Multiva DM300, DM400, DM350 Maintance Manual

DM300

DM350

DM400

Starting from serial nr. 02265510

Original manual 01 / 2012

O

O

O

P

P

P

E

E

E

R

R

R

A

A

A

T

T

T

I

I

I

O

O

O

N

N

N

A

A

A

N

N

N

D

D

D

M

M

M

A

A

A

I

I

I

N

N

N

T

T

T

E

E

E

N

N

N

A

A

A

N

N

N

C

C

C

E

E

E

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

DISC CULTIVATOR

Contents

1. FOREWORD............................................................................................................................................................................1

1.1. Purpose of use ..................................................................................................................................................................1

1.2. Type plate...........................................................................................................................................................................2

2. SAFETY INSTRUCTIONS......................................................................................................................................................3

2.1. Warning labels..................................................................................................................................................................3

2.2. Connecting and disconnecting the cultivator......................................................................................................4

2.3. Transport on public roads ............................................................................................................................................4

2.4. Using the disc cultivator................................................................................................................................................4

2.5. Maintenance......................................................................................................................................................................4

3. MEASURES BEFORE USING THE MACHINE..................................................................................................................5

3.1. Connecting the cultivator to a tractor......................................................................................................................5

3.2. Towing equipment..........................................................................................................................................................5

4. ADJUSTING THE MACHINE...............................................................................................................................................6

4.1. Adjusting the position of the machine....................................................................................................................6

4.2. Adjusting cultivation depth.........................................................................................................................................6

4.3. Adjusting the levelling disc..........................................................................................................................................7

4.4. Lateral adjustment of the disc shaft..........................................................................................................................8

4.5. Roller scraper.....................................................................................................................................................................9

5. STUBBLE CULTIVATION................................................................................................................................................... 10

5.1. Cultivation pattern.......................................................................................................................................................10

6. MAINTENANCE, INSPECTION........................................................................................................................................ 12

6.1. Inspections after 10 hours of use or daily............................................................................................................12

6.2. Inspections every 200 hours or yearly...................................................................................................................12

7. MAINTENANCE, LUBRICATION.....................................................................................................................................13

7.1. Lubrication every ten hours or daily...................................................................................................................... 13

7.2. Lubrication every 50 hours........................................................................................................................................ 13

7.3. Lubrication every 200 hours or once per season..............................................................................................13

7.4. Lubrication every 1000 hours (towed)................................................................................................................. 13

8. STORAGE..............................................................................................................................................................................14

9. WEAR PARTS....................................................................................................................................................................... 14

9.1. Washing and cleaning.................................................................................................................................................14

10. WARRANTY .........................................................................................................................................................................15

11. EC DECLARATION OF CONFORMITY..........................................................................................................................16

Connection socket according to SFS 2473....................................................................................................................... 17

1

1. FOREWORD

Multiva farming machinery is manufactured in Finland. The modern production technology, excellent

raw materials, careful production and excellent finishing guarantee a high-class product.

Thank you for selecting a high-quality Multiva disc cultivator. We hope that the product you selected

will meet your requirements and serve you for a long time. Please read this manual carefully before

operating the machine. The inspection and maintenance measures listed in this manual are crucially

important for flawless machine operation and the validity of the warranty.

All instructions, warnings and prohibitions regarding the use of the machine must always be observed.

They have been issued to ensure the safety of the user and durability of the machine.

This operation and maintenance manual covers the following disc cultivator models:

DiscMaster 300, 350 and 400 starting from serial number 02265510

1.1. Purpose of use

The Multiva disc cultivator is intended for shallow primary tillage (stubble cultivation) in the autumn or

spring, the main purpose of which is to loosen and aerate the soil, bury plant residue and prepare the

soil for cultivation. The disc cultivator can also be used for seedbed preparation. Use of the disc

cultivator for any other purpose is prohibited! Stubble cultivation performed with the disc cultivator

buries plant residue under the surface layer of the soil and compresses the surface of the field. The

machine is particularly well-suited to stubble cultivation, thanks to its excellent efficiency in burying

plant residue and its adjustable working depth.

The Multiva cultivators are equipped with thick 5 mm conical discs that can penetrate hard soil

extremely well. To prevent breakage due to rocks and other obstacles, the discs have been fitted with

rubber suspension mechanisms. The weight of the cultivator (adjustable with additional weight), its

open frame structure and the dense row of roller plates are also essential in achieving an even result.

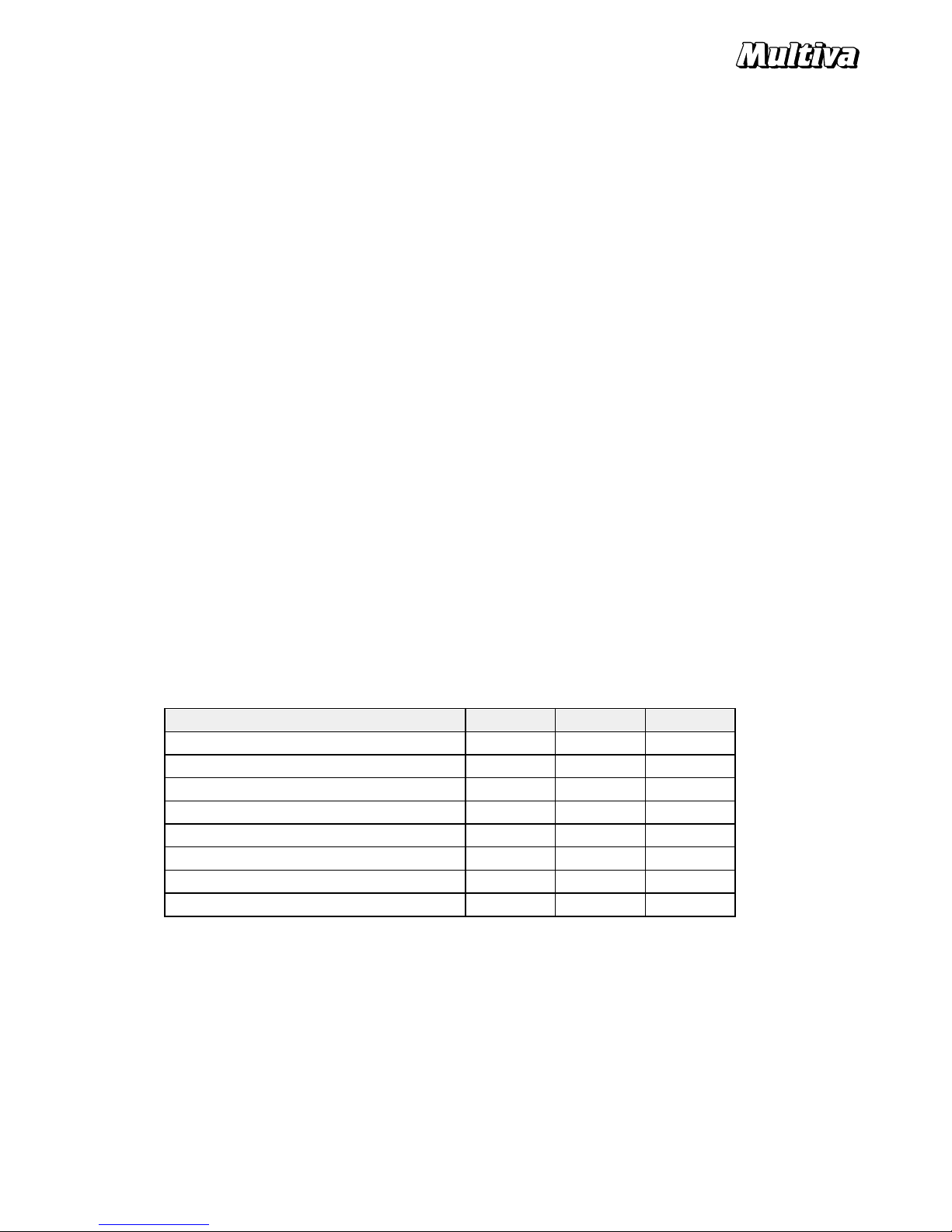

Technical specifications

With standard equipment

DiscMaster 300 350 400

Working width cm

300 350 400

Discs, pcs

23 27 31

Disc diameter, mm

510 510 510

Section count

1 1 1

Power requirement, bhp (spring/autumn)

100/120 115/140 130/160

Transport width, m

3,35 3,6* 4*

Weight with standard equipment, kg

1930 2110 2340

Towing equipment, kg

765 765 765

* levelling disc in the transport mount

Due to ongoing product development, products and specifications discussed herein are subject

to change.

2

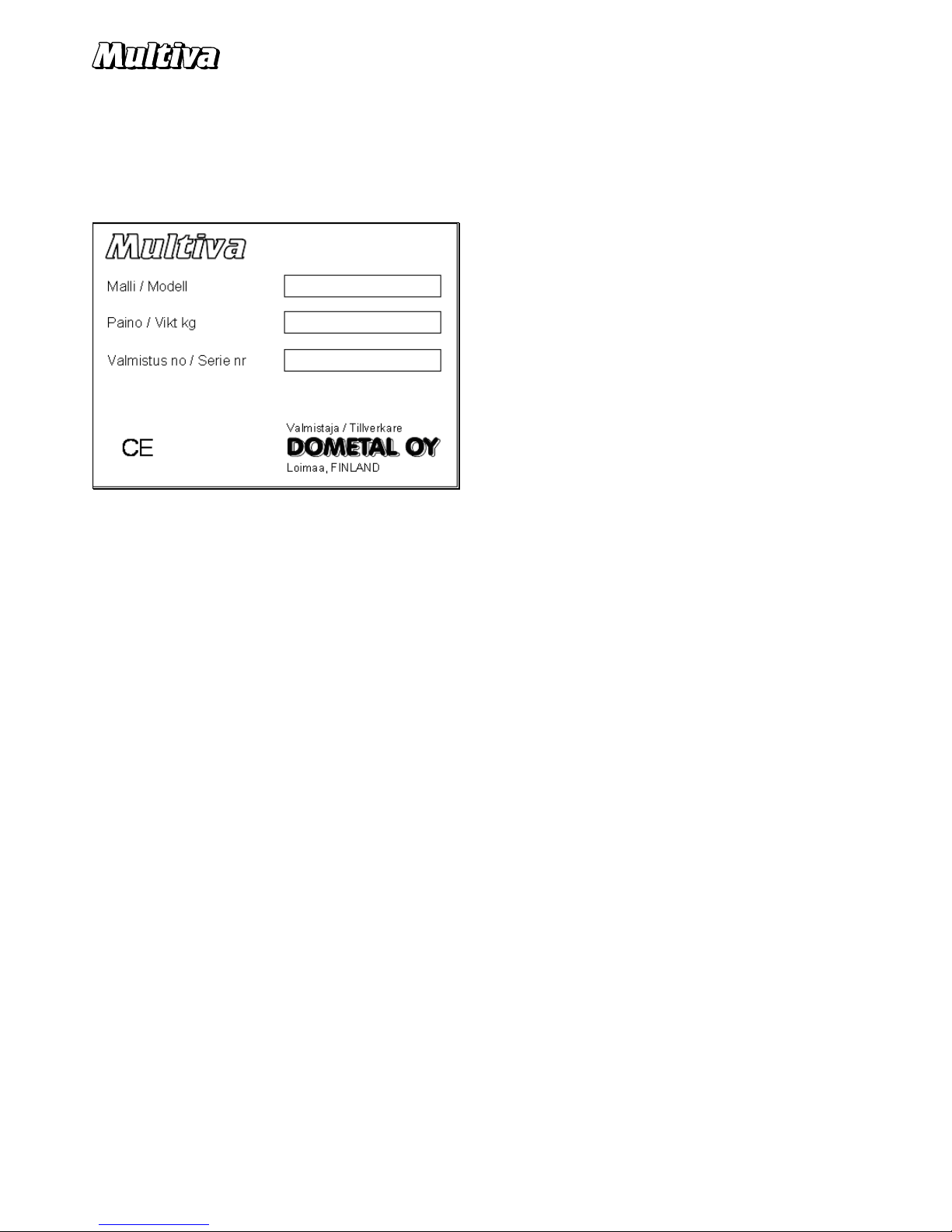

1.2. Type plate

The disc cultivator carries a type plate containing the information listed here. Write down the type plate

information in the fields provided below. When discussing with a seller or factory representative, please

state the model and serial number of the machine. This will help to prevent unnecessary delays and

misunderstandings.

3

2. SAFETY INSTRUCTIONS

These safety instructions and safety distances must without exception be followed when using the

machine. The machine must be configured according to this manual and this manual must be utilised in

the operation and maintenance of the machine.

Never allow any person to ride the machine during work or transport!

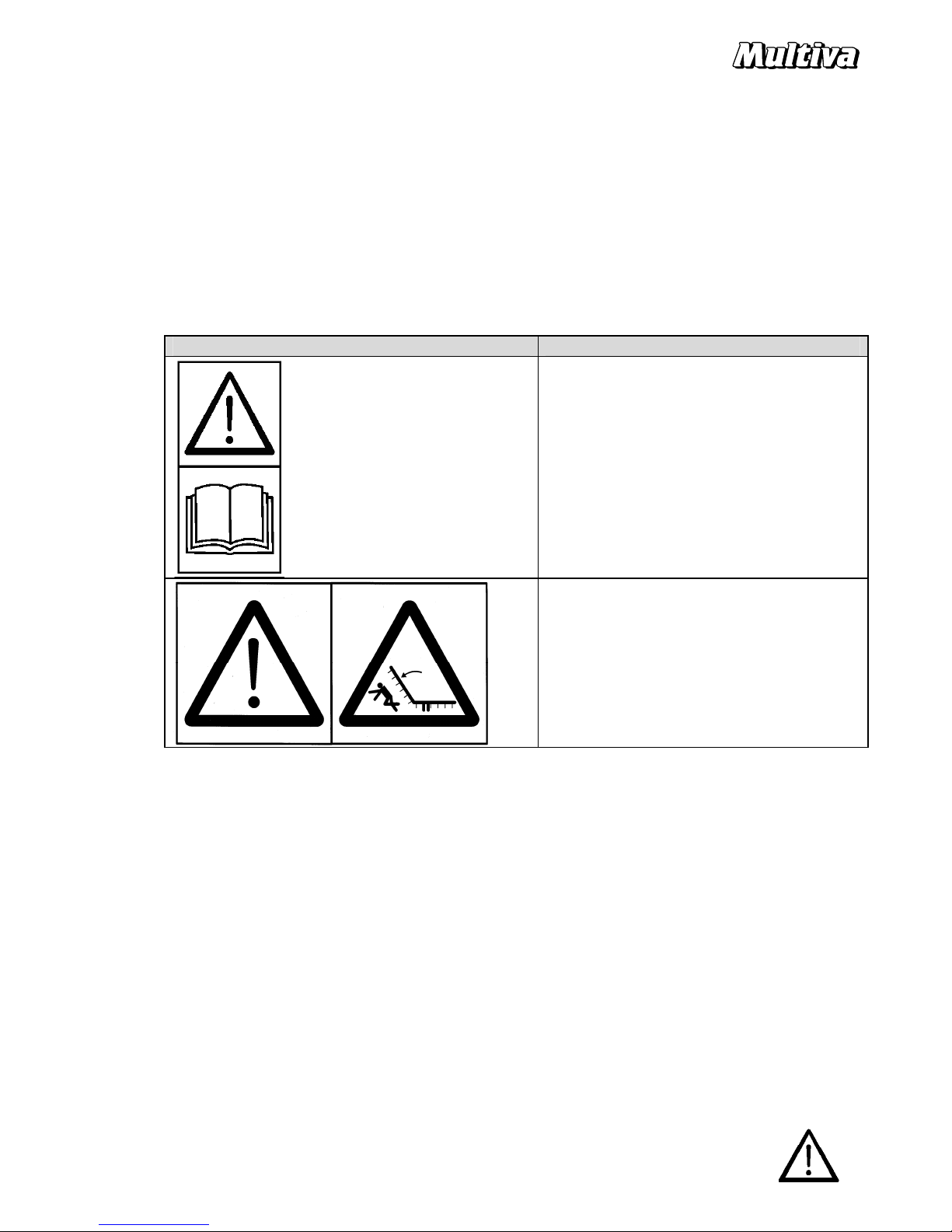

2.1. Warning labels

The machine contains the warning labels listed below. Always observe the safety instructions of these

labels. Do not remove the machine’s warning labels.

Warning label Explanation

CAREFULLY READ THE OPERATION MANUAL

AND THE SAFETY INSTRUCTIONS – ESPECIALLY

BEFORE CONNECTING THE MACHINE TO A

TRACTOR!

CRUSHING HAZARD!

WHEN THE MACHINE IS IN OPERATION,

MAINTAIN A 5-METRE SAFETY DISTANCE FROM

THE MACHINE.

Loading...

Loading...