MultiSmart

Pump Station Manager & RTU

MultiSmart Installation & Operation Manual

Page 2 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

NOTICE

This Manual is the support documentation for the

installation, commissioning and opera tio n of the

MultiTrode MultiSmart Pump Station Manager/RTU

and Reservoir Monitor.

Revision 20

15 May 2013

This manual is used for v3.1.0 of the MultiSmart Pump Station Manager

This document is proprietary to MultiTrode Pty Ltd (the company) and for sole use within the

company notwithstanding that this doc ument may from time to tim e be made available to the

company’s subcontractors, suppliers, customers and others for purposes associated with

manufacturing and other processes as aut horised on an individual basis by Multi Trode Pty Ltd

or their representative. In such cases where the document has been issued to external

parties, its contents shall not be transcri bed, copied, relayed, or divulged to any other party

whatsoever and after satisfying the requirements f or which the document was originally iss ued

to any external party shall be either returned to the company, or destroyed as required by the

company’s document control procedure and as attested to by the recipient at the time of taking

possession of the document. MultiTrode Pty Ltd shall not be held l i able in any way whats oever

for any act or omission, either direct or consequential, arising from the use of t he information

contained herein.

MULTITRODE is a registered trade mark of MultiTrode Pty Ltd in Australia and many countries worldwide. PUMPVIEW and MULTISMART

are trademarks of MultiTrode Pty Ltd and pending A ustralian trade mark registration. Australian Design Registration is pending for the

MultiSmart Pump Station Manager and RTU Remote and Base Modules. Patent Pending in Australia. © 2012 MultiTrode Pty Ltd. This

publication is protected by copyright. No part of this publication may be reproduced by any process, electronic or otherwise, without the

express written permission of MultiTrode Pty Limited.

MultiSmart_IO_Manual_R20 Page 3 of 260

MultiSmart Installation & Operation Manual

1

Warnings & Cautions ...................................................................................................................... 9

1.1 Information to User ................................................................................................................ 9

1.2 Documentation Standards ...................................................................................................... 9

1.3 Installation Notes ................................................................................................................... 9

2 Glossary & Symbols ..................................................................................................................... 10

3 Major New Features & Enhancements in Recent Firmware Releases ...................................... 11

3.1 Version 3.1.0 ........................................................................................................................ 11

Part 1 – Operations ................................................................................................................................... 12

4 Introduction ................................................................................................................................... 12

4.1 Range of Options ................................................................................................................. 12

4.2 Intuitive Operator Interface ................................................................................................... 13

4.3 Intuitive Engineering Interface .............................................................................................. 13

4.4 "Out of the Box" Control of a Pump Station .......................................................................... 14

5 Operator Interface ......................................................................................................................... 15

5.1 LCD Panel ............................................................................................................................ 15

5.2 LED Indicators ..................................................................................................................... 16

5.3 Buttons ................................................................................................................................. 16

5.4 Using the Interface ............................................................................................................... 16

Part 2 – Installation & Commissioning ................................................................................................... 33

6 Mounting Instructions ................................................................................................................... 33

6.1 Mounting the Operator Interface Display .............................................................................. 33

6.2 Mounting the Pump Station Manager ................................................................................... 35

6.3 Connecting the Operator Interface to the Pump Station Manager ....................................... 35

7 MultiSmart Boards ........................................................................................................................ 36

7.1 Power Supply ....................................................................................................................... 38

7.2 Default Wiring Setup for Pump Control Board ...................................................................... 39

7.3 Pump Control Board ............................................................................................................ 44

7.4 CPU Board ........................................................................................................................... 48

7.5 DSP Board ........................................................................................................................... 49

7.6 Energy Monitoring & Motor Protection Board ....................................................................... 56

8 PumpView Hardware Setup .......................................................................................................... 58

8.1 Fault Finding ........................................................................................................................ 58

8.2 Configuring PumpView for a Serial Cellular Modem ............................................................ 59

8.3 Configuring PumpView for an Ethernet Cellular Router ....................................................... 60

9 Quick Commissioning Guide ....................................................................................................... 63

9.1 Setup Wizard Flow Diagrams ............................................................................................... 64

9.2 Setup Wizard Notes ............................................................................................................. 68

9.3 Unassign Any Faults Not Used ............................................................................................ 70

9.4 Level Simulation Mode ......................................................................................................... 72

9.5 Maintenance Mode .............................................................................................................. 72

Part 3 – Advanced Settings ..................................................................................................................... 74

10 High Level Overview ..................................................................................................................... 74

10.1 MultiSmart Pump Station Manager Overview ...................................................................... 74

10.2 Pump Station Manager ........................................................................................................ 75

10.3 Reservoir Monitor ................................................................................................................. 76

10.4 Pump Control Module .......................................................................................................... 77

10.5 Energy Monitoring and Motor Protection .............................................................................. 78

10.6 Supply Protection ................................................................................................................. 79

10.7 Data Logger ......................................................................................................................... 79

10.8 Flow ..................................................................................................................................... 79

10.9 Fault Module ........................................................................................................................ 79

10.10 Security ................................................................................................................................ 79

10.11 PLC Extension (IEC 61131-3) .............................................................................................. 79

Page 4 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

10.12 Logic Engine ........................................................................................................................ 79

10.13 RTU...................................................................................................................................... 80

11 Security .......................................................................................................................................... 82

11.1 Selecting any Digital Input Tag ............................................................................................ 85

11.2 Security Key Setup .............................................................................................................. 86

11.3 Accessing MultiSmart Without a Security Key ..................................................................... 87

12 Fill / Empty & Pump Setpoints, Alarm Setpoints, Delays .......................................................... 88

12.1 Fill / Empty (Charge / Discharge) ......................................................................................... 88

12.2 Default Pump and Alarm Setpoints ...................................................................................... 88

12.3 Changing Pump and Alarm Levels Setpoints ....................................................................... 89

12.4 Setting Pump & Alarm Delays .............................................................................................. 91

13 Pumps and Groups ....................................................................................................................... 93

13.1 Change Alternation & Fixed Duty ......................................................................................... 94

13.2 Moving Pumps Between Groups, or Changing the Order of Pumps .................................... 96

13.3 Adding or Deleting Groups & Changing Group Alternation .................................................. 96

13.4 Decommissioning Pumps ..................................................................................................... 97

14 Configuring I/O, Fault & Level Devices ....................................................................................... 98

14.1 Digital Inputs ........................................................................................................................ 98

14.2 Assigning Faults to Digital Inputs ......................................................................................... 98

14.3 Unassigning Fault Inputs.................................................................................................... 100

14.4 Configuring Digital Inputs ................................................................................................... 100

14.5 Configuring Analog Inputs .................................................................................................. 103

14.6 Advanced Analog Input Options ......................................................................................... 104

14.7 External Digital & Analog Modules ..................................................................................... 104

14.8 Configuring Level Devices ................................................................................................. 109

14.9 Configuring Faults .............................................................................................................. 122

14.10 Configuring Analog Outputs ............................................................................................... 130

14.11 Configuring Digital Outputs ................................................................................................ 131

15 Profiles ......................................................................................................................................... 135

15.1 Profile Selection Methods .................................................................................................. 136

15.2 Configuring the Setpoints of Profiles .................................................................................. 138

15.3 Configuring Other Profile Properties .................................................................................. 138

16 Station Optimization ................................................................................................................... 140

16.1 Station Optimization Menu ................................................................................................. 141

16.2 Additional Parameters ........................................................................................................ 148

17 Energy Monitoring and Motor Protection .................................................................................. 150

17.1 Setting Motor Protection Values ......................................................................................... 151

17.2 Insulation Resistance Tester .............................................................................................. 154

17.3 Reassigning (Motor) Current Inputs used in Motor Protection ........................................... 158

17.4 Calculating Efficiency ......................................................................................................... 159

18 Supply Protection ........................................................................................................................ 160

18.1 Battery Test ........................................................................................................................ 162

19 Datalogger ................................................................................................................................... 163

19.1 Configuring the Event Logger ............................................................................................ 164

19.2 Crisis Logger ...................................................................................................................... 166

19.3 Interval Logger ................................................................................................................... 168

19.4 Filtering the Data Viewed in the History Page .................................................................... 168

19.5 Storing the Datalogger on the SD Card ............................................................................. 170

19.6 Configuring the datalogger to write directly to an SD Card ................................................ 173

19.7 Adding Comments and Deleting Logs ................................................................................ 173

20 Flow .............................................................................................................................................. 174

20.1 Configure General Flow Setting ......................................................................................... 174

20.2 Configuring Analog Inputs for Flow Measurement ............................................................. 175

20.3 Configuring Analog Inputs for Inflow Measurement ........................................................... 176

MultiSmart_IO_Manual_R20 Page 5 of 260

MultiSmart Installation & Operation Manual

20.4 Configuring Digital Inputs for Flow Measurement .............................................................. 176

20.5 Configuring Calculated Flow Settings ................................................................................ 177

20.6 Flow Alarms ....................................................................................................................... 178

20.7 Smart Outflow .................................................................................................................... 179

20.8 Estimating Duration to Overflow ......................................................................................... 180

21 Reservoir Monitor ........................................................................................................................ 181

21.1 Communications Configuration .......................................................................................... 181

21.2 User Interface .................................................................................................................... 183

21.3 Connection Manager .......................................................................................................... 183

22 RTU Module ................................................................................................................................. 185

22.1 Communications Screen .................................................................................................... 185

22.2 Communication Protocols .................................................................................................. 185

22.3 Enabling and Viewing of DNP and MODBUS Logs ............................................................ 199

22.4 IP Address & Routing Settings ........................................................................................... 200

23 Variable Frequency Drive (VFD) ................................................................................................. 201

23.1 Enabling VFD ..................................................................................................................... 201

23.2 Individual Pump Parameters .............................................................................................. 202

23.3 Setup an Analog Output for use with a VFD Drive ............................................................. 203

23.4 Controlling a VFD Drive Using MODBUS ........................................................................... 203

23.5 Displaying VFD speed on Main Screen.............................................................................. 203

23.6 Calculating Efficiency using VFD ....................................................................................... 203

24 PLC Extension IEC 61131-3 (ISaGRAF) ..................................................................................... 204

24.1 Setting up the Workbench .................................................................................................. 205

24.2 Setting up I/O ..................................................................................................................... 206

24.3 MultiSmart Functions & I/O Blocks ..................................................................................... 206

24.4 Downloading ISaGRAF Resources to MultiS mar t .............................................................. 212

24.5 Compiling and Downloading Multiple Resources ............................................................... 212

24.6 Viewing the Status of ISaGRAF Variables ......................................................................... 212

24.7 The Tags Button ................................................................................................................ 213

24.8 The Params Button ............................................................................................................ 213

24.9 Disabling ISaGRAF Resources .......................................................................................... 213

24.10 Backing Up ISaGRAF Resources ...................................................................................... 213

24.11 ISaGRAF Application Examples ........................................................................................ 214

25 Logic Engine ................................................................................................................................ 215

25.1 MultiSmart Tags ................................................................................................................. 215

25.2 Logic Engine Tags ............................................................................................................. 216

25.3 Mathematical Operators ..................................................................................................... 217

25.4 MultiSmart Logic Functions ................................................................................................ 217

25.5 Advanced Functions .......................................................................................................... 218

25.6 Logic Examples .................................................................................................................. 219

25.7 Uploading Logic Files Using FTP ....................................................................................... 220

25.8 Enabling Logic Files ........................................................................................................... 221

26 SMS Server .................................................................................................................................. 222

27 Customizing the Display ............................................................................................................. 225

27.1 Naming Pumps .................................................................................................................. 225

27.2 Pump Data Display ............................................................................................................ 225

27.3 Bottom Section ................................................................................................................... 226

28 Restarting the MultiSmart ........................................................................................................... 227

29 Site Keys and Enabling New Modules ....................................................................................... 227

29.1 Software Modules Available ............................................................................................... 227

29.2 Enabling Software Modules with a New Site Key ............................................................... 228

30 Upgrading MultiSmart Firmware ................................................................................................ 228

30.1 Upgrading via PC Configuration Utility ............................................................................... 228

31 Backing Up & Restoring Configuration Settings ...................................................................... 229

Page 6 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

31.1 Resetting Defaults .............................................................................................................. 229

31.2 Restore a Backup .............................................................................................................. 230

31.3 Back Up Current Configuration .......................................................................................... 231

32 More Advanced Configuration ................................................................................................... 232

32.1 Default Mode vs. Showing Less Options............................................................................ 232

33 Web Server .................................................................................................................................. 233

33.1 Web Page Security ............................................................................................................ 233

33.2 Security Key Setup ............................................................................................................ 234

34 Troubleshooting .......................................................................................................................... 235

34.1 There is no level displayed on my unit ............................................................................... 235

34.2 Every time the pump starts I see a Contactor Auxiliary fault .............................................. 235

34.3 My unit is showing a “Current Config Fail” fault .................................................................. 236

34.4 My unit has started with the message “Fail Safe Mode”..................................................... 236

34.5 PPP2 Manager Connection Error ....................................................................................... 236

34.6 My unit keeps restarting ..................................................................................................... 236

35 Appendix A – Fault Message Glossary ..................................................................................... 237

36 Appendix B – Display Mounting Template – Metric Units ....................................................... 241

37 Appendix C – Display Mounting Template – US / Imperial Units ............................................ 242

38 Appendix D – MultiSmart Security Explained ........................................................................... 243

39 Appendix D – MultiSmart Web Security Explained .................................................................. 245

40 Appendix E – Setting Up WITS-DNP Communications ............................................................ 247

40.1 Basic Configuration ............................................................................................................ 247

40.2 Connection Details ............................................................................................................. 248

40.3 Handling of Redundant Channels with Connection Details ................................................ 249

40.4 Device On/Off Scan ........................................................................................................... 249

40.5 Scheduled Connection ....................................................................................................... 249

40.6 Point On/Off Scan .............................................................................................................. 250

40.7 Analogue Range/Scaling.................................................................................................... 250

40.8 Analogue Limits ................................................................................................................. 250

40.9 Counter Limits .................................................................................................................... 251

40.10 Point Archives .................................................................................................................... 251

40.11 Binary States ...................................................................................................................... 251

40.12 Profiles ............................................................................................................................... 251

40.13 Rate of Change .................................................................................................................. 251

40.14 Object Flag Actions ............................................................................................................ 252

40.15 Minimum, Maximum, and Mean ......................................................................................... 252

40.16 Integral Values ................................................................................................................... 252

40.17 State Counter ..................................................................................................................... 253

40.18 State Runtime .................................................................................................................... 253

40.19 Profile Control Value .......................................................................................................... 253

40.20 Bulk Configurations and Versions ...................................................................................... 254

40.21 Event Logs ......................................................................................................................... 255

41 Technical Specifications ............................................................................................................ 256

41.1 Processor Unit ................................................................................................................... 256

41.2 RTU/Communications ........................................................................................................ 256

41.3 Firmware/Application Upgrade Capability .......................................................................... 256

41.4 I/O Standard Modules ........................................................................................................ 256

41.5 I/O-3MP: Motor Protection I/O Board ................................................................................. 256

41.6 Power (per unit) ................................................................................................................. 256

41.7 Power Supply & Environmental .......................................................................................... 256

41.8 Product Dimensions ........................................................................................................... 256

42 MultiTrode Terms & Conditions of Sale .................................................................................... 257

MultiSmart_IO_Manual_R20 Page 7 of 260

MultiSmart Installation & Operation Manual

Summary of Tables

Table 1 – Power Supply Specifications ......................................................................................................................................... 38

Table 2 – Serial Port Pin Outs ...................................................................................................................................................... 49

Table 3 – Max. Cable Length at Specific Baud Rates ................................................................................................................... 52

Table 4 – Can BUS and Can ID Settings ...................................................................................................................................... 53

Table 5 – Key Setup Parameters (can only be modified through the Setup Wizard) .................................................................... 68

Table 6 – Alternation Schemes ..................................................................................................................................................... 93

Table 7 – Digital Input Fault Sources ............................................................................................................................................ 98

Table 8 – Advanced Digital Input Options ................................................................................................................................... 101

Table 9 – Digital Input Mode Examples ...................................................................................................................................... 102

Table 10 – Digital Input Capa b ilities ........................................................................................................................................... 102

Table 11 – Advanced Analog Input Options................................................................................................................................ 104

Table 12 – Advanced Probe Settings ......................................................................................................................................... 112

Table 13 – Probe Length in Inches ............................................................................................................................................. 115

Table 14 – DuoProbe Calibration Parameters ............................................................................................................................ 116

Table 15 – Advanced Fault Parameters ..................................................................................................................................... 123

Table 16 – Fault Actions Parameters .......................................................................................................................................... 125

Table 17 – Digital Output Sources .............................................................................................................................................. 132

Table 18 – Advanced Digital Output Options .............................................................................................................................. 133

Table 19 – Station Optimization Parameters .............................................................................................................................. 140

Table 20 – Pump Reversal Parameters ...................................................................................................................................... 143

Table 21 – Well Washer Parameter s .......................................................................................................................................... 146

Table 22 – CT & FLC Parameters .............................................................................................................................................. 152

Table 23 – Motor Protection Faults ............................................................................................................................................. 152

Table 24 – Basic Fault Options ................................................................................................................................................... 153

Table 25 – IRT Parameters......................................................................................................................................................... 154

Table 24 – Basic IRT Parameters ............................................................................................................................................... 156

Table 26 – Supply Protection Faults ........................................................................................................................................... 161

Table 27 – Supply Protection Fault Parameters ......................................................................................................................... 161

Table 28 – Battery Test Parameters ........................................................................................................................................... 162

Table 29 – Event Datalogger Param eter s ................................................................................................................................... 165

Table 30 – Crisis Logger Configuration for “Trigger” Parameters ............................................................................................... 167

Table 31 – Interval Logger Configuration Parameters ................................................................................................................ 168

Table 32 – Predefined Filters Available in General Filters .......................................................................................................... 169

Table 33 – Filenames for Each Type of Datalog file ................................................................................................................... 171

Table 34 – General Flow Fault Parameters ................................................................................................................................ 174

Table 35 – Smart Outflow Parameters ........................................................................................................................................ 179

Table 36 – Advanced Serial Port Parameters ............................................................................................................................. 195

Table 37 – VFD Parameters ....................................................................................................................................................... 202

Table 38 – ISaGRAF Device Names .......................................................................................................................................... 206

Table 39 – Example of MultiSmart Tags ..................................................................................................................................... 216

Table 40 – Logic Engine Mathematic Operators ......................................................................................................................... 217

Table 41 – Logic Engine Functions ............................................................................................................................................. 217

Table 42 – Logic Engine Advanced Functions ............................................................................................................................ 218

Table 43 - Customize Display - Pump Data ................................................................................................................................ 226

Table 44 - Customize Display - Bottom 3 Lines .......................................................................................................................... 226

Page 8 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

1 Warnings & Cautions

1.1 Information to User

Read through this m anual to obtain a good working kno wledge in order to get max imum perform ance from

the MultiSmart for your application. After reading, place the manual in a safe place for future reference.

1.2 Documentation Sta ndards

DANGER:

THIS SYMBOL IS USED WHERE NON-COMPLIANCE COULD RESUL T IN INJURY OR DEATH.

WARNING:

THIS SYMBOL IS USED WHERE NON-COMPLIANCE COULD RESULT IN INCORRECT

OPERATION, DAMAGE TO OR FAILURE OF THE EQUIPMENT.

NOTE:

THIS SYMBOL IS USED TO HIGHLIGHT AN ISSUE OR SPECIAL CASE WITHIN THE BODY OF

THE MANUAL.

1.3 Installa ti on Note s

WARNING:

THE MULTIS MART INSTALLATION AND WIRING MUST BE PERFORMED BY QUALIFIED

PERSONNEL.

DANGER:

THE MULTISMART HAS NO USER SERVICEABLE PARTS. TO REDUCE THE RISK OF

ELECTRIC SHOCK, LEAVE ALL SERVICING TO QUALIFIED MULTITRODE TECHNICAL STAFF.

DANGER:

INSTALLATION OR USE OF THIS EQUIPMENT OTHER THAN IN ACCORDANCE WITH THE

MANUFACTURERS INSTRUCTIONS MAY RESULT IN EXPOSURE TO HARM, SERIOUS I NJURY

OR DEATH.

MultiSmart_IO_Manual_R20 Page 9 of 260

MultiSmart Installation & Operation Manual

Abbreviations, Symbols & Units

2 Glossary & Symbols

Terminology

Activation Level

Alternate Mode

Deactivation Level

Decommissioned Pump

Duty (Lead) Pump

Empty (Discharge) Mode

Fill (Charge) Mode

Fixed Sequence

InterPump Start Delay

InterPump Stop Delay

Probe

Standby (Lag) Pump

The point at which a pump or alarm is switched On.

The Pump Station Manager automatically switches the lead (duty) pump each cycle.

The point at which a pump or alarm is switched Off.

A pump that has been removed from duty or an installation, e.g. for maintenance

purposes.

The main pump or the first pump to start within a pumping cycle.

When the Pump Station Manager is set to empty a tank or pit.

When the Pump Station Manager is set to fill a tank or pit.

Pump 1 or pump 2 is fixed as the lead (duty) pump.

The delay between any two pumps starting.

The delay between any two pumps stopping.

MultiTrode manufactures a range of conductive level sensors. They have many

advantages over traditional devices such as ball floats. Advantages include:

resistance to fatty deposit build-up, tangle-free and an adjustable sensitivity to liquid

to prevent false readings.

The secondary pump or the next pump to start within a pumping cycle.

ISaGRAF

PSM

Ω

EMC

Hz

LED

MTU

N/C

N/O

RTU

VAC

VDC

ISaGRAF is a control software environment which supports all of the internationally

recognised IEC 61131-3 control languages and offers a combination of highly

portable and robust control engine.

Pump Station Manager

Resistance Value (Ohm)

Electromagnetic Compatibility

Frequency (Hertz)

Light Emitting Diode

Master Terminal Unit

Normally Closed

Normally Open

Remote Telemetry Unit

Alternating Current Voltage

Direct Current Voltage

VFD

Page 10 of 260 MultiSmart_IO_Manual_R20

Variable Frequency Drive

MultiSmart Installation & Operation Manual

3 Major New Features & Enhancements in Recent Firmware Releases

3.1 Version 3.1.0

Version 3.1.0 includes a large number of enhancements and bug fixes. This section lists some of the major

highlights of this release.

3.1.1 New Features

• Enhanced security features supporting different levels of security for accessing screens

• SMS Server functionality for sending SMS messages on alarm conditions

• Web-based monitoring services and web security for accessing web pages

• Well cleanout can now be controlled by watching current drawn

• Ability to calculate statistics whenever event triggers occur (e.g. average, minimum, and maximum

current while the pump is running)

• Support for DNP Secure Authentication Version 5

• Support for WITS-DNP V2.0

3.1.2 Screen Changes

• Setup Wizard redesign – once completed, users are prompted to set up additional common features

• Device network information now displayed on a Network page under the Info group of pages

• Deactivating faults now show time until reset

• Faults in the fault screen are now shown in order of most recent fault first

MultiSmart_IO_Manual_R20 Page 11 of 260

MultiSmart Installation & Operation Manual

Part 1 – Operations

4 Introduction

Congratulations on your purchase of the MultiTrode MultiSmart Pump Station Manager.

Depending on the options you have purchased, the unit may be configured as either a Pump Station

Manager or a Reservoir Monitor or as a Remote Telemetry Unit. The generic product description of

MultiSmart Pump Station Manager is used throu ghout the manual and for conveni ence refers to any of the

three configurations.

The pump station manager is an "out of the box" Pump Station Manager for water and sewerage pump

stations. The large LCD s creen with sof t-ke ys eliminates the n eed for selec tor switches, p ush buttons , fault

lights, meters, accumulators and other additional panel items. This simplifies panel wiring and reduces

costs.

The product has a very low “whole of life” cost compared with a PLC due to the pum p control functionality

already developed in the product. Users simply configure the parameters, rather than program the unit. This

reduces engineering cost and greatly increases reliability.

The MultiSmart pump station manager has t h e op tio n o f an IEC 6 113 1-3 PLC program m ing lan gua ge so that

additional functionality can be added by the user if required.

The MultiSm art has fully open communications and c an be supplied with Modbus and DNP3 protocols. A

MultiSmart can also be shipped just as an RTU without any pump control functionality or user interface.

The Reservoir Mon itor is a version of the product for monitoring reservoi rs and communic ating with remote

pump stations.

MultiSmart is fully config urable f rom the LCD us er inter face. H owever, ther e is al so a PC -based Configurator

program with comprehensive functionali t y now availa b le.

4.1 Range of Options

The functionality of the basic product can be enhanced with additional software modules, such as:

• DNP3 RTU with security

• Security key - based on the ‘Dallas Key’

• VFD control - variable frequency/speed drive

• “Energy Monitoring and Motor protection” option which allows power, energy, power factor and

pump efficiency monitoring as well as 3-phase currents, motor protection functions and insulation

resistance tests (requires energy monitoring and motor protection I/O module)

• Logic engine (for custom logic additions)

• ISaGRAF (IEC 61131-3) PLC programming

• Well Mixer

• PumpView – a web-based monitoring and control system via the cellular/mobile network

• SMS Server - for sending SMS messages in the event of configured alarm conditions

The product can be shipped with these software modules enabled or they can be enable d in the field with the

appropriate enable code. T o the base uni t, an add itio nal I/O boar d can b e instal led in t he fac tory to all ow for

either an expansion of I/O or motor protection options.

Page 12 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

4.2 Intuitive Operator Interface

The MultiSmart has screens which have been designed for operators of pump stations. The operator can see

at a glance:

• Level

• Pump mode

• Pump availability

• Detailed fault information

• Date/time of each fault occurring and clearing

• Single or 3-phase supply, DC supply

• Fault and event history (up to 50,000 records, or millions of records with SD card)

• Accumulators (starts, hours, faults, etc)

• Pump efficiency (requires energy monitoring, motor protection and flow enabled)

• Status of all I/O

• Status of a communications link

• Duration to Overflow

4.3 Intuitive Engineering Interface

The product has clear menu screens for altering:

• Pump set points

• Alarm set points

• Delays

• Alternation and grouping

• Level device and backup level device

• Number of pumps

• I/O and fault configuration

• Supply protection

• Energy Monitoring and Motor protection (where installed)

• Station optimization parameters (max run time, max off time, max starts per hour, plus many more)

• Data logging parameters

• Communications

• Profiles

MultiSmart_IO_Manual_R20 Page 13 of 260

MultiSmart Installation & Operation Manual

gases or powders.

4.4 "Out of the Box" Control of a Pump Station

When the unit is first power ed up, it starts controlling a pum p station using its def ault parameters. Although

it’s shipped with this basic configurat ion, the configur ation can be easily modified to suit a wide range of

applications by running through the Setup Wizard.

The Setup W izard takes into ac count the MultiTrode probe or other level devices, fill or em pty applications,

number of pumps, num ber of wells, station power supply, type of pum p sensors and DNP comm unication

settings.

Even though the basic setup meets most of the normal pump station requirements, with a few button presses

the MultiSmart can be setup to perform most of the complex pump station management requirements.

Changing between a reser voir and a pump station, the number of pum ps, the number of wells, or empty

(discharge) to fill ( charge) is done through t he Setup W izard an d takes onl y a few m inutes, whi ch is far less

time than that required to implement the same functionality using a standard PLC.

Complete station setups can be saved and/or loaded via an SD card or USB.

If the extensive rang e of existing features do not cover a part icular requirement, additional functionality can

be added by writing new code using either Logic Engine (a simple Boolean language) or ISaGRAF (a suite of

PLC languages).

WARNING:

Do not use this unit in environments that may contain flammable/explosive or chemically aggressive

Page 14 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

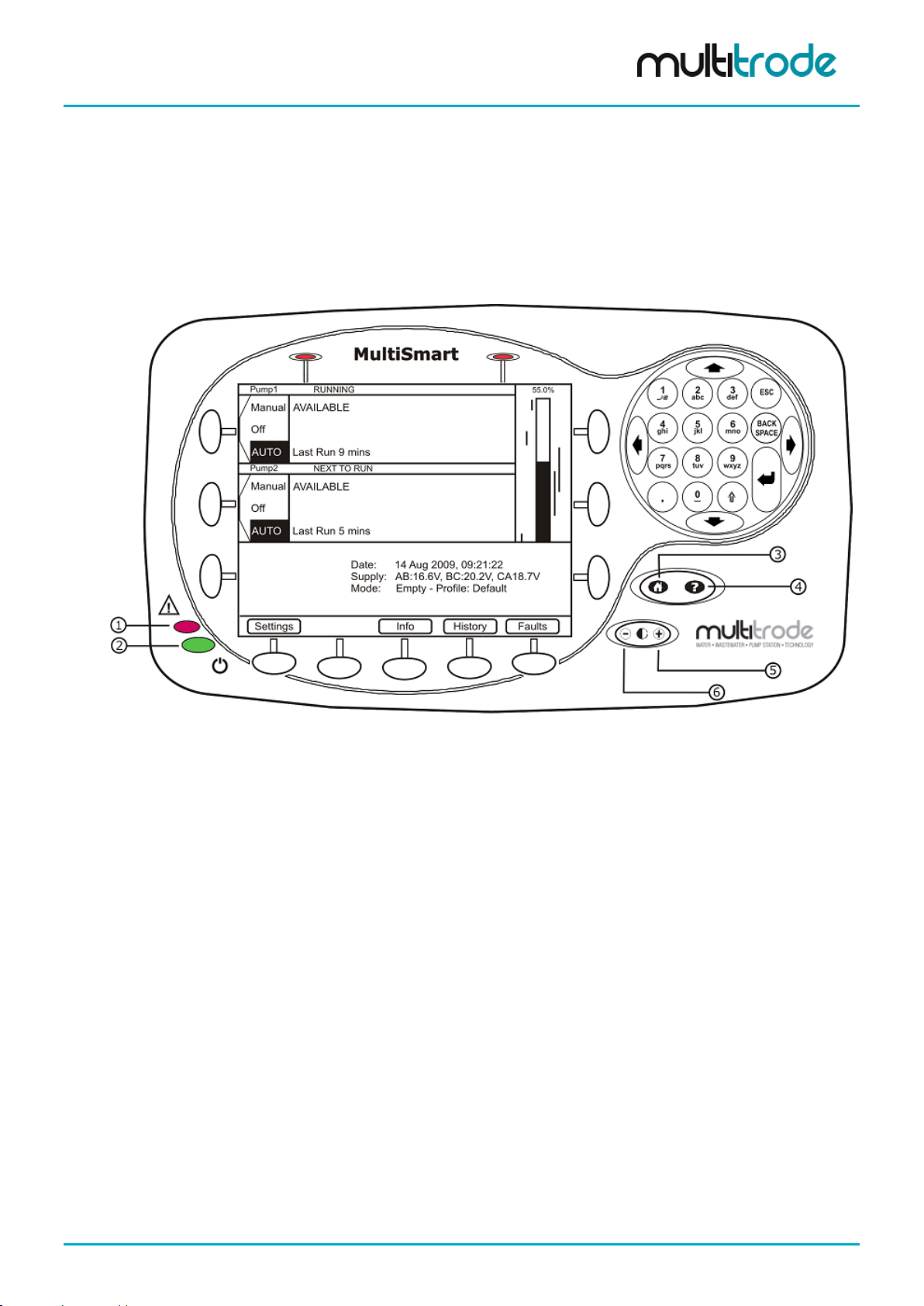

5 Operator Interface

The MultiSmart pum p station m anager has an easy to use in terface f eaturing a large graphica l LCD. A large

amount of critical information is displa yed on the main screen, m aking it simple for an operator to determ ine

the current status of the pump station at a glance.

The buttons (or soft-keys) aroun d the edge of the screen ar e used t o access f eatures, depending on what is

displayed at the time.

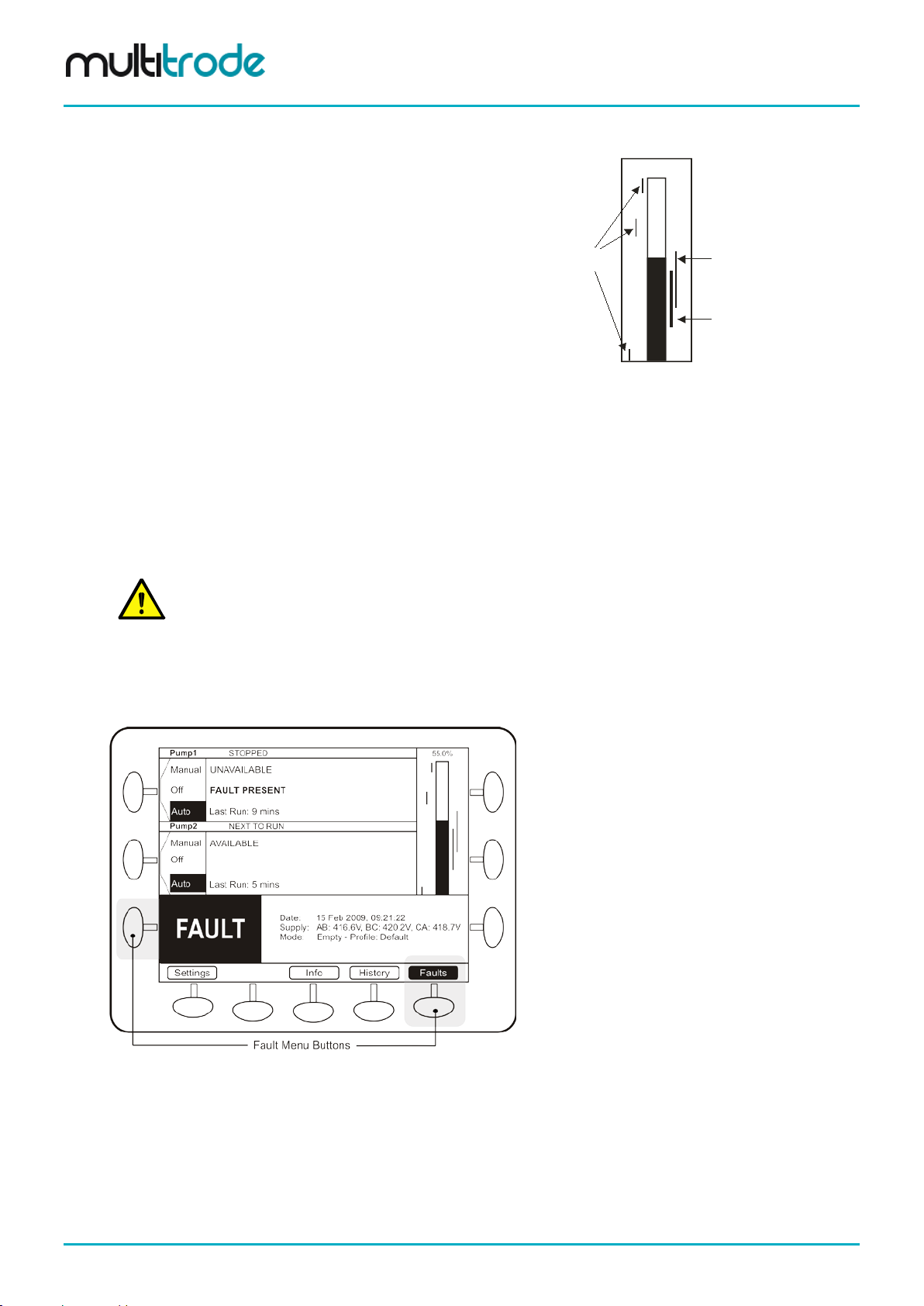

Figure 1 – MultiSmart Display

1. Fault Indication LED (Red)

2. Power Status LED (Green)

3. Home Button

4. Help Button

5. Increase Contrast

6. Decrease Contrast

5.1 LCD Panel

The large LCD gives the oper ator a clear view of how the pum p station is opera ting. Water levels are shown

graphically. A back light turns on when any of the display butto ns are pushed. The back light turns off again

after a set time of inactivity (this time is user configurable).

MultiSmart_IO_Manual_R20 Page 15 of 260

MultiSmart Installation & Operation Manual

5.2 LED Indicators

5.2.1 Power

The Power LED is at the bottom left hand corner of the display and indicates that the DC supply is connected

and turned on.

5.2.2 Faults

The fault LED is above the power LED. It flashes on ce a second when a fault is detec ted. This gives the

operator a quick indication of whether a fault is present without having to access the LCD screen.

5.3 Buttons

5.3.1 Home/Help Button

The Home/Help button has two positions:

• Press ing the Home icon returns the user to the main status screen.

• Pressing the Help icon displays online help for the currently displayed screen.

5.3.2 Contrast Button

The contrast button is us ed to adjust the LCD scr een’s contr ast. Press “ +” or “–“ as required to optimis e the

display for the light conditions.

5.3.3 Display Buttons

Eleven buttons are loc ated ar ound the ed ge of the LC D displa y. These ar e used to ac cess m enu item s and

other data on the display. For any screen, the display indicates what each button is used for.

5.3.4 Numerical Keypad

A numerical keypad is locat ed at the right of the interface. This is us ed to enter alpha-numeric character s

during configuration.

5.4 Using the Interfa ce

5.4.1 Main Status Screen

Pressing the Home butt on turns on the LCD backlight and als o returns the MultiSmart displa y to the main

status screen. The following screen displays the current status of all pumps connected to the MultiSmart:

Figure 2 – Main Status Screen

Page 16 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

5.4.1.1 Pump Mode The buttons located next to each pump are used to switch the pump into Manual (Hand), Off, or Auto modes.

• Auto – I n this mode a pum p starts when the activation s etpoint is reache d. The pum p automaticall y

stops when the deactivation setpoint is reached.

• Off – This turns a pump off, so pump run commands are ignored b y the of f pump regardless of leve l.

In order to meet secur ity requirements, the Of f mode can be disabled from the advanced menu. (If

changed while the pump is already in the Off mode, it stays off until the mode changes).

• Manual (Hand) – is semi-automatic manual, as the mode returns automatically to Auto when the

deactivation setpoint of the pump is reached. (This prevents pumps from being left on

unintentionally).

A pump is placed into Full Manual m ode as follows: when the pump is in Off mode, instead of just

briefly pressing the Auto/Off/Manual button, press and hold it on. This puts the pump into Full

Manual mode for as long as the button is pressed.

5.4.1.2 Running Status The Running Status of each pump appears to the right of the Pump Name. The various states are:

• Stopped – Pump is stopped

• Starting in x seconds – Pump is about to start and a delay is counting down

• Running – Pump is running

• Stopping in x seconds – Pump is about to stop and a delay is counting down

• Next to Run – Indicates the next pump to run. (Not applicable in multiple well configurations).

• Request to Run – The controller is waiting for the feedback from the contactor. (A contactor

auxiliary is wired in and the command to run a pump has been sent).

• External Run - If the pump is started by an external control method (for example, via a manual

override switch), the contactor will be closed but no run command would have been sent by the

controller, hence External Run is displa yed. The Mu ltiSmart c ontinues to up date the pum p run time

statistics and other relevant historical data. As well, the relevant faults and warnings are generated.

• Reversing in x seconds – The pump is about to reverse

• Reversing for x seconds – The pump is currently being reversed

• Decommissioned – The pump has been taken out of service

5.4.1.3 Availability Status The Availability of each pump is displayed below the Running Status. The states are:

• Available – There are no curr ent faults for this pump. The pum p is available to run ( this condition

does not consider the mode of the pump, so if the pump is OFF, the pump will not run).

• Unavailable – A fault is present or a fault requires manual acknowledgment.

• Hold Out – The text,” Hold Out” flashes indicating a fault is present and the pump is unavailable.

• Inhibit – Station or individual pump inhibited from SCADA

5.4.1.4 Fault Status The Fault Status of each pump is displayed below the Availability Status. The states are:

• Fault Present

• Ack Required – A fault condition has cleared and is not holding out the pump, but requires

acknowledgement.

• Reset Required – A fault condition has cl eared and is holding out the pum p, so requires reset (see

Section 5.4.2).

• Reset in x sec – A f ault condition has clear ed and the pum p will auto-reset when the count down is

complete.

MultiSmart_IO_Manual_R20 Page 17 of 260

MultiSmart Installation & Operation Manual

A bar graph is displayed next to the pumps and shows:

55.0%

Lag (Standby) Pump

activation and deactivation levels

Lead (Duty) Pump

activation and deactivation levels

Level Alarms

Figure 3 – Level Indication

than 1 well.

5.4.1.5 Level Indication and Setpoints Display

• Current liquid level

• Each pump’s activation and deactivation levels

• Level alarms that have been enabled

5.4.1.6 Soft-keys The buttons at the bottom of the screen are used to access the following areas:

• Settings - used to configure the MultiSmart pump station manager

• Info: displays full station and pump information

• History: shows alarms and event history

• Faults: shows details of current fault conditions

NOTE:

When the unit is controlling 5 or more pumps, a Next Pumps button also appears on the bottom line

allowing access to pumps 5 and 6, etc. This button is also present when the unit is configured for more

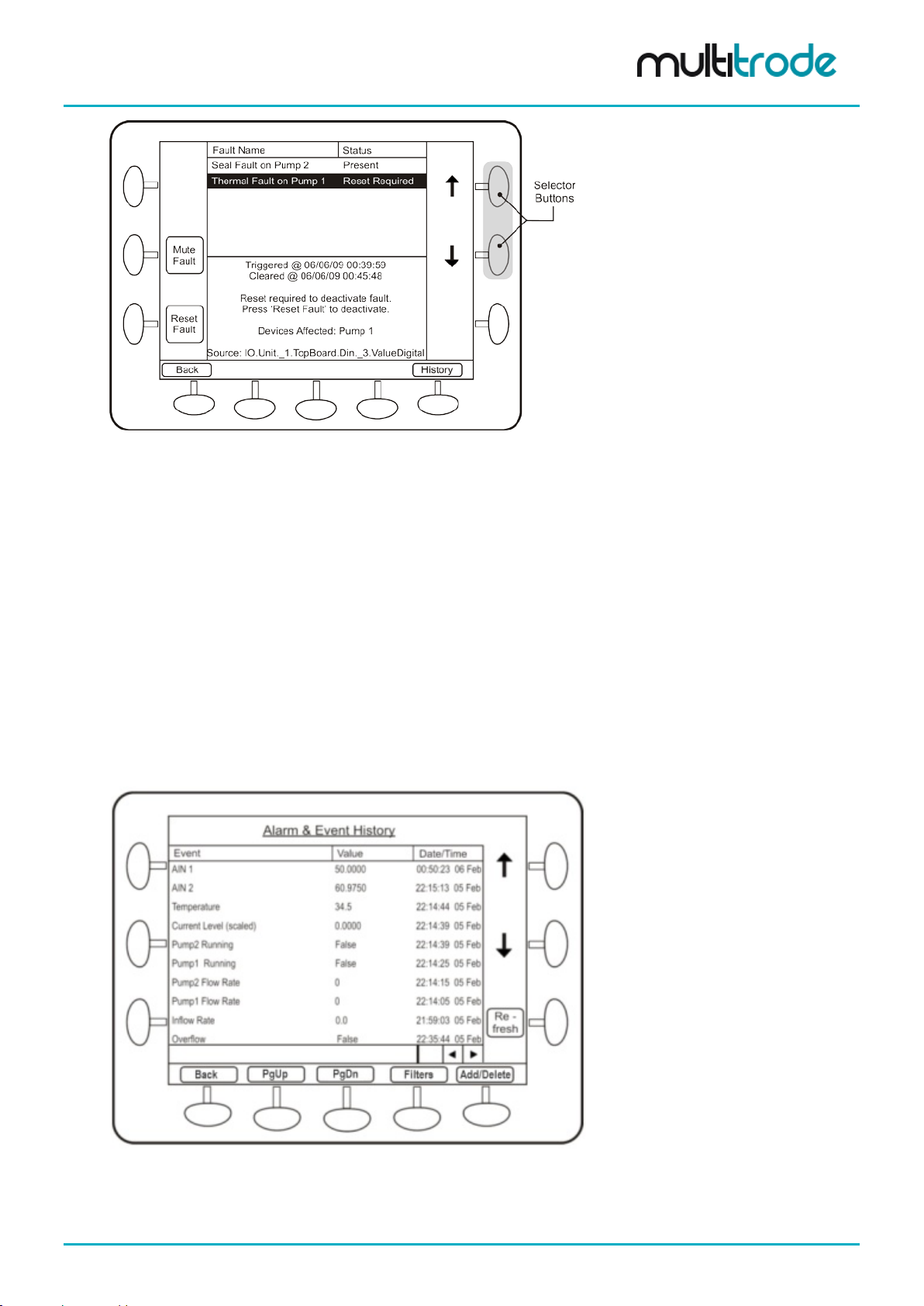

5.4.2 Faults / History

When a fault occurs, a large FAULT box is displayed at the bottom of the screen. At the s ame time, the fault

status changes to Fault Present.

Figure 4 – Fault Indication

The left Fault soft-key butt on flashes when a fault is p res ent. Pus hing t his button (or the rig ht Faul ts bu tton)

displays a screen which det ails the fault. (Appendix A contains a description of all faults displayed).

Page 18 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

Figure 5 – Fault Reset Screen

Use the selector buttons to select each fault in turn.

From this screen the opera tor can reset the fault if the f ault condition is no long er present. If the fault is still

present, the Reset Fault button does not appear.

A Mute Fault button appears for faults that can be muted. It is used to s top sirens or flashing li ghts t hat may

have been activated by the fault.

A Reboot Unit button app ears for a Config Changed - Reboot Required fault. Pres sing this butt on will save

current values and then reboot the unit. Press the Yes button to confirm a restart of the controller. This

process takes one to two minutes to complete.

By default, digital out put 4 (DO4) is linked to th e high-le vel alarm and can be m uted. The digital out put can

be configured for Pulsed or Steady operation and is typically connected to an external warning light or alarm.

• The Mute button is only available for other faults if the user has configured them to be mutable.

• Press ing the History button displays the entire fault & event history log.

• Press ing the Main button returns the operator to the main status screen.

Figure 6 – Fault History S creen

Section 19.4 explains more about Filters and section 19.7 explains the Add/Delete button.

MultiSmart_IO_Manual_R20 Page 19 of 260

MultiSmart Installation & Operation Manual

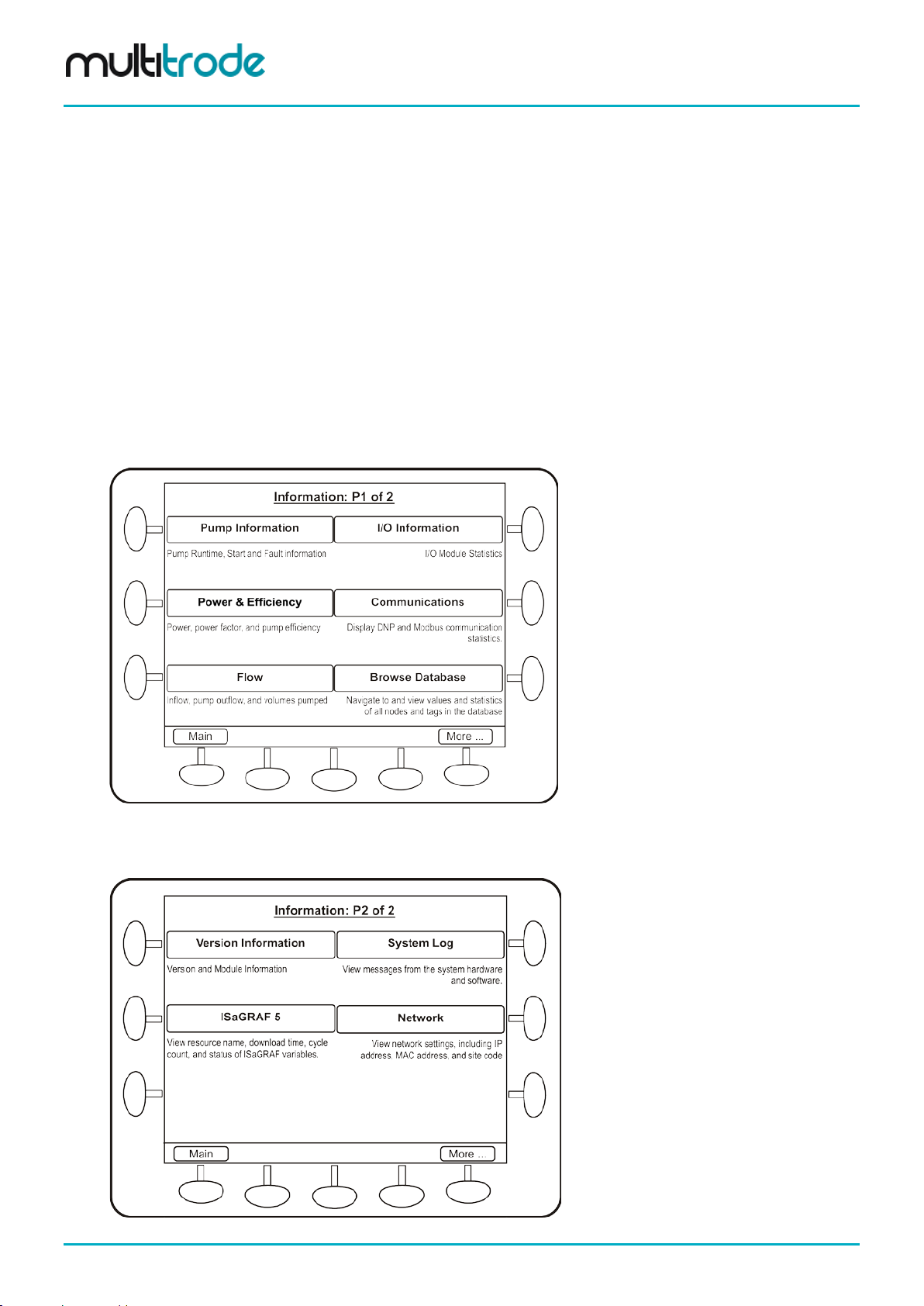

5.4.3 Information Screen

The Information screens show:

• Hours run, starts and faults for each pump and the station

• The status of all I/O

• Flow data (when the optional flow module is installed)

• System log (identifies any application problems)

• Version and modules installed in the unit

• Power and Efficiency – kW, kVA, power factor, pump efficiency, energy accumulators (kWh and

kVAh) for various periods: toda y/ yesterd a y; this week /las t week

• Communications statistics for DNP3/ Modbus slave and the current DNP3 Modbus tag values

• Option to browse MultiSmart internal tag database

• Option to view ISaGRAF 5 tags and values useful for PLC programming

To navigate to the Information screen, press the Info button on the main operator screen.

Figure 7 – Information Screen 1 of 2

Pressing More displays the second scr een, which includes the Version button which gives details on the

firmware version installed on the unit. (Free firmware upgrades are available from the MultiTrode website).

Figure 8 – Information Screen 2 of 2

Page 20 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

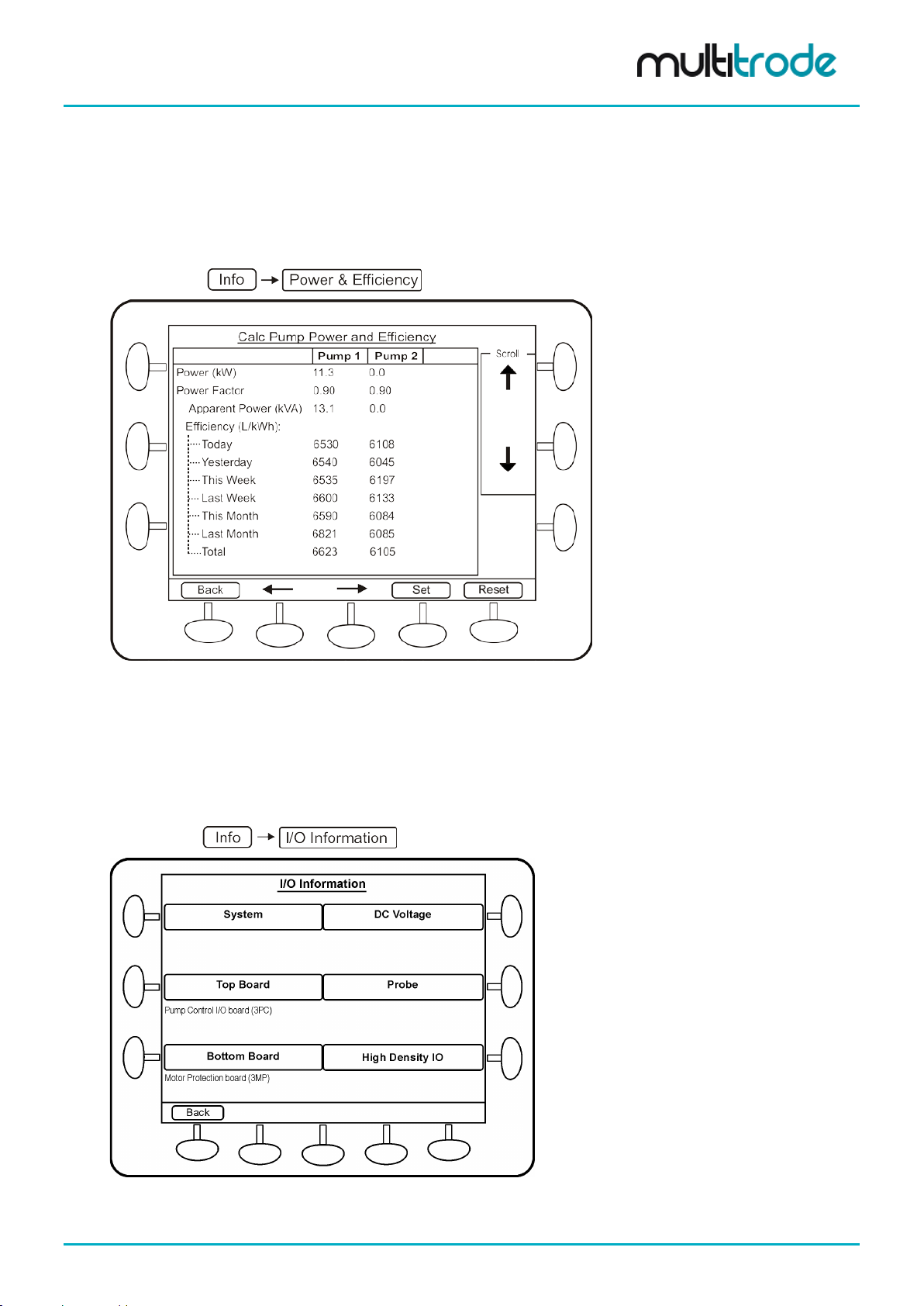

5.4.3.1 Power & Efficiency This screen shows the power fac tor and ef ficienc y of the pumps . Efficienc y, energ y and appare nt ener gy of

the present day, yesterday, this week, last week, this month, last month and totals are displayed on this

screen. There is also a Benchmark Efficiency (further down the screen) which can be entered as a

comparison value (see section 17.1).

Navigate to:

Figure 9 – Power Efficiency Screen

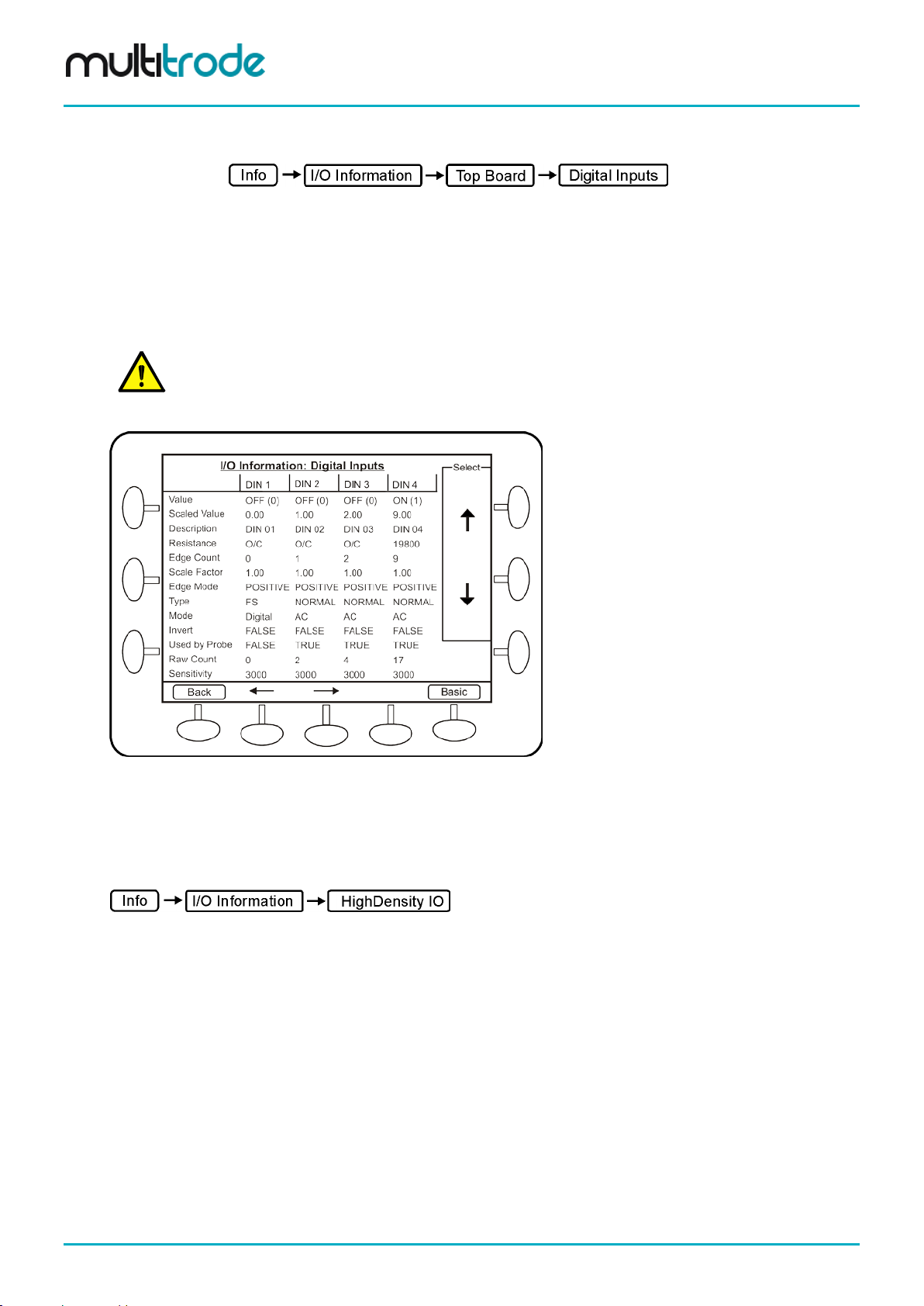

5.4.3.2 I/O Information Information about the S ystem, DC Voltage, Top Board, Bott om Boar d and Probe c an be seen in this s creen.

The I/O information sc reens are especiall y useful in troubles hooting input/output related issues. Insulation

Resistance test (IRT) can be accessed from within the I/O information sc reen, (the test is only performed

when the pumps are not running).

Navigate to:

Figure 10 – I/O Information Screen

MultiSmart_IO_Manual_R20 Page 21 of 260

MultiSmart Installation & Operation Manual

in the digital inputs advanced options.

To determine the configuration and current state of the digital inputs, navigate to the I/O Information: Digital

Inputs screen.

The current state of a digital input is displayed on the top line: Value.

Press the Advanced button to displa y configuration inform ation on the digita l inputs, f or example Mo de and

Sensitivity.

The resistance as measured by the input is also displayed in Advanced mode. When the measured

resistance is below the Sensitivity, then the inp ut turns on (unless it is in verted, in which cas e the reverse i s

true).

NOTE:

The Sensitivity used by the probe (default of 22k ohms, Section 14.8.3

) is not the same Sensitivity found

Figure 11 – Digital Inputs Information Screen

High Density IO info page screens display the state of all digital inputs/outputs on one page for one

unit/board at a time. T he unit name and board name are displa yed at the top. By pressing the N ext/Prev

button, the I/O for the next/previous unit/board can be viewed.

To determine the current state of all digital input s/outputs, navigate to the I/O Information: High Density IO

Page 22 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

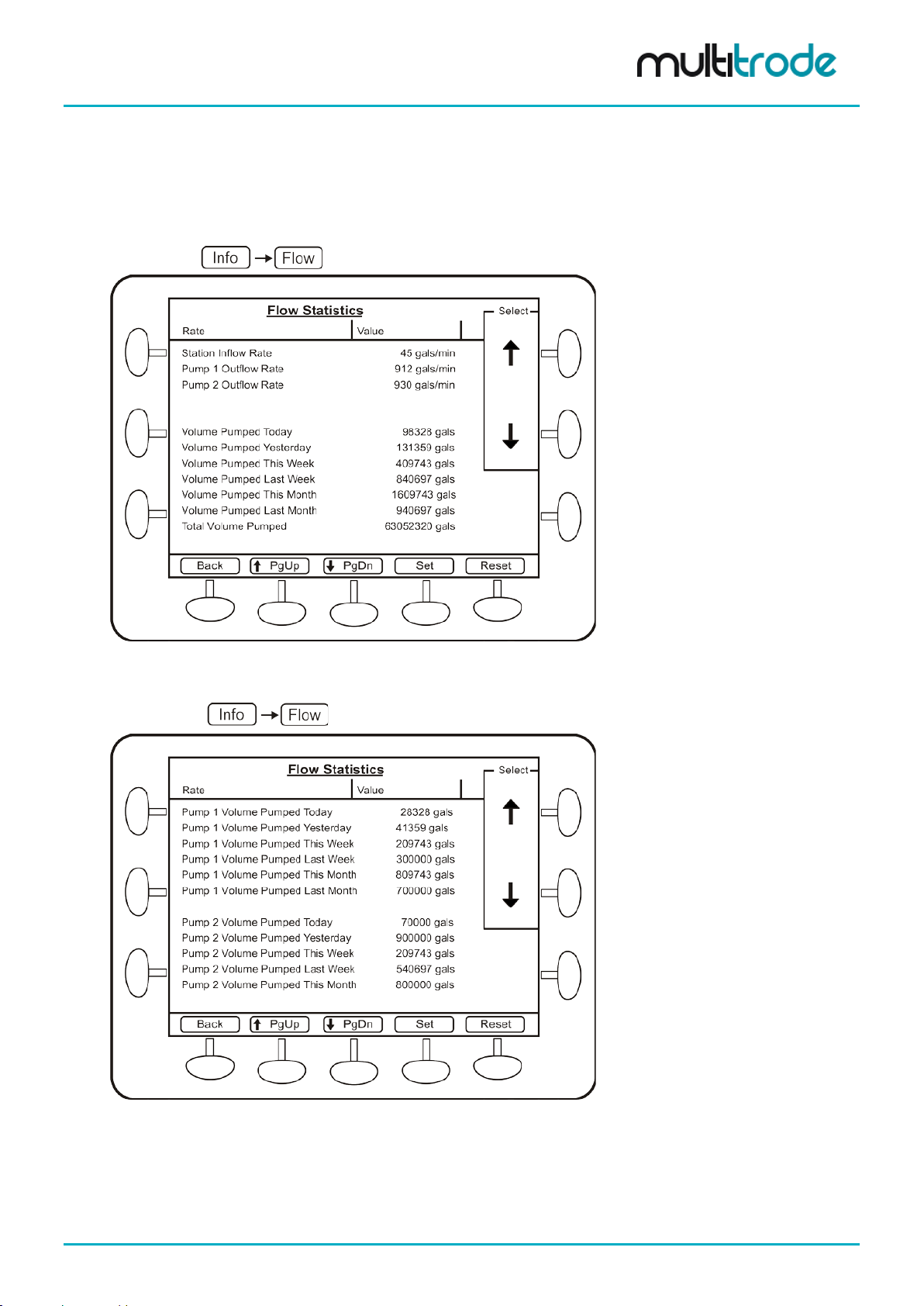

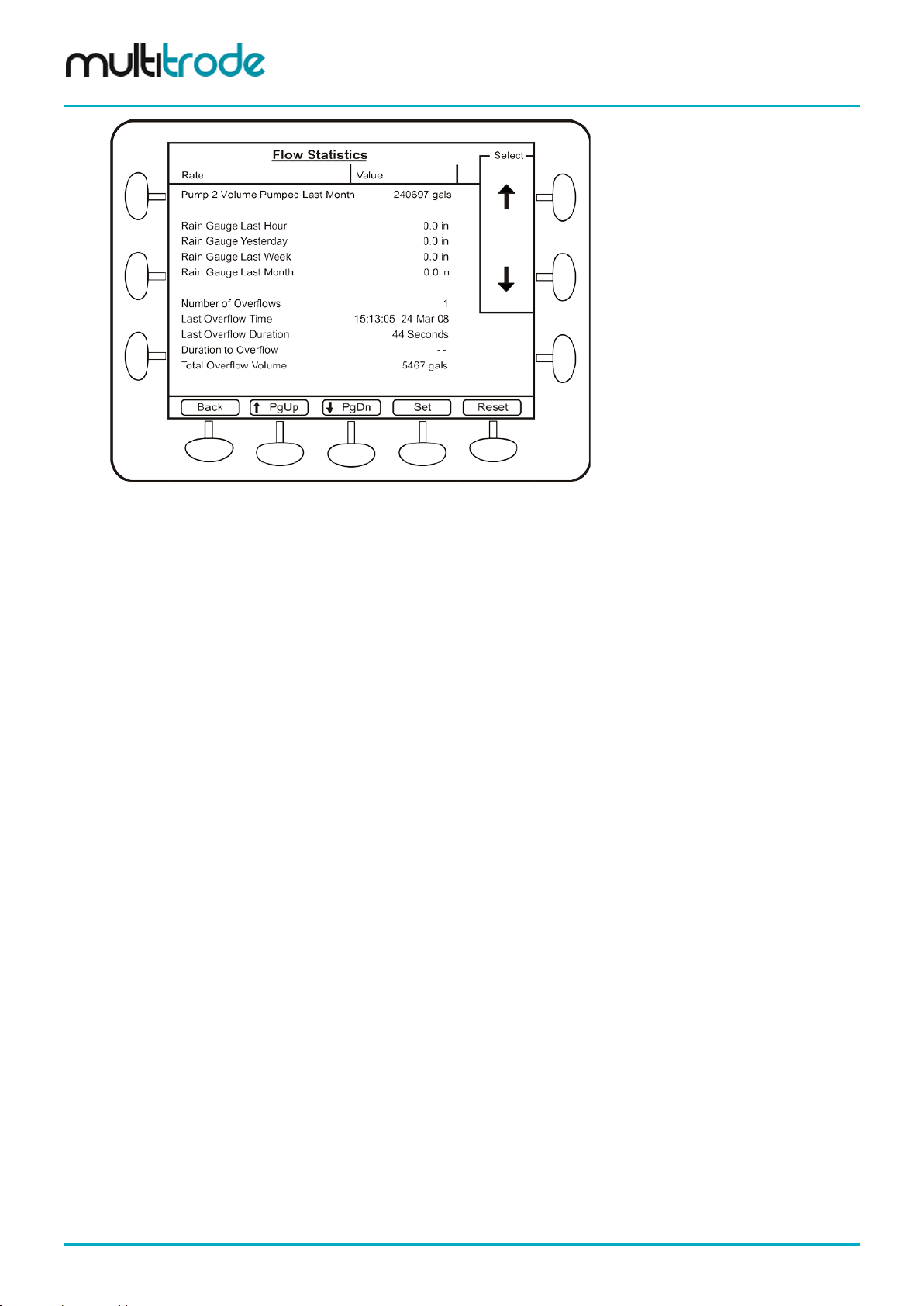

5.4.3.3 Flow The station inflow rate, pum p outflow rat e, volum e pumped dur ing a range of inter vals, number of overflows ,

last overflow tim e, last overf low duration, duratio n to overf low, and total o verflow volume can be se en in th is

screen.

Navigate to:

Figure 12 – Flow Screen – Part 1

Navigate to: and scroll down.

Figure 13 – Flow Screen - Part 2

MultiSmart_IO_Manual_R20 Page 23 of 260

Figure 14 – Flow Screen - Part 3

MultiSmart Installation & Operation Manual

Page 24 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

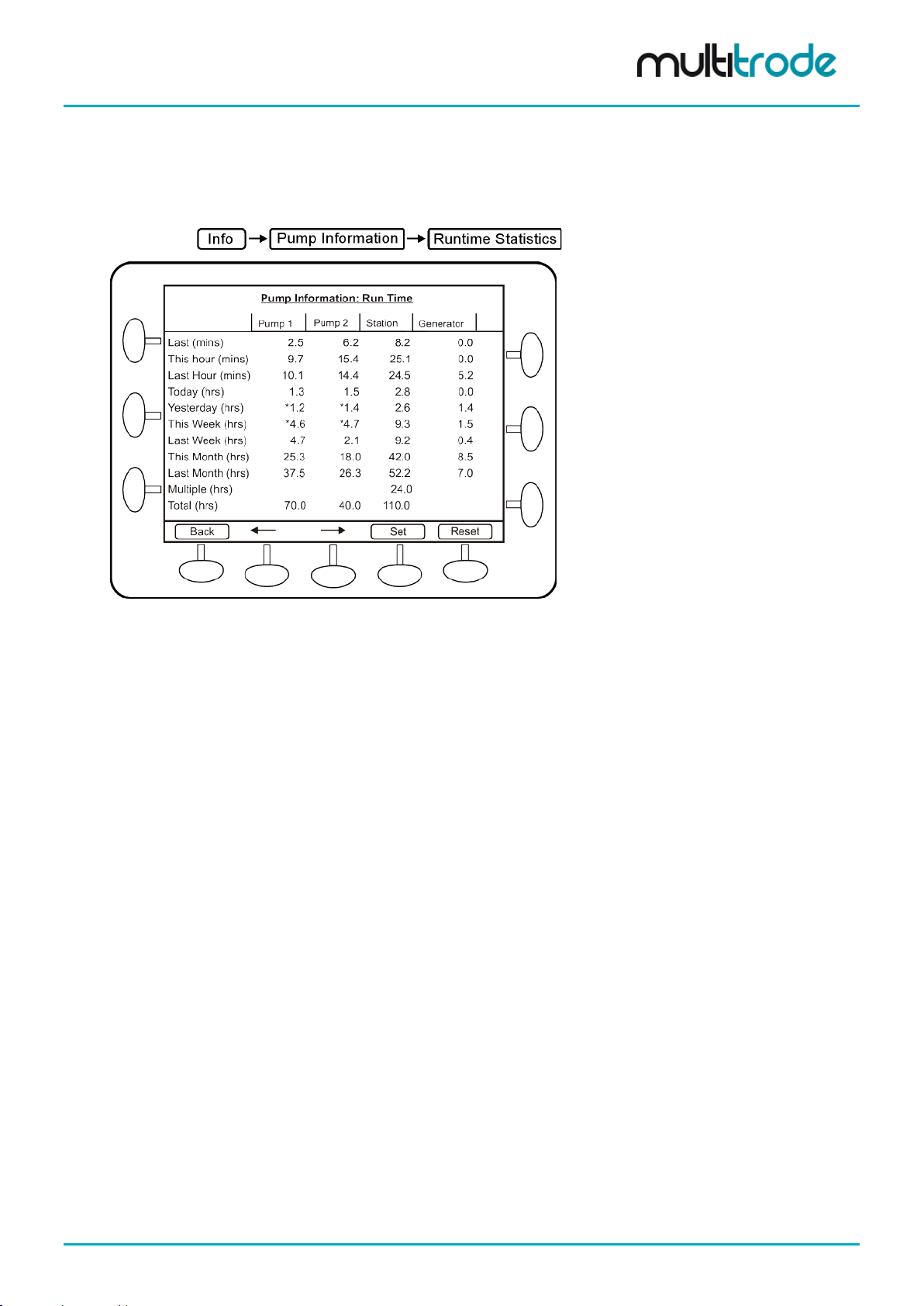

5.4.3.4 Pump Information Under this screen, the Runtime, Start, Reverse and Fault statistics as well as IRT information can be

accessed. These options are illustrated in this section.

(a) Runtime Statistics

Navigate to:

Figure 15 – Pump Run Time Statistics

Runtime is calculated base d on when the pum p is considered run ning via the con tactor auxil iary status. T his

includes when the pump is externally run (determined via the contactor auxiliary status). If no contactor

auxiliary is wire d in, the runtime is c alculated from when t he pump is called for by MultiSmart, and ext ernal

pump runs (e.g. via external switch) will not be included. This is also the case for Starts (below).

In the case of the runtime statistic s, t he station runtime may not equal th e sum of the pum p runtimes. For

example, if Pum p 1 is running for 1 hour by itself, followed b y Pum p 2 running for 1 hour by itself, then both

pumps run for 1 hour together . The Pump 1 an d Pump 2 runtim es will be 2 hour s each whereas the Station

runtime will be 3 hours since both the pumps were running together for an hour.

For the Generator Run Time s tatistics to be calculate d, a digital input m ust be wired into the MultiSm art and

configured as the Generator Running fault.

MultiSmart_IO_Manual_R20 Page 25 of 260

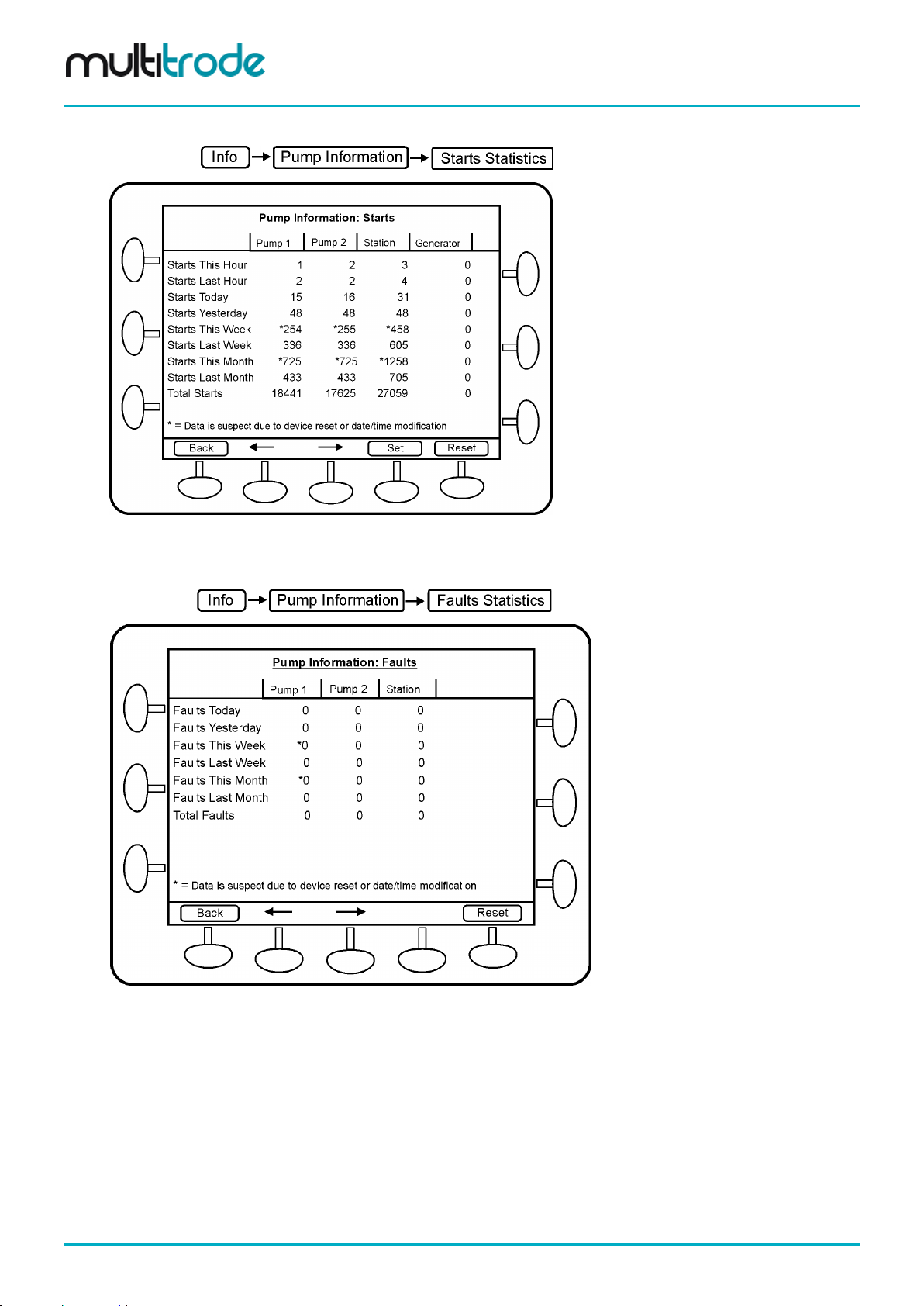

(b) Start Statistics

MultiSmart Installation & Operation Manual

Navigate to:

Figure 16 – Pump Start Statistics

(c) Fault Statistics

Navigate to:

Figure 17 – Fault Statistics

This screen disp lays the total fau lts that occurred, tod ay, yesterda y, this week an d last week for each pum p

and the station.

Page 26 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

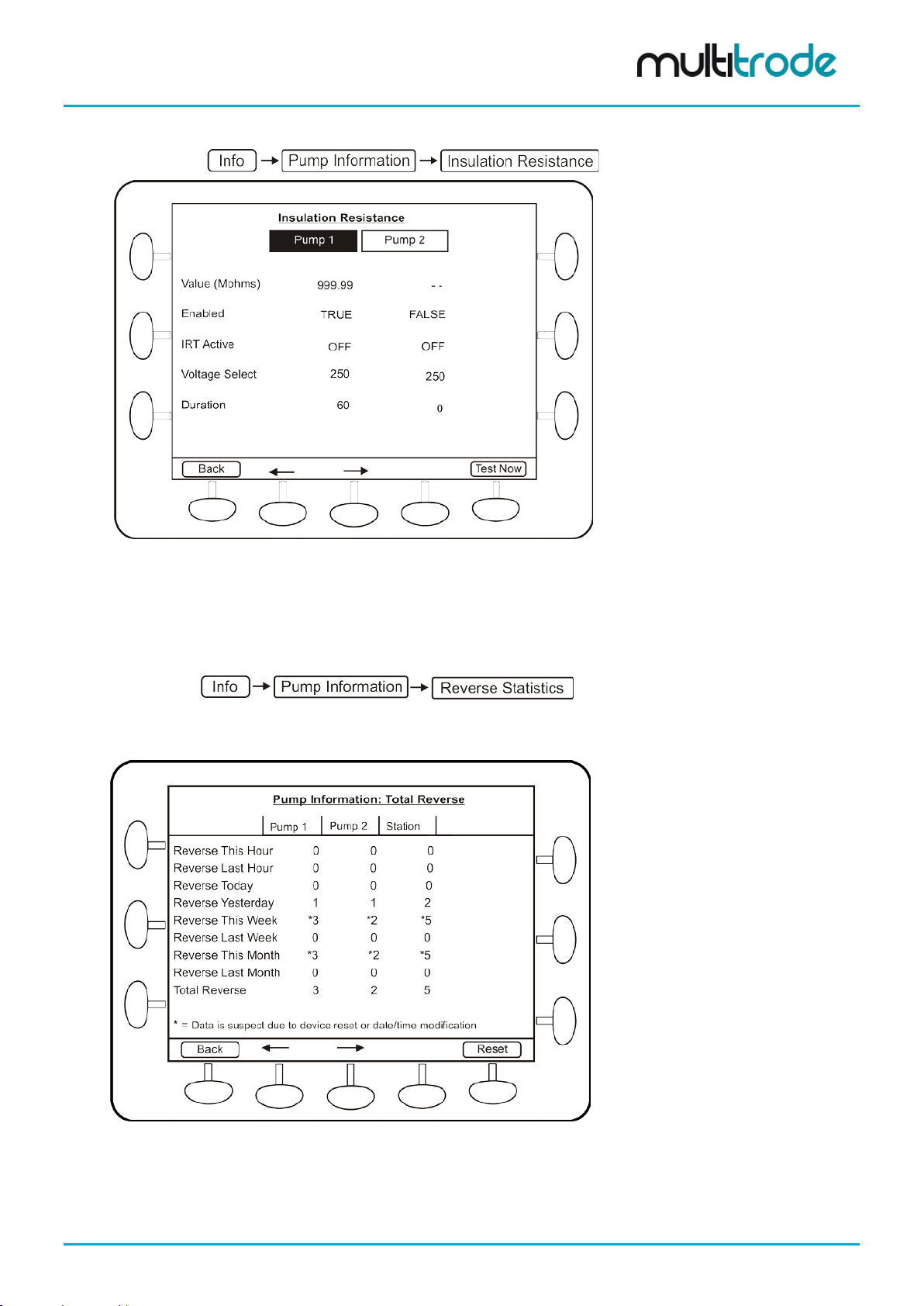

(d) Insulation Resistance

Navigate to:

Figure 18 – Insulation Resistance

The insulation resistanc e t e s t c an be acti va ted f r om this screen. The result of the test and re lat ed values are

displayed in this screen. This test can on ly be performed when the pump is not running. (IR T can also be

accessed from the I/O information screen).

(e) Reverse Statistics

Navigate to:

Pump reverse information can be viewed here. Three different Reverse Statistic s can be viewed.

(i) Total Reversals

Figure 19 – Pump Total Reversal Statistics

This gives the total reversal statistics for the pumps as well as the station.

MultiSmart_IO_Manual_R20 Page 27 of 260

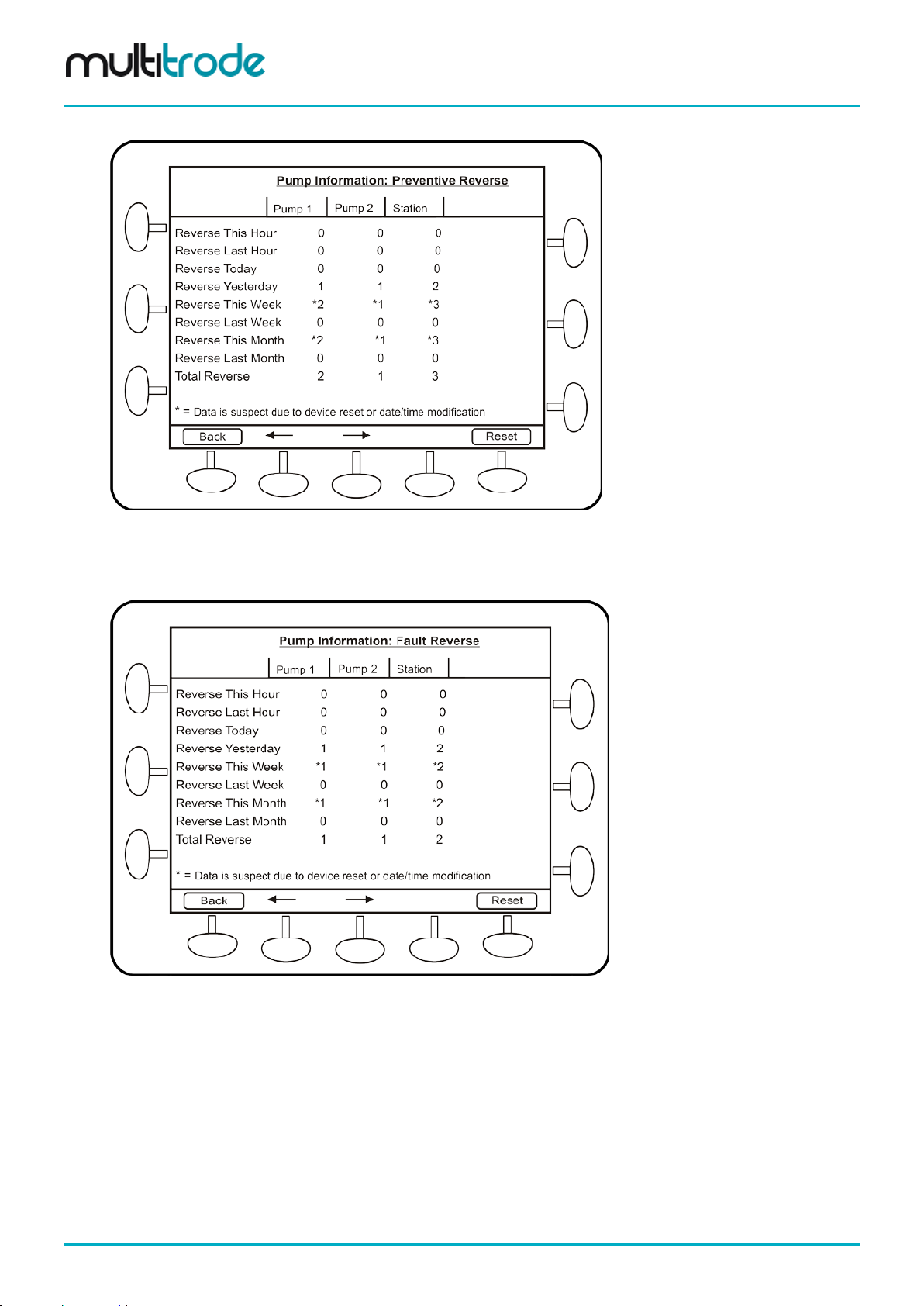

(ii) Preventative Reversals

MultiSmart Installation & Operation Manual

Figure 20 – Pump Preventative Reversal Statistics

This gives the preventative reversals statistics, which is reversals on start/stop.

(iii) Fault Reversals

Figure 21 – Pump Fault Reversal Statistics

This gives the blockage removal reversal statistics (reversals triggered by faults).

Page 28 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

5.4.3.5 Communications The DNP and Modbus master and s lave status and values can be seen from this menu. Vie wing the tag

values in real-time helps with trouble shooting communication errors. If logging is enabled (via the Advanced

menu) and the View Log button is pressed, then the related communications messages are displayed. (If

both DNP and Modbus m asters and slaves are present, a sec ond screen is created to cover al l stats and

values).

Navigate to:

Figure 22 – Communications

5.4.3.6 Browse Database The Browse Database menu option lists all nodes within the r eal-tim e database in the MultiSmart. The t ags

are categorized and group ed into nodes as illustrated below. Each node can co ntain a list of tags as well as

a number of child nodes. This screen allows for the selection and display of the real-time value of a tag.

Navigate to:

Figure 23 – Browse Database

MultiSmart_IO_Manual_R20 Page 29 of 260

MultiSmart Installation & Operation Manual

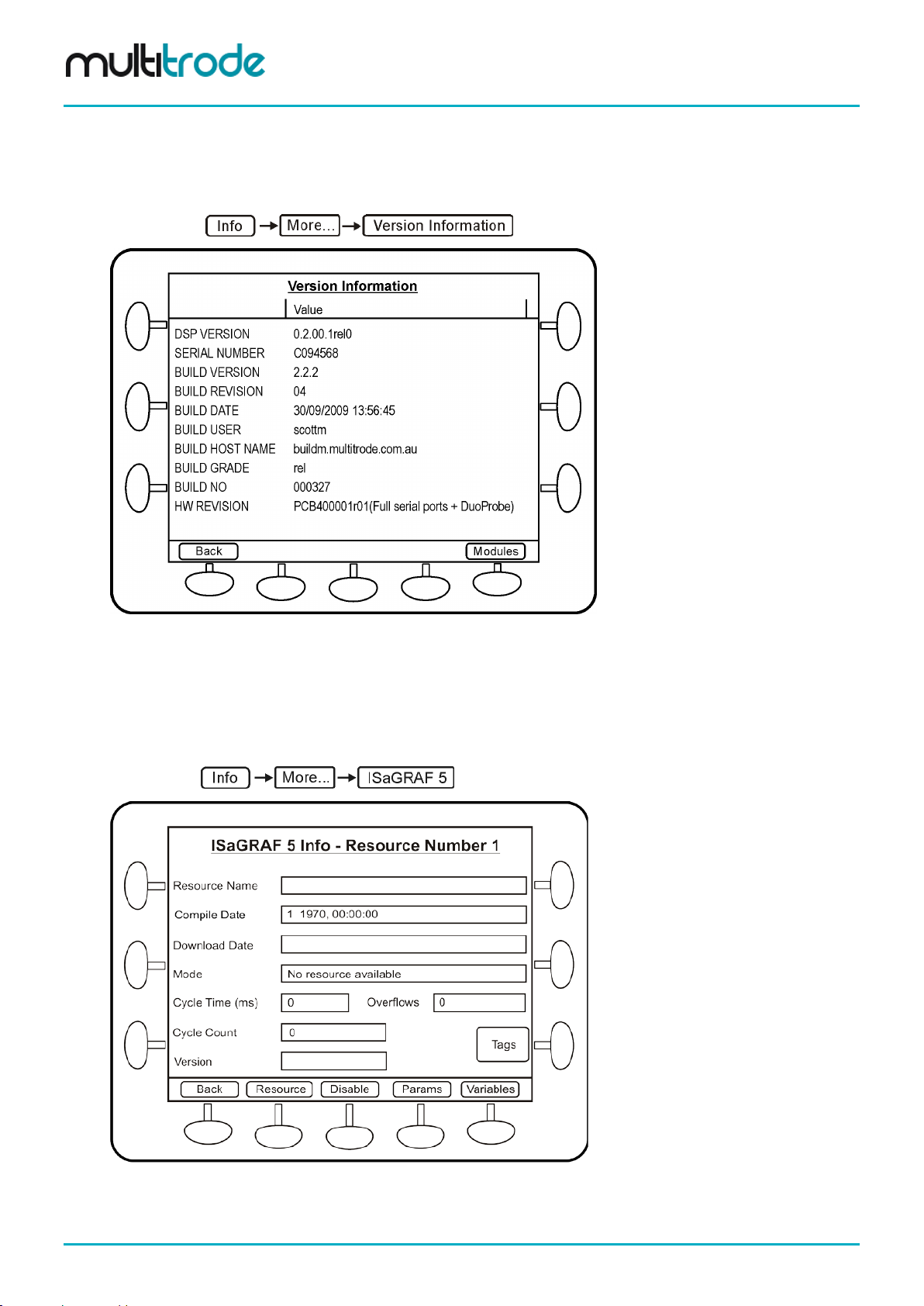

5.4.3.7 Version Information The hardware and soft ware versions and the MultiSm art serial number are displayed in this screen. This

information ma y be requir e d if MultiSmart technical s upport is reques t ed. (The MultiSmar t f irm ware vers ion i s

listed beside the Build Version).

Navigate to:

Figure 24 – Version Information

5.4.3.8 ISaGRAF 5 This screen displays ISaGRAF resource information including compile date, download rate, mode, cycle

time, cycle overf low, cycle count, and tags. Parameters and v ariables can be viewed through th is screen.

Also the value of parameters can be changed from this menu.

Navigate to:

Figure 25 – ISaGRAF Resource Summary Screen

Page 30 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

Pressing Resource cycles to the next “application” and Disable allows the user to stop one or many

ISaGRAF “Resources” from running.

5.4.3.9 System Log System Log displays any system errors with a time stamp.

Navigate to:

Figure 26 – System Log

5.4.4 Settings Screen

Changes to the operation of the MultiSmart unit can be do ne by accessing this m enu. Most of the general

pump station requirements can be configured from the sub-sections under Settings. Howe ver a wide range

of advanced configuration options are also available, and can be accessed and configured through the

Advanced button in the Settings menu.

Figure 27 – Settings Screen

MultiSmart_IO_Manual_R20 Page 31 of 260

MultiSmart Installation & Operation Manual

NOTE:

to bring the new changes into effect immediately.

Some of the settings require a reboot of the MultiSmart unit for it to come into effect after the change,

whereas many others com e into eff ect as s oon as th e c hanges ar e sa ved. If a res tart is r equire d, MultiSmart

prompts the user with two options, Restart Now and Restart Later, as shown in t he figure below.

Figure 28 – Reboot Screen

If Restart Now is selected , the unit saves the current values and reboots immediately before any further

configuration changes can be performed. If further configuration changes are needed, choose Restart

Later.

If Restart Later is selected, the MultiSmart resumes norm al operation, however the new changes do not

come into effect until after a reboot, a nd the restart prompt is no longer dis pl a yed . A fault is displa yed o n th e

main screen to remind the user that a reboot is required.

The restart option in some cases is not displayed. For example, for some major changes like adding a

new DNP slave profile, the MultiSmart skips the restart option prompt and performs an automatic reboot

Page 32 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

gases or powders.

Part 2 – Installation & Commissioning

WARNING:

Do not use this unit in environments that may contain flammable/explosive or chemically aggressive

6 Mounting Instructions

The MultiSmart pum p station manager is mounted o n a standard DIN rail on a panel inside an enclosure.

The operator interface is usually mounted on the (dead) front door of the enclosure. The two units are

connected together with the cable supplied.

6.1 Mounting the Operator Interface Display

The operator interf ace (LCD) is m ounted to the door with 8 x M4 hex head screws (supplied). A 2 5mm (1”)

hole must be cut to ac commodate the cable c onnecting the interface to th e controller. Drilling d imensions

are given below. Note, t his dr a wing is not to scale. (See Appendix B for a mounting template).

MultiSmart_IO_Manual_R20 Page 33 of 260

MultiSmart Installation & Operation Manual

Figure 29 – Mounting the Displ ay

Page 34 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

6.2 Mounting the Pump Station Manager

The pump station manager is designed to mount onto 35mm DIN rail. Overall dimensions are given below.

Figure 30 – Mounting the Controller

6.3 Connecting the Ope rator Interface to the Pump Station Manager

The interface and pum p station manager are connect ed together with a supplied cable. Connect one end

into the RJ45 socket on the back of the interface. Connect the other end into the RJ45 socket marked

DISPLAY on the MultiSmart CPU Board.

Figure 31 – Connecting the display interfa ce

MultiSmart_IO_Manual_R20 Page 35 of 260

MultiSmart Installation & Operation Manual

correctly carried out or if there is fault or damage on the product.

gases or powders.

power cable.

7 MultiSmart Boards

General Precautions

Electrical Hazard:

• A certified electrician must supervise all electrical work. Comply with all local codes

and regulations.

• Before starting work on the unit, make sure that the unit is isolated from the power

WARNING:

Do not use this unit in environments that may contain flammable/explosive or chemically aggressive

Requirements

supply and cannot be energized.

• Make sure that all unused conductors are insulated.

• There is a risk of electrical shock or explosion if the electrical connections are not

These general requirements apply for electrical installation:

• The mains voltage and frequency must agree with the specifications for the product.

• Circuit breakers must be installed between the main voltage line and this unit.

• All fuses and circuit breakers must have the proper rating, and comply with local regulations.

• The cables must be in accordance with the local rules and regulations.

Cables

These are the requirements to follow when you install cables:

• The cables must be in good condition, not have any sharp bends, and not be pinched.

• The sheathing must not be damaged and must not have indentations or be embossed (with

markings, etc.) at the cable entry.

• The minimum bending radius must not be below the accepted value.

Earthing (Grounding)

Electrical Hazard:

•

You must earth (ground) all electrical equipment. This applies to the pump

equipment, the driver, and any monitoring equipment. Test the earth (ground) lead to

verify that it is connected correctly.

• If the power cable is jerked loose by mistake, the earth (ground) conductor should be

the last conductor to come loose from its terminal. Make sure that the earth (ground)

conductor is longer than the phase conductors. This applies to both ends of the

Page 36 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

The MultiSmart pump s tation manager has up to four boards plugged int o it depending on the application.

The most common configuration is shown below.

Pump Control I/O Board (3PC) - The pump control board monitors the single or 3-phase supply and

provides digital and a nalog I/O. Level sensing can b e from a MultiTrode conduc tive probe or any 4-20mA

device (e.g. pressure tr ansducer, ultrason ic device). Pump f aults can be contact closur es or pump specif ic

inputs such as seal , PT C th ermistor or Flygt FLS and CLS. Digital outpu ts dr i ve t he pump contactors. (I/O =

20 x DIN, 2 x AIN, 7 x DOUT, 1 x AOUT)

CPU Board - Houses the microprocessor running the MultiSmart unit, provides two Ethernet ports, two

RS232 ports, two RS485 ports , an iButton (security key) port, c onnects to the displa y, and has SD card and

USB ports.

WARNING:

THE DIGITAL INPUTS ARE VOLT-FREE INPUTS. DO NOT APPLY ANY SOURCING VOLTAGE TO THEM.

DSP Board

This board handles the I/O and communicates between multiple I/O Mod ule modules.

Energy Monitoring and Motor Protection (3MP)

Monitors single or 3-phase motor currents direct from a CT, and provides motor protection and power

monitoring. The board also carries out an automatic 1000VDC insulation resistance test of the motor

windings (I/O = 9 x IIN, 3 x IRT, 3 x AOUT, 5 x DOUT).

Figure 32 – MultiSmart Boards

MultiSmart_IO_Manual_R20 Page 37 of 260

MultiSmart Installation & Operation Manual

20-90% Relative Humidity noncondensing

-40°F ~ 185°F / -40°C~ +85 °C,

(10~95% Relative Humidity)

7.1 Power Suppl y

The MultiSmart pump station manager runs from an external 12 – 24 VDC (+/- 5%) power supply. This

external DC supply is connected to the DSP board as shown below:

Figure 33 – Power Supply

7.1.1 Power Consumption

The MultiSmart unit cons umes up to 30W per unit during initial s tart-up, (inrush current) and 15W per unit

during continuous operation.

7.1.2 Power Supply Requirements

The MultiSmart m ust be used in conjunction with a power supply that m eets or exceeds the specifications

listed in Table 1 – Power Supply Specifications.

NOTE:

To maintain UL compliance of the product, the power supply must also be UL Listed.

OUTPUT

INPUT

ENVIRONMENT

DC Voltage 12 – 24 VDC

Power >30W

Voltage Tolerance + - 2.0%

Line Regulation + - 0.5%

Load Regulation + - 0.5%

Voltage Range 85 ~ 264VAC (120~370VDC)

Frequency Range 47-63Hz

Working Temp 14°F ~ 140°F / -10°C ~ +60°C

Working Humidity

Table 1 – Power Supply Specifications

Page 38 of 260 MultiSmart_IO_Manual_R20

Storage Temp/ Humidity

MultiSmart Installation & Operation Manual

7.2 Default Wiring Setup for Pump Control Board

While many different conf igur atio ns of t he MultiSmart are possible, five comm on configurat io ns ar e illustrated

in this section. These def ault conf igurations c an be a pplied b y completi ng the S etup Wizard in the Settings

menu. After a default c onfiguration has been applied, changes can be made as required. Refer to Section

7.3 for a complete description of the Pump Control I/O Board.

7.2.1 Default 1 – 10 Sensor Probe and 2 Pumps

Figure 34 – Default 1

MultiSmart_IO_Manual_R20 Page 39 of 260

MultiSmart Installation & Operation Manual

7.2.2 Default 2 – 10 Sensor Probe and 3 Pumps

Figure 35 – Default 2

Page 40 of 260 MultiSmart_IO_Manual_R20

MultiSmart Installation & Operation Manual

7.2.3 Default 3 – Analog Level Device and 2 Pumps

Figure 36 – Default 3

MultiSmart_IO_Manual_R20 Page 41 of 260