the float position of the valve is not activated. If the float position

remains activated during height adjustment, this may result in the changing of the harrow's working

depth between sections during tillage!

NB! Optima T800 - T1000 : The raising cylinders of side sections must be connected to a hydraulic

output with a float position. The float position of the side section's raising cylinders must always be

activated during tillage. The float position allows the oil to flow freely in both hoses.

Adjust the pulling arms of the tractor to a height at which they do not become in contact with the

drawbar or hydraulic hoses during turning. When you unhitch the harrow from the tractor, remember to

also disconnect the hydraulic connectors.

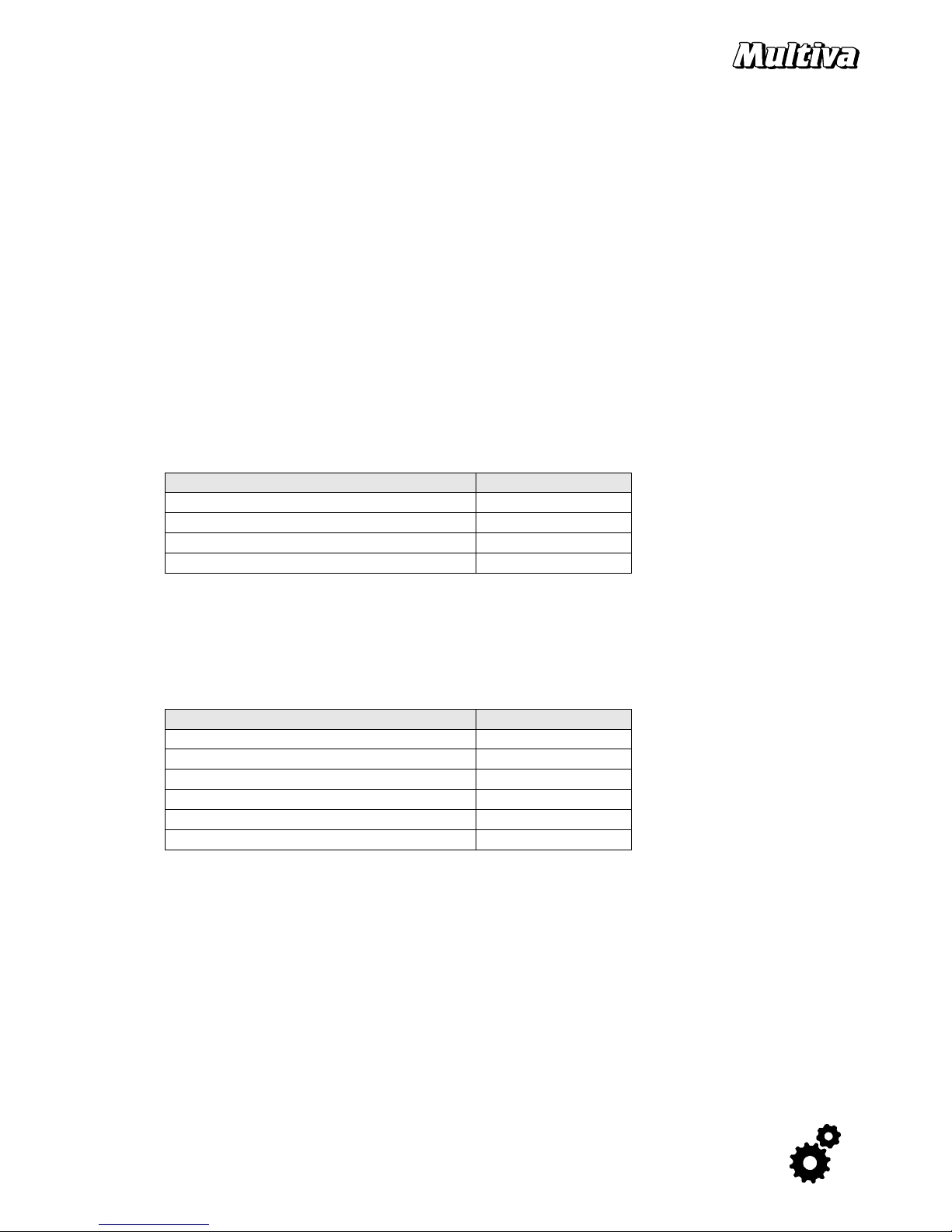

Action

Marking the hose

Working depth

- down

1 x red

Working depth

- up 2 x red

Levell

ing board up / open side sections

1 x black

Levelling board down / close side sections

2 x black

Action

Marking the hose

Working depth

- down

1 x red

Working depth

- up 2 x red

Close side sections

1 x black

Open side sections

2 x black

Levelling board down

1 x blue

Levelling board up

2 x blue

8

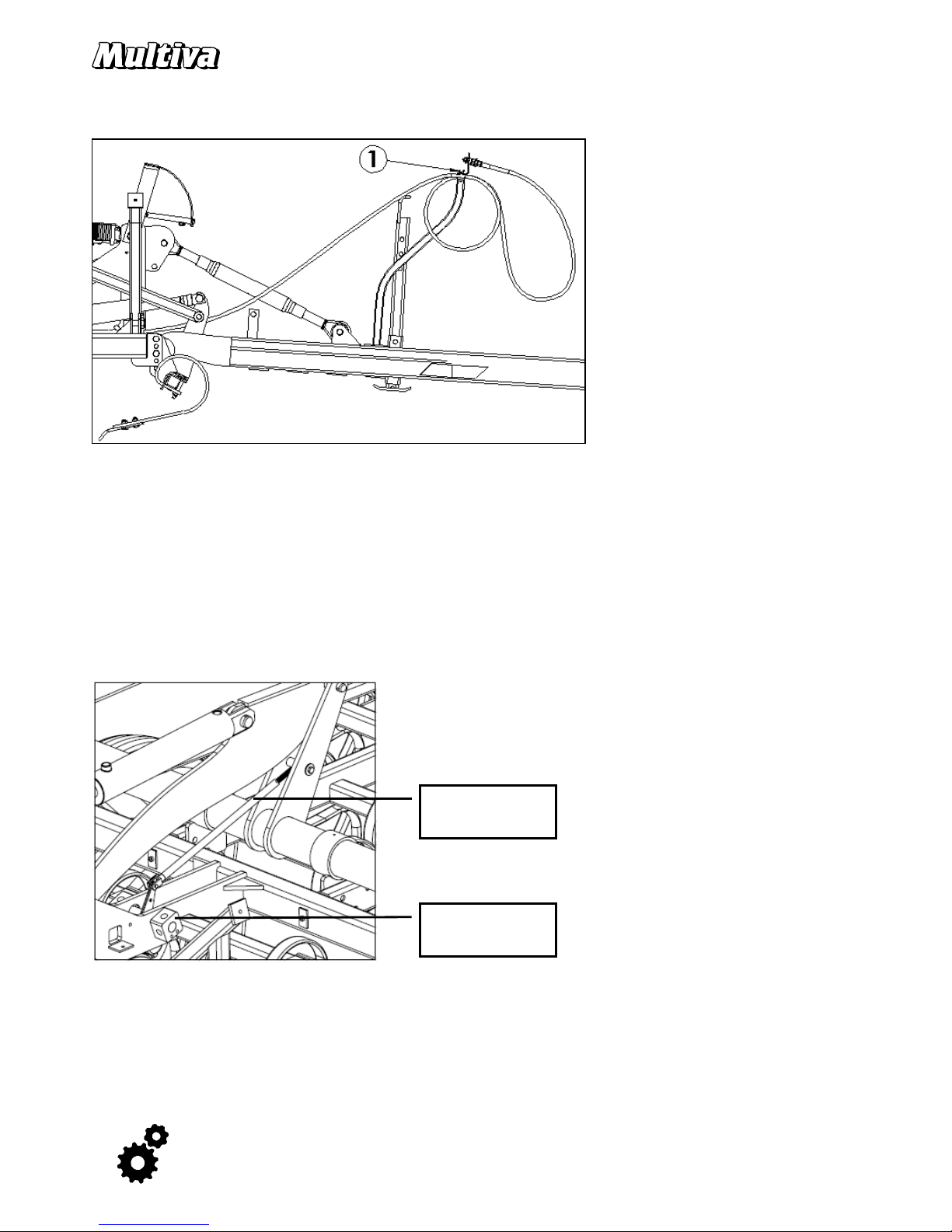

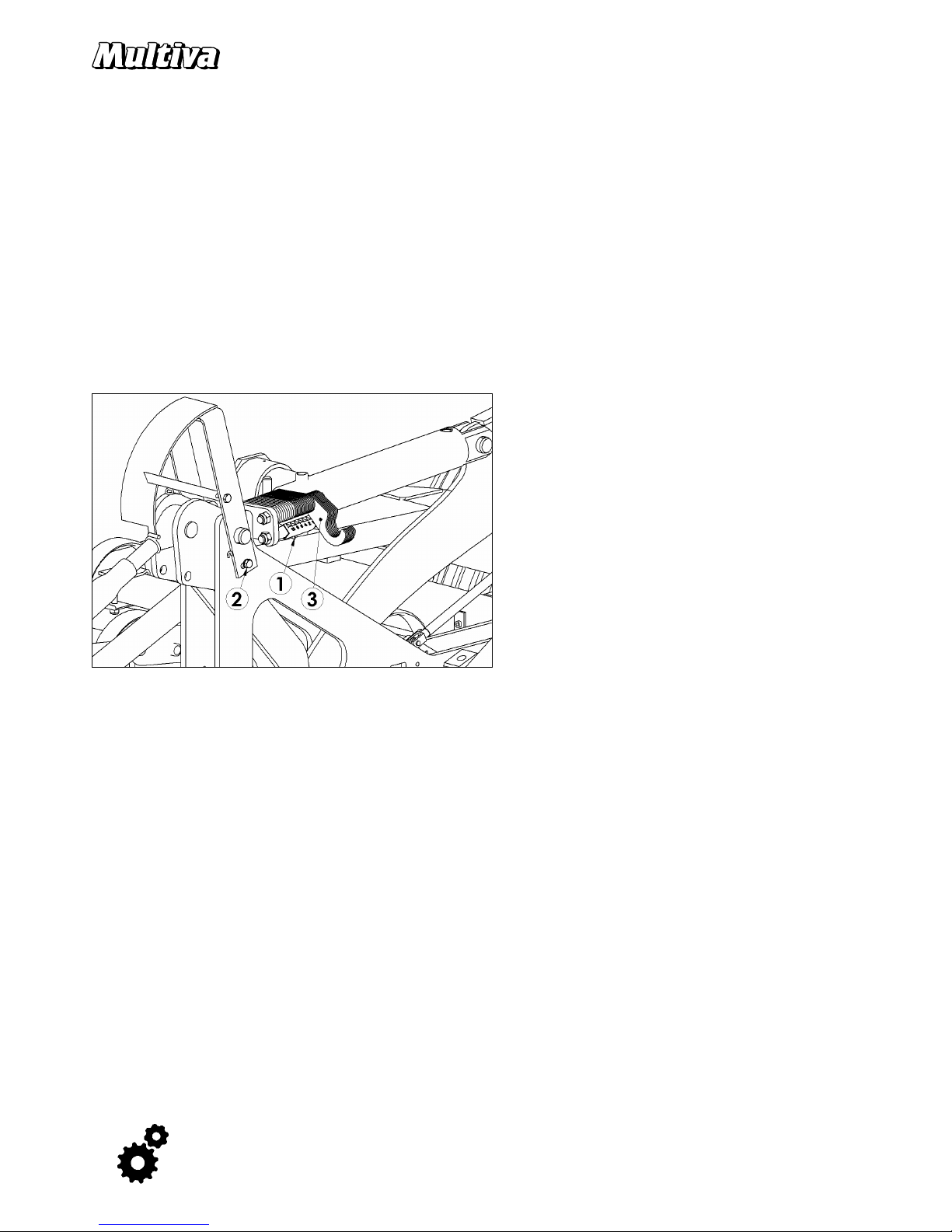

3.3. Adjusting hydraulic hoses

After hitching the harrow to the tractor, adjust the hydraulic hoses between the hose rack and tractor to

a suitable length. The length of the hoses can be adjusted by loosening the hose rack lock (point 1 in

the illustration, x 3). Extra hose is left looped in the rack. Tighten the bolts after making the adjustment.

The length of the hoses is correct when the hoses do not become in contact with the tractor's pulling

arms during turning. The length of the hoses is too short if they tense up and disconnect from the

tractor's hydraulic connector during turning. The smallest allowed diameter for a hose loop is 200 mm.

If the diameter is too small, the loop must be opened and the hoses placed on the rack without looping.

If the loop is too small, there is a danger of breaking the hoses. Turn off the tractor and release the

pressure from the hydraulics before handling the hydraulic hoses

3.4. Side section and front levelling board hydraulics selector valve, Optima T500 - T700

In models Optima T500 - T700, the levelling board hydraulics and the side section hydraulics function

alternately using the same tractor valve, depending on the height adjustment of the machine. When

the harrow is raised up for transport, the selector valve in the frame of the machine directs the hydraulic

pressure to the lifting cylinders of the side sections. When the machine is in work position, the valve

directs the pressure to the levelling board cylinders. The valve operates automatically when the height

of the machine is adjusted between the work and transport positions. The selector valves are located in

front of the axles, in the centre section of the harrow and they are actuated from the axles through the

actuator arm.

Actuator arm of

the selector

Selector valve

9

Troubleshooting in the event that the side sections cannot be raised, Optima T500 - T700 :

Feel whether the pressure reaches the hoses of the side sections' lifting cylinders when the side sections

are raised.

• There is pressure -> Check that the hydraulic return connector is properly attached to the

tractor and that the hoses are not pinched anywhere. Quick connectors are not always

compatible with the tractor's connectors. Also test in another hydraulic return. Change another

quick connector to the hose.

• No pressure -> Lift the harrow up to the transport position. Check whether the selector valve

spindles are moving. The spindles can be moved manually by twisting their actuator bar. Check

whether the actuator bar of the selector valves is properly attached and that it is not kinked. If

the levelling board is working also when the harrow is raised up, the problem is that the

spindles of the selector valves have not moved.

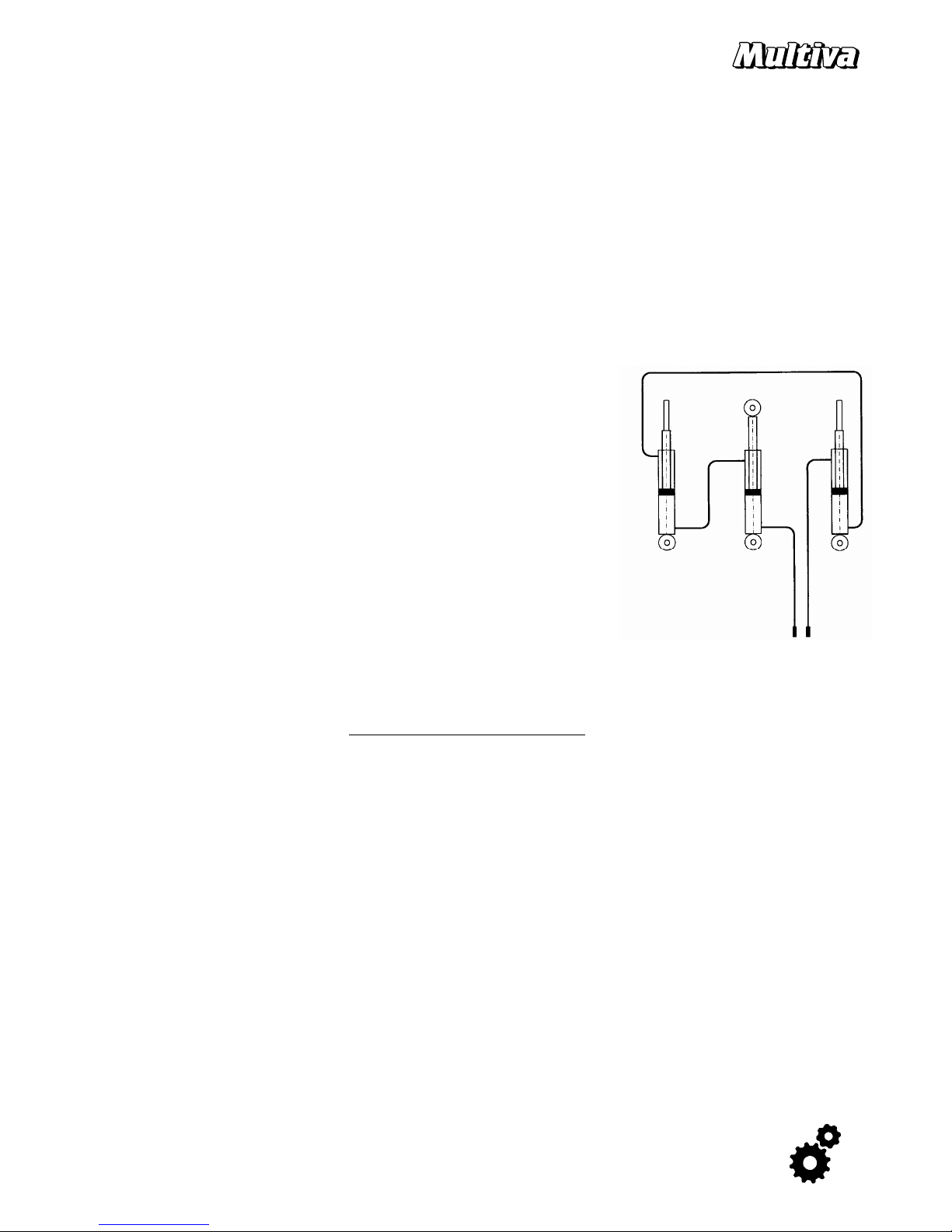

3.5. Operating principle of the front levelling board and depth adjustment hydraulics

The front levelling boards and the depth adjustment in models

equipped with fully hydraulic depth adjustment are operated by

three series-connected cylinders. The series-connection of

cylinders means that the oil flows from the piston side of one

cylinder to the rod side of the other cylinder. The oil only flows

through the tractor's valve to the first and last cylinder. All the

cylinders in the series are of different sizes, so that the oil volume

of the piston side corresponds to the volume of the next

cylinder’s rod side. Both the levelling board and depth

adjustment circuits have a double operated pilot valve that keeps

the working depth set even in the case that the valve of the

tractor leaks.

3.6. Synchronizing the cylinders

Series-connected cylinders must be set to the same level for them to work precisely.

Cylinders are synchronized by fully extending the cylinder rods using tractor hydraulics and maintaining

the pressure for about 30 seconds, and running the motor on low rpm. When the cylinder rod is fully

out, the oil can flow through a small opening past the piston to the next cylinder. Hydraulic oil flows

through all cylinders in the circuit, setting them to the same level and bleeding possible air out from the

system. Moving the cylinders back and forth will not synchronize them.

Synchronizing of depth and levelling board cylinders must always be carried out at the beginning of an

operation period. And always after changing a cylinder or a hydraulic hose to these circuits. Depth

adjustment cylinders must be synchronized at times also during tillage keeping the pressure on for a

few seconds.

10

3.7. Harrow position adjustment

The horizontal position of the frame in relation to the vertical position is adjusted with the top link 1.

The adjustment ensures the even working depth of all tines. The position adjustment is tractor-specific

and depends on the height of the tractor's tow hitch. When the top link is shortened, the front end of

the frame lowers - correspondingly, lengthening the rod raises the front end. The top link must be

locked in place when the right position is found.

The adjustment must be checked during work as the tractor and the harrow may sink differently in the

field.

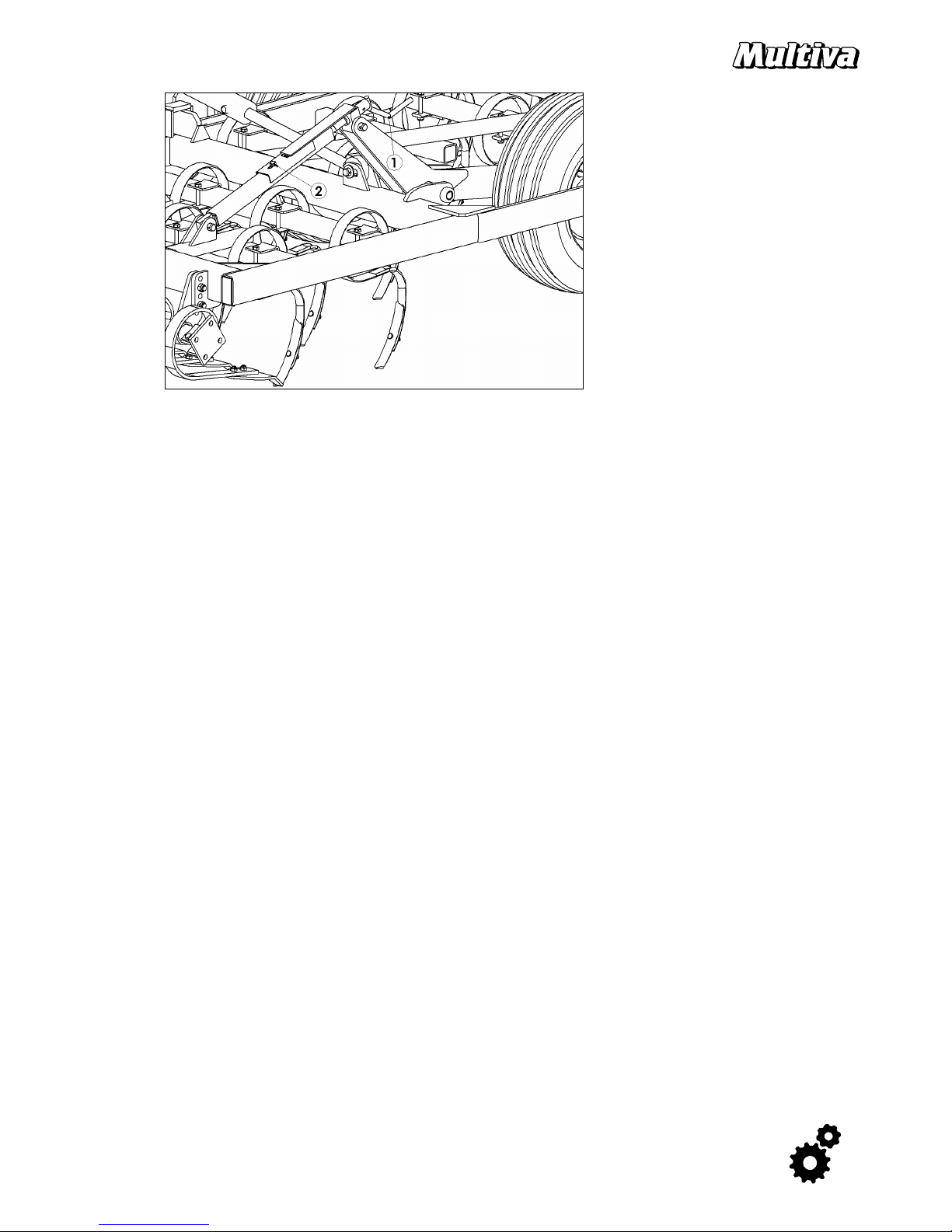

3.8. Basic adjustment of the side sections

The aim of the adjustment is to ensure that both side sections are at the same depth with regard to the

centre block. The factory adjustments must be checked when the machine is commissioned on the field.

NB! Before making adjustments, make sure that the depth cylinders are equalised and that the raising

cylinders of the side sections are not supporting the side sections.

The adjustment is performed by loosening the locking nut at the end of the cylinder (point 1). By

rotating the cylinder rod (point 2), you can adjust the depth of the side sections. By extending the

cylinder rod, the working depth of the side section decreases and by shortening it the working depth

increases. One rotation affects 5 mm to the cultivation depth.

Harrows

500 -

700 800 - 1500

Locking nut

key 36 mm

55 mm

Cyli

nder rod

key 24 mm

36 mm

11

Optima T500 and T550

Standard models with mechanical cranks for depth adjustment:

The centre section limiter pieces adjust the working depth similar to other models.

The working depth of side sections is always separately adjusted from the side section crank (point 1).

When the crank is turned, the working depth grows. One revolution of the side section adjustment

crank corresponds to one limiter piece in the depth adjustment of the centre section. The scale of the

side section depth adjustment can be moved to correspond to the depth scale of the centre section by

loosening the tightening bolt (point 2), 17 mm key.

12

4. USE AND ADJUSTMENT OF THE HARROW

Depending on the model of the harrow, some of the equipment mentioned in this manual are

installed as standard and some are available as options.

4.1. Seedbed preparation

The Multiva Optima T s-tine harrows are designed to perform seedbed preparation of soil, to which

primary tillage has already been carried out, to prepare the soil for seeding. The harrow is used to

loosen and crumble the soil to achieve a sufficiently fine result. The requirements for the even and

optimal growth of the cultivated plant include a seedbed that is as even as possible and the correct

surface crumb structure. An even seedbed is also important for the depth-holding of the seeder's

coulters.

The tillage effect is determined by changing the working depth, number of tillage rounds, number of

tillage times, tillage speed and directions as well as the tillage intensity of the levelling boards and cage

roller.

The correct tillage depth is the depth of sowing for the plant. On clay and silt soils, there must be a

sufficient amount of fine crumbs on top of the soil. This layer of crumbs forms a barrier against

evaporation, preventing the excessive drying of the soil. The surface of the seed layer must have larger

crumbs. They reduce the risk of slaking and maintain the seedbed loose. Particularly on silt soil, the

surface layer should not be tilled excessively fine. The primary objective of seedbed preparation of

easily cultivated sand, mull and peat soil is to level the soil for seeding.

In favourable conditions, the Multiva s-tine harrow may only need one tillage run. However, the number

of tillage passes must always be selected according to conditions. If several tillage passes are carried

out, the run directions should be made perpendicular to each other. This ensures the maximum

evenness of the seedbed.

The suitable tillage speed for the operation of the s-tine and rear harrow is, depending on the

conditions, 8 – 12 km/h. With excessive tillage speed, the tillage characteristics of the s-tine suffer.

NB! Optima T s-tine harrow should not be used for the primary tillage of unprepared soil.

4.2. Tillage technique

Suitable tillage technique is influenced by several factors, e.g. the size and form of the block and

direction of seeding. Correctly selected tillage technique reduces required work and ensures the best

possible result. If several tillage passes are made, the last pass should be performed in the intended

direction of seeding. This reduces unnecessary tilting of the seeder unit. If possible, it is recommended

to drive parallel to the longest side of the block to minimise the time spent on turning.

Turn the wide harrow smoothly or rise it up a bit when turning around at the end of a field strip.

Do not reverse the harrow while the tines are in the soil.

13

4.3. Starting and setting into work position

Raise the harrow to transport height. Ensure that the safety distance of the side sections is clear. Lower

the side sections. The lock pieces on the side sections open automatically. Maintain the hydraulics

actuated until the cylinders are fully extended.

1250 and 1500 models have valves that divide the oil to the outermost side sections. When opening the

wings, inner sections open first and then the outermost wings turn open. Outermost wings turn first

when setting the harrow to the transport position.

Before tillage, it is recommended to each time perform the synchronization of the front levelling boards

and depth adjustment as described in section 3.6. This ensures that the levelling board and working

depth cylinders operate accurately. When the synchronization is performed sufficiently often, the

hydraulics needs to be recirculated only for a few seconds. If you notice that the relative position of the

front levelling boards or the working depth adjustment has changed, the tractor must be stopped and

synchronization should be performed.

NB! Check the tightness of all bolts after 10 hours of tillage. In particular, the attaching bolts of s-tines or

levelling board tines may become loose during the first hectares.

4.4. Transport position

Raise the depth adjustment of the harrow to the

highest position. After this, raise the side sections

using the other valve to transport position. They lock

automatically with the locking piece springs (point

1). However, ensure that the locking piece has locked

the sections to top position before transport (point

2). If the sections are not locked, lower them slightly

and raise them again to top position.

When the sections are raised, the tractor valve must be activated until the lock piece of the side section

has without doubt risen up from the bottom position and locked the side sections up. Only after this

can the valve be left in hold position. Some of the tractor valves might produce such a high reaction

pressure that the force of the lock piece string may not be sufficient to lock the side sections. In this

case, the tractor valve should be set to float position and it should be simultaneously ensured that the

side sections actually lock.

Ensure that the harrow is sufficiently clean when you go to public roads.

14

4.5. Adjusting working depth

Working depth must always be measured from behind the harrow, from tilled soil and the harrow

should be adjusted according to each field block and the sown plant. The adjustment must be carried

out according to the hardest soil of the block. On softer areas, the working depth may be decreased

during tilling by using the depth adjustment hydraulics and the depth indicator.

The lowest working depth of the harrow is adjusted with the limiter pieces of the centre section

cylinder. Limiter pieces can limit the depth in steps of 5 mm. The harrow must be slightly raised up so

that the adjustment can be made. Note a danger of crushing. Turn off the tractor always before making

any adjustments.

NB!

Limiter pieces must be in either of the extreme positions, ie. either turned against the piston rod or

fully to the side.

4.6. Adjusting the depth scale

The scale under the limiter pieces can be adjusted to correspond to the actual working depth by

opening the wing nut located under the scale (point 1). After the adjusting, the scale is locked with the

wing nut.

The working depth indicator (in front of the harrow, in the centre) can be adjusted to show the true

depth in centimetres. After you have adjusted the harrow to desired depth, measure the true working

depth from the tilled soil behind the harrow. The scale is set to indicate the same working depth.

Loosen the locking bolt of the scale (point 2), using a 17 mm key, and turn the scale.

15

4.7. Using the levelling boards

The purpose of the levelling boards is to crush clods and even out the level changes of the surface of

the field. A correctly adjusted levelling board crushes and mills clods but does not gather a large wall of

soil in front. This also creates fuel savings as the excessive use of the levelling board requires a great

deal of power from the tractor.

Basic adjustment:

The rod of the harrow cylinders is threaded so that the sections can be adjusted to the same position.

The adjustment is carried out by loosening the lock nut (36 mm key) and rotating the piston rod (point

2, 24 mm key). Lengthening the rod raises the front levelling board and shortening it lowers the board.

Before making any adjustments, we recommend to tillage for a while and synchronize the levelling

board. This ensures that the misalignment of the levelling boards is not caused by the differences

between the cylinders.

Basic height adjustment:

Changing the height level can be done by opening two bolts from each attachment brackets (point 1

above). With the high position, the front levelling board is more vertical and it breaks, for instance,

slaked surface better. With the low position, the levelling board mills the clods smaller more efficiently.

Factory setting is at the high position. It is recommended for almost all conditions. Lower position can

be considered on very shallow cultivation.

Basic height levels of the front levelling board. Low – high.

16

The relation between the front and rear levelling boards in Optima T harrows can be quickly changed by

using the crank adjustment at the back end of the harrow. The adjustment position can be seen from

the scale.

4.8. Using the rear harrow

The purpose of the rear harrow is to even out the ridges caused by the s-tine harrow and to sort out the

soil material in the tilled layer. The rear harrow sorts out the small crumbs to the bottom of the tilled

layer and moves the large ones to the surface. As a result, the tilled layer does not evaporate the

moisture and endures the effects of rain without slaking.

Angle adjustment:

The angle of the rear harrow is adjusted from the harrow fixing piece using the adjusting pin (point 1).

The rear harrow has three different positions. When the tines of the rear harrow are at their most vertical

position in relation to the ground, the harrow sorts out the fine material most efficiently to seeding

depth and produces the most even result. By making the angle of the rear harrow less steep, the

passing of plant residue is improved. If necessary, the rear harrow can be locked up by turning the tines

backward to the front and locking them to this position with an adjustment pin or by setting the lower

limiter sufficiently high.

Height adjustment:

The height is adjusted so that the tines of the harrow even out the ridges left by the s-tines, but do not

leave any grooves. The lowest position can be limited with position of the pins 2. Both ends of the

harrow section must be set to the same level.

The tilling power of the harrow can be increased by limiting the upwards movement by setting another

pin above the bar. This should be used carefully and only on even fields. NB. Harrow must be able to

rise up so that it will never have to bear the weight of the harrow. It is recommended to place the upper

pins to the highest position holes and leave the harrow to work on its own weight.

17

4.9. Using the cage roller

The cage roller is intended to crumble clods and even out the ridges left by the s-tines of the harrow.

The weighing of the cage roller is adjusted with a crank. Turning the crank clockwise increases the

weighing of the roller and turning the crank counter-clockwise decreases it ( point 1). Normally there

should be at least 50 mm of visible thread of the adjustment crank below the nut. Weighing can be

increased on hard soils to achieve more effective tillage and leveling.

4.10. Front support wheel ( T1000 – T1500 only)

Support wheel stabilize the movements of the side wings. The weighing is adjusted so that the wheel

rests lightly on the ground when tillage is performed to working depth. The requirement is that the

wheel can be turned manually.

Excessive weighing raises the front end of the harrow and stresses the support wheel. If the weighing is

not strong enough, the wheel does not touch the ground and thus it does not support the moving of

the harrow.

18

5. MAINTENANCE

In spare part and equipment issues, we recommend contacting the supplier or, if necessary, the

manufacturer of the machine.

5.1. Wear parts

Mounting of a new s-tine: Set the tine clamp first on to the frame bar. Turn the s-tine through the clamp

and place the bolt to the hole. Use a new nyloc nut if the nut has been opened already before. Make

sure that the clamp is straight aligned with the frame bar both diagonally and horizontally. Tighten the

bolt again after one day of harrowing.

S-tine points can be reversed by using the old bolt and nut, but they must be changed when replacing

the points.

NB. Never keep the oval headed bolt with hands when turning it.

5.2. Changing a wheel

Removing a wheel from the middle section requires some space under the harrow:

Raise the harrow up by using the depth hydraulics. Lower down the hitch of the tractor to raise the rear

part of the harrow. Place a pair of axle stands under the frame to the rear part of the harrow. Raise the

tractor’s hitch up so that the whole harrow rises higher. Make sure that the harrow is firmly supported

before any service work.

Side wing wheels can be removed by lowering the wing down on the axle stands.

When changing 250 or 300 wheel, you must first rotate off the grease nipple of the hub. Otherwise it

will cling to the rim.

19

6. MAINTENANCE PROGRAMME, INSPECTIONS

The following pages contain detailed instructions.

The table can be applied in practice depending on the size of the harrow and amount of field to be

cultivated. Service work should be carried out when either the hectares or working days are reached.

Table columns:

1 ) After the first 20 ha or after one work day

2 ) After the first 200 ha or after 5 work days

3 ) Every 500 ha or once in an operating period

1 )

<20 ha

2 )

<200 ha

3 )

500 ha

Bolt tightening torques

X X

Tyre pressures

X X

Wheel hub bearing clearance

X X

Bogie bearing clearance

X X

Hydraulics

X

Side section locking

X

Selector valve operation

,

Optima

500 – 700 X

Front support wheel bearing clearance

, Optima 1000

– 1500 X

6.1. Bolt tightening torques

The fixing bolts of tines and blades can become loose during the first tilled hectares.

6.2. Tyre pressure

250/65

-

14.5"

3.0 bar

300/65

-

12" 3.6 bar

340/55

-

16" 4 bar

Bolt size, hardness

Key mm

Torque Nm

Tine blades

M10-45,

8.8 15

/ 17 50

S-t

ine

clamps

M12-100

, 8.8 19 90

11x45 levelling board t

ines M12-90,

8.8 19 90

10x80 front levelling board tines

M12-100,

10.9

19

120

Levelling board blades

M12-35,

8.8 19 90

Wheel bolts

M16

27

250

Towing eye, bolted

M20-180,

10.9

30

400

Towing eye, plate

M16-60, 8.8

M20-50, 8.8

24

30

210

400

20

6.3. Wheel hub bearing clearance

The bearing clearance of the wheel hubs must be inspected regularly to avoid the bearings to get

damaged. It is very important to tighten them especially during the first operating period, after

50 – 200 ha, when the taper roller bearings have settled in. After that it is enough to check them

every 500 ha or once in an operating period.

Checking and adjusting the bearing play:

Checking is made before greasing the hubs. You would not be able to feel the play if the bearings are

just greased.

The harrow is lowered on the tines so that the wheels are lifted off the ground. Take a firm grip on the

wheel and twist it to feel the bearing play. The wheel must rotate without resistance, but there should

not be any appreciable slack in the hub. You can check the tightness of the wheel bolts at the same

time.

When you tighten the bearing, remove the hub bearing cup. Remove the locking pin of the castle nut of

the axis and tighten the nut while simultaneously rotating the wheel until you feel slight resistance in

the bearing. After this, loosen the nut until the locking pin fits the hole of the next nut, where the

bearing is rotating. If the nut is already in line with the hole, loosen the nut until the next hole becomes

visible (a maximum of 30 degrees). Tighten the hub cap. Press grease to the nipple until it comes out

through the sealing.

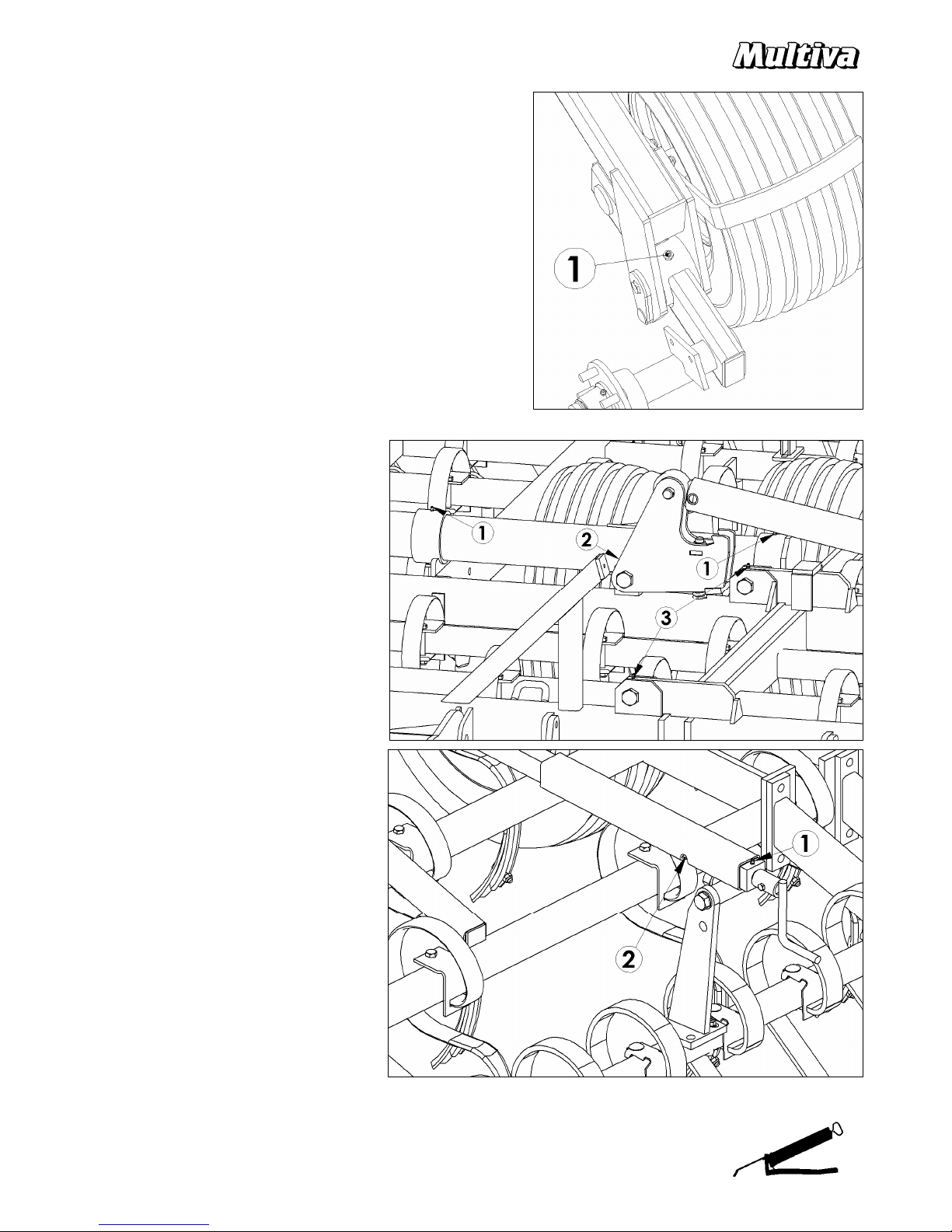

6.4. Bogie bearing clearance

The bogie axles have tapered roller bearings. Checking is made before greasing the bogies. The bearing

clearance is checked by lowering the harrow so that it is supported by the tines and the wheels are off

the ground so that the bogie can move without obstructions. The bogie must move smoothly and there

should not be any play when the bogie is twisted.

The bogie axle clearance is adjusted with the bolt 1 in the bogie plug. The fixing bolt of the locking

plate of the bolt 3 is loosened and the locking plate 2 is removed. After this, the adjustment bolt is

tightened until there is no play. The lock plate is re-installed and if necessary, the adjustment bolt

loosened so that the lock plate can be fitted. The fixing bolt of the lock plate 3 is re-placed and

tightened.

6.5. Hydraulics

Check the tightness of the hydraulic systems and tighten the couplings if necessary.

21

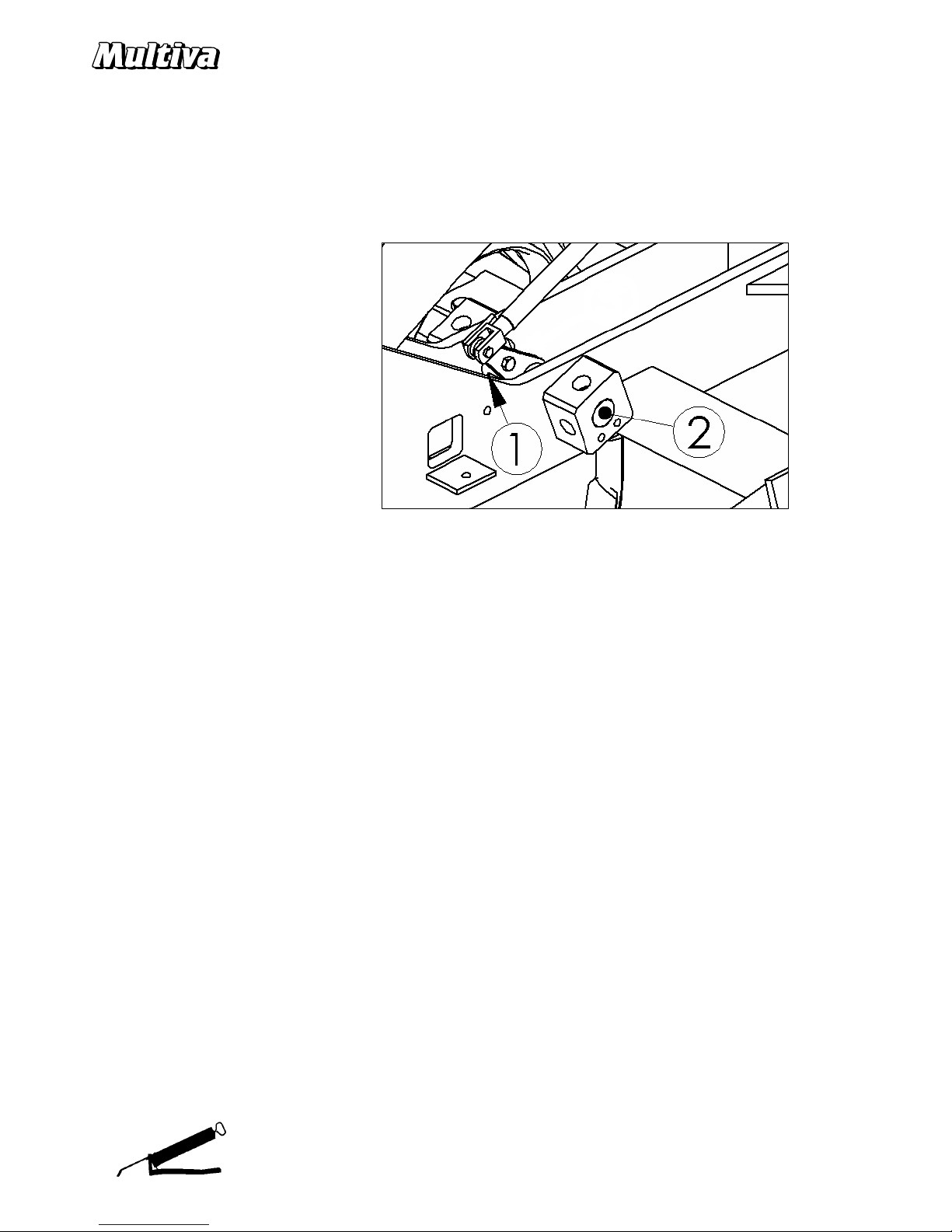

6.6. Side section locking

The operation of the side section locking must be

checked once every operating period before

commissioning the machine.

There is a spring between the plates of the lock

piece that presses the cams behind the plate in the

side section (point 1).

Lock plates should press against the side section

plates so that the cams remain behind the plate

(point 2).

Optima 500-700 :

Side section cylinder opens the locking piece automatically

before the sections start to open. The movement of the lock

piece can be adjusted with screw 3.

Optima 800-1500 :

Small cylinders open the locking pieces first and the the

oil pressure is directed to the side section cylinders.

The movement of the lock piece can be adjusted on the

length of the piston rod 3.

6.7. Front support wheel bearing clearance

Vertical axle of the support wheel has taper roller bearings. Bearing play can be adjusted by opening the

cap and tightening the crown nut. There is a same principle that with the wheel hubs. There should not

be any appreciable slack in the axle.

22

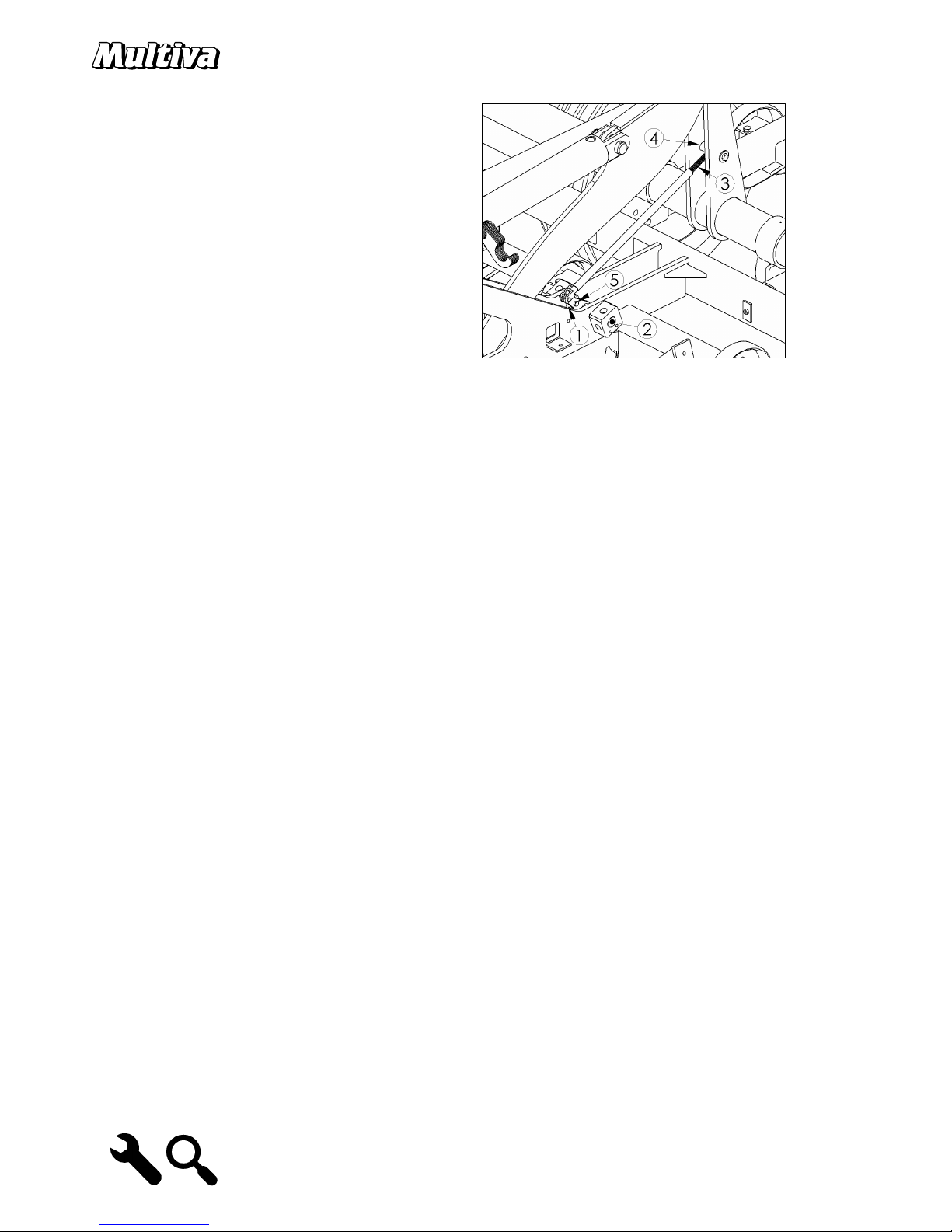

6.8. Selector valve operation

Optima 500 – 700. When the machine is commissioned,

ensure that the selector valve lever is moving without

obstructions.

The movement is checked by lowering the harrow

approximately 50 mm down from the transport position

and moving the actuator arm back and forth.

The locknut at the end of the thread of the actuator arm

must be adjusted so that there is a clearance of a few

millimetres in the actuator arm when the harrow is at

the top transport position.

The spring in the actuator arm of the selector (point 3)

can compress. The valve has a limiter against which the

valve spindle stops in the harrow working position.

The bolt 5 must not be tightened too much. You should be able to rotate the bolt by hand.

23

7. MAINTENANCE PROGRAMME, LUBRICATION

All lubrication points must be re-lubricated after the machine has been washed. DO NOT use a jet

cleaner to directly spray the labels or parts with bearings. Maintain a minimum distance of 30 cm

between the nozzle of the cleaner and the sprayed target.

Clean the lubrication nipples before lubrication. Wipe off excess lubricant. In all points, the lubricant

grease must be applied in the nipple until excess clean grease can be seen coming out of the target.

Some lubrication points only require a few drops -these are specified later on. The lubricant should be

general purpose grease that contains lithium soap and EP additives.

So called pin greases should never be used to lubricate the harrow. Using this type of grease may break

the bearings.

Table columns:

1 ) Daily

2 ) Every 500 ha or once in an operating period

1 )

2 )

500 ha

Cage roller bearings

X

Cage

roller weighing adjustment threads

X

Side section

hinges

X

Wheel hubs

X

Mechanical depth adjustment threads, Optima T500

- T550

X

Towing eye

X

Bogie bearings

X

Middle axle

X

Side section locking

X

Side section

hinges

X

Levelling board adj

ustment threads

X

Hydraulic cylinder

s

pherical bearing

s X

Drawbar piston rod

X

Selector valve spindles, Optima T500

- T700

X

Front support wheel adjustment threads

,

Optima 1000

- 1500

X

24

Cage roller bearings

2 pcs / roller. Point 2.

Cage roller weighing adjustment thread

1 pc / roller. Point 1.

A few drops of grease is applied to the threads

Side section hinges

Point 2.

Wheel hubs

Point 3.

Mechanical depth adjustment threads, Optima

T500

Point 1.

A few drops of lubrication grease is applied to the threads

Towing eye

The towing eye is lubricated by applying lubrication grease to the front and bottom edges.

Rotating towing eye has a grease nipple.

25

Bogie bearings

Point 1. Ensure that the grease actually goes to the

bearings. Lift the bogies slightly off the ground using

the depth adjustment. Swing the bogie and press

the grease until it comes out through the sealing.

Middle axle bearings

Collars at the centre and the

ends. Point 1.

Side section locking

Point 2.

Side section hinges

Point 3.

Levelling board adjustment

Points 1 and 2.

A few drops of grease is

applied to the lubrication

nipples.

26

Hydraulic cylinder spherical bearings

A few presses of lubrication grease is applied to all lubrication nipples.

Drawbar top link

A few drops of lubrication grease is applied to the lubrication nipples.

Selector valve spindles

2 pcs. Point 2. Spray liquid lubricant on

the axle of the spindle from between the

frame plates (point 1) and from outside

the valve (point 2).

In addition to the most important grease nipples mentioned above, the harrow also has other grease

nipples that are not specified here. They should be lubricated once in an operating period.

27

8. STORAGE

The drawbar of the harrow can be raised up, whereupon the machine uses less storage space.

Raising the drawbar:

1. Lower down the harrow.

2. Disconnect the harrow from the tractor and move the tractor away.

3. Use a proper lifting band and a machine like a front loader to support the drawbar.

4. Remove the upper pin of the top link and remove also the hose bracket from the drawbar.

5. Raise the drawbar up so that you can place a bolt to the hole. Use at least M16 bolt.

The machine must be cleaned and lubricated carefully for long term storage. The hydraulic cylinders

should be set to reveal a minimum amount of the chromed piston rod during storage. The uncovered

piston rod sections must be protected with petrolatum or thick oil.

The tines suffer from supporting the entire weight of the machine for a longer period of storage

(winter). The best way to store the harrow is to elevate it using the centre section corners as support,

whereupon no weight is placed on the tines or tires. The harrow can also be stored by setting all

adjustment pieces in place to the depth adjustment and lowering the harrow on the limiter pieces

during storage.

The tires, bearings and hydraulic hoses can be damaged as a result of long-term outdoor storage.

28

9. WARRANTY

Multiva agricultural machines come with a one-year warranty.

Warranty policy:

1. The manufacturer shall replace, free-of-charge, any parts that become unusable due to defective

workmanship or defective raw materials within the warranty period. However, any parts subject to

wear are not covered by the warranty.

2. Damage caused by misuse, inadequate service, changes unauthorised by the manufacturer, traffic

accidents and other reasons beyond feasible inspection are excluded from the coverage under this

warranty.

3. Damage caused by powering the machine with a clearly over-sized tractor is also excluded.

4. If a failure is repaired by a third party, the manufacturer will only compensate the costs for the

repairs if this procedure has been agreed upon in advance with a representative of the

manufacturer.

5. The manufacturer is not liable for loss of income due to downtime caused by damage or for any

other indirect losses caused by damaged machinery.

29

Appendix 1. EC DECLARATION OF CONFORMITY

DOMETAL OY

Kotimäentie 1

FI-32210 Loimaa

Finland

hereby states that the machine in question

Multiva Optima T500, T600, T700, T800, T900, T1000, T1250, T1500 S-tine harrows

meet the requirements of Machinery Directive 2006/42/EC.

The following standards were applied in the design of the machine:

ISO 4254-1:2013

Loimaa 12.1.2016

Vesa Mäkelä

Kotimäentie 1

FI-32210 Loimaa

Finland

The undersigned is also authorised to compile technical documentation for the above machines.

Translation

30

Appendix 2. Hydraulic schematic Optima T500

Side wings and leveling board Depth control

31

Appendix 3. Hydraulic schematic Optima T600-700

Side wings and leveling board Depth control

32

Appendix 4. Hydraulic schematic Optima T800-900

Depth control Leveling board

Side wings

33

Appendix 5. Hydraulic schematic Optima T1000

Depth control Leveling board

Side wings

34

Appendix 6. Hydraulic schematic Optima T1250

Depth control Leveling board

Side wings

35

Appendix 7. Hydraulic schematic Optima T1500

Leveling board

Depth control

Side wings

36

37

Appendix 8. Connection socket according to SFS 2473

1/L Left turn si

gnal

yellow

2/54G

Free

-

3/31

Ground

white

4/R Right turn signal

green

5/58R

Right rear light

+

reg. plate light

brown

6/54

Brake light

red

7/58L

Left rear light

black

1/L

6/54

2/54G

7/58L

3/31

4/R

5/58R

Loading...

Loading...