Page 1

MT56DSU-S

Syncronous 56K bps

Data Service Unit

User Guide

Page 2

MT56DSU-S User Guide

PN: S000327A

Copyright ©2003 by Multi-Tech Systems, Inc.

All rights reserved. This publication may not be reproduced, in whole or in part, without prior written permission from Multi-

Tech Systems, Inc.

Multi-Tech Systems, Inc. makes no representations or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability or fitness for any particular purpose. Furthermore, Multi-Tech

Systems, Inc. reserves the right to revise this publication and to make changes from time to time in the content hereof

without obligation of Multi-Tech Systems, Inc. to notify any person or organization of such revisions or changes.

Revision Date Description

A 12/30/2003 Initial release of MT56DSU-S User Manual on CD.

Trademarks

MultiTech and the MultiTech logo are trademarks of Multi-Tech Systems, Inc. All other references are trademarks of their

respective companies.

Technical Support

France support@multitech.fr +33 1-64 61 09 81

India support@multitechindia.com +91 124 6340778

U.K. support@multitech.co.uk +44 118 959 7774

U.S., Canada support@multitech.com 1 800 972-2439

Rest of World support@multitech.com +763 717-5863

World Headquarters

Multi-Tech Systems, Inc.

2205 Woodale Drive

Mounds View, Minnesota 55112 U.S.A.

(763) 785-3500 or (800) 328-9717

U.S. FAX (763) 785-9874

Technical Support (800) 972-2439

www.multitech.com

Page 3

Content s

Chapter 1 - Introduction..................................................................................... 5

1.1 Introduction ............................................................................................. 6

1.2 About This Manual .................................................................................. 6

1.3 Description ............................................................................................. 7

1.4 CSU/DSU Basics ................................................................................... 7

1.4.1 DSU Functions .....................................................................................7

1.4.2 CSU Functions .....................................................................................7

1.5 Features ................................................................................................. 8

1.6 Specifications ......................................................................................... 9

Chapter 2 - Front & Back Panel Descriptions................................................ 10

2.1 Introduction ........................................................................................... 11

2.2 Front Panel ........................................................................................... 11

2.3 Back Panel ........................................................................................... 12

2.3.1 POWER Connector .............................................................................12

2.3.2 RS232 Connector................................................................................12

2.3.3 LINE Connector ..................................................................................12

2.4 Switch Settings ..................................................................................... 13

2.5 Shunts .................................................................................................. 14

Chapter 3 - Unpacking & Setup....................................................................... 15

3.1 Introduction ........................................................................................... 16

3.2 Unpacking ............................................................................................. 16

3.3 Telecom Safety Warnings..................................................................... 16

3.4 Setup .................................................................................................... 17

3.5 V.35 Shunt ............................................................................................ 18

Chapter 4 - Diagnostics.................................................................................... 19

4.1 Introduction ........................................................................................... 20

4.1.1 Loopback Test....................................................................................20

4.1.2 Line Loopback Test ............................................................................21

4.1.3 DSU Loopback Test............................................................................2 1

4.1.4 DSU Back-to-Back Test .....................................................................2 2

Page 4

Chapter 5 - Service & Warranty....................................................................... 23

5.1 Multi-Tech Systems, Inc. Warranty & Repairs Policies ......................... 24

5.1.1 Warranty .............................................................................................24

5.1.2 U.S. and Canadian Customers............................................................24

5.1.3 International Customers (outside U.S.A. and Canada)........................25

5.1.4 International Distributors.....................................................................25

5.2 Repairs ................................................................................................. 26

5.2.1 Repair Procedures for U.S. and Canadian Customers ........................2 6

5.2.2 Repair Procedures for International Customers...................................26

5.2.3 Repair Procedures for International Distributors.................................. 27

5.2.4 Replacement Parts .............................................................................27

5.3 Technical Support ................................................................................. 27

5.4 Internet Site .......................................................................................... 27

Appendix............................................................................................................ 28

Appendix A - Application Examples ................................................................ 29

Introduction......................................................................................................29

Local Area Data Set Application ......................................................................29

DDS Point-To-Point Application....................................................................... 29

DDS Multipoint (Polled) Application .................................................................3 0

Appendix B - Interface Signals and Connector Pinouts ................................. 31

RJ-48 Connector.............................................................................................. 31

DB25S Connector ............................................................................................32

DB25S Connector with V.35 Interface .............................................................33

Loopback Cable (MTS P/N 45640100)............................................................ 34

Back-To-Back Cable (MTS P/N 45050000).....................................................35

Appendix C - Regulatory Information ............................................................. 36

FCC Regulations for Telephone Line Interconnection ......................................36

Canadian Limitations Notice ............................................................................37

Page 5

Chapter 1 - Introduction

Page 6

Chapter 1 - Introduction

1.1 Introduction

The Multi-Tech Systems MultiDSU, model number MT56DSU-S is a synchronous 56 Kbps data service unit

(DSU). As a combined DSU and Channel Service Unit (CSU), it provides a direct connection to the

DATAPHONE

Equipment (DTE) device to remote equipment using DDS network lines at 56 Kbps speeds for point-to-point

and multi-point service.

®

Digital Service (DDS) network. The MT56DSU-S connects a synchronous Data Terminal

Figure 1-1. MultiDSU Modem

1.2 About This Manual

Chapter 1 - Introduction contains an introduction to the MT56DSU-S product and its features and functions.

Chapter 2 - Front and Rear Panel Descriptions provides front panel LED descriptions and rear panel

connector descriptions, DIP-switch settings, and an RS232/V.35 shunt description.

Chapter 3 - Unpacking and Setup provides unpacking, safety warnings, setup procedures, and how to

change the shunt from the default RS232 position to the V.35 position.

Chapter 4 - Diagnostic Testing explains how to set up and run a diagnostic test.

Chapter 5 - Service and Warranty provides instructions on getting service for your MultiDSU at the factory, a

statement of the limited warranty, information about our user bulletin board service, and space for recording

information about your MultiDSU prior to calling Multi-Tech's Technical Support. The final three sections

explain how to use our bulletin board service (BBS), and get support through CompuServe and the Internet.

Appendix A - Application Examples illustrates several DSU/CSU uses that may help in understanding your

particular installation site.

Appendix B - Interface Signal and Connector Pinouts lists the various electronic signals and connector

pinouts related to the MT56DSU-S.

Appendix C - Regulatory Information

6

Page 7

Chapter 1 - Introduction

1.3 Description

The MT56DSU-S is compact, easy to operate and has the features to allow flexibility in meeting your

transmission requirements. The DDS is a service for transmission of digital signals via digital transmission

facilities exclusively. The MT56DSU-S is designed to meet AT&T Technical Publication 62310 requirements.

As such, the MT56DSU-S provides all the functions required on the customer side of the network.

You will find the MT56DSU-S easy to install, use and maintain. It is recommended that you read the entire

manual early in your experience with the MT56DSU-S so you can appreciate all of the MT56DSU-S features

and options.

1.4 CSU/DSU Basics

A DSU (Data Service Unit) and a CSU (Channel Service Unit) are typically connected to provide the interface

between DTE (data terminal equipment) and a DDS or other four-wire network.

The DSU processes serial synchronous digital data over the DDS network or other four-wire unloaded

twisted-pair network.

The MT56DSU-S contains the functions of a DSU and CSU in a single package.

1.4.1 DSU Functions

The DSU encodes data as pulses on the communications line by converting the customer data stream to

bipolar format for transmission over the digital network.

1.4.2 CSU Functions

The CSU terminates the digital circuit at the customer site. It performs line conditioning functions, ensures

network compliance with FCC rules, and responds to test commands (either from the Telco central office (CO)

or from the DSU).

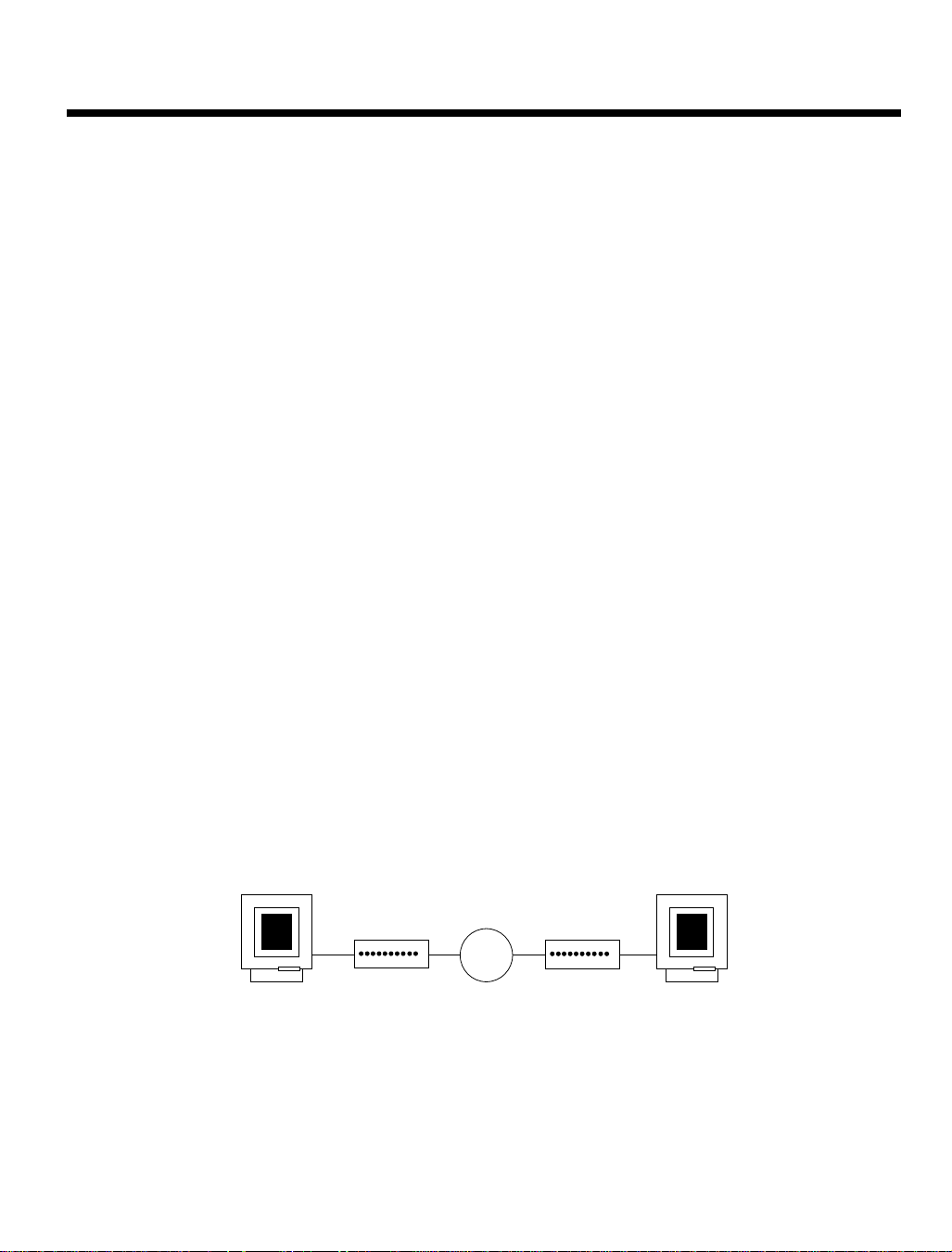

The figure below shows the MT56DSU-S in a basic DDS network installation.

DDS

Network

DTE

Figure 1-2. Basic DSU/CSU Configuration

DSU

DSU

DTE

7

Page 8

Chapter 1 - Introduction

1.5 Features

The MT56DSU-S provides many useful features. Standard features include V.35 and EIA-232-D interfaces on

the data port (DTE device) and a synchronous rate of 56 Kbps on both the data port and trunk, and userselectable clocking option.

Your Multi-Tech DSU/CSU provides the following features:

Supports direct connection to the DATAPHONE Digital Data Service (DDS) or compatible network

Standard EIA-232-D and V.35 interfaces on the data port (DTE device) and DDS interface on the line

• Multiple selectable clocking

- Internal clocking

- DDS (slave) clocking

• Multiple MT56DSU-S-activated diagnostic tests

- Local loopback test

- Digital loopback test

• Multiple Telco-activated diagnostic tests

- DSU loopback test

- CSU loopback test

8

Page 9

1.6 Specifications

Model Number: MT56DSU-S

Device Operation: combined DSU and CSU

Data Rates:

Synchronous 56 Kbps (Data port and line)

Interfaces:

Data (RS232) DB25S (female) - Data port

Data (V.35) DB25S (female) - Data port with an adapter cable

Line (DDS) RJ-48 8-position keyed jack - Line

Power Requirements: 115V AC, 50-60 Hz, 2 Watts

Temperature: 32 to 120° F (0 to 50° C)

Humidity: 20 to 90% (non-condensing)

Dimensions: 1" H x 4.125" W x 5.5" D

2.5 cm H x 10.8 cm W x 14.2 cm D

Weight: 8 oz. (224 g)

Certification: FCC Part 15 Class B

FCC Part 68

UL Listed

Compatibility: AT&T Pubs 62310

FIC Codes: 04DU5-56

USOC Jack: RJ-48S

Transmitter/Receiver:

Modulation bipolar return to zero (BRZ)

Transmit Level 1.4V peak (+6dBm) into 135 Ohm at 56 Kbps

Output Impedance 135 ohms

Receive Levels +6 to -45 dBm

Input Impedance 135 ohms

Delay Times (in secs.)

RTS/CTS DCD on DCD off

0.4 0.3 0.2

Chapter 1 - Introduction

9

Page 10

Chapter 2 - Front & Back

Panel Descriptions

Page 11

Chapter 2 - Front & Back Panel Descriptions

2.1 Introduction

This chapter describes the front panel LEDs and back panel connectors. The front panel has one row of

LEDs. Two back panel connectors provide the data and DDS or LADS connections. A circular power

connector is provided to connect the external power supply.

2. 2 Front Panel

The front panel has five LEDs that provide the status of the line. The V35 LED lights if V.35 interface signaling

is used. The line LEDs display status whether the line is transmitting or receiving frames, and line status.

Figure 2-1. Front Panel

TD Transmit Data (TD) LED blinks when data is being transmitted - on for a space and

off for a mark.

RD Receive Data (RD) LED blinks when data is being

received - on for a space and off for a mark.

V35 The V35 LED lights when the shunt is in the V35 position.

NS The No Signal (NS) LED lights when no signal is received from the network or when

the signal is too weak for normal operation.

OOS The Out Of Service (OOS) LED lights when an outage condition occurs. This

happens when there is a failure in the digital service that is detected by the network

and the Telco sends a repetitive OOS sequence.

CD The Carrier Detect (CD) LED lights when a carrier signal is received from the

network.

11

Page 12

Chapter 2 - Front & Back Panel Descriptions

2.3 Back Panel

All the cable connections, including one power connection and two signal connections, are made at the back

panel of the DSU. The RS232 connector is used to connect the DSU to an RS232 or V.35 device, and the

LINE connector connects to a DDS or LADS (Local Area Data Set) circuit. The cable connections are shown

in Figure 2-2 and defined in the following sections.

POWER

Figure 2-2. Back Panel

RS232

LINE

2.3.1 POWER Connector

The POWER connector is used to connect the external wall type transformer power supply to the DSU. The

wall transformer plugs directly into an AC outlet.

2.3.2 RS232 Connector

The RS232 (Data) connector is used to connect the DSU to a sync device, such as, multiplexers, routers, or

legacy equipment such as cluster controllers. The RS232 connector is a DB-25 female connector located on

the back panel of the DSU.

The RS232 data connector interface can be switched to a V.35 interface. For the V.35 interface, an internal

data shunt has to be moved from the default RS232 position to the V.35 position. To change the shunt, refer

to the "Shunt" paragraph in this chapter. Also refer to Appendix A for special cabling requirements for the

V.35 mode.

2.3.3 LINE Connector

The LINE connector is used to connect the DSU to a 56K DDS circuit or LADS. This connector is an RJ-48

(keyed) jack on the back panel of the unit.

12

Page 13

Chapter 2 - Front & Back Panel Descriptions

2.4 Switch Settings

An 8-position DIP switch is located on the right side of the MT56DSU-S printed circuit board (when viewed

from the front, as in Figure 2-3). The DIP switch functions are described in the following table.

1 2 3 4 5 6 7 8

DIP-Switch

Figure 2-3. Switch Settings

Table 2-1. Switch Settings

Switch Mode Position Description

1 Reset UP* Normal

DOWN Reset

2 Clocking UP* DDS

DOWN Internal

3 Loopback UP* Normal

DOWN Loopback

4-8 Not Used

*Factory default setting

13

Page 14

Chapter 2 - Front & Back Panel Descriptions

2.5 Shunts

V.35 signal levels are more reliable for high speed data and/or longer cable distances. For higher speeds

and/or longer distances, V.35 is preferred. EIA-232-D signal levels are intended for data rates of 19.2 Kbps or

less and cable lengths of 50 feet or less.

There are two shunt positions in the middle left side of the printed circuit board that configure the data port for

either RS232 or V.35 operation. The shunt positions are shown in Figure 2-3.

V.35 Shunt Position

The shunt position closest to the DIP switches is for RS232 data interface and the other one is for V.35 data

interface. The shunt is shown in the RS232 (default) position in Figure 2-3. To change the position of a

shunt, refer to the V.35 Shunt in Chapter 3.

RS232 Shunt Position

Figure 2-3. Shunts

14

Page 15

Chapter 3 - Unpacking & Setup

Page 16

Chapter 3 - Unpacking & Setup

3.1 Introduction

This chapter describes the unpacking of the DSU, cable connections depending on whether EIA-232-D or

ITU-T V.35 interface signaling is used on the data port, and how to configure the unit dependent on your site

situation. Once the DSU is configured, then the data port can be connected to your data device.

3.2 Unpacking

The shipping box contains the DSU, power adapter, and a documentation CD with a User's Guide. Inspect

the contents for signs of any shipping damage. If damage is observed, do not power up the unit, contact

Multi-Tech's Technical Support for advice (refer to Chapter 5 - Warranty). If no damage is observed, place

the DSU in its final location and verify the signal levels (EIA-232-D or ITU-T V.35) for the data port, and

connect your cables, phone lines, and power supply.

3.3 Telecom Safety Warnings

1. Never install telephone wiring during a lightning storm.

2. Never install telephone jacks in wet locations unless the jack is specifically designed for wet locations.

3. This product for use with UL and cUL listed computers.

4. Never touch uninsulated telephone wires or terminals unless the telephone line has been disconnected

at the network interface.

5. Use caution when installing or modifying telephone lines.

6. Avoid using a telephone (other than a cordless type) during an electrical storm. There may be a remote

risk of electrical shock from lightning.

7. Do not use the telephone to report a gas leak in the vicinity of the leak.

8. To reduce the risk of fire, use only 26AWG or larger telecommunications cord.

16

Page 17

Chapter 3 - Unpacking & Setup

3.4 Setup

Perform the following procedure to connect your cables and, if necessary, change to V.35 signaling on the

data port.

1. If the DTE device has a V.35 interface, the internal shunt must be moved to the V.35 position and a V.35

adapter cable must be connected to the data connector (labeled “RS232”). Refer to V.35 Shunt for

procedures on moving the shunt to the V.35 position. Refer to Appendix A for cable details.

If the DTE device has an EIA-232-D interface, a standard RS232 (straight-thru) cable can be used.

POWER

RS232

LINE

To DTE Device

To Power Outlet

To Line Jack

Figure 3-1. Back Panel Connections

2. Connect the external wall transformer power supply to the DSU, then plug the power supply into a live

AC outlet. The DSU has no power switch; however, when power is applied to the unit, the front panel

LEDs will light.

3. Connect the DTE device to the RS232 connector on the back of the DSU.

4. Connect an RJ-48 phone cable to the LINE connector on the back of the DSU. Connect the other end of

the phone cable to the local access line jack.

17

Page 18

Chapter 3 - Unpacking & Setup

3.5 V.35 Shunt

Either EIA-232-D or ITU-T V.35 electrical signal interface can be selected on the Data connector. Units are

shipped with EIA-232-D signal levels selected. Use the following procedure to select V.35.

CAUTION : This procedure requires opening the unit. Like most products of this type, this product contains

components that are sensitive to static and static discharge. Use your best efforts to avoid static discharge

when contacting the components inside this unit.

WARNING: Always disconnect the power cord before opening the enclosure to avoid any chance of electric

shock.

1. Unplug the power cord.

2. The enclosure consists of two halves. Using a Phillips screwdriver, remove the two screws from the

bottom of the unit. Remove the top half.

3. Carefully pry the shunt out of its RS232 socket and insert it into the V.35 socket.

V.35 Shunt Position

4. Carefully reassemble the unit, making sure no foreign objects are accidentally left inside.

5. The DSU is now configured for V.35 signal levels. To connect to a device with a 34-pin Winchester

female V.35 connector, use an adapter cable with a 25-pin female connector at one end and a 34-pin

Winchester male connector at the other end. Using the signal pin designations in Appendix A, you can

make or order a cable from most any cable vendor.

RS232 Shunt Position

Figure 3-2. Shunts

18

Page 19

Chapter 4 - Diagnostics

Page 20

Chapter 4 - Diagnostics

4.1 Introduction

The DSU is set to a default of Normal (non-diagnostic) mode at the factory. When diagnostics are to be run,

change the Loopback DIP switch as described in Chapter 2 of this manual.

When a failure occurs in the digital facility (Telco equipment), the network will detect the failure and send a

repetitive OOS signal sequence to your equipment. Your equipment can detect local loop failure by the

absence or distortion of the digital signal. If an OOS is received when data is expected, check the remote (farend) transmitting equipment. If the remote equipment is transmitting properly, contact your telephone

company. If the Telco is required to perform remote tests, the channel will be temporarily interrupted and loss

of data may occur.

The following sections describe the tests that are available for the DSU.

4.1.1 Loopback Test

This test allows you to test the local DTE and local DSU. Use the following steps to perform the Loopback

Test.

1. Set DIP switch #3 to the down position.

2. Send data from your DTE, it should be “looped back” to your DTE. If you have access to a Bit Error Rate

Tester, this can be used in place of the DTE.

DTE

(Or BERT Tester)

Figure 4-1. Loopback Test Diagram

Local DSU

(In Loopback Test Mode)

20

Page 21

Chapter 4 - Diagnostics

4.1.2 Line Loopback Test

This test enables you to test the local DTE, the local DSU, the communications link, and the remote DSU. Use

the following steps to perform the Trunk Loopback Test.

1. Set DIP switch #3 on the remote DSU to the down position.

2. Send data from the local DTE, it should be looped back to the local DTE. If you have access to a Bit Error

Rate Tester, this can be used in place of the local DTE.

Network

Local DTE

(or BERT Tester)

Local DSU

Remote DSU

(In Line Loopback Test Mode)

Figure 4-2. Line Loopback Test Diagram

4.1.3 DSU Loopback Test

This test lets you verify proper DSU operation by matching a transmitted signal to the “looped-back” receive

signal. Refer to Appendix B for cable description.

1. Obtain a DSU Loopback cable (#45640100) from Multi-Tech, or assemble one. Refer to Appendix B for

instructions on building the Loopback cable.

2. Plug the Loopback cable into the back panel Line jack.

3. Send data from your DTE, it should be “looped back” to your DTE. If you have access to a Bit Error Rate

Tester, this can be used in place of the DTE.

Loopback

DTE

Figure 4-3. DSU Loopback Test

DSU

being tested

Cable

21

Page 22

Chapter 4 - Diagnostics

4.1.4 DSU Back-to-Back Test

This test lets you connect two DSUs with a back-to-back cable to verify proper DSU operation. Using a DSU

that is known to be operational, you can test a second DSU that is suspect.

1. Obtain a DSU Back-to-Back cable (#45050000) from Multi-Tech, or assemble one. Refer to Appendix B

for instructions on building the Back-to-Back cable.

2. Plug the cable into each DSU’s Line jack.

3. On the “good” DSU, set DIP switch #3 to the down position.

4. Set one DSU to internal clocking and the other DSU to DDS clocking.

5. Send data from your DTE, it should be “looped back” to your DTE. If you have access to a Bit Error Rate

Tester, this can be used in place of the DTE.

DTE

“Suspect”

DSU

Back-to-Back

Cable

Figure 4-4. DSU Back-to-Back Test Diagram

“Good” DSU in

Loopback Mode

22

Page 23

Chapter 5 - Service & Warranty

Page 24

Chapter 5 - Service & Warranty

5. 1 Multi-Tech Systems, Inc. Warranty & Repairs Policies

5.1.1 Warranty

Multi-Tech Systems, Inc., (hereafter “MTS”) warrants that its products will be free from defects in material or

workmanship for a period of two, five, or ten years (depending on model) from date of purchase, or if proof of

purchase is not provided, two, five, or ten years (depending on model) from date of shipment.

MTS MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

This warranty does not apply to any products which have been damaged by lightning storms, water, or power

surges or which have been neglected, altered, abused, used for a purpose other than the one for which they

were manufactured, repaired by Customer or any party without MTS’s written authorization, or used in any

manner inconsistent with MTS’s instructions.

MTS’s entire obligation under this warranty shall be limited (at MTS’s option) to repair or replacement of any

products which prove to be defective within the warranty period or, at MTS’s option, issuance of a refund of

the purchase price. Defective products must be returned by Customer to MTS’s factory – transportation

prepaid.

MTS WILL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES, AND UNDER NO CIRCUMSTANCES WILL

ITS LIABILITY EXCEED THE PRICE FOR DEFECTIVE PRODUCTS.

5.1.2 U.S. and Canadian Customers

In the event that service is required, products may be shipped, freight prepaid, to our Mounds View,

Minnesota, factory:

Multi-Tech Systems, Inc.

2205 Woodale Drive

Mounds View, MN 55112

Attn: Repairs, Serial #______

A Returned Materials Authorization (RMA) is not required. Return shipping charges (surface) will be paid by

MTS. Please include inside the shipping box a description of the problem, a return shipping address (must

have street address, not P.O. Box), a telephone number, and if the product is out of warranty, a check or

purchase order for repair charges.

For out of warranty repair charges, go to: www.multitech.com. Extended two-year overnight replacement

agreements are available for selected products. Please call MTS at 888 288-5470, extension 5308, or visit

our web site at www.multitech.com for details on rates and coverages.

Please direct your questions regarding technical matters, product configuration, verification that the product

is defective, etc., to our Technical Support department at 800 972-2439 or e-mail tsupport@multitech.com.

Please direct your questions regarding repair expediting, receiving, shipping, billing, etc., to our Repair

Accounting department at 800 328-9717 or +763 785-3500, or e-mail mtsrepair@multitech.com.

Repairs for damages caused by lightning storms, water, power surges, incorrect installation, physical abuse,

or user-caused damages are billed on a time-plus-materials basis.

24

Page 25

Chapter 5 - Service & Warranty

5.1.3 International Customers (outside U.S.A. and Canada)

Your original point of purchase reseller may offer the quickest and most economical repair option for your

Multi-Tech product. You may also contact any Multi-Tech sales office for information about the nearest

distributor or other repair service for your Multi-Tech product: www.multitech.com.

In the event that factory service is required, products may be shipped, freight prepaid, to our Mounds View,

Minnesota, factory. Recommended international shipment methods are via Federal Express, UPS or DHL

courier services, or by airmail parcel post; shipments made by any other method will be refused. A Returned

Materials Authorization (RMA) is required for products shipped from outside the U.S.A. and Canada. Please

contact us for return authorization and shipping instructions on any international shipments to the U.S.A.

Please include inside the shipping box a description of the problem, a return shipping address (must have

street address, not P.O. Box), your telephone number, and if the product is out of warranty, a check drawn on

a U.S. bank or your company’s purchase order for repair charges. Repaired units will be shipped freight

collect, unless other arrangements are made in advance.

Please direct questions regarding technical matters, product configuration, verification that the product is

defective, etc., to our Technical Support department nearest you, as listed at http://www.multitech.com/

COMPANY/offices/DEFAULT.ASP., or e-mail tsupport@multitech.com. When calling the U.S., please direct

questions regarding repair expediting, receiving, shipping, billing, etc., to our Repair Accounting department

at +763 717-5631 in the U.S.A., or e-mail mtsrepair@multitech.com.

Repairs for damages caused by lightning storms, water, power surges, incorrect installation, physical abuse,

or user-caused damages are billed on a time-plus-materials basis.

5.1.4 International Distributors

Procedures for international distributors of Multi-Tech products are on the Distributor Web site at http://

www.multitech.com/PARTNERS/login/.

25

Page 26

Chapter 5 - Service & Warranty

5.2 Repairs

5.2.1 Repair Procedures for U.S. and Canadian Customers

In the event that service is required, products may be shipped, freight prepaid, to our Mounds View,

Minnesota factory:

Multi-Tech Systems, Inc.

2205 Woodale Drive

Mounds View, MN 55112

Attn: Repairs, Serial # ____________

A Returned Materials Authorization (RMA) is not required. Return shipping charges (surface) will be paid by

MTS. Please include, inside the shipping box, a description of the problem, a return shipping address (must

have street address, not P.O. Box), your telephone number, and if the product is out of warranty, a check or

purchase order for repair charges. For out of warranty repair charges, go to

Extended two-year overnight replacement service agreements are available for selected products. Please

call MTS at (888) 288-5470, extension 5308 or visit our web site at: www.multitech.com for details on rates

and coverages.

Please direct your questions regarding technical matters, product configuration, verification that the product

is defective, etc., to our Technical Support department at (800) 972-2439 or email

Please direct your questions regarding repair expediting, receiving, shipping, billing, etc., to our Repair

Accounting department at (800) 328-9717 or (763) 717-5631, or email mtsrepair@multitech.com.

www.multitech.com

tsupport@multitech.com.

Repairs for damages caused by lightning storms, water, power surges, incorrect installation, physical abuse,

or user-caused damages are billed on a time-plus-materials basis.

5.2.2 Repair Procedures for International Customers

Your original point of purchase Reseller may offer the quickest and most economical repair option for your

Multi-Tech product. You may also contact any Multi-Tech sales office for information about the nearest

distributor or other repair service for your Multi-Tech product. Visit our website at: www.multitech.com

In the event that factory service is required, products may be shipped, freight prepaid to our Mounds View,

Minnesota factory. Recommended international shipment methods are via Federal Express, UPS or DHL

courier services, or by airmail parcel post; shipments made by any other method will be refused. A Returned

Materials Authorization (RMA) is required for products shipped from outside the U.S.A. and Canada. Please

contact us for return authorization and shipping instructions on any International shipments to the U.S.A.

Please include, inside the shipping box, a description of the problem, a return shipping address (must have

street address, not P.O. Box), your telephone number, and if the product is out of warranty, a check drawn on

a U.S. bank or your company’s purchase order for repair charges. Repaired units shall be shipped freight

collect, unless other arrangements are made in advance.

Please direct your questions regarding technical matters, product configuration, verification that the product

is defective, etc., to our Technical Support department nearest you or email

calling the U.S., please direct your questions regarding repair expediting, receiving, shipping, billing, etc., to

our Repair Accounting department at: +(763) 717-5631 in the U.S.A., or email mtsrepair@multitech.com.

tsupport@multitech.com. When

26

Page 27

Chapter 5 - Service & Warranty

Repairs for damages caused by lightning storms, water, power surges, incorrect installation, physical abuse,

or user-caused damages are billed on a time-plus-materials basis.

5.2.3 Repair Procedures for International Distributors

Procedures for International Distributors of Multi-Tech products are on the distributor web site:

www.multitech.com

5.2.4 Replacement Parts

SupplyNet, Inc., can supply you with replacement power supplies, cables and connectors for selected MultiTech products. You can place an order with SupplyNet via mail, phone, fax or the Internet at the following

addresses:

Mail: SupplyNet, Inc.

614 Corporate Way

Valley Cottage, NY 10989

Phone: 800 826-0279

Fax: 914 267-2420

Email: info@thesupplynet.com

Internet: http://www.thesupplynet.com

5.3 Technical Support

Multi-Tech Systems has an excellent staff of technical support personnel available to help you get the most

out of your Multi-Tech product. If you have any questions about the operation of this unit, please call 800 9722439 (USA and Canada) or 763 785-3500 (international and local). Please have modem information

available. You can also contact Technical Support by e-mail at the following addresses:

Country Email Telephone

U.S.A., Canada tsupport@multitech.com 800 972-2439

France: support@multitech.fr +(33) 1-64 61 09 81

India: support@multitechindia.com +91 (124) 6340778

U.K.: support@multitech.co.uk +(44) 118 959 7774

Rest of world: tsupport@multitech.com +763 717-5863

Please note the status of the modem before contacting Technical Support. Status information can include the

state of the LED indicators, screen messages, diagnostic test results, problems with a specific application,

etc.

5. 4 Internet Site

Multi-Tech is a commercial provider on the Internet. Multi-Tech has a Web site at: www.multitech.com.

27

Page 28

Appendix

Page 29

Appendix

Appendix A - Application Examples

Introduction

This section illustrates several types of applications in which the MT56DSU-S is typically used. These types

include:

Local Area Data Set

DDS point-to-point application

DDS multipoint (polled) application

Local Area Data Set Application

In this application, two pairs of wires provide the connection between two MT56DSU-S devices. The two pairs

can be up to the equivalent of 3 miles of AWG #26 wire at 56 Kbps, or longer for subrate applications.

The figure below depicts a typical Local Area Data Set application.

Up to 3 miles

of AWG 26 wire

@ 56 Kbps

DTE

DSU

(Requires two pairs

of interconnection wires)

DSU

DTE

Figure A-1. Local Area Data Set Application

DDS Point-To-Point Application

In this application, the MT56DSU-S provides the interface between the DDS line and the DTE at your site.

Your network provider will provide (at your request) a DDS line connecting the desired locations. The figure

below depicts a sample DDS Point-to-point application.

DDS

Network

DTE

DSU

DSU

Figure A-2. DDS Point-to-Point Application

DTE

29

Page 30

Appendix

DDS Multipoint (Polled) Application

Since your Central Office (CO) equipment must include “Multipoint Junction Units” (MJUs) and other special

arrangements for this type of service, you may need to coordinate efforts with your network service provider.

The MT56DSU-S at the host end is the Master Station (also called the “Control Station”), which typically has

RTS forced on. The attached MT56DSU-Ss are called “Remote stations” and have RTS controlled by the

DTE.

Multipoint DDS provides communication between a control station and two or more remote stations. All data

transmitted by the control station is sent to each remote station. For data transmitted from the remote stations,

the MJUs combine bit streams from the remote stations into a single, serial bit stream sent to the control

station.

The figure below shows a typical Multipoint (Polled) application.

DSU

(“Master Station”)

Host with

Database

Application

DDS Network

with

Multipoint

DTE

DTE

DSU

(“Remote Station”)

DSU

(“Remote Station”)

Equipment

DSU

(“Remote Station”)

DSU

(“Remote Station”)

DTE

DTE

Figure A-3. DDS Multipoint (Polled) Application

30

Page 31

Appendix B - Interface Signals and Connector Pinouts

RJ-48 Connector

Appendix

Pin 1

As viewed from the rear

Figure B-1. Connector

DESCRIPTION

This connector ties the MT56DSU-S to the DDS Network. The RJ-48 connector is keyed for proper insertion

of a keyed RJ-48 plug.

PIN IDENTIFICATION

Pin Description Destination

1 Transmit Pair To Line

2 Transmit pair To Line

3 N/C

4 N/C

5 N/C

6 N/C

7 Receive Pair From Line

8 Receive Pair From Line

Pin 8

Key

31

Page 32

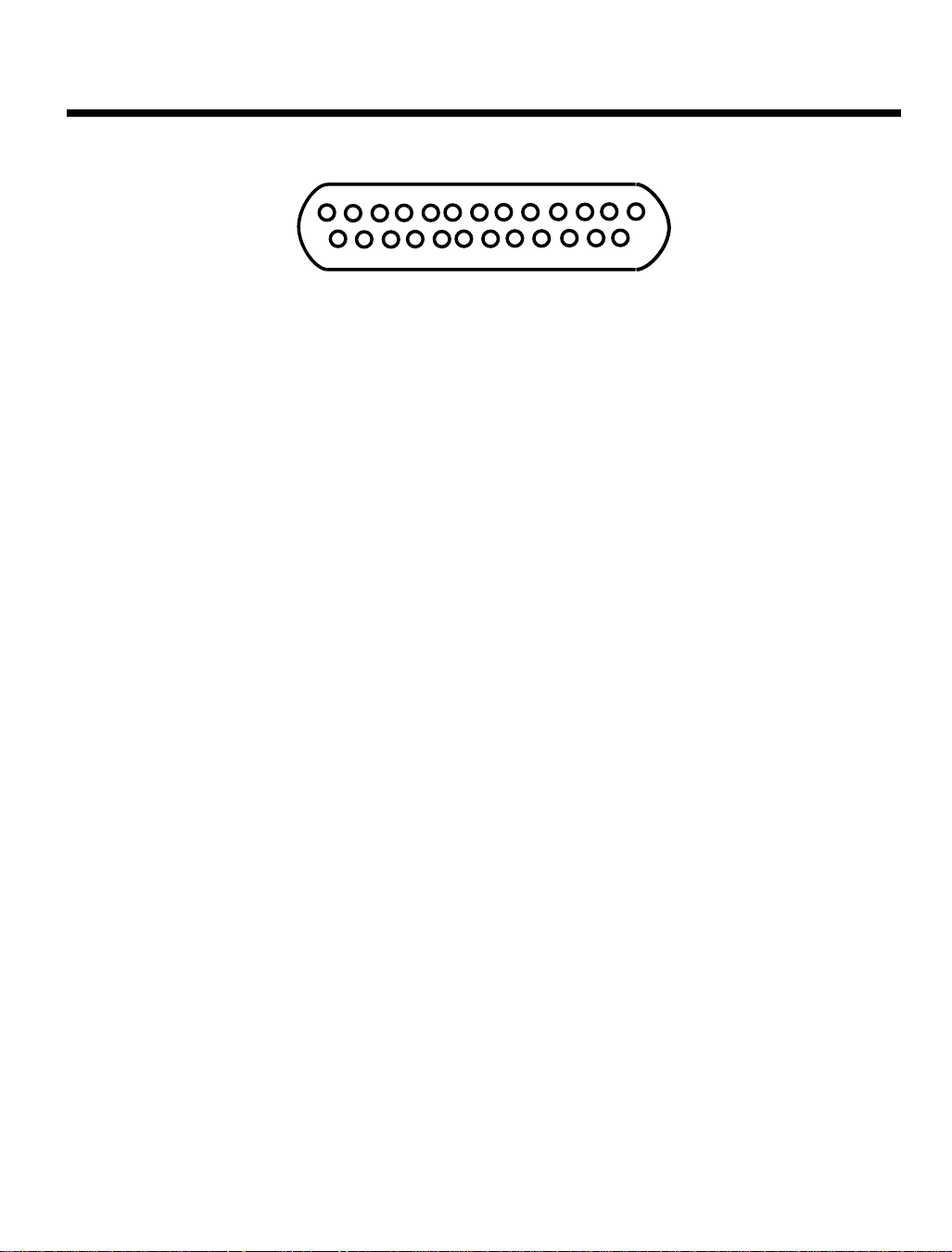

DB25S Connector

13 12 11 10 9 8 7 6 5 4 3 2 1

25 24 23 22 21 20 19 18 17 16 15 14

Figure B-2. Connector

DESCRIPTION

This connector ties the MT56DSU-S to the DTE. The DB25S connector has the following pinout

configuration.

PIN IDENTIFICATION

Pin Description Signal

1 Chassis Ground

2 Transmit Data SD

3 Received Data RD

4 Request To Send RTS

5 Clear To Send CTS

6 Data Set Ready DSR

7 Signal Ground SG

8 Carrier Detect CD

15 Transmit Clock TC

17 Receive Clock RC

20 Data Terminal Ready DTR

Appendix

32

Page 33

Appendix

DB25S Connector with V.35 Interface

13 12 11 10 9 8 7 6 5 4 3 2 1

25 24 23 22 21 20 19 18 17 16 15 14

Figure B-3. Connector

DESCRIPTION

The DB25 connector also ties the MT56DSU-S to a DTE with a V.35 interface. When a V.35 interface device

is connected to a MT56DSU-S, the internal shunt has to be moved to the V.35 position. The V.35 interface for

the DB25 connector has the following pinout configuration.

PIN IDENTIFICATION

Pin Description

1 Chassis Ground

7 Signal Ground

4 Request To Send

5 Clear To Send

6 Data Set Ready

8 Carrier Detect

20 Data Terminal Ready

2 Transmit Data (A)

12 Transmit Data (B)

3 Receive Data (A)

22 Receive Data (B)

15 Transmit Clock (A)

21 Transmit Clock (B)

17 Receive Clock (A)

18 Receive Clock (B)

33

Page 34

Appendix

Loopback Cable (MTS P/N 45640100)

1

8

Figure B-5. Loopback Cable Connector

DESCRIPTION

This cable lets you test the MT56DSU-S when a second DSU is not available. When the DSU generates a

signal, this cable “loops” the signal back to the DSU for comparison to the original signal sent. You can

order this cable (#45640100) from Multi-Tech, or build one using the instructions below. Refer to Chapter 4

for test procedures.

SCHEMATIC

TRANSMIT

1

TRANSMIT

2

3

4

RJ48S

5

6

RECEIVE

7

RECEIVE

8

6"

Figure B-6.

BUILD INSTRUCTIONS

1. Strip cable insulation 3/4"

2. Cut wires 3, 4, 5, 6 off.

3. Strip wires 1, 2, 7, 8 1/4"

4. Solder wires 1 and 8 together.

5. Solder wires 2 and 7 together.

6. Cover solder connections with 1" of shrink tube.

34

Page 35

Appendix

Back-To-Back Cable (MTS P/N 45050000)

1

8

Figure B-7. Back-toBack Cable Connector

DESCRIPTION

This cable lets you test a suspect DSU by connecting it to a known good DSU. It tests the suspect DSU by

connecting its Transmit signal to the Receive circuits of the good DSU. You can order this cable from MultiTech (#45050000), or build one using the instructions below. Refer to Chapter 4 for test procedures.

SCHEMATIC

8

7

6

5

4

3

2

1

RJ48S

RJ48S

1

2

3

4

5

6

7

8

7"

Figure B-8.

BUILD INSTRUCTIONS

1. Strip cable installation 3/4".

2. Strip wires 1,2,7 and 8 on one end of cable and 8,7,2 and 1 on other end 1/4".

3. Cut unstripped wires off.

4. Solder wire 1 on one connector to 8 on the other.

5. Solder wire 2 on one connector to 7 on the other.

6. Solder wire 7 on one connector to 2 on the other.

7. Solder wire 8 on one connector to 1 on the other.

8. Cover solder connections with 1" of shrink tube.

35

Page 36

Appendix

Appendix C - Regulatory Information

FCC Regulations for Telephone Line Interconnection

1. This equipment complies with Part 68 of the FCC rules. On the outside surface of this equipment is a

label that contains, among other information, the FCC registration number and ringer equivalence

number (REN). If requested, this information must be provided to the telephone company.

2. As indicated below, the suitable jack (USOC) connecting arrangement for this equipment is shown in

Appendix B. If applicable, the facility interface codes (FIC) and service order codes (SOC) are also

indicated.

3. The ringer equivalence number (REN) is used to determine the quantity of devices which may be

connected to the telephone line. Excessive REN’s on the telephone line may result in the devices not

ringing in response to an incoming call. In most, but not all areas, the sum of the REN’s should not

exceed five (5.0). To be certain of the number of devices that may be connected to the line, as

determined by the total REN’s, contact the telephone company to determine the maximum REN for the

calling area.

4. If this equipment causes harm to the telephone network, the telephone company will notify you in

advance. But if advance notice isn’t practical, the telephone company will notify the customer as soon as

possible. Also, you will be advised of your right to file a complaint with the FCC if you believe it is

necessary.

5. The telephone company may make changes in its facilities, equipment, operations, or procedures that

could affect the operation of the equipment. If this happens, the telephone company will provide advance

notice in order for you to make necessary modifications in order to maintain uninterrupted service.

6. If trouble is experienced with this equipment (the model of which is indicated below) please contact

Multi-Tech Systems, Inc. at the address shown below for details of how to have repairs made. If the

trouble is causing harm to the telephone network, the telephone company may request you remove the

equipment from the network until the problem is resolved.

7. No repairs are to be made by you. Repairs are to be made only by Multi-Tech Systems or its licensees.

Unauthorized repairs void registration and warranty.

8. This equipment cannot be connected to public coin service provided by the telephone company.

(Contact the state public utility commission, public service commission or corporation commission for

information.)

Manufacturer: Multi-Tech Systems, Inc.

Model Number: MT56DSU-S

FCC Pt 68 Registration #: AU7USA-24704-XD-N

Ringer Equivalence: N/A

SOC Codes: 6.0N

Modular jack (USOC): RJ-48S

Service Center in U.S.A.: Multi-Tech Systems, Inc.

2205 Woodale Drive

Mounds View, MN 55112 USA

(763) 785-3500 or (800) 328-9717

U.S. Fax (763) 785-9874

36

Page 37

Appendix

Canadian Limitations Notice

Notice: The ringer equivalence number (REN) assigned to each terminal device provides an indication of the

maximum number of terminals allowed to be connected to a telephone interface. The termination of a

interface may consist of any combination of devices subject only to the requirement that the sum of the ringer

equivalence numbers of all the devices does not exceed 5.

Notice: The Industry Canada label identifies certificated equipment. This certification means that the

equipment meets certain telecommunications network protective, operational and safety requirements. The

Industry Canada does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of

the local telecommunications company. The equipment must also be installed using an acceptable method of

connection. The customer should be aware that compliance with the above conditions may not prevent

degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated

by the supplier. Any repairs or alterations made by the user to this equipment, or equipment malfunctions,

may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility,

telephone lines and internal metallic water pipe system, if present, are connected together. This precaution

may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact the appropriate

electric inspection authority, or electrician, as appropriate.

37

Page 38

S000327A

Loading...

Loading...