Page 1

User’s Guide

Page 2

Page 3

Notices

For further assistance

please contact us at:

Worldwide Headquarters

2195 Keating Cross Road

Saanichton, BC

Canada V8M 2A5

Tel: 1-250-652-7100

Fax: 1-250-652-0411

Email: support@pwrm.com

www.pwrm.com

© 2003 Power Measurement

Printed in Canada

Revision Date: May 9, 2003

70000-0176-01

Danger

This symbol indicates the presence of dangerous voltage within and

outside the product enclosure that may constitute a risk of electric

shock, serious injury or death to persons if proper precautions are not

followed.

Caution

This symbol alerts the user to the presence of hazards that may cause

minor or moderate injury to persons, damage to property or damage

to the device itself, if proper precautions are not followed.

Note

This symbol directs the user’s attention to important installation,

operating and maintenance instructions.

Installation Considerations

Installation and maintenance of the ION 7500 / ION 7600 meter should only be

performed by qualified, competent personnel that have appropriate training and

experience with high voltage and current devices. The meter must be installed in

accordance with all Local and National Electrical Codes.

DANGER

Failure to observe the following instructions may result in severe injury or death.

During normal operation of the ION 7500 / ION 7600 meter, hazardous voltages

are present on its terminal strips, and throughout the connected potential

transformer (PT), current transformer (CT), digital (status) input, control power

and external I/O circuits. PT and CT secondary circuits are capable of generating

lethal voltages and currents with their primary circuit energized. Follow

standard safety precautions while performing any installation or service work

(i.e. removing PT fuses, shorting CT secondaries, etc).

The terminal strips on the meter base should not be user-accessible after

installation.

Do not use digital output devices for primary protection functions. These

include applications where the devices perform energy limiting functions or

provide protection of people from injury. Do not use the ION 7500 / ION 7600 in

situations where failure of the devices can cause injury or death, or cause

sufficient energy to be released that can start a fire. The meter can be used for

secondary protection functions.

Do not HIPOT/Dielectric test the digital (status) inputs, digital outputs, or

communications terminals. Refer to the label on the ION 7500 / ION 7600 meter

for the maximum voltage level the device can withstand.

Page 4

CAUTION

Observe the following instructions, or permanent damage to the meter may occur.

The ION 7500 / ION 7600 meter offers a range of hardware options that affect

input ratings. The ION 7500 / ION 7600 meter’s serial number label lists all

equipped options. Applying current levels incompatible with the current inputs

will permanently damage the meter. This document provides installation

instructions applicable to each hardware option.

The ION 7500 / ION 7600 meter’s chassis ground must be properly connected to

the switchgear earth ground for the noise and surge protection circuitry to

function correctly. Failure to do so will void the warranty.

Terminal screw torque: Barrier-type (current, voltage, and relay terminal screws:

1.35 Nm (1.00 ft-lbf) max. Captured-wire type (digital inputs/outputs,

communications, power supply: 0.90 Nm (0.66 ft.lbf) max.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense. The Ringer Equivalence Number (REN) for the ION 7500 / ION 7600

optional internal modem is 0.6. Connection to the ION 7500 / ION 7600 internal

modem should be made via an FCC Part 68 compliant telephone cord (not

supplied). The ION 7500 / ION 7600 cannot be used on a public coin phone service

or party line services.

Network Compatibility Notice for the Internal Modem

The internal modem in meters equipped with this option is compatible with the

telephone systems of most countries in the world, with the exception of Australia

and New Zealand. Use in some countries may require modification of the internal

modem’s initialization strings. If problems using the modem on your phone

system occur, please contact Power Measurement Technical Services

Standards Compliance

CSA: Certified to CAN/

CSA C22.2 No.1010-1

Certified to

UL 3111

CE: approved

Page 5

Limitation of Liability

Power Measurement Ltd. (“Power Measurement”) reserves the right to make changes in the

device or its specifications identified in this document without notice. Power Measurement

advises customers to obtain the latest version of the device specifications before placing

orders to verify that the information being relied upon by the customer is current.

Regardless of whether any remedy set forth herein fails of its essential purpose, except to

the extent the following limitation is prohibited by applicable law, Power Measurement

shall not, in any event or under any legal claim or theory (whether based on contract,

indemnity, warranty, tort (including negligence and strict liability) or otherwise), be liable

to the original purchaser or any other person or entity for special, indirect, incidental,

punitive, liquidated, special or consequential damages whatsoever with respect to any

purchased product, including, without limitation, business interruption, loss of use, profit

or revenue, even if Power Measurement has been advised of the possibility of such

damages. To the extent that a limitation or exclusion of consequential damages are

prohibited by applicable law, then Power Measurement’s liability shall be limited to twice

the amount of the relevant purchased product. Not to limit the foregoing, a) Power

Measurement shall not be liable for any claim (other than a claim solely for the breach of one

of the above Warranties that is made in accordance with the above described procedures)

made by the original purchaser, its employees, agents, or contractors for any loss, damage,

or expense incurred due to, caused by, or related to any purchased product; and b) the

above Warranties are the original purchaser's exclusive remedy and Power Measurement

hereby expressly disclaims all other warranties, express or implied, including, without

limitation, warranties of non-infringement and the implied warranties of merchantability

and fitness for a particular purpose.

These limited Warranties shall not apply to any product that has been subject to alteration,

accident, misuse, abuse, neglect or failure to exactly follow Power Measurement's

instructions for operation and maintenance. Any technical assistance provided by Power

Measurement's personnel or representatives in system design shall be deemed to be a

proposal and not a recommendation. The responsibility for determining the feasibility of

such proposals rests with the original purchaser and should be tested by the original

purchaser. It is the original purchaser’s responsibility to determine the suitability of any

product and associated documentation for its purposes. The original purchaser

acknowledges that 100% "up" time is not realizable because of possible hardware or

software defects. The original purchaser recognizes that such defects and failures may cause

inaccuracies or malfunctions. Only the terms expressed in these limited Warranties shall

apply and no distributor, corporation or other entity, individual or employee of Power

Measurement or any other entity is authorized to amend, modify or extend the Warranties

in any way.

The information contained in this document is believed to be accurate at the time of

publication, however, Power Measurement assumes no responsibility for any errors which

may appear here and reserves the right to make changes without notice.

ION, ION Enterprise, ION Meter Shop, ION Setup, ION Wire, ION Reader, PEGASYS,

PowerView, ION 6200, ION 7300, ION 7330, ION 7350, ION 7500, ION 7600, ION 7700, ION

8300, ION 8400, ION 8500, COM32, COM128, Vista, VIP, Designer, Reporter, MeterM@il,

WebMeter, EtherGate, ModemGate, Xpress Card, Feature Packs and “smart energy

everywhere” are either registered trademarks or trademarks of Power Measurement. All

other trademarks are property of their respective owners.

Covered by one or more of the following patents:

U.S. Patent No's 6397155, 6186842, 6185508, 6000034, 5995911, 5828576, 5736847, 5650936,

D459259, D458863, D435471, D432934, D429655, D429533.

Canadian Patent No's 2148076, 2148075.

Other patents pending.

Page 6

Page 7

Contents

Chapter 1 Introduction ..................................................................... 11

Chapter 2 Using The Front Panel ....................................................... 21

◆ ION 7500 and ION 7600 Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

◆ The ION meter in an Enterprise Energy Management System . . . . . . . . . . . . . . . 14

Data Display and Analysis Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Communications Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Digital and Analog I/O Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The Meter is Factory-Configured and Ready to Operate . . . . . . . . . . . . . . . . . . . . . . . 17

◆ Firmware Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

◆ Using this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Getting More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

◆ Displaying Data with the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Display Screen Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Default Front Panel Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

◆ Configuring the Meter with the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

The Front Panel’s Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Basic Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Main Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Demand Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Network Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Serial Communications Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

PQ (Power Quality) Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Format Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Display Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Time Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Meter Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Security Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

◆ Custom Front Panel Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Creating a Front Panel Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 3 Default Meter Functionality 49

◆ Default Meter Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Communications Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Data Logging Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Energy Pulsing Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Power Quality Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setpoint Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Page 8

Meter Clock Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Demand Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Time of Use Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Factory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

◆ Third Party Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Using the Modbus RTU Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Using the Modbus/TCP Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Using the DNP 3.00 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

◆ Restoring the Factory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Chapter 4 Using ION Software ......................................................... 87

◆ ION Enterprise Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

◆ ION Enterprise: ION Management Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Configuring Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

◆ ION Enterprise: Vista . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Displaying Data with Vista . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Customizing the Vista Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

◆ ION Enterprise: Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Basics of ION Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Designer’s Main Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Viewing Real-time Data in Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Changing Setup Registers with Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Customizing Frameworks in Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

◆ ION Enterprise: Reporter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Pre-configured Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Report Creation and Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

◆ ION Setup Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Configuring Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Basic Meter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Displaying Data with ION Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Chapter 5 Features and Applications .............................................. 125

◆ Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

RS-232 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

RS-485 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Internal Modem Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Infrared Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

◆ Internet Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

WebMeter and MeterMail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

WebReach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Page 9

Telnet and Hyperterminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

◆ Digital and Analog I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Specifying a Port in an ION Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Using the Onboard Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Using the Onboard Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

◆ Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

◆ Meter Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Standard Meter Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

◆ Data and Event Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Event Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Logging and Recording Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Logging Configurations for ION 7500 Revenue Applications . . . . . . . . . . . . . . . . . . 152

◆ Alerting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Alerting ION Software via the Alarm Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Alerting via an Alphanumeric Pager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Alerting via a Numeric Pager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Alerting via Email . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

◆ Calculating Power Availability: Number of Nines . . . . . . . . . . . . . . . . . . . . . . 158

Chapter 6 Hardware Reference ...................................................... 159

◆ Standard Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

COM1 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

COM2 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

COM3 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

◆ I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

◆ Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

◆ Retrofit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Terminal Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Communications Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

I/O Expansion Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

◆ TRAN Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Page 10

Appendix A Technical Notes .............................................................. 183

◆ Current Probe Inputs Basic Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

◆ Custom Front Panel Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

◆ Digital and Analog I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

◆ MeterM@il® Internal Email Server Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

◆ ION® Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

◆ WebMeter® Internal Web Server Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

◆ Modem AT Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

◆ Power Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

◆ Power Quality: ION® Meters and EN50160 . . . . . . . . . . . . . . . . . . . . . . . . . . 301

◆ Sub-Metering with a Modbus Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

◆ Telnet and HyperTerminal Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

◆ The ION® Meter as an Ethernet Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

◆ The ION® Meter as a ModemGate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

◆ Time Synchronization & Timekeeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

◆ Upgrading ION® Device Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Page 11

CHAPTER

. . . . . . . . . . . . . . . . . . .

1 Introduction

ION 7500™ and ION 7600™ intelligent metering and control devices provide

revenue-accurate, true RMS measurements of voltage, current, power and energy,

and are complemented by extensive I/O capabilities, comprehensive logging, and

advanced power quality measurement and compliance verification functions. The

meters come with an extensive selection of pre-configured data screens and

measurements, so you can use the meters “out of the box” or customize them to fit

your unique requirements.

ION 7500 and ION 7600 meters can replace numerous transducers, traditional

meters, and control circuits. You can integrate the meters with ION

other energy management, SCADA, automation and billing systems, via multiple

industry-standard communication channels and protocols.

®

software or

In This Chapter

◆ ION 7500 and ION 7600 Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

◆ The ION meter in an Enterprise Energy Management System . . . . . . . . . . . 14

Data Display and Analysis Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Communications Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Digital and Analog I/O Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The Meter is Factory-Configured and Ready to Operate . . . . . . . . . . . . . . . . . . . . 17

◆ Firmware Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

◆ Using this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Getting More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Page 11

Page 12

ION 7500 and ION 7600 Meters ION 7500 / ION 7600 User’s Guide

ION 7500 and ION 7600 Meters

The ION 7500™

The ION 7500 and ION 7600 are intelligent metering and control devices suited to

a wide range of applications. The meters can be used as stand-alone devices, but

their extensive capabilities are fully realized when used with ION software, as part

of an enterprise energy management (EEM) system.

EEM systems give energy suppliers, service providers, and large industrial and

commercial energy consumers the tools to meet all the challenges and

opportunities of the new energy environment. EEM systems use real-time

information and control to directly address a broad range of requirements

throughout the power delivery chain and across an entire enterprise. These

systems offer an integrated solution to managing new billing structures,

distributed generation, energy purchasing, energy cost control, operational

efficiency, and power quality and reliability.

ION technology uniquely delivers the benefits of enterprise energy management

through an efficient, economical, and scalable architecture using web-enabled

software and intelligent metering and control devices. ION systems place

intelligence everywhere it’s needed, delivering information and control to

everyone that needs it, wherever they are. This gives all parties the necessary

information to make the best energy decisions, and the control to act on them.

Systems can span widely dispersed geographic locations and multiple points

within each site. A single, shared system delivers a broad range of functionality

that can satisfy the needs of many different groups within an enterprise, while

integrating seamlessly with existing systems.

Page 12 Chapter 1 - Introduction

Page 13

ION 7500 / ION 7600 User’s Guide ION 7500 and ION 7600 Meters

ION Enterprise™ is a powerful web-ready software suite that can process,

analyze, store, and share information from across your entire organization. Its

compatibility and flexibility means you can introduce individual components, at a

pace you decide, while maintaining your original investments. You can access

information and alarms from any workstation, pager, PDA, or cell phone locally or

around the world, in the format you require. You can also perform coordinated

load and equipment control functions, either manually or automatically. ION

software collects data automatically from ION meters and third-party devices, so

you can manage a single site or a global network of devices. ION software and

hardware products reduce cost of installation and ownership by leverage existing

corporate networks and popular networking technologies, including serial,

wireless, modem, Ethernet and Internet links.

A wide selection of ION intelligent metering and control devices are available,

with choices to meet the specific needs of various key points within an enterprise.

Devices offer a range of high accuracy metering, power quality and reliability

analysis, data and event logging, alarming, control and communications.

This manual discusses ION 7500 and ION 7600 meter default functionality, as well

as features and applications. Throughout the manual, the term “meter” refers to

both meter models. All differences between the models, such as a feature specific

to one model, are indicated with the appropriate model number.

These meters can be used effectively in numerous energy supply-side (utility) and

demand-side applications. Some common meter applications are:

◆ Revenue metering

◆ Substation automation

◆ Power quality monitoring (with Flicker)

◆ Commercial/industrial operations metering

◆ Demand and power factor control

◆ SCADA (supervisory control and data acquisition)

◆ Distributed generation (generator) monitoring and control

Chapter 1 - Introduction Page 13

Page 14

The ION meter in an Enterprise Energy Management System ION 7500 / ION 7600 User’s Guide

The ION meter in an Enterprise Energy Management System

Applications that include the meter typically require additional equipment.

Display and analysis software tools are almost always used to manage, interpret

and distribute the data measured or logged by a meter. There are usually a variety

of tools used, and often these tools are connected using different communications

standards and protocols. In many cases, a meter must also provide control

capabilities and device-level data sharing.

The meter can adapt to many situations. Advanced communications allow data to

be shared simultaneously across multiple networks, built-in I/O provides

monitoring and control capabilities, and a variety of display and analysis tools can

be used to monitor your power system.

Internet Connectivity

- MeterM@il

- WebMeter functionality

- XML compatibility

Power System Connections

Phase voltage, phase current, ground current,

and neutral current from Wye, Delta, or

N

single-phase power systems

N

N

Onboard I/O

-

Pulses

Breaker Status

-

Control Signals

-

Energy Pulses

On-Site Data Display

- 320 by 240 pixel LCD

Remote Data Display

Vista

-

WebReach

-

Data Display and Analysis Tools

Not only does the meter’s front panel allow meter configuration and data display,

but the meter also integrates seamlessly with display and analysis software

available from Power Measurement. ION Enterprise software is the network and

device configuration software that also lets you analyze and monitor your system

and produce reports for any department in an organization. Furthermore, you can

use data acquired by the meter in a variety of third-party systems. ION software is

designed to make use of all the available advanced capabilities.

Data Analysis Tools

-

Power Monitoring Network

Third-Party Software for

-

Modbus, DNP 3.00, Mv90

Corporate Network

Communications

-

RS-232 and high speed RS-485

Internal Modem

-

-

Optical infrared

10 Base-T and 10 Base-FL Ethernet

-

Interoperability

-

Protocols: ION, Modbus Master, Modbus RTU,

-

Modbus TCP,

to RS-485 gateway), EtherGate (Ethernet

to RS-485 gateway), GPS: Arbiter,

GPS:True Time/Datum

DNP 3.00, ModemGate (modem

Page 14 Chapter 1 - Introduction

Page 15

ION 7500 / ION 7600 User’s Guide Data Display and Analysis Tools

The Front Panel

Local monitoring and standalone applications are facilitated by the meter’s front

panel interface. The front panel combines real-time display features with limited

device configuration functions.

The front panel is often used in combination with an ION software system,

providing an interface for field personnel.

WebMeter® Embedded Web Server Feature

An on-board web server combined with an Ethernet port provides quick and easy

access to real-time energy and basic power quality information without special

software: this is WebMeter functionality. The built-in web pages display a range of

energy and basic power quality information through the web-enabled device;

these pages even support basic meter configuration tasks.

MeterM@il® Internal E-Mail Server Feature

Configure the meter to automatically email high-priority alarm notifications or

scheduled system-status update messages to anyone, anywhere within the facility

or around the world. Specify the type of event that triggers an email alert, such as

power quality disturbances or logged data at any pre-determined interval, and

have your ION software administrator program the meter to respond with a

MeterM@il message when these events occur. MeterM@il messages can be

received like any email message over a workstation, cell phone, pager, or PDA.

XML Compatibility

The meters can exchange information using industry-standard XML format. This

simple machine-readable format supports easy integration with custom reporting,

spreadsheet, database, and other applications.

ION Enterprise™ Software

The complete ION Enterprise software package enables the meter to be part of a

fully networked information system with other meters and local and wide-area

computer networks. ION Enterprise is recommended for all power monitoring

systems where advanced analysis and control capabilities are required.

ION Enterprise provides tools for managing your power monitoring network,

logging data, analyzing real-time and logged data, generating power system

reports, and creating custom functionality at the meter level.

ION Enterprise also offers two ways to remotely view information through a web

browser: WebReach and Microsoft Terminal Services.

◆ WebReach only requires an URL to display a meter’s real-time data and select

views of historical and waveform data from a web browser; there is no client

machine configuration. WebReach is a data display application; there is no

control functionality available through it.

◆ Microsoft Terminal Services enable full ION Enterprise functionality, including

control features. Some client machine configuration is required.

Chapter 1 - Introduction Page 15

Page 16

Communications Protocols ION 7500 / ION 7600 User’s Guide

ION Setup™ Software

ION Setup is a meter configuration tool designed specifically to configure and test

meters. ION Setup offers an intuitive graphical interface for performing basic

meter setup, installing templates into meters, viewing real-time and reset

accumulated values, verifying meter calibration and measurements, and setting

up advanced security.

Communications Protocols

The meter can be integrated into various industry-standard networks. Data that is

measured by the meter can be made available to other devices using the Modbus

Master, Modbus RTU, Modbus TCP, and DNP 3.00 protocols, as well the MV-90

translation system. You can also configure the meter to import data from devices

on these networks. With these advanced communications functions, the power of

the meter can be utilized in most existing power monitoring systems. Any data

display and analysis software that works with Modbus RTU or DNP 3.00 devices

will also function with the meter.

The standard meter includes a selectable RS-232/RS-485 port (the factory default is

RS-232), a high-speed RS-485 port, and an IrDA optical port for communications

in the field. Order options include a 10Base-T Ethernet port or 10Base-FL fiberoptic port, and a 33.6 kbps internal modem (both FCC and CTR-21 compliant).

Depending on the hardware options purchased, up to four separate ports can

communicate simultaneously.

The communications card is retrofittable – it can be replaced while the meter is in

the field.

Digital and Analog I/O Options

The meter has digital inputs and outputs that connect to the captured-wire

terminals near the base of the unit. Additionally, a LED on the front panel is

configured for energy pulsing. An optional analog I/O card can also be ordered

with your meter. There are retrofit instructions for this I/O card, if you desire the

card on a previously purchased meter.

Digital Inputs

The meter contains eight self-excited digital inputs capable of detecting a pulse

rate of 20 pulses/second and timestamping transitions with 1ms resolution. They

can be used for monitoring external contacts or pulse counting applications. These

inputs use a current sensing technique to monitor contact status by providing an

internal 30 VDC supply for self-excitation.

Relay Outputs

The meter contains four solid-state Form A outputs and three mechanical Form C

relays. The solid-state outputs have a maximum voltage rating of 30 VDC and

maximum current rating of 100 mA. The mechanical relays are rated at 250 VAC /

30 VDC and can switch up to 10A loads.

Page 16 Chapter 1 - Introduction

Page 17

ION 7500 / ION 7600 User’s Guide The Meter is Factory-Configured and Ready to Operate

Analog Inputs and Analog Outputs

The meter offers an optional Analog I/O expansion card with numerous options:

◆ four 0 to 1 mA analog inputs

◆ four 0 to 20 mA analog inputs

◆ four -1 to 1 mA analog outputs

◆ four 0 to 20 mA analog outputs

◆ four 0 to 20 mA analog inputs & four 0 to 20 mA outputs

◆ four 0 to 1 analog inputs and four -1 to 1 mA analog outputs

NOTE

All options have an additional eight digital inputs on the card.

The Meter is Factory-Configured and Ready to Operate

Even though the meter is fully customizable, it is shipped from the factory with

many pre-configured functions. Once you have performed the installation and

basic setup, all of the basic measurements, energy calculations and recording

functions are ready to operate right out of the box. You may find that the factory

configuration aptly serves your purposes, allowing you to forego additional

configuration.

Chapter 1 - Introduction Page 17

Page 18

Firmware Revision History ION 7500 / ION 7600 User’s Guide

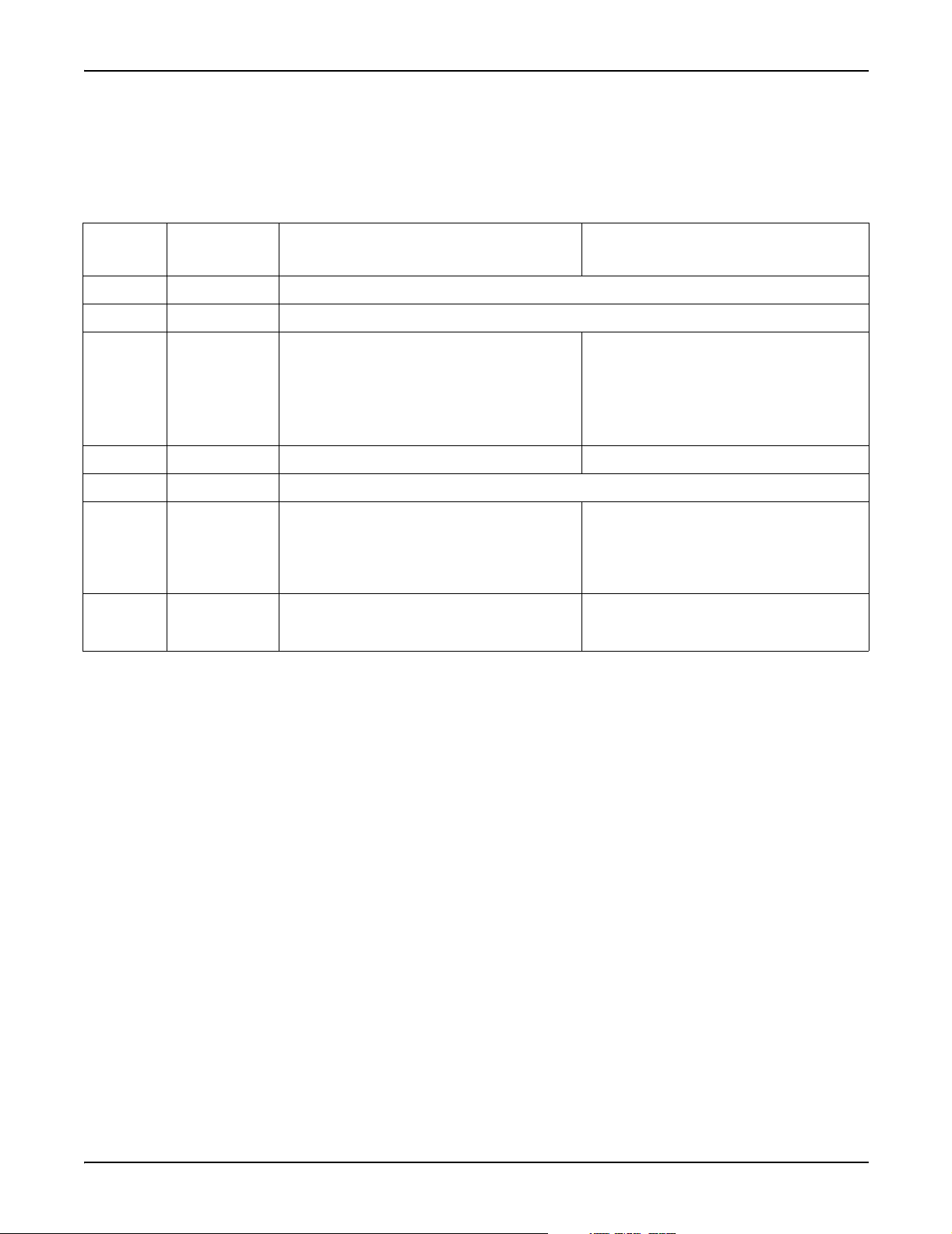

Firmware Revision History

The table below lists the features related to a particular firmware release for your

meter.

Firmware

Version

Release Date Firmware Enhancements Template Improvements

v201 Aug. 10, 2000

v203 Apr. 14, 2000

v206 Jan. 12, 2001

v207 Feb. 22, 2001

v210 May 16, 2001

v222 Nov. 28, 2001

v231 Aug. 6, 2002

◆ Initial release of the ION 7600 meter

◆ Implemented the ModemGate protocol

◆ Analog I/O

◆ WebMeter

◆ MeterM@il

◆ new and enhanced ION Modules

◆ Hardware improvements:

1 Amp current input option,

Modicon Modbus TCP communications

◆ Tre n d i n g D i s p l ay featur e ◆ New Trend Display Module

◆ NICT and TRAN support added

◆ Modbus Master capability

◆ DNP enhancements

◆ Hardware improvements:

Option to order ION 7500 with 4 MB or 8 MB of Log

Memory

◆ Internet Phase 2

◆ Stack replacement

◆ Hardware improvements

◆ Revenue Log Module enhancements

◆ Sag/Swell Events on V4

◆ Number of Nines display screen

◆ 9 additional DNP Slave modules

◆ 4 additional Calibration Pulser modules

◆ The maximum allowable number of the following ION

Modules has been increased (see addendum for

actual numbers):

◆ Integrator, Data Recorder, Sliding Window Demand,

External Boolean, Minimum, Maximum, Display, Set

Point

◆ Log Mail module replaced by the Log Export module

◆ New Web Page module

Page 18 Chapter 1 - Introduction

Page 19

ION 7500 / ION 7600 User’s Guide Using this Guide

Using this Guide

This User’s Guide is directed at three types of user: the typical user or operator, the

system administrator, and the advanced user. You might not fit into any of these

groups directly, or perhaps you are both an operator and an administrator. These

classifications are intended to make this guide easier to navigate with respect to

which information is appropriate to your needs.

Typical User or Operator

Most users simply want to display the data provided by the factory-configured

meter. These users want fast access to data through the front panel, ION software,

or a third-party protocol such as Modbus or DNP.

System Administrator or Manager

Some users need to make minor adjustments so that their meters “fit” their power

systems: data recording intervals, demand sub-intervals and other parameters

may need to be set before the meter’s setup is complete. These users will use the

front panel, or ION software to change settings in the device’s operating software.

(ION Enterprise is highly recommended.)

Advanced User or Systems Integrator

Advanced users may want to make use of the flexibility and power provided by

the device’s operating software. These users will need to become familiar with the

ION architecture, and the ION software tools used to customize the device’s

operation.

Before You Can Use this Guide

By the time you are ready to use this guide, your meter should be installed, basic

setup should have been performed, and communications/basic operation should

have been verified. If the unit is not yet installed and operational, refer to the

Installation & Basic Setup Instructions shipped with the meter.

Getting More Information

Additional information is available from Power Measurement. Check our web site

at www.pwrm.com, contact your local Power Measurement representative, or

contact Power Measurement directly (contact information is provided on the first

page of this document). Documents that are related to the installation, operation

and application of the meter are as follows:

Installation & Basic Setup Instructions

This brief guide is shipped with each meter. It details the mounting, wiring and

basic setup of the device.

ION Programmer’s Reference

This online reference contains detailed descriptions of all modules in an ION

meter.

Chapter 1 - Introduction Page 19

Page 20

Getting More Information ION 7500 / ION 7600 User’s Guide

ION Enterprise Administrator Guide

This guide explains the installation and configuration of the ION Enterprise

software suite.

Online ION Enterprise Help

Each ION Enterprise software component has an in-depth online help system.

Technical Notes

Appendix A contains technical notes that provide details for meter features and

custom configurations. These technical notes are also available from our website

which is regularly updated with new and revised technical notes.

Application Notes

Online application notes offer detailed, high-level descriptions of real-world

situations, where Power Measurement’s ION devices and ION software provide

beneficial solutions.

Page 20 Chapter 1 - Introduction

Page 21

CHAPTER

. . . . . . . . . . . . . . . . . . .

2 Using The Front Panel

The meter’s front panel is used for both display and configuration purposes. The

liquid crystal display (LCD) screen and the numerous selection, navigation, and

configuration buttons allow quick access to basic meter configuration provided by

special setup screens. The front panel also provides access to the settings of many

other meter functions. Although you can customize the type of data you want

displayed, this cannot be done through the meter’s front panel.

In This Chapter

Displaying Data with the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Display Screen Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Default Front Panel Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configuring the Meter with the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . 31

The Front Panel’s Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Basic Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Main Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Demand Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Network Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Serial Communications Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

PQ (Power Quality) Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Format Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Display Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Time Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Meter Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Security Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Custom Front Panel Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Creating a Front Panel Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Page 21

Page 22

Displaying Data with the Front Panel ION 7500 / ION 7600 User’s Guide

Displaying Data with the Front Panel

The front panel LCD (liquid crystal display) provides a detailed graphics and text

display that has been factory configured to show many of the parameters

measured by the meter.

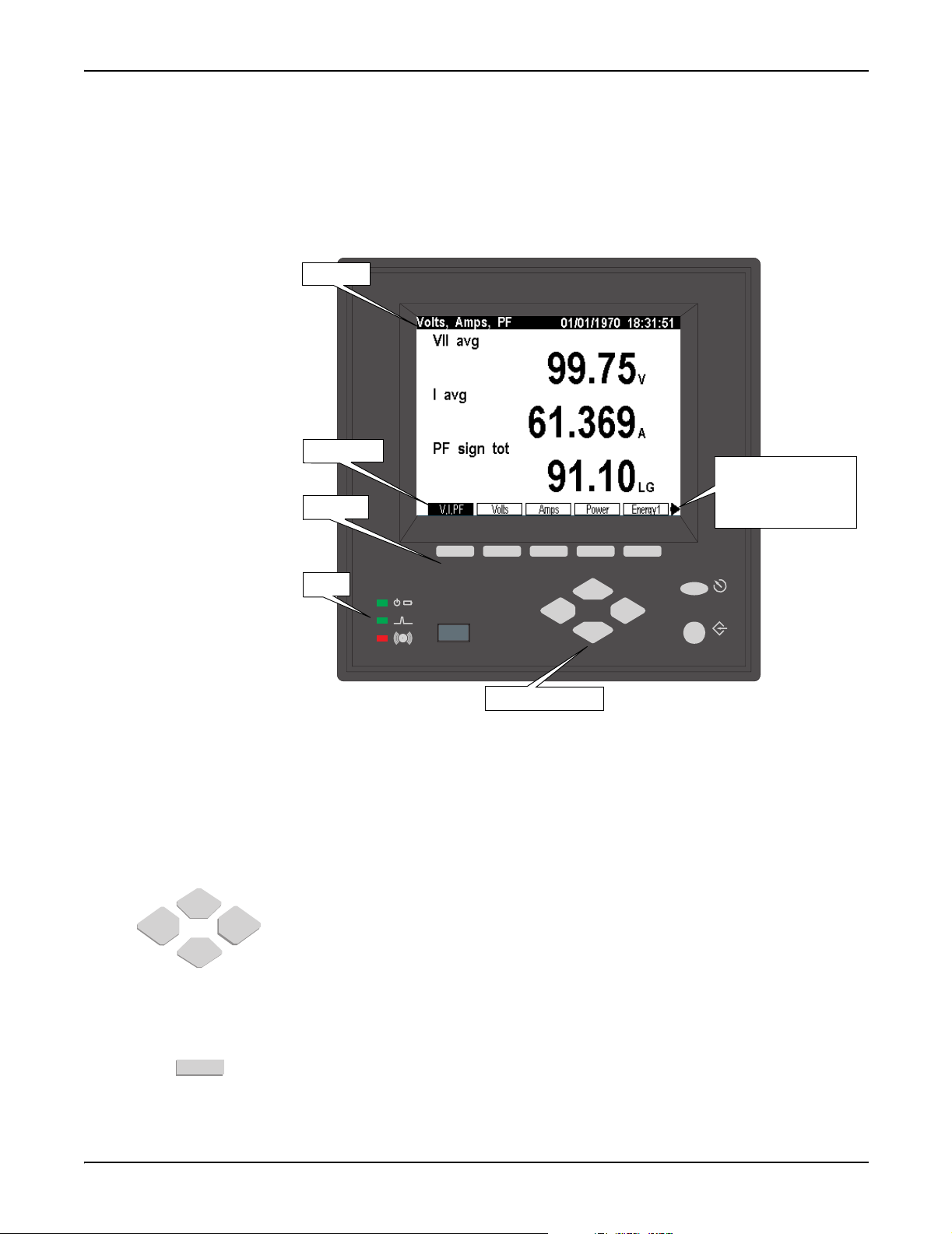

Status Bar

Softkey Titles

The arrow indicates

that another group of

Softkeys

screens is available on

the left.

LEDs

Navigation buttons

ESC

PROG

The meter’s display can show numeric data screens, event logs, phasor diagrams,

bar graphs, and harmonics histograms.

Using the Front Panel Buttons to Display Data

The front panel has numerous buttons: softkeys, navigation buttons, program

buttons. Program buttons are used when configuring the meter (see page 32). Use

the following buttons to view data on the front panel display screens.

Navigation Buttons

The horizontal navigation buttons (Left/Right keys) select a different set of five

Softkey titles to access different data screens. The vertical navigation buttons

(Up/Down keys) are used to navigate within certain data display screens, such as

within a Trend Display’s graph and log screens or an Event Log screen, once one

has been selected.

Softkeys

A Softkey button selects the data screen available in the corresponding Softkey title

when pressed.

Page 22 Chapter 2 - Using The Front Panel

Page 23

ION 7500 / ION 7600 User’s Guide Display Screen Types

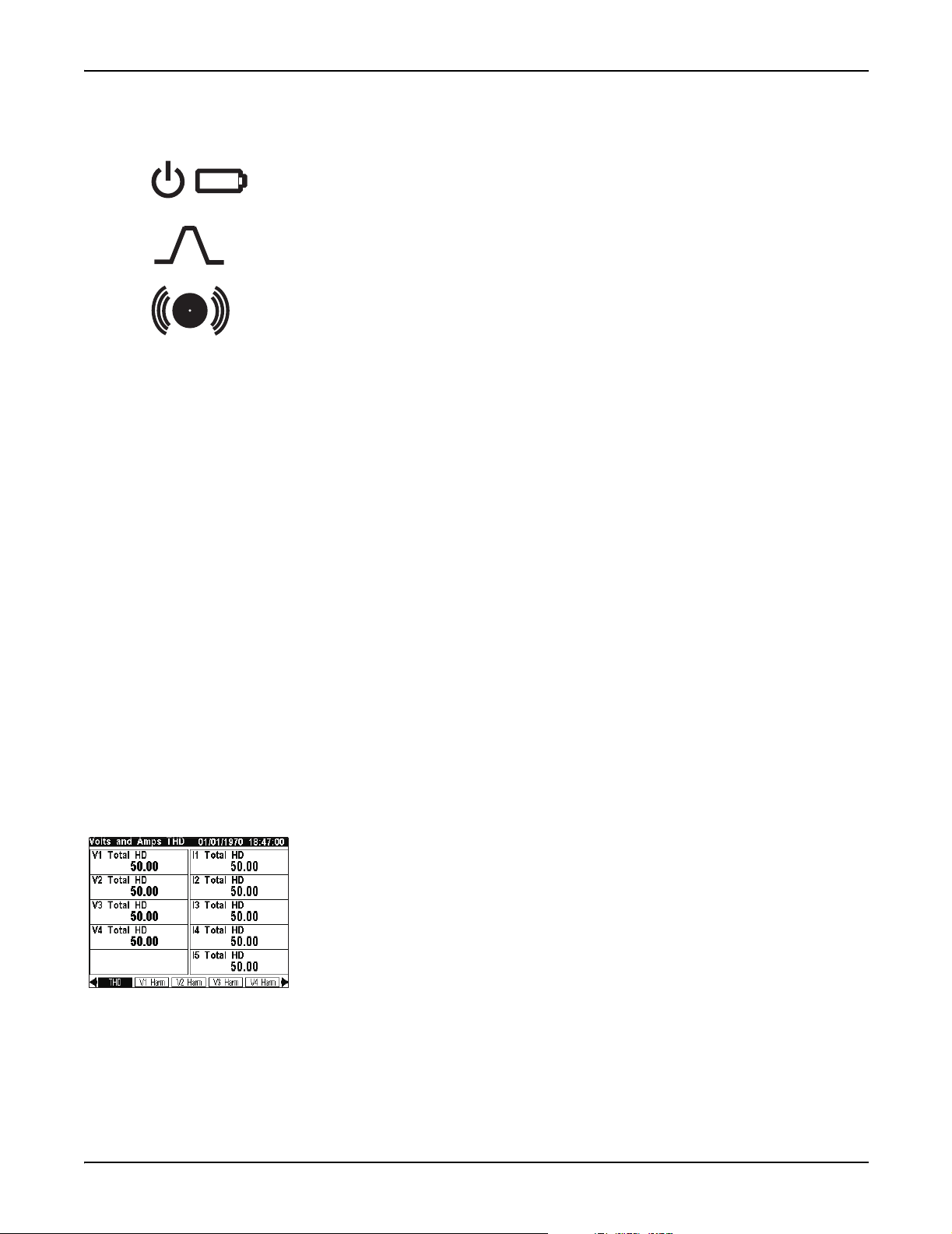

Front Panel LEDs

The front panel LEDs are as follows:

The green operation LED (top) should always be on when the meter is in

service. Contact Technical Services if this is not the case.

The green LED in the middle is factory configured to be a Wh (del+rec) pulser.

During the course of normal operation, this LED should blink intermittently as

the meter measures power system energy.

The red LED (bottom) on the front panel of the meter is provided for custom

applications. Possible applications include sag/swell alarming, setpoint

annunciation, and tariff notification. Like all the other outputs on the meter, this

port can be controlled by a Digital Output, Pulser, or Calibration Pulser module.

Backlight Operation and Display Contrast

The front panel display is factory configured to dim five minutes after the last

button press.If the front panel is dimmed, press any button to return the LCD to

full brightness. The front panel display is adjusted at the factory to the optimal

contrast level. If the contrast needs adjusting or want to change the backlight timeout period, you can do so from the Display Setup menu (see page 41).

Status Bar

The Status Bar of the meter is located along the top of all display screens. When in

data display mode, the Status Bar shows: the date in MM/DD/YYYY format

(configurable), the current local time in 24 hour format, and the data display screen

title.

Display Screen Types

The meter’s front panel displays measurements, configurable settings, and current

configuration data in various forms. These data display screens are described

below. Configuration (Setup menu) displays are described in the chapter "Default

Functionality."

Numeric Displays

Numeric displays can show multiple parameters at a time: two, three, three with a

timestamp, four, eight, ten (shown), or twenty. When displaying numeric values

for current and power quantities, the front panel shows resolution to three decimal

places by default. All other values are displayed to two decimals of accuracy. If

you want to see finer resolutions, use Vista software to display the data.

If the front panel is unable to read a numeric value, or if the value is not available,

it displays a dash (—).

Chapter 2 - Using The Front Panel Page 23

Page 24

Display Screen Types ION 7500 / ION 7600 User’s Guide

Automatic Units

The front panel automatically scales the units for basic measurements, such as

voltage, current and power parameters. For example, a measurement of 2,000

Watts is displayed as 2.000 kW. A measurement of 2,000,000 Watts is displayed as

2.000 MW. The meter makes these conversions using your PT and CT ratios.

The meter only performs these automatic units if the measurement is derived

solely from the Power Meter module’s output.

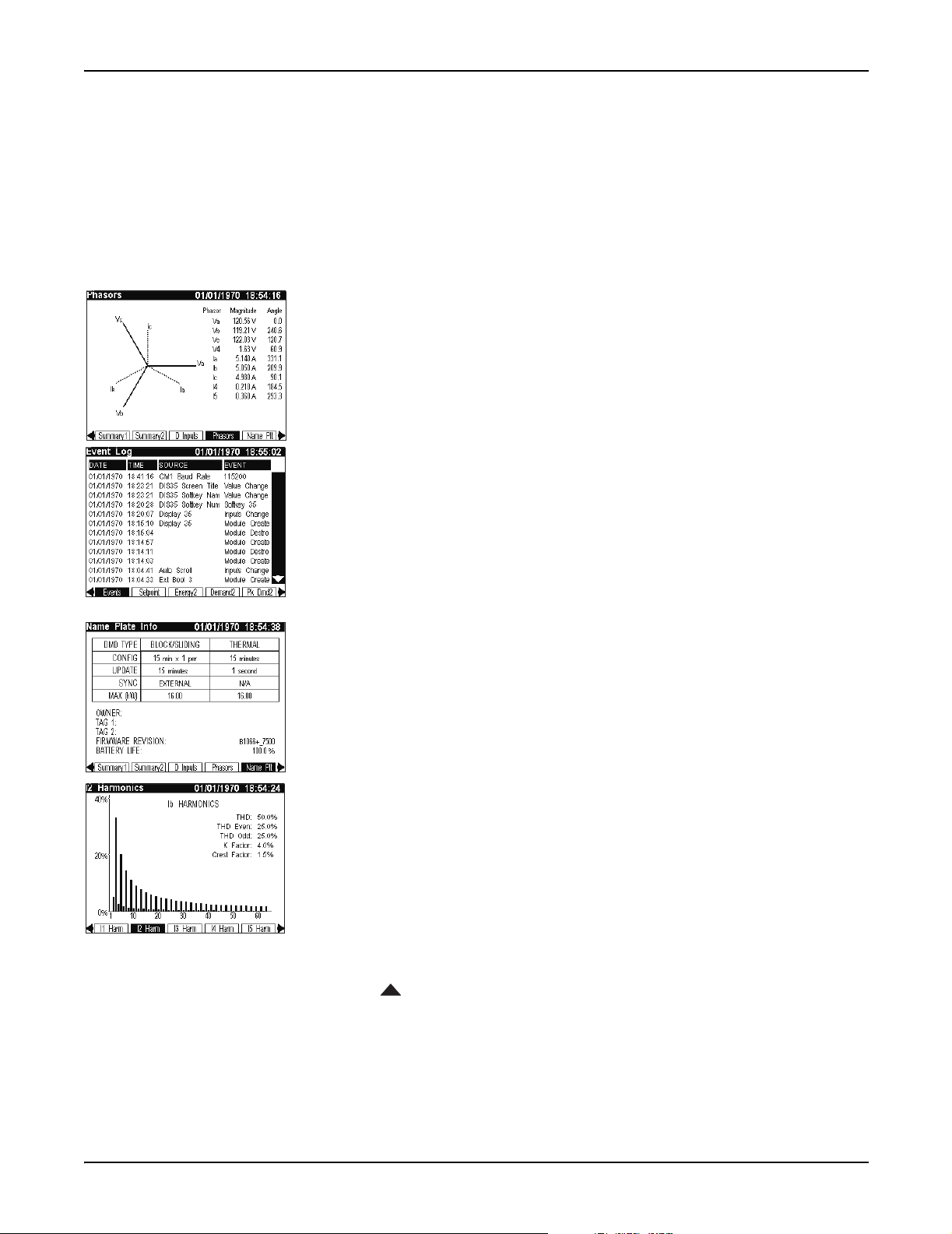

Phasor Diagram Displays

Phase information can be displayed in phasor diagram format. Phasor diagrams

are accompanied by tables that state the angle and magnitude of each phasor.

In cases where phasors are too small to be represented graphically, they are only

shown as table entries.

Event Log Displays

Event Log displays alert you to recent events written to the meter’s event log. The

vertical (Up/Down) navigation buttons are used to move through the list.

Details on altering the meter’s Event Log characteristics, such as log depth and

logging frequency, using Designer can be found in the "Default Functionality"

chapter.

Nameplate Displays

Like Event Log displays, Nameplate displays show information in tabular format.

Default nameplates show owner, meter, and power system details.

See the section "Time-Of-Use Configuration" in the Default Meter Functionality

chapter for details on configuring the T

AG strings.

Histogram Displays

Harmonics content is displayed in histogram format. Harmonics are displayed

from the 2

displayed above the histogram (K Factor and Crest Factor only appear in current

harmonic histograms).

Use the vertical navigation buttons on the meter front panel to select individual

harmonics (from 2

them (V

An arrow appears below the harmonic selected. Harmonic magnitude is

displayed as an absolute value and as a percentage of the fundamental. The phase

angle of each harmonic is also provided. To return to the THD values, position the

arrow below the fundamental.

nd

to the 63rd harmonic, with Total Harmonic Distortion (THD) values

nd

to 40th) in the histogram and view data specific to each of

, V2, V3, I1, I2, and I3 only).

1

Page 24 Chapter 2 - Using The Front Panel

Page 25

ION 7500 / ION 7600 User’s Guide Display Screen Types

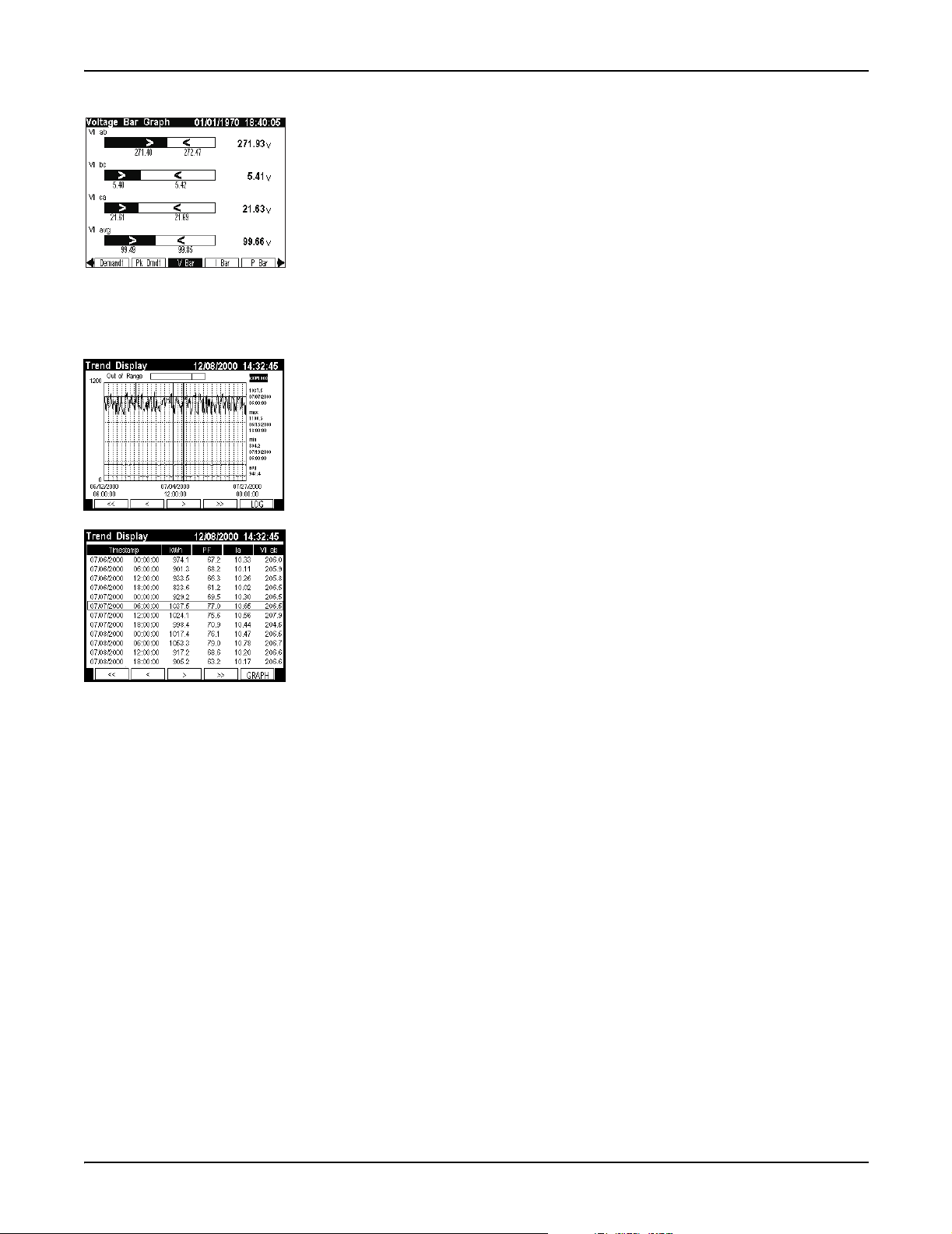

Trend Bar Graph Displays

Bar graph displays can show up to four real-time (numeric) parameters along with

their upper and lower extremes.

Each bar graph automatically scales its output based on the magnitude of its

extremes. The real-time value of each bar graph is displayed to the right of the

graph. Note that scaling is applied separately to each bar graph in the display. Do

not compare the magnitudes of two values based on the size of their bars.

In the trend bar graph shown on the left, the present value of Vll ab is 271.93 V. The

bar graph also indicates that it has gone as low as 271.40 V and as high as 272.47 V.

Trend Displays

The Trend Display screen graphs the historical data of up to four different

parameters simultaneously. A movable cursor that consists of the intersection of a

vertical line and a horizontal line displays the value and timestamp of any plotted

data within a parameter. The cursor displays the values of one parameter at one

time only. With the Up and Down navigation keys, the cursor can move from one

parameter to another.

In addition, a Trend Display log screen displays data logs for any graphed

parameter – up to 3360 logs for each parameter. That is equivalent to 35 days worth

of 15 minute data. The graph is updated when a new set of values is recorded. The

highest supported update speed is once per second.

The ION 7500 front panel displays three preconfigured trending screens: V-Trend

(voltage), I-Trend (current), and P-Trend (power). The ION 7600 must be

configured using Designer in order to provide Trend Display. Contact Technical

Services if you require your ION 7600 to be configured for Trend Display.

Chapter 2 - Using The Front Panel Page 25

Page 26

Default Front Panel Display Screens ION 7500 / ION 7600 User’s Guide

Default Front Panel Display Screens

The meter is factory configured to display a number of data screens on its front

panel:

42 display screens for the ION 7500

48 display screens for the ION 7600

Each of these screens is accessible with a corresponding Softkey. See the “Button

Functions” section for instructions on using the front panel buttons for data

display.

NOTE

Each display screen is listed with the corresponding softkey name and the screen title.

Screens Shown in Display Cycle

Ten data display screens are included in the automatic display cycle. By default,

the front panel scrolls repeatedly through the following screens in the order

presented.

For details on screen type (e.g. three parameter, vector diagram, etc.) refer to the

technical note Custom Front Panel Displays.

1. V,I,PF (Volts, Amps, PF)

This numeric display screen contains the average line-to-line voltage, average

current, and the total signed power factor.

2. Volts (Volts)

This numeric display screen shows the line-to-line voltages Vll ab, Vll bc, and

Vll ca.

3. Amps (Amps)

This is a numeric screen containing currents I a, I b, and I c.

4. Power (Total Power)

This numeric display screen contains total kW, kVAR, and kVA values.

5. Energy1 (Energy Delivered)

This numeric display screen shows delivered (imported) energy values for kWh,

kVARh, and kVAh.

6. Demand1 (Demand Delivered)

This numeric display screen contains delivered values (kW, kVAR, and kVA) in

the previous demand period. By default, these values come from a sliding

window demand (rolling block) calculation.

Page 26 Chapter 2 - Using The Front Panel

Page 27

ION 7500 / ION 7600 User’s Guide Default Front Panel Display Screens

7. Pk Dmd1 (Peak Demand Del)

This is a numeric display screen with timestamps that contains maximum

delivered demand values for kW, kVAR, and kVA. The timestamps show the

date and time at which the values were last updated. By default, these values

come from a sliding window demand calculation.

8, 9, 10. V Bar, I Bar, P Bar (Voltage, Current, and Power Bar Graphs)

These three screens are trend bar graph displays. They show real time values for

voltage (Vll ab, Vll bc, Vll ca, Vll avg), current (I a, I b, I c, I avg) and

power (kW tot, kVAR tot, kVA tot, PF lag tot). The bar graphs also indicate the

maximums and minimums recorded for these values.

Additional Data Display Screens

Most of the default data screens are not included in the default scrolling cycle. To

view the other display screens, you must find the group of five Softkey titles that

contains the data screen you want, and then press the corresponding Softkey.

NOTE

The numbers on the left correspond to the Display module’s Softkey number in the ION 7600 meter’s

display framework. The Softkey numbering for an ION 7500 differs slightly due to V trend, I trend, and

P trend taking the place of Softkeys 13, 14, and 15 respectively. The ION 7500 does not support display

screens for EN50160 data and statistics.

11. Summary1 (Volts/Amps Summary)

This numeric display provides many important voltage, current, phase, and

frequency measurements on a single screen.

12. Summary2 (Power Summary)

This numeric display provides real, reactive, and apparent power

measurements for phase a, b and c (as well as their total). Signed Power Factor

measurements are also provided on this screen.

13. D Inputs (Digital Inputs)

This numeric display screen shows the status of the eight on-board digital

inputs. The present state of all inputs is shown (as Off or On) and the number

(Cnt) of state changes since the last reset is recorded.

14. DI - I/O (DI on I/O Card)

This numeric display screen contains the status and counters for the digital

inputs on the I/O card.

15. D Outputs (Digital Outputs)

This numeric display screen contains the mode and status for the relay and solid

state outputs.

16. Anlg - I/O (Analog In and Out)

This numeric display screen contains scaled analog inputs (AIn scaled) and

normalized analog outputs (AOn normalized), where n ranges from 1 to 4 for

both inputs and outputs.

Chapter 2 - Using The Front Panel Page 27

Page 28

Default Front Panel Display Screens ION 7500 / ION 7600 User’s Guide

17. Phasors (Phasors)

This screen is a phasor diagram display that shows the magnitude and the

relative angular difference between all phase voltage (V a, V b, V c, V 4) and

current (I a, I b, I c, I 4, I 5) fundamental components.

18. Name Plt (Name Plate Info)

The Name Plate Info screen contains the following information: Owner,

and

TAG 2 from the Factory module, firmware revision of the ION meter, and a

battery life indicator.

installed location. The Owner and

TAG 1 and TAG 2 typically identify the meter’s user and

TAG registers are configurable with the

Designer software.

19. Events (Event Log)

The Event Log display alerts you to events written to the meter’s event log.

D

ATE, TIME, SOURCE, and EVENT information are provided. The up and down

Navigation buttons allow you to move through the list.

20. Setpoint (Setpoint Status)

This numeric display screen displays the status of the setpoint parameters

defined in the Vista Setpoints diagram.

21. Energy2 (Energy Received)

This numeric display screen shows received (exported) energy values for kWh,

kVARh, and kVAh.

22. Demand2 (Demand Received)

This numeric display screen shows received power quantities (kW, kVAR, and

kVA) in the present demand period. By default, these values are from a sliding

window demand (rolling block) calculation.

23. Pk Dmd2 (Peak Demand Rec)

TAG 1

This is a numeric display screen with timestamps. It shows the maximum

received demand quantities (kW, kVAR, and kVA) and the time at which they

were recorded. By default, these values are from a sliding window demand

(rolling block) calculation.

24. THD (Volts and Amps THD)

This numeric display screen contains the total harmonic distortion on all phase

voltage and current inputs.

25, 26, 27, 28. V1 Harm, V2 Harm, V3 Harm, V4 Harm (Harmonics)

These four histogram display screens show the harmonic content on the phase

voltage inputs.

29, 30, 31, 32, 33. I1 Harm, I2 Harm, I3 Harm, I4 Harm, I5 Harm (Harmonics)

These five histogram display screens show the harmonic content on the phase

current inputs.

34. TOU (Active Rate / Season)

This eight parameter display screen shows kWh delivered values for each all

four of the possible time of use (TOU) rates (rates A, B, C, and D).

Page 28 Chapter 2 - Using The Front Panel

Page 29

ION 7500 / ION 7600 User’s Guide Default Front Panel Display Screens

35. TOU Egy (TOU Energy Del)

This numeric display screen shows the energy (in kWh) delivered for each time

of use (TOU) rate (rates A, B, C, and D).

36, 37. TOU Dmd1 & TOU Dmd2 (TOU Peak Demand 1 and 2)

These two screens are numeric displays with timestamps. Together they show

the maximum delivered kilowatts for each time of use (TOU) rate (rates A, B, C,

and D). The timestamps show the date and time at which the values were last

updated. By default, these values come from a sliding window demand (rolling

block) calculation.

NOTE

The four TOU screens may only be important if you are using the meter in a billing application (i.e. you

are a power provider). Typically, power consumers ignore the Time-Of-Use front panel displays.

EN50160 Data and Statistics Displays (ION 7600 only)

The remaining front panel screens display data to help you determine EN50160

voltage compliance. Unless compliance to this standard is of concern, you may

ignore these displays. More details about EN50160 are provided in the technical

note Power Quality: ION Meters and EN50160.

38. PQ Freq (PQ Power Frequency)

This numeric display shows the following EN50160 Power Frequency data:

Nominal Frequency, period (10 second) Freq mean, minimum, and maximum.

It also shows the EN50160 frequency compliance statistics: Freq N (the number

of valid evaluation periods), Freq N

(a count of non-compliance), and Freq N2

1

(the number of invalid evaluation periods).

39. PQ Vmag1 (PQ Supply Voltage 1)

This bar graph display shows the following EN50160 Voltage Magnitude data

for all three voltage phases: period (10 minute) mean, minimum, and maximum.

40. PQ Vmag2 (PQ Supply Voltage 2)

This numeric display shows the following EN50160 Voltage Magnitude

compliance statistics for all three voltage phases: mag N and mag N1.

41. PQ Flk1 (PQ Flicker 1)

This bar graph display shows the following EN50160 Flicker data for all three

voltage phases: present Pst, minimum Pst, and maximum Pst.

42. PQ Flk2 (PQ Flicker 2)

This numeric display shows the following EN50160 Flicker data for all three

voltage phases: present Pst, present Plt, and compliance statistics (Flck N and

Flck N

).

1

43. PQ Vdist (PQ Volt Disturbance)

This numeric display shows the following EN50160 Overvoltage and Dip data

for all three voltage phases: expected nominal, minimum Dip, and maximum

Overvoltage.

Chapter 2 - Using The Front Panel Page 29

Page 30

Default Front Panel Display Screens ION 7500 / ION 7600 User’s Guide

44. PQ Vunb (PQ Volt Unbalance)

This numeric display contains the following EN50160 Voltage Unbalance data:

V unbal mean, V unbal mean min, V unbal mean max, and compliance

indicators (unbal N and unbal N

).

1

45. PQ Vhrm1 (PQ Volt Harmonics 1)

This bar graph display shows the following EN50160 Harmonics data: THD

mean, THD mean mn, THD mean max for all three voltage phases (10-minute

mean values, min and max values are updated every new observation period).

46. PQ Vhrm2 (PQ Volt Harmonics 2)

This numeric display shows EN50160 Harmonics compliance statistics for all

three voltage phases: Hrm N, Hrm N

, Hrm N2.

1

47. Avblty (Power Availability)

This numeric display provides the following measurements: availability (with

up-time in parts per million), number of nines, and evaluation time (in days).

48. Pr - Avblty (Previous Availability)

This three parameter display with timestamp indicates the number of

availability resets (including the most recent event’s timestamp), the previous

availability (with its timestamp), and the previous number of nines (with its

timestamp).

Trending Display Screens in the ION 7500

The ION 7500 meter supports trending display in its framework. Each trending

display has two views - graph and log - which are accessible via softkey once you

are displaying the trend screen. As previously mentioned, the softkey numbering

for an ION 7500 meter’s display screens must be adjusted from the numbering

presented for the ION 7600

V Trend (Voltage Trend Display)

The voltage trend display graphs the VII avg trend. This display is Softkey 13.

I Trend (Current Trend Display)

The current trend display graphs the I avg trend. This display is accessed with

Softkey 14.

P Trend (Power Trend Display)

The power trend display graphs the KW tot trend. This display is accessed with

Softkey 15.

Page 30 Chapter 2 - Using The Front Panel

Page 31

ION 7500 / ION 7600 User’s Guide Configuring the Meter with the Front Panel

Configuring the Meter with the Front Panel

The front panel allows you to setup and configure the meter at its installed

location. When you change a setting in the front panel’s Setup menu, you are

actually altering the setup register value of an ION module. (ION module links

cannot be added or deleted using the front panel.) The front panel’s Setup menu

also provides you with quick access to parameter resets for common cumulative

parameters.

The Front Panel’s Setup Menu

To access the Front Panel’s Setup Menu, press that PROG (programming) button.

Pressing the

Each time you enter programming mode, the front panel

helps you keep track of your configuration changes by

marking the Setup menu (and sub-menu) items that you

have accessed. These check-marks are cleared when you

exit programming mode.

ESC (escape) button returns you to the data display screens.

Use the Softkey buttons

to make choices when

Softkey titles appear

above them.

Use the Navigation buttons

to select (highlight) choices

and enter numerical data.

The arrow indicates that

there are more Setup

menu items available by

scrolling down the menu.

Use the ESC (escape)

button to return to a

previous (higher) menu

and exit the Setup menu.

Press the PROG (programming)

button to access the Setup menu

and enter configuration changes.

Chapter 2 - Using The Front Panel Page 31

Page 32

The Front Panel’s Setup Menu ION 7500 / ION 7600 User’s Guide

Using the Front Panel Buttons for Configuration

Use the front panel buttons as follows to adjust the settings:

PROG

PROG

ESC

Press the

programming mode, the

computer keyboard. Press the

changes, passwords, and trigger resets.

ESC

Press the

change.

Navigation

Highlight menu items with the vertical (Up/Down) buttons.

Entering numbers: when a digit is highlighted, pressing the Up button increments

the number by one, and pressing the Down button decreases it. Move the cursor to

an adjacent digit with the horizontal (Left/Right) buttons.

PROG (programming) button to access the Setup Menu. Once in

PROG button functions just like an Enter key on a

PROG button to select a highlighted item or accept

ESC (escape) button to return to a higher menu or abort a configuration

CONFIRM

ESC TO CANCEL

PROG TO CONFIRM

Softkeys

Press a Softkey button when Softkey options become available (when titles appear

in the Softkey title bar). Use Softkeys to select the parameters that you want to

configure from the various sub-menus.

Passwords

All configuration functions in the front panel are password protected. The

password is set to 0 (zero) in the factory. This password allows you to access the

Security setup menu and to disable or change the password for a custom value.

The front panel only prompts you for the meter password before you make your

first configuration change.

Setup Mode Timeout

Once the meter has been configured, the front panel automatically exits the Setup

menu five minutes after the last button press is detected. If the front panel returns

to data display mode, you must re-enter the Setup menu and provide the valid

meter password to resume making configuration changes.

Confirming Configuration Changes

The CONFIRM screen appears whenever you attempt to change the meter’s

settings through the front panel. This allows you to abort an unwanted

configuration change. The front panel also informs you when an entry is out of

range. In either case, you must press the

PROG button to return to the setup screen.

WRITING ERROR Screen

If the CONFIRM screen does not appear for a valid entry, or the display reports a

WRITING ERROR, repeat the configuration change. If the problem persists,

contact Technical Services.

Page 32 Chapter 2 - Using The Front Panel

Page 33

ION 7500 / ION 7600 User’s Guide Basic Setup Menu

Basic Setup Menu

The Basic Setup menu contains values that typically do not need to be reconfigured

once the meter is put into service. The Basic Setup menu item provides access to the

following power monitoring system settings:

Sub-Menu Register Default Description

Volts Mode 4 Wire Wye The power system’s configuration

PT Primary 120 The Potential Transformer’s primary winding voltage rating for VA, VB, and VC

PT/CT Setup

V4 Setup

I4/I5 Setup

V Polarity

1

I Polarity

Current

2

Probe

PT Secondary 120 The Potential Transformer’s secondary winding voltage rating for VA, VB, and VC

CT Primary 5 The Current Transformer’s primary winding current rating for IA, IB, and IC

CT Secondary 5 The Current Transformer’s secondary winding current rating for IA, IB, and IC

V4 Primary 120 The potential transformer’s primary winding rating on input V4

V4 Secondary 120 The potential transformer’s secondary winding rating on input V4

I4 Primary 5 The current transformer’s primary winding rating on input I4

I4 Secondary 5 The current transformer’s secondary winding rating on input I4

I5 Primary 5 The current transformer’s primary winding rating on input I5

I5 Secondary 5 The current transformer’s secondary winding rating on input I5

VA Polarity Normal The polarity of the potential transformer on VA

VB Polarity Normal The polarity of the potential transformer on VB

1

VC Polarity Normal The polarity of the potential transformer on VC

V4 Polarity Normal The polarity of the potential transformer on V4

IA Polarity Normal The polarity of the current transformer on IA

IB Polarity Normal The polarity of the current transformer on IB

IC Polarity Normal The polarity of the current transformer on IC

I4 Polarity Normal The polarity of the current transformer on I4

I5 Polarity Normal The polarity of the current transformer on I5

Probe Type Factory Default Current Probe Input setting – selects phase angle correction method for I1, I2, I3

1

Polarities can be normal or inverted.

2

Applicable to meters ordered with the current probe input option.

All Basic Setup menu items are setup registers in the Power Meter module. See the

online ION Programmer’s Reference for details.

The Current Probe phase calibration registers are setup registers in the Factory

module that can be configured in a Telnet or HyperTerminal session. Up to three

separate groups of registers (Factory Default, User Defined 1, and User Defined 2) can

be set up for three different Current Probes. In the Basic Setup menu, the Probe Type

register is used to activate one of those register groups. Only the selected group is

used in the meter’s calculations.

Chapter 2 - Using The Front Panel Page 33

Page 34

Main Setup Menu ION 7500 / ION 7600 User’s Guide

Main Setup Menu

Press the PROG button to enter the main setup menu. The following table

summarizes the front panel’s Setup menu functions:

Setup Menu Item Description

Basic Setup Changes basic settings in the power measurement system configuration

Demand Setup Sliding Window (Rolling Block) and Thermal Demand settings

COM1 Setup RS-232 or RS-485 port setup

COM2 Setup High-speed RS-485 port setup

COM3 Setup Optical port (infrared) and optional internal modem setup

Network Setup Ethernet Network addressing

PQ Setup Sets the criteria (including nominal voltage) for disturbance detection

Format Setup Customizes the style and values appearing on the display screens

Display Setup Customizes display appearance and update rate

Time Setup Clock and meter time settings

Security Setup Modify and enable/disable password functions

Meter Resets Reset functions for factory and user determined cumulative parameters

Highlight the Setup menu item that you want to access with the vertical navigation

buttons. To select the item, press the

item is described on the following pages.

Demand Setup Menu

Demand Setup provides access to all of the factory-configured parameters for

sliding window demand (rolling block) and thermal demand.