Page 1

PARTS MANUAL

SERIES

MODEL HTX-44K4

MODEL HTX-44K5

MODEL HTX-44Y4

MODEL HTX-44Y5

RIDE-ON POWER TROWEL

(KUBOTA/YANMAR DIESEL ENGINE)

Revision #18 (08/28/12)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N 21658

Page 2

HTX-44K/Y RIDE-ON TROWEL — PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 3

HTX-44K/Y RIDE-ON TROWEL — SILICOSIS/RESPIRATORY HAZARDS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 3

Page 4

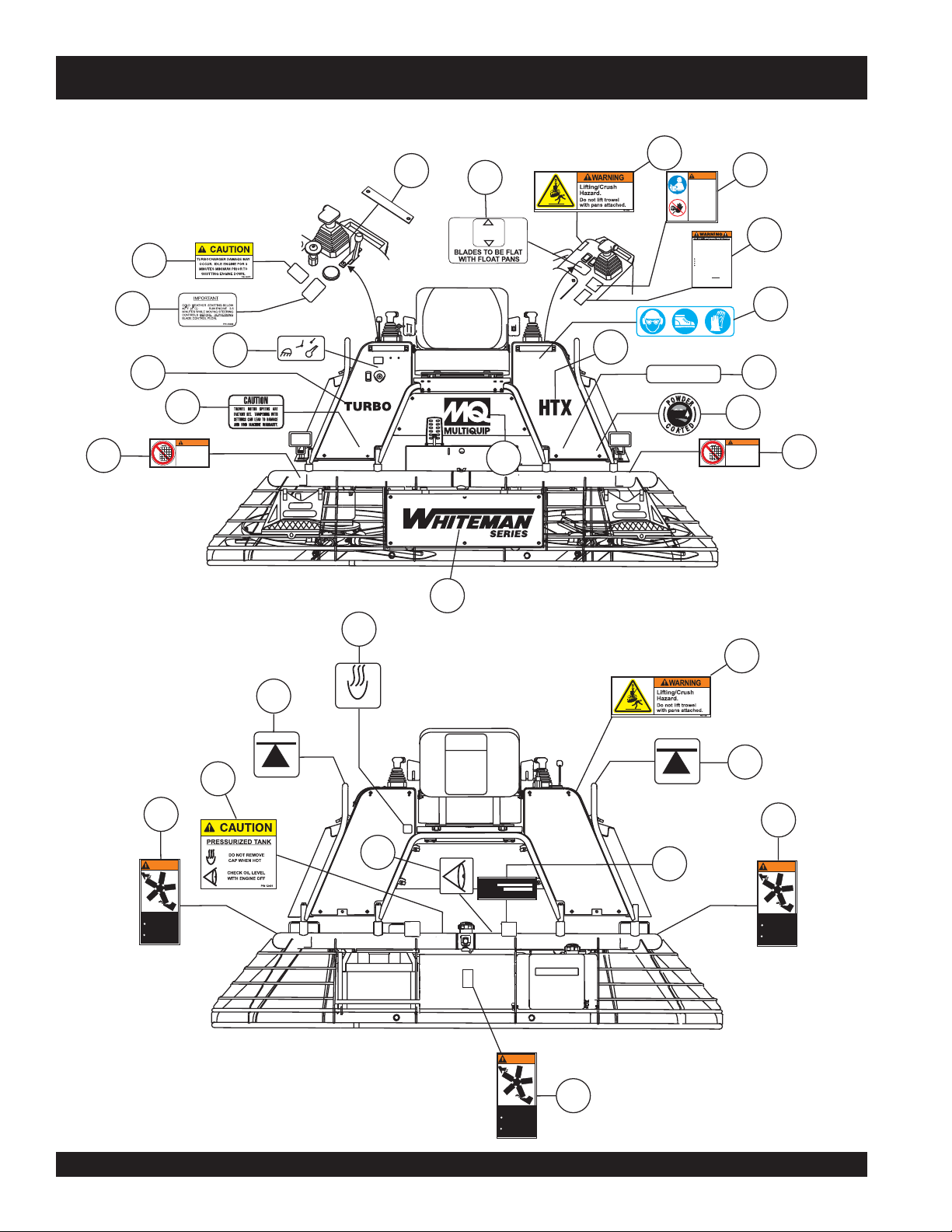

HTX-44K/Y RIDE-ON TROWEL — TABLE OF CONTENTS

MQ WHITEMAN HTX-44K/Y

RIDE-ON POWER TROWEL

(KUBOTA/YANMAR ENGINE)

Table of Contents............................................................. 4

Parts Ordering Procedures ............................................... 5

Explanation Of Code In Remarks Column ........................6

Suggested Spare Parts ....................................................7

Nameplate and Decals ..................................................8-9

Frame Assembly ....................................................... 10-11

Platform Assembly .................................................... 12-13

Cooler Valve Bypass Assembly ................................ 14-15

Hydraulic Assembly .................................................. 16-19

Burp Tank/Suction Filter Assembly............................ 20-21

Pump Levers Assembly ............................................ 22-23

Engine Assembly (KUBOTA) ..................................... 24-25

Engine Assembly (YANMAR) .................................... 26-29

Pivot Assembly ......................................................... 30-31

5-Blade Stabilizer Ring Assembly ............................. 32-33

4-Blade Stabilizer Ring Assembly ............................. 34-35

5-Blade Spider Assembly (Tapered LH) ..................... 36-37

5-Blade Spider Assembly (Tapered RH) .................... 38-39

4-Blade Spider Assembly (Tapered LH) ..................... 40-41

4-Blade Spider Assembly (Tapered RH) .................... 42-43

Seat Frame Assembly (KUBOTA) .............................. 44-45

Seat Frame Assembly (YANMAR) ............................. 46-47

Front Panel Assembly (Right-Side) ............................ 48-49

Frame Assembly (Right-Front) ................................... 50-51

Frame Assembly (Right-Rear) ................................... 52-53

Frame Assembly (Left-Front/Rear)............................. 54-55

Right-Hand Valve Assy. KUBOTA S/N 2000885 & BELOW .......... 56-57

Right-Hand Valve Assy. KUBOTA/YANMAR S/N 2000886 & ABOVE ...........58-59

Left-Hand Valve Assembly ........................................ 60-61

Spray Assembly ........................................................62-63

Fuel Tank Assembly (KUBOTA) .................................64-65

Fuel Tank Assembly (YANMAR) ................................ 66-67

Battery Assembly ...................................................... 68-69

Electrical Wiring Diagram................................................70

Hydraulic Diagram ..........................................................71

NOTE

Specification and part number

are subject to change without

notice

.

Terms and Conditions of Sale .........................................72

PAGE 4 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 5

r

Best Deal!

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

Order via Internet

Order parts on-line using Multiquip’s SmartEquip website!

N View Parts Diagrams

N Order Parts

N Print Specification Information

(Dealers Only)

:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact you

District Sales Manager for more information.

January 1

Effective:

st

, 2006

Goto www.multiquip.com and click on

Order Parts

Order via Fax

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

to log in and save!

(Dealers Only)

:

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

When ordering parts, please supply:

R Dealer Account Number

R Dealer Name and Address

R Shipping Address (if different than billing address)

R Return Fax Number

R Applicable Model Number

R Quantity, Part Number and Description of Each Part

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

R Specify Preferred Method of Shipment:

UPS/Fed Ex DHL

N Priority One Truck

N Ground

N Next Day

N Second/Third Day

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

www.multiquip.com

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 5

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

Page 6

EXPLANATION OF CODE IN REMARKS COLUMN

r

”

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

QTY. Column

Numbers Used — Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or othe

parts that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

same unique symbol will be included when this item is

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarified in the “Remarks” Column.

Serial Number Break — Used to list an effective serial

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use — Indicates that the part

is used only with the specific model number or model

number variant listed. It can also be used to show a

part is NOT used on a specific model or model number

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

available items. Examples include battery cables, shims,

and certain washers and nuts.

“Not Sold Separately” — Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

for sale through Multiquip.

PAGE 6 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 7

HTX-44K/Y RIDE-ON TROWEL— SUGGESTED SPARE PARTS

HTX-44K RIDE-ON TROWEL

1 TO 3 UNITS WITH KUBOTA TURBO DIESEL ENGINE

Qty. P/N Description

4 ....... 20673 .................. LATCH, RUBBER HOOD

2 ....... 20674 .................. GRAB HANDLE

1 ....... 11098 .................. CIRCUIT BREAKER

1 ....... 12017 .................. RELAY, KILL

1 ....... 21470 .................. SWITCH, ON-OFF

1 ....... 20165 .................. PALM HANDLE KIT

2 ....... 12548 .................. PUMP SPRAY

10 ..... 21597 .................. BUMPER

5 ....... 21468 .................. KNOB

1 ....... 21341 .................. CABLE, CONTROL THUMB RELEASE 46"

4 ....... 21052 .................. LIGHT

1 ....... 10568 .................. THROTTLE CABLE

2 ....... 2829 .................... ARM TROWEL

6 ....... 11039 .................. BUSHING

3 ....... 2143 .................... SPRING, R.S.

3 ....... 9111 .................... SPRING, L.S.

1 ....... 21211 .................. SPIDER, SERVICE KIT, 5-BLADE

1 ....... 21751 .................. SPIDER, SERVICE KIT, 4-BLADE

2 ....... 20938 .................. THRUST COLLAR KIT

2 ....... 21231 .................. ISOLATOR

1 ....... 21301 .................. PUMP ROD

1 ....... 12056 .................. STEERING CYLINDER

1 ....... 20652 .................. CYLINDER PITCH

2 ....... 21107 .................. SUCTION FILTER

2 ....... 21266 .................. BEARING BLOCK ASSY. RH

2 ....... 21267 .................. BEARING BLOCK ASSY. LH

2 ....... 1627132090 ......... OIL FILTER

2 ....... 7000043081 ......... FUEL FILTER

2 ....... 1735111083 ......... AIR CLEANER ELEMENT (KUBOTA)

1 ....... 406021 ................ GAUGE, ENGINE STATUS

2 ....... 1628297010 ......... FAN BELT

1 ....... 20511 .................. IGNITION SWITCH

2 ....... 12940 .................. IGNITION KEY ONLY

HTX-44Y RIDE-ON TROWEL

1 TO 3 UNITS WITH YANMAR TURBO DIESEL ENGINE

Qty. P/N Description

20 ..... 11534 .................. U-TYPE NUT

2 ....... 20674 .................. GRAB HANDLE

1 ....... 11098 .................. CIRCUIT BREAKER

1 ....... 21870 .................. RELAY, KILL SWITCH

1 ....... 21470 .................. SWITCH, ON-OFF

1 ....... 20165 .................. PALM HANDLE KIT

2 ....... 12548 .................. PUMP SPRAY

10 ..... 21597 .................. BUMPER

5 ....... 21468 .................. KNOB

1 ....... 21341 .................. CABLE, CONTROL THUMB RELEASE 46"

4 ....... 21052 .................. LIGHT

1 ....... 10568 .................. THROTTLE CABLE

2 ....... 2829 .................... ARM TROWEL

6 ....... 1207 .................... SCREW, HHC 5/16-18X1-3/4 TROWEL ARM

6 ....... 11039 .................. BUSHING

6 ....... 2143 .................... SPRING, R.S.

3 ....... 9111 .................... SPRING, L.S.

1 ....... 21212 .................. SPIDER, SERVICE KIT

2 ....... 20939 .................. THRUST COLLAR KIT

2 ....... 21231 .................. ISOLATOR

1 ....... 21301 .................. PUMP ROD

1 ....... 12056 .................. STEERING CYLINDER

1 ....... 20652 .................. CYLINDER PITCH

2 ....... 21107 .................. SUCTION FILTER

2 ....... 21266 .................. BEARING BLOCK ASSY.

2 ....... 129150-35152 ..... OIL FILTER

2 ....... 119802-55800 ..... FUEL FILTER

1 ....... 21741 .................. FUEL PUMP

1 ....... 406021 ................ INDICATOR, ENGINE STATUS

2 ....... P822768 .............. AIR CLEANER CARTRIDGE

2 ....... 119865-42290 ..... FAN BELT

1 ....... 1E01363590 ........ IGNITION SWITCH

2 ....... 12627 .................. IGNITION KEY ONLY

1 ....... 68900479 ............ UPPER RADIATOR HOSE

1 ....... 68900480 ............ LOWER RADIATOR HOSE

NOTE

Part numbers on this Suggested Spare

Parts List may supercede/replace the

P/N's shown in the test pages of this

manual.

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 7

Page 8

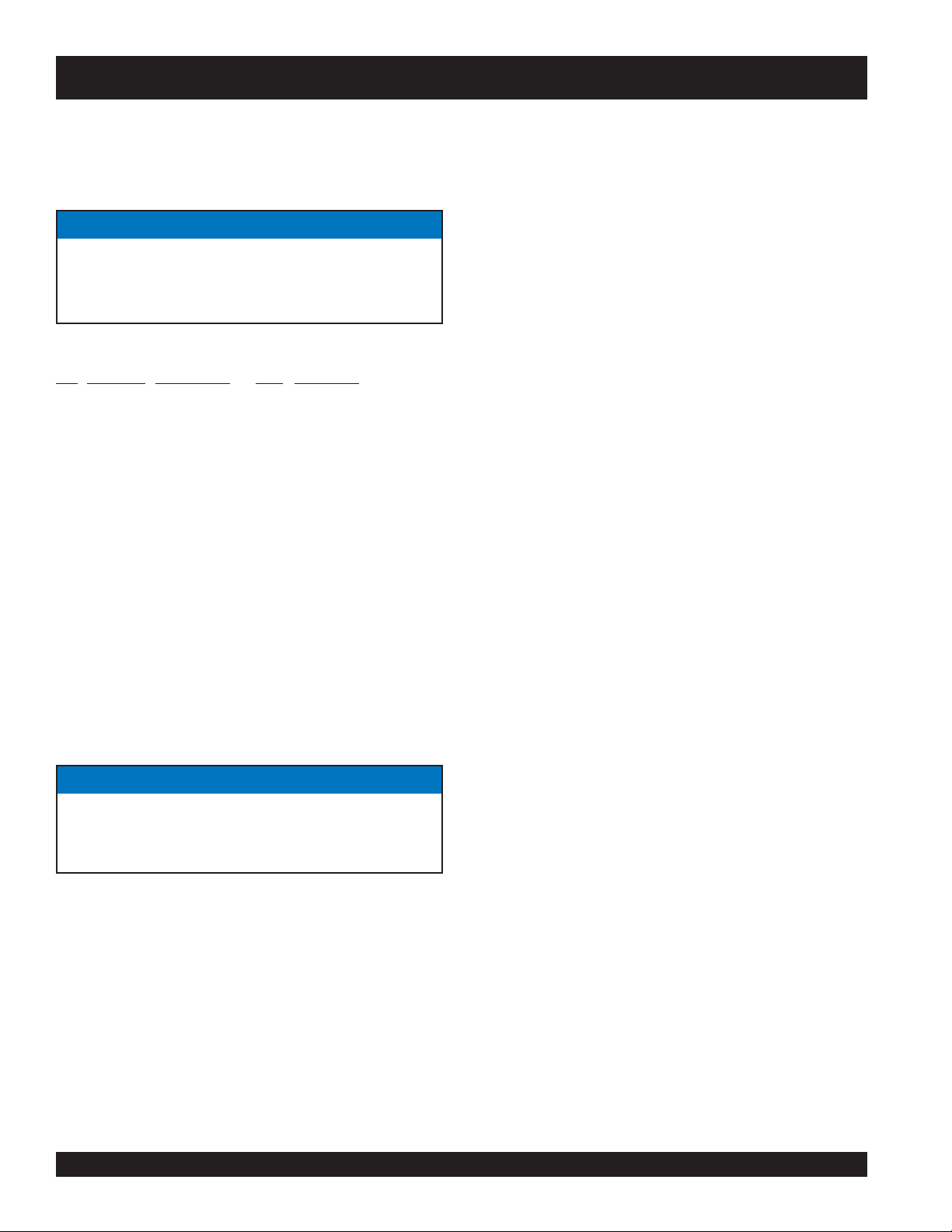

HTX-44K/Y RIDE-ON TROWEL — NAMEPLATE AND DECALS.

P/N35168

P/N35168

P/N35168

NAMEPLATE AND DECALS.

6

9

7

H

E

HIG

N

G

I

N

E

S

P

E

E

D

W

O

L

LOW

LEFT

PITCH

ONLY

8

MORE PITCH

LESS PITCH

TWIN

PITCH

WARNING

Toavoid injury,

youMUST read

andunderstand

operator’smanual

beforeusing this

machine.

Thismachine to

beoperated by

qualified

personnelonly.

Askfor training

asneeded.

Engine exhaust and some of

itsconstituents,andsome dust created

bypower sanding, sawing, grinding,

drillingandotherconstructionactivities

containschemicalsknown to the State

of California to cause cancer, bir th

defectsand otherreproductive harm.

Someexamplesofthese chemicalsare:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfromchemically

treatedlumber.

Yourriskfrom these exposures varies,

dependingonhowoftenyoudo thistype

ofwork.To reduce your exposureto

thesechemicals: workin aALWAYS

well ventilated area, and work with

approvedsafety equipment, such as

dustmasksthat are speciallydesigned

tofilterout microscopic particles.

10

P/N35137

11

1

5

3

2

WARNING

Avoidinjury.

DoNOT operate with

guardsremoved.

Replaceguard before

operatingmachine.

12

4

15

DIESEL FUEL

13

14

WARNING

Avoidinjury.

DoNOT operate with

guardsremoved.

Replaceguard before

P/N21665

16

operatingmachine.

1

P/N21665

17

21

9

20

HOT

20

19

18

WARNING

ROTATINGBLADE

HAZARD

Keephands

andfeet clear

ofguard rings.

Stopengine

beforeservicing.

P/N35168

PAGE 8 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

22

MODEL

SERIAL NO.

WARNING

ROTATINGBLADE

HAZARD

Keephands

andfeet clear

ofguard rings.

Stopengine

beforeservicing.

23

18

P/N35168

18

WARNING

ROTATINGBLADE

HAZARD

Keephands

andfeet clear

ofguard rings.

Stopengine

beforeservicing.

P/N35168

Page 9

HTX-44K/Y RIDE-ON TROWEL — NAMEPLATE AND DECALS.

NAMEPLATE AND DECALS.

NO. PART NO. PART NAME QTY. REMARKS

1 21665 DECAL, WARNING, REPLACE GUARDS ................. 2 ............ SAFETY ITEM

2 20953 DECAL, CAUTION ROTOR SPEED SETTING ......... 1 ............ SAFETY ITEM

3 21590 DECAL, TURBO LOGO 1

4 2814 DECAL, LIGHT, IGNITION SWITCH 1

5 20486 DECAL, HYDRAULIC RIDER COLD START 1

6 20872 DECAL, CAUTION TURBOCHARGER ...................... 1 ............ SAFETY ITEM

7 11712 DECAL, ENGINE SPEED PLATE 1

8 21169 DECAL, BLADE PITCH 1

9 21455 DECAL, WARNING, LIFT CRUSH HAZARD ............. 1 ............ SAFETY ITEM

10 35137 DECAL, WARNING, READ MANUAL ........................ 1 ............ SAFETY ITEM

11 20525 DECAL, WARNING, PROPOSITION 65 .................... 1 ............ SAFETY ITEM

12 36099 DECAL, HELMET, BOOT, GLOVES (ISO BLUE) ...... 1 ............ SAFETY ITEM

13 11811 DECAL, DIESEL FUEL 1

14 13118 DECAL, POWDER COATED 1

15 21580 DECAL, HTX LOGO 1

16 20936 DECAL, MQ LOGO 1

17 21589 DECAL, WHITEMAN LOGO 1

18 35168 DECAL, WARNING, ROTATING BLADE HAZARD .... 3 ............ SAFETY ITEM

19 12401 DECAL, CAUTION, PRESSURIZED TANK ............... 1 ............ SAFETY ITEM

20 DECAL, LIFT POINT ................................................. 2 ............ PART OF DECAL KIT 11246

.................................................................................................. SAFETY ITEM

21 DECAL, HOT SURFACE ........................................... 1 ............ PART OF DECAL KIT 11246

.................................................................................................. SAFETY ITEM

22 DECAL, HYDRAULIC OIL CHECK ............................ 1 ............ PART OF DECAL KIT 11246

.................................................................................................. SAFETY ITEM

23 NAMEPLATE ............................................................. 1 ............ CONTACT MQ PARTS DEPT.

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 9

Page 10

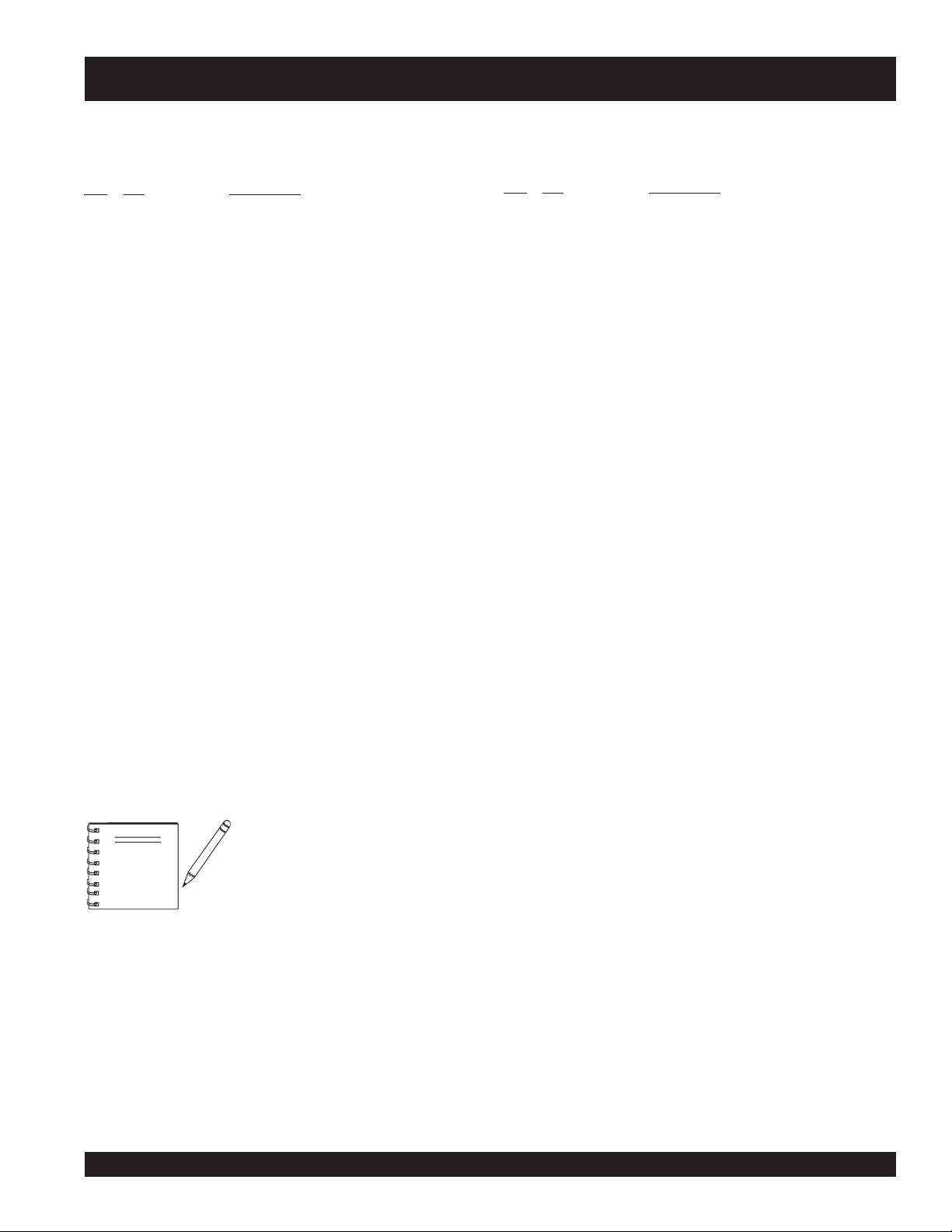

FRAME ASSY.

HTX-44K/Y RIDE-ON TROWEL — FRAME ASSY.

8

4

2

9

1

11

10

3

2

5

6

7

PAGE 10 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 11

HTX-44K/Y RIDE-ON TROWEL — FRAME ASSY.

FRAME ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0948 WASHER, FLAT, 1/4 SAE 4

2 11534 NUT U TYPE 1/4-20 8

3 12287 SCREW, THP 1/4-20 X 3/4 SS 6

4 20610 FRAME W/A ......................................................... 1 ........... KUBOTA

4 21935 FRAME W/A ......................................................... 1 ........... YANMAR

5 20697 PANEL, FRONT .................................................... 1 ........... SAFETY ITEM

6 21374 STEP, W/A ........................................................... 2 ........... SAFETY ITEM

7 21468 KNOB, PLASTIC 1/4-20 X 1 STUD 2

8 21471 GATE, HTHA FRAME REAR ................................ 1 ........... SAFETY ITEM

9 21490 CLAMP, TUBE 18MM STAUFF LN4180PP 2

10 21597 BUMPER, STEM 1" DIA X .5" STEMx.31TK 2

11 26250 SCREW, HHC 1/4-20 x 1-3/4 2

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 11

Page 12

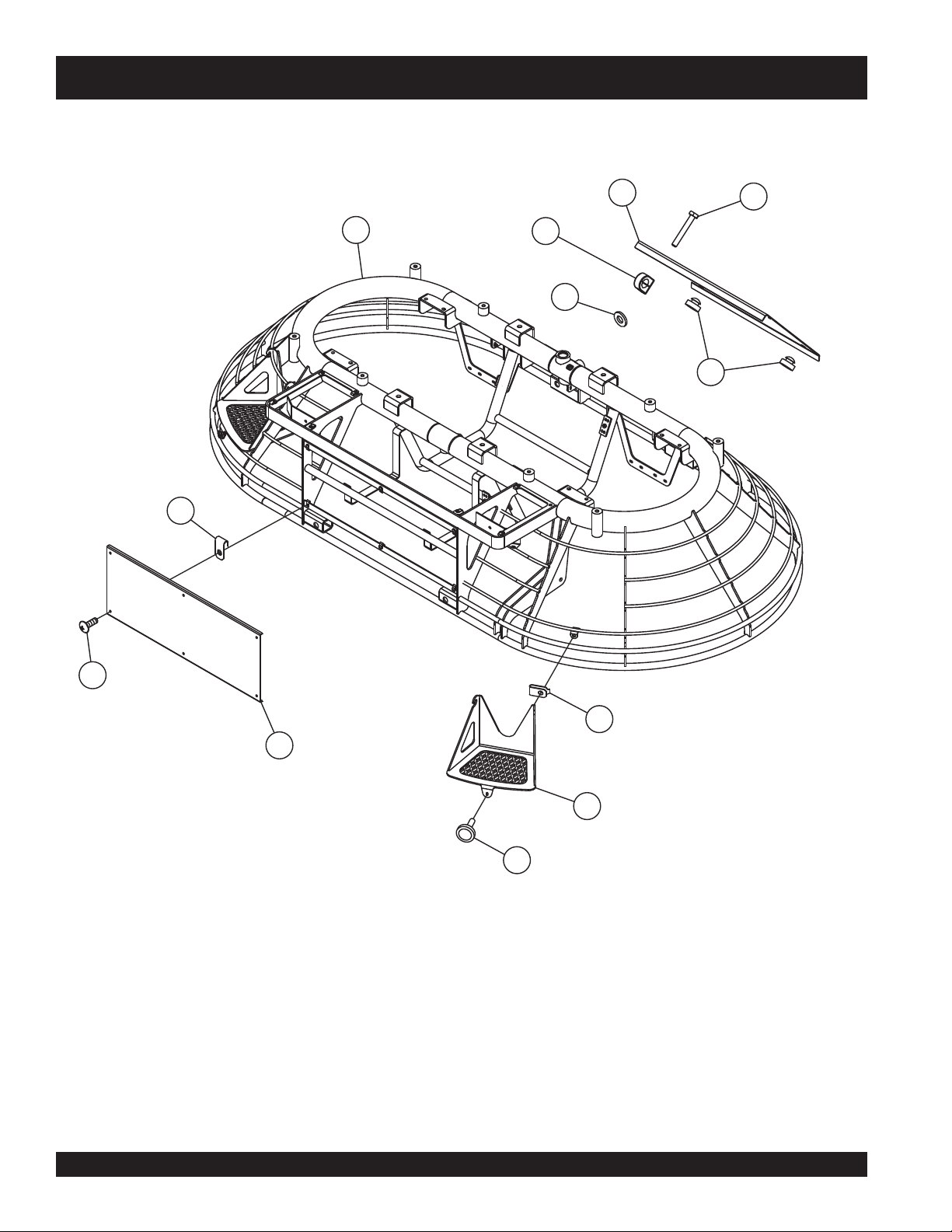

PLATFORM ASSY.

HTX-44K/Y RIDE-ON TROWEL — PLATFORM ASSY.

12

4

15

7

5

13

11

31

1

8

24

7

29

26

6

7

8

8

7

8

3

1

19

25

19

32

23

17

8

5

16

22

8

14

2

33

20

21

28

9

30

27

4

12

18

4

13

10

PAGE 12 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 13

HTX-44K/Y RIDE-ON TROWEL — PLATFORM ASSY.

PLATFORM ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0131 A SCREW, HHC 1/4-20 x 3/4 8

2 0202 SCREW, HHC 5/16-18 X 1 1

3 0205 SCREW, HHC 3/8-16 x 1 2

4 0300 B WASHER, FLAT 5/16 SAE 3

5 0424 SCREW, HHC 1/4-20 x 1-1/4 2

6 0730 SCREW, HHC 1/4-20 x 1 1

7 0948 WASHER, FLAT 1/4 7

8 10024 NUT, NYLOC 1/4-20 11

9 10133 NUT, NYLOC 3/8-16 2

10 11534 NUT U-TYPE 1/4-20 8

11 11643 ROD END, 1/4-28 MALE RH 1

12 1207 SCREW, HHC 5/16-18 X 1-3/4 2

13 12287 SCREW, THP 1/4-20 X 3/4 SS 8

14 20692 HINGE, TOOLBOX ACCESS PANEL 1

15 20694 PEDAL, HYDRAULIC PUMP 1

16 20698 DOOR PLATE 1

17 20699 CLEVIS, PUMP SPEED CONTROL .............. 1 .............. KUBOTA

17 21961 CLEVIS, PUMP SPEED CONTROL .............. 1 .............. YANMAR

18 20720 PLATFORM, OPERATOR W/A 1

19 21262 ROD END, 5/16-24 MALE LH 2

20 21389 LEVER W/A, PUMP CTRL LINKAGE 1

21 21391 SPACER,1.0 OD X .318 ID X .75L 1

22 21392 MOUNT, PUMP CTRL LEVER PIVOT 1

23 21394 ROD, PUMP CTRL HEX 8.0L .........................1 .............. REPLACES P/N 21394

24 21395 ROD, PUMP CTRL HEX 12.38L 1

25 21583 SCREW, HHC 5/16-24 X 1-1/2 GRD 8 1

26 21611 SCREW, THP 1/4-20 X 5/8 SS 5

27 21614 ROD END, 5/16-24 MALE RH HD 1

28 22016 NUT, 5/16-18 X .63 PLATED ........................... 1 .............. REPLACES P/N 2656

29 560020 LATCH, LIFT AND TURN 1

30 6014 C NUT, HEX FINISH 5/16-24 1

31 6904 NUT, HEX FINISH 1/4-28 1

32 8131 NUT, HEX FINISH L. H. 5/16-24 2

33 933213 WASHER, FWSH 1 OD X 5/16 3

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 13

Page 14

HTX-44K/Y RIDE-ON TROWEL — COOLER/VALVE BYPASS ASSY.

COOLER/VALVE BYPASS ASSY.

21

31

8

1

32

7

20

14

5

1

E

29

A

33

19

15

10A

16

C

10

27

RIGHT

13

B

D

13

9

11

6

10A

18

LEFT

34

24

22

23

2

25

4

B

26

41

17

NOTES:

FAN GUARD CANNOT BE PURCHASED

1

SEPARTELY. SEE ITEM 21.

A

12

27

YANMAR

ONLY

40

35

SHAFT

SIDE

SEAL KIT

28

C

36

REAR

SEAL

KIT

D

18

34

22

HYDRAULIC PUMP

E

PORTS SIDE-VIEW

D

3

C

E

37

SEAL KIT

CHARGE

PUMP

12

38

COMPLETE

SEAL

KIT

39

REPAIR

SEAL

KIT

PAGE 14 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 15

HTX-44K/Y RIDE-ON TROWEL — COOLER/VALVE BYPASS ASSY.

COOLER/VALVE BYPASS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 2691 SCREW, HHC 1/2-13 X 1 4

2 3322 FITTING, 90 10MJ-10MO 1

3 3365 FITTING, STR 10MJ-10MO 1

4 3464 FITTING, 90 10MJ-10MO EXTRA LONG 1

5 10176 NUT, NYLOC 1/2-13 4

6 12139 VALVE, RELIEF DT370 MOMF-125 1

7 12147 FITTING, QC DIAGN PARKER PD-361 2

8 12148 CAP, DUST DIAG PARKER PD6-285 2

9 12331 FITTING, STR 10MO-6FO 2

10 16336 FITTING, 45 10MJ-10MO ................................... 2 ....... KUBOTA

10A 3365 FITTING, STR 10MJ-10MO ................................ 2 ....... YANMAR

11 21056 VALVE, HYD BYPASS SEAT SWITCH 1

12 21093 FITTING, TEE 10MJ-10MJ-10MO RUN 2

13 21096 FITTING, STR 10MJ-12MO 4

14 21129 COOLER, HYD MF15 ......................................... 1 ....... INCLUDES ITEMS W/

15 21130 FITTING, STR 16MO-16MO ADJ 1

16 21194 FITTING, 45 12MJ-16MO 1

17 21287 PUMP ASSY, TANDEM SAUER M25 1 INCLUDES ITEMS W/>

18 21289 MOTOR, HYDRAULIC (EATON) .......................... 2 ....... S/N 2001367-BELOW INCLS. ITEMS W/$

18 21855 MOTOR, HYDRAULIC (SAUER-DANFOSS) ........ 2 ....... S/N 2001368-ABOVE INCLS. ITEMS W/+

19 21585 FITTING, STR 10MO-6FO 1

20*# 68197 FAN 1

21

22$ 21770 KEY, MOTOR, EATON 2

22+ 21899 KEY, MOTOR, SAUER DANFOSS 2

23 21889 COIL, PARKER 1

24 21888 POPPET SOLENOID 1

25 21519 HOSE ASSY., .38 ID X 29L 90 ONE END 1

26 21162 HOSE ASSY., 1/2” ID X 57.5 LG 45 ONE END 1

27 21158 HOSE ASSY., 1/2” ID X 24 LG STR ENDS 3

28 21161 HOSE ASSY., 1/2” ID X 44.5 45 END 90 END 1

29 21296 HOSE ASSY., 3/4 ID X 15.25 90 END R4 1

30 21102 HOSE ASSY., 5/8 ID X 20 LG 45 ENDS 1

31*# 12171 SEAL, WPACK 16-18 2

32*# 12179 TERMINAL, WPACK MALE 14-16GA 2

33*# 12176 CONNECTOR, WPACK 2PIN SHROUD 1

34$ 202861003 SHAFT/BEARING HYD. MOTOR, EATON ........... 2....... S/N 2001367 AND BELOW

34+ 11009878 SHAFT/BEARING HYD. MOTOR, DANFOSS ..... 2 ....... S/N 2001368 AND ABOVE

35% 61237000 SEAL KIT, SHAFTSIDE, EATON ........................ 1 ....... S/N 2001367 AND BELOW

36% 61238000 SEAL KIT, REAR, EATON ................................... 1 ....... S/N 2001367 AND BELOW

37 163S8168 SEAL KIT, CHARGE PUMP ................................ 1 ....... SAUER DANFOSS

38 9900374000 SEAL KIT, COMPLETE (EATON) ........................ 2 ....... INCLUDES ITEMS W/%

38 151B0113 SEAL KIT, COMPLETE, SAUER DANFOSS ...... 2 ....... S/N 2001368 AND ABOVE

39 4510016 REPAIR/SEAL KIT, PUMP M25 DANFOSS ........ 1 ....... S/N 2001368 AND ABOVE

40 21997 FITTING, STR-10FJ X 10MJ .............................. 1 ....... YANAMAR ONLY

41> 163D70517 CHARGE PUMP, SAUER DANFOSS 1

68229 FAN, MOTOR ASSEMBLY .................................. 1 ....... INCLUDES ITEMS W/#

*

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 15

Page 16

HYDRAULIC ASSY.

HTX-44K/Y RIDE-ON TROWEL — HYDRAULIC ASSY.

RIGHT

1

2

LEFT

4

6

6

9

SUCTION

17

24

HOSE

KIT

B

H

4A

A

TO RELIEF

BLOCK

12

15

16

8

H

1

14

5

7

G

21

E

7

F

14

C

LEFT

A

B

11

3

3

2

23

D

3

E

F

19

3

D

18

3

MIDDLE

RIGHT

11

10

G

3

C

SUCTION

FILTER

20

3

1

NOTES:

FOR COMPONENT PARTS SEE

1

RIGHT-HAND VALVE ASSY.

FOR COMPONENT PARTS SEE

2

LEFT-HAND VALVE ASSY.

DISCARD ITEMS 2, 3,12, 18 AND 20

3

S/N BF2001228 AND BELOW

PAGE 16 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

11

HYDRAULIC PUMP

PORTS SIDE-VIEW

22

C

G

Page 17

HTX-44K/Y RIDE-ON TROWEL — HYDRAULIC ASSY.

HYDRAULIC ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 3322 FITTING,90 10MJ-10MO 3

2 CLAMP, 1-1/4 HOSE ................................................ 1 ..... DISCARD S/N BF2001228 & BELOW

3 FITTING, 45 12BARB-12MO.................................... 1 ..... REPLACED BY HOSE KIT ITEM 24

3

*

4 11698 HOSE ASSY., .38 IDX 15.5 STR ENDS ................. 2 ..... KUBOTA

4 21772 HOSE ASSY., .38 IDX 15.5 STR ENDS ................. 1 ..... YANMAR

4A 21771 HOSE ASSY., .38 IDX 11.5 STR ENDS ................. 1 ..... YANMAR

5 11721 FITTING, STR 6MJ-6MO 2

6 11722 FITTING, 90 6MJ-6MO 2

7 11780 FITTING, 45 6MJ-6MO 2

8 12148 CAP, DUST DIAG PARKER PD6-285 1

9 12159 FITTING,TEE 6MJ-6MO-6MJ 2

10 CLAMP, HOSE 1-3/4 ID ........................................... 1 ..... DISCARD S/N BF2001228 & BELOW

11 16336 FITTING, 45 10MJ-10MO 3

12 HOSE ASSY., 3/4 ID X 16.25 -16 STR END R4 ...... 1 ..... REPLACED BY HOSE KIT ITEM 24

12

13 20831 VALVE ASSY., LH STEERING W/SWITCH 1

14 21695 HOSE ASSY., .38 ID X 40 -6FJX-6FJ 90 LONG 2

15 21595 FITTING, TEE 16MJ-12MO-16MJ 1

16 12546 FITTING, QD 4MO DIAGN PARKER PD341 1

17 21146 HOSE ASSY., .5 ID X 24 LG 45 ONE END 1

18 HOSE ASSY., 1.0 ID X 30L 90 ONE END R4 .......... 1 ..... REPLACED BY HOSE KIT ITEM 24

18

19 21201 HOSE ASSY., .38 ID X 36.5 LG STR ENDS ........... 2 ..... KUBOTA

19 21995 HOSE ASSY., .38 ID X 40.5 LG STR ENDS ........... 2 ..... YANMAR

20 FITTING, 90 16BARB-20MO .................................... 1 ..... REPLACED BY HOSE KIT ITEM 24

20

21 21158 HOSE ASSY., .5 ID X 22.5 STR ENDS 1

22 12901 HOSE ASSY., .5 ID X 16.5 STR END 1

23 11723 FITTING, 90 6MJ-8MO 1

24 21834 HTX SUCTION HOSE KIT ....................................... 1 INCLUDES ITEMS W/* INSTALLED

21815 FITTING, 45 12MJ X-12MO ..................................... 1 ..... S/N BF2001229 AND ABOVE

21819 HOSE ASSY., 3/4 ID X 17.50 -16 STR END ............ 1 ..... S/N BF2001229 AND ABOVE

*

21818 HOSE ASSY., 1.0 ID X 30L 90 ONE END ............... 1 ..... S/N BF2001229 AND ABOVE

*

21814 FITTING, 90 16MJ X -20MO .................................... 1 ..... S/N BF2001229 AND ABOVE

*

................................................................................. ON UNITS S/N BF2001228 & BELOW

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 17

Page 18

HTX-44K/Y RIDE-ON TROWEL — HYDRAULIC ASSY. (CONT.)

HYDRAULIC ASSY. (CONT.)

RIGHT

12

C

A

B

20

D

E

31

23

17

32

L

20

F

1

25

32

14

BOTTOM VIEW

OF RH STEERING

ASSEMBLY

A

26

18

RIGHT

27

4

K

C

L

B

28

23

D

E

J

2

5

19

23

3

30

F

C

22

21

HOSES

29

20

32

31

6

LEFT

11

8

3

9

B

16

10

13

15

7

1

2

A

10

17

18

J

K

9

24

23

20

32

TYPICAL

3 PLACES

PAGE 18 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

NOTES:

FOR COMPONENT PARTS SEE

1

RIGHT-HAND VALVE ASSY.

APPLY LOCTITE P/N 4 PLACES

2

ITEM 8 IS NO LONGER REQUIRED.

3

SPACER IS INCLUDED WITH ITEM 9.

Page 19

HTX-44K/Y RIDE-ON TROWEL — HYDRAULIC ASSY. (CONT.)

HYDRAULIC ASSY. (CONT.)

NO. PART NO. PART NAME QTY. REMARKS

1#

2#

3 1207 SCREW, HHC 5/16-18 X 1-3/4 5

4

*

5 10136 WASHER, FLAT 3/8 SAE 4

6 10176 NUT, NYLOC 1/2-13 6

7#

8 11141 SPACER, ROD END ................................................. 12 ............... NOT REQUIRED

9*% 21944 ROD END, 1/2-20 MALE RH ....................................... 6 ............... REPLACES P/N 11142

10

11 26867 HOSE ASSY., .38 ID X 63” JF J-6FJ 2

12 11721 FITTING, STR 6MJ-6MO 3

13#*12038 BELLOW, STG CYLINDER 3

14 12056 CYLINDER, STEERING WITHOUT ROD END ........... 3 ............... INCLUDES ITEMS W/#

15#*12060 PLATE, BELLOWS MOUNTING 3

16 13178 SCREW, HHC 1/2-13 X 2-1/4 6

17 20140 CYLINDER, STEERING W/ ROD END ....................... 3 ............... INCLUDES ITEMS W/

18 20652 CYLINDER, HYD PITCH 1.5 BORE 2

19 20780 VALVE ASSY., HYD PITCH 1

20 0183 PIN, COTTER 4

21 20912 COVER, 0.75 CLAMP STAUFF GD-3D 5

22 20913 CLAMP, 0.75 OD TUBE STAUFF 3190/190 DPP 5

23 21095 FITTING, STR 4MJ-4MO 5

24 21098 HOSE ASSY., 1/4 ID X 82 STR ENDS 2

25 21114 FITTING, STR 6FO-6MO 1

26 21115 FITTING, STR 6MJ-6MO LONG 1

27 21159 FITTING,45 4MJ-4MO 1

28 21160 HOSE ASSY., 1/4 ID X 47 STR ENDS 2

29 12055 HOSE ASSY., .38 ID X36 45 ONE END .................... 2 ............... KUBOTA

29 21201 HOSE ASSY., .38 ID X36.5 STR ENDS ..................... 2 ............... YANMAR

30 21376 SCREW, HHC 5/8-11 X 1.50 8

31 35149 FITTING,ORIFICE 4MJ-4MOX0.02 2

32 19974 PIN 4

0161 C WASHER, LOCK 5/16 SAE 12

*

0300 B WASHER, FLAT 5/16 SAE 12

*

4196 SCREW, HHC 3/8-16 X 3/4 4

10229 SCREW HHC 5/16 - 20 X 1 12

*

....................................................................................................... INCLUDED ITEM W/ITEM 9

11146 NUT, HEX JAM 1/2-20 6

*

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 19

Page 20

HTX-44K/Y RIDE-ON TROWEL — BURP TANK/SUCTION FILTER ASSY.

BURP TANK/SUCTION FILTER ASSY.

C

C

B

B

A

15

16

8

20

1

HYDROSTATIC

DRIVE SYSTEM

OIL

CHEVRON ISO 22

AGMA GR 5EP

4

19

18

12

1

BURP TANK

7

6

5

A

14

17

11

SUCTION

FILTER

10

NOTES:

USE HYDROSTATIC DRIVE SYSTEM OIL, CHEVRON

1

AW/MV ISO68 OR 10W30 GR 5EP. OIL CAPACITY IS 5.5 GALLONS

(20.82 LITERS) LESS FILTER CHANGE. WITH FILTER

CHANGE (CHECK SIGHT GLASS) ADD .5 GAL/1.89 LITERS.

VALVE ASSY.

1

2

C

1

13

3

PAGE 20 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 21

HTX-44K/Y RIDE-ON TROWEL — BURP TANK/SUCTION FILTER.

BURP TANK SUCTION FILTER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 3333 CLAMP, HOSE WORM #12 11/16 TO 1-1/4 2

2 3366 FITTING, 45 12BARB-12MO 1

3 3461 FITTING, 90 12BARB-12MO 1

4 11534 NUT U TYPE 1/4-20 2

5 11696 HOSE ASSY., .38 ID X35.5 STR ENDS 1

6 11722 FITTING, 90 6MJ-6MO 1

7 11725 FITTING, STR 6MJ-1/4MP 1

8 12287 SCREW, THP 1/4-20 X 3/4 SS 2

10 21106 HOUSING, FLTR SUC ZINGA SF-100 1

11 21107 FILTER, SUCTION 5" 10 MICRON SYNTH LHA 1

12 21109 SIGHT GLASS, DASH 12 ORB PLASTIC 1

13 21154 HOSE, 3/4 ID X 37 MEGAVAC 1

14 21193 GUAGE, FILTER COND ZINGA GV-10 1

15 21400 PLUG, HYD TANK HAND WHEEL 1

16 21406 O-RING, HYD DASH16 BUNA90 1

17 21407 FITTING, STR 20MO-20MO ADJ 1

18 21510 TANK W/A, HYD BURP 1

19 21513 BREATHER, FILTER 10 MICRON 1/4MP PLASTIC 1

20 HYDROSTATIC DRIVE SYSTEM OIL ........................AR .................. SOURCE LOCALLY

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 21

Page 22

PUMP LEVERS ASSY.

HTX-44K/Y RIDE-ON TROWEL — PUMP LEVERS ASSY.

13

3

1

10

12

6

5

2

15

14

7

1

2

13

10

11

6

5

9

8

4

9

8

PAGE 22 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

4

NOTES:

1

APPLY LOCTITE P/N 60091

2 PLACES.

Page 23

HTX-44K/Y RIDE-ON TROWEL — PUMP LEVERS ASSY.

PUMP LEVERS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0161 C WASHER, LOCK, 5/16 MED 2

2 0161 D NUT, HEX FINISH 5/16-18 2

3 0243 SCREW, SHC 5/16-18 X 1-3/4 2

4 0447 WASHER, FLAT 1/2 SAE 2

5 1207 SCREW, HHC 5/16-18 X 1-3/4 2

6 3233 WASHER, FENDER 1.5 OD X 3/8 ID 2

7 5023 B NUT, HEX FINISH 3/8-24 PLAIN 1

8 5054 A WASHER, LOCK, 1/2 MED 2

9 5218 SCREW, HHC 1/2-13 X 1-1/2 2

10 21231 ISOLATOR, PLATE / STUD 5/16 2

11 21266 BEARING BLOCK ASSY., PUMP CTRL RH 1

12 21267 BEARING BLOCK ASSY., PUMP CTRL LH 1

13 21290 LEVER W/A, PUMP CONTROL M25 2

14 21301 ROD, PUMP ACTUATOR M25 1

15 21342 NUT, HEX FINISH 3/8-24 LH 1

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 23

Page 24

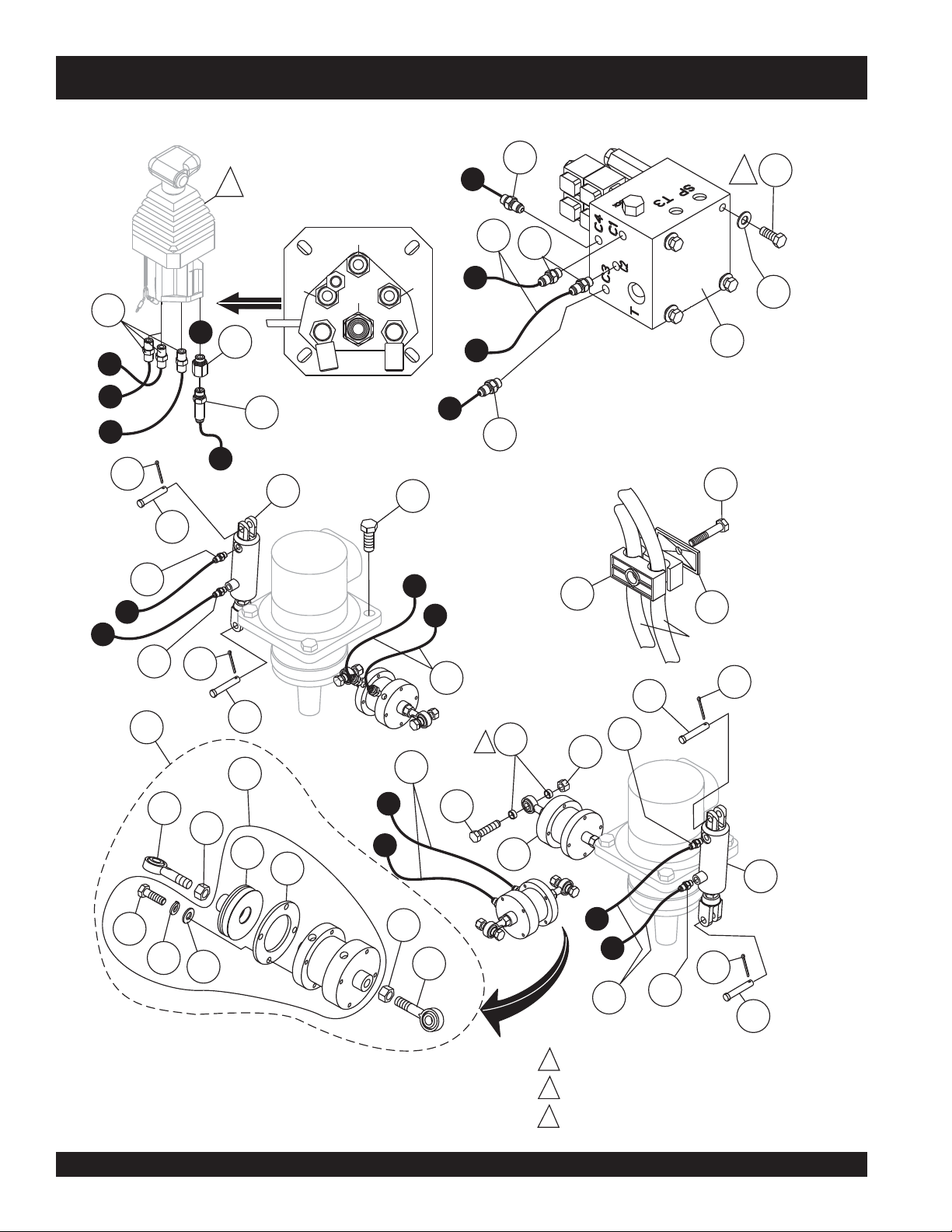

HTX-44K RIDE ON TROWEL — ENGINE ASSY. (KUBOTA)

ENGINE ASSY. (KUBOTA, S/N A62001524 AND BELOW)

24

17

16

19

6

36

26

13

21

27

1

5

33

32

14

42

4

3

10

18

29

28

39

31

35

45

23

8

40

41

12

16

7

2

9

20

43

11

8

30

24

11

17

25

30

48

15

44

12

46

4

38

6

22

37

47

34

PAGE 24 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 25

HTX-44K RIDE ON TROWEL — ENGINE ASSY. (KUBOTA)

ENGINE ASSY. (KUBOTA, S/N A62001524 AND BELOW)

NO. PART NO. PART NAME QTY. REMARKS

1 0161 C WASHER, LOCK, 5/16 MED 1

2 0166 SCREW, HHC 3/8-16 X 7/8 1

3 0202 SCREW, HHC 5/16-18 X 1 1

4 0205 SCREW, HHC 3/8-16 X 1 2

5 0479 WASHER, EXT SHKP 3/8 PLTD 1

6 10133 NUT, NYLOC 3/8-16 3

7 10136 WASHER, FLAT 3/8 SAE 1

8 10176 NUT, NYLOC 1/2-13 4

9 10320 BRACKET, REAR LIGHT 1

10 10434 CLAMP, HOSE WORM #32, 1-9/16 TO 2 1

11 11662 SCREW, HHC M10-1.25 X 25MM 8

12 8128 CLAMP, HOSE SUPPORT 5/16 2

13 20123 HOSE, AIR CLEANER 1

14 20728 MOUNT, KUBOTA ENGINE HTX-44T 1

15 20729 MOUNT/W, ENGINE HTX-44T 2

16 20742 ISOLATOR, RB2 RING & BUSHING 4

17 20743 WASHER, ISOLATOR SNUBBING 4

18 20965 MUFFLER, KUBOTA 1505 HTH 1

19 21242 CLAMP, HOSE 13/16 3/8 BLT HOLE 1

20 21355 BRACKET PUMP CONTROL CABLE 1

21 3TNV84TKSA ENGINE, KUBOTA V 1505-TE 1

22 21522 MOUNT, RADIATOR 2

23 PLATE, SERIAL RIDERS .......................................... 1 .......... CONTACT MQ PARTS DEPT.

24 2549 SCREW, HHC 1/2-13 X 3 4

25 2623 SCREW, HHC 5/16-18 X 1-1/4 1

26 26405 CLAMP, HOSE 1-3/4 ID 1

27 2866 SCREW, HHC M8-1.25 X 20MM 1

28 29504 SWITCH, THERMAL 230 F 1

29 29506 TERMINAL, BLADE TO #8 RING ADAPT 1

30 2955 WASHER, LOCK, 7/16 ZINC 8

31 4014 SCREW, #2-3/16 U-DRIVE 2

32 5054 A WASHER, LOCK 1/2 MED 2

33 5218 SCREW, HHC 1/2-13 X 1-1/2 2

34 11983 RESERVOIR BOTTLE 1

35 20327 AIR CLEANER ASSY., KUBOTA V1505-TE ............... 1 .......... INCLUDES ITEMS W/

36

37 20320 RADIATOR KIT 1

38 20319 FUEL FILTER KIT 1

39 20316 FAN 1

40 11378 COUPLING PUMP 1

41 11605 FLANGE, DRIVE ENGINE 3-HOLE 1

42 21504 BELL HOUSING 1

43 20317 FLYWHEEL KIT 1

44 29344 TIMER, GLOW PLUG 1

45 1538111250 BAND, AIR CLEANER 1

46 1628297010 FAN BELT 1

47 1627132090 FILTER, OIL 1

48 5283 NUT, NYLOC 5/16-18 2

1735111083 ELEMENT, AIR CLEANER 1

*

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 25

Page 26

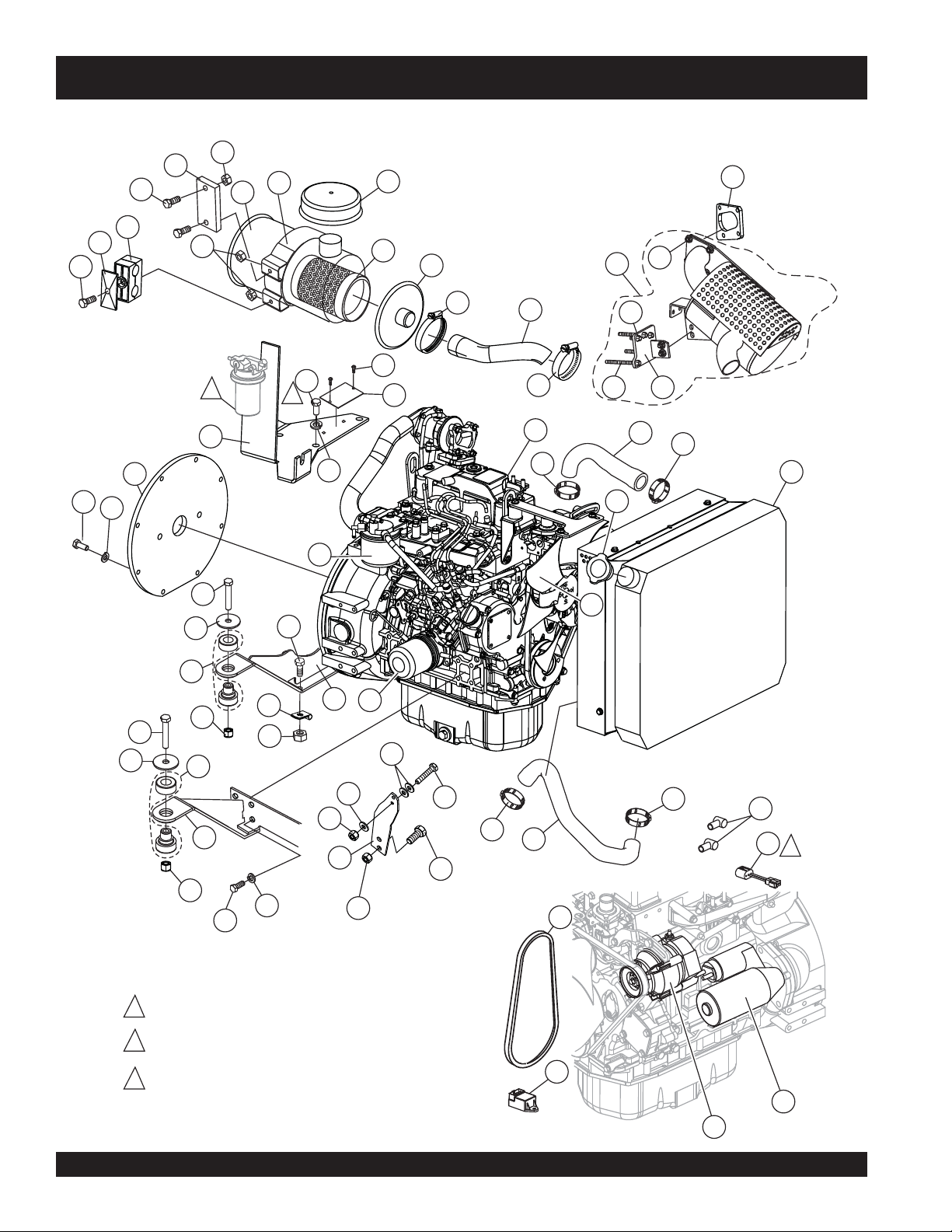

HTX-44Y RIDE ON TROWEL — ENGINE ASSY. (YANMAR)

ENGINE ASSY. (YANMAR, S/N AG2001525 AND ABOVE)

39

39

14

15

62

16

63

59

58

57

56

55

13

12

8

17

18

11

60

1

4

3

61

54

7

4

3

53

19

1

20

10

24

21

9

20

22

52

44

43

48

23

45

50

51

42

44

43

47

45

49

39

42

41

46

40

47

3

39

4

NOTES:

FUEL WATER SEPERATOR. SEE FUEL TANK ASSY.

1

CONNECTS FROM WIRE HARNESS TO ALTERNATOR.

2

APPLY LOCTITE P/N 60091 (4PLACES)

3

PAGE 26 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

37

38

20

32

33

34

20

35

2

6

2

36

Page 27

HTX-44Y RIDE ON TROWEL — ENGINE ASSY. (YANMAR)

ENGINE ASSY. (YANMAR, S/N AG2001525 AND ABOVE)

NO. PART NO. PART NAME QTY. REMARKS

1 21895 ENGINE, YANMAR 3TNV84T 1

2 2762 TERMINAL BOOT 2

3 2955 WASHER, LOCK 7/16 ZINC 15

4 16056 SCREW, HHC M10 - 1.5 X 25MM GR 8.8 19

6 21745 PIGTAIL, ALTERNATOR PLUG 1

7 21921 COUPLER, HAYES 1

8 21951 MUFFLER .................................................................. 1 ........... INCLUDES ITEMS W/

9

*

10

11

12

13 21950 GASKET, MUFFLER 1

14 G065432 HOUSING, AIR CLEANER DONALDSON 1

15 20120 CLAMP, AIR CLEANER 1

16 PMAF25436 CARTRIDGE, AIR CLEANER DONALDSON 1

17 29218 HOSE CLAMP, 3" DIA 1

18 21948 HOSE, AIR INTAKE 1

19 962015 HOSE CLAMP, 2" DIA 1

20 CLAMP, HOSE RADIATOR ........................................ 4 ........... PURCHASE LOCALLY

21 68900479 HOSE, RADIATOR UPPER 1

22 79000511 RADIATOR 1

23 129612-44700 FAN 1

24 69300002 CAP, RADIATOR 1

32 68900480 HOSE, RADIATOR LOWER 1

33 119865-42290 V-BELT, YANMAR 1

34 29344 GLOW PLUG TIMER 1

35 129423-77200 ALTERNATOR 1

36 12960877010 STARTER MOTOR

22018 BRACKET, MUFFLER-LOWER HTX YANMAR 1

22022 SCREW, HEX FLANGE M8-1.25 X 90 MM GR 10.9 3

*

22021 SCREW, HEX FLANGE M8-1.25 X 20 MM GR 10.9 4

*

15227 NUT, HEX FLANGED M8-1.25 GR 10 6

*

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 27

Page 28

HTX-44Y RIDE ON TROWEL — ENGINE ASSY. (YANMAR CONT.)

ENGINE ASSY. (YANMAR, S/N AG2001525 AND ABOVE)

39

59

62

16

63

55

56

57

58

39

14

15

13

12

8

17

18

11

60

1

4

3

61

54

7

4

3

53

19

1

20

10

24

21

9

20

22

52

44

43

48

23

45

50

51

42

44

43

47

45

49

39

42

41

46

40

37

38

20

32

47

3

4

NOTES:

FUEL WATER SEPERATOR. SEE FUEL TANK ASSY.

1

CONNECTS FROM WIRE HARNESS TO ALTERNATOR.

2

APPLY LOCTITE P/N 60091 (4PLACES)

3

39

33

34

PAGE 28 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

20

35

2

6

2

36

Page 29

HTX-44Y RIDE ON TROWEL — ENGINE ASSY. (YANMAR CONT.)

ENGINE ASSY. (YANMAR, S/N AG2001525 AND ABOVE)

NO. PART NO. PART NAME QTY. REMARKS

37 3513 SCREW, HHC 10-32 X 1 1

38 0655 SCREW, HHC 5/16-18 X 3/4 6

39 5283 NUT, NYLOC 5/16 - 18 6

40 21649 LEVER, THROTTLE 1

41 10019 NUT, NYLOC 10-32 1

42 2203 WASHER, FLAT #10 3

43 2549 SCREW, HHC 1/2 - 13 X 3 4

44 20743 WASHER, ISOLATOR SNUBBING 4

45 20742 ISOLATOR, RB2 RING & BUSHING 4

46 21844 MOUNT, ENGINE FRONT RAD 44 YANMAR 1

47 10176 NUT, NYLOC 1/2-13 4

48 0202 SCREW, HHC 5/16 - 18 X 1 ZINC 1

49 8128 CLAMP, HOSE SUPPORT 5/16 1

50 21830 MOUNT, ENGINE REAR 44 YANMAR 1

51 129150-35152 OIL FILTER 1

52 119802-55800 FUEL FILTER 1

53 2955 WASHER, LOCK 7/16 ZINC 15

54 21847 BRACKET, THROTTLE HTX YANMAR 1

55 0300 A SCREW, HHC 5/16-18 X 2 1

56 20912 COVER, 0.75 OD TUBE STAUFF 1

57 20913 CLAMP, 0.75 OD TUBE STAUFF 1

58 2623 SCREW, HHC 5/16 - 18 X 1.25 2

59 21989 SPACER, 0.75 X 2.0 X 4.5 1

60 4014 SCREW, 2-3/16 P-K TYPE U DRIVE 2

61 NAMEPLATE ........................................................ 1 ........ CONTACT MQ PARTS

62 H001378 RAIN/AIR CAP 1

63 P539422 LID, AIR CLEANER 1

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 29

Page 30

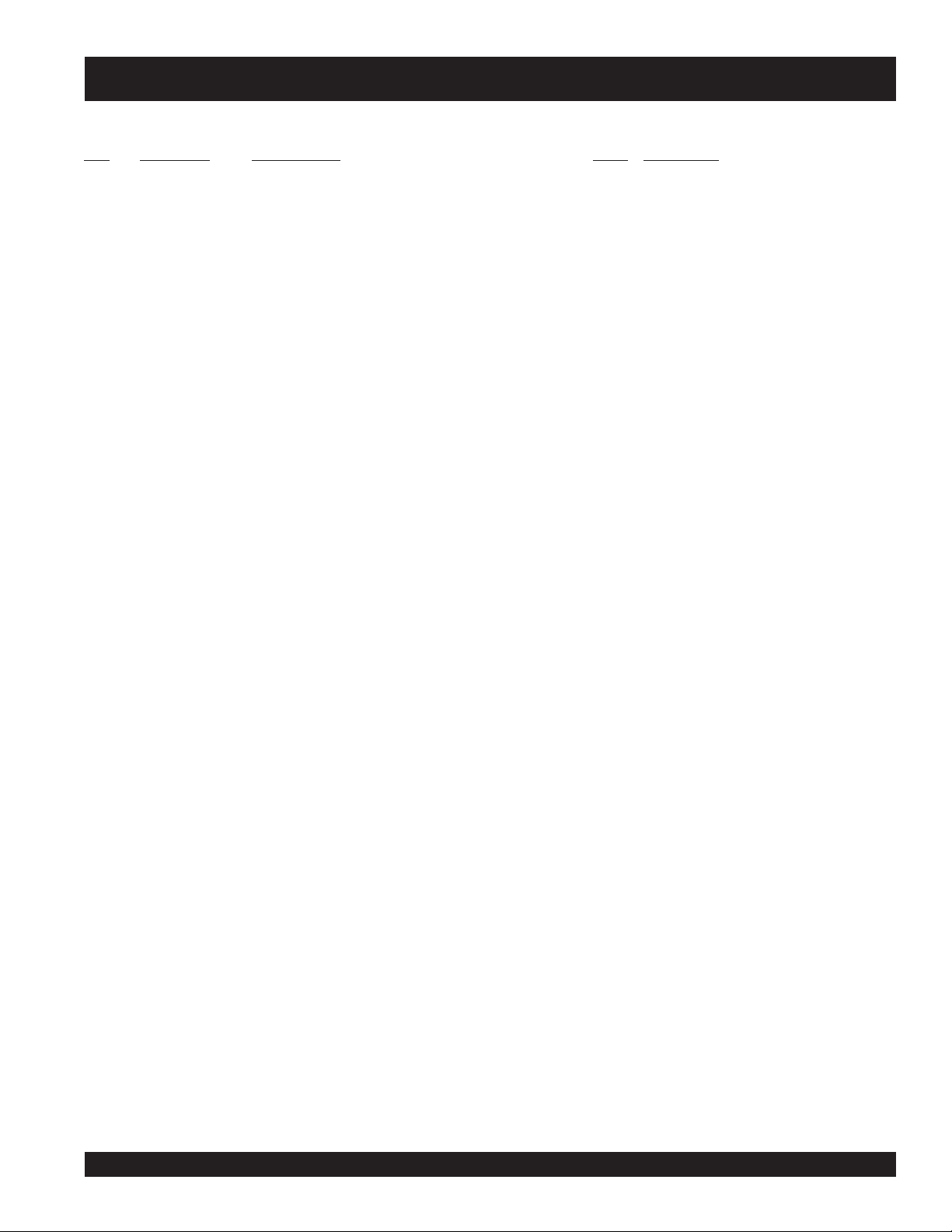

PIVOT ASSY.

HTX-44K/Y RIDE-ON TROWEL — PIVOT ASSY.

PAGE 30 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 31

HTX-44K/Y RIDE-ON TROWEL — PIVOT ASSY.

PIVOT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0166 A WASHER, LOCK, 3/8 MED 12

2 0183 PIN, COTTER 1/8 1-1/4 4

3 0448 WASHER, FLAT 7/16 SAE 4

4 10136 WASHER, FLAT 3/8 SAE 8

5 10176 NUT, NYLOC 1/2-13 6

6# 10221 BUSHING, IGLIDE # TF-1618-16 6

7 1023 SCREW, HHC 3/8-16 X 1-1/4 12

8 11555 ROCKER BLOCK ................................................ 6 ................... INCLUDES ITEMS W/#

9 13178 SCREW, HHC 1/2-13 X 2-1/4 6

10 20630 HOUSING,DRIVE MOTOR W/A,LH 1

11 20639 TRUNNION/W PITCH AND PIVOT 1

12 20640 HOUSING,DRIVE MOTOR W/A,RH 1

13 20641 YOKE, PITCH-MACHINED 2

14 20643 HOUSING, LOWER MOTOR MACHINED 2

15 20787 CLEVIS, STEERING CYLINDER 3

16 21022 PIN,YOKE PIVOT 2

17 21707 WASHER, FLAT 3/8 NORDLOC 16

18 2691 SCREW, HHC 1/2-13 X 1 3

19 5054 A WASHER, LOCK, 1/2 MED 3

20 915105 SCREW, HHC 3/8-16 X 1 GRD8 ........................ 16 .................. JAN. 28, 2008 AND BELOW

20 22228 SCREW, HHF 3/8-16 X 1 GRD8 ......................... 16 .................. JAN. 29, 2008 AND ABOVE

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 31

Page 32

HTX-44K/Y RIDE-ON TROWEL — 5-BLADE STABILIZER RING ASSY.

5-BLADE STABILIZER RING ASSY.

7

8

1

SEE DETAIL “A”

NOTES:

TO PURCHASE BLADES

1

CONTACT UNIT SALES DEPT.

6

1

4

DETAIL “A”

TYPICAL 10 PLACES HTX-44K5

TYPICAL 10 PLACES HTX-44Y5

4

5

3

2

PAGE 32 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 33

HTX-44K/Y RIDE-ON TROWEL — 5-BLADE STABILIZER RING ASSY.

5-BLADE STABILIZER RING ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 12095 RING, STABILIZER HTX-44K5 2

2 1237 SCREW, SHC 5/16-18 X 7/8 NYLOC 10

3 0161 C WASHER, LOCK, 5/16 MED 10

4 6014 C NUT, HEX FINISH 5/16-24 20

5 1723 ROD END, 5/16-24 MALE RH 10

6 BLADE ASSY. ........................................................... 10 ...................CONTACT UNIT SALES

7 0105 SCREW, HHCS 5/16-18 X 1-1/2 ................................ 30 ...................KUBOTA

7 1207 SCREW, HHC 5/16-18 X 1- 3/4" ................................ 30 ................... YANMAR

8 1061 C WASHER, LOCK 5/16" 30

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 33

Page 34

HTX-44K/Y RIDE-ON TROWEL— 4-BLADE STABILIZER RING ASSY.

4-BLADE STABILIZER RING ASSY.

5

6

4

SEE DETAIL “A”

DETAIL “A”

1

4

3

1

1

2

APPLY LOCTITE 242 BLUE

1

OR EQUIVALENT.

PAGE 34 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 35

HTX-44K/Y RIDE-ON TROWEL — 4-BLADE STABILIZER RING ASSY.

4-BLADE STABILIZER RING ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0161 C WASHER, LOCK, 5/16 MED 8

2 1237 SCREW, SHC 5/16-18 X 7/8 NYLOC 4

3 1723 ROD END, 5/16-24 MALE RH 4

4 6014 C NUT, HEX FINISH 5/16-24 8

5 9148 RING, STABILIZER HTX-44K5 1

6 BLADE ASSY. ............................................................. 8 ...................CONTACT UNIT SALES

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 35

Page 36

HTX-44K/Y RIDE ON TROWEL — 5-BLADE SPIDER ASSY. (TAPERED LH)

5-BLADE SPIDER ASSY. (TAPERED LH)

7

5

3

4

2

5

1

6

8

4

26

16

17

1

14

15

13

18

1

21

20

19

2

22

23

24

25

NOTE:

3

APPLY LOCTITE P/N 60091

1

5 PLACES

2

APPLY LOCTITE P/N 60098

TORQUE TO 130 FT. LBS

3

LEFT-SIDE SPIDER ASSEMBLY

4

P/N 20180 INCLUDES ALL ITEMS

WITHIN DASHED LINES.

THRUST COLLAR ASSEMBLY

5

P/N 20938 INCLUDES ALL ITEMS

WITHIN DASHED LINES.

12

11

9

PAGE 36 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

10

Page 37

HTX-44K/Y RIDE ON TROWEL — 5-BLADE SPIDER ASSY. (TAPERED LH)

5-BLADE SPIDER ASSY. (TAPERED LH)

NO. PART NO. PART NAME QTY. REMARKS

1*$# 1162 A CAP, GREASE ZERK #2 6

2*$ 2621 ZERK, GREASE STR 1/4-28 1

3*$ 12316 BUSHING, THRUST COLLAR 1

4

*

5

*

6

*

7 20938 THRUST COLLAR ASSY. .............................................. 1................. INCLUDES ITEMS W/

8 20180 SPIDER ASSY., LH 5 BLD............................................. 1................. INCLUDES ITEMS W/#

9# 2829 ARM, TROWEL, HD/HRT EXT. 5

10# 9006 PIN, ROLL 5/16 X 2 5

11# 11903 LEVER, TROWEL ARM HYD L.S. 5

12# 9111 SPRING, LS ARM RETURN HD/HT, SMALL BOSS 5

13# 1875 WASHER, INT. SHKP. 3/8 5

14# 1322 SCREW, RETAINING 5

15# 11039 BUSHING, ARM 2 PIECE 10

16# 0121 A FITTING, PLUG 3/8 MP SQ HEAD 1

17# 20041 SPIDER, HTH TAPER 5 BLD HTX-44K5 ........................ 1.................INCLUDES ITEMS W/%

18#% 11602 SCREW, HHC 3/8-16 X 1/4 5

19# 0164 B SCREW, HHC ROUNDED 3/8-16 SPCL GR8 5

20# 1876 NUT, HEX JAM 3/8-16 CLASS 2B 5

21# 0166 A WASHER, LOCK, 3/8 MED 5

22 20073 RETAINER, SPIDER 1

23 4388 WASHER, LOCK, 3/4 MED 1

24 20179 SCREW, HHC 3/4 -16 X 2, GR 8 1

25 20121 PLUG, SPIDER SNAP IN 1

26 21770 KEY, 3/8 X 2 1

12779 BEARING, THRUST 6017 2RS W/FLANGE 1

11431 THRUST COLLAR W/ BUSHING.................................... 1................. INCLUDES ITEMS W/$

11419 PLATE, WEAR 1

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 37

Page 38

HTX-44K/Y RIDE-ON TROWEL — 5-BLADE SPIDER ASSY. (TAPERED RH)

5-BLADE SPIDER ASSY. (TAPERED RH)

7

5

3

4

2

5

1

6

8

4

26

17

16

18

1

19

15

20

13

21

11

22

14

1

12

23

NOTE:

3

2

9

10

24

25

PAGE 38 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

APPLY LOCTITE P/N 60091

1

5 PLACES

2

APPLY LOCTITE P/N 60098

TORQUE TO 130 FT. LBS

3

RIGHT-SIDE SPIDER ASSEMBLY

4

P/N 20181 INCLUDES ALL ITEMS

WITHIN DASHED LINES.

THRUST COLLAR ASSEMBLY

5

P/N 20938 INCLUDES ALL ITEMS

WITHIN DASHED LINES.

Page 39

HTX-44K/Y RIDE ON TROWEL — 5-BLADE SPIDER ASSY. (TAPERED RH)

5-BLADE SPIDER ASSY. (TAPERED RH)

NO. PART NO. PART NAME QTY. REMARKS

1*$# 1162 A CAP, GREASE ZERK #2 6

2*$ 2621 ZERK, GREASE STR 1/4-28 1

3

$ 20426 BUSHING, THRUST COLLAR 1

*

4

*

5

*

6

*

7 20938 THRUST COLLAR ASSY. .............................................. 1................. INCLUDES ITEMS W/

8 20181 SPIDER ASSY., RH 5 BLD ............................................ 1 ................. INCLUDES ITEMS W/#

9# 2829 ARM, TROWEL, HD/HRT EXT. 5

10# 9006 PIN, ROLL 5/16 X 2 5

11# 11904 LEVER, TROWEL ARM HYD R.S. 5

12# 2143 SPRING, RS ARM RETURN HD/HT, SMALL BOSS 5

13# 1875 WASHER, INT. SHKP. 3/8 5

14# 1322 SCREW, RETAINING 5

15# 11039 BUSHING, ARM 2 PIECE 10

16# 0121 A FITTING, PLUG 3/8 MP SQ HEAD 1

17# 20041 SPIDER, HTH TAPER 5 BLD HTX-44K5 ........................ 1.................INCLUDES ITEMS W/%

18#% 11602 SCREW, HHC 3/8-16 X 1/4 5

19# 0164 B SCREW, HHC ROUNDED 3/8-16 SPCL GR8 5

20# 1876 NUT, HEX JAM 3/8-16 CLASS 2B 5

21# 0166 A WASHER, LOCK, 3/8 MED 5

22 20073 RETAINER, SPIDER 1

23 4388 WASHER, LOCK, 3/4 MED 1

24 20179 SCREW, HHC 3/4 -16 X 2, GR 8 1

25 20121 PLUG, SPIDER SNAP IN 1

26 12687 KEY, 3/8 X 2 1

12779 BEARING, THRUST 6017 2RS W/FLANGE 1

11431 THRUST COLLAR W/ BUSHING.................................... 1................. INCLUDES ITEMS W/$

11419 PLATE, WEAR 1

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 39

Page 40

HTX-44K RIDE ON TROWEL — 4-BLADE SPIDER ASSY. (TAPERED LH)

4-BLADE SPIDER ASSY. (TAPERED LH)

7

5

3

4

2

5

1

6

25

16

17

8

4

18

1

15

12

20

19

13

14

11

22

9

21

1

23

10

24

PAGE 40 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

3

2

NOTE:

APPLY LOCTITE P/N 60091

1

4 PLACES

2

APPLY LOCTITE P/N 60098

TORQUE TO 130 FT. LBS

3

LEFT-SIDE SPIDER ASSEMBLY

4

P/N 21666 INCLUDES ALL ITEMS

WITHIN DASHED LINES.

THRUST COLLAR ASSEMBLY

5

P/N 20938 INCLUDES ALL ITEMS

WITHIN DASHED LINES.

Page 41

HTX-44K RIDE ON TROWEL — 4-BLADE SPIDER ASSY. (TAPERED LH)

4-BLADE SPIDER ASSY. (TAPERED LH)

NO. PART NO. PART NAME QTY. REMARKS

1*$# 1162 A CAP, GREASE ZERK #2 5

2*$ 2621 ZERK, GREASE STR 1/4-28 1

3*$ 20426 BUSHING, THRUST COLLAR 1

4

*

5

*

6

*

7 20938 THRUST COLLAR ASSY. .............................................. 1................. INCLUDES ITEMS W/

8 21666 SPIDER ASSY., LH 4 BLD............................................. 1................. INCLUDES ITEMS W/#

9# 2829 ARM, TROWEL, HD/HRT EXT. 4

10# 9006 PIN, ROLL 5/16 X 2 4

11# 11903 LEVER, TROWEL ARM HYD L.S. 4

12# 9111 SPRING, LS ARM RETURN HD/HT 4

13# 1875 WASHER, INT. SHKP. 3/8 4

14# 1322 SCREW, RETAINING 4

15# 11039 BUSHING, ARM 2 PIECE 8

16# 0121 A FITTING, PLUG 3/8 MP SQ HEAD 1

17# 21751 SPIDER, PLATE ............................................................ 1................. INCLUDES ITEMS W/%

18#% 11602 SCREW, HHC 3/8-16 X 1/4 4

19# 0164 B SCREW, HHC ROUNDED 3/8-16 SPCL GR8 4

20# 1876 NUT, HEX JAM 3/8-16 CLASS 2B 4

21# 0166 A WASHER, LOCK, 3/8 MED 4

22 20073 RETAINER, SPIDER 1

23 4388 WASHER, LOCK, 3/4 MED 1

24 20179 SCREW, HHC 3/4 -16 X 2, GR 8 1

25 12687 KEY, 3/8 X 2 1

12779 BEARING, THRUST 6017 2RS W/FLANGE 1

11431 THRUST COLLAR W/ BUSHING.................................... 1................. INCLUDES ITEMS W/$

11419 PLATE, WEAR 1

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 41

Page 42

HTX-44K RIDE ON TROWEL — 4-BLADE SPIDER ASSY. (TAPERED RH)

4-BLADE SPIDER ASSY. (TAPERED RH)

7

5

3

4

2

5

1

6

25

16

17

8

4

1

14

19

15

13

20

21

11

18

12

1

22

9

10

PAGE 42 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

23

24

NOTE:

APPLY LOCTITE P/N 60091

1

4 PLACES

2

3

2

APPLY LOCTITE P/N 60098

TORQUE TO 130 FT. LBS

3

LEFT-SIDE SPIDER ASSEMBLY

4

P/N 21667 INCLUDES ALL ITEMS

WITHIN DASHED LINES.

THRUST COLLAR ASSEMBLY

5

P/N 20938 INCLUDES ALL ITEMS

WITHIN DASHED LINES.

Page 43

HTX-44K RIDE ON TROWEL — 4-BLADE SPIDER ASSY. (TAPERED RH)

4-BLADE SPIDER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1*$# 1162 A CAP, GREASE ZERK #2 5

2*$ 2621 ZERK, GREASE STR 1/4-28 1

3

$ 20426 BUSHING, THRUST COLLAR 1

*

4

*

5

*

6

*

7 20938 THRUST COLLAR ASSY. .............................................. 1................. INCLUDES ITEMS W/

8 21667 SPIDER ASSY., RH 4 BLD ............................................ 1 ................. INCLUDES ITEMS W/#

9# 2829 ARM, TROWEL, HD/HRT EXT. 4

10# 9006 PIN, ROLL 5/16 X 2 4

11# 11904 LEVER, TROWEL ARM HYD R.S. 4

12# 2143 SPRING, RS ARM RETURN HD/HT 4

13# 1875 WASHER, INT. SHKP. 3/8 4

14# 1322 SCREW, RETAINING 4

15# 11039 BUSHING, ARM 2 PIECE 8

16# 0121 A FITTING, PLUG 3/8 MP SQ HEAD 1

17# 21751 SPIDER, PLATE ............................................................ 1................. INCLUDES ITEMS W/%

18#% 11602 SCREW, HHC 3/8-16 X 1/4 4

19# 0164 B SCREW, HHC ROUNDED 3/8-16 SPCL GR8 4

20# 1876 NUT, HEX JAM 3/8-16 CLASS 2B 4

21# 0166 A WASHER, LOCK, 3/8 MED 4

22 20073 RETAINER, SPIDER 1

23 4388 WASHER, LOCK, 3/4 MED 1

24 20179 SCREW, HHC 3/4 -16 X 2, GR 8 1

25 12687 KEY, 3/8 X 2 1

12779 BEARING, THRUST 6017 2RS W/FLANGE 1

11431 THRUST COLLAR W/ BUSHING.................................... 1................. INCLUDES ITEMS W/$

11419 PLATE, WEAR 1

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 43

Page 44

HTX-44K RIDE-ON TROWEL — SEAT FRAME ASSY. (KUBOTA)

SEAT FRAME ASSY. (KUBOTA)

19

23

29

20

22

24

TEMPLATE

18

21

25

NEW

STYLE

20

19

16

14

17

12

15

1

5

OLD

STYLE

KILL

SWITCH

14

5

8

1

2

27

26

28

6

11

NOTES:

WHEN OLD STYLE SEAT, PARTS ORDER STOCK HAS

BEEN DEPLETED (ITEMS 14, 15 AND 17), NEW STYLE

1

SEAT MUST BE ORDERED (ITEMS 18 THRU 29).

13

3

4

10

9

6

7

PAGE 44 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 45

HTX-44K RIDE-ON TROWEL — SEAT FRAME ASSY. (KUBOTA)

SEAT FRAME ASSY. (KUBOTA)

NO. PART NO. PART NAME QTY. REMARKS

1 0300 B WASHER, FLAT 5/16 SAE 4

2 5283 NUT, NYLOC 5/16-18 4

3 10024 NUT, NYLOC 1/4-20 4

4 11534 NUT U TYPE 1/4-20 4

5 11821 SCREW, SHC M8-1.25 X 25 GR10.9, NP 2

6 12287 SCREW, THP 1/4-20 X 3/4 SS 4

7 13287 NUT, NYLOC #8-32 4

8 15161 STOP, RUBBER BUMPER 7

9 15175 SCREW, PAN HEAD 8-32 X 3/4 4

10 20673 LATCH, RUBBER HOOD 2

11 20676 PANEL,SEAT FRAME FRONT CENTER ........................ 1 ........... SAFETY ITEM. SEE NOTE

12 20679 PLATFORM, OPERATOR SEAT 1

13 20685 BLOCK, OPERATOR SEAT-PIVOT 2

14 20995 ARM REST ASSY., SET OF 2 1

15 21420 BASIC SEAT, W/KILL SWITCH (NO ARMS) .................. 1 ........... SAFETY ITEM. SEE NOTE

....................................................................................................... INCLUDES ITEM W/

16 26385 SCREW, HHC 1/4-20 X 2.25 4

17

18 21860 SEAT, ASSY., NO ARMS ................................................ 1 ........... SAFETY ITEM

19 21868 ARM REST KIT, SET OF 2 ............................................. 1 ........... INCLUDES ITEM W/#

20# 21869 SCREW, 5/16-18 X 5/8 SELF TAP BUTTON 2

21 21870 SWITCH, KILL, DELTA SYSTEMS 644-62 ..................... 1 ........... SAFETY ITEM

22 21936 CONNECTOR BODY - 2 PIN MICH. SEAT ...................... 1 ........... SAFETY ITEM

23 21924 WIRE ASSY., 16 GA RED X 11" ..................................... 1 ........... SAFETY ITEM

24 21923 WIRE ASSY., 16 GA VIOLET/ORANGE X 12.50" .......... 1 ........... SAFETY ITEM

25 21865 SEAT ADJUSTER KIT, MICHIGAN V-2805 1

26 21597 BUMPER STEM 1.0" D X .5 X .31 7

27 19468 GROMMET, MINOR-PNZ 4004 1

28 20909 SCREW, HHC 1/4-20 X 2.00 4

29 21916 TEMPLATE, PLATFORM SEAT

21609 SEAT, CUSHION W/KILL SWITCH.................................. 1 ........... SEE NOTE

*

*

NOTE

WHEN OLD STYLE SEAT, PARTS ORDER STOCK HAS BEEN DEPLETED (ITEMS 14, 15 AND 17)

NEW STYLE SEAT MUST BE ORDERED (ITEMS 18 THRU 29).

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 45

Page 46

HTX-44Y RIDE-ON TROWEL — SEAT FRAME ASSY. (YANMAR)

SEAT FRAME ASSY. (YANMAR)

14

5

15

17

12

18

19

20

NEW

STYLE

8

14

5

9

7

10

1

6

2

13

3

4

11

PAGE 46 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 47

HTX-44Y RIDE-ON TROWEL — SEAT FRAME ASSY. (YANMAR)

SEAT FRAME ASSY. YANMAR)

NO. PART NO. PART NAME QTY. REMARKS

1 0300 B WASHER, FLAT 5/16 SAE 4

2 5283 NUT, NYLOC 5/16-18 4

3 10024 NUT, NYLOC 1/4-20 4

4 11534 NUT U TYPE 1/4-20 4

5# 21869 SCREW, 5/16-18 X 5/8 SELF TAP BUTTON 2

6 12287 SCREW, THP 1/4-20 X 3/4 SS 4

7 19468 GROMMET, MINOR-PNZ 4004 1

8 21870 SWITCH, KILL, DELTA SYSTEMS 644-62 ..................... 1 ........... SAFETY ITEM

9 21865 SEAT ADJUSTER KIT, MICHIGAN V-2805 1

10 21597 BUMPER STEM 1.0" D X .5 X .31 7

11 20676 PANEL,SEAT FRAME FRONT CENTER ........................ 1 ........... SAFETY ITEM

12 20679 PLATFORM, OPERATOR SEAT 1

13 20685 BLOCK, OPERATOR SEAT-PIVOT 2

14 21868 ARM REST KIT, SET OF 2 ............................................. 1 ........... INCLUDES ITEM W/#

15 21860 SEAT, ASSY., NO ARMS ................................................ 1 ........... SAFETY ITEM

17 20909 SCREW, HHC 1/4-20 X 2.00 ........................................... 4

18 21923 WIRE ASSY., 16 GA VIOLET/ORANGE X 12.50" .......... 1 ........... SAFETY ITEM

19 21924 WIRE ASSY., 16 GA RED X 11" ..................................... 1 ........... SAFETY ITEM

20 21936 CONNECTOR BODY - 2 PIN MICH. SEAT ...................... 1 ........... SAFETY ITEM

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 47

Page 48

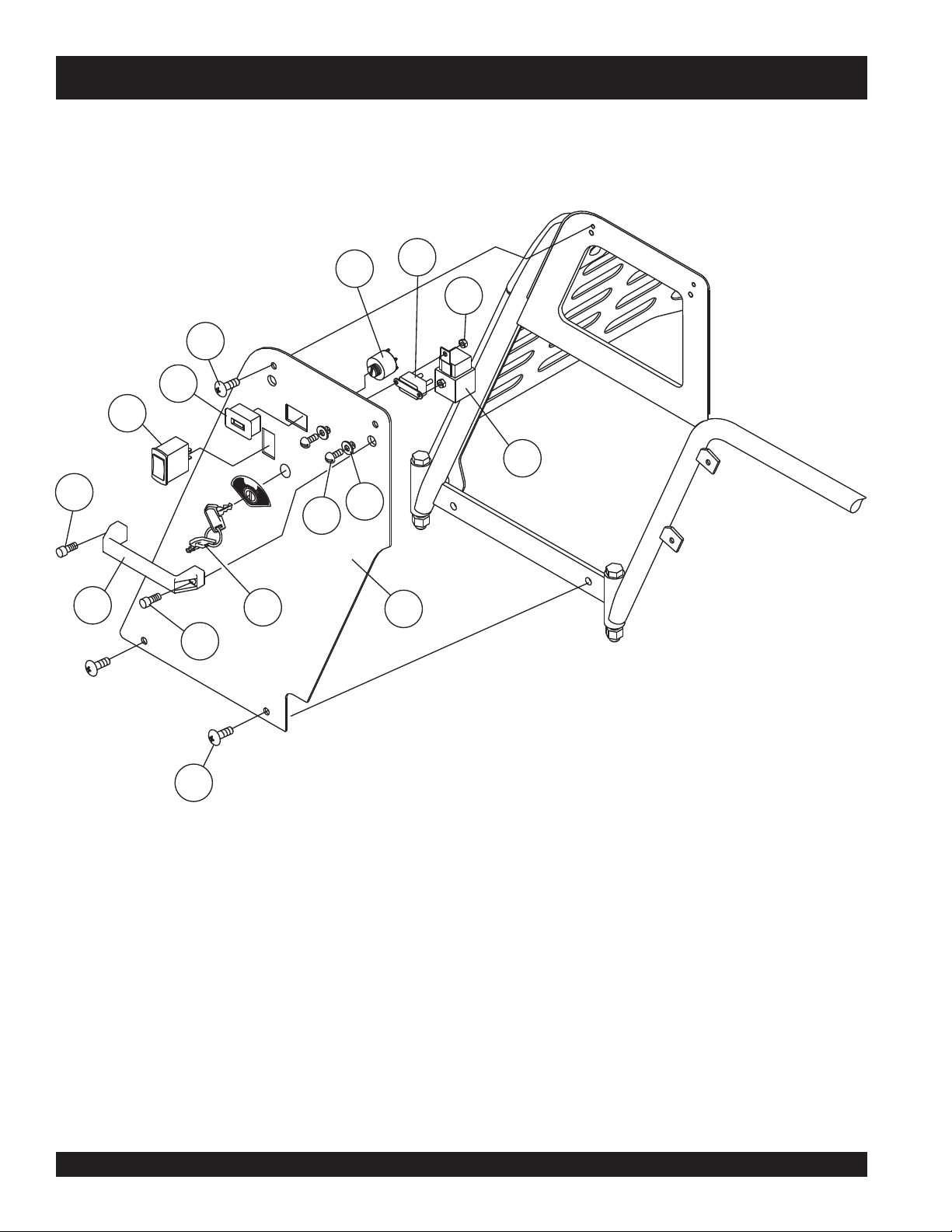

HTX-44K/Y RIDE-ON TROWEL — FRONT PANEL ASSY. (RIGHT-SIDE)

FRONT PANEL ASSY. (RIGHT-SIDE)

11

9

8

12

11

6

E

R

P

T

A

A

F

E

F

H

U

A

H

C

E

R

P

S

T

A

R

T

E

R

E

G

C

O

N

T

A

7A

7

4

3

5

S

W

I

T

C

C

H

T

S

D

T

A

E

R

M

T

A

R

R

A

G

E

1

2

10

6

PAGE 48 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 49

HTX-44K/Y RIDE-ON TROWEL — FRONT PANEL ASSY. (RIGHT-SIDE)

FRONT PANEL ASSY. (RIGHT-SIDE)

NO. PART NO. PART NAME QTY. REMARKS

1 2203 WASHER, FLAT # 10 SAE 2

2 5065 B SCREW, RHM 10-32 X 1/2 2

3 10019 NUT, NYLOC 10-32 2

4 11098 CIRCUIT BRKR,WAYTEK#46540 40 AMP 1

5 12017 RELAY, KILL ................................................................... 1 ........... SAFETY ITEM

6 12287 SCREW, THP 1/4-20 X 3/4 SS 4

7 20511 SWITCH, IGNITION ........................................................ 1 ........... KUBOTA

7 1E01363590 SWITCH, IGNITION ........................................................ 1 ........... YANMAR

7A 12940 KEY, IGNITION ............................................................... 2 ........... KUBOTA

7A 12627 KEY, IGNITION ............................................................... 2 ........... YANMAR

8 406000 SWITCH, ROCKER DP-DT 1

9 20674 HANDLE, GRAB ............................................................. 1 ........... SAFETY ITEM

10 20677 PANEL, SEAT FRAME FRONT RIGHT ........................... 1 ........... SAFETY ITEM

11 21575 SCREW, SHC 5/16-18 X 3/4 2

12 29640 HR METER, SENDEC RECT FLUS MT 1

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 49

Page 50

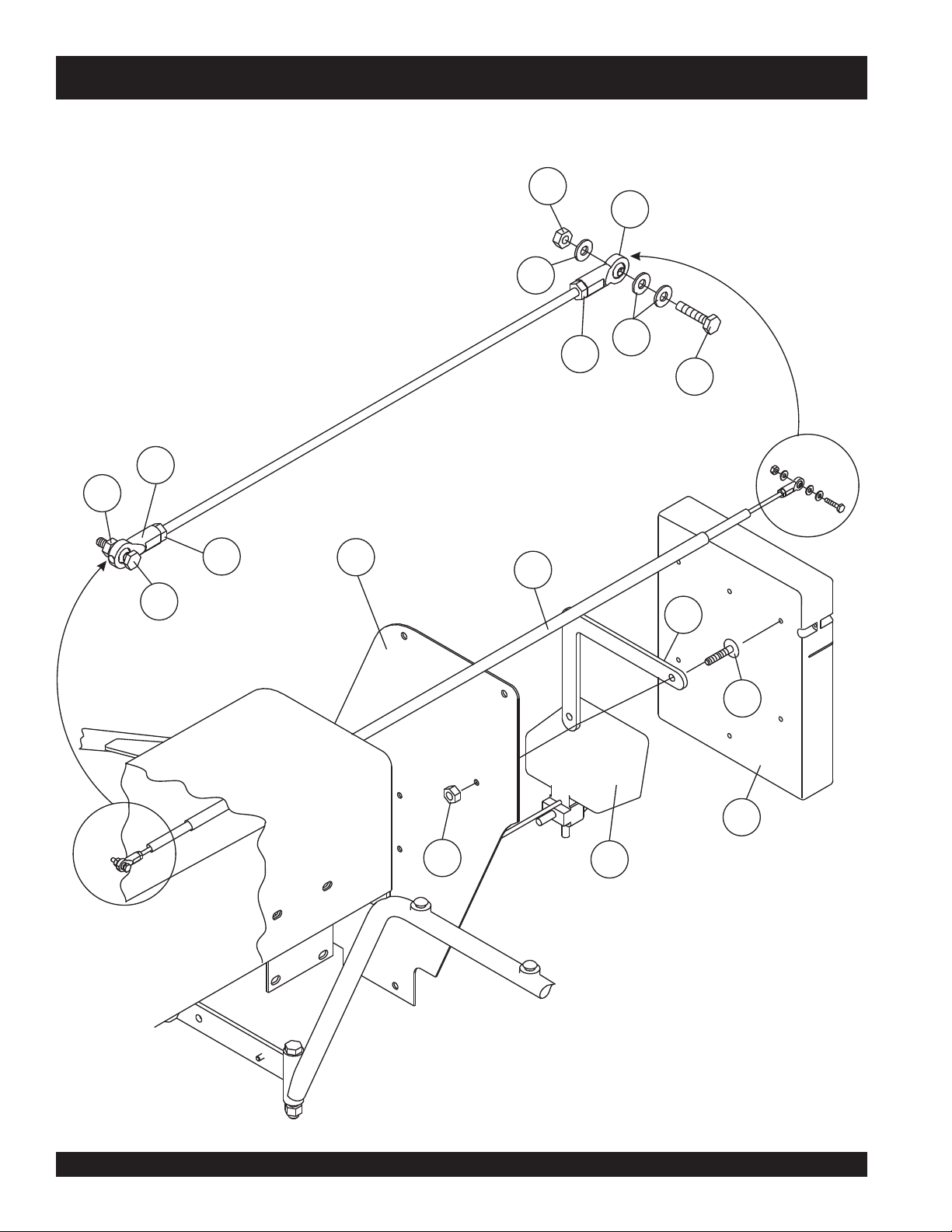

HTX-44K/Y RIDE-ON TROWEL — FRAME ASSY. (RIGHT-FRONT)

FRAME ASSY. (RIGHT-FRONT)

10

7

1

4

9

3

6

12

5

8

2

11

PAGE 50 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 51

HTX-44K/Y RIDE-ON TROWEL — FRAME ASSY. (RIGHT-FRONT)

FRAME ASSY. (RIGHT-FRONT)

NO. PART NO. PART NAME QTY. REMARKS

1 8087 SCREW, HHC 1/2-13 X 4 4

2 8128 CLAMP, HOSE SUPPORT, 5/16 1

3 11379 LEVER, THROTTLE 1

4 11712 ENGINE SPEED DECAL 1

5 12287 SCREW, THP 1/4-20 X 3/4 SS 4

6 12288 SCREW, THP 1/4-20 X 1 2

7 12355 BRACKET, LIGHT 2

8 19266 NUT, BLIND 1/4-20 X 10GA 4

9 20680 GUARD W/GRILL ........................................................... 1 ......... SAFETY ITEM (KUBOTA)

9 21925 GUARD W/GRILL ........................................................... 1 ......... SAFETY ITEM (YANMAR)

10 21052 LIGHT, SPEAKER WIDE FLOOD ................................... 1 .........SAFETY ITEM

11 21341 CABLE, CTRL THUMB RELEASE 46" 1

12 406021 GAUGE, ENGINE STATUS 1

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 51

Page 52

HTX-44K/Y RIDE-ON TROWEL — FRAME ASSY. (RIGHT-REAR )

FRAME ASSY. (RIGHT-REAR)

2

5

5

2

3

3

1

4

4

1

9

8

6

11

7

12

10

PAGE 52 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 53

HTX-44K/Y RIDE-ON TROWEL — FRAME ASSY. (RIGHT-REAR )

FRAME ASSY. (RIGHT-REAR)

NO. PART NO. PART NAME QTY. REMARKS

1 0937 NUT,HEX #10-32 2

2 2153 ROD END, 10-32 FEMALE RH 2

3 2203 WASHER, FLAT # 10 SAE 5

4 3513 SCREW, HHC 10-32 X 1 2

5 10019 NUT, NYLOC 10-32 2

6 10568 CABLE, THROTTLE 1

7 12287 SCREW, THP 1/4-20 X 1 5

8 19266 NUT, BLIND 1/4-20 X 10GA 5

9 20678 PANEL, SEATFRAME RIGHT-REAR ............................... 1 ........... SAFETY ITEM

10 21052 LIGHT, SPEAKER WIDE FLOOD 1

11 21604 SPACER, DOCUMENT BOX 1

12 29057 DOCUMENT BOX, (CP90007-07) 1

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 53

Page 54

HTX-44K/Y RIDE-ON TROWEL — FRAME ASSY. (LEFT-FRONT/REAR)

FRAME ASSY. (LEFT-FRONT/REAR)

1

7

14

18

1

11

13

3

1

9

12

KUBOTA

15

8

10

6

2

19

20

12

25

26

1

22

24

23

21

18

16

17

YANMAR

10

PAGE 54 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 55

HTX-44K/Y RIDE-ON TROWEL — FRAME ASSY. (LEFT-FRONT/REAR)

FRAME ASSY. (LEFT-FRONT/REAR)

NO. PART NO. PART NAME QTY. REMARKS

1 12287 SCREW, THP 1/4-20 X 3/4 SS 12

2 13287 NUT, NYLOC #8-32 ......................................................... 2 ........... KUBOTA

3 15175 SCREW, PAN HEAD 8-32 X 3/4 ...................................... 2 ........... KUBOTA

4 19266 NUT, BLIND 1/4-20 X 10GA 4

5 20660 SEAT FRAME W/A 1

6 20673 LATCH, RUBBER HOOD ................................................ 1 ........... KUBOTA

7 20674 HANDLE, GRAB ............................................................. 1 ........... SAFETY ITEM

8 20675 PANEL, SEAT FRAME FRONT LEFT ............................. 1 ........... SAFETY ITEM

9 20678 PANEL, SEAT FRAME REAR LEFT ............................... 1 ........... SAFETY ITEM

10 20680 GUARD/W, GRILL W/A.................................................... 1 ........... SAFETY ITEM (KUBOTA)

10 21925 GUARD/W, GRILL W/A.................................................... 1 ........... SAFETY ITEM (YANMAR)

11 20693 PANEL, RADIATOR COVER ............................................ 1 ........... SAFETY ITEM

12 21052 LIGHT, SPEAKER WIDE FLOOD ................................... 2 ........... SAFETY ITEM

13 21470 SWITCH, ON-OFF-ON 2

14 21575 SCREW, SHC 5/16-18 X 3/4 2

15 21597 BUMPER,STEM 1"DIA X.5"STEMX.31TK 2

16 21894 CLIP, FAST LEAD ........................................................... 2 ........... YANMAR

17 21893 SCREW, FAST LEAD ..................................................... 2 ........... YANMAR

18 21986 WASHER, FAST LEAD - STAINLESS ............................ 2 ........... YANMAR

19 121252-44510 RADIATOR BOTTLE 1

20 0131 A SCREW, HHC 1/4 - 20 X 3/4 4

21 21947 BRACKET, RADIATOR BOTTLE MOUNT 1

22 12125644600 BRACKET, RADIATOR BOTTLE 1

23 0948 WASHER, FLAT 1/4 SAE 4

24 10024 NUT, NYLOC 1/4-20 6

25 10024 NUT, NYLOC 1/4-20 6

26 12287 SCREW, THP 1/4 - 20 X 3/4 SS 2

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 55

Page 56

HTX-44K RIDE-ON TROWEL — RIGHT-HAND VALVE ASSY.

RIGHT-HAND VALVE ASSY. (KUBOTA S/N 2000885 AND BELOW)

6

4

2

5

1

3

PAGE 56 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 57

HTX-44K RIDE-ON TROWEL — RIGHT-HAND VALVE ASSY.

RIGHT-HAND VALVE ASSY. (KUBOTA S/N 2000885 AND BELOW)

NO. PART NO. PART NAME QTY. REMARKS

1

*

2

*

3 20830 VALVE ASSY., RIGHT HAND STG W/O SWITCH .......... 1 ........... INCLUDES ITEMS W/

4

*

5

*

6

*

16083 NUT, HEX M12 P1.75 1

20149 PALM HANDLE, RIGHT HAND W/O SWITCH 1

20832 RH STEERING VALVE 1

20834 ADAPTOR, RH PALM HANDLE 1

21631 BOOT, STEERING VALVE 1

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 57

Page 58

HTX-44K/Y RIDE-ON TROWEL — RIGHT-HAND VALVE ASSY.

RIGHT

LEFT

RIGHT-HAND VALVE ASSY. (KUBOTA/YANMAR - S/N 2000886 AND ABOVE)

9

15

16

17

12

13

14

10

2

1

9

8

7

3

4

6

1

5

NOTES:

ITEMS 12, 13 AND 14 CANNOT BE

1

PURCHASED SEPARATELY.

PAGE 58 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

PALM

HANDLE

KIT

Page 59

HTX-44K/Y RIDE-ON TROWEL — RIGHT-HAND VALVE ASSY.

RIGHT-HAND VALVE ASSY. (KUBOTA/YANMAR - S/N 2000886 AND ABOVE)

NO. PART NO. PART NAME QTY. REMARKS

1#*$ 1318 TERMINAL, BULLET, FEMALE, 18-22 1

2#*$ 4692 TERMINAL, BULLET MALE 14-16 1

3#*$ 16083 NUT, HEX M12 P1.75 1

4*$ 20155 PALM HANDLE, W/SWITCH, RIGHT .............................. 1 ........... INCLUDES ITEMS W/#

5 20165 PALM HANDLE KIT, L/R HANDLES W/O BOOT ............. 1 ........... INCLUDES ITEMS W/$

6 20829 VALVE ASSY., W/SWITCH ............................................. 1 ........... INCLUCES ITEMS W/

7

*

8

*

9%*21631 BOOT, STEERING VALVE 1

10 432233013 GUIDE PLATE KIT .......................................................... 1 ........... INCLUDES ITEMS W/%

11% BOOT, STEERING VALVE .............................................. 1 ........... SEE NOTE BELOW

12% NUT ................................................................................. 1 ........... SEE NOTE BELOW

13% GUIDE PLATE BUSHING ............................................... 1 ........... SEE NOTE BELOW

14% UPPER GUIDE PLATE ................................................... 1 ........... SEE NOTE BELOW

15 321800006 VALVE 4

16 421801100 SPRING, RETURN 4

17 430033036 LOWER GUIDE PLATE 1

20832 VALVE, RH STEERING 1

20834 ADAPTOR, RH PALM HANDLE 1

*

NOTE

ITEMS 12 THRU 14 CANNOT BE PURCHASED SEPARATELY

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 59

Page 60

HTX-44K/Y RIDE-ON TROWEL — LEFT-HAND VALVE ASSY.

RIGHT

LEFT

LEFT-HAND VALVE ASSY.

7

7

9

3

8

8

4

2

6

1

5

PALM

HANDLE

KIT

PAGE 60 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

Page 61

HTX-44K/Y RIDE-ON TROWEL — LEFT-HAND VALVE ASSY.

LEFT-HAND VALVE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1#*$ 1318 TERMINAL, BULLET, FEMALE, 18-22 1

2#*$ 4692 TERMINAL, BULLET MALE 14-16 1

3#*$ 16083 NUT, HEX M12 P1.75 1

4*$ 20150 PALM HANDLE, W/SWITCH, LEFT ................................ 1 ........... INCLUDES ITEMS W/#

5 20165 PALM HANDLE KIT, L/R HANDLES W/O BOOT ............. 1 ........... INCLUDES ITEMS W/$

6 20831 VALVE ASSY. W/SWITCH .............................................. 1 ........... INCLUCES ITEMS W/

7

*

8

*

9

*

20833 VALVE, LH STEERING 1

21053 ADAPTOR, LH PALM HANDLE 1

21631 BOOT, STEERING VALVE 1

*

HTX-44K/Y RIDE-ON TROWEL— PARTS MANUAL — REV. #18 (08/28/12) — PAGE 61

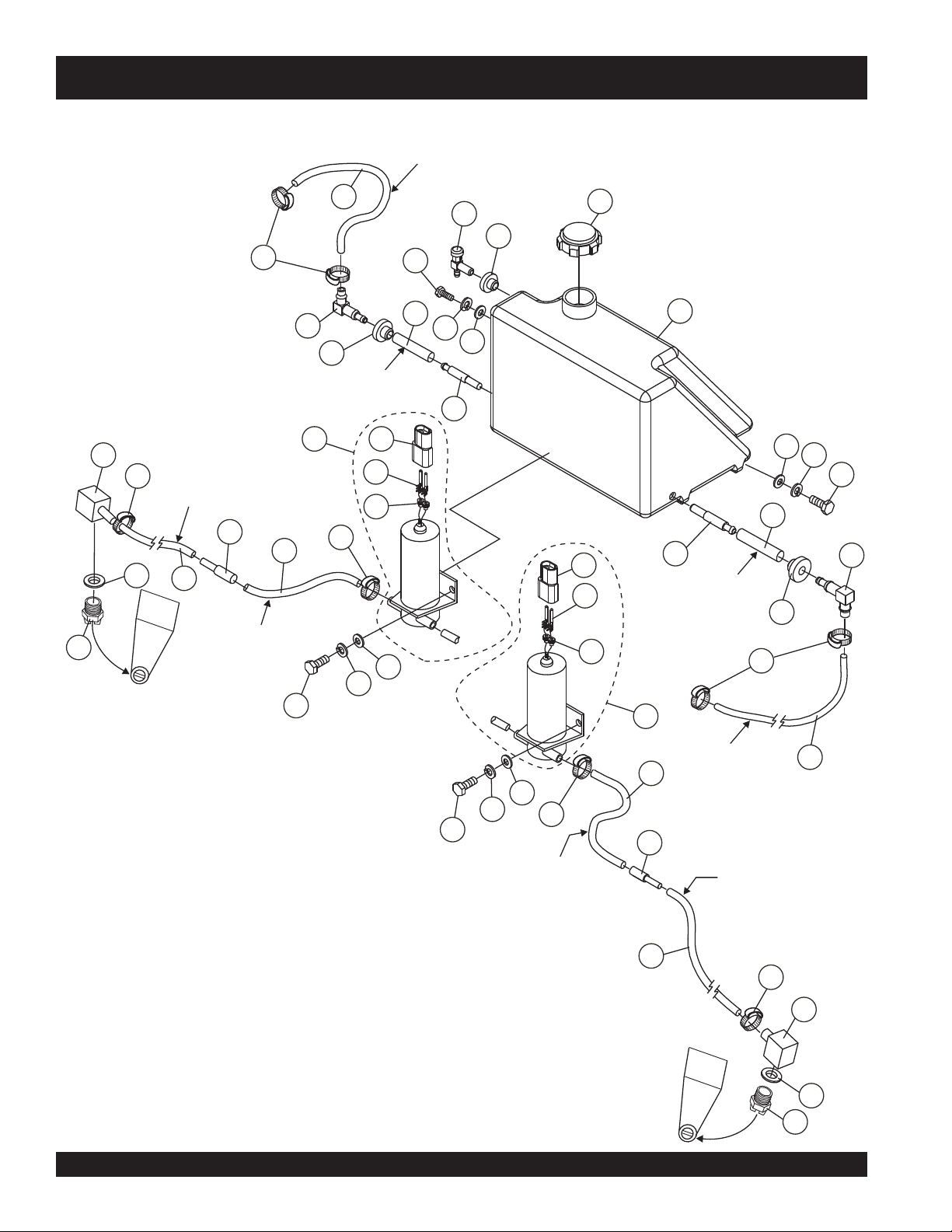

Page 62

SPRAY ASSY.

TO PUMP “A”

INPUT

HTX-44K/Y RIDE-ON TROWEL — SPRAY ASSY.

24 IN.

(610 MM)

6

7

75 IN.

(1,905 MM)

8

5

18

21

BRACKET IS WELDED

TO FRAME

7

19

14 IN.

(356 MM)

19

17

4

16

1

9

16

20

2

3

3IN.

(76.2 MM)

14

10

15

12

13

11

20

3

2

1

7

PUMP

“A”

12

13

PUMP “A”

INPUT

11

3

2

1

PUMP “B”

INPUT

PUMP

“B”

10

TO PUMP “B”

INPUT

15

3IN.

(76.2 MM)

16

7

9

8IN.

19

(203 MM)

3

2

7

1

8

18 IN.

(457 MM)

45 IN.

(1,143 MM)

18

BRACKET IS WELDED

TO FRAME

PAGE 62 — HTX-44K/Y RIDE-ON TROWEL — PARTS MANUAL — REV. #18 (08/28/12)

19

7

6

5

21

Page 63

HTX-44K/Y RIDE-ON TROWEL — SPRAY ASSY.