Page 1

OPERATION AND PARTS MANUAL

SERIES

WM120PM Series

POLY-MECHANICAL

WM120SM Series

STEEL-MECHANICAL

PLASTER/MORTAR MIXERS

Revision #7 (09/15/11)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingand otherconstruction activities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-based paints.

Crystallinesilica from bricks.

Cementand othermasonry products.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingon howoften youdo thistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 3

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 3

Page 4

TABLE OF CONTENTS

Here's How To Get Help ........................................... 3

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Operation and Safety Decals ................................... 6

Rules For Safe Operation ..................................... 7-8

Specifications ........................................................... 9

General Information ............................................... 10

Whiteman — Plaster/ Mortar

Mixer

Controls .................................................................. 11

Electric Motor ......................................................... 12

Towing .................................................................... 13

Paddle Blade Adjustment .................................. 14-15

Initial Start-Up ................................................... 16-17

Maintenance ..................................................... 18-19

Troubleshooting (Engine) ....................................... 20

Troubleshooting (Engine/Mixer) ............................. 21

Explanation Of Codes In Remarks Column ........... 22

Suggested Spare Parts .......................................... 23

Engine Side Paddle Assembly .......................... 24-25

Tow Side Paddle Assembly ...............................26-27

Paddle Shaft Assembly ..................................... 28-29

Polyethylene Drum Assembly ........................... 30-31

Steel Drum Assembly........................................32-33

Cab Assembly ...................................................34-35

Frame, Wheel, Tire and Hub Assembly ............ 36-37

Name Plate and Decals .................................... 38-39

Engines

Wisconsin Engine Assembly ............................. 40-41

Honda Engine Assembly ...................................42-43

Motor

Electric Motor Assembly.................................... 44-45

Transmissions

Transmission Assembly.....................................46-47

Terms and Conditions Of Sale — Parts ................. 48

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 5

PARTS ORDERING PROCEDURES

r

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet

Order parts on-line using Multiquip’s SmartEquip website!

N View Parts Diagrams

N Order Parts

N Print Specification Information

Goto www.multiquip.com and click on

Order Par ts

Order via Fax

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

(Dealers Only)

to log in and save!

(Dealers Only)

:

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact you

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

:

Domestic (US) Dealers Call:

1-800-427-1244

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

R Dealer Account Number

R Dealer Name and Address

R Shipping Address (if different than billing address)

R Return Fax Number

R Applicable Model Number

R Quantity, Part Number and Description of Each Part

www.multiquip.com

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 5

When ordering parts, please supply:

R Specify Preferred Method of Shipment:

UPS/Fed Ex DHL

N Priority One Tr uck

N Ground

N Next Day

N Second/Third Day

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

Page 6

OPERATION AND SAFETY DECALS

The safety instruction decals shown must be on all Whiteman Mixers

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

SHUT OFF ENGINE BEFORESHUT OFF ENGINE BEFORE

SHUT OFF ENGINE BEFORE

SHUT OFF ENGINE BEFORESHUT OFF ENGINE BEFORE

PUTTING HANDS IN MIXING DRUMPUTTING HANDS IN MIXING DRUM

PUTTING HANDS IN MIXING DRUM

PUTTING HANDS IN MIXING DRUMPUTTING HANDS IN MIXING DRUM

P/N EM948423

SAFETY INSTRUCTIONS

1. Read owners manuals before operating.

2. Keep unauthorized and untrained people away from machine during operation.

3. Make sure all safety devices are in place before this machine is started.

4. Make sure engine is turned off and spark plug wire is disconnected before cleaning the

machine.

5. Keep hands and fingers away from moving objects.

6. Do not operate machine in an enclosed area. Proper ventilation is required.

7. Never leave machine unattended when operating.

8. Always stop engine and allow engine to cool before adding fuel or oil.

WHITEMAN CONCRETE PRODUCTS — A MULTIQUIP COMPANY — CARSON, CALIFORNIA

P/N 924801

PAGE 6 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 7

RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the WM-120PM or WM-120SM mixers:

GENERAL SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by persons under 18

years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steeltoed boots and other protective devices required

by the job.

NEVER touch the hot exhaust manifold, muffler or cylinder. Allow

these parts to cool before

servicing engine or mixer.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot

with

■

The engine section of this mixer requires an adequate free

flow of cooling air. Never operate the mixer in any enclosed or

components can cause serious burns.

narrow area where free flow of the

air is restricted. If the air flow is

restricted it will cause serious

damage to the mixer or engine and

may cause injury to people.

Remember the mixer's engine

gives off DEADLY carbon

monoxide gas.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacture does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

Always check the machine for loosened threads or bolts before

starting.

■

■

Always refuel in a well-ventilated area, away from sparks and

open flames.

■

Always use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT

machine. Fire or explosion could result

from fuel vapors, or if fuel is spilled on a

hot engine.

NEVER operate the mixer in an explosive atmosphere or near

combustible materials. An explosion or fire could result

causing severe

bodily harm or even death.

smoke around or near the

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 7

Page 8

RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the WM120S/WM120P Mixer:

GENERAL SAFETY

■

Stop the engine when leaving the mixer unattended.

■

Block the unit when leaving or when using on a slope.

■

Maintain this equipment in a safe operating condition at all

times.

■

Always stop the engine before servicing, adding fuel and oil.

■

NEVER Run engine without air filter. Severe engine may

occur.

■

Always service air cleaner frequently to prevent carburetor

malfunction.

■

Always be sure the operator is familiar with proper safety

precautions and operations techniques before using mixer.

■

Always store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

NEVER Run engine without air cleaner. Severe engine

damage may occur.

■

Always read, understand, and follow procedures in Operator’s

Manual before attempting to operate equipment.

■

Always be sure the operator is familiar with proper safety

precautions and operations techniques before using pump.

■

Always store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

CAUTION:

■

DO NOT operate this equipment unless all

guards and safety devices are attached and in

place.

Caution must be exercised while servicing this equipment.

Rotating and moving parts can cause injury if contacted.

■

When towing, an adequate safety chain must be fastened to

the frame, refer to page 14.

■

Keep all inexperienced and unauthorized people away from

the equipment at all times.

■

Unauthorized equipment modifications will void all warranties.

■

Check all fasteners periodically for tightness. Also check

towing tongue bolt, lock nut and wheel lug nuts for wear.

■

Stop the engine and disconnect the spark plug before allowing

anybody’s hands in the mixing drum.

■

Never pour or spray water over the engine or electric motor.

■

Always stand clear of dump handle when mixer is in operation.

Any binding of material between the mixer blades and drum

will cause drum and handle to quickly move in the discharge

position.

■

Depending on type of mixer, test the

the gasoline engine or electric motor before operating. The

purpose of these switches is to shut down the engine or motor

of the mixer.

Emergencies

■

Always know the location of the nearest

and

first aid kit

Also know the phone numbers of the nearest

doctor

invaluable in the case of an emergency.

Maintenance Safety

■

NEVER lubricate components or attempt service on a running

machine.

■

Always allow the machine a proper amount of time to cool

before servicing.

■

Keep the machinery in proper running condition.

■

Fix damage to the machine immediately and always replace

broken parts.

■

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

■

DO NOT use food or plastic containers to dispose of

hazardous waste. Emergencies

■

Always know the location of the nearest

and

first aid kit

Also know the phone numbers of the nearest

doctor

invaluable in the case of an emergency.

. Know the location of the nearest telephone.

and

fire department

. Know the location of the nearest telephone.

and

fire department

ON/OFF

switch for either

fire extinguisher

ambulance

. This information will be

,

fire extinguisher

ambulance

. This information will be

,

PAGE 8 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 9

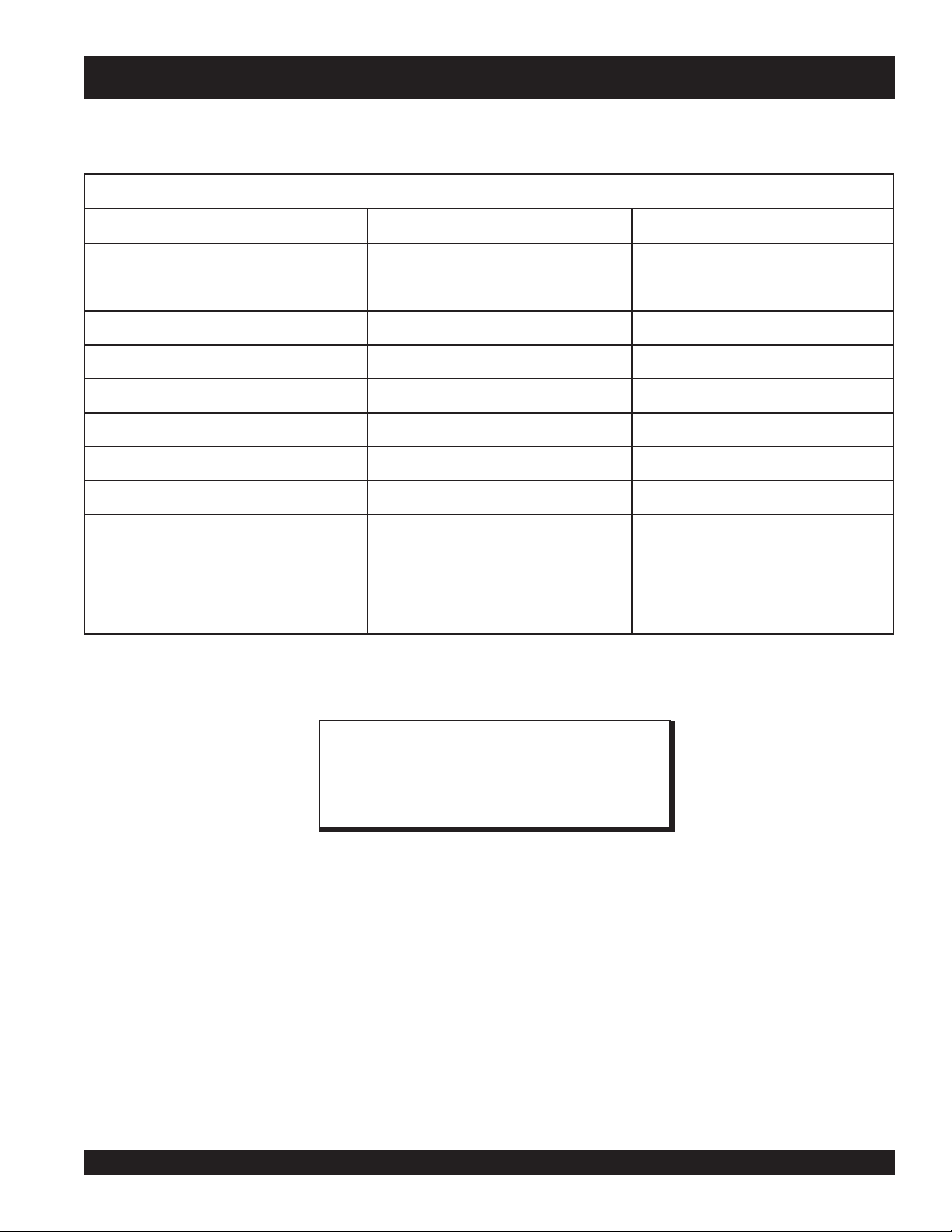

WM120P/S — SPECIFICATIONS

srexiMseireSS/P021MW.1elbaT

RETEMARAPNOITACIFICEPS

)sretil(tf.uc-yticapaC)043(21)043(21

sgab-yticapacgaB4ot5.34ot5.3

).gk(sbl-thgieW)494(090,1)494(

).mc(.ni-HxWxraBwoT/whtgneL )251x031x802(06x15x28)251x031x802(06x15x28

).mc(ni-eldnaHpmuD/WthgieH)19

).mc(ni-thgieHegrahcsiD)191(57)191(57

evirDlacinahceMlacinahceM

noitcApmuDlaunaMlaunaM

secruoSrewoP

MP021MWMS021MW

1(57)191(57

irtcelE064/032esahP-elgniSPH5

c

cirtcelE064/032esahP-eerhTPH5

adnoHPH11

3-DLNEA.csiWPH2.9

iSPH5

090,1

064/032esahP-elgn

cirtcelE

cirtcelE064/032esahP-eerhTPH5

adnoHPH11

3-DLNEA.csiWPH2.9

NOTE

In accordance with our established policy of constant

improvement, we reserve the right to amend these

specifications at any time without notice.

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 9

Page 10

WM120P/S — GENERAL INFORMATION

GENERAL

The Whiteman WM-120PM and WM120SM Series plaster and

mortar mixers are shipped completely assembled and have

been factory tested.

The drum batch capacity of these mixers is between 3.5 and

4.0 bags. With proper care, they will give continuous service

year-after-year.

These mixers can be powered by either gasoline or electric

motors. The power from the engine is transmitted via the clutch/

reduction assembly directly to the paddle shaft. Therefore

providing high mixer torque and eliminating V-belts .

BEFORE STARTING

Before starting the engine, read the engine owners manual

and thoroughly understand the safety information.

Check the items listed below:

OIL LEVELS

Be sure to check the oil levels in the engine and engine reduction

unit before starting the unit.

HARDWARE

Check all hardware on the mixer before starting. Periodically

inspect all hardware. Loose hardware can contribute to early

component failure and poor performance. Use the torque chart

below as a general guideline and keep all hardware tight:

GASOLINE ENGINE CARE

For care and operation of the gasoline engine, refer to the

engine manufacturer’s operating instructions furnished with the

engine. We recommend draining and refilling the engine

crankcase at least every thirty hours of operation. Check the

engine oil level daily.

GASOLINE MIXER OFF/ON SWITCH

This feature is on gasoline engine mixers only. Located on the

side of the engine cover. The purpose of this switch is to start

and stop the mixer in normal operation.

ELECTRIC MOTOR MIXER OFF/ON SWITCH

This feature is on electric motor mixers only. This switch is located

on top of the motor. Lift the engine cover to gain access to this

switch. The purpose of this switch is to start and stop the mixer

in normal operation. Never use the electric motor in an explosive

environment.

ENGINE THROTTLE AND CHOKE CONTROLS

Please refer to the engine owners manual for specific

instructions.

HARDWARE DIA TORQUE (LB./FT.)

5/16"- 18 24

3/8" - 24 37

1/2" - 13 39

1/2" - 13 (Grade 8) 90

PAGE 10 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 11

WM-120P/S — CONTROLS

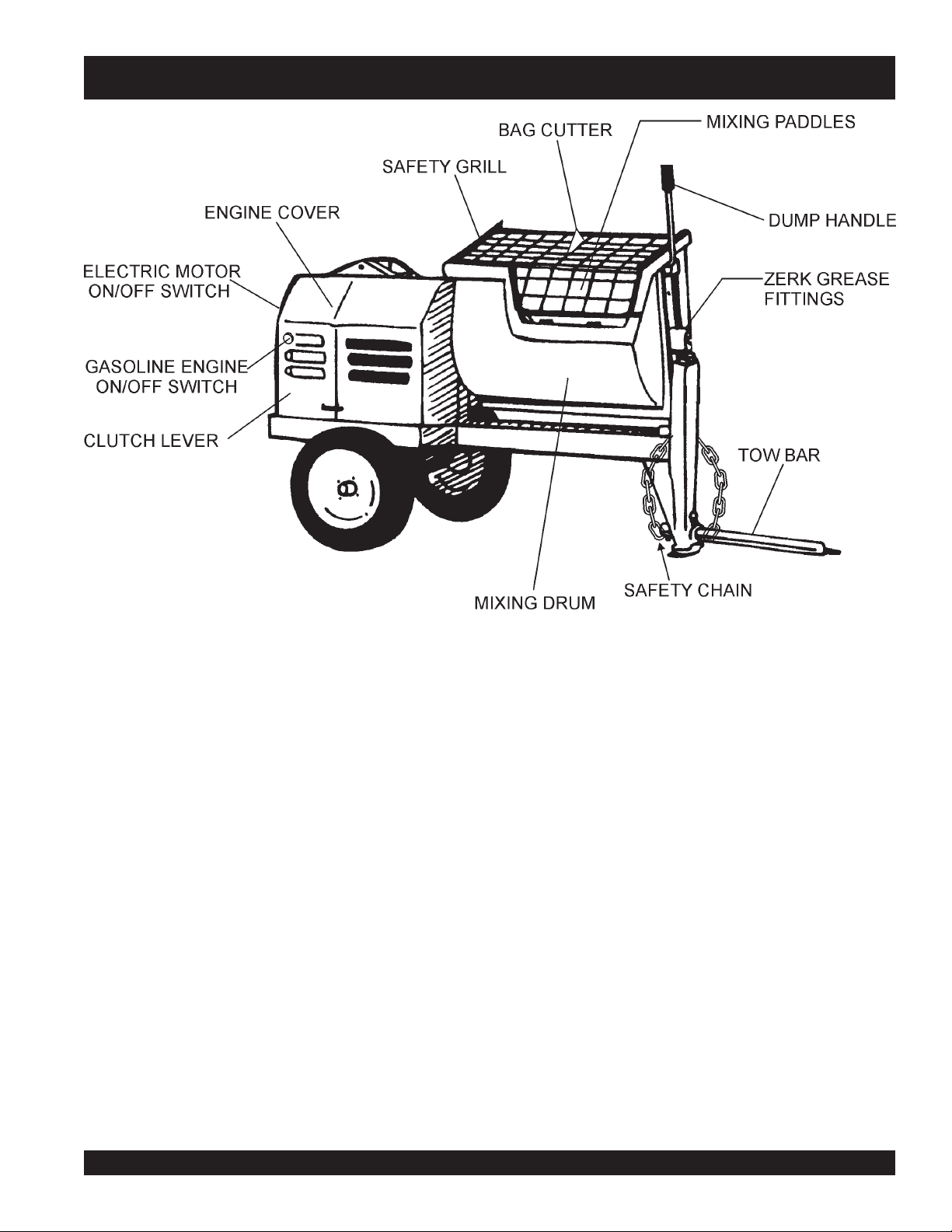

Figure 1. Mixer

Safety Grill — Provided for operator safety. This safety grill is

designed to keep hands and solid objects out of the mixing drum

when in use. This grill should be closed at all times when mixer

is in use. DO NOT remove the grill or grill opening bar. Keep the

grill clean by washing it down daily.

Bag Cutter— This feature allows compound mixing bags to be

opened easily, therefore allowing the contents of the bag to fall

directly into the mixing drum.

Mixing Paddles — Used in the mixing of material. This unit

uses four different types of paddles to provide a fast uniform mix.

Dump Handle — Pull this handle downward to dump the contents

of the drum. Push the handle upward to return the drum to its

vertical position.

Zerk Fitting — There is, on each end of the mixing drum a zerk

grease fitting. These fittings lubricate the dumping mechanism.

Lubricate both fittings at least twice a week.

Mixing Drum — Made of either

materials such as concrete, mortar, plaster are to be placed into

this drum for mixing. Always clean the drum after each use.

Tow Bar — When towing is required, connect tow bar to a

vehicle Reference page 14.

Engine Cover — Lift this cover to gain access to the engine

compartment.

ON/OFF Switch (gasoline) — This switch is provided on

with gasoline

engine cover. When activated it will shut down the engine.

ON/OFF Switch (electric) — This switch is provided on mixers

with electric motors. To gain access to this switch, lift the engine

cover. When activated it will shut down the electric motor.

Clutch Lever — Push the clutch lever forward, toward the tow

tongue end of the mixer to engage clutch. Once clutch is

engaged paddle shaft will rotate. To disengage clutch pull the

clutch backwards towards the engine.

polyethylene

engines only and is located on the side of the

or

steel

. Mixing

mixers

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 11

Page 12

WM-120P/S — ELECTRIC MOTOR

ELECTRIC MOTOR

For lubrication care and operation of the electric motor, refer to

your electric motor instruction booklet furnished with the motor.

Protect the electric motor from dust as much as possible and

keep ventilating openings clean.

It is strongly recommended that all electrical wiring be

done by a

should be given to the electric switch as well as the

over-and-under voltage protection devices as per

regulations set forth in the local electrical safety code

CAUTION:

■

electric motor

■

DO NOT spray water at any time on the

.

DO NOT operate electric motor in a

handbook.

explosive environment.

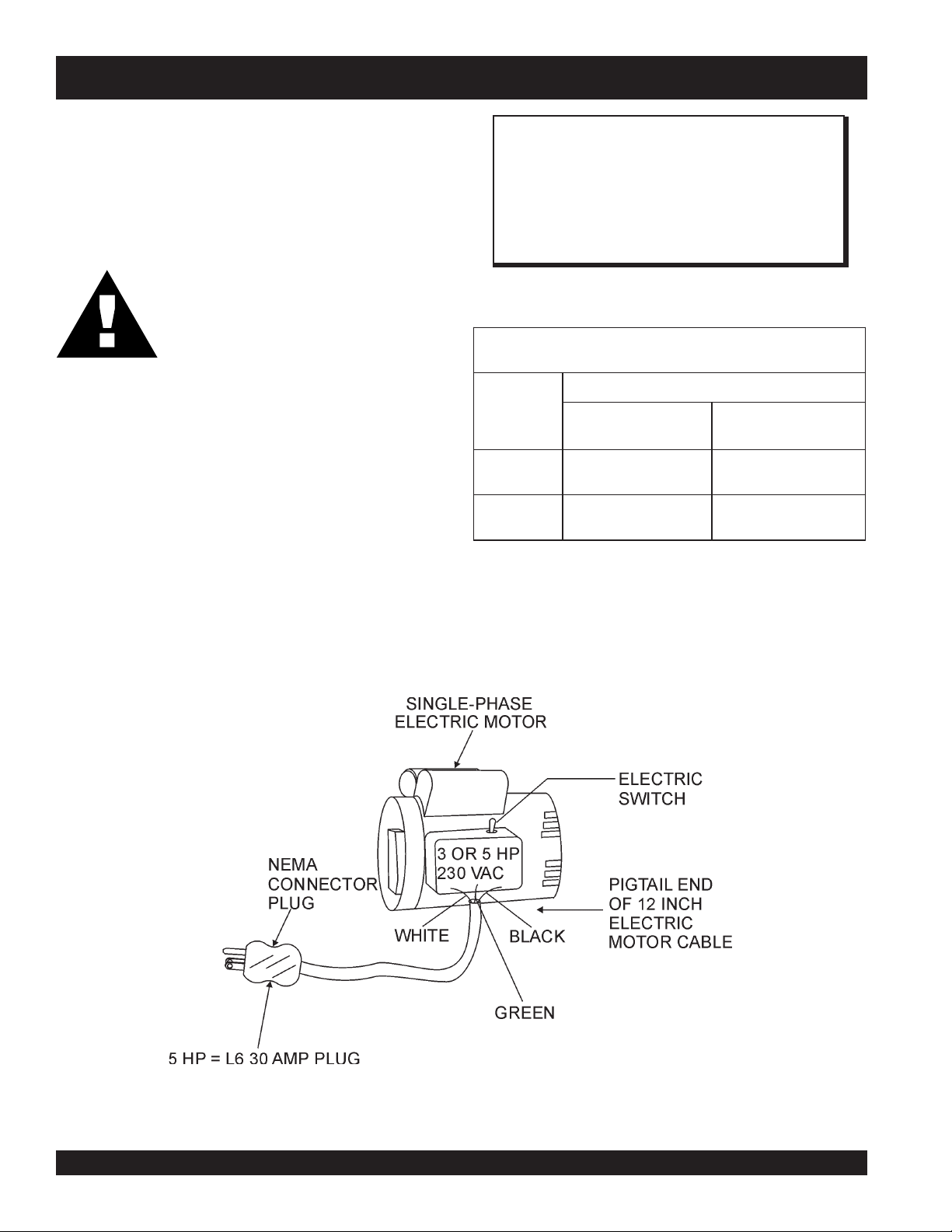

The electric motor for this mixer is available in either a 5 HP

single-phase or 5 HP 3-phase configuration. The input voltage

requirement for these motors is either 230 VAC or 440 VAC only.

ELECTRIC MOTOR CONNECTION

A 12 inch electrical cable (Figure 2) with a pigtail at one end is

provided with the electrical motor for hookup to a power source.

Table 1. shows the required NEMA connector for the desired

motor horsepower rating. In addition, Table 2 also shows the

matching NEMA approved connector for the required extension

cord.

NOTE

licensed electrician

rotoM

rewopesroH

gnitaR

PH3935049N/PP02-6

PH5745049N/PP03-6L845049N/PR03-6L

L045049N/PR02-6L

. Special attention

rotcennoCgulPAMENAMENgnitaM

noitamrofnIgniriWrotoMcirtcelE.2elbaT

esahPelgniS-tloV032

rotcennoCelcatpeceR

Figure 2. Single Phase Electric Motor with 12 inch Pigtail Cable

PAGE 12 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 13

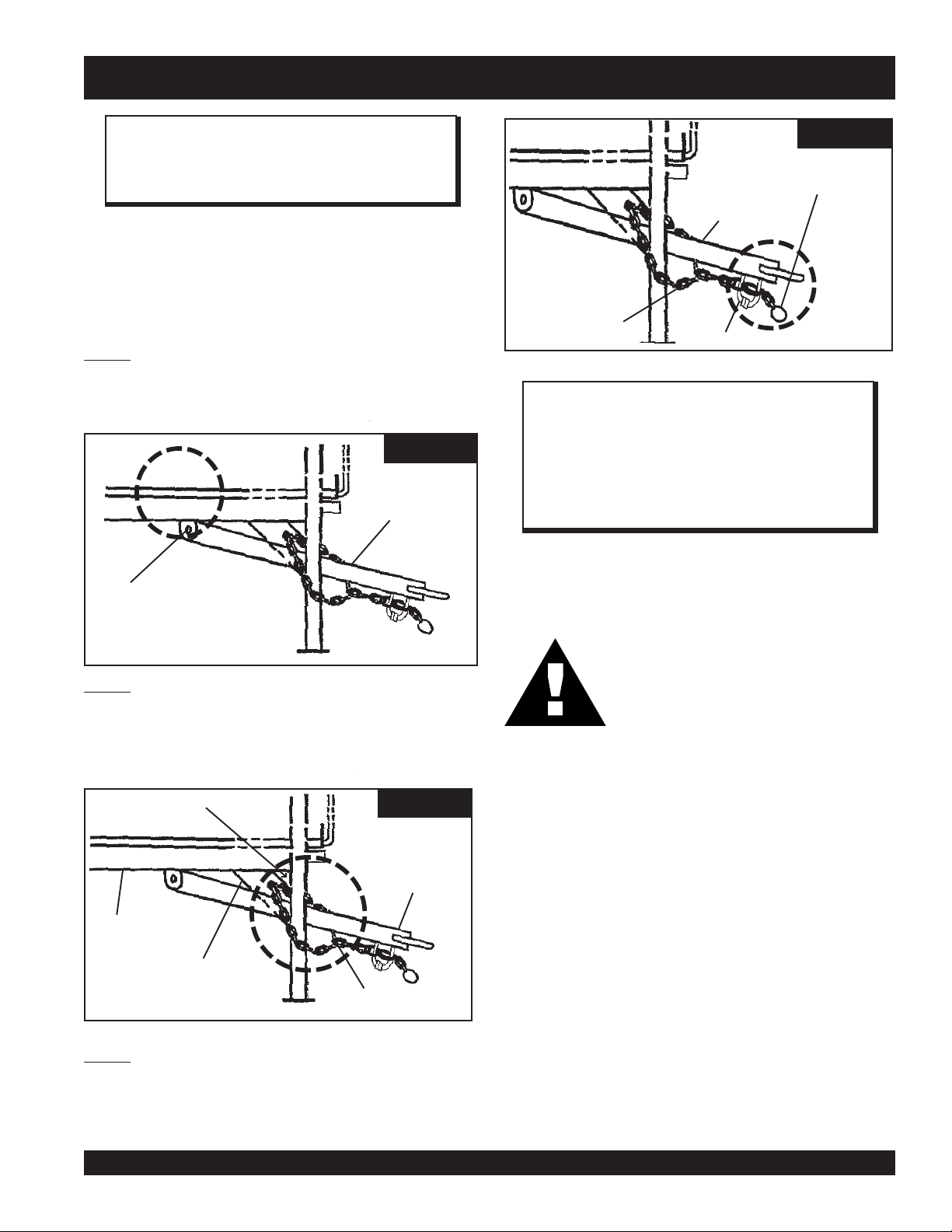

WM-120P/S — TOWING

NOTE

Before towing, check with local and state laws for proper

compliance.

The tow bar and chain must be properly attached to the mixer

and towing vehicle prior to towing. Refer to the following

installation instruction:

Step 1.

Insert the Draw Bar into the main frame. Secure, utilizing the 3/4"

bolt (grade 5) and nylock nut. Tighten to 100 foot pounds.

STEP 1

DRAW BAR

BOLT & NUT

REMOVE EXCESS

CHAIN (SLACK)

It is critical that the length of the chain be properly

adjusted, to prevent the

stand from dropping to the ground (contact) in the event

the Draw Bar becomes disconnected from the towing

vehicle.

If a new safety chain is required use P/N 13363. For a new

connector link use P/N 01004.

STEP 3

VEHICLE

CONNECTOR LINK

DRAW BAR

BOTTOM CONNECTOR LINK

NOTE

Draw Bar

and the front mixer

CAUTION:

Step 2.

Install the chain through the hole located between the frame

gusset and frame angle. Loop the chain together and place under

the Draw Bar. Secure with connector link.

INSERT CHAIN THROUGH

THE HOLE

FRAME ANGLE

FRAME GUSSET

CONNECTOR LINK

Step 3.

STEP 2

DRAW BAR

BALL HITCH COUPLER

1. Check vehicle hitch, ball, and coupler for signs of wear or

damage. Replace any parts that are worn or damaged

before towing.

2. Use only the 2" ball diameter as indicated on your coupler.

Use of any other ball diameter will create an extremely

dangerous condition which can result in separation of the

coupler and ball or ball failure.

3. Be sure the coupler is secured to the hitch ball and the lock

lever is down tight and locked.

Recheck tightness again after towing about 50 miles.

4. Check that trailer safety chains are properly connected.

■

Check the following before towing:

Extend the chain along the length of the Draw Bar, remove excess

chain (slack) and secure to bottom connector link. Secure the

chain to the towing vehicle, using the connector link.

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 13

Page 14

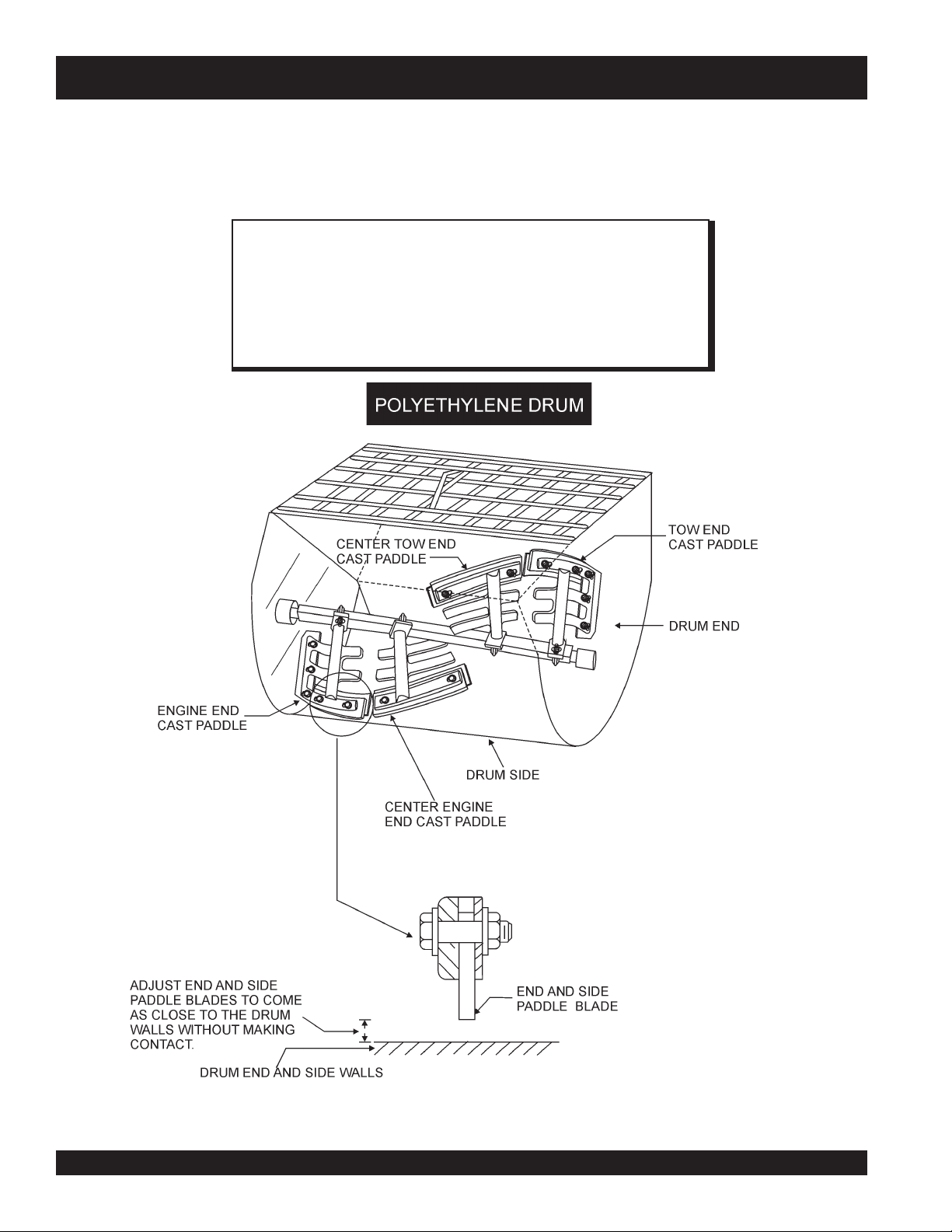

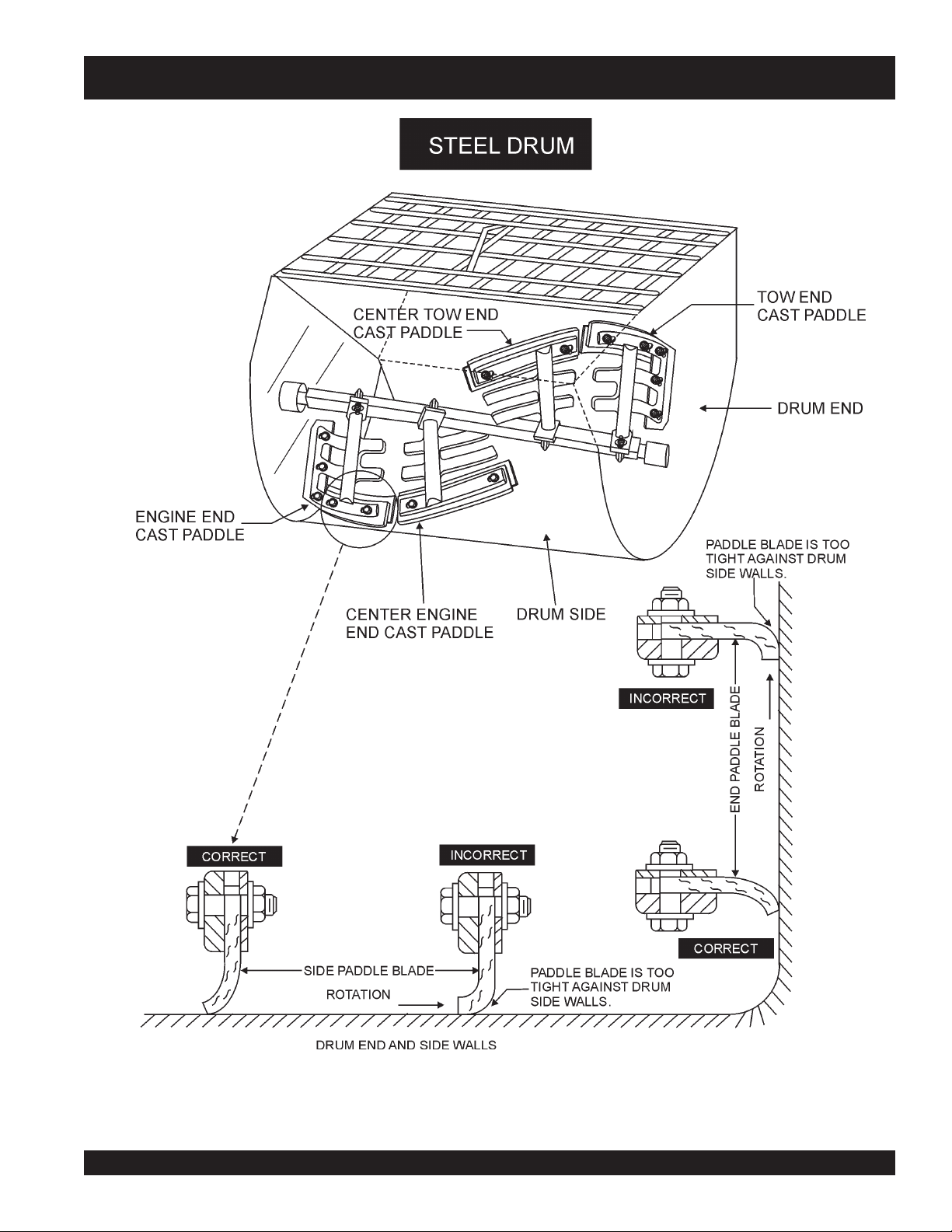

WM-120P/S — PADDLE BLADE ADJUSTMENT

Paddle blade adjustment is dependent on drum type,

using a polyethylene drum. Figure 4 illustrates the paddle blade adjustment when using a steel drum. When using a polyethylene

drum the paddle blade should come as close as possible to the drum end and side walls without making contact. If material builds

up on the drum, use a rubber mallet to dislodge the material without adverse effect to the drum.

EPOXY COMPATIBILITY - There are some epoxies and other chemicals

used in certain applications that are

Since Whiteman Industries cannot control the end user's application of this

product, we

exposed to incompatible chemicals.

will not

polyethylene

assume responsibility for the resulting damages when

or

steel

. Figure 3 illustrates the paddle blade adjustment when

NOTE

not

compatible with polyethylene drums.

B

Figure 3. Paddle Blade Adjustment, Polyethylene Drum

PAGE 14 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 15

WM-120P/S — PADDLE BLADE ADJUSTMENT

Figure 4. Paddle Blade Adjustment, Steel Drum

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 15

Page 16

WM-120P/S — INITIAL START-UP

This section is intended to assist the operator with the initial

start-up of the WM-120P/S mixer. It is extremely important that

this section be read carefully before attempting to use the mixer

in the field.

DO NOT use your mixer until this section is thoroughly

understood.

STARTING THE ENGINE (gasoline only)

The following steps outline the procedure for starting the engine.

Depending on the type of engine employed in the mixer the

steps may vary slightly. If your mixer has an electric motor

disregard this section.

1. Move the fuel shut-off lever (Figure 5) to the ON position.

CAUTION:

Failure to understand the operation of the WM-

120P/S mixer could result in severe damage

to the mixer or personal injury.

See Figure 1 (Page 10) for the location of any control referenced

in this manual.

LUBRICANTS

ENGINE OIL

1. Remove the engine oil dipstick from its holder.

2. Determine if the engine oil is low, add correct amount of

engine oil to bring oil level to a normal safe level.

CLUTCH OIL

1. Check the oil level in the clutch compartment, fill with 30

SAE engine oil if needed.

2. To start a cold engine, move the choke lever (Figure 6) to

the CLOSED position.

Figure 5. Fuel Shut-OFF Lever

REDUCTION GEAR OIL

1. Check the oil level in the reduction gear compartment, fill

with 90 SAE transmission oil if needed.

ZERK GREASE FITTINGS

1. Check the zerk grease fittings at each end of the mixing

drum. These grease fittings lubricate the dumping

mechanism. If the dumping handle is stiff or hard to move

lubricate these fittings.

3. Move the throttle lever (Figure 7) away from the slow

FUEL

1. If your mixer has a gasoline engine, determine if the engine

fuel is low. If fuel is low, remove the fuel filler cap and fill

unleaded

with

gasoline.

position, about 1/3 of the way toward the fast position.

CAUTION:

Handle fuel safely. Motor fuels are highly

flammable

mishandled. DO NOT smoke while refueling.

Do not attempt to refuel mixer if the engine is

hot or running. Always allow engine to

before refueling.

and can be dangerous if

cool

Figure 6. Choke Lever

Figure 7. Throttle lever Lever

PAGE 16 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 17

WM-120P/S — INITIAL START-UP

4. Turn the engine switch (Figure 8) to the ON position.

Figure 8. Engine ON/OFF Switch

5. Located on the engine cover is the main

(Figure 9). Pull this switch outward to start the engine.

start/stop

switch

MIXING

1. The paddle shaft inside the drum should be rotating at this

time.

2. Lift the mixing bag compound onto the steel grate over the

bag cutter and let the contents fall into the drum.

3. Add water, and mix compound to desired consistency, then

dump.

NOTE

Be sure to stand clear of the

mixer is operational. Any binding of material between

the mixer blades and the drum will cause the drum

handle to move to the discharge position, thus causing

bodily harm.

STARTING THE ELECTRIC MOTOR

1. After the electric motor has been connected to a power

source by a licensed electrician it can then be ready for

use.

2. Set the electric motor's ON/OFF switch (Figure 11) to the

ON position.

dump handle

when the

Figure 9. Main ON/OFF Switch

6. Pull the

resistance, then pull briskly. Return the starter grip gently.

Push the clutch lever forward, toward the tow tongue end

of the mixer. When engine starts adjust throttle lever so that

paddle shaft inside mixer rotates between 30 - 40 RPM's.

The number of RPM's will vary depending on engine type

and load.

starter grip

Figure 10. Starter Grip

(Figure 10) lightly until you feel

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 17

Figure 11. Main ON/OFF Switch

3. Engage the clutch lever and verify that the paddle shaft is

rotating, then follow steps 1, 2 and 3 outlined in the mixing

section above.

STOPPING THE MIXER (gasoline)

1. Push the main

the engine.

start/stop

switch (Figure 9) inward to stop

turn the fuel shut-off valve to the OFF position

3. Disconnect the spark plug.

4. Clean drum of all debris and foreign matter.

STOPPING THE MIXER (electric)

1. Place the electric motor's

the OFF position.

2. Disconnect the electric motor's extension cord from its

power source.

3. Clean drum of all debris and foreign matter.

start/stop

switch (Figure 11) in

Page 18

WM-120P/S — MAINTENANCE

WHEEL BEARINGS

After every 3 months of operation, remove the hub dust cap and

inspect the wheel bearings. Once a year, or when required,

disassemble the wheel hubs remove the old grease and repack

the bearings forcing grease between rollers, cone and cage

with a good grade of high speed wheel bearing grease (never

use grease heavier than 265 A.S.T.M. penetration (“No. 2.”) Fill

the wheel hub with grease to the inside diameter of the outer

races and also fill the hub grease cap.

Reassemble the hub and mount the wheel. Then tighten the

adjusting nut, at the same time turn the wheel in both directions,

until there is a slight bind to be sure all the bearing surfaces are

in contact.

Then back-off the adjusting nut 1/6 to 1/4 turn or to the nearest

locking hole or sufficiently to allow the wheel to rotate freely

within limits of .001" to .010" end play. Lock the nut at this position.

Install the cotter pin and dust cap, and tighten all hardware.

SHAFT SEALS

CAUTION:

IMPORTANT -DRUM HEAD SEAL CARE

Grease seals every 40 hours of operation using

any grade #1 lithium base grease. Apply

grease until visible inside of mixing tub (over

grease). this will purge seal system of

contamination.

CLUTCH REDUCTION ASSEMBLY LUBRICATION

PADDLE SHAFT BEARINGS

The paddle shafts in the Whiteman WM120P/S mixers rotate in

sealed ball bearings, which require no additional lubrication as

they are packed and sealed at the factory.

There is, on each end of the mixing drum, an zerk grease fitting.

Oil these fittings two or three times each week as they lubricate

the dumping mechanism of the mixing drum.

CAUTION:

BOLT CONNECTOR

A 5/8 " x 4 1/4" bolt is used as a connector pin located between

the reduction gear assembly and the paddle shaft. It is designed

to protect the transmission in the event a rock or other object

should get caught between the paddle blade and the drum, this

pin may shear. It is recommended that an extra bolt be kept on

hand so as to quickly make a replacement, if necessary.

This connector pin bolt is special. When replacing this

bolt consult the parts section of this manual for the

correct part number.

■

Failure

two or three times a week will cause the

dumping mechanism to stiffen, making the

mixer hard to dump.

to lubricate the zerk grease fittings

NOTE

The clutch reduction assembly has two separate compartments.

Each of which must be filled with its proper lubricant and checked

at regular intervals.

clutch compartment

The

number 30 SAE engine oil which can be poured through the

filler hole located just above the clutch inspection door on the

opposite side of the transmission. Fill the clutch compartment

with 30 SAE engine oil until it overflows the oil level plug located

on the shifter side of the clutch compartment . Check this oil level

every two or three months and add oil as required. Drain and

refill once a year.

reduction gear, upper compartment

The

number 90 SAE oil, as used in automobile transmissions. The

filler plug is at the top of the reduction gear case and the oil level

plug is on the same side of the case as the clutch lever. Fill the

reduction gear compartment with 90 SAE transmission oil until it

overflows the oil level plug. Check this oil level every two or

three months and add oil as required. Drain and refill once a

year.

should be filled with a good grade of

should be filled with

BEARING BRACKET

Grease the bearing bracket every month.

CLEANING

Always disconnect the spark plug wire before cleaning the inside

of the drum.

Never pour or spray water over the gasoline engine or electric

motor.

For consistent performance, long life and high quality mixing,

thoroughly clean the mixer inside and out at the end of each

day’s operation. To prevent lumps of dried mortar from forming

and contamination of future batches, do not allow a buildup of

materials to form on the blades or anywhere inside the drum.

PAGE 18 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 19

Clutch Adjustment Mechanical 12 CF Mixer

If the rotating mixing paddles appear to be losing rotational speed,

it may be necessary to adjust the clutch. For optimum

performance Multiquip recommends 35-55 lbs. applied pressure

to the hand clutch lever. After the first initial operating hours (8)

check the clutch for proper ensasment pressure.

Clutch Adjustment Procedure

CAUTION:

Always stop the engine, disconnect the spark

plug or electrical power cord before attempting

this procedure.

WM-120P/S — MAINTENANCE

1. To gain access to the " Gear Reduction Compartment"

remove the four 9/16-inch hex head bolts that secure the

hood to the engine and remove engine hood.

2. Drain the clutch compartment oil by removing the magnetic

3/8 plug located at the bottom of the Gear Reduction

Assembly.

NOTE

The Gear Reduction Compartment consist of two

compartments, a lower and upper.The

compartment houses the clutch, the

compartment contains the actual gear reduction.

Remember each compartment requires a different type

of lubricating oil.

3. To gain access to the "

the six 1/2-inch capscrews and lockwashers that secure

the clutch inspection door. Remove door and gasket.

4. Check that the clutch is disengaged by pulling the shifter

lever towards the rear of the mixer.

5. Refer to Figure 12 for steps 5A through 5 G:

A. Rotate the clutch using the recoil starter until the

adjustment lock

Using a flat blade screwdriver loosen the adjustment bolt

just enough to release the adjustment lock.

B. Using a punch, rotate the

one notch at a time in the counter-clockwise direction until

a firm 35 to 55 lbs. pressure is felt when engaging the

clutch lever (the lever should snap into the engaged

position).

clutch Inspection door

(Figure 12) P/N EM934040 is visible.

adjusting ring

lower

uppe

r

" remove

P/N EM 934045

If the clutch cannot be adjusted, it may be necessary to

inspect or replace the clutch.

C. When the clutch has been satisfactorly adjusted reinstall

the

D. Reinstall the

inch capscrews and lockwashers, and also check that the

gasket is not worn or broken.

E. When the clutch has been satisfactorly adjusted reinstall

the

F. Remove the 3/8-inch square head pipe plug located on

the lower clutch compartment. Refill the clutch

compartment with 2 1/4 quarts of SAE 30 motor oil to the

level of the plug. When done reinstall plug.

G. Reinstall spark plug wire or electric power cord. Start

engine, check for proper clutch engagement and inspect

for any oil leaks.

Any questions regarding the above procedure please

contact the Multiquip Service Dept. at 1-800 421-1244.

Figure 12. Clutch Adjustment Lock Location

NOTE

adjustment lock

clutch Inspection door

adjustment lock

P/N EM 934040 and tighten lock bolt.

using the six 1/2-

P/N EM 934040 and tighten lock bolt.

NOTE

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 19

Page 20

WM-120P/S — TROUBLESHOOTING (ENGINE)

Practically all breakdowns can be prevented by proper

handling and maintenance inspections, but in the event of a

breakdown, please take a remedial action following the

diagnosis based on the Engine Troubleshooting (Table 3)

information shown below and on the proceeding page. If the

problem cannot be remedied, please leave the unit just as it

is and consult our company's business office or service

MOTPMYS MELBORPELBISSOP NOITULOS

?tignihcaersi

?leuFoN leuFddA

?knatleufniretaW .knatleufecalperrohsulF

?deggolcretlifleuF retlifleufecalpeR

?roterubrackcutS .msinahcemtaolfkcehC

gnitratsrooP

?dersigulpkrapS .tinunoitingirotsinartkcehC.deluofsigulpkrapS

leuffieesotroterubractcepsnI

?etihw-eulbsigulpkrapS

GNITOOHSELBUORTENIGNE.3ELBAT

enilleufkcehC

erastejroterubraC.gnikaelriadetcejni,noisserpmoctneiciffusnI

.)wolfrevo(deggolc

?gulp

?liooN .deriuqersalioddA

?gnitratsnopu

?esool

"noisserpmoc

"noisserpmoc"

on"tuptuorewoptneiciffusnI

?esoolsigulpkrapS .gulpkrapsecalpeR

?sgnirnotsipnroW .sgnirnotsipecalpeR

tuptuorewoptneiciffusnI

?daeh

krapsfopittatneserpkrapsoN

sknilbpmalmralaerusserpliO

?revonruttonlliwenignE .tniojlexayrassecenfidnanotsipdnarednilycecalpeR

stlobgnitcennocdaehrednilyC

?degamadteksagdaehrednilyC .teksagdaehrednilycecalpeR

?taesevlavfonoitcnuflaM .sevlavtaes-eR

renaelc-rianinoitcnuflaM

?deggolcretlifria,metsys

ecafretnimorfnignikaelriA

rednilycdnaroterubracneewteb

/tratS

.stlobgnitcennocdaehrednilycnethgiT

.retlifriaecalperronaelC

.teksagdaehrednilyc

.deluoffigulpkrapsecalpeR.nekorbhctiwspotS

."rosneslio"tiucricnwodtuhscitamotuAkcehC

.nekorbrodekcarcdrocegatlovhgih,nekorbtinunoitingirotsinarT

ecalpeR.daehrednilycdnaroterubracneewtebstlobnethgiT

?metsysleufninoitcnuflaM

.retlifleufecalperronaelC

.roterubracecalperronaelC

.taolfroterubrackcehC

PAGE 20 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 21

WM-120P/S — TROUBLESHOOTING (ENGINE/MIXER)

)DEUNITNOC(GNITOOHSELBUORTENIGNE.3ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

tuptuorewoptneiciffusnI

staehrevodna"noisserpmoc"

leufhcumotsnruB

ylsuoinitnocsiroloctsuahxE

"ETIHW"

ylsuoinitnocsiroloctsuahxE

"KCALB"

?stcudorp

?ytisocsiv

?sgnirnroW sgnirecalpeR

?nafgniloocninoitcnuflaM .nafgniloocecalperrokcehC

?deggolcretlifekat-niriA .retlifekat-niriaecalperronaelC

tsuahxefonoitalumuccarevO

?gulpkrapsgnorW .gulpkrapsepytdetseggusserutcafunamhtiwgulpkrapsecalpeR

gnorwsiliognitacirbuL

?deggolcrennaelcriA .renaelcriaecalperronaelC

tesneebtonsahevlavekohC

?noitisoptcerrocehtot

nolaes,evitcefedroterubraC

?nekorbroterubrac

tnemtsujdaroterubracrooP

?hcirootsnurenigne"

.sevlavkcehcdnanaelC

.yrassecenfiecalper,relffumkcehC

.ytisocsivtcerrochtiwliognitacirbulecalpeR

.noitisoptcerrocehtotevlavekohctsujdA

.laesroroterubracecalpeR

.roterubractsujdA

GNITOOHSELBUORTREXIM.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?niprotcennocnekorB

.etatortonlliwsedalB

?hctulcdetsujda-simroevitcefeD .hctulcecalperrotsujdA

murdmorfgnikaellairetaM

.sdne

)tlit(egrahcsidottluciffidmurD

?slaes

?deggolcretlifria

?stekcarb

tfahselddapevitcefedronroW

,metsysrenaelc-rianinoitcnuflaM

troppusmurdnrowroevitcefeD

.thgitootdetsujdasedalB .murdfosllawedishcuottsomlayehtlitnusedalbtsujdA

.slaesecalperrotsujdA

.retlifriaecalperronaelC

.ecalperrotekcarbotesaergylppA

.gniredronehw751369N/PesU.niprotcennocecalpeR

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 21

Page 22

WM-120P/S— — EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarified in the “Remarks” Column.

QTY. Column

Numbers Used — Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other

parts that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

same unique symbol will be included when this item is

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break — Used to list an effective serial

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use — Indicates that the part

is used only with the specific model number or model

number variant listed. It can also be used to show a

part is NOT used on a specific model or model number

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

available items. Examples include battery cables, shims,

and certain washers and nuts.

“Not Sold Separately” — Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

for sale through Multiquip.

PAGE 22 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 23

WM-120P/S— SUGGESTED SPARE PARTS

WM-120PS 1 TO 3 UNITS

Qty. P/N Description

6 ............ 491010 ............ RUBBER LATCH ASSY.

1 ............ EM200293 ...... PADDLE ARM TOW SIDE

1 ............ EM200294 ...... PADDLE ARM CENTER TOW SIDE

1 ............ EM200295 ...... PADDLE ARM CENTER ENGINE SIDE

1 ............ EM200296 ...... PADDLE ARM ENGINE SIDE

3 ............ EM200863 ...... RUBBER BLADE KIT (STEEL DRUM)

3 ............ EM204625 ...... RUBBER BLADE KIT (PLASTIC DRUM)

2 ............ EM200297 ...... U-BOLT

2 ............ EM200268 ...... U-BOLT

2 ............ 3530 ................ PADDLE SHAFT, SEAL KIT

2 ............ EM902153 ...... BEARING, PADDLE SHAFT

3 ............ EM963157 ...... CONNECTOR BOLT

1 ............ EM934041 ...... CLUTCH, DRIVEN MEMBER

NOTE

Part numbers on this Suggested

Spare Parts List may supercede/

replace the P/N shown in the text

pages of this book.

WM-120PS 5 TO 10 UNITS

Qty. P/N Description

10 .......... 491010 ............ RUBBER LATCH ASSY.

2 ............ EM200293 ...... PADDLE ARM TOW SIDE

2 ............ EM200294 ...... PADDLE ARM CENTER TOW SIDE

2 ............ EM200295 ...... PADDLE ARM CENTER ENGINE SIDE

2 ............ EM200296 ...... PADDLE ARM ENGINE SIDE

6 ............ EM200863 ...... RUBBER BLADE KIT (STEEL DRUM)

3 ............ EM204625 ...... RUBBER BLADE KIT (PLASTIC DRUM)

4 ............ EM200297 ...... U-BOLT

4 ............ EM200268 ...... U-BOLT

4 ............ 3530 ................ PADDLE SHAFT, SEAL KIT

4 ............ EM902153 ...... BEARING, PADDLE SHAFT

5 ............ EM963157 ...... CONNECTOR BOLT

2 ............ EM934041 ...... CLUTCH, DRIVEN MEMBER

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 23

Page 24

ENGINE SIDE PADDLE ASSY.

WM-120P/S — ENGINE SIDE PADDLE ASSY.

USED IN POLYETHYLENE AND STEEL DRUMS

PAGE 24 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 25

WM-120P/S — ENGINE SIDE PADDLE ASSY.

ENGINE SIDE PADDLE ASSY.

NO PART NO PART NAME QTY. REMARKS

3 EM200296 PADDLE ARM ENGINE SIDE 1

4 EM200295 PADDLE ARM CENTER ENGINE SIDE 1

5 0300B FLAT WASHER 5/16 28

6 0161D HEX NUT 5/16 14

7

# EM203433 END BACK-UP BLADE 2

*

8 0161C LOCK WASHER 5/16 14

9 1207 HHCS 5/16-18 1 3/4" 14

11 EM200292 PADDLE ARM INSERT CASTING 8

12 EM200297 END PADDLE U-BOLT 2

13 EM200268 CENTER PADDLE J-BOLT 2

14

# EM203432 CENTER BACK-UP BLADE 4

*

15

# EM507519 TOP PLASTIC BLADE .......................................... 4 ...... POLYETHYLENE DRUM ONLY

16

# EM507518 END PLASTIC BLADE .......................................... 2 ...... POLYETHYLENE DRUM ONLY

17 5054A LOCk WASHER 1/2" 8

18 968011 HEX NUT 1/2-13 8

19

20

EM200212 TOP RUBBER BLADE .......................................... 4 ...... STEEL DRUM ONLY

*

EM200213 END RUBBER BLADE .......................................... 2 ...... STEEL DRUM ONLY

*

EM200863 BLADE KIT(STEEL DRUM ONLY) ........................ 1 ...... INCLUDES ITEMS W/

EM204625 BLADE KIT, (POLY DRUM ONLY) ......................... 1 ...... INCLUDES ITEMS W/

AND MTG. HDW.

*

# AND MTG. HDW.

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 25

Page 26

TOW SIDE PADDLE ASSY.

WM-120P/S — TOW SIDE PADDLE ASSY.

USED IN POLYETHYLENE AND STEEL DRUMS

PAGE 26 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 27

WM-120P/S — TOW SIDE PADDLE ASSY.

TOW SIDE PADDLE ASSY.

NO PART NO PART NAME QTY. REMARKS

1 EM200293 PADDLE ARM TOW SIDE..................................... 1 ...... INCLUDES S/N 72395319

2 EM200294 PADDLE ARM CENTER TOW SIDE 1

5 0300B FLAT WASHER 5/16 28

6 0161D HEX NUT 5/16 14

7

# EM203433 END BACK-UP BLADE 2

*

8 0161C LOCK WASHER 5/16 14

9 1207 HHCS 5/16-18 1 3/4" 14

11 EM200292 PADDLE ARM INSERT CASTING 8

12 EM200297 END PADDLE U-BOLT 2

13 EM200268 CENTER PADDLE U-BOLT 2

14

# EM203432 CENTER BACK-UP BLADE 4

*

15

# EM507519 TOP PLASTIC BLADE .......................................... 4 ...... POLYETHYLENE DRUM ONLY

16

# EM507518 END PLASTIC BLADE .......................................... 2 ...... POLYETHYLENE DRUM ONLY

17 5054A LOCL WASHER 1/2" 8

18 968011 HEX NUT 1/2-13 8

19

20

EM200212 TOP RUBBER BLADE .......................................... 4 ...... STEEL DRUM ONLY

*

EM200213 END RUBBER BLADE .......................................... 2 ...... STEEL DRUM ONLY

*

EM200863 BLADE KIT(STEEL DRUN ONLY) ........................ 1 ...... INCLUDES ITEMS W/

EM204625 BLADE KIT, (POLY DRUM ONLY) ......................... 1 ...... INCLUDES ITEMS W/

EM203028 HDW. KIT, (FOR RUBBER OR POLY BLADES) ... 1 ...... INCLUDED IN BLADE KITS

AND MTG. HDW.

*

# AND MTG. HDW.

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 27

Page 28

TOW SIDE PADDLE ASSY.

WM-120P/S — PADDLE SHAFT ASSY.

PAGE 28 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 29

WM-120P/S — PADDLE SHAFT ASSY.

TOW SIDE PADDLE ASSY.

NO PART NO PART NAME QTY. REMARKS

1

*

2 13348 RING, SNAP 1

3 13349 SPACER, SNAP RING 1

4 13353 SHAFT, PADDLE WM120PM ................................. 1 .... POLYETHYLENE DRUM ONLY

4 13344 SHAFT, PADDLE WM120PM ................................. 1 .... STEEL DRUM ONLY

5 EM902153 BEARING, BALL 2

6

*

7 3024 SPRING PADDLE SHAFT 2

8 3047 SPACER, 2 X 1-1/8 X 1/4L 1

9 3061 SPACER 2-7/8 X 2-1/8 X .105 14

10

11 5028B PIN, COTTER 1/8 X 2 ............................................. 1 .... POLYETHYLENE DRUM ONLY

12 8164 NUT, SLOTTED HEX JAM ...................................... 1 .... POLYETHYLENE DRUM ONLY

13002 SEAL BEARING 1-1/2 ID 2

3019 SEAL PADDLE SHAFT, 1-1/8 ID 4

3494 SEAL, URETHANE 1-1/4 ID 2

*

3530 PADDLE SHAFT SEAL KIT .................................... 1 .... INCLUDES ITEMS W/

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 29

Page 30

POLYETHYLENE DRUM ASSY.

WM-120P/S — POLYETHYLENE DRUM ASSY.

PAGE 30 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 31

WM-120P/S — POLYETHYLENE DRUM ASSY.

POLYETHYLENE DRUM ASSY.

NO PART NO PART NAME QTY. REMARKS

1 10133 NUT, NYLOC 3/8-16 16

2 10136 WASHER, FLAT, 3/8 SAE 2

3 10176 NUT, NYLOC 1/2-13 7

4 1023 SCREW, HHC 3/8-16 X 1 1/4 4

5 1162 A CAP, GREASE ZERK 4

6 1284 SCREW, HHC 3/8-16 X 1 1/2 2

7 13211 WASHER, FLAT, 1/2 USS 1

8 13270 GRATE, 120 STATIONARY W/A 1

9 13357 TUB FRAME W/A, 120PM 1

10 13361 BEARING BRACKET 2

11 13362 BAR, GRATE OPENING 1

12 1665 SCREW, HHC 3/8-16 X 2 2

13 511583 DRUM LATCH 1

14 EM203335 HINGE, GRILL CLOSING BAR 1

15 2621 ZERK, GREASE STR 1/4-28 4

16 3006 SUPPORT DISC-BRG. 2

17 3042 DRUM, PLASTIC 12 CU. FT. MIXER 1

18 3101 GRIP, 1” 1

19 3249 CAP, DUST 1

20 3291 BOSS, BEARING 2

21 3309 GRATE, MOVEABLE W/A 1

22 3480 SCREW, FHC 3/8-16 X 2. PLATED 8

23 3512 HANDLE, DUMP W/A 1

24 5218 SCREW, HHC 1/2-13 X 1 1/2 7

25 9503 NUT, NYLOC 5/8-11 1

26 010022 KEY, 3/8 SQ X 1 3/4 1

27 200255 COUPLER, PADDLE SHAFT 1

28 963157 SCREW, HHC 5/8-11 X 4-1/2, GR2 1

29 9503 NUT, NYLOC 5/8-11 2

30 961019 SCREW, SQHS, 3/8-16 X 1-1/4, CUP 2

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 31

Page 32

STEEL DRUM ASSY.

WM-120P/S — STEEL DRUM ASSY.

PAGE 32 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 33

WM-120P/S — STEEL DRUM ASSY.

STEEL DRUM ASSY.

NO PART NO PART NAME QTY. REMARKS

1 EM010022 KEY, 3/8 SQ X 1 3/4 1

2 10176 NUT, NYLOC 1/2-13 17

3 13211 WASHER, FLAT, 1/2 USS 4

4 13277 BOSS, BEARING 2

5 13345 BEARING BRACKET 2

6 13346 TUB, STEEL 1

7 EM200079 SHIM, BEARING BRKT. .135 2

8 EM200080 SHIM, BEARING BRKT. .187 2

9 EM200255 COUPLER, PADDLE SHAFT 1

10 EM201537 DUMP LEVER 1

11 EM201731 DRUM LATCH 1

12 EM203335 HINGE, GRILL CLOSING BAR 1

13 EM203344 BAR, GRILL OPENING 1

14 EM203449 GRILL, DRUM 1

15 2621 ZERK, GREASE STR 1/4-28 4

16 3214 SCREW, HHC 1/2-13 X 1 1/4 3

17 3249 CAP, DUST 1

18 5218 SCREW, HHC 1/2-13 X 1 1/2 12

19 7170 PIN, HITCH CLIP, 5/32 X 3-5/16 1

20 EM924015 PIN, COTTER, 3/16 X 1 2

21 9503 NUT, NYLOC 5/8-11 2

22 EM961019 SCREW, SQHS, 3/8-16 X 1-1/4, CUP 2

23 EM963157 SCREW, HHC 5/8-11 X 4-1/2, GR2 1

24 1162A CAP, GREASE ZERK 1

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 33

Page 34

CAB ASSY.

WM-120P/S — CAB ASSY.

PAGE 34 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 35

WM-120P/S — CAB ASSY.

CAB ASSY.

NO PART NO PART NAME QTY. REMARKS

1 EM202957 CAB DOOR, COMPLETE ASSY. 1

2 1284 HHCS 3/8-16 X 1.1/2” 4

3 4001 FLAT WASHER 3/8” 8

4 202771 CAB FRONT SUPPORT ANGLE 1

5 10133 LOCK NUT 3/8-16 4

6 13333 LATCH PIN ASSY. 2

7 491010 RUBBER LATCH ASSY. 2

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 35

Page 36

FRAME, WHEEL, TIRE AND HUB ASSY.

WM-120P/S — FRAME, WHEEL, TIRE AND HUB ASSY.

PAGE 36 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 37

WM-120P/S — FRAME, WHEEL, TIRE AND HUB ASSY.

FRAME, WHEEL, TIRE AND HUB ASSY.

NO PART NO PART NAME QTY. REMARKS

1 10176 LOCK NUT 1/2-13 8

2 EM204086 TRANSMISSION SUPPORT BAR 2

3 5218 HHCS 1/2-13 X 1.1/2” 4

4 2549 HHCS 1/2-13 X 3” 4

5 0447 FLAT WASHER 1/2” 14

6 EM202765 FRAME W/A 1

7 EBC-1 BALL HITCH TOW BAR 1 CONTACT UNIT SALES DEPT.

8 ELC-1 PINTLE EYE TOW BAR 1 CONTACT UNIT SALES DEPT.

9 EDC-1 PIN HOLE TOW BAR 1 CONTACT UNIT SALES DEPT.

10 5070B LOCK NUT 3/4-10 1

11 EM963580 HHCS 3/4-10 X 4.1/2” 1

12 8244 HEX NUT 1/2-20 4

13 5054A LOCK WASHER 1/2” 4

14 EM201225 AXLE SPRING 2

15 EM966204 SQUARE AXLE U-BOLT 1.1/2” 2

16 EM202983 AXLE 1

17 13363 SAFETY CHAIN ASSY. 2

18# EM941278 GREASE CAP 2

19# EM968302 AXLE NUT 2

20# EM923161 AXLE WASHER 2

21# EM903113 OUTER BEARING CONE 2

22# EM903012 OUTER BEARING CUP 2

24# EM941257 WHEEL 13 X 4.1/2-5 ON 4.1/2” BC 2

25# EM941279 SERRATED WHEEL STUD 10

26# EM941277 HUB INC. 2

27# EM903169 INNER BEARING CUP 2

28# EM903168 INNER BEARING CONE 2

29# EM914324 SEAL 2

31 EM941280 WHEEL NUT 10

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 37

Page 38

NAME PLATE AND DECALS

WM-120P/S — NAME PLATE AND DECALS

PAGE 38 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 39

WM-120P/S — NAME PLATE AND DECALS

NAME PLATE AND DECALS

NO PART NO PART NAME QTY. REMARKS

1

*

2

*

3 PLATE, SERIAL NO. 1 CONTACT MQ SERVICE DEPT. W/MODEL & S/N

SEE DECAL ILLUSTRATIONS ON PAGE 7.

EM948423 DECAL : CAUTION 1

924801 DECAL : SAFETY INSTRUCTIONS 1

DCLWM120PS KIT, DECAL 1 INCLUDES ITEMS W/

*

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 39

Page 40

WISCONSIN ENGINE ASSY.

WM-120P/S — WISCONSIN ENGINE ASSY.

PAGE 40 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 41

WM-120P/S — WISCONSIN ENGINE ASSY.

WISCONSIN ENGINE ASSY.

NO PART NO PART NAME QTY. REMARKS

1 EM937029 9.2HP WISCONSIN ENGINE 1

2 EM940734 KILL SWITCH 1

3 EM203298 ENGINE KILL GROUND WIRE 1

4 EM203299 ENGINEKILL WIRE 1

5 0169 HHCS 3/8-16 X 3” 4

6 10136 FLAT WASHER 3/8” 8

7 EM100235 ENGINE SHIM .030

EM100236 ENGINE SHIM .018

EM100237 ENGINE SHIM .010

8 EM203007 ENGINE PAD .187

EM203016 ENGINE PAD .135

EM203017 ENGINE PAD .060

9 10133 LOCK NUT 3/8-16 4

10 EM912104 1” PIPE NIPPLE X 10” LONG 1

11 5081 1’ 90 DEG. ELBOW 1

12 EM912097 1’ PIPE NIPPLE X 5” LONG 1

13 EM010009 SQ KEY 1/4 X 1/4 X 1” 1

14 EM961045 SHSS 5/16-18 X 1/2” NYLOC 1

15# EM925013 LEVER PIN 3

16# EM925018 SHORT LINK PIN 3

17# EM925016 LONG LINK PIN 3

18# EM959012 LEVER 6

19# EM934054 ROLLER 3

20# 5117 COTTER PIN 9

21# EM934053 CONNECTING LINK 6

22 9503 SLOTTED HHCS 1/4-20 X 1/2” 1

23# EM934040 ADJUSTING LOCK 1

24# EM934039 CLUTCH HOUSING 1

25# EM918009 SPRING 3

26# EM934041 SPLINED CENTER W/FACING 1

27# EM934042 PRESSURE PLATE ASM 1

28# EM934043 RELEASE SLEEVE 1

29# EM934045 ADJUSTING RING 1

30# EM963289 BOLT 2

31# EM969009 LOCK NUT 2

32

# EM934044 RELEASE BEARING ASM 1

33 EM801570 PILOT BUSHING 1

34 EM934022 CLUTCH ASM ............................................................. 1 .......... INCLUDES ITEMSW/#

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 41

Page 42

HONDA ENGINE ASSY.

WM-120P/S — HONDA ENGINE ASSY.

PAGE 42 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 43

WM-120P/S — HONDA ENGINE ASSY.

HONDA ENGINE ASSY.

NO PART NO PART NAME QTY. REMARKS

1 EM203039 11HP HONDA ENGINE 1

2 EM940734 KILL SWITCH 1

3 EM203298 ENGINE KILL GROUND WIRE 1

4 EM203035 ENGINE KILL WIRE 1

5 9154 HHCS 3/8-16 X 1.3/4” 4

6 10136 FLAT WASHER 3/8” 8

7 EM100235 ENGINE SHIM .030 AR

EM100236 ENGINE SHIM .018 AR

EM100237 ENGINE SHIM .010 AR

8 EM203007 ENGINE PAD .187 AR

EM203016 ENGINE PAD .135 AR

EM203017 ENGINE PAD .060 AR

9 10133 LOCK NUT 3/8-16 4

10 EM204550 MOTOR MOUNT 2

11 EM203038 ADAPTER KIT ............................................................. 1 .......... INCLUDES ITEMS W/

12

13 EM927066 SQ KEY 1

14 EM961045 SHSS 5/16-18 X 1/2”NYLOC 1

15# EM925013 LEVER PIN 3

16# EM925018 SHORT LINK PIN 3

17# EM925016 LONG LINK PIN 3

18# EM959012 LEVER 6

19# EM934054 ROLLER 3

20# 5117 COTTER PIN 9

21# EM934053 CONNECTING LINK 6

22 9503 SLOTTED HHCS 1/4-20 X 1/2” 1

23# EM934040 ADJUSTING LOCK 1

24# EM934039 CLUTCH HOUSING 1

25# EM918009 SPRING 3

26# EM934041 SPLINED CENTER W/FACING 1

27# EM934042 PRESSURE PLATE ASM 1

28# EM934043 RELEASE SLEEVE 1

29# EM934045 ADJUSTING RING 1

30# EM963289 BOLT 2

31# EM969009 LOCK NUT 2

32# EM934044 RELEASE BEARING ASM 1

33 1475 WIRE SPLICE 1

34 EM203149 EXHAUST DEFLECTOR 1

35

36 EM801570 PILOT BUSHING 1

37 EM934022 CLUTCH ASM ............................................................. 1 .......... INCLUDES ITEMS/W#

38

39

11090 STUD, 3/8 SHC 4

*

EM203040 SLEEVE 1

*

13377 OIL SEAL 4

*

13379 COPPER WASHER 4

*

*

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 43

Page 44

ELECTRIC MOTOR ASSY.

WM-120P/S — ELECTRIC MOTOR ASSY.

PAGE 44 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 45

WM-120P/S — ELECTRIC MOTOR ASSY.

ELECTRIC MOTOR ASSY.

NO PART NO PART NAME QTY. REMARKS

1 EM939228 5 HP 1 PHASE ELECT MOTOR 1

1 EM239229 5 HP 3 PHASE ELECT MOTOR 1 “

2 1023 HHCS 3/8-16 X 1.1/4” 8

3 10136 FLAT WASHER 3/8” 16

4 EM204549 MOTOR MOUNT 2

5 10133 LOCK NUT 3/8-16 8

6 EM010009 SQ KEY 1

7 EM801570 BUSHING 1

8 EM934042 PRESSURE PLATE ASM 1

9# EM934043 RELEASE SLEEVE 1

10# EM934045 ADJUSTING RING 1

11# EM963289 BOLT 2

12# EM969009 LOCK NUT 2

13# EM934044 RELEASE BEARING ASM 1

14# EM961045 SHSS 5/16-18 X 1/2” NYLOC 1

15# EM925013 LEVER PIN 3

16# EM925018 SHORT LINK PIN 3

17# EM925016 LONG LINK PIN 3

18# EM959012 LEVER 6

19# EM934054 ROLLER 3

20# 5117 COTTER PIN 9

21# EM934053 CONNECTING LINK 6

22 9503 SLOTTED HHCS 1/4-20 X 1/2” 1

23# EM934040 ADJUSTING LOCK 1

24# EM934039 CLUTCH HOUSING 1

25# EM918009 SPRING 3

26# EM934041 SPLINED CENTER W/FACING 1

27 EM204526 MOUNT BRKT 1

28 10019 LOCK NUT 10-32 3

29 2203 FLAT WASHER #10 6

30 EM201794 PIG TAIL 1

31 0174 90 DEG ELBOW 1

32 EM98187 MOTOR STARTER 1 PHASE 1

32 EM98191 MOTOR STARTER 3 PHASE 1

33 EM940198 HEATER 1 PHASE 1

33 EM940209 HEATER 3 PHASE 1

34 8133 RHMS 10-32 X 3/4” 3

35 EM940184 REDUCER BUSHING 1

36 EM012295

37 EM100235 ENGINE SHIM .030

EM100236 ENGINE SHIM .018

EM100237 ENGINE SHIM .010

38 EM203007 ENGINE PAD .187

EM203016 ENGINE PAD .135

EM203017 ENGINE PAD .060

39 EM934022 CLUTCH ASM ............................................................. 1 .......... INCLUDES ITEMS/W#

CONDUIT 1

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 45

Page 46

TRANSMISSION ASSY.

WM-120P/S — TRANSMISSION ASSY.

PAGE 46 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 47

WM-120P/S — TRANSMISSION ASSY.

TRANSMISSION ASSY.

NO PART NO PART NAME QTY. REMARKS1

1# 2200 HHCS 3/8-24 X 2" 1

2# EM600029 SHIFTER SHAFT 1

3# EM914005 SEAL 1

4# EM600028 CLUTCH YOKE 1

5# 0181B LOCK WASHER 1/4” 2

6# 0730 HHCS 1/4-20 X 1” 2

7# EM926029 SNAP RING 2

8# EM600023 BEARING RETAINER 1

9# EM600022 BEARING RETAINER GASKET 1

10# 914209 SEAL 1

11# EM902091 BALL BEARING 4

12# EM600016 INPUT PINION SHAFT 1

13# EM911329 SQ HEAD MAG. PINE PLUG 3/8” 2

14# EM600020 INTERNAL GEAR 1

15# EM010062 SQ KEY 3/8 X 1.3/8” 1

16# EM600131 OUTPUT DRIVE PINION 1

17# 10136 FLAT WASHER 3/8” 1

18# EM902161 BALL BEARING 1

19 EM963157 HHCS 5/8-11 X 4.1/2” GD2 1

20 EM961019 SQHSS3/8-16 X 1.1/4” CUP 2

21 EM200255 PADDLE SHAFT COUPLER 1

22 EM010022 SQ KEY 3/8 X 3/8 X 1.3/4’ 1

23 9503 LOCK NUT 5/8-11 1

24# 600015 OUTPUT SHAFT 1

25# 914207 OIL SEAL 1

26# 600014 TRANSMISSION COVER 1

27# EM600133 OUTPUT SHAFT GEAR 1

28# EM926036 SNAP RING 1

29#

30# EM600012 MAIN TRANSMISSION HOUSING 1

31# EM911356 BREATHER VENT PIPE PLUG 1/2” 2

32# 1729 ROLL PIN 1

33# EM600024 LOCK PLATE 1

34# EM927048 WOODRUFF KEY #A 1

35# 10133 LOCK NUT 3/8-16 1

36# EM600021 TRANSMISSION COVER GASKET 1

37 EM600018 SHIFTER LEVER 1

38# 0161C LOCK WASHER 3/8” 17

39# 0202 HHCS 5/8-16 X 1” 17

40# 4196 HHCS 3/8-16 X 3/4” 6

41# 1875 INTER. SHKP WASHER 3/8” 6

42# EM931233 SHIFTER COVER 1

43# EM600026 SHIFTER COVER GASKET 1

44# EM300999 STUD 7/16-14 X 2.1/16” 4

45# 2955 LOCK WASHER 7/16” 4

46# EM968010 HEX NUT 7/16-14 4

47# EM925109 DOWEL PIN 3

48 EM801965 GASKET 1

49 EM600000 COMP.TRANS. ASM. ................................................ 1 ............. INCLUDES ITEMS W/#

EM911064 SQ HEAD PINE PLUG 1/2 NPT 2

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 47

Page 48

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and

the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and

credit will be allowed, subject to the following

provisions:

A Returned Material Authorization 1.

must be approved by Multiquip prior to

shipment.

To obtain a Return Material Authorization, 2.

a list must be provided to Multiquip

Parts Sales that defines item numbers,

quantities, and descriptions of the items

to be returned.

The parts numbers and descriptions a.

must match the current parts price

list.

The list must be typed or computer b.

generated.

The list must state the reason(s) c.

for the return.

The list must reference the sales d.

order(s) or invoice(s) under

which the items were originally

purchased.

The list must include the name e.

and phone number of the person

requesting the RMA.

A copy of the Return Material Authorization 3.

must accompany the return shipment.

Freight is at the sender’s expense. All 4.

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

Parts must be in new and resalable 5.

condition, in the original Multiquip

package (if any), and with Multiquip part

numbers clearly marked.

The following items are not returnable:6.

Obsolete parts. (If an item is in the a.

price book and shows as being

replaced by another item, it is

obsolete.)

Any parts with a limited shelf life b.

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

Any line item with an extended c.

dealer net price of less than

$5.00.

Special order items.d.

Electrical components.e.

Paint, chemicals, and lubricants.f.

Decals and paper products.g.

Items purchased in kits.h.

The sender will be notified of any material 7.

received that is not acceptable.

Such material will be held for five 8.

working days from notification, pending

instructions. If a reply is not received

within five days, the material will be

returned to the sender at his expense.

Credit on returned parts will be issued 9.

at dealer net price at time of the original

purchase, less a 15% restocking

charge.

In cases where an item is accepted, for 10.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

Credit issued will be applied to future 11.

purchases only.

PRICING AND REBATES

Prices are subject to change without prior

notice. Price changes are effective on a

specific date and all orders received on or

after that date will be billed at the revised price.

Rebates for price declines and added charges

for price increases will not be made for stock

on hand at the time of any price change.

Multiquip reserves the right to quote and

sell direct to Government agencies, and to

Original Equipment Manufacturer accounts

who use our products as integral parts of their

own products.

SPECIAL EXPEDITING SERVICE

A $35.00 surcharge will be added to the

invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of

the item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profit or good will or for any

other special, consequential or incidental

damages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are

made in connection with the sale of parts or

trade accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes nor

authorizes any person to assume for it

any other obligation or liability whatever in

connection with the sale of its products. Apart

from such written statement of warranty,

there are no warranties, express, implied or

statutory, which extend beyond the description

of the products on the face hereof.

Effective: February 22, 2006

PAGE 48 — WM120PM/SM— OPERATION AND PARTS MANUAL — REV. #7 (09/15/11)

Page 49

NOTE PAGE

WM120PM/SM — OPERATION AND PARTS MANUAL — REV. #7 (09/15/11) — PAGE 49

Page 50

OPERATION AND PARTS MANUAL

©

r

HERE’S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

UNITED STATES

Multiquip Corporate Office MQ Parts Department

18910 Wilmington Ave.

Carson, CA 90746

Contact: mq@multiquip.com

Mayco Parts Warranty Department

Tel. (800) 421-1244

Fax (800) 537-3927

800-427-1244

310-537-3700

Fax: 800-672-7877

Fax: 310-637-3284

800-306-2926

310-537-3700

Service Department Technical Assistance

800-421-1244

310-537-3700

Fax: 800-672-7877

Fax: 310-637-3284

Fax: 310-537-4259 800-478-1244 Fax: 310-631-5032

^^^^^*^^^^^^^^^^^^^^^^^^^^^^^^^*^6668

800-421-1244, Ext. 279

310-537-3700, Ext. 279

Fax: 310-537-1173

MEXICO UNITED KINGDOM

MQ Cipsa Multiquip (UK) Limited Head Office

Carr. Fed. Mexico-Puebla KM 126.5

Momoxpan, Cholula, Puebla 72760 Mexico

Contact: pmastretta@cipsa.com.mx

Tel: (52) 222-225-9900

Fax: (52) 222-285-0420

Unit 2, Northpoint Industrial Estate,

Global Lane,

Dukinfield, Cheshire SK16 4UJ

Contact: sales@multiquip.co.uk

Tel: 0161 339 2223

Fax: 0161 339 3226

CANADA

Multiquip

4110 Industriel Boul.

Laval, Quebec, Canada H7L 6V3

Contact: jmartin@multiquip.com

COPYRIGHT 2010, MULTIQUIP INC.

Multiquip Inc, the MQ logo and the Whiteman logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All othe

trademarks are the property of their respective owners and used with permission.

This manual

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change specifications, design or the information published

in this publication at any time without notice and without incurring any obligations.

MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remain with the unit if resold.

Tel: (450) 625-2244

Tel: (877) 963-4411

Fax: (450) 625-8664

Your Local Dealer is:

Loading...

Loading...