Page 1

Server Farm

Model MA3a

User Guide

Page 2

User Guide

88311200, Revision A

MultiArray

User Configurable Multiple-processor

III

(Model # MA3a)

Rack Mount Chassis

This publication may not be reproduced, in whole or in part, without prior expressed written permission from

Multi-Tech Systems, Inc.

All rights reserved.

Copyright © 1998, by Multi-Tech Systems, Inc.

Multi-Tech Systems, Inc. makes no representations or warranties with respect to the contents hereof and

specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

Furthermore, Multi-Tech Systems, Inc. reserves the right to revise this publication and to make changes from

time to time in the content hereof without obligation of Multi-Tech Systems, Inc. to notify any person or

organization of such revisions or changes.

Record of Revisions

Revision Description

A Manual Released. All pages at revision A.

(12/7/98)

Patents

This Product is covered by one or more of the following U.S. Patent Numbers:

5.355.365; 5.355.653; 5.452.289; 5.453.986

. Other Patents Pending.

5.301.274; 5.309.562

Trademarks

Multi-Tech, MultiArray , and the Multi-Tech logo are trademarks of Multi-Tech Systems, Inc.

Multi-Tech Systems, Inc.

2205 Woodale Drive

Mounds View , Minnesota 55112

(612) 785-3500 or (800) 328-9717

Fax (612) 785-9874

Tech Support (800) 972-2439

BBS (612) 785-3702 or (800) 392-2432

Internet Address: http://www.multitech.com

Fax-Back (612) 717-5888

;

Page 3

Contents

Chapter 1 - Introduction and Description

Introduction ................................................................................................................................................ 6

Manual Organization .................................................................................................................................. 7

T echnical Specifications............................................................................................................................. 8

Dimensions .......................................................................................................................................... 8

Power Supply....................................................................................................................................... 8

Safety................................................................................................................................................... 8

Environmental...................................................................................................................................... 8

Chapter 2 - Installation Quick Start

Unpacking ................................................................................................................................................ 10

Safety Warnings....................................................................................................................................... 10

Pre-Installation Notes................................................................................................................................11

Configuration Considerations ....................................................................................................................11

9-Pin DSUB Openings ....................................................................................................................... 12

Backplane Board ............................................................................................................................... 13

Hardware Installation Procedure .............................................................................................................. 14

Installing PC Boards .......................................................................................................................... 14

Internal SBC Cabling ......................................................................................................................... 16

Disk Drive Installation ........................................................................................................................ 18

8-Bay Disk Drive Cabling................................................................................................................... 20

Installing a Disk Drive into Horizontal Chassis................................................................................... 22

Replacing Cover....................................................................................................................................... 25

Mounting Optional Rails (MARAIL) .......................................................................................................... 25

External Cabling ....................................................................................................................................... 26

SBC Board Cabling............................................................................................................................ 26

NIC Cabling ....................................................................................................................................... 26

ISI Board Cabling............................................................................................................................... 26

Powering Up............................................................................................................................................. 27

Chapter 3 - Software Loading

Introduction .............................................................................................................................................. 30

Configuring Multiple SBCs ....................................................................................................................... 30

Software Documentation .......................................................................................................................... 30

Chapter 4 - Troubleshooting

Troubleshooting........................................................................................................................................ 32

Diagnostic Tests ....................................................................................................................................... 33

Before Calling Technical Support ............................................................................................................. 33

iii

Page 4

Chapter 5 - Warranty, Service and Technical Support

Introduction .............................................................................................................................................. 36

Limited Warranty ...................................................................................................................................... 36

On-line Warranty Registration............................................................................................................ 36

Tech Support ............................................................................................................................................ 37

Recording MultiArray Information ...................................................................................................... 37

Service ..................................................................................................................................................... 38

The Multi-Tech BBS ................................................................................................................................. 39

About CompuServe.................................................................................................................................. 40

About the Internet..................................................................................................................................... 40

About the Multi-Tech Fax-Back Service ................................................................................................... 40

iv

Page 5

Chapter 1 - Introduction and Description

Page 6

MultiArray User Guide

Introduction

The MultiArrayIII™ user-configurable multiple-processor server farm (model MA3a) is designed

to consolidate up to nine network servers into a single system that can be mounted in a standard

19-inch rack enclosure. The MA3a contains a user-configurable 20-slot segmented backplane

that sits on the floor of the chassis. On the upper left front of the chassis sits an 8-bay, 3½"

vertical disk drive chassis. A combination 3½" floppy disk drive and 5¼" CD-ROM (both included

in the basic chassis) resides on the upper-right front. Dual redundant hot-swappable power

supplies make up the bottom of the front side. The configurable backplane allows you to

customize for unique applications and third-party components by combining segments. For

example, combining the first two segments into a 6-slot arrangement allows for a 32-port

asynchronous data/fax communications server. The front of the MA3a is shown in Figure 1-1,

below.

A

115115

C

B

I

H

J

D

115115

E

G

F

F

J

Figure 1-1. MultiArrayIII

The vertical, 8-bay 3½" disk drive chassis (A) slides out for ease of installing and connecting

cables to the hard drives. Each subsegment has its own power switch (B) so that all the

components of a subsegment, including disk drives, can be independently powered on or off

(these features will be discussed in more detail later in this guide and in the MultiArray User

Guide). In addition, the muxing feature provides access to the CD-ROM and floppy drives via the

Binary Coded Decimal (BCD) display and muxing switch (C), allowing for smooth software

loading on all segments.

The horizontal drive chassis (D) contains a 3½" floppy disk drive and a 5¼" CD-ROM. In addition,

an open slot allows for the addition of an additional drive, i.e., a ninth hard drive or tape device.

The horizontal chassis also slides out for ease of drive installation and cable connections.

Individual segments access the CD-ROM and floppy drives via the muxing switch (C), which is

set to match the segment number for the appropriate SBC.

The power supply chassis located under the drive chassis contains two dual redundant hotswappable power supplies (E). The power supply area is located in the lower portion of the

chassis and is accessible from the front of the chassis. Power to the power supplies is controlled

by two master power switches (F) which light to indicate power, and each power supply module is

controlled by individual power switches (G). Power to each module is indicated by an LED (H)

and voltage switches on the individual modules (I) allow for selection of 1 15V or 230V operation.

The alarm reset switch (J) allows the alarm to be reset in the event of a power supply failure.

6

Page 7

Manual Organization

This manual tells you how to install your MultiArray hardware. For information on the Multi-Tech

or third party PentiumTM Based Single Board Computer (SBC), Network Interface Card (NIC),

Intelligent Serial Interface (ISI) Boards, etc., refer to the user documentation shipped with the

board. For information on running software on the MultiArray , refer to the applicable software

user documentation, shipped with your software package. The information contained in each

chapter is as follows:

Chapter 1 - Introduction and Description

Chapter 1 begins with an introduction to the MultiArray and continues with a description of its

hardware features. The chapter ends with a list of technical specifications.

Chapter 2 - Installation Quick Start

Chapter 2 provides the PC board and/or disk drive installation procedure, rack mounting

procedure, and cable connections for your MultiArray .

Chapter 3 - Software Loading

Chapter 3 discusses some software options available for the MultiArrayIII.

Chapter 1 - Introduction and Description

Chapter 4 - Troubleshooting

Chapter 4 covers possible steps to take in the event of a MultiArrayIII failure.

Chapter 5 - Warranty Service and Tech Support

Chapter 5 provides a description of the MultiArray’s two-year warranty, and offers instructions on

how to receive service for your MultiArray at the factory . In addition, this chapter provides

information about accessing our user bulletin board service (BBS) as well as receiving support

via our various Internet resources.

7

Page 8

MultiArray User Guide

Technical Specifications

The MultiArray

III

conforms to the following specifications:

Dimensions

Height: 10.75" (27 cm)

Width: 19" (48 cm)

Depth: 25" (63.5 cm)

Weight: 100 lbs. (45.35 kg)

Power Supply

AC Input

Operating Range: 1 15-230 VAC

180-270 V AC switch (switch must change on all four power supplies)

Frequency: 47-63 Hz

Current: 6A @ 115V

3A @ 230 V

Fuse: 5A @ 115V, 60 Hz

2.5A @ 230V, 50 Hz

Efficiency: 80%

DC Output

Output: +5V @ 60A (70A peak)

+12V @ 28A

-5V @ 1A

-12V @ 1A

Load Regulation: ±5% (+5, +12)

±10% (-5, -12)

Line Regulation: ±1% (+5,+12) ±2% (-5,-12)

Transient T ime: 50ms max

Ripple: ±1% (p-p)

Hold Time: 16ms min

PG Delay: 100-500ms after 5V output

Safety

Over Voltage Protection: 120% (+5)

Over Current Protection: 130%

Environmental

Temperature: 0-40o C

Humidity: 10% - 90% RH

Fan Rating: 35cfm (thermostatically controlled) each fan

Noise: 30db (A) each fan

8

Page 9

Chapter 2 - Installation Quick Start

Page 10

MultiArray User Guide

Unpacking

Check the items on the MultiArray shipping list to ensure that you have received the correct

accessories. Your MultiArray should include:

• MA3a chassis (with included CD-ROM and floppy drives)

• Two AC power cords

• Accessory kit (with jumper cards and ribbon cables)

• Driver diskette

• This Quick Start Guide

• User Guide diskette

• Tucows® accessory CD

Unpack and inspect the MultiArray rack for visible shipping damage. If damage is observed, do

not power-on the rack; contact Multi-Tech's Tech Support for advice (refer to Chapter 5 for

information on service and support). If no damage is observed, place the rack on a flat, stable

surface to begin installation and configuration.

Save the packing material for possible future use (e.g., return or relocation).

Safety Warnings

1. Both power cords must be unplugged to remove all power from the chassis. Each

redundant power supply has it’s own power cord and supplies power to various

components in the chassis. Therefore, both power supplies must be powered on for the

system to operate properly .

2. The power supply cords are intended to serve as the disconnect device. The outlet

sockets must be installed near the equipment and be easily accessible.

3. To reduce the risk of shock, all openings should be covered during normal operation of

equipment.

4. If the battery fails on the SBC and it needs to be serviced, refer to your SBC manual for

shipping instructions.

5. All servicing to be done by qualified personnel only.

10

Page 11

Pre-Installation Notes

Due to the high flexibility of the MultiArray, the options for configuration are many and varied. You

may be installing Multi-Tech components throughout, or combining components from other

vendors. For this reason this quick start guide, and these installation instructions, are written in

such a way as to be relevant to all possibilities. This means that when installing various

components such as PC boards and disk drives, you will be referenced to the user

documentation for that product, rather than given specific instruction for only one brand

component.

The installation process is provided in a sequential order (as listed below) and if you plan to

install components in a different order , take time to read through the manual first, so that

important notes and cautions will not be over looked. The installation process is as follows:

• Configuration Considerations

• Hardware Installation

Installing PC Boards

Installing SBC Boards

Installing NIC Boards

Installing ISI Boards

Internal SBC Cabling

Installing Disk Drives

Disk Drive Cabling

• Replacing Cover

• Mounting Rails (optional - for rack mounting)

• External Cabling

• Power Up

Chapter 2 - Installation Quick Start

Before you begin please read through the following important notes, and then proceed with the

procedures that follow.

Configuration Considerations

The MultiArray can be configured to meet your particular site requirements. The number and type

of PC boards and/or hard and floppy disk drives, CD-ROM, or tape drive installed in the

MultiArray rack varies depending on your site requirements.

Several configuration considerations should be resolved before the MultiArray is installed.

• Power requirements for each component should be added together to ensure that the power

supply rating is not exceeded.

• Disk drive, CD-ROM, and tape drive cables are long enough to reach their SBC.

• If additional RAM is added to a SBC, ensure that the power requirements are not exceeded.

• The SBC must have the HDD Block Mode function disabled in the BIOS for the CD-ROM

muxing to work properly . Refer to your SBC Owner’s Manual for instructions.

• If you are running Windows on a segment in the MA3a, the AUTORUN function for the CDROM must be disabled. If not disabled, the CD-ROM will be accessed every time the user

switches the CD-ROM from one segment to another.

• If a segment has accessed a particular CD or floppy disk and a new disk is now going to be

accessed, the ejection and insertion of the new CD or floppy must occur at the segment

which intends to access it. Otherwise, the SBC will think the last disk or CD accessed is still

there.

• If an MS9E is used with the MA3a, it is recommended that a 9-pin serial mouse be used

instead of a PS/2 mouse. The PS/2 mouse may exhibit lock-up problems where it needs to

be unplugged and plugged back in to work again.

• Do not attach ribbon cables to the Mux card if they will not be used.

11

Page 12

MultiArray User Guide

9-Pin DSUB Openings

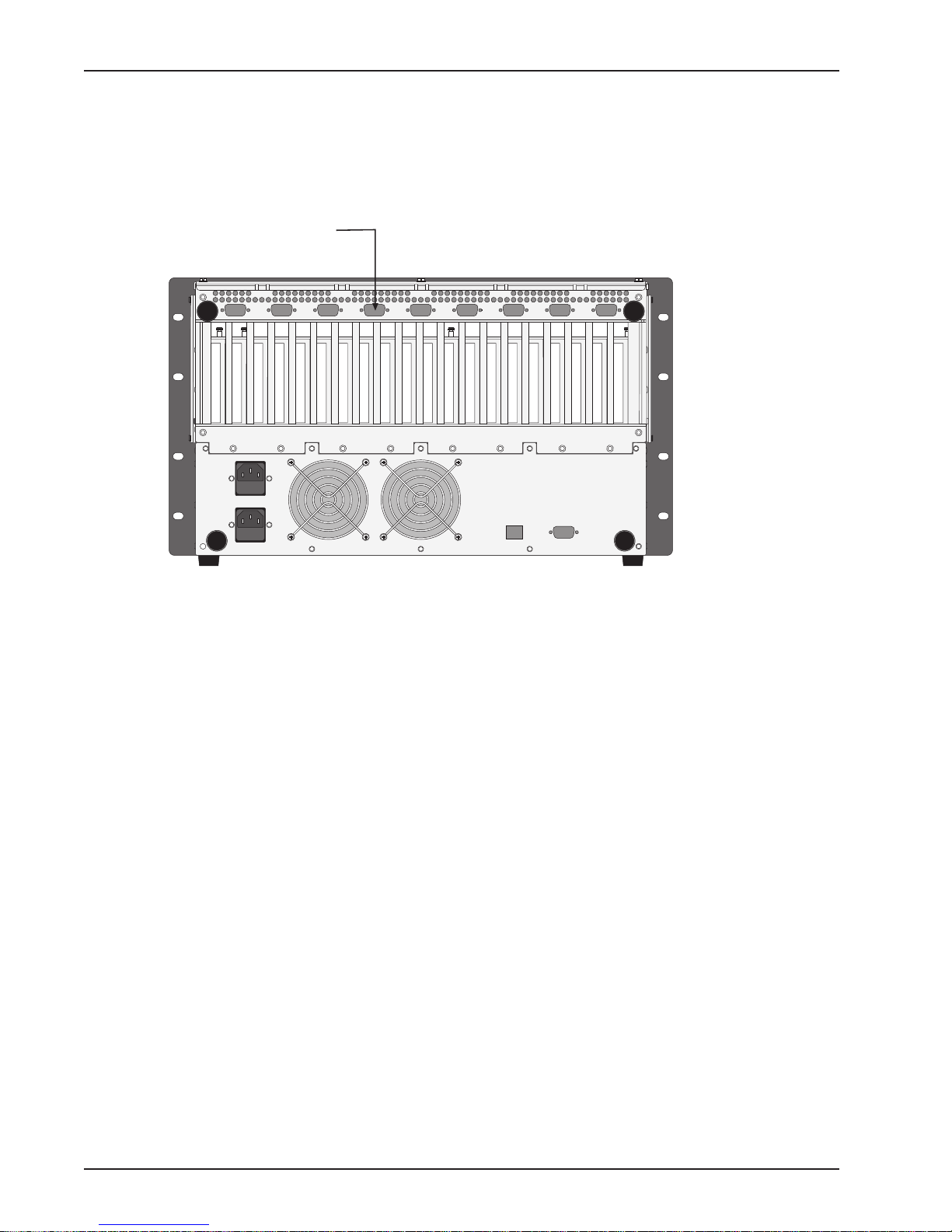

If the 9-pin DSUB openings will be used on the upper back panel of the MA3a chassis, the

coverplates need to be removed. Use a screwdriver (or similar tool) to punch the metal insert out

from the inside. The 9-pin connector can then be bolted to the chassis. Figure 2-1 shows the 9pin openings on the back panel of the MA3a.

9-Pin DSUB

Openings

Figure 2-1. 9-Pin DSUB Openings

12

Page 13

Chapter 2 - Installation Quick Start

Backplane Board

The user configurable backplane shown in Figure 2-2 allows you to combine subsegments (2card slots, i.e., SUB 1 NIC and CPU with SUB2 NIC and CPU) into a 4-slot segment. The first

two segments can be combined into a 6-slot segment along with the second and remaining three

segments being combined into 4-slot segments. Combining the first two segments is

accomplished by inserting a bus jumper circuit board (see Figure 2-3) into connector P5.

Inserting a bus jumper circuit board into connectors P2 through P4 converts the remaining

segments into 4-slot segments. Power can be individually switched on each subsegment

enabling an individual subsegment to be powered down rather than the complete backplane. The

voltage LEDs along the right edge are for power to segments 1-3. The LEDs along the left edge

are for power to segments 4 and 5.

Segment 5 Segment 4 Segment 3 Segment 2 Segment 1

12V

5V

-5V

-12V

P4

P3

P2

P1

P5

123456789

CPUCPUCPUCPUCPUCPUCPUCPUCPU NICNICNICNICNIC NICNICNICNIC

12V

5V

-5V

-12V

Figure 2-2. User Configurable Backplane

The four-pin molex connectors on the front end of the backplane (labeled 1-9) are used to

connect power to the drive in the horizontal disk drive chassis (1) and the drives in the 8-bay disk

drive chassis (2-9). The associated power cables (pre-attached) are Y cables that allow for

connection to either a floppy or hard drive, and have been labeled on both ends for ease of

installation.

The four 4-slot segments (SEGMENT 2 through SEGMENT 5) can have any combination of four

boards, with the exception that a SBC needs to be in the first slot to the left of the bus jumper

circuit board. To activate a 4-slot segment, all you have to do is install the bus jumper circuit

board (MTCLUSTER2-1) in connector P1 to make SEGMENT 2 a 4-slot segment, in P2 for

SEGMENT 3, P3 for SEGMENT 4 and P4 for SEGMENT 5 and apply power to the subsegments

(both subsegments must be powered on). The bus jumper circuit board shown in Figure 2-3

takes all the signals, except power, from one 2-slot segment and jumpers them to the next 2-slot

segment.

MTCLUSTER2-1

Front

Figure 2-3. Bus Jumper Circuit Board

13

Page 14

MultiArray User Guide

Hardware Installation Procedure

Depending on the individual configuration, the installation procedure may involve installing SBC

boards, NICs, ISI boards, hard disk drives, and tape drives into your MultiArray rack, cabling, and

mounting the rack in a standard 19-inch rack enclosure. Perform the following procedures to

install your MultiArray .

WARNING: Anytime power has to be removed from the complete rack, turn off the Master Power

switches inside the front door. To turn of f power to a subsegment, press the power switch for that

subsegment located under the vertical drive bay.

1 Remove the top cover by loosening the seven retaining screws on the top of the MA3a

chassis. Slide the cover towards the back of the chassis until the holes in the cover align

with the retaining screw heads. Lift the cover straight up and set it aside.

2 If you are installing boards using the factory default segment configuration (shown in

Figure 2-4), then proceed to Step 1 of the SBC installation procedure. Or:

T o change from 2-slot segments to 4-slot segments:

Locate a bus jumper circuit board (Figure 2-3) and insert it into connector P1, P2, P3 or

P4 depending on the segment you are activating. Proceed with the installation of your

boards.

T o change from 4-slot segments to 2-slot segments:

Remove the bus jumper circuit board (Figure 2-3) from the 4-slot segment you want to

change. Proceed with the installation of your boards.

Installing PC Boards

Perform the following procedures to install the PC board(s). Figure 2-4 shows a typical segment

installation.

OPEN

12V

5V

-5V

-12V

12345678

12V

5V

-5V

-12V

NIC

SOCKET 7

LOCK

IRQJUMPERS

15 12 11 10 7 5 4 3 2

12345678

OPEN

ISI (x2)

M1

M2

BANK 1

M3

M4

BANK 2

SBC

Figure 2-4. Component installation

14

Page 15

Chapter 2 - Installation Quick Start

Note: Installing SBCs in a 4-slot segment requires an SBC to the left of the bus jumper.

Installing SBC Boards

1 Verify SBC board configuration; refer to the hardware configuration and installation

section in the SBC user documentation.

2 Remove the slot cover plate on an open slot marked “CPU,” depending on how the

backplane is configured, and retain the cover plate mounting screw.

3 Install the SBC board into the open slot, securing it to the chassis with the screw you

removed in step 2. See Figure 2-4.

4 If you are installing multiple SBCs, repeat steps 1-3 until all SBC boards have been

installed. If Network Interface Cards (NICs) or Intelligent Serial Interface (ISI) cards are

being installed, perform those procedures below now and then proceed to the Internal

SBC Cabling procedures that follow.

Installing NIC Boards

1 Verify NIC configuration; refer to the installation section in the appropriate NIC Owner's

Manual.

2 Remove the slot cover plate on an open slot marked “NIC,” depending on how the

backplane is configured, and retain the cover plate mounting screw.

3 Install the NIC into the open slot, securing it to the chassis with the screw you removed in

step 2. See Figure 2-4.

4 If you are installing multiple NICs, repeat steps 1-3 until all NIC boards have been

installed. If Intelligent Serial Interface (ISI) cards are being installed, perform those

procedures below now and then perform the Internal SBC Cabling procedures that follow.

Installing ISI Boards

1 Verify ISI board configuration; refer to the hardware installation section in the appropriate

ISI Owner's Manual.

2 Remove the slot cover plate on an open slot, depending on how the backplane is

configured, and retain the cover plate mounting screw.

3 Install the ISI into the open slot, securing it to the chassis with the screw you removed in

step 2. See Figure 2-4.

4 If you are installing multiple ISIs, repeat steps 1-3 until all ISI boards have been installed.

When finished, proceed to the Internal SBC Cabling procedures that follow.

15

Page 16

MultiArray User Guide

Internal SBC Cabling

The internal cabling process involves the connection of each individual SBC to the mux card in

the MA3a chassis. The mux board connectors are shown in Figure 2-5.

HDD2

SFDD1

SHDD1

HDD1

CD-ROM Drive

Floppy Drive

Power for CD-ROM

and Floppy Drives

SFDD8

SFDD9

HDD9 HDD8

SFDD7

SHDD8

SHDD5

SFDD4

SHDD4

SFDD6

SHDD6

SHDD7SHDD9

HDD7

SFDD5

HDD6 HDD5 HDD4 HDD3

SFDD3

SFDD2

SHDD2

SHDD3

Figure 2-5. MA3a Mux Board Connectors

The connectors in Figure 2-4 have been labeled with acronyms that designate their segment

number and connection type. The three types of connector labels are SHDDn, SFDDn, and

HDDn (where n is the segment slot in which the corresponding SBC is installed). The “S”

indicates that the connection is between the mux board and the SBC. The designation of “FDD”

and “HDD” relate to the Floppy Disk Drive and Hard Disk Drive connectors accordingly. For

example, SFDD3 would indicate the connector is used to connect the floppy disk drive connector

on the SBC in segment 3. The information in this section details the SBC connections. For

information on connecting hard drives, refer to the Disk Drive Cabling section later in the guide.

Important: The SBC must have the HDD Block Mode function disabled in the BIOS for the CDROM muxing to work properly . Refer to your SBC user documentation for instructions.

16

Page 17

Chapter 2 - Installation Quick Start

SBC Connections

Figure 2-6 shows the two connections between the mux card and the SBC.

Floppy Drive

Connector

34-pin Ribbon

Pin 1

Cable (15)

40-pin Ribbon

Cable (13)

OPEN

12345678

SBC

Hard Drive

Connector

SOCKET 7

LOCK

Pin 1

Floppy Drive

Connector

Hard Drive

Connector

M2

M3

M4

BANK 1

BANK 2

M1

Mux Card

Figure 2-6. Ribbon Cable Connections

In this example, connector SHDD6 (40-pin) connects to the 40-pin hard drive connector on the

SBC board installed in segment 6. Connector SFDD6 (34-pin) connects to the 34-pin floppy drive

connector on the SBC board (Figure 2-10 shows the connection between the mux card and a

hard drive on the same segment).

Make all necessary SBC connections, and then proceed with the Disk Drive Installation section

that follows.

17

Page 18

MultiArray User Guide

Disk Drive Installation

Installing Drives in the 8-Bay Disk Drive Chassis

1 Open the front door on the rack.

Note: Although you can remove the front door for installation purposes, you must replace the

door prior to applying power to the unit.

2 Remove the two top front drive chassis mounting screws. See Figure 2-7.

3 Loosen, but do not remove, the two rear drive chassis mounting screws. See Figure 2-7.

Rear Drive Chassis

Mounting Screw

Front Drive Chassis

Mounting Screw

Figure 2-7. 8-Bay Drive Chassis Mounting Screws

4 Slide the chassis out the front of the MultiArray to the end of the slide travel.

5 If any disk drives are installed in the 8-bay disk drive chassis, remove the ribbon (data)

and power cables from the disk drives.

6 Remove the two rear chassis mounting screws and slide the chassis out the front of the

MultiArray .

18

Page 19

Chapter 2 - Installation Quick Start

7 Select the slot to install the disk drive and slide it into the slot. See Figure 2-8.

Drive Mounting

Screws (4 per device)

8-Bay Vertical

Drive Chassis

Disk Drives

(Hard or Floppy Drives)

Chassis Mounting

Screws (4)

Figure 2-8. Disk Drive Installation

8 Align the disk drive with the mounting holes in the top of the chassis and secure the drive

to the chassis with the four mounting screws provided with the drive. T wo mounting

screws in the top of the disk drive and two in the bottom.

9 Continue installing disk drives until complete.

10 Slide the 8-bay disk drive chassis partially into the MultiArray while guiding the bottom of

the chassis frame into the two plastic guides on the floor of the chassis area. Secure the

chassis slides with the two rear chassis mounting screws. Keep the chassis extended as

far out as possible for ease of connecting cables to the drives. When secured, proceed

with the 8-Bay Disk Drive Cabling section that follows.

19

Page 20

MultiArray User Guide

8-Bay Disk Drive Cabling

The disk drive cabling process involves making the connections between each disk drive and the

mux card via the ribbon (data) cables, and between each drive and the power connectors on the

backplane via the Y cables. The mux board connectors are shown in Figure 2-9.

HDD2

SFDD1

SHDD1

HDD1

CD-ROM Drive

Floppy Drive

Power for CD-ROM

and Floppy Drives

SFDD8

SFDD9

HDD9 HDD8

SFDD7

SHDD8

SHDD5

SFDD4

SHDD4

SFDD6

SHDD6

SHDD7SHDD9

HDD7

SFDD5

HDD6 HDD5 HDD4 HDD3

SFDD3

SFDD2

SHDD2

SHDD3

Figure 2-9. MA3a Mux Board Connectors

The connectors in Figure 2-8 have been labeled with acronyms that designate their segment

number and connection type (see the Internal SBC Cabling section for a description). The

information in this section details the disk drive connections. For information on the SBC

connections, refer to the SBC Cabling section of this guide.

Hard Drive Connections

1 Connect the ribbon (data) cable supplied with the MultiArray to the data connector on the

hard drive ensuring that pin 1 of the cable mates with pin 1 of the drive. These

connectors are 40-pin box connectors. See Figure 2-10.

Caution: Hard disk drives with IDE interfaces can connect to the SBC. Drives with other

interfaces, such as SCSI, can not be connected to the SBC. Refer to the drive publications for

data cabling and possible interface board installation.

20

Pin 1

Hard Drive

Connector

40-pin Ribbon

Cable (9)

Hard

Disk Drive

Figure 2-10. Disk Drive Connection

Mux Card

Page 21

Chapter 2 - Installation Quick Start

2 If the drive has an IDE interface, connect the other end of the ribbon cable to its

associated Mux connector, insuring that pin 1 of the cable mates with pin 1 of the Mux

connector. See Figure 2-10.

3 Connect the power cable associated with the SBC to the disk drive ensuring that pin 1 of

the cable mates with pin 1 of the drive connector. The power cables are a Y-cable with a

small connector for a floppy disk drive and a large connector for a hard disk drive. See

Figure 2-1 1.

Note: The Y-cables are labeled from 1 to 9 on all three connectors of each cable. The power

cables are associated with the subsegments of the five segments labeled on the backplane. The

power cable for segment 1 is labeled 1. The two power cables associated with segment 3 are

labeled as subsegment 1 power cable being labeled as 4 and subsegment 2 power cable being

labeled as 5.

Segment 5 Segment 4 Segment 3 Segment 2 Segment 1

12V

5V

-5V

-12V

P4

P3

P2

P1

CPUCPUCPUCPUCPUCPUCPUCPUCPU NICNICNICNICNIC NICNICNICNIC

12V

5V

-5V

-12V

P5

123456789

Figure 2-11. Y-Power Cable

4 If you are cabling multiple drives, repeat steps 1-3 until complete. When you are finished,

slide the 8-bay disk drive chassis all the way into the MultiArray and tighten the back two

mounting screws and replace the two front mounting screws. If you are installing a drive

in the horizontal drive chassis, proceed to the next section. If your installation is

complete, proceed to the External Cabling section of this chapter.

Hard or Floppy

Drive Drive

21

Page 22

MultiArray User Guide

Installing a Disk Drive into Horizontal Chassis

Your MA3a comes pre-configured with a floppy and CD-ROM drive installed in the combination

horizontal drive chassis. The data and power cables from these drives have already been

connected. If you wish to add a disk drive, proceed with the following procedure.

1 Remove the two top front combination horizontal chassis mounting screws. See Figure

2-12.

2 Loosen, but do not remove, the two top rear chassis mounting screws. See Figure 2-12.

3 Slide the chassis out the front of the MultiArray to the end of the slide travel.

Rear Drive Chassis

Mounting Screw

Front Drive Chassis

Mounting Screw

Figure 2-12. Combination Horizontal Chassis Mounting Screws

4 Remove the ribbon (data) and power cables from the installed disk drives.

5 Remove the two rear chassis mounting screws and slide the chassis out the front of the

MultiArray .

Chassis Mounting

Screws (4)

Horizontal Drive

Chassis

Floppy Disk

Drive

CD-ROM

Drive Mounting

Screws (4 per device)

Figure 2-13. Combination Horizontal Chassis

22

Page 23

Chapter 2 - Installation Quick Start

6 To mount a half height drive in the combination horizontal chassis, the drive has to first

be attached to the half height disk drive mounting bracket. To mount the drive to the

bracket, place the drive in the bracket and secure it to the four side tabs or the four

bottom tabs on the bracket. Use the four mounting screws supplied with the drive.

7 To mount the bracket and half height drive to the horizontal chassis, slide the bracket into

the chassis and rest on the four tabs. Secure the bracket to the chassis using four

bracket mounting screws.

8 Slide the horizontal chassis partially into the MultiArray while guiding the bottom of the

chassis frame into the two plastic guides on the floor of the chassis area. Secure the

chassis to the slides with the two rear chassis mounting screws. Keep the chassis

extended as far out of the MultiArray as possible for ease of connecting cables to the

devices.

9 Connect one end of the 9” ribbon (data) cable supplied with the MultiArray to the data

connector on the device ensuring that pin 1 of the cable mates with pin 1 of the device.

See Figure 2-14.

Caution: Disk drives with IDE interfaces can be connected to the Mux connector. Drives with

other interfaces, such as SCSI interfaces, can not be connected to the SBC. Refer to the drive

publications for data cabling and possible interface board installation.

Note: Due to the length of the CD-ROM drive, it must stay in the bottom bay of the horizontal

drive chassis.

Mux Card

Pin 1

Hard Drive

Connector

40-pin Ribbon

Cable (9)

Hard

Disk Drive

Figure 2-14. Drive Data Connection

10 If the drive has an IDE interface, connect the other end of the ribbon cable to its

associated Mux connector (HDD1) ensuring that pin 1 of the cable mates with pin 1 of

the Mux connector.

23

Page 24

MultiArray User Guide

1 1 Connect the power cable to the disk drive ensuring that pin 1 of the cable mates with pin

1 of the drive connector. The power cables are a Y-cable with a small connector for a

floppy disk drive and large connector for a hard disk drive. See Figure 2-15.

Segment 5 Segment 4 Segment 3 Segment 2 Segment 1

12V

5V

-5V

-12V

P4

P3

P2

P1

Hard or Floppy

Drive Drive

Figure 2-15. Y-Power Cable

CPUCPUCPUCPUCPUCPUCPUCPUCPU NICNICNICNICNIC NICNICNICNIC

12V

5V

-5V

-12V

P5

123456789

Note: The Y-cables are labeled from one to nine on all three connectors on each cable. The

power cables are associated with the subsegments of the five segments labeled on the

backplane. The power cable for segment 1 is labeled 1.

12 Reconnect the data cables to the floppy and CD-ROM drives. See Figure 2-16.

Mux Card

Pin 1

40-pin Ribbon

Cable (9)

Pin 1

34-pin Ribbon

CD-ROM Drive

Cable (12)

Floppy

Disk Drive

Figure 2-16. Floppy and CD-ROM Drive Data Connections

24

Page 25

13 Reconnect the power cables to the floppy and CD-ROM drives. See Figure 2-17.

Figure 2-17. Floppy and CD-ROM Drive Power Connections

13 Slide the chassis all the way into the MultiArray and tighten the back two mounting

screws and replace the two front mounting screws.

Replacing Cover

Chapter 2 - Installation Quick Start

Mux Card

Floppy

Disk Drive

CD-ROM Drive

Align the holes in the cover with the retaining screws on the MA3a chassis. Replace the top

cover and slide towards the front of the chassis. Tighten the seven retaining screws.

Mounting Optional Rails (MARAIL)

If you are installing the MultiArray in a standard rack enclosure, perform the following steps to

install the optional mounting rails prior to cabling and power-up.

1 Attach the left hand rail (Figure 2-18) to the left side of the rack using the five 10x32

mounting screws.

2 Attach the right hand rail to the right side of the rack using the five 10x32 mounting

screws.

3 Replace the top cover.

4 Place the MultiArray rack in the standard 19-inch rack enclosure and secure the rails to

the enclosure.

Left Hand

Rail

Rail

Mounting

Screws (5)

Figure 2-18. Installing Rails

010

0

0

1

1

1

25

Page 26

MultiArray User Guide

External Cabling

The descriptions below are appropriate for Multi-Tech products. For other vendor components,

refer to the user documentation for that component.

Note 1: Prior to making the external connections, make sure that the chassis cover has been

replaced and all retaining screws tightened.

Note 2: If you are using the MultiArray in tandem with the Multi-Tech Video/Keyboard/Mouse

Switch (model MS9E), refer to the MS9E Owner’s Manual for additional cabling instructions.

SBC Board Cabling

The SBC board cabling involves connection to the three bracket side connectors. The bracket

side connectors are:

• Video connector

• COM 1 connector

• Keyboard connector

Refer to the Pentium SBC Owner's Manual for more information on the SBC board connectors

and cabling.

NIC Cabling

Since there are a number of network protocols (e.g., Ethernet) as well as various NIC media

supported (UTP, coax, etc.) the list of connections may vary. A typical set of bracket side

connectors for an Ethernet connection are:

• Coax (BNC connector)

• UTP (RJ-45 connector)

Refer to the applicable NIC Owner’s Manual for more information on the NIC connectors and

cabling.

ISI Board Cabling

The ISI board cabling typically involves connecting an octopus cable to the DB-78 connector on

the ISI board. Attach the other ends of the octopus cable to the modems, multiplexers, X.25

PADS, etc..

Refer to the applicable ISI Owner's Manual for more information on the ISI board connectors and

cabling.

26

Page 27

Powering Up

Before powering-on the MultiArray verify the following information:

• Verify that both power cords are attached to the unit and to a live AC outlet. Both of the

power cords must be plugged in for the system to operate properly .

• Verify that the slide switch on all four power modules is set for the appropriate AC voltage

(either 1 15V or 230V).

• Verify that the power switch for each of the four power modules is on before master power

switches are turned on.

To power-on the MultiArray:

• Press the Master Power switches on the front of the chassis to the On Position. Then, ensure

that the populated subsegments are also powered up. See Figure 2-18.

Chapter 2 - Installation Quick Start

Individual Segment Power Switches

115115

BCD Display and

Toggle Switch

115115

Master Power Switches

Figure 2-18. On/Off Switch

• Once the unit has been powered, refer to the Power-Up Notes that follow prior to loading any

software.

Power-Up Notes

Note 1: For the CD-ROM and Floppy drives to be initialized on each SBC, toggle the BCD

display to match the segment. Power-on that segment. Once it has booted, change the BCD

display to the next segment and power it on. Continue this process until all populated segments

are on.

Note 2: If the disk is changed in the CD-ROM or floppy drive, the only SBC that will recognize it

will be the segment selected on the BCD display . The disk (CD or floppy) must be ejected and

reinserted for each segment in order for that segment to see the new disk.

Troubleshooting Power-Up

This system contains two sets of dual power supplies. The right set powers the first five

segments and the left set powers segments 6-9. If a group of segments does not power up,

check that the power switches for each power system are turned on. All individual power supply

module switches should be left on and the master power switches used to turn power to the

segments on and off.

27

Page 28

MultiArray User Guide

28

Page 29

Chapter 3 - Software Loading

Page 30

MultiArray User Guide

Introduction

This chapter discusses software options available on the MultiArray . The hardware installation

procedures in Chapter 2 of this manual must be performed before starting any software loading

or operating procedures.

Configuring Multiple SBCs

When configuring multiple SBCs from a single floppy disk drive, ensure that the diskette is writeprotected or remove the diskette from the disk drive before toggling the BCD display to another

segment. If the diskette is not write-protected or removed from the disk drive, the diskette may

get corrupted when the BCD display is toggled from one segment to the other.

Software Documentation

Operating procedures consist of loading the optional software. Refer to the applicable software

manual for software loading and operation.

30

Page 31

Chapter 4 - Troubleshooting

Page 32

MultiArray User Guide

T roubleshooting

The recommended troubleshooting process for the MultiArray is to determine the following

results:

• Is the rack plugged in and does the wall plug have power.

• If power supply ALARM sounds:

1) Check to see if power supply LEDs are ON and fans are running.

2) If power supply LED is OFF, check that power supply is turned on.

3) If power supply LED is OFF and fans are not running, turn power supply module off

for at least 10 minutes. Then, turn back on. If power supply module still fails, then

replace the power supply module.

4) Push Alarm Reset Switch (red button) to turn of f (reset) alarm.

5) Power supply module can be replaced by turning module off, removing screw and

pulling module out. Put the new module in, replace the screw, and turn the module

on.

• If a subsegment power switch is ON and its LED for that group of segments is OFF, and

the four main power LEDs on the backplane are ON, the subsegment is bad. Contact

Tech Support for assistance in returning unit, refer to Chapter 5.

• If one of the eight power LEDs (two sets of four LEDs) on the backplane is OFF, the

power supplies may be defective or a defective backplane. Contact Tech Support for

assistance in returning unit, refer to Chapter 5.

• If intermittent problems with SBCs, SBC will not power up correctly , or fans seem to be

slowing down, check the following:

1) Check that the disk drive cables are connected correctly, pin 1 to pin 1 (red line) on

all cables from SBC to mux board.

2) Check that other SBC cables are connected correctly .

3) If cabled correctly and a problem still exists, move SBC to another segment, if

problem goes away, subsegment is bad. Contact Tech Support for assistance in

returning unit, refer to Chapter 5.

4) If problem still exists after moving to another segment, problem is probably in SBC,

replace SBC.

• Disk drive does not work, check the following:

1) Subsegment power switch is turned ON.

2) Check that disk drive is cabled correctly , pin 1 on drive to pin 1 (red line) on cable.

3) Check for 5 and 12 volts on subsegment power cable. The 5V is the red lead (left

side) and 12V is the yellow lead (right side). The center two leads are ground. If

either voltage is 5% less than its designated value, subsegment is bad. Either move

boards to another segment or contact Tech Support for assistance in returning unit.

Refer to Chapter 5.

5V

Red

4) Check that ribbon cables and power cable for the same segment are connected to

the drive (i.e., cables for segment 6 are connected to drive if segment 6 is intended

segment).

32

12V

Yellow

Page 33

Diagnostic Tests

The SBC operates much like any stand-alone PC, and the MultiArray will run almost any diskettebased off-the-shelf diagnostic program. These programs are available at any software re-seller ,

and can quickly help isolate component failures.

Before Calling Technical Support

For immediate help in finding and fixing MultiArrayIII problems, record the error condition and call

Multi-Tech’s Technical Support Department (refer to Chapter 5 of this manual).

Chapter 4 - Troubleshooting

33

Page 34

MultiArray User Guide

34

Page 35

Chapter 5 - Warranty, Service and Technical Support

Page 36

MultiArray User Guide

Introduction

This chapter starts out with statements about your MultiArray’s 2-year warranty . The next section,

Tech Support, should be read carefully if you have questions or problems with your MultiArray. It

includes the technical support telephone numbers, space for recording your product information,

and an explanation of how to send in your MultiArray should you require service. The final three

sections explain how to use our bulletin board service (BBS), and get support through

CompuServe and the Internet.

Limited Warranty

Multi-Tech Systems, Inc. (“MTS”) warrants that its products will be free from defects in material or

workmanship for a period of two years from the date of purchase, or if proof of purchase is not

provided, two years from date of shipment. MTS MAKES NO OTHER WARRANTY,

EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. This warranty does not

apply to any products which have been damaged by lightning storms, water, or power surges or

which have been neglected, altered, abused, used for a purpose other than the one for which

they were manufactured, repaired by the customer or any party without MTS’s written

authorization, or used in any manner inconsistent with MTS’s instructions.

MTS’s entire obligation under this warranty shall be limited (at MTS’s option) to repair or

replacement of any products which prove to be defective within the warranty period, or, at MTS’ s

option, issuance of a refund of the purchase price. Defective products must be returned by

Customer to MTS’s factory transportation prepaid.

MTS WILL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES AND UNDER NO

CIRCUMSTANCES WILL ITS LIABILITY EXCEED THE PURCHASE PRICE FOR DEFECTIVE

PRODUCTS.

On-line Warranty Registration

To register your MultiArray on-line, click on the following link:

http://www.multitech.com/register

36

Page 37

Tech Support

Multi-Tech has an excellent staff of technical support personnel available to help you get the most

out of your Multi-Tech product. If you have any questions about the operation of this unit, call 1800-972-2439. Please fill out the MultiArray information (below), and have it available when you

call. If your MultiArray requires service, the tech support specialist will guide you on how to send

in your MultiArray (refer to the next section).

Recording MultiArray Information

Please fill in the following information on your Multi-Tech MultiArray . This will help tech support in

answering your questions (the same information is requested on the Warranty Registration link

listed above).

Model No.: _________________________

Serial No.: _________________________

The model and serial numbers are on the bottom of your MultiArray chassis.

Please note the type of external link device that is connected to your ProxyServer before calling

tech support. Also, note the status of your MultiArray including, screen messages, diagnostic test

results, problems with a specific application, etc. Use the space below to note the MultiArray

status:

Chapter 5 - Warranty, Service and T ech Support

________________________________________________________________________________________________________

________________________________________________________________________________________________________

________________________________________________________________________________________________________

________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________

37

Page 38

MultiArray User Guide

Service

If your tech support specialist decides that service is required, your MultiArray may be sent

(freight prepaid) to our factory . Return shipping charges will be paid by Multi-Tech Systems.

Include the following with your MultiArray:

• a description of the problem.

• return billing and return shipping addresses.

• contact name and phone number.

• check or purchase order number for payment if the MultiArray is out of warranty. (Check

with your technical support specialist for the standard repair charge for your MultiArray).

• if possible, note the name of the technical support specialist with whom you spoke.

If you need to inquire about the status of the returned product, be prepared to provide the serial

number of the product sent.

Send your MultiArray to this address:

MULTI-TECH SYSTEMS, INC.

2205 WOODALE DRIVE

MOUNDS VIEW, MINNESOTA 55112

ATTN: SERVICE OR REPAIRS

You should also check with the supplier of your MultiArray on the availability of local service and/

or loaner units in your part of the country .

38

Page 39

The Multi-Tech BBS

For customers who do not have Internet access, Multi-Tech maintains a bulletin board system

(BBS) that mirrors its FTP site. Information available from the BBS includes new product

information, product upgrade files, and problem-solving tips. The phone number for the MultiTech BBS is (800) 392-2432 (USA and Canada) or (612) 785-3702 (international and local).

The BBS can be accessed by any asynchronous modem operating at 1200 bps to 33,600 bps at

a setting of 8 bits, no parity , and 1 stop bit (8-N-1).

To log on to the Multi-Tech BBS

1. Set your communications program to 8-N-1.

2. Dial our BBS at (800) 392-2432 (USA and Canada) or (612) 785-3702 (international and

local).

3. At the prompts, type your first name, last name, and password; then press ENTER. If

you are a first time caller, the BBS asks if your name is spelled correctly. If you answer

yes, a questionnaire appears. You must complete the questionnaire to use the BBS on

your first call.

4. Press ENTER until the Main Menu appears. From the Main Menu you have access to

two areas: the Files Menu and News. For help on menu commands, type ?.

Chapter 5 - Warranty, Service and T ech Support

To Download a file

If you know the file name

1. From the Main Menu, type F to access the Files Menu, then type D.

2. Enter the name of the file you wish to download from the BBS.

3. If a password is required, enter the password.

4. Answer Y or N to the automatic logoff question.

5. Select a file transfer protocol by typing the indicated letter, such as Z for Zmodem (the

recommended protocol).

6. If you select Zmodem, the transfer will begin automatically . If you select another protocol,

you may have to initiate the transfer yourself. (In most datacomm programs, the P AGE

DOWN key initiates the download.)

7. When the download is complete, press ENTER to return to the File Menu.

8. To exit the BBS, type G and press ENTER.

If you don’t know the file name

1. From the Main Menu, type F to access the Files Menu. For a list of file areas, type L,

press ENTER, then type L and press ENTER again. (If you do not type the second L,

you will list all of the files on the BBS.)

2. Mark each file area you would like to examine by typing its list number and pressing

ENTER.

3. Enter L to list all the files in the selected file areas. Enter C to go forward in the file list

and P to go back.

4. To mark one or more files for download, type M, press ENTER, type the list numbers of

the files, and press ENTER again.

39

Page 40

MultiArray User Guide

5. Enter D. You will see a list of the files you have marked. Enter E if you would like to edit

the list; otherwise enter D again to start the download process.

6. Select a file transfer protocol by typing the indicated letter, such as Z for Zmodem (the

recommended protocol).

7. If you select Zmodem, the file will transfer automatically . If you select another protocol,

you may have to initiate the transfer yourself. (In most data communications programs,

the P AGE DOWN key initiates the download.)

8. When the download is complete, press ENTER to return to the File Menu.

9. To exit the BBS, type G and press ENTER.

About CompuServe

In addition to the BBS, Multi-Tech provides support through CompuServe’s Modem V endor

Forum (GO MODEMVEN). Refer to your Compuserve documentation for special operating

procedures.

About the Internet

Multi-Tech is a commercial user on the Internet, and we retrieve messages from our customers

on a periodic basis. If you prefer to receive technical support via the Internet, you can contact

Tech Support at the following address:

http://www.multitech.com/_forms/email_tech_support.htm

Multi-Tech’s presence includes a Web site at:

http://www.multitech.com

and an ftp site at:

ftp://ftp.multitech.com

About the Multi-Tech Fax-Back Service

Multi-Tech’s fax-back system provides 24-hour access to sales, marketing, and technical

literature. Dial 612-717-5888, follow the voice prompts, and request document number 10 for a

catalog of available documents. For convenience, have your fax number handy:

_________________________. From the catalog of available documents, you can order

newsletters, white papers, press releases, etc. from the sales and marketing index (pages 1-4),

or order basic modem operation and troubleshooting guides from the technical support and

engineering index. Just enter the applicable FB Doc. # from the left column of the catalog.

40

Loading...

Loading...