Page 1

PARTS AND OPERATION MANUAL

WRS-5200 Ride-On

Roller Screed

© COPYRIGHT 2001, MULTIQUIP INC.

Revision #2 (08/09/02)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

Page 2

PAGE 2 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800/427-1244 or 310/537-3700

FAX: 800/672-7877 or 310/637-3284

SERVICE DEPARTMENT

800/478-1244 or 310/537-3700

FAX: 310 - 537-4259

WARRANTY DEPARTMENT

800/421-1244, EXT. 279 or 310/537-3700

FAX: 310 - 537-1173

MAIN

800/421-1244 or 310/537-3700

FAX: 310 - 537-3927

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 3

Page 4

TABLE OF CONTENTS

WRS-5200 RIDE-ON ROLLER

SCREED.

Here's How To Get Help .............................................3

Table Of Contents ......................................................4

Training Checklist ....................................................... 5

Daily Pre-Operational Checklist .................................6

Parts Ordering Procedures ........................................7

Operation and Safety Decals ..................................... 8

Specifications .............................................................9

Safety Message Alert Symbols .......................... 10-11

Rules for Safe Operation ................................... 12-13

Features ................................................................... 14

Assembly Instructions ........................................ 15-21

Machine Controls ............................................... 22-23

Machine Start-up and Operation ....................... 24-25

Maintenance and Adjustment Procedures......... 26-27

Suggested Training ............................................ 28-29

Form Specifications .................................................30

Screed Rails .............................................................31

18 and 22 Foot Screed Lengths ..............................32

26 and 28 Foot Screed Lengths ..............................33

30 and 32 Foot Screed Lengths ..............................34

36 and 40 Foot Screed Lengths ..............................35

44 Foot Screed Lengths ..........................................36

48 and 52 Foot Screed Lengths ..............................37

Assembly Drawings

Frame Asssembly (Operator End) ..................... 38-39

Frame Asssembly (Engine End) ........................ 40-43

Control Panel Asssembly ................................... 44-47

Engine Assembly ............................................... 48-51

Frame Assembly ................................................ 52-55

Hydraulic Assembly ............................................ 56-59

Pressure Washer Assembly ............................... 60-61

Wiring Diagram

Wiring Diagram .................................................. 62-63

Terms and Conditions Of Sale — Parts ................... 64

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 5

TRAINING CHECKLIST

TSILKCEHCGNINIART

.ON NOITPIRCSED ?KO ETAD

1 .yletelpmoclaunaMs’rotarepOdaeR

2

3 .erudecorpgnileufer,metsysleuF

4 .)deppiuqefi(sthgildnayarpsfonoitarepO

5 .)gninnurtonenihcam(slortnocfonoitarepO

6 .noitarepohctiwslliktaes,slortnocytefaS

7 .serudecorppotsycnegremE

8 .serudecorptnemtsujdaniahC

9 .serudecorpgnignahcniahC

01 .elttorhtekohcenigne,enihcamfoputratS

11 .sebutevirdhtiwgnirevuenaM

21 .noitarepoebutekirtS

31 .selkcubnrutrebmacdnanworcfotnemtsujdA

dnaenignefognikcehc,stnenopmocfonoitacol,tuoyalenihcaM

.slevellioxobraeg

41 .erudecorpnwodtuhS

51 .)spooltfil(enihcamfognitfiL

61 .egarotsdnatropsnartenihcaM

71 .rehsawerusserpfonoitarepO

81 .erudecorppunaelC

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 5

Page 6

YADLIOENIGNE

1

2

3

4

5

6

7

8

9

01

11

21

31

41

51

61

71

81

91

02

12

22

32

42

52

62

72

82

92

03

13

DAILY PRE-OPERATION CHECKLIST

TSILKCEHCNOITAREPO-ERPYLIAD

SAGLLIF

KNAT

NOITAREPO

SRUOH

ROTAREPO

)SLAITINI(

YBDENAELC

)SLAITINI(

STNEMMOC

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

PAGE 6 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 7

PARTS ORDERING PROCEDURES

■■

■ Dealer account number

■■

■■

■ Dealer name and address

■■

■■

■ Shipping address (if different than billing address)

■■

■■

■ Return fax number

■■

■■

■ Applicable model number

■■

■■

■ Quantity, part number and description of each part

■■

■■

■ Specify preferred method of shipment:

■■

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

■■

■

UPS Ground Service at no charge for freight

■■

■■

■

PS Third Day Service at one-half of actual freight cost

■■

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

UPS

Special

For faxed orders only

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 7

800/6-PARTS-7 • 800-672-7877

Page 8

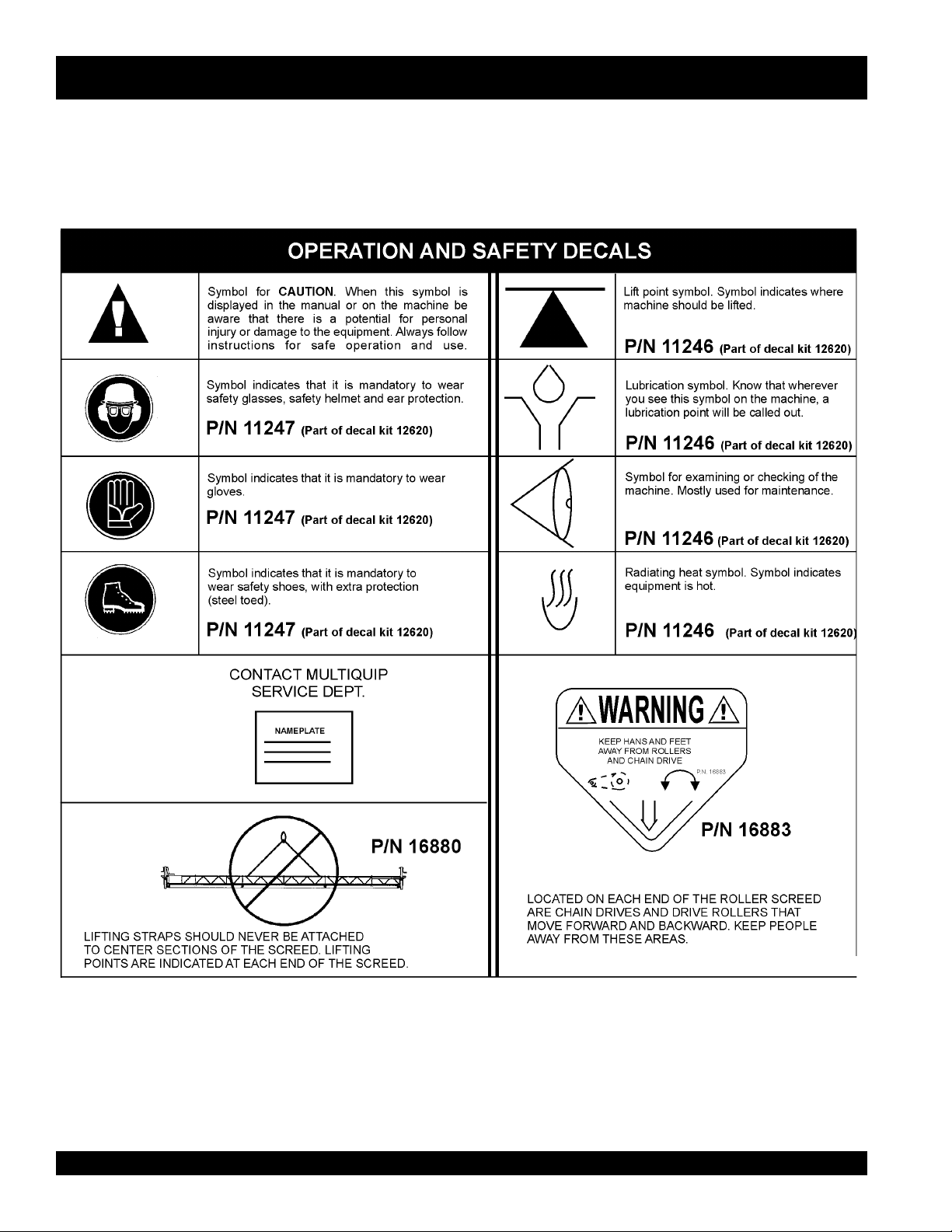

OPERATION AND SAFETY DECALS

Machine Safety Decals

The WRS-5200 Ride-On Roller Screed is equipped with a number of safety decals. These decals are provided for operator safety

and maintenance information. The illustration below and on the next page shows these decals as they appear on the machine.

Should any of these decals become unreadable, replacements can be obtained from your dealer.

PAGE 8 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 9

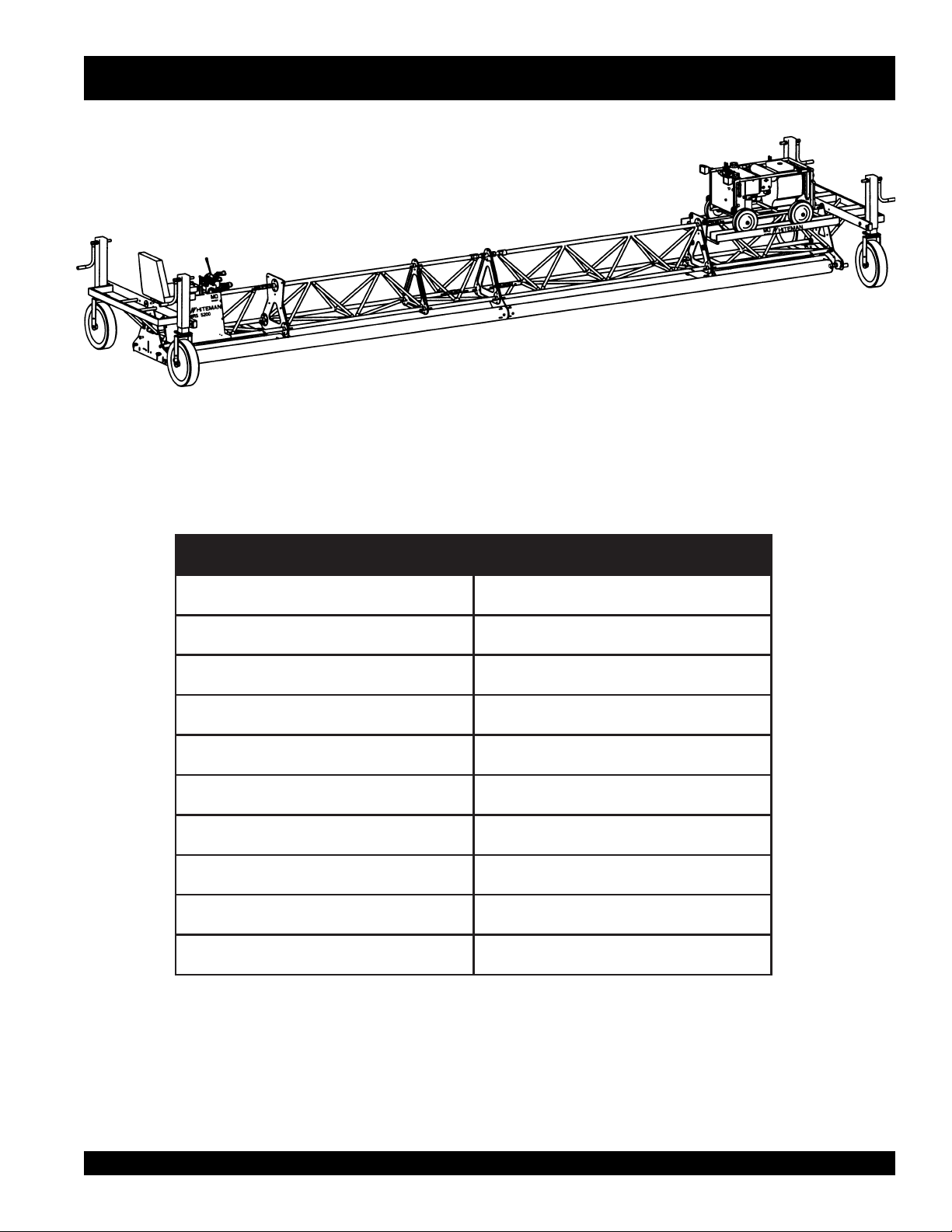

WRS-5200 — SPECIFICATIONS

Figure 1. WRS-5200 Ride-On Roller Screed

)snoitceS9xaM(htgneL)sretem48.51(.TF25

)sdnEtA(htdiW)sretem1.2(.TF7

)htgneL.xaM(thgieW).gk086(SBL005,1

)tinUrewoP(thgieW)gk722(.SBL005

deepSebuTekirtSMPR054xaM

deepSebuTevirDMPR051.xaM

erusserPgnitarepOciluardyHISP0002.xaM

liOciluardyH64OSIVMWA

enignEnanOPH02

leuFenilosaGdedaelnU

SNOITACIFICEPSDEERCSRELLOR.1ELBAT

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 9

Page 10

WMS MULTI-USE SCREED — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when

operating this equipment. Failure to read and understand the

Safety Messages and Operating Instructions could result in

injury to yourself and others.

HAZARD SYMBOLS

NOTE

This Owner's Manual has been developed to provide

complete instructions for the safe and efficient operation

of the Multiquip Model WRS-5200 Ride-On Roller

Screed. Refer to the engine manufacturers instructions

for data relative to its safe operation.

Before using this mini-screed, ensure that the

operating individual has read and understands all

instructions in this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

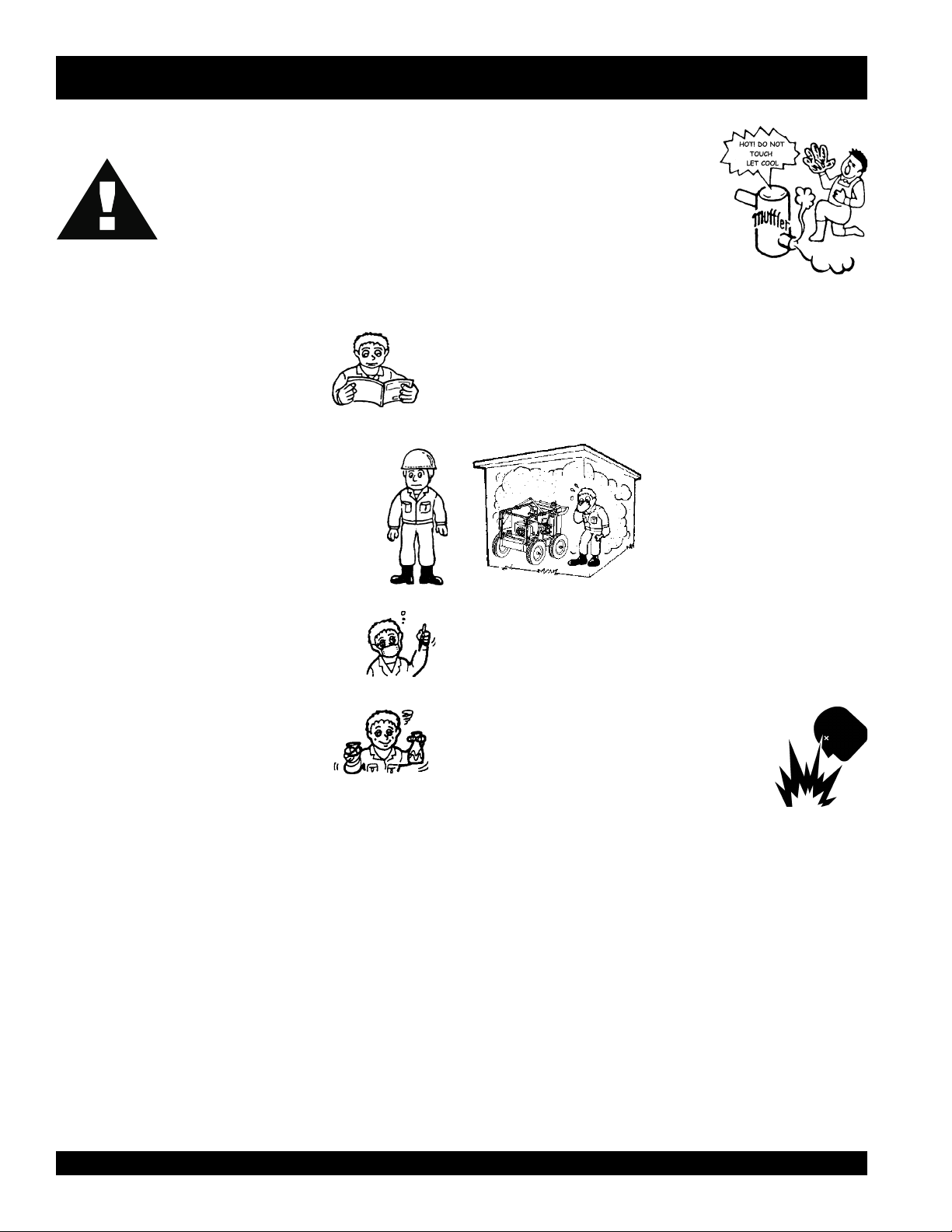

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

GASOLINE is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGER: You WILL be KILLED or

SERIOUSLY injured if you do not follow

directions.

WARNING: You CAN be KILLED or

SERIOUSLY injured if you do not follow

directions.

CAUTION: You CAN be injured if you

do not follow directions.

Potential hazards associated with WRS-5200 Ride-On Roller

Screed operation will be referenced with Hazard Symbols which

appear throughout this manual, and will be referenced in

conjunction with Safety Message Alert Symbols.

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. Never operate the engine with heat

shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep fingers, hands, hair and

clothing away from all moving parts to prevent

injury.

PAGE 10 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 11

WMS MULTI-USE SCREED — SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the engine ON/OFF switch in

the OFF position, and remove the ignition key

when the machine is not in use.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Respiratory Hazard

ALWAYS wear approved respiratory

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your trash pump, other property, or

the surrounding environment.

NOTE

This mini-screed, other property, or the

surrounding environment could be damaged

if you do not follow instructions.

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 11

Page 12

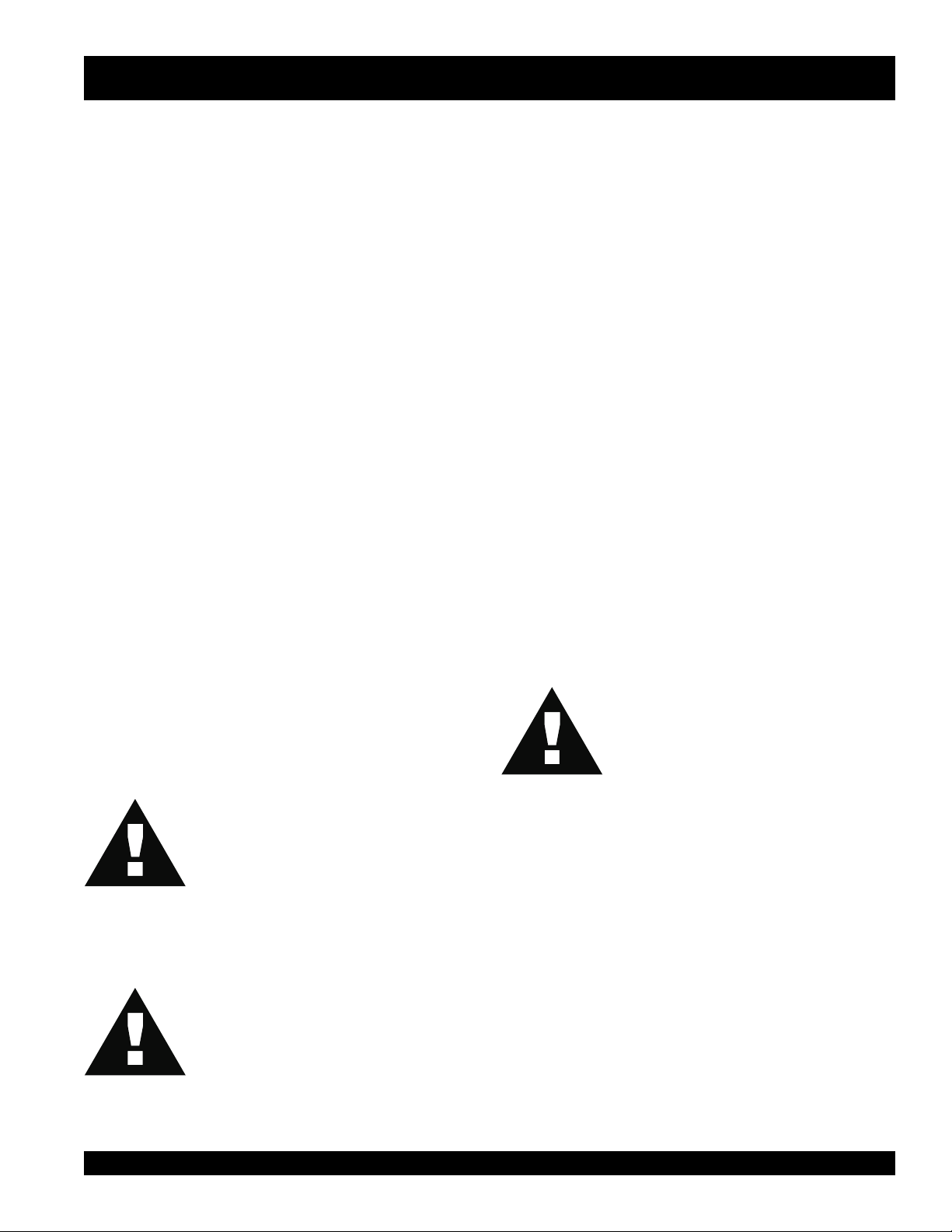

WRS-5200 — RULES FOR SAFE OPERATION

■

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

The following safety guidelines should always be used when

operating the WRS-5200 Ride-On Roller Screed.

:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is for

industrial use only.

GENERAL SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by

persons under 18 years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steeltoed boots and other protective devices required

by the job.

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

engine or trowel.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

with

■

The power units's engine requires an adequate free flow of

cooling air. NEVER operate the screed in any enclosed or

hot

components can cause serious burns.

narrow area where free flow of the

air is restricted. If the air flow is

restricted it will cause serious

damage to the machine or engine

and may cause injury to people.

Remember the machine's engine

gives off

monoxide gas.

DEADLY

carbon

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under

the influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

ALWAYS check the machine for loosened threads or bolts

before starting.

■

ALWAYS try to do most work during daylight hours or

■

■

■

■

■

with sufficient artificial lighting. Visibility must be good

for this machine to be used effectively and safely.

■

Check the safety kill switch. It is recommended to test

the engine kill switch prior to each use to ensure the

switch is operating properly.

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT smoke near the screed. Fire

or explosion could result from fuel vapors,

or if fuel is spilled on a hot engine.

NEVER operate the screed in an explosive atmosphere or

near combustible materials. An explosion or fire could result

causing severe

Topping-off to filler port is dangerous, as it tends to spill fuel.

NEVER store the machine with fuel in the tank for an

bodily harm or even death.

extended period of time. Always clean up spilled fuel

immediately!

PAGE 12 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 13

WRS-5200 — RULES FOR SAFE OPERATION

The following safety guidelines should always be used when

operating the WRS-5200 Screed:

GENERAL SAFETY

■

DO NOT operate this equipment unless all guards and safety

devices are attached and in place.

■

Use proper heavy lifting techniques when moving equipment.

This screed is very heavy. It should be lifted only with a lifting

device (i.e. crane, forklift, etc.) with a lifting capacity of at least

one ton.

■

Check to make sure that the operating area is clear before

starting the engine.

■

ALWAYS have throttle at idle position while starting the

engine.

■

ALWAYS keep clear of rotating or moving parts while

operating this equipment.

■

NEVER leave the machine unattended while running.

■

Refuel in a well-ventilated area, away from sparks and open

flames.

■

Moving Parts - Shut down the engine and disconnect battery

before performing service or maintenance functions. Contact

with moving parts can cause serious injury.

■

Unauthorized equipment modifications will void all

warranties.

■

Disconnect battery and spark plug wires before attempting

service.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

:

MAINTENANCE SAFETY

■

Disconnect the battery and spark plug wires before attempting

any type of service.

■

Securely support any machine components that must be

raised.

■

NEVER lubricate components or attempt service on a running

machine.

■

Allow the machine a proper amount of time to cool before

servicing.

■

Keep the machinery in proper running condition.

■

Make sure that there is no buildup of concrete, grease, oil or

debris on the machine.

■

Fix damage to the machine immediately and always replace

broken parts.

■

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

■

DO NOT use food or plastic containers to dispose of

hazardous waste.

■

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

Lifting the Screed and Power unit

DANGERDANGER

DANGER

DANGERDANGER

Temperatures

■

High Temperatures – Allow the machine

and engine to cool before adding fuel or

performing service and maintenance functions.

hot

Contact with

serious burns.

components can cause

■

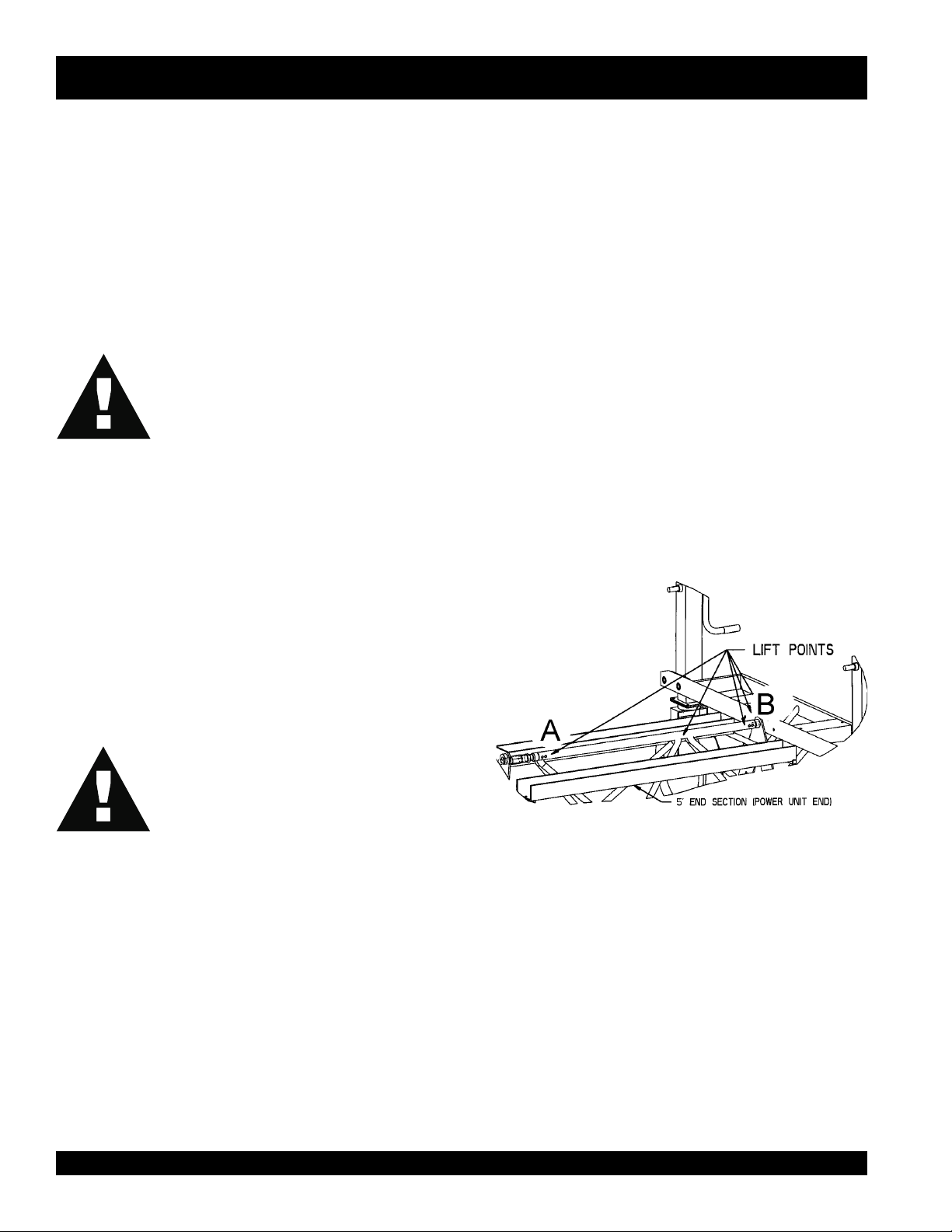

Use straps of adequate lifting capacity to lift the drive roller

and strike tube.

■

To lift the power unit, attach a crane or lifting device of

adequate lifting capacity to the power unit's lifting bail.

:

■

When lifting of the screed or power unit is

required, NEVER stand underneath the

screed or power unit The possibility exist that

severe bodily harm or even death may occur.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

:

Emergencies

■

Always know the location of the nearest

extinguisher

location of the nearest telephone. Also know

the phone numbers of the nearest

doctor

will be invaluable in the case of an emergency.

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 13

and

and

fire department

first aid kit

. Know the

ambulance

. This information

fire

,

Page 14

WRS-5200 — FEATURES

A. DESIGN

⇒

Ride-on design for easy maneuverability on the job.

⇒

Designed to meet tight paving specifications.

⇒

Hydraulic power for easy operation.

⇒

20 HP gasoline engine.

⇒

Rubber coated drive tubes controlled independently of

each other for simple alignment corrections.

⇒

Crown and camber adjustments that are easily adjusted.

⇒

Powder coated paint finish for longer life, professional

appearance and easy clean up.

B. FLEXIBILITY

D. PRODUCTIVITY

⇒

Ride-on design for easy maneuverability on the job.

Strikes off over 10,000 square feet per hour.

⇒

Instant forward/reverse screeding action. Strikes off

concrete more quickly than conventional methods.

⇒

Screed bays from 15 to 50 feet wide using a combination of strike tubes. Comes complete with six tubes

(two 18 ft.; two 14 ft.; one 16 ft.; one 8 ft.).

⇒

Ideal for handling low slump

concrete.

C. QUALITY

⇒

Assists in achieving optimum F-numbers using standard finishing techniques.

⇒

Produces a floor with excellent surface aggregate consolidation, resulting in a harder, longer wearing surface

finish.

PAGE 14 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 15

WRS-5200 — ASSEMBLY INSTRUCTIONS

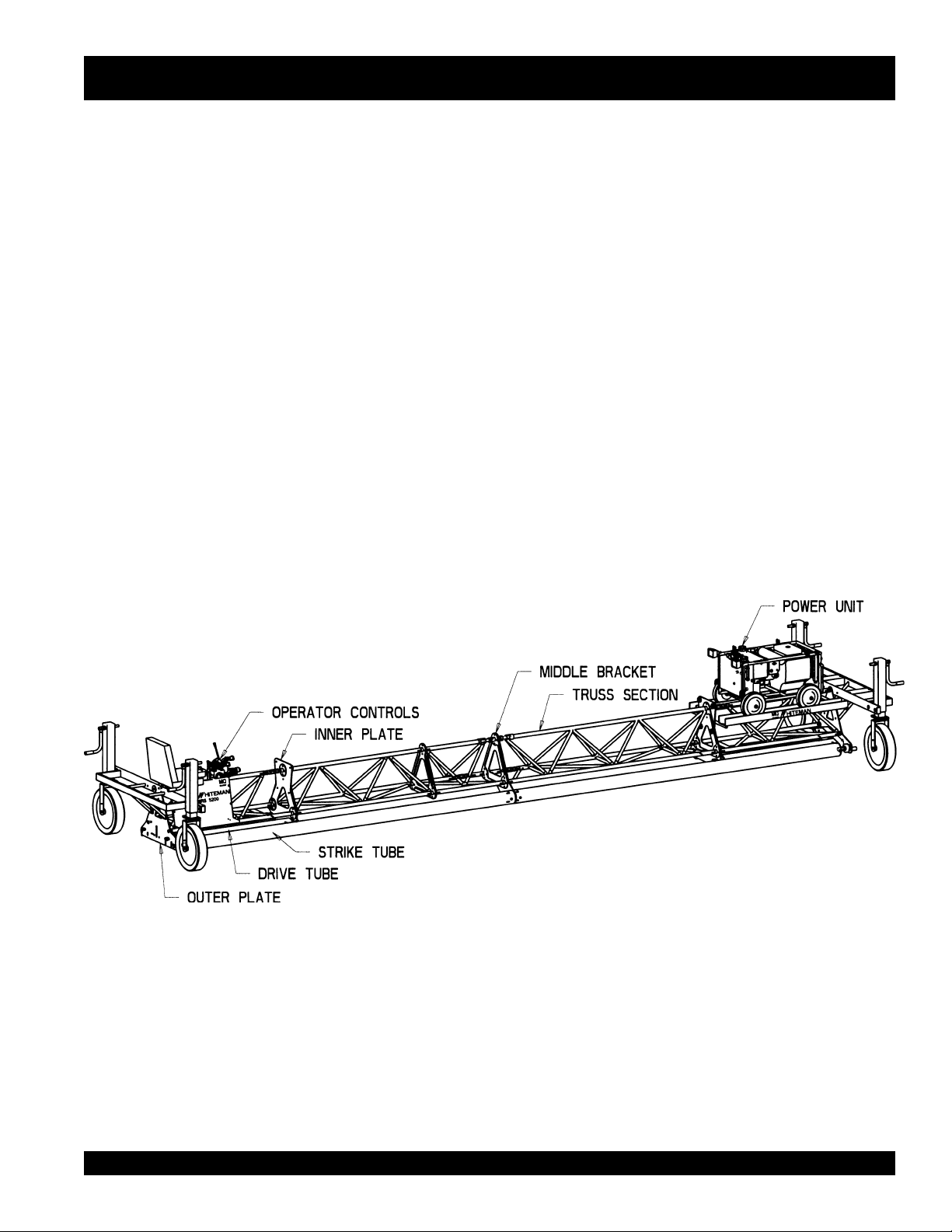

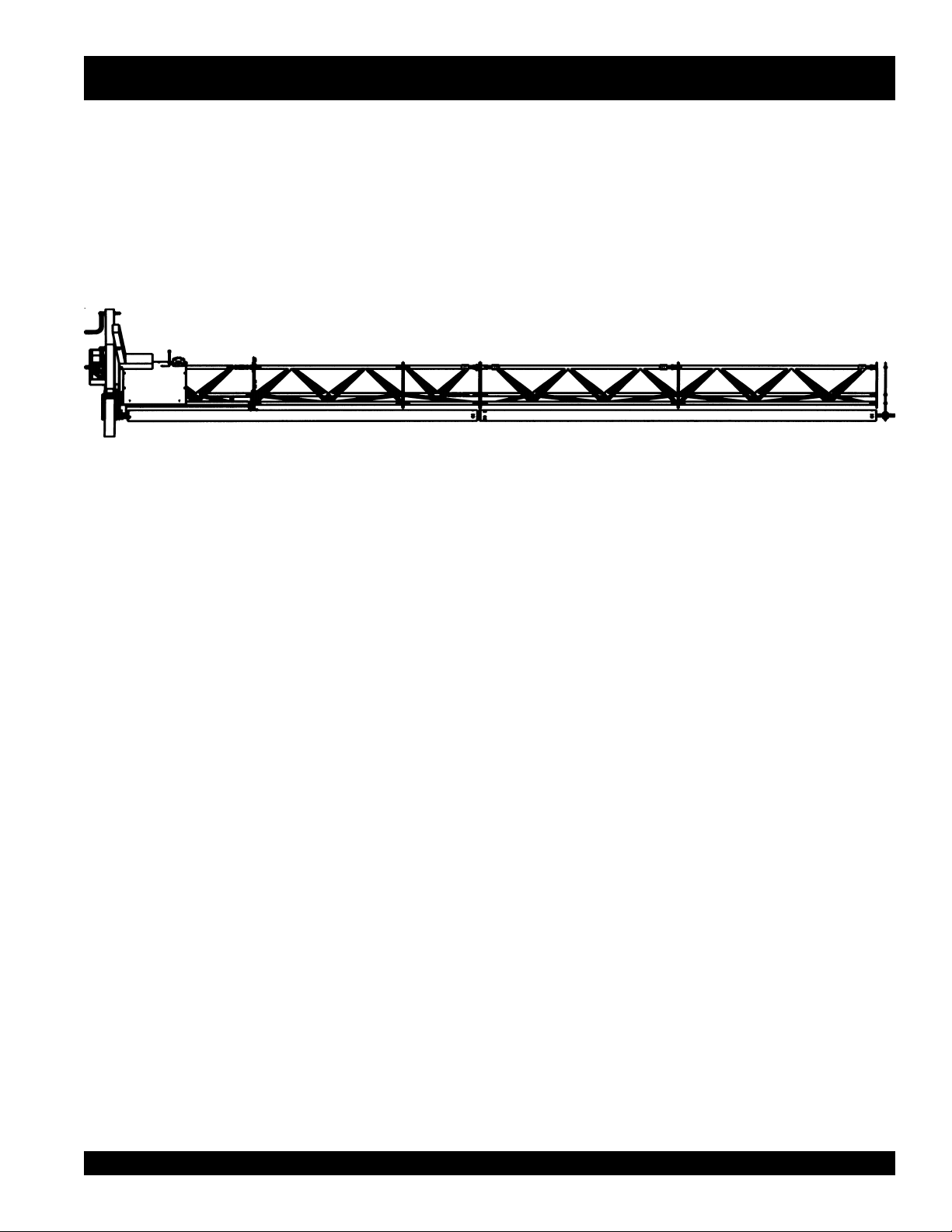

A. ROLLER SCREED PARTS ILLUSTRATION

See Figure 2 below for general parts location.

B. PUTTING INTO SERVICE

The purpose of the instructions section of this manual is to

explain the intended setup, use and maintenance procedures

recommended by Whiteman Industries.

Before packaging and shipment, this Whiteman Ride-on Roller

Screed was run and tested at the factory. If there are ANY

problems, please contact the Multiquip Service Department.

Make sure that all manuals and instructions are read carefully before putting your new Whiteman Roller Screed into

service. Improper setup, use or maintenance of this equipment could result in personnel injury or damage to the equipment. Listed in Figure 2, are the location of main parts

described in the next section.

Figure 2. General Parts Location

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 15

Page 16

WRS-5200 — ASSEMBLY INSTRUCTIONS

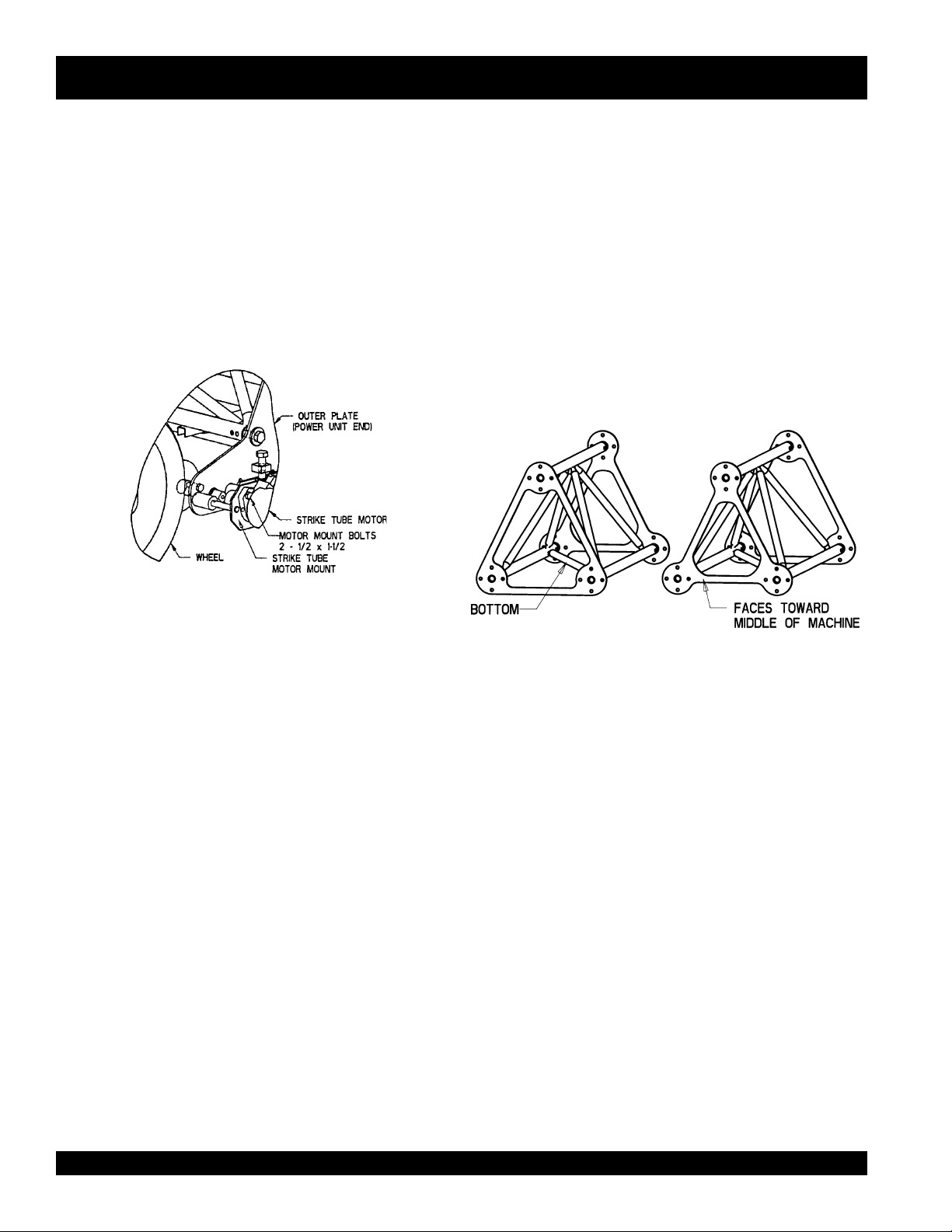

C. POWER UNIT ASSEMBLY

The power unit comes completely assembled. However,

before operating the screed, the hydraulic strike tube motor

from the power unit must be bolted to the motor mount, which

comes with the screed, as shown in Figure 3. This takes

two bolts, ½ X 1-1/2.

IMPORTANT: If you change power units, leave the strike

tube motor mount with the roller screed for the next power

unit

.

Figure 3. Strike Tube Motor Assembly

D. ROLLER SCREED ASSEMBLY

2. Description

The WRS 5200 Ride-On Roller Screed is made up of truss

sections (Figure 4) which vary in length from 3 to 9 feet.

These truss sections support the 6 inch tubing (strike tube)

which runs along the front of the machine. This strike tube

comes in four different lengths, 8, 14, 16 and 18 feet. By

coordinating the truss section and strike tube lengths, various roller screed lengths can be assembled.

Table 2 shows the different combination of truss

sections and strike tube lengths to get the desired

roller screed length. Dimensions are in feet

Figure 4. Truss End Plate

Table 2. ROLLER SCREED ASSEMBLY

LENG.(FT)* TRUSS SECTION (FT)** LETTER CODE ON TRUSS

SECTION STRIKE TUBE(FT)

18 5,8,5 L,RM8,R 18

22 5,9,3,5 L,L14,R8,R 14,8

26 5,4,9,3,5 L,L18,L14,R8,R 18,8

28 5,9,3,6,5 L,L14,R8,R14,R 14,14

30 5,9,8,3,5 L,L14,RM8,R8,R 14,16

32 5,9,3,6,4,5 L,L14,R8,R14,R18,R 14,18

36 5,9,8,3,6,5 L,L14,RM8,R8,R14,R 14,8,14

40 5,9,8,3,6,4,5 L,L14,RM8,R8,R14,R18,R 14,8,18

44 5,9,8,8,3,6,5 L,L14,LM8,RM8,R8,R14,R 14,16,14

44 5,4,9,8,3,6,4,5 L,L18,L14,RM8,R8,R14,R18,R 18,8,18

48 5,9,8,8,3,6,4,5 L,L14,LM8,RM8,R8,R14,R18,R 14,16,18

52 5,4,9,8,8,3,6,4,5 L,L18,L14,LM8,RM8,R8,R14,R18,R 18,16,18

* Actual concrete form width should be at least 2 foot less than screed length.

** Left side of Table I in the truss section represents the power unit end

PAGE 16 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 17

WRS-5200 — ASSEMBLY INSTRUCTIONS

It is important in the assembly of the roller screed to keep

truss sections on the appropriate side. To help with this,

each truss section is stamped with a letter and a number.

This stamping is located on the top pipe of each section.

For example, L14, would represent left or the power

unit end and combine this section (9 feet) with the

end section (5 feet), gives you 14 feet. This is the

strike tube length. The stamping on the 9 foot truss

section would be L14. Examples of the assembly for

different screed lengths are shown in Appendix C.

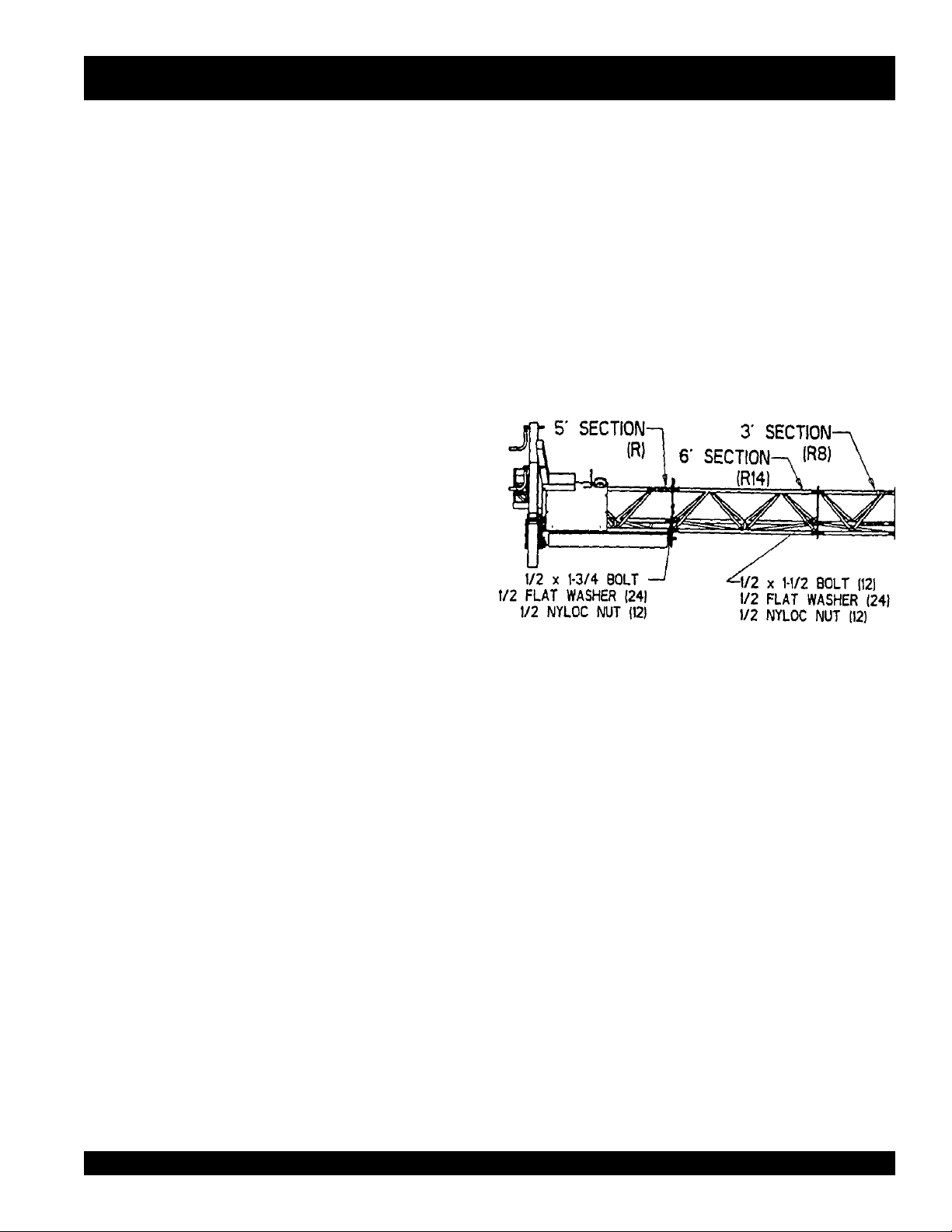

2. Assembly of the Roller Screed

To begin with, bolt together truss sections that match the

length of the strike tubes desired. Find the length of roller

screed wanted in the Appendix C and match the strike tubes

and truss sections. Use 1-1/2” long bolts where 2 joints

come together and 1-3/4” long bolts where 3 joints meet.

Don’t bolt truss sections from other strike tube lengths together yet.

As an example, the assembly of a 44’ roller screed is shown.

First check the Appendix C and find the length of screed

wanted. Lay the parts as shown in the drawing out in the

assembly area. Assemble the truss sections to match the

strike tube lengths. For this screed, the strike tube lengths

are 14’, 16’ and 14’. The following Figures, 4, 5 and 6, are

the truss sections assembled to match the strike tubes.

Task 1.

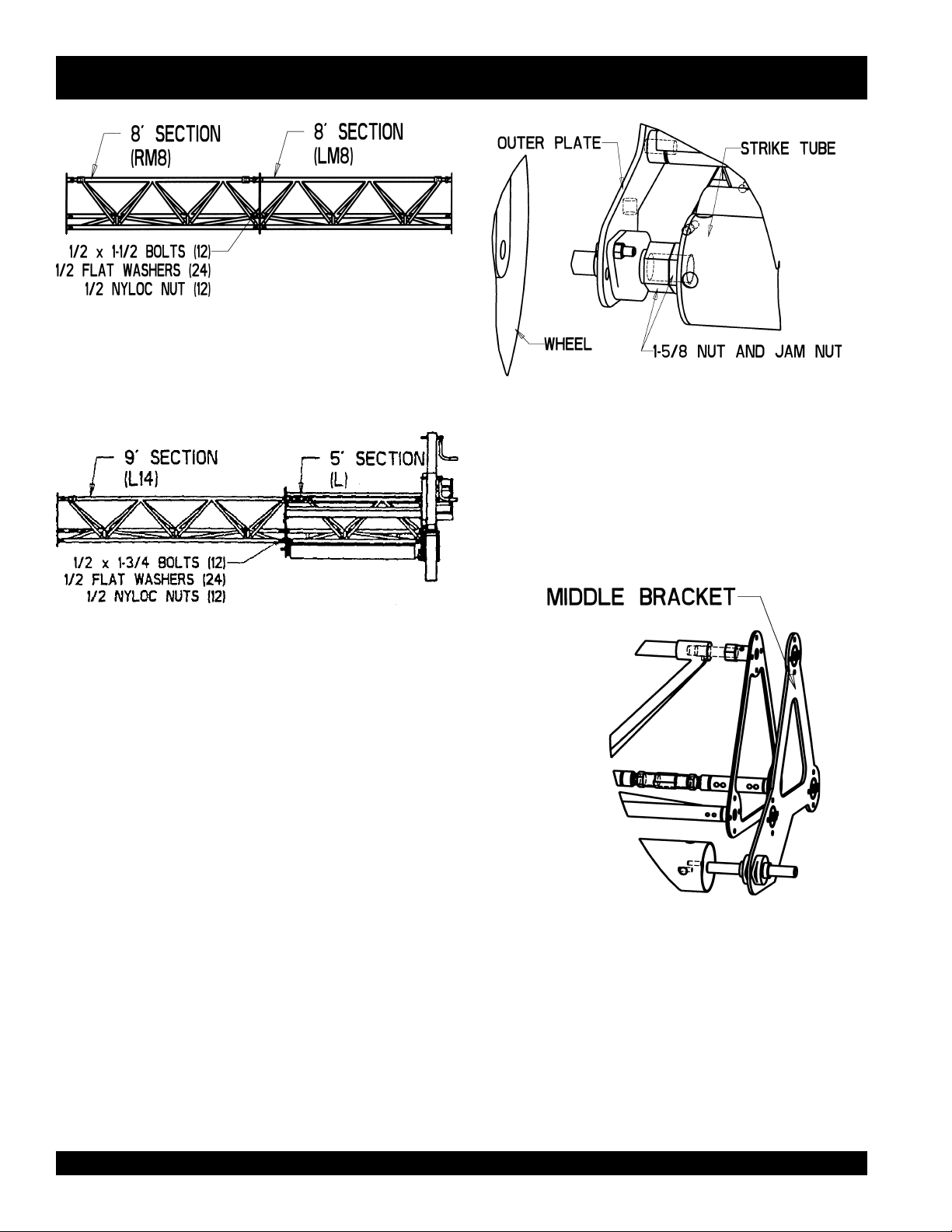

Assemble right, left and middle truss sections. See Figures

5, 6, and 7.

As an example, the assembly of a 44’ roller screed is shown.

First check the Appendix C and find the length of screed

wanted. Lay the parts as shown in the drawing out in the

assembly area. Assemble the truss sections to match the

strike tube lengths. For this screed, the strike tube lengths

are 14’, 16’ and 14’.

Figure 5. Right Section 14 Feet

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 17

Page 18

Figure 6. Middle Section 16 Feet

WRS-5200 — ASSEMBLY INSTRUCTIONS

Figure 8. Strike Tube Mount

Task 3.

Take the middle bracket and insert the splined shaft of it into

the other end of the strike tube as shown in Figure 9. Slide

the middle bracket pins into the section just made.

Figure 7. Left Section 14 Feet

Task 2.

Once the assemblies mentioned above are finished, start

on one end, take the strike tube and insert it into the 1-3/8

bearing mounted on the outer plate as shown in Figure 8.

The 1-5/8 nut and jam nut should be turned in until they are

against the strike tube hub.

Figure 9. Middle Bracket Mount

PAGE 18 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 19

WRS-5200 — ASSEMBLY INSTRUCTIONS

Task 4.

If another middle bracket is not required, go to the next paragraph. Two middle brackets are required for three strike tubes,

one for two strike tubes. If another middle bracket is required, insert the middle strike tube into the splined shaft of the

middle bracket mentioned above. Assemble the truss sections and middle bracket using the ½ X 1-3/4 bolts. Working your

way across, take the next middle bracket and insert the splined shaft into the middle strike tube as shown in Figure 9 & 10.

Figure 10. Middle Section

Task 5

Now go to the other end of the roller screed, take the strike

tube there and insert it into the second middle bracket’s

splined shaft. As you pull the last 14’ section (Figure 7) into

place, insert the end of the strike tube into the bearing as

you did in Figure 7. Use ½ x 1-3/4 bolts to bolt the two truss

sections and the middle bracket together.

Task 6.

Once the truss sections are together, string the four long

hydraulic hoses through the middle of the trusses. Two male

and two female quick connects are required at the other

end, one male and female of the 5/8” hose and the same for

the ½” hose.

Task 7.

Put the tarps on the appropriate section. The section of the

tarp where two nylon straps are close together should fit

over a truss joint. All tarps were made to full length per

section.

The tarp for the right section (13’11”) will have two places for

the truss joint. It will have a 4 foot section (which for this

set-up will be folded back under the next section of tarp) and

a 6 and 3 foot section

.

The middle tarp (16’) has a place for the truss joint right in

the middle.

The left tarp (13’5”) has one truss joint located 4 foot in from

the end. For this set-up, the 4 foot section will be folded

back under the 9 foot.

The buckles on the tarp should be on the back side (strike

tube is on front side) and the tarp drain hole on the bottom

when finished.

Task 8.

Two more items need to be added on the outside of the

tarps. These are the 50 foot electric cord and the pump

lever cable. Before buckling the tarp, put the cable and cord

behind enough buckles to hold them in place.

Task 9.

Adjust the 1-5/8” nuts on the strike tubes next to the outer

plates so the other end of the strike tube next to the middle

bracket is spaced from 1/16 to 1/8.”

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 19

Page 20

WRS-5200 — ASSEMBLY INSTRUCTIONS

Task 10.

Place the power unit on the appropriate end and the roller

screed is ready to use.

D. HANDLING

1. Moving the Machine

WARNING!

DO NOT ATTEMPT TO LIFT THE SCREED

FROM THE MIDDLE SECTIONS.

Your Whiteman roller screed was designed to be moved

and handled in several ways. Casters that can be lowered

are provided to move the machine on and off forms and for

moving short distances. When using the casters and

moving short distances, the power unit may be left on the

roller screed.

⇒

When lifting the roller screed to load for transporting or

other purposes, the power unit should be taken off.

⇒

Care should be taken to lift the machine correctly. With

a fork lift, one end at a time can be lifted onto the transport. Lifting straps should be placed around the top pipe

in the 5’ end sections. Figure 10 illustrates the recommended lifting points.

⇒

Care should These lifting positions are the same for both

ends. Attach a lifting strap to one of these points. The

safety snap pins in the top turnbuckles of the truss sections are not designed to carry the weight of the machine during lifting. The top of the truss sections should

always be kept in compression. Lifting with straps or

forks from center sections may damage the machine or

bend these pins. Figure 11 shows lifting points A & B.

Lifting point “B” can be used with any screed length while

lifting point “A” should only be used for screed lengths

longer than 32 feet.

If lifting the roller screed is planned for transporting or other

reasons, some precautions should be followed.

WARNING!

NEVER TRANSPORT SCREED WITH

THE POWER UNIT ON THE MACHINE

.

Figure 11. Lifting Points

PAGE 20 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 21

WRS-5200 — ASSEMBLY INSTRUCTIONS

2. Strike Tube Handling

The strike tubes are a critical component of the roller screed.

If the strike tubes are damaged, it is possible they will not

turn true. Care should be taken to store extra tubes on a

fully supported level surface. Never lift the unit from the

strike tubes.

E. Removable Components

The seat section and power unit are removable. Having

these pieces removable means you can easily take most of

the critical components from the machine with you. This

provides a way to better care for your equipment between

jobs.

To remove the seat, undo the cord and cable from the power

unit and the quick connect hydraulic lines from the stack

valve. Windup the cord and cable.

To remove the power unit, attach lifting straps, front-left and

back-right and lift with fork lift.

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 21

Page 22

WRS-5200 — MACHINE CONTROLS

Operators Position)

1. Electric Box (Figure 12).

WARNING!

WARNING!

NEVER DISABLE OR DISCONNECT THE

EMERGENCY KILL SWITCH.

Your Whiteman Ride-On Roller Screed is equipped with a

safety emergency kill switch. Note: It is provided for operator safety and injury may result if it is disabled, disconnected

or improperly maintained.

Below the kill switch is the “High/Low” toggle switch. This

throttle switch has only two positions.

The choke button is to the right of the Hi/Low switch. To

activate this switch, you must hold it down.

2. Light Switch.

The light switch is located on the fuse box which is mounted

on the radiator end of the power unit.

3. Drive Tube Speed Control Lever (Figure 13).

Located on the far left, above the electric box, this long

handle controls the variable speed of the drive tubes. This

lever should be in the “Straight Up” position when starting

the engine.

THE THROTTLE CONTROL CANNOT BE USED TO STOP THE EN-

GINE.

4. Drive Tube Direction Control Levers (Figure 13).

Figure 12. Electric Box

The key switch, shown in Figure 12, is located to the right of

the kill switch. The key switch should not work if the kill

switch is in the down “Down” position.

THE THROTTLE CONTROL CANNOT BE

USED TO STOP THE ENGINE.

Located in the center, these two levers control the direction

of travel for the drive tubes. They are independent of each

other, so one end can travel forward while the other travels

back. Using the levers in this way lets you steer the roller

screed.

Figure 13. Operator Controls

PAGE 22 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 23

WRS-5200 — MACHINE CONTROLS

In order for the drive tubes to move the screed, the “Screed

Operation” valve lever on the power unit must be engaged.

5. Strike Tube Control Lever (Figure 13)

On the far right is the strike tube cable control. Pushing the

lever to the center is the “Neutral Position”. Shifting the

lever either direction determines which way the strike tube

turns. The farther you push/pull the lever, the faster the

strike tubes turn.

6. Form Specifications

Refer to Appendix B for more information on the recommended

type of concrete form to be used.

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 23

Page 24

WRS-5200 — MACHINE START-UP AND OPERATION

A. START-UP

The following steps are intended as a basic guide to machine start-up and operation. Following these procedures

will help preserve and maintain the life of this equipment.

⇒

Check oil levels in engine and hydraulic reservoir.

⇒

Check to make sure there is a full tank of fuel before

starting.

⇒

On the power unit, put the screed operation valve lever

in the “Screed Operation” position.

⇒

Put the two drive tube direction control levers shown in

Figure 12 in the “Middle” position.

⇒

Adjust the drive tube speed control lever shown in Figure 12 to the “Straight Up” position.

⇒

Put throttle switch in “Low,” the “Kill Switch” in the “Up”

position, and depress the “Choke Switch”, if necessary,

while turning the key.

⇒

While sitting in the seat, turn the key and start the engine.

B. CLEANUP

Never allow any concrete to harden on the roller screed.

Immediately after use, wash any concrete off the screed.

Be careful not to spray water on the engine while it is still

hot.

To operate the pressure washer, attach a garden hose to the

pump and turn on the water. Next plug in the quick connect

hoses from the pressure washer to the power unit, adjust

the three way valve on the power unit as indicated by the

decal to the “Pressure Washer” position.

“Clean out” plates for the ends of the center strike tubes

(8’and 16’ tubes) should be removed and the ends cleaned

after each use.

Back off the 1-5/8 nut and jam nut on the outside strike

tubes next to the outer plate. Slide the strike tube away

from the middle bracket and clean the ends.

The solid scraper bars that prevent build-up on the drive

tubes should be removed and cleaned as well as the strike

tube wipers mounted in front of the 5 foot sections.

⇒

Once the engine is warm, put the toggle switch on throttle

control to the “High” position to begin operation.

PAGE 24 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 25

WRS-5200 — MACHINE START-UP AND OPERATION

WARNING!

PETROLEUM PRODUCTS ARE FLAMMABLE.

⇒

Lubricate all grease zerks after cleaning the machine

while the chain guards are off, including bearings on the

middle brackets which hold the splined shafts.

Never fill the gas tank while the engine is running or hot.

Petroleum products can cause damage to the environment

so spills should be cleaned up immediately.

C. MAINTENANCE

Note: See the engine manual supplied with your machine

for appropriate engine maintenance schedules and troubleshooting guide for problems.

There is a “Daily Preparation Checklist” in the front section

of this manual. Please feel free to make copies of it and use

it on a daily basis.

Weekly (30-40 Hours)

⇒

Check and clean or replace the engine air filter as necessary.

⇒

Replace the engine oil and filter as necessary, see engine manual.

⇒

Check bolts for tightness on truss sections.

Monthly (100-125 Hours)

⇒

Check air pressure in tires.

Yearly (500-600 Hours)

WARNING!

⇒

Replace hydraulic fluid and filters.

DISCONNECT BATTERY CABLES AND

SPARK PLUG WIRES BEFORE ATTEMPTING ANY SERVICE OR MAINTENANCE ON

THIS MACHINE.

⇒

Check set screws on the middle bracket bearings which

hold the splined shaft in place. If loose, add some liquid

locking agent to the set screws and re-tighten. A “stop”

inside the strike tube prevents the splined shafts from

ever moving too far.

D. MAINTENANCE SCHEDULE

Daily (8-10 Hours)

⇒

Check the fluid levels in the engine and hydraulic reserve , fill as necessary.

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 25

⇒

Note: After the first 100 hours, replace the hydraulic

filter cartridges.

Page 26

WRS-5200 — MAINTENANCE AND ADJUSTMENT PROCEDURES

WARNING!

DO NOT AT ANY TIME MAKE ADJUSTMENTS TO THE ROLLER SCREED WITHOUT STOPPING THE ENGINE AND DISCONNECTING THE SPARK PLUG WIRE.

A. ADJUSTING STRIKE TUBE HEIGHT

Strike tube height is adjusted by raising or lowering the height

of the drive tubes. Figure 14 illustrates this. The chain idler

will also need adjusting in the same direction of travel as the

drive tubes. Loosen the two bolts which hold each drive

tube bearing and adjust the ¾” bolt to desired height. Tighten

the bearing bolts and chain idle adjustment when finished.

Adjust the strike tube so it is just clearing the concrete form.

B. CROWN ADJUSTMENT

To adjust the crown, pull the 3/8” safety snap pin and adjust

the screw with the wrench provided. Shown in Figure 15.

Figure 14. Strike Tube Adjustment

Figure 15. Crown and Camber Adjustment

C. CAMBER ADJUSTMENT

To modify the camber in the screed, adjust the turnbuckle

which is shown in Figure 15. Loosen the two jam nuts and

adjust the screw with the wrenches provided. A plum line

stretched along the front of the machine will help to adjust

straightness to.

PAGE 26 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 27

WRS-5200 — MAINTENANCE AND ADJUSTMENT PROCEDURES

D. STRAIGHTNESS OF STRIKE TUBES

Should strike tubes begin turning unevenly, contact your local Multiquip representative for information on strike tube

straightening procedures.

To determine if a strike tube is turning uneven, place a 2 x 4

stud on the ground in the center of the strike tube as it sits

on the machine. Slide it close to the strike tube. Take the

strike tube motor off the end. Spin the strike tube by hand. If

a gap of over 1/8 inch shows up, contact your representative.

E. AUXILIARY HUB

An auxiliary hub, shown in Figure 16, for use with different

strike tubes is provided. Using the hub provides additional

combinations of roller screed lengths. Two ½ x 2-1/4 bolts

are provided for the purpose of bolting the hub to the strike

tube end.

Wiper bars should be adjusted to approximately 1/8” distance from the strike tube. The turnbuckle in the top pipe of

the 5’ section is also an adjustment for the wiper bar. This

adjustment can be used when the end of the wiper bar is too

close to the strike tube. IMPORTANT: Never let anything

rub grooves into the strike tube( i.e. wiper bars, concrete

forms, bolts, etc.) because those grooves in the strike tube

will be transferred into the concrete.

H. STRIKE TUBE ADJUSTMENT NUT

The strike tube adjustment nut, shown in Figure 8, should

be adjusted so the inner edge of the strike tube next to the

middle bracket is spaced at about 1/16 to 1/8”. Note: The

strike tube will bottom out on the splined shaft when 1/16” is

left and further adjustment will bend the outer plate.

I. SPLINED SHAFT SET SCREWS

Each roller screed comes with two middle brackets as shown

in Figure 9. Bearings mounted on the middle bracket hold

the splined shaft. The set screws in the bearings should be

checked for tightness occasionally.

J. REVERSING END CASTER BRACKETS

Figure 17 illustrates how end caster brackets can be reversed. This allows the roller screed to fit into areas close to

walls and columns.

Figure 16. Auxiliary Hub

F. CHANGING THE HYDRAULIC FILTER

Usually the hydraulic filter and oil will be changed at the

same time. If not, creating a back suction on the hydraulic

tank will stop the flow of hydraulic oil when changing the

filters.

G. SCRAPER AND WIPER BAR ADJUSTMENT

Scraper bars should be adjusted to approximately 1/8” distance from the drive tubes.

Figure 17. Reversing Caster Brackets

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 27

Page 28

WRS-5200 — SUGGESTED TRAINING

WARNING!

READ THE INSTRUCTION MANUAL COMPLETELY BEFORE ATTEMPTING MACHINE OPERATION!

The following steps are intended as a basic guide to help in the operation of this

equipment.

A. FAMILIARIZATION WITH EQUIPMENT

Take a walk around the machine. Take notice of all the major

components on the machine like the control handles, the

engine, the strike tubes and the truss sections. Look at the

machine construction. Check the fuel and hydraulic system. Look at the engine and find the oil dipstick. Check the

oil levels in the engine and hydraulic tank. Make sure the

machine has fuel enough for the planned operation.

While seated in the operator’s position, note the locations of

the controls. On the left is the electric box with four switches

which were described in the startup section of this manual.

Just above the electric box on the left is the speed control

lever for the drive tubes.

In the center are the levers of the stack valve which operate

the drive tubes forward and reverse on both ends and finally

on the right side is the lever for running the strike tubes. The

speed of the strike tubes depends on the how far you push/

pull the lever. The cable from this lever is attached to the

hydraulic pump lever on the power unit.

B. FIRST MACHINE OPERATION

Now, following the startup procedure found in the “Machine

Start-up and Operation” section of this manual, start the

engine and let it warm up. Remember that when warming up

an engine, let the engine idle. When the engine is warm, test

the kill switch. The engine should die and the key should not

crank the engine with the emergency kill switch down.

Restart the engine. Before operating the roller screed, check

for people around the machine. As a suggestion, imagine a

rectangle that envelopes the entire machine. Never let anyone into that rectangle while you are operating the machine.

Always be aware of your surroundings.

Practice running the roller screed in a straight line. As you

become comfortable maneuvering the roller screed, try turning off one side of the drive tubes and then the other. This

adjusts how parallel the screed moves with the forms, and

also allows you to steer around the columns.

C. CONCEPTS FOR USE OF ROLLER SCREED

The purpose of the roller screed is to strike off the surface of

the concrete at a predetermined grade. The quality of

screeding has a big effect on floor levelness and flatness.

This machine was designed to be able to go back and forth

on the forms, working the concrete to the desired grade.

The strike tube rotation should always push the concrete

forward into the areas that don’t have concrete yet.

Depending on the slump of the concrete, several passes

might be required for the right strike off grade. On the last

pass over the concrete, rotate the strike tube in the opposite

direction and go slowly forward. This leaves a thin layer

which can be easily bull floated.

PAGE 28 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 29

WRS-5200 — SUGGESTED TRAINING

A pressure washer is available as an option with this machine. Figure 18 shows the components that come with this option.

This is a hydraulic-motor driven pump pressure washer which is connected to the power unit with quick connect fittings.

The pressure washer runs at 1500 psi and comes complete with a 50 foot pressure wash hose, trigger gun with insulated

wand and a turbo nozzle.

Figure 18. Pressure Washer

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 29

Page 30

WRS-5200 — FORM SPECIFICATIONS

The Whiteman WRS-5200 roller screed provides all of the

benefits of labor savings, high productivity and enhanced

floor flatness/levelness qualities. To order to maximize these

benefits, care must be taken to insure a successful application. :Inadequate substrate and form support can lead to

form failure causing unnecessary job delays, and expenses

while contributing to poor floor flatness and floor levelness

ratings. The intent of these specifications is to establish

minimum guidelines to help the contractor choose the most

economical and effective form work/support system to fit

any job site needs.

It is recommended that at least the day prior to the concrete

pour, a dry run be accomplished to test the load capacity of

the forms and substrate. Proper job planning is essential to

a successful application.

The WRS-5200 weighs approximately 4000 .lbs (at 52 feet

of screed) approx. 2000 lbs. per side. Any screed support

(forms, rails, rail supports and substrate) must withstan0a

2s0s.0 lb. “point load” at a 2:1 safety factor.

WOOD FORMS-

Wood forms are NOT

Because of the concentrated bearing loads by the screed,

wood is not a good support material. Nominal 2x (1-1/2’7

No.2 Douglas fir is calculated to support a maximum of 1000

lb. The grain could crush and splinter causing level variations and potential failure. 4x (3-1/2") lumber for edge form

should be acceptable.

SCREED RAILS AND SUPPORT-

Screed rails (Figure 19) and supports, independent of slab

edge forming are a preferred method. Due to strength, deflection and traction considerations, 2.5" x 2.5" x 875 (3/16")

wall structural steel tubing with adjustable supports spaced

as shown in the attached drawings. Standard deflection with

a 3/16" wall thickness for the above configuration is 1/6" in 4

ft. Refer to standard material charts for other configurations.

STEEL FORMS-

a

preferred method of screed support.

SUBGRADE/DECK FORMS-

Subgrade must be sound enough to support slab edge forms

and bracing as well as the load imposed by the screed and

its supports. Potential deflection, as in the case with metal

and plywood decks, should be considered when determining

brace and support spacing. Soil subgrades must be well

compacted and must be able to support bearing pressures

greater, than or equal to those imposed by the screed supports and the slab forming. For proper bearing support, shims

should be used to adequately distribute loads where grade

is not level or is soft. Use standard AC:[ concrete form pressures when calculating lateral loads on slab edge forms

Paving forms with 90° lip-edge at bottom with stake pockets

is preferred. If soft or unleveled subgrade is encountered, a

2x bearing pad and/or shims should be used under the steel

forms for additional bearing support. Depending on slab thickness and subgrade, forms may require diagonal bracing.

These specifications are provided as a service to illustrate

the application of MQ - WHITEMAN products only and are

not intended to be fully directive or cover all engineering

details, MQ - WHITEMAN will not be responsible for the

improper application of its products.

PAGE 30 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 31

WRS-5200 — SCREED RAILS

Figure 19. Screed Rails

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 31

Page 32

WRS-5200 — 18 AND 22 FOOT SCREED LENGTHS

PAGE 32 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 33

WRS-5200 — 26 AND 28 FOOT SCREED LENGTHS

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 33

Page 34

WRS-5200 — 30 AND 32 FOOT SCREED LENGTHS

PAGE 34 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 35

WRS-5200 — 36 AND 40 FOOT SCREED LENGTHS

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 35

Page 36

WRS-5200 — 44 FOOT SCREED LENGTHS

PAGE 36 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 37

WRS-5200 — 48 AND 52 FOOT SCREED LENGTHS

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 37

Page 38

WRS-5200 — FRAME ASSEMBLY (OPERATOR END)

FRAME ASSEMBLY (OPERATOR END)

PAGE 38 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 39

WRS-5200 — FRAME ASSEMBLY (OPERATOR END)

FRAME ASSEMBLY (OPERATOR END)

NO PART NO PART NAME QTY. REMARKS

1 0166 Screw, HHC 3/8-16 x 7/8 1

2 0300 B Washer, Flat, 7/16 SAE 10

3 0448 Washer, Flat, 7/16 SAE 1

4 10133 Nut, Nyloc 3/8-16 6

5 10176 Nut, Nyloc 1/2-13 6

6 1284 Screw, HHC 3/8-16 x 1-1/2 4

7 16223 Bearing, 1-3/8 3

8 16225 Sprocket 2

9 16226 Sprocket, Idler 1

10 16227 Chain, Roller 1

11 16231 Caster, (includes wheels and bracket) 2

12 16303 Mount, Idler Sprocket 1

13 16372 Spacer, 1/4 I

14 16378 Pull Handle W/A 1

15 16469 Bracket, Caster W/A OPER End 1

16 16492 Tube, Drive Rear W/A 1

17 16493 Tube, Drive Front W/A 1

18 16521 Screw, HHCS 1/2-13 x 4 GD 8 4

19 16524 Screw, HHCS 1/2-13 x 1-1/4 GD 8 12

20 16525 Screw, HHCS 1/2-13 x 1-1/2 GD 8 3

21 16529 Screw, HHCS 3/4-10 x 2 GD 8 3

22 16530 Screw, HHC 7/16-14 x 1 1

23 16533 Key, 5/16 x 5/16 x 7/8 2

24 16538 Bearing Adjustment W/A Short 2

25 16539 Bearing Adjustment W/A Long 1

26 16627 Bolt, Shoulder 5/8 x 3/4 PLTD 4

27 16628 Bolt, Shoulder 3/4 x 2-1/4 PLT 4

28 16629 Nut, Nyloc 1/2-13 GD 8 18

29 16658 Wiper, Solid W/A 2

30 16659 Mount, Solid Wiper W/A 3

31 16681 Mount, Wiper Right 1

32 16683 Jack, Screed W/A 2

33 16685 Handle, Jack W/A 2

34 16689 Name Plate, Screed 1

35 16695 Arm, Wiper W/A 2

36 16703 Guard, Chain W/A Control End 1

37 16781 Screw, HHCS 1/2 - 13 x 2. 1/4 GD 8 8

38 16868 Bar, Scraper W/A 2

39 16880 Decal, Lifting Warning 1

40 16883 Decal, Chain Drive Warning 1

41 16890 Screw, HHC 3/4 x 2-1/2 GD 5 1

42 16927 Chain, Roller Offset 1

43 4014 Screw, 2-3/16 P-K Type U Drive 2

44 5054 A Washer, Lock, 1/2 Medium 1

45. 5283 Nut, Nyloc 5/16-18 10

46 9154 Screw, HHC 3/8-16 x 1-3/4 2

47 9503 Nut, Nyloc 5/8-11 4

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 39

Page 40

FRAME ASSEMBLY (ENGINE END)

WRS-5200 — FRAME ASSEMBLY (ENGINE END )

PAGE 40 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 41

WRS-5200 — FRAME ASSEMBLY (ENGINE END )

FRAME ASSEMBLY (ENGINE END)

NO PART NO PART NAME QTY. REMARKS

1 0166 Screw, HHC 3/8 - 16 x 7/8 1

2 0189 Grip, Handle 2

3 0300 B Washer, Flat, 5/16 SAE 10

4 0448 Washer, Flat, 7/16 SAE 1

5 10133 Nut, Nyloc 3/8 -16 14

6 10176 Nut, Nyloc 1/2 -13 6

7 1284 Screw, HHC 3/8 -16 x 1-1/2 4

8 16223 Bearing, 1-3/8 3

9 16225 Sprocket 2

10 16226 Sprocket, Idler 1

11 16227 Chain, Roller 1

12 16231 Caster, (includes wheels & bracket) 2

13 16270 Scraper Bar W/A 1

14 16273 Chain Guard W/A 1

15 16303 Mount, Idler Sprocket 1

16 16372 Spacer, 1/4 1

17 16378 Pull Handle W/A I

18 16442 Mount, Power, Unit Short 2

19 16446 Mount, Power, Unit Long 2

20 16492 Tube, Drive Rear W/A 1

21 16493 Tube, Drive Front W/A I

22 16521 Screw, HHCS 1/2 -13 x 4 GD 8 4

23 16524 Screw, HHC 1/2-13 x 1. IA GD 8 12

24 16525 Screw, HHC 1/2 -13 x 1. I/2 GD 8 3

25 16529 Screw, HHC 3/4 -10 x 2 GD 8 3

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 41

Page 42

WRS-5200 — FRAME ASSEMBLY ENGINE END (CONT).

FRAME ASSEMBLY ENGINE END (CONT.)

PAGE 42 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 43

WRS-5200 — FRAME ASSEMBLY ENGINE END (CONT).

FRAME ASSEMBLY ENGINE END (CONT.)

NO PART NO PART NAME QTY. REMARKS

26 16530 Screw, HHC 7/16 -14 x 1 1

27 16533 Key, 5/16 x 5/16 x 7/8 2

28 16538 Bearing Adjustment W/A Short 2

29 16539 Bearing Adjustment W/A Long 1

30 16563 Decal MQ Multiquip Whiteman 2

31 16627 Bolt, Shoulder 5/8 x ~A PLTD 4

32 16628 Bolt, Shoulder 3/4 x - 2 1/4 PLT 4

33 16629 Nut, Nyloc 1/2-13 GD 8 18

34 16632 Bracket, Caster W/A (power unit end) 1

35 16658 Wiper, Solid W/A 2

36 16659 Mount, Solid Wiper W/A 3

37 16683 Jack, Screed W/A 2

38 16685 Handle, Jack W/A 2

39 16693 Bolt, Carriage 3/8-16 x 2 4

40 16695 Arm, Wiper W/A 2

41 16751 Arm, Power Unit Outer Plate 1

42 16781 Screw, HHCS 1/2-13 x 2.1/4 GD 8 8

43 16868 Bar, Scraper W/A 2

44 16880 Decal, Lifting Warning 1

45 16883 Decal, Chain Drive Warning 1

46 16890 Screw, HHC 3/4 x 2-1/2 GD5 1

47 16927 Chain, roller Offset 1

48 5054 A Washer, Lock, 1/2 Medium 1

49 5283 Nut, Nyloc 5/16-18 10

50 9154 Screw, HHC 3/8-16 x 1-3/4 6

51 9503 Nut, Nyloc 5/8-11 4

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 43

Page 44

CONTROL PANEL ASSEMBLY

WRS-5200 — CONTROL PANEL ASSY.

PAGE 44 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 45

WRS-5200 — CONTROL PANEL ASSY.

CONTROL PANEL ASSEMBLY

NO PART NO PART NAME QTY. REMARKS

1 0161 C Washer, Lock 5/16 Medium 4

2 0300 B Washer, Flat, 5/16 SAE 4

3 0655 Screw, HHC 5/16-18 x 3/4 4

2 0937 Nut, Hex 10-32 2

5 0949 Nut, Flex Finish 1/4-20 2

6 10019 Nut, Nyloc 10-32 1

7 10024 Nut, Nyloc 1/4-20 8

8 10133 Nut, Nyloc 3/8-16 11

9 1023 Screw, HHC 3/8-16 x 1-1/4 3

10 11247 Decal Set, Safety Clothing 1

11 11379 Hand Throttle Control 1

12 11718 Fitting, 1/2" Female Pipe 90 ELL 1

13 16219 Motor, Drive Tube 2

14 16220 Valve, Flow Control 1

15 16221 Value, Stack 1

16 16389 Switch, Toggle 1

17 16391 Switch, Button 1

18 16394 Cable, Tube Speed 1

19 16402 Grid, Non-Skid 2

20 16504 Stabilizer, Operator 4

21 16506 Mount, Operator Guard W/A 1

22 16510 Switch, Kill 1

23 16511 Block, Contact 1

24 16536 Mount, Operator Guard W/A (ENG END) 1

25 16537 Box, Electric W/A 1

26 16562 Decal, WRS-5200 2

27 16563 Decal, MQ Multiquip Whiteman 2

28 16564 Fitting, 1/2 Female QC 4

29 16565 Fitting, 1/2 Male QC 4

30 16566 Fitting, 3/4 Female QC 3

31 16567 Fitting, 3/4 Male QC 3

32 16568 1/2" Female Cover 2

33 16569 1/2" Male Cover 2

34 16570 3/4" Female Cover 1

35 16571 3/4" Male Cover 1

36 16577 Hose, 606" OAL 1/2 Hose-12NP x 12NP 2

37 16578 Hose, 594" OAL 1/2 Hose-SNP x 8FJ 2

38 16579 Hose, 60" OAL 1/2 Hose-SFJ x 8NP 2

39 16580 Fitting, 10 BOSS O-R x 8MJ 45EL 4

40 16582 Fitting, 12 BOSS O-R x 8MJ I/2MP 1

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 45

Page 46

CONTROL PANEL ASSEMBLY (CONT.)

WRS-5200 — CONTROL PANEL ASSY. (CONT.)

PAGE 46 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 47

WRS-5200 — CONTROL PANEL ASSY. (CONT.)

CONTROL PANEL ASSEMBLY (CONT.)

NO PART NO PART NAME QTY. REMARKS

41 16583 Fitting, 1/2 Male Run TE x 1/2 FP 1

42 16585 Fitting, Bushing 1/2 FP x 3/4 MP 2

43 16586 Fitting, 8 BOS O-R x 1/2 FP RIG 3

44 16587 Fitting, STRT, 80-Rx 10MJ I

45 16588 Fitting, 90SWVL, 10FJ x 1/2 MP I

46 16589 Fitting, 1/2MP x 1/2MP 90 EL 3

47 16590 Fitting, 1/2MP x 1/2MP 45 EL 2

48 16591 Fitting, 1/2MP x 5/SMJ I

49 16592 Fitting, 12 BOS O-R x 3/4 FP 90L 1

50 16596 Fitting, 3/4MP x 1/2MP HEX NIPP I

51 16599 Tube, HYD STL (Stack Valve) 1

52 16606 Fitting, 1/2MP x 5/SMJ 90 EL I

53 16636 Box, Electric Lid I

54 16717 Fitting, Ferrule 5/8 Tube HYD 1

55 16718 Fitting, Nut 5/8 Tube HYD 1

56 16730 Handle, Speed Control 1

57 16748 Guard, Rider W/A 1

58 16758 Decal, Sheet WRS-5200 1

59 16779 Wire Asm, Control End I

60 16780 Wire Asm, Electric Box I

61 16788 Handle, Tapered 1

62 16882 Decal, Injury Warning I

63 16926 Decal, Screed Set Up I

64 2153 Rod End, 10-32 Female RH I

65 2351 Seat, High Back I

66 2815 Harness, Onan-not for service I

67 3513 Screw, HHC 10-32 x 1 I

68 4514 Screw, HHC 1/4-20 x 5/8 2

69 5277 Screw, HHC 1/4-20 x 1-I/2 8

70 8381 Boot, Toggle Switch I

71 9154 Screw, HHC 3/8-16 x 1-3/4 8

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 47

Page 48

ENGINE ASSEMBLY

WRS-5200 — ENGINE ASSY.

PAGE 48 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 49

WRS-5200 — ENGINE ASSY.

ENGINE ASSEMBLY

NO PART NO PART NAME QTY. REMARKS

1 0131 A Screw, HHC 1/4-20 x 3/4 2

2 0166 A Washer. Lock 3/8 Medium 8

3 0181 B Washer, Lock 1/4 Medium 4

4 0730 Screwy, HHC 1/4-20 x 1 2

5 0948 Washer. Flat 1/4 SAE 4

6 10019 Nut, Nyloc 10-32 7

7 10133 Nut. Nyloc 3/8-16 16

8 0136 Washer, Flat 3/8 SAE 16

9 10176 Nut. Nyloc 1/2-13 4

10 1023 Screw, HHC 3/8-16 x 1-1/4 2

11 1284 Screw, HHC 3/8-16 x 1-1/2 2

12 13178 Screw, HHC 1/2-13 x 2-1/4 1

13 26991 Engine Briggs & Stratton 28 HP (Diesel) 1

13 16212 Engine Onan 20 HP P220G (Gasoline) 1

14 16214 Pump. Piston 1

15 16215 Pump, Gear 1

16 16216 Lever, Pump 1

17 16233 Wheel 4

18 16317 Tank, HYD W/A 1

19 16320 Tank, Gas W/A 1

20 16354 Handle, W/A 2

21 16390 Block, Terminal 1

22 16393 Box, Fuse 1

23 16396 Pin, Lever Detachable 1

24 16397 Socket, 4-Way 1

25 16399 Socket, 9-Way 1

26 16403 Cap, Gas 1

27 16405 Cap, Hyd 1

28 16406 Isolators, Vibration 4

29 16499 Light Fixture, W/A 2

30 16500 Nut, Wing 1/2-13 1

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 49

Page 50

ENGINE ASSEMBLY (CONT.)

WRS-5200 — ENGINE ASSY. (CONT.)

PAGE 50 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 51

WRS-5200 — ENGINE ASSY. (CONT.)

ENGINE ASSEMBLY (CONT.)

NO PART NO PART NAME QTY. REMARKS

31 16501 Mount, Cable 1

32 16535 Bar, Lift W/A 1

33 16560 Power Unit W/A 1

34 16689 Name Plate, Screed 1

35 16721 Screw, HHC 3/8-24 x 1-3/4 2

36 16722 Fuse, 20 AMP Flat Type 2

37 16723 Nut, Hex Fin 8-32 2

38 16882 Decal, Injury Warning 1

39 16908 Decal, Pressure Washer 1

40 1724 Grip, Handle QP 4

41 19251 Spacer, 5/8 x 1/2 x 9/16 Long 4

42 19266 Nut, Blind 1/4-20 x 10GA 4

43 19316 Fitting, 1/4MPT x 5/16 Hose, Brass 1

44 19317 Bushing, Reducer 3/8 x 1/4, Brass 1

45 19473 Clamp, Worm Hose, #4 (1/4-5/8) 2

46 2207 Solenoid, 12V 1

47 2449 Battery Box 1

48 2691 Screw, HHC 1/2-13 x 1 2

49 3242 Screw, HHC 1/2-13 x 1-3/4 4

50 3458 Screw, RMIVI 8-32 x 1 2

51 3615 Set Collar, 3/4 id 4

52 4014 Screw, 2-3/16 P-K Type U Drive 2

53 4370 Screw, HHC 3/8-16 x 2-1/4 2

54 4671 Battery, GR. UI, Wet, W/Tag 1

55 4682 Switch, Light 1

56 5054A Washer, Lock, 1/2 medium 1

57 5277 Screw, HHC 1/4-20 x 1-1/2 3

58 60028 Hose, .312id Rubber Fuel 2

59 8133 Screw, RHM 10-32 x 3/4 6

60 8381 Boot. Toggle Switch 1

61 911329 Plug, Pipe, 3/SMag. SQ Head 1

62 9154 Screw, HHC 3/8-16 x 1-3/4 10

63 167001 Solenoid, Choke 1

64 16701 Solenoid, Hi/Lo 1

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 51

Page 52

FRAME ASSEMBLY

WRS-5200 — FRAME ASSY.

PAGE 52 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 53

WRS-5200 — FRAME ASSY.

FRAME ASSEMBLY

NO PART NO PART NAME QTY. REMARKS

1 10138 Screw, SHS 1/4-20 x 1/2 1

2 1162A Cap, Grease Zerk, #2 Yellow 11

3 16222 Shaft, Splined 2

4 16223 Bearing, 1-3/8 2

5 16224 Bearing, 1-1/4 4

6 16255 Mount, Axle Power Unit 6

7 16298 Coupling, Striker Tube 1

8 16458 Nut, 1-5/8-12 GD 8 4

9 16459 Nut, Jam 1-5/8-12 GD 8 4

I0 16482 Tube, Strike 18' W/A 2

11 16483 Tube, Strike 14' W/A 2

12 16484 Tube, Strike 16' W/A 1

13 16485 Tube, Strike 8' W/A 1

14 16496 Wrench, Small Double 1

15 16497 Wrench, Large Double 2

16 16514 Turnbuckle, 1-5/16-16 2

17 16515 Nut, JAM 1-5/16-16 Right Hand 2

18 16516 Nut, JAM 1-5/16-16 Left Hand 2

19 16522 Screw, HHC 3/4-10 x 3-1/2 GD 8 2

20 16523 Screw, HHC 3/4-10 x 3-1/2 GD 8 6

21 16525 Screw, HHC 1/2-13 x 1-1/2 GD 8 50

22 16526 Screw, HHC 1/2-13 x 1-3/4 GD 8 52

23 16544 Frame, 3' W/A 1

24 16546 Frame, Section 4' Operator End 2

25 16547 Frame, Section 5' Operator End 1

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 53

Page 54

FRAME ASSEMBLY (CONT.)

WRS-5200 — FRAME ASSY. (CONT)

PAGE 54 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 55

WRS-5200 — FRAME ASSY. (CONT)

FRAME ASSEMBLY (CONT.)

NO PART NO PART NAME QTY. REMARKS

26 16548 Frame, Section 6' 1

27 16549 Frame, Section 8' Oper End 1

28 16550 Frame, Section 8' Engine End 1

29 16551 Frame, Section 5' Engine End 1

30 16552 Frame, Section 9' 1

31 16629 Nut, Nyloc 1/2-13 GD 8 102

32 16630 Washer, Flat, 1/2 Hardened PLT 196

33 16631 Mount, Strike Tube Motor 1

34 16633 Plate, Outer W/A Oper End 1

35 16634 Plate, Inner W/A Oper End 1

36 16648 Plate Outer W/A Engine End 1

37 16649 Plate, Inner W/A Engine End 1

38 16653 Bracket, Middle W/A 2

39 16667 Turnbuckle, Drive Tube W/A 2

40 16676 Screw, HHC 7/16-14 x 2" GD 8 4

41 16677 Nut, Nyloc 7/16-14 GD 8 4

42 16699 Screw, FHM 1/4-20 x I/2 PLTD 8

43 16727 Tarp, 13'-11" 1

44 16728 Tarp, 13'-6" 1

45 16729 Tarp, 16'-5" 1

46 16743 Pin, Section Safety Snap 5

47 16756 Hub, Strike Tube Aux. 1

48 16781 Screw, HHCS 1/2-13 x 2. 1/4 GD 8 2

49 16786 Screw, SHS 1/2-13 x 3/4 16

50 16880 Decal, Lifting Warning 5

51 16925 Decal, Lube and Lifting 1

52 19485 Ferrule, Copper 1/6 10

53 2621 Fitting, Grease, Strt, IA-28 5

54 5054 A Washer, Lock, V2 Medium 2

55 60035 Wire Rope, 1/16dia Galvanized 2

56 60055 Trim Edge, 1-1/4", (BLT 1/4) 23

57 7170 Pin, Hitch Clip, 5/32 x 3-5/16 1

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 55

Page 56

HYDRAULIC ASSEMBLY

WRS-5200 — HYDRAULIC ASSY.

PAGE 56 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 57

WRS-5200 — HYDRAULIC ASSY.

HYDRAULIC ASSEMBLY

NO PART NO PART NAME QTY. REMARKS

1 0786 Screw, BHC 1/4-20 x 3/8 Nyloc 1

2 11402 Filter, Hyd Oil 2

3 11721 Fitting-06MO-R x -06MJIC 4

4 13220 Fitting, Strt, 3/4 MPT x 3/4 Barb 3

5 16213 Cooler, Hyd Oil 1

6 16217 Valve, Selector, 3-way 1

7 16218 Filter, Head 2

8 16327 Fitting, 3/4 BOS Run J Tee 1

9 16328 Fitting, 3/4 FJ x 3/8 MJ Reducer 2

10 16329 Fitting, 3/4JFX x Tube Nut 2

11 16331 Fitting, 3/4 MP x 5/8J 2

12 16332 Fitting, Bulkhead Nut, 5/8 1

13 16333 Fitting, 3/8J x 3/8J 1

14 16334 Fitting, Bulkhead Nut, 3/8 1

15 16336 Fitting, 10 BOS O-R x 10MJ 45EL 2

16 16340 Tee, Bulkhead 3/4 Run 1

17 16344 Fitting, Tee 3/4 MP x 3/4 FP 1

18 16346 Bushing, 1-3/4 5

19 16409 Motor, Strike Tube 1

20 16564 Fitting, 1/2 Female QC 1

21 16565 Fitting, 1/2 Male QC 1

22 16566 Fitting, 3/4 Female QC 1

23 16567 Fitting, 3/4 Male QC 1

24 16568 1/2" Female Cover 1

25 16569 1/2" Male Cover 1

26 16570 3/4" Female Cover 1

27 16571 3/4" Male Cover 1

28 16572 Fitting, 8 BOSS O-Ring x 3/4 FPT (RIGID) 1

29 16574 Hose, 80" OAL 5/8 Hose-10 FJ x 12 FJ 1

30 16575 Hose, 75" OAL 5/8 Hose-10 FJ x 12 FJ 1

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 57

Page 58

HYDRAULIC ASSEMBLY (CONT.)

WRS-5200 — HYDRAULIC ASSY. (CONT)

PAGE 58 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 59

WRS-5200 — HYDRAULIC ASSY. (CONT)

HYDRAULIC ASSEMBLY (CONT.)

NO PART NO PART NAME QTY. REMARKS

31 16576 Hose, 75" OAL 3/8 Hose-3/8 FJ x 3/8 FJ 1

32 16581 Fitting, 4 BOSS O-R x 6 MJ 90 ELB 1

33 16585 Fitting, Bushing 1/2 FP x 3/4 MP 2

34 16594 Valve, Loop Flushing 1

35 16597 Fitting, 1/2 MP x 5/8 MJ Bulkhead 4

36 16598 Nut, 5/8 Bulkhead 4

37 16660 Tube, HYD Steel (Manifold to HYD Tank) 1

38 16601 Tube, HYD Steel (PAD. Return) 1

39 16602 Tube, HYD Steel (PAD. Supply) 1

40 16603 Tube, HYD Steel (Valve to Female QC) 1

41 16604 Tube, HYD Steel (Valve to Male QC) 1

42 16605 Tube, HYD Steel (Valve to Tank) 1

43 16606 Fitting, 1/2 MP x 5/8 MJ 90 EL 2

44 16607 Tube, HYD Steel (Valve to Manifold) 1

45 16608 Fitting, 3/4 MP x 8 MJ 90 EL 1

46 16609 Fitting, 12 FJ (SWIV) x 12 MJ 45 EL 1

47 16610 Hose, 6C2AT-69FJX-64FJX 1

48 16611 Hose, 6C2AT-6FJX-64FJX 1

49 16612 Hose, 6C2AT-6FJX-69FJX 1

50 16613 H6se, 6C2AT-6FJX-69FJX 1

51 16614 Hose, 12C2AT-129FJX-12FJX 1

52 16615 Hose, 8C2AT-89FJX-SFJX 1

53 16616 Hose, 6C2AT-6FJX-69FJX 1

54 16617 Fitting, 10 BOS O-Rx 8 MJ 1

55 16618 Fitting, 12 BOS O-R x 12 MJ Strt 1

56 3461 Fitting, 12 BOS O-RxV4Bar90EL 1

57 3368 Fitting, 3/4 MP x 5/8 MJ 90 EL 5

58 16698 Fitting, 5/8 FJ x 5/8 MJ 45 EL 1

59 16717 Fitting, Ferrule 5/8 Tube HYD 7

60 16718 Fitting, Nut 5/8 Tube HYD 7

61 16846 Fitting, 5/8 FJ x5/8 MJ 90 Elbow 1

62 3333 Clamp, 1-1/4 Hose 4

63 3336 Gauge, Temp Sight 1

64 3462 Hose, Suction 2

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 59

Page 60

PRESSURE WASHER ASSEMBLY

WRS-5200 — PRESSURE WASHER ASSY.

PAGE 60 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 61

WRS-5200 — PRESSURE WASHER ASSY.

PRESSURE WASHER ASSEMBLY

NO PART NO PART NAME QTY. REMARKS

1 0655 Screw, HHC 5/16-18 x 3/4 4

2 16407 Washer, Pressure 1

3 16564 Fitting, 1/2 Female QC 3

4 16565 Fitting, 1/2 Male QC 3

5 16568 1/2" Female Cover 1

6 16569 1/2" Male Cover 1

7 16573 Hose, OAL 74", 1/2 Hose-SMNP x 8MNP 2

8 16590 Fitting, 1/2 MP x 1/2 MP 45 EL 2

9 16689 Name Plate, Screed 1

10 16741 Pressure Washer W/A 1

11 4014 Screw, 2-3/16 P-K Type U Drive 2

12 5283 Nut, Nyloc 5/16-18 4

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 61

Page 62

WIRE ASSEMBLY

WRS-5200 — WIRE ASSY.

PAGE 62 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 63

WRS-5200 — WIRE ASSY.

WIRE ASSEMBLY

NO PART NO PART NAME QTY. REMARKS

1 16397 Socket, 4-Way 1

2 16398 Plug, 4-Way 1

3 16759 Wire, Lite to Lite Power Unit 2

4 16760 Wire, Lite to Socket Power Unit 2

5 16761 Wire, Grd to 4 SCK Power Unit 1

6 16762 Wire, Socket to Fuse Power Unit 1

7 16763 Wire, SOL to Fuse Power Unit I

8 16764 Wire, Start SOL-Fuse Power Unit I

9 16776 Wire, Choke to GRD Power Unit 1

10 16777 Wire, HI/LO to BATT Power Unit 1

11 16778 Main Wire ASM, Power Unit 1

12 16782 Wire, SOL to GILD Power Unit 1

13 16783 Wire, BATT to GILD Power Unit 1

14 16784 Wire, ST Rel to GRD Power Unit 1

15 16785 Wire, ST Rel to Junc Power Unit 1

16 2655 Hour meter 1

17 60037 Loom, 5/8 dia HI Temp, Black 3

18 60056 12/16 Sow 4

19 60221 Loom, .375 Split 9

20 8239 Rivet, Pop 1/8 x .400 2

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 63

Page 64

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 10 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and the

carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip is $15.00 net. Customers will be asked

for instructions regarding handling of orders

not meeting this requirement. If possible, additional fast moving parts will be added to the

order to total $15.00 minimum.

RETURNED GOODS POLICY

Return shipments will be accepted and credit

will be allowed, subject to the following provisions:

1. A Returned Material Authorization must

be approved by Multiquip prior to shipment. A copy of the Authorization must

accompany the shipment to the designated Warehouse. A copy of the original

Multiquip invoice to the customer must

also accompany the shipment.

2. Parts being returned must be listed as

currently supplied on the current parts

list.

3. Parts must be in new and resalable condition, in the original Multiquip package,

with Multiquip part numbers clearly

marked.

4. Any item with a list price of $1.00 or less

5. Any parts with a limited shelf life (such as

6. Special order items are not returnable for

7. Engine parts other than 2-cycle engine

8. Credit on returned parts will be issued at

9. Credit issued will be applied to future

10. All parts must be returned freight prepaid

The sender will be notified of any material

received not meeting the above provisions.

Such material will be held for 30 days from

notification, pending instructions. If a reply is

not received within 30 days, the material will

be returned to the seller at his expense.

PRICING AND REBATES

Prices are subject to change without prior

notice.

Price changes are effective on a specific date

and all shipments on or after that date will be

billed at the revised price.

Rebates for price declines and added charges

for price increases will not be made for stock

on hand at the time of any price change.

Multiquip reserves the right to quote and sell

direct to Government agencies, and to Original Equipment Manufacturer accounts who

use our products as integral parts of their own

products.

SPECIAL EXPEDITING SERVICE

will not be accepted.

gaskets, seals, “O” rings, filters, etc.) that

are over six months old will not be accepted.

credit.

parts will not be accepted.

dealer net price at time of original purchase, less a 15% restocking charge.

purchases only.

to Multiquip’s designated receiving point.

Freight is at the sender’s expense.

A $20.00 to $50.00 surcharge will be added to

the invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

LIMITATION OF SELLER’S LIABILITY

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of the

item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profit or good will or for any

other special, consequential or incidental damages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are made

in connection with the sale of parts or trade

accessories nor as to any engine not manufactured by Multiquip. Such warranties made in

connection with the sale of new, complete units

are made exclusively by a statement of warranty packaged with such units, and Multiquip

neither assumes nor authorizes any person to

assume for it any other obligation or liability

whatever in connection with the sale of its

products. Apart from such written statement of

warranty, there are no warranties, express,

implied or statutory, which extend beyond the

description of the products on the face hereof.

PAGE 64 — WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL — REV. #2 (08/09/02)

Page 65

NOTE PAGE

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (08/09/02) — PAGE 65

Page 66

PARTS MANUAL

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800/427-1244 or 310/537-3700

FAX: 800/672-7877 or 310/637-3284

SERVICE DEPARTMENT

800/478-1244 or 310/537-3700

FAX: 310 - 537-4259

WARRANTY DEPARTMENT

800/421-1244, EXT. 279 or 310/537-3700

FAX: 310 - 537-1173

MAIN

800/421-1244 or 310/537-3700

FAX: 310 - 537-3927

MULTIQUIP INC.

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 800-421-1244

FAX: 310-537-3927

E-MAIL: mq@multiquip.com

WWW: multiquip.com

Quebec, Canada • Manchester, UK • Rio De Janiero, BR • Guadalajara, MX

Atlanta • Boise • Dallas • Houston • Newark

Loading...

Loading...