Page 1

OPERATION AND PARTS MANUAL

SERIES

MODEL HTH44T

RIDE-ON POWER TROWEL

(

KUBOTA V1505 DIESEL ENGINE

Revision #8 (03/27/12)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

)

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N 20210

Page 2

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 3

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metaland

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metaland

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials beingused.

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 3

— PAGE RM

Page 4

HTH44T— TABLE OF CONTENTS

Proposition 65 Warning ............................................ 2

Silicosis/Respiratory Warnings ................................. 3

Table of contents ...................................................... 4

Parts ordering procedures ....................................... 5

Training Checklist ..................................................... 6

Daily Pre-Operation Checklist .................................. 7

Safety Message Alert Symbols ............................ 8-9

Rules For Safe Operation ...................................... 10

Operation And Safety Decals ................................. 11

Specifications ......................................................... 12

General Information ............................................... 13

WHITEMAN — HTH44T RIDEON POWER TROWEL

Controls and Indicators ..................................... 14-15

Initial Start-Up .................................................... 16-19

Maintenance....................................................... 20-25

Troubleshooting .................................................. 26-27

Explanation of Codes In Remarks Column ............ 28

Suggested Spare Parts & Service Items ................29

Pivot Assy. (Left)................................................. 30-31

Pivot Assy. (Right) .............................................. 32-33

Twin Pitch Assy. (Left/Right) .............................. 34-37

Engine (Kubota) ................................................. 38-39

Engine Flange (Kubota) .................................... 40-41

Engine Fuel (Kubota) ......................................... 42-43

Hydraulic Steering (Left) .................................... 44-45

Hydraulic Steering (Right) ................................. 46-47

Steering Valve Assy. (Left) ................................. 48-49

Steering Valve Assy. (Right) ............................... 50-51

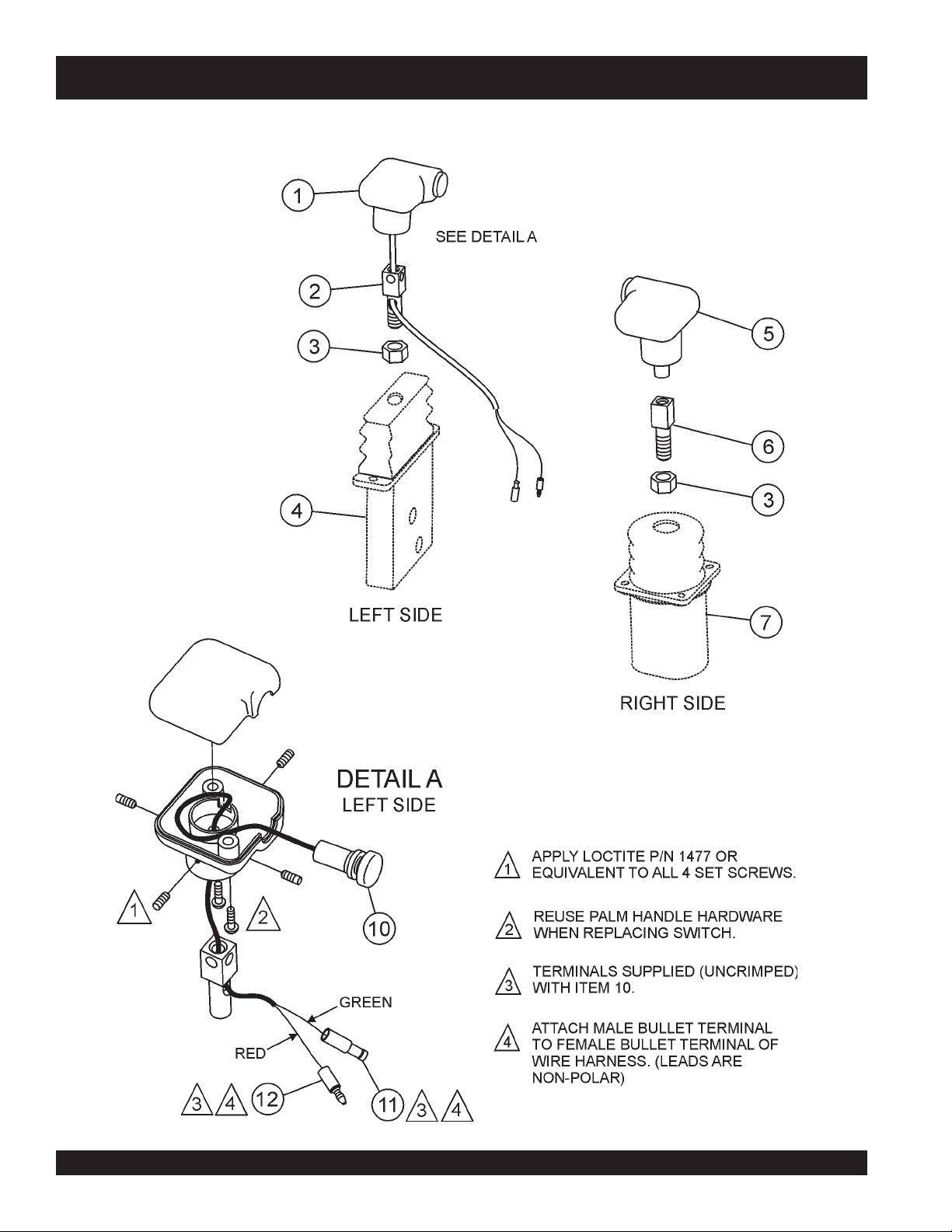

Palm Handles (Left and Right) .......................... 52-53

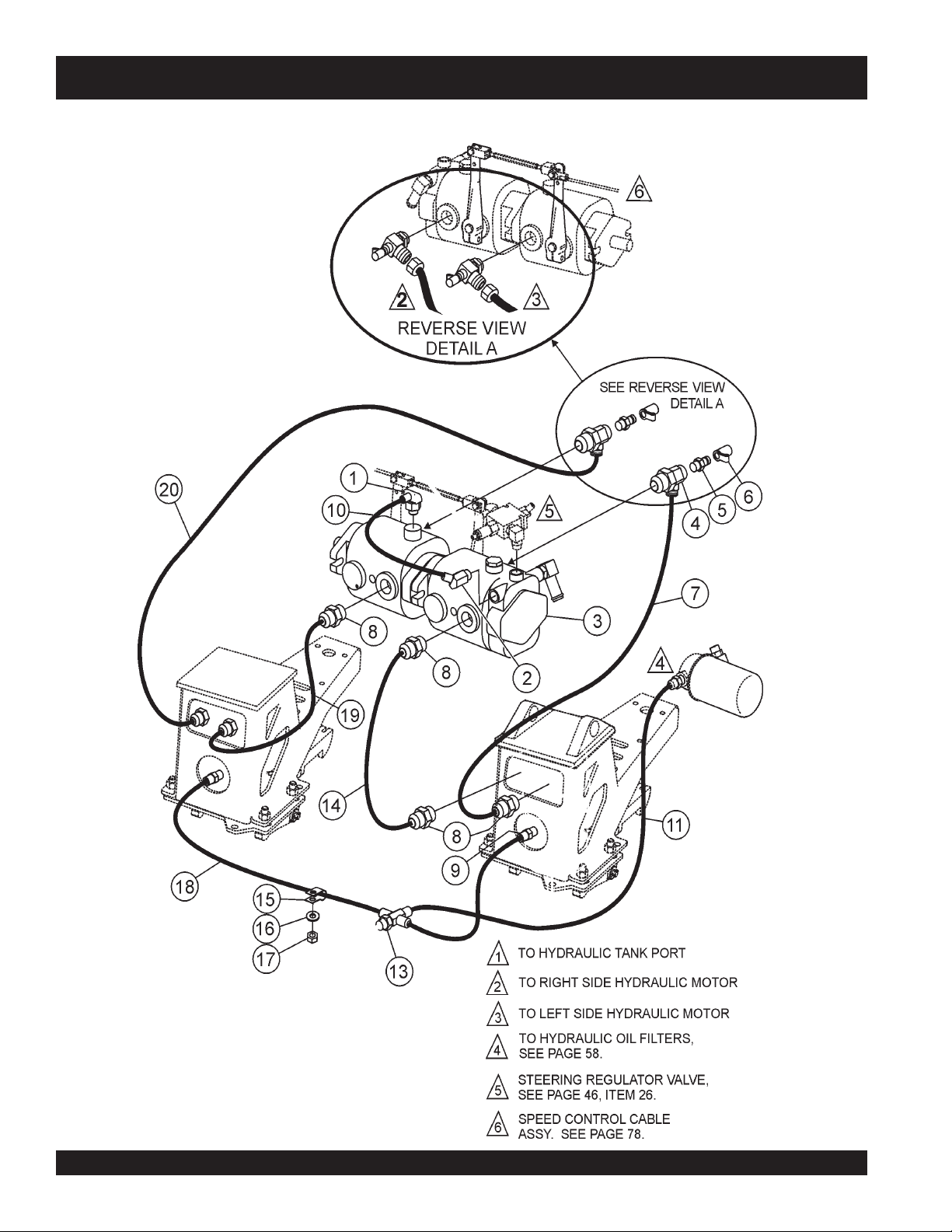

Hydraulic Drive Assembly .................................. 54-55

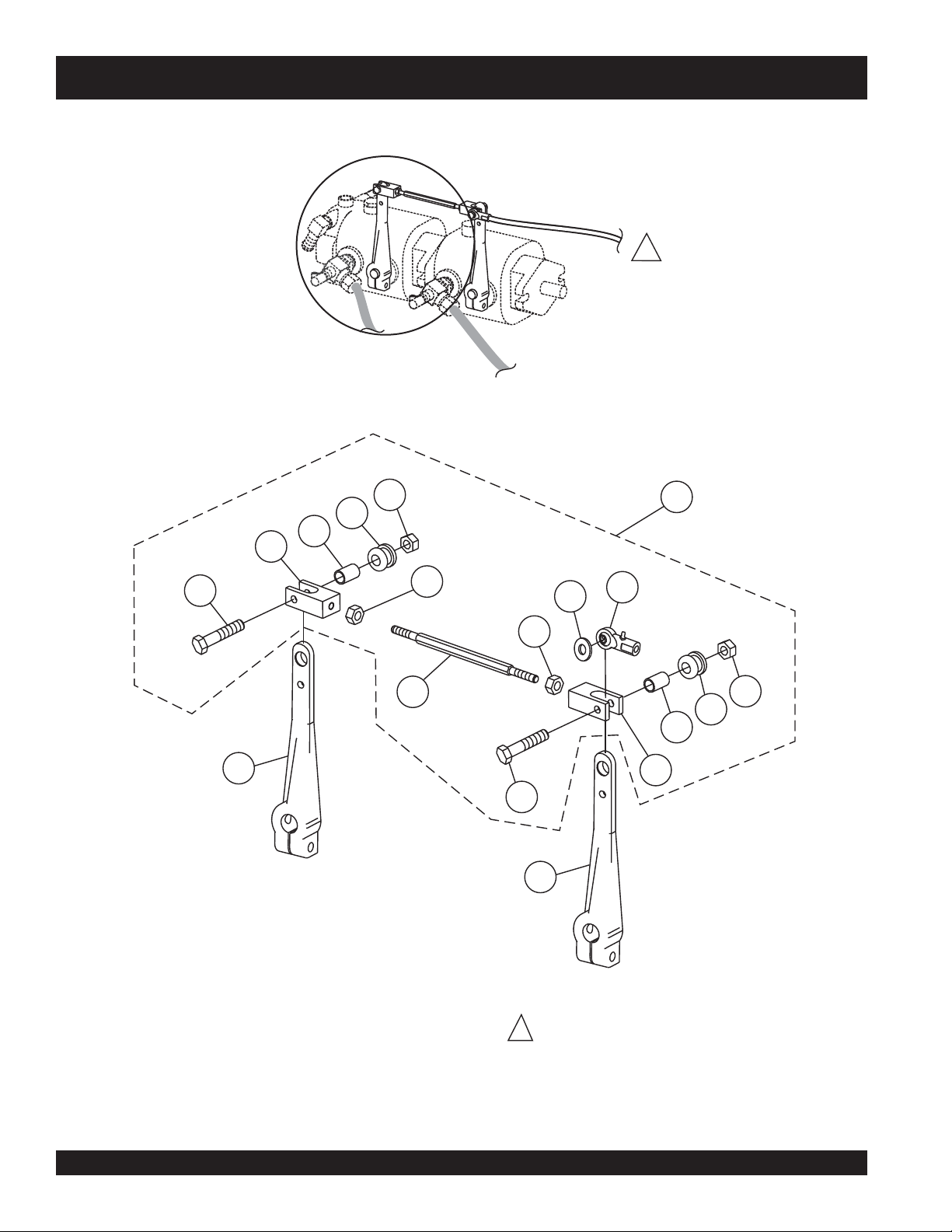

Hydraulic Drive Pump Lever Assy. .................... 56-57

Hydraulic Drive Filters and Cooling................... 58-59

Five Blade Spider Assy. (Left) ........................... 60-61

Five Blade Spider Assy. (Right) ......................... 62-63

Stabilizer Ring Assy. .......................................... 64-65

Locator Decals ................................................... 66-67

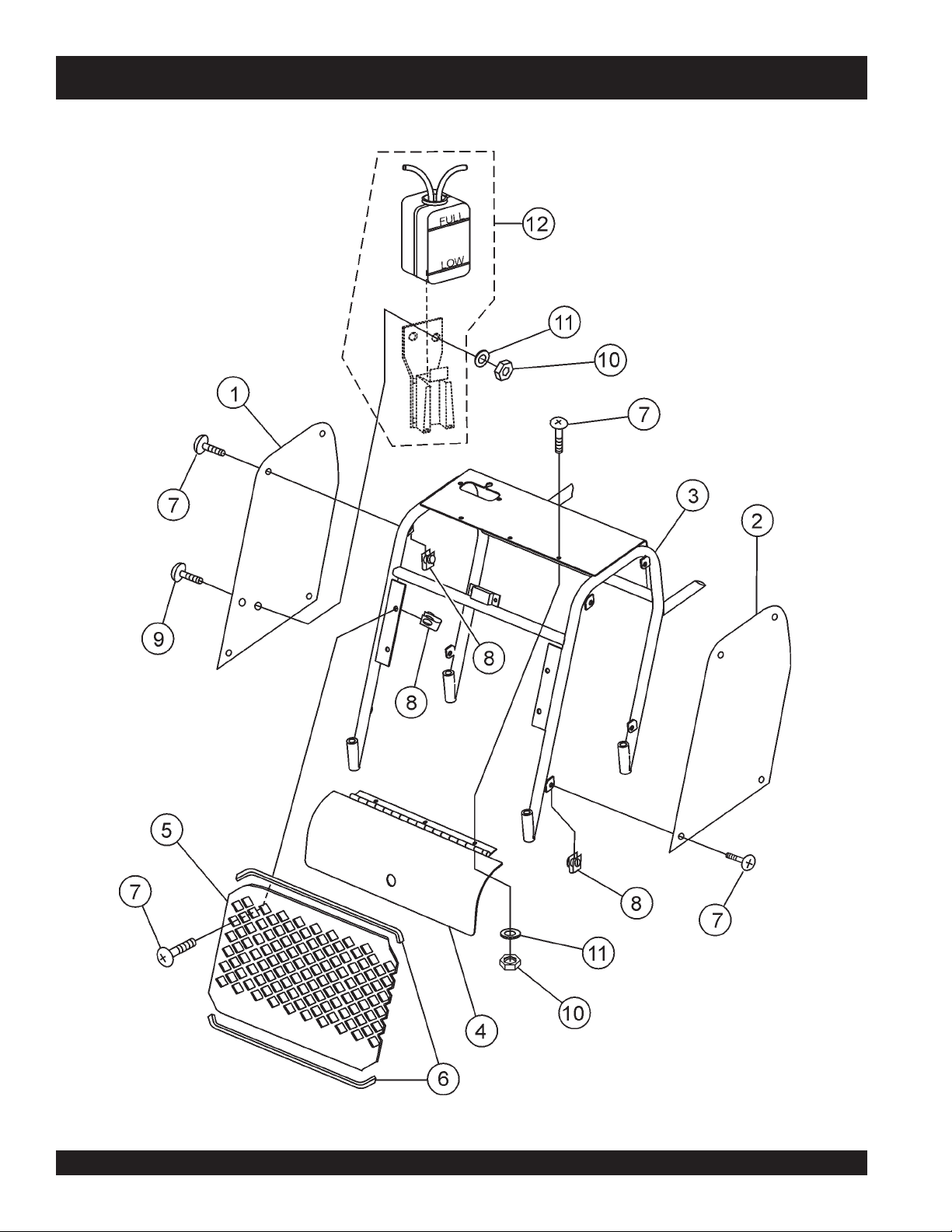

Top Panel (Left) .................................................. 68-69

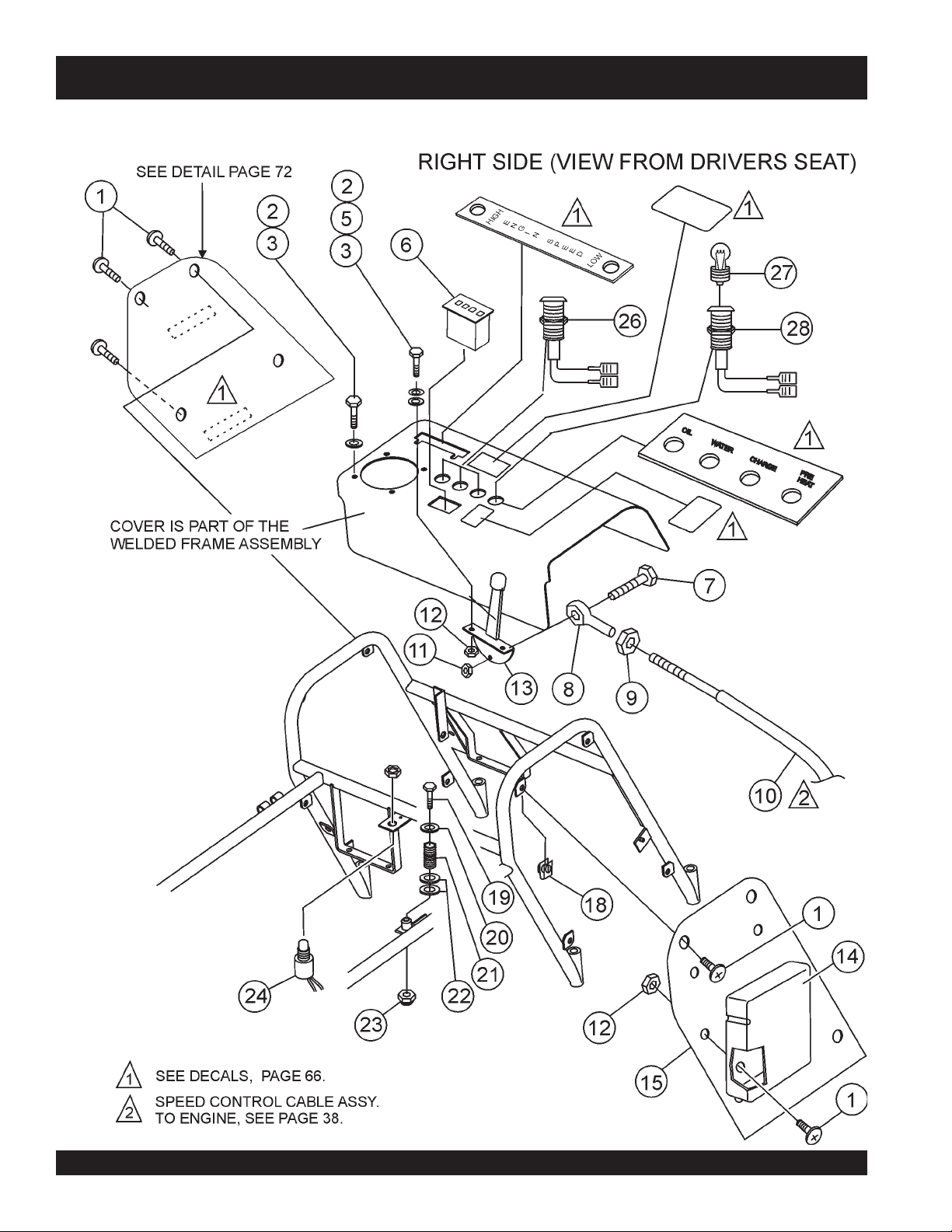

Top Panel (Right) ............................................... 70-71

Front Panel (Right) ............................................. 72-73

Seat and Frame ................................................. 74-75

Frame and Fuel Tank ......................................... 76-77

Foot Pedals ........................................................ 78-79

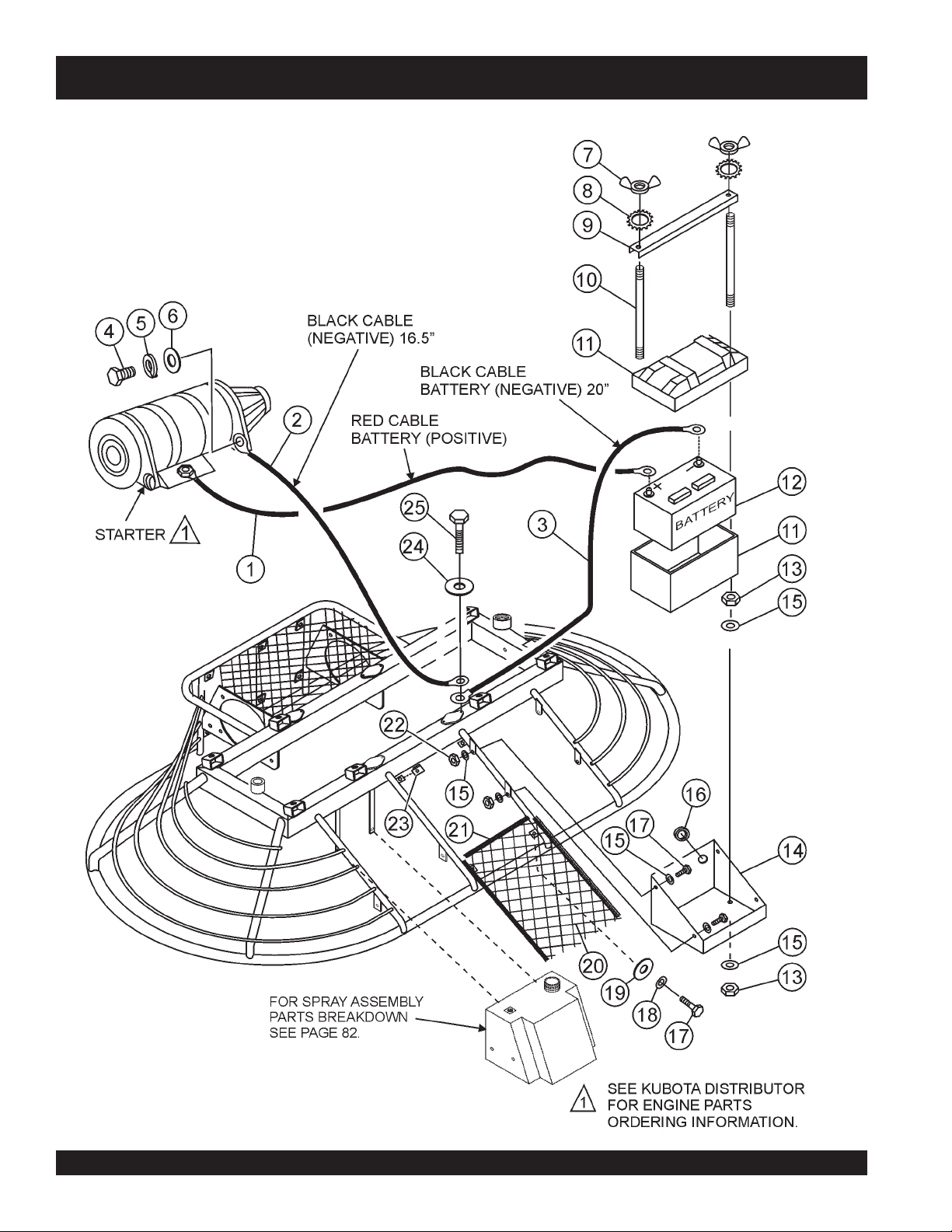

Battery ................................................................ 80-81

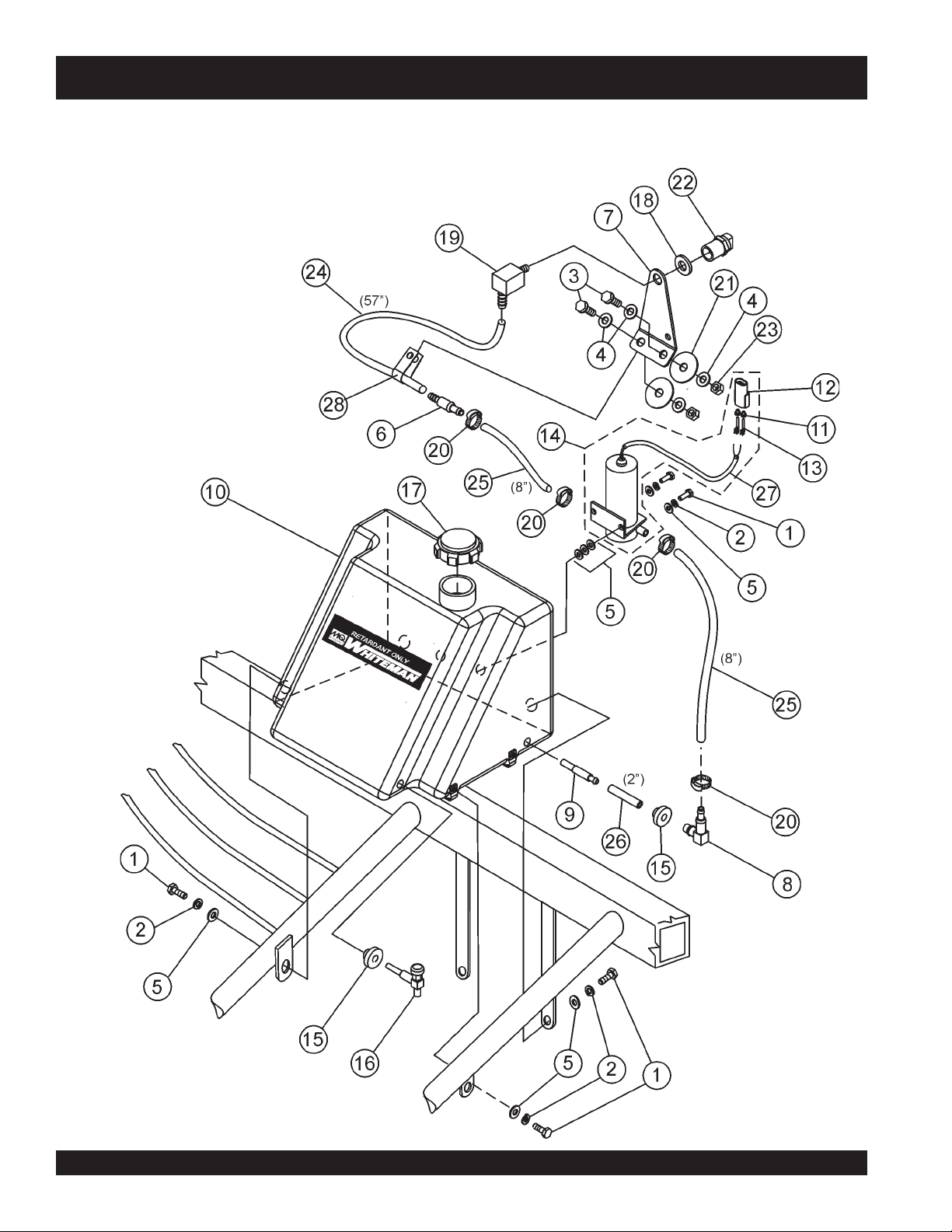

Spray Assy. ........................................................ 82-83

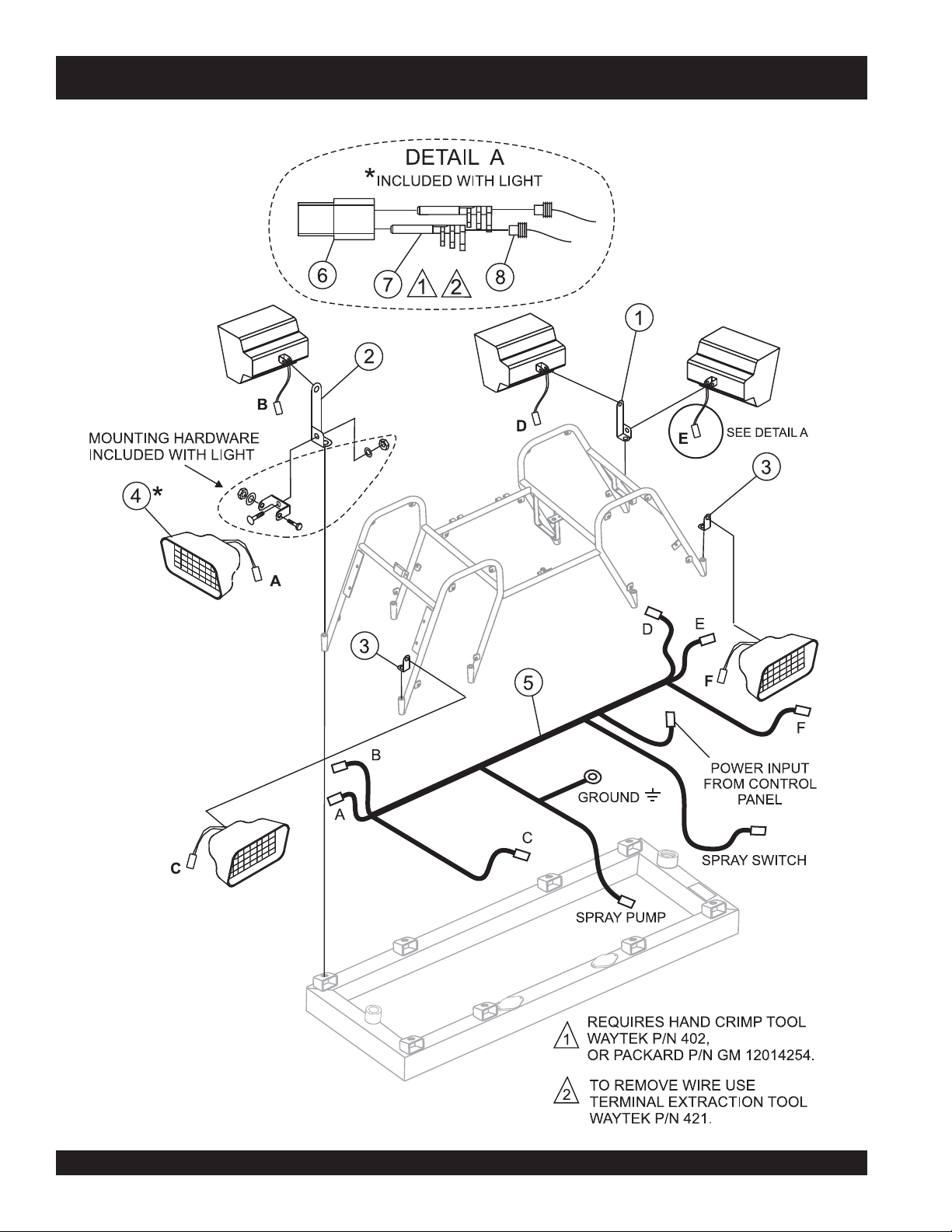

Light Assy. .......................................................... 84-85

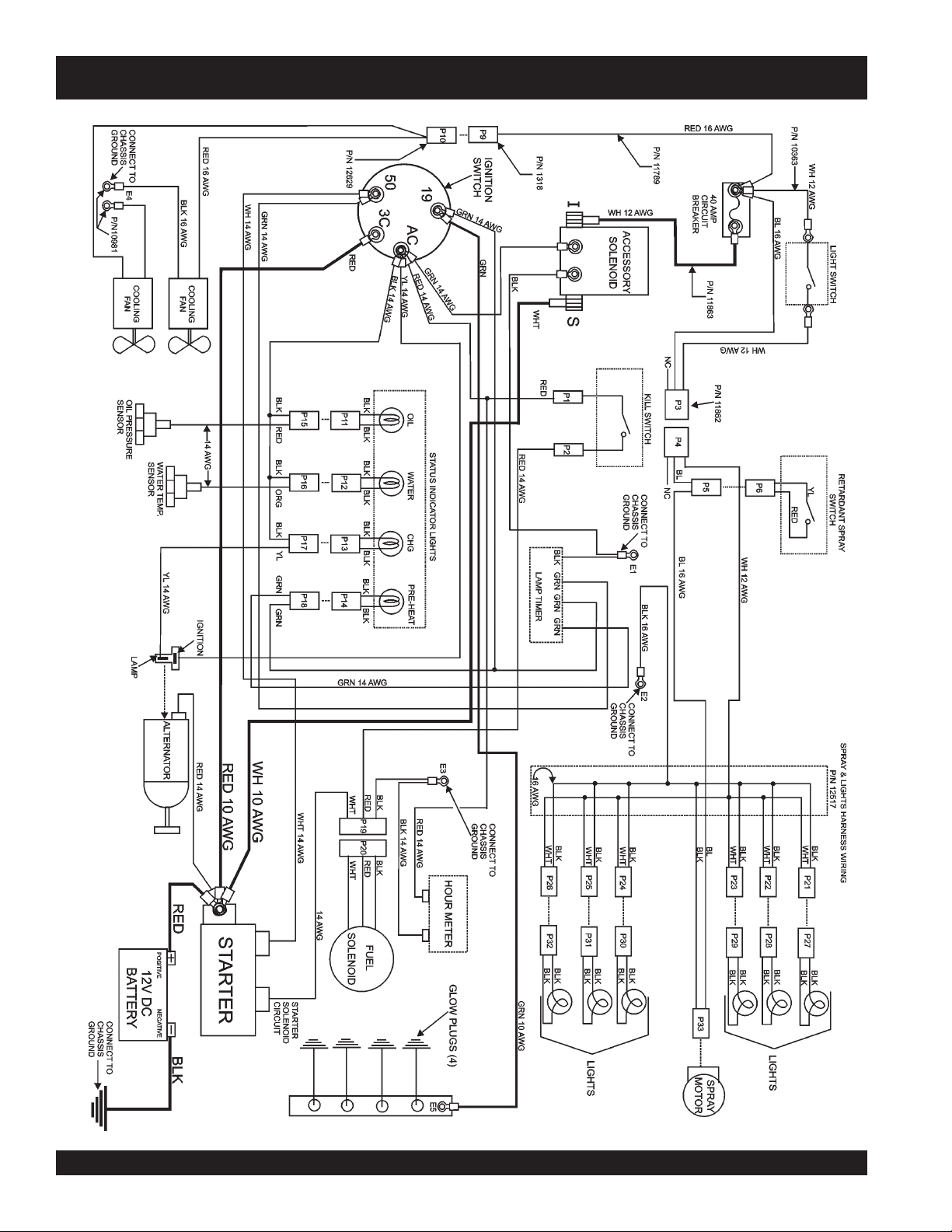

Wiring Diagram ....................................................... 86

KUBOTA V1505 ENGINE

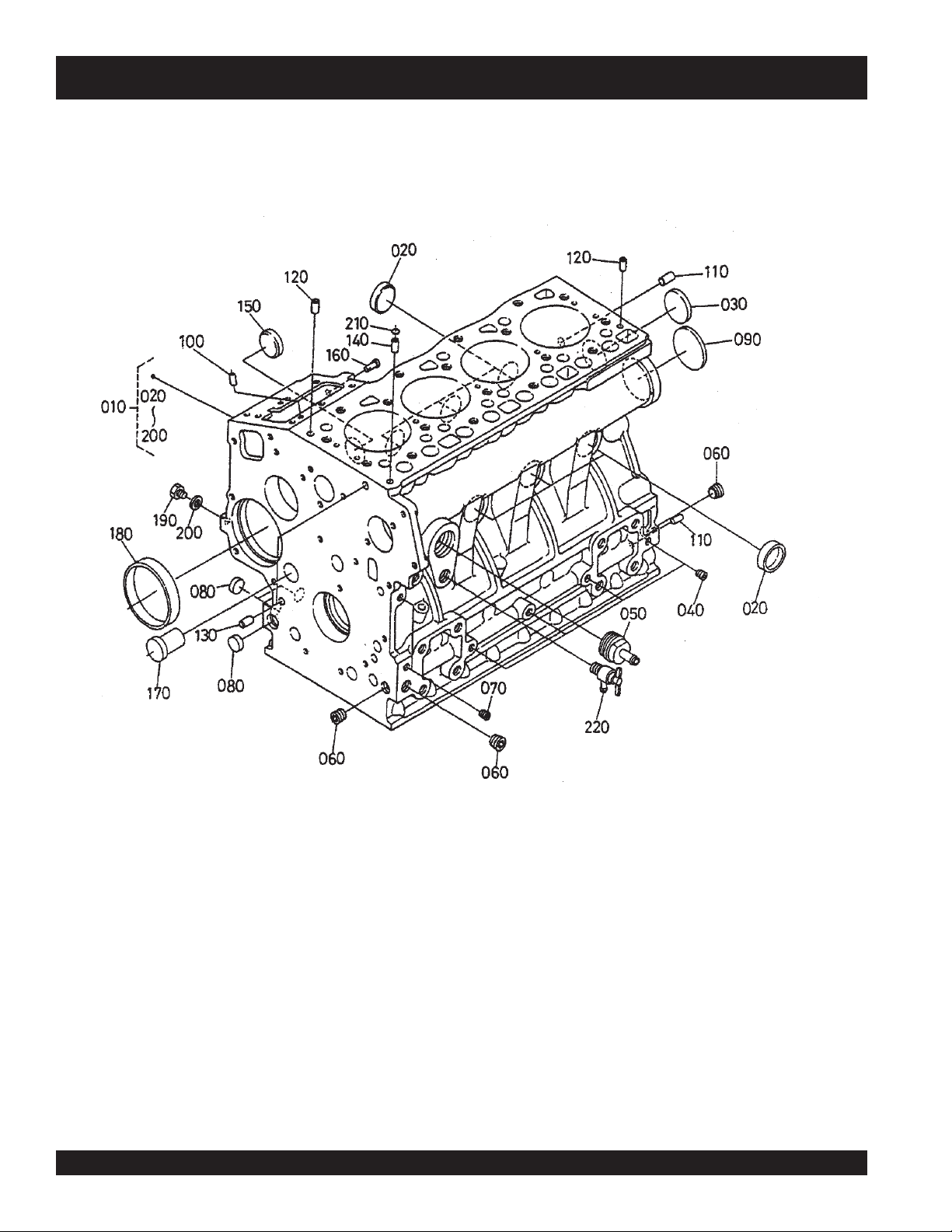

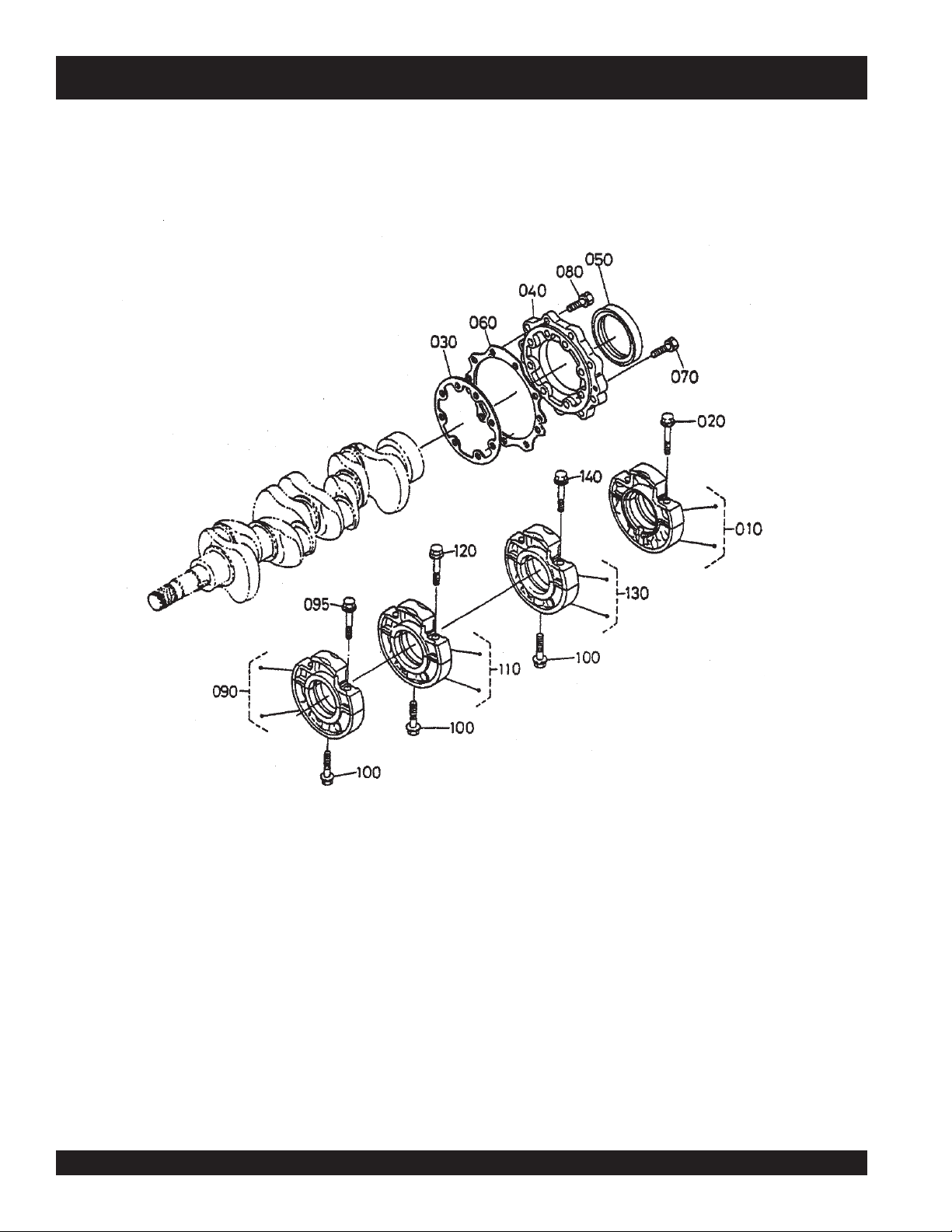

Crankcase Assembly ......................................... 88-89

Oil Pan Assembly ............................................... 90-91

Cylinder Head Assembly .................................... 92-93

Gear Case Assembly ......................................... 94-95

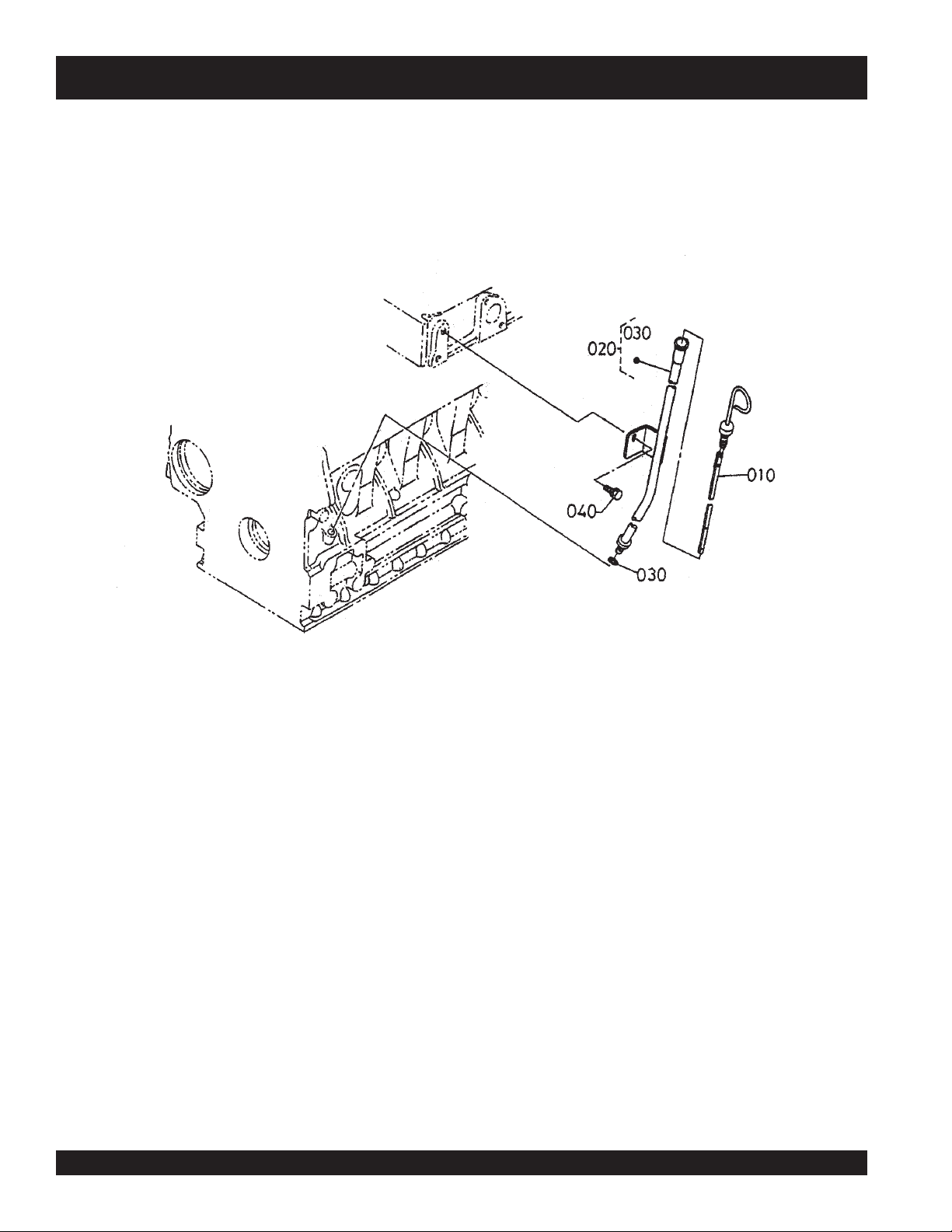

Dipstick and Guide Assembly ............................ 96-97

Main Bearing Case Assembly ............................ 98-99

Camshaft and Idle Gear Shaft Assembly ....... 100-101

Piston and Crankshaft Assembly ................... 102-103

Flywheel Assembly ........................................ 104-105

Fuel Camshaft and Governor Shaft Assy. ...... 106-107

Engine Stop Lever Assembly ......................... 108-109

Stop Solenoid Assembly ................................. 110-111

Injection Pump Assembly ............................... 112-113

Nozzle Holder Assembly ................................ 114-115

Nozzle Holder Assy(Component Parts) ......... 116-117

Fork Lever (Governor) Assembly ................... 118-119

Fuel Pump (Mechanical) Assembly................ 120-121

Alternator and Pulley Assembly ..................... 122-123

Alternator (Component Parts) Assembly ....... 124-125

Starter Assembly ............................................ 126-127

Starter (Component Parts) Assembly ............ 128-129

Oil Switch/Thermometer & Plug Assy. ........... 130-131

Water flang and Thermostat Assembly .......... 132-133

Water Pump Assembly ................................... 134-135

Water Pipe Assembly ..................................... 136-137

Fan Assembly................................................. 138-139

Valve and Rocker Arm Assembly ................... 140-141

Inlet Manifold Assembly ................................. 142-143

Exhaust Manifold Assembly ........................... 144-145

Turbo-Charger Assembly ............................... 146-147

Oil Pipe Turbo-Charger Assembly .................. 148-149

Hydraulic Pump Assembly ............................. 150-151

Oil Cooler Assembly....................................... 152-153

Glow Plug/Lamp and Timer Assembly ........... 154-155

Engine Stand Assembly ................................. 156-157

Accessories and Service Parts Assy. ............. 158-159

Labels............................................................. 160-161

Terms and Conditions of Sale — Parts ................. 162

PAGE 4 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 5

r

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Parts

Order via Fax

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

(Dealers Only)

to log in and save!

(Dealers Only)

:

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact you

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

:

Domestic (US) Dealers Call:

1-800-427-1244

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Tr uck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 5

— PAGE RM

Page 6

HTH44T— TRAINING CHECKLIST

TRAINING CHECKLIST

This checklist will lists some of the minimum requirements for

machine maintenance and operation. Please feel free to detach

it and make copies. Use this checklist whenever a new operator

is to be trained or it can be used as a review for more

experienced operator’s.

.ON NOITPIRCSED ?KO ETAD

1 .yletelpmoclaunaMs’rotarepOdaeR

TSILKCEHCGNINIART

2

3 erudecorpgnileufer,metsysleuF

4 .)deppiuqefi(sthgildnayarpsfonoitarepO

5 .)gninnurtonenihcam(slortnocfonoitarepO

6 .noitarepohctiwslliktaes,slortnocytefaS

7 .serudecorppotsycnegremE

8 .ekohcenigne,)atobuK(taeh-erp,enihcamfoputratS

9 .revohagniniatniaM

01 gnirevuenaM

11 gnihctiP

21 ™hctiPniwT.srewotneewtebhctipedalbgnihctaM

31 .seuqinhcetgnihsinifetercnoC

41 .enihcamfonwodtuhS

.slevel

liociluardyhdnaenignefognikcehc,stnenopmocfonoitacol,tuoyalenihcaM

51 .)spooltfil(enihcamfognitfiL

61 .egarotsdnatropsnartenihcaM

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

PAGE 6 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 7

DAILY PRE-OPERATION CHECKLIST

1 .levellioenignE

2 .levelliociluardyH

3 .leveltnaloocrotaidaR

4 .sedalbfonoitidnoC

5 .noitarepohctipedalB

6 .noitarepo)taes(hctiwslliK

7 .noitarepolortnocgnireetS

COMMENTS:

HTH44T— DAILY PRE-OPERATION CHECKLIST

TSILKCEHCNOITAREPO-ERPYLIAD

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 7

— PAGE RM

Page 8

HTH44T— SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when operating

this equipment. Failure to read and understand the Safety

Messages and Operating Instructions could result in injury to

yourself and others.

HAZARD SYMBOLS

NOTE

This Owner's Manual has been developed to provide

complete instructions for the safe and efficient operation

of the MQ Whiteman HTH44T Ride-On Power Trowel.

For engine maintenance information, please refer to the

engine manufacturers instructions for data relative to its

safe operations.

Before using this Ride -On Power Trowel, ensure that

the operating individual has read and understands

all instructions in this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you about

potential hazards that could injure you or others. The Safety

Messages specifically address the level of exposure to the

operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

Gasoline is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT fill the fuel tank

while the engine is running or hot. DO NOT

overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or

sparks from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGER: You WILL be KILLED or

SERIOUSLY injured if you DO NOT follow

directions.

WARNING: You CAN be KILLED or

SERIOUSLY injured if you DO NOT follow

directions.

CAUTION: You CAN be injured if you

DO NOT follow directions.

Potential hazards associated with HTH44T Ride-on Power

Trowel operation will be referenced with Hazard Symbols which

appear throughout this manual, and will be referenced in

conjunction with Safety Message Alert Symbols.

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. NEVER operate the engine with

heat shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep fingers, hands, hair and

clothing away from all moving parts to prevent

injury.

PAGE 8 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 9

HTH44T— SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting

ALWAYS place the ON/OFF switch in the

OFF position, and remove the key.

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

NOTE

This Ride-On Power Trowel, other property,

or the surrounding environment could be

damaged if you do not follow instructions.

Respiratory Hazard

ALWAYS wear approved respiratory

protection.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Equipment Damage Messages

Other important messages are provided throughout this manual

to help prevent damage to your trowel, other property, or the

surrounding environment.

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 9

— PAGE RM

Page 10

HTH44T— RULES FOR SAFE OPERATION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by

qualified personnel only! This equipment is

for industrial use only and should not be

regarded as a toy.

The following safety guidelines should always be used when

operating the HTH44T Ride-on Power Trowel:

GENERAL SAFETY

■

DO NOT operate or service this equipment before reading

this entire manual.

■

This equipment should not be operated by persons under

18 years of age.

■

DO NOT operate this equipment unless all guards and

safety devices are attached and in place.

■

ALWAYS use proper

equipment. This ride-on trowel is very heavy. It should be

lifted only with a lifting device (i.e. crane, forklift, etc.) with

a lifting capacity of at least one ton.

■

ALWAYS check to make sure that the operating area is

clear before starting the engine.

heavy

lifting techniques when moving

trained and

Emergencies

Maintenance Safety

■

Disconnect the battery and spark plug wires before

attempting any type of service.

■

Securely support any machine components that must be

raised.

■

NEVER lubricate components or attempt service on a

running machine.

■

ALWAYS allow the machine a proper amount of time to

cool before servicing.

■

Keep the machinery in proper running condition.

■

High Temperatures – Allow the machine

and engine to cool before adding fuel or

performing service and maintenance

hot

functions. Contact with

cause serious burns.

■

ALWAYS know the location of the

nearest

Know the location of the nearest telephone.

Also know the phone numbers of the

nearest

department

invaluable in the case of an emergency.

fire extinguisher

ambulance, doctor

. This information will be

components can

and

first aid kit

and

.

fire

■

ALWAYS test the safety

equipment.

■

NEVER place your feet inside the guard rings while starting

or operating this equipment.

■

NEVER operate this equipment without proper

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job. Avoid wearing

jewelry or loose fitting clothing that may snag on the controls

or moving parts, this can cause a serious injury.

■

ALWAYS keep clear of rotating or moving parts while

operating this equipment.

■

NEVER leave the machine

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

■

ALWAYS use extreme caution when working with

flammable liquids

allow it to cool

Fire or explosion could result from flames or sparks, or if

fuel is spilled on a hot engine.

■

Moving Parts – Shut down the engine before performing

service or maintenance functions. Contact with moving

parts can cause serious injury.

.

DO NOT smoke around or near the machine.

kill switch

unattended

. When refueling,

before operating the

stop the

protective

while running.

engine and

■

■

■

■

■

Make sure that there is no buildup of concrete, grease, oil

or debris on the machine.

Fix damage to the machine immediately and always replace

broken parts.

Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor oil, fuel and

fuel filters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

PAGE 10 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 11

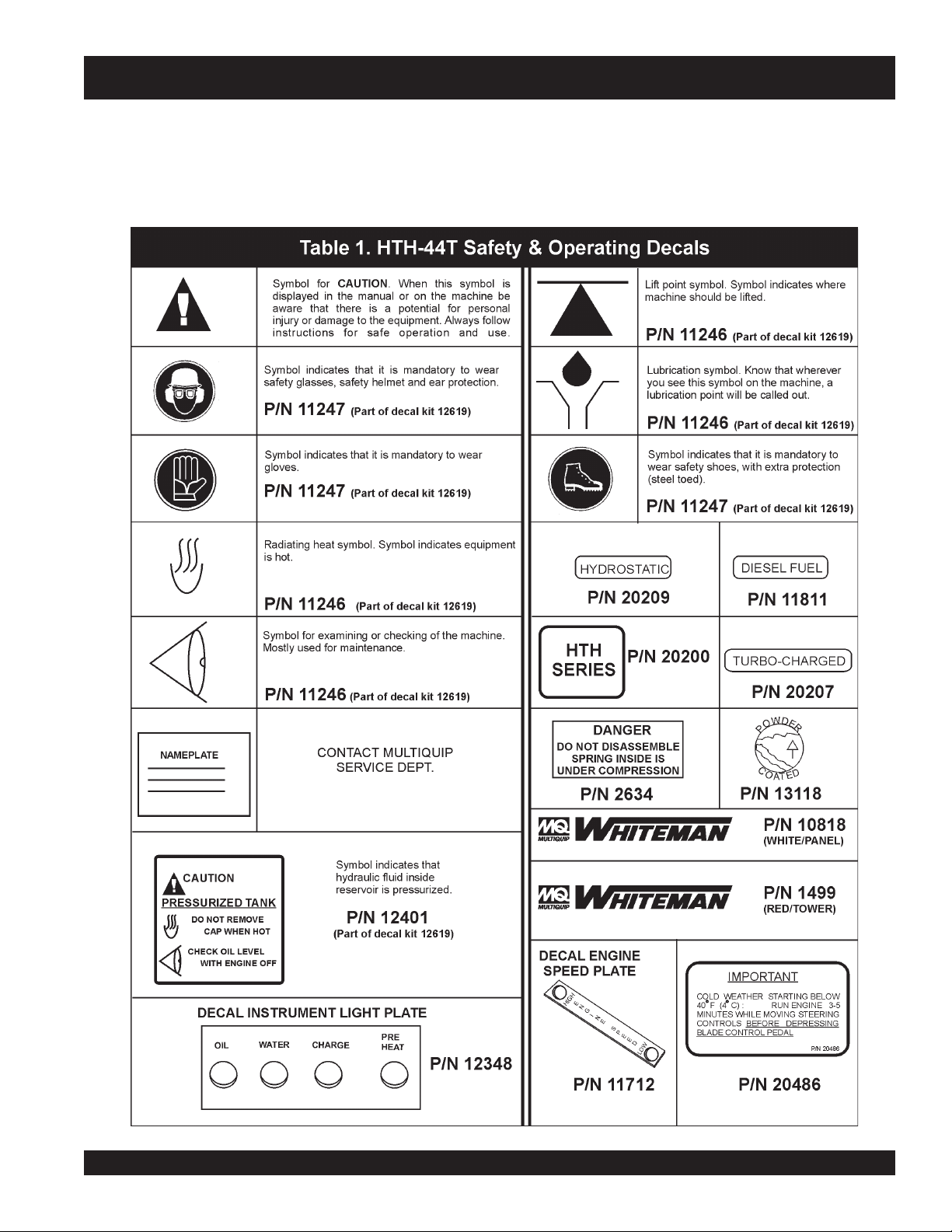

HTH44T— OPERATION AND SAFETY DECALS

Machine Safety Decals

The HTH44T series Ride-on Power Trowel is equipped with a number of safety decals. These decals are provided for operator

safety and maintenance information. Table 1 below illustrates these decals as they appear on the machine. Should any of these

decals become unreadable, replacements can be obtained from your dealer.

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 11

— PAGE RM

Page 12

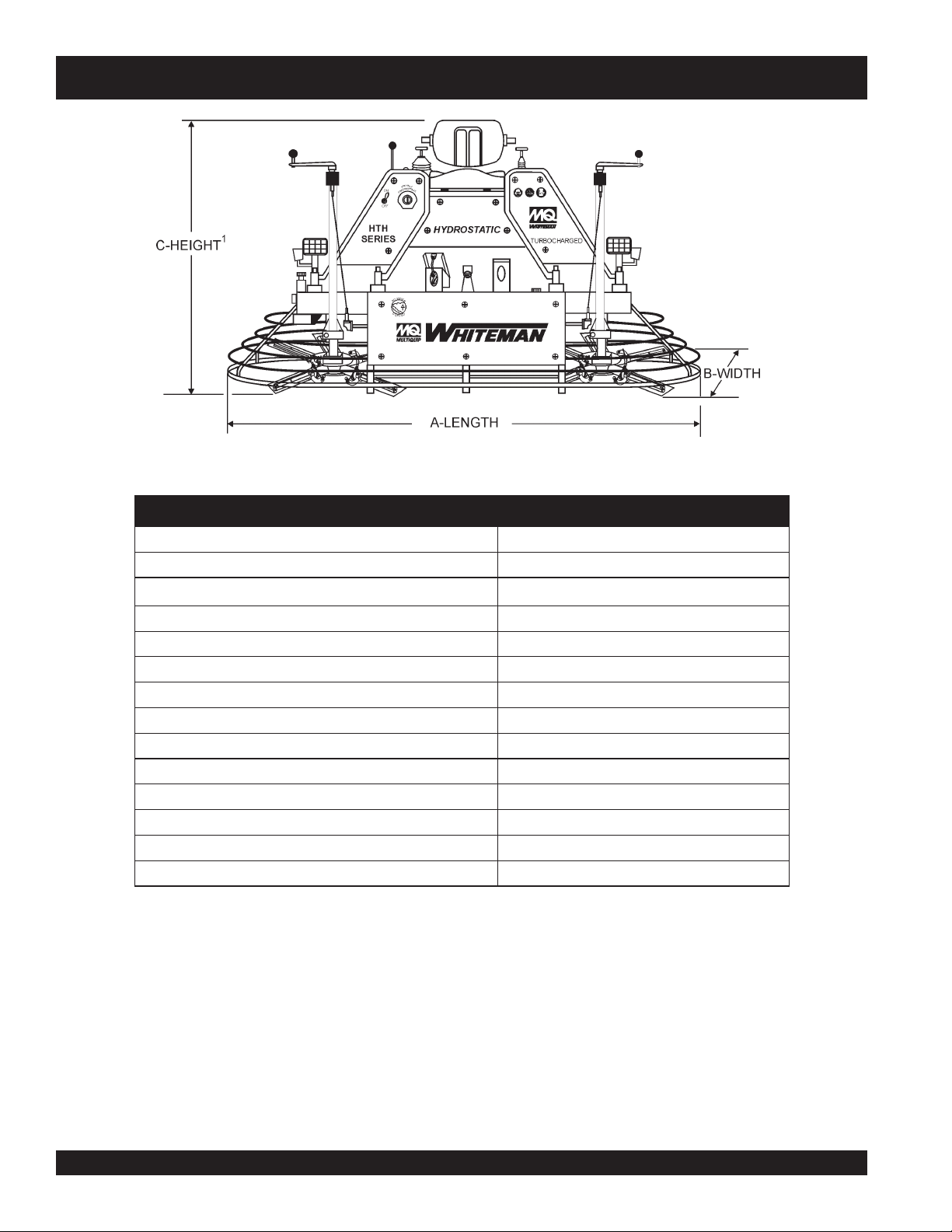

HTH44T— SPECIFICATIONS

Figure 1. HTH44T Dimension /Specifications

snoitacificepST44-HTH.2elbaT

)mc(.ni–htgneL–A )8.342(00.69

)mc(.ni–htdiW–B )721(0.05

1

)mc(.ni–thgieH–C

gnitarepO).sgk(.sbl–thgieW )007(545,1

gnippihS).sgk(.sbl–thgieW )838(848,1

2

ABd–erusserPdnuoS

2

s/tf–noitarbiV

2)3

s/m(

)s/m(MPF–deepSpiTedalB )9.9(4291

.P.H–enignE 44

)sretil(snollag–knaTleuF )54(21

MPR–rotoR 061ot0

)mc(.ni–htdiWhtaP )332(29

4

liOciluardyH

enignE ET-5051VleseiDatobuK

NOTE:

1. This value includes the seat height.

2. Sound pressure is a weighted measure. Measured at the

operators ear position while the ride-on trowel is operating

at full throttle on concrete in a manner most often

experienced in “

may vary depending upon the condition of the concrete.

Hearing protection is always recommended.

3. The vibration level indicated is the maximum RMS (Root

Mean Square) value obtained at the handle grip while

operating the ride-on trowel on curing concrete in a

normal

” circumstances. Sound pressure

manner

most often experienced in “

Values were obtained from all three axes of motion. The

values shown represent the maximum RMS value from

these measurements.

4. “AW” stands for

viscosity

and is similar to 10W-30-motor oil. It is recommended

that AW MV 68 hydraulic oil be used. If this type of

hydraulic oil is not available then use 10W-30.

)241(0.65

ABT

ABT

86VMWA

normal

anti-wear

. The 68 refers to the general viscosity range

and “MV” stands for

” circumstances.

multi-

PAGE 12 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 13

HTH44T— GENERAL INFORMATION

HTH44TRIDE-ON TROWEL FAMILIARIZATION

The HTH44T series Ride-On Power Trowels are designed for

the floating and finishing of concrete slabs.

Take a walk around the HTH44T Ride-On Power Trowel. Take

notice of all the entire major components (see Figures 2 and

3, pages 14 and 15) like the engine, blades, pitch towers, air

cleaner, ignition switch etc. Check that there is always oil in

the engine, and hydraulic oil in the hydraulic oil reservoir.

Read all the safety instructions carefully. Safety instructions

will be found throughout this manual and on the machine. Keep

all safety information in good, readable condition. Operators

should be well trained on the operation and maintenance of

the HTH44T Ride-On Power Trowel.

Before using your HTH44T Ride-On Power Trowel, test it on a

flat watered down section of finished concrete. This trial test run

will increase your confidence in using the trowel and at the same

time it will familiarize you with the trowel’s controls and indicators.

In addition you will understand how the trowel will handle under

actual conditions.

Engine

The HTH44T Ride-On Power Trowel is available with a standard

V1505-TE Kubota diesel engine. Refer to the engine owner’s

manual for specific instructions regarding engine operation. This

manual is included with the ride-on trowel at the time of shipping

from Whiteman. Please contact your nearest Multiquip Dealer

for a replacement should the original manual disappear.

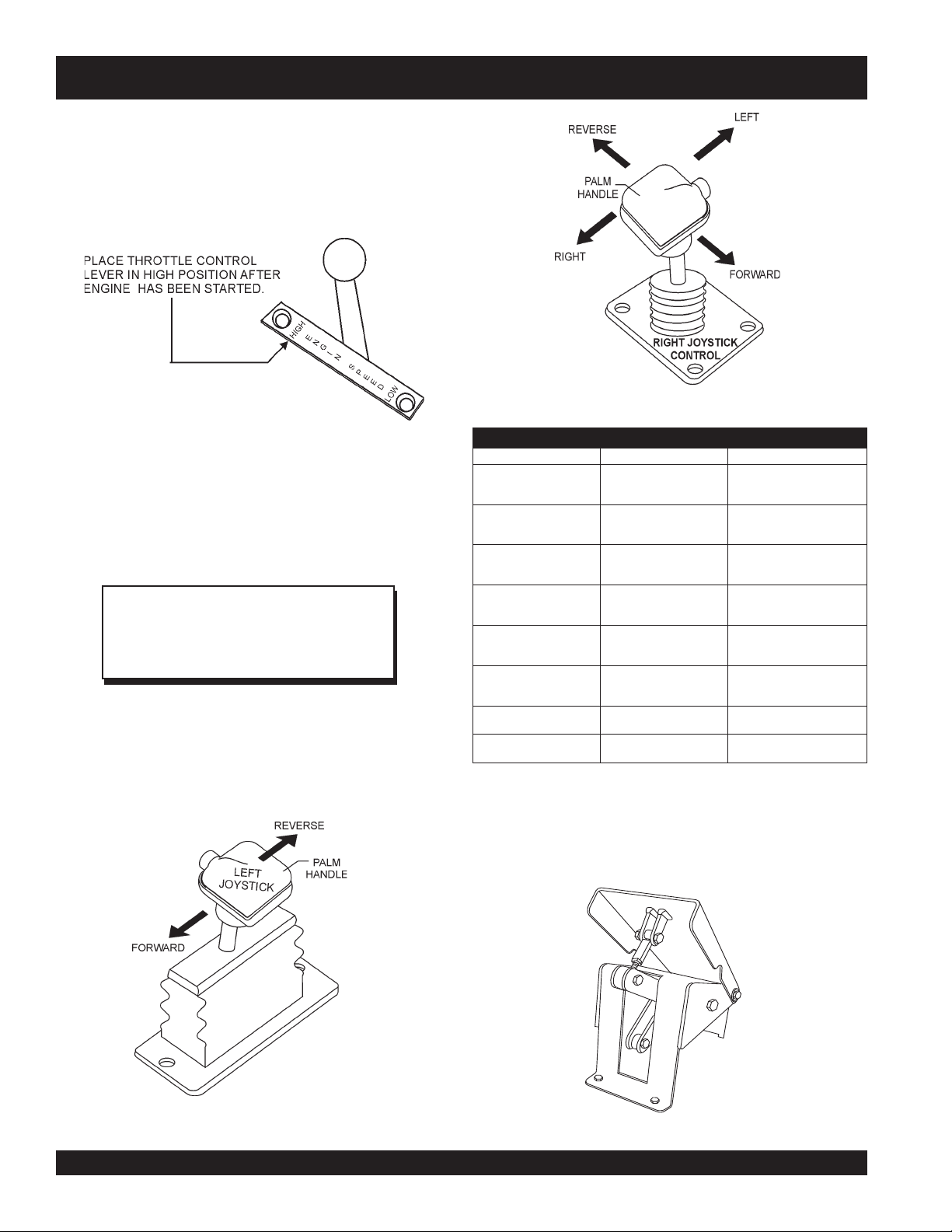

Dual joystick controls located to the left and right of the operator

are provided for steering the HTH44T Ride-on Power Trowel.

The joysticks are linked to three hydraulic steering cylinders

located within the frame of the machine. When the right side

steering joystick is moved either forward or backward it will

cause that side of the Ride-on Power Trowel to move in either

a forward or reverse direction. Moving the same joystick left

or right causes the trowel to move in either the left or right

direction.

When the left side steering joystick is moved, it will cause the

left side of the Ride-on Power Trowel to travel in either a

forward or reverse direction.

Hydraulic Pump

Delivers a continuous controlled flow of hydraulic fluid to the

hydraulic motors.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Moving the Ride-On Trowel

This Ride-on Power Trowel is very

and awkward to move around. Use proper

heavy lifting procedures and DO NOT

attempt to lift the Ride-on Power Trowel by

the guard rings

heavy

Blades

The blades of the Ride-on Power Trowel finish the concrete as

they are swirled around the surface. Blades are classified as

float (10 or 8 inches wide), and finish (6 inches wide). The

HTH44T is equipped with five blades per rotor equally spaced

in a radial pattern and attached to vertical rotating shaft by

means of a

Hydraulic Motor

Independent hydrostatic drive motors are coupled to the

engine-powered hydrostatic pumps. Each motor drives a spider

assembly.

Hydraulic Steering

spider assembly.

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 13

The HTH44T series Ride-on Power Trowel is designed to be

moved and handled several ways. The easiest way to lift the

.

ride-on trowel is to utilize the lift loops that are welded to the

frame. These lift loops are located to the left and right sides of

the operator’s seat (Figure 3, Page 15).

A strap or chain can be attached to these lift loops, allowing a

forklift or crane to lift the Ride-on Power Trowel up onto a slab

of concrete. The strap or chain should have a minimum 2,000

pounds (1000-kg) lifting capacity and the lifting gear must be

capable of lifting at least this amount.

Training

For proper training, please use the “TRAINING CHECKLIST”

located in the front of this manual (Page 6). This checklist will

provide an outline for an experienced operator to provide

training to a new operator

— PAGE RM

Page 14

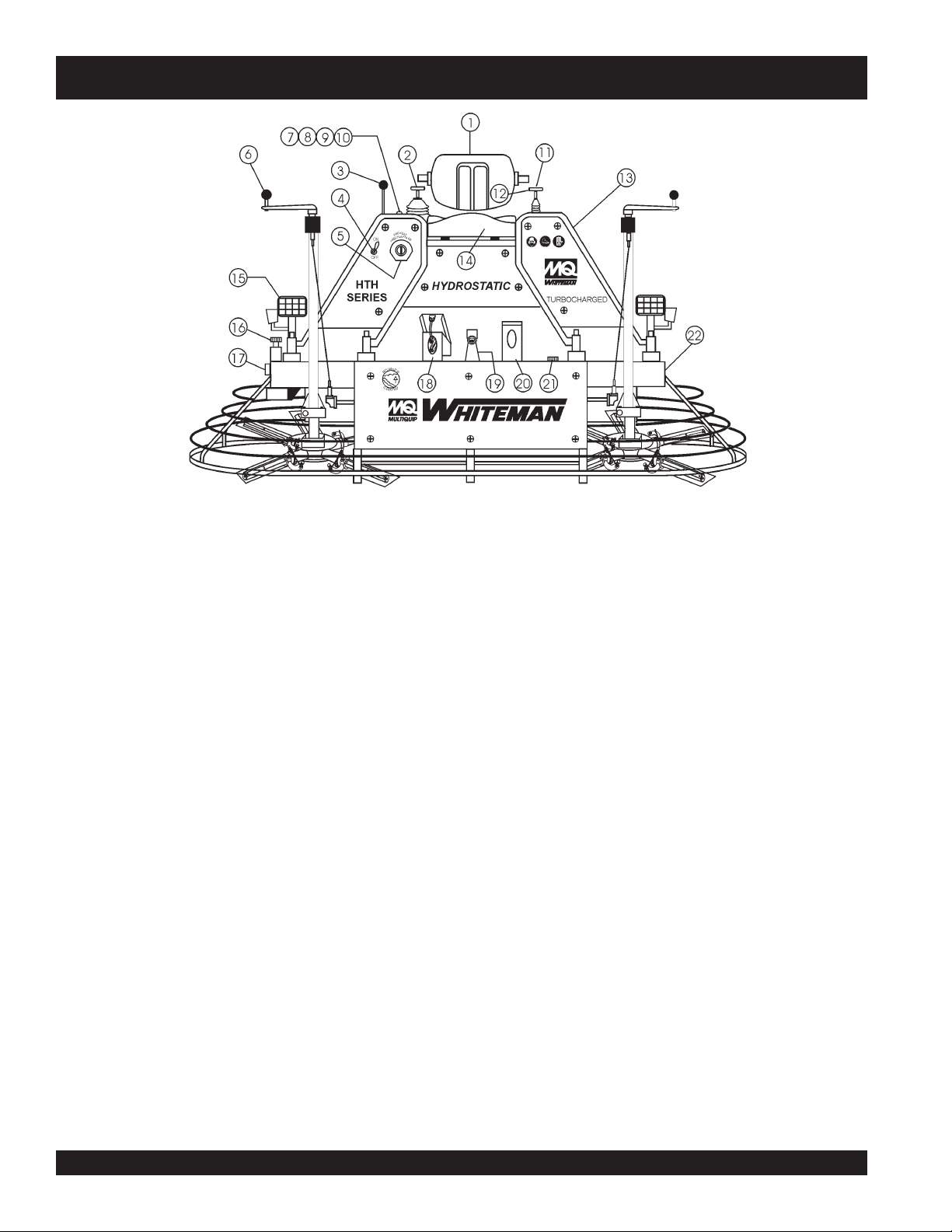

HTH44T— CONTROLS AND INDICATORS

Figure 2. HTH44T Controls and Indicators (Front)

Figures 2 and 3 (pages 12 and 13) show the location of the

controls, indicators and general maintenance parts. The

function of each control, indicator or maintenance part is

explained below:

1. Seat – Place for operator to sit. Engine will not start unless

operator is seated. Seat is adjustable.

2. Steering Control (right side) -Allows the unit to move

in either a forward, reverse left or right direction.

3. Throttle Control Lever – Controls the speed of the

engine. Move the hand lever forward to increase engine

speed (high), backwards to decrease engine speed (low).

4. Light Switch – When activated, turns on six halogen

lights. Lights offer better visibility when working indoors.

5. Ignition Switch – With key inserted turn clockwise to

start engine.

6. Twin Pitch Control – Both pitch towers are linked

together. One crank may be turned to adjust the blade

pitch simultaneously or individually control for each set

of blades.

7. Pre-Heat Indicator Light - Lights blue during engine

start-up. Indicates that engine glow plugs are being preheated. Light will go off after approximately 10 seconds.

8. Charge Indicator Light - Lights red when electrical

system is not charging properly.

9. Water Indicator Light - Lights red when water

temperature is high.

10. Oil Indicator Light - Lights red when oil pressure is low.

11. Steering Control (left side) -Allows the unit to move in a

forward or reverse direction only.

12. Retardant Spray Control Button – When pressed allows

retardant spray to flow through the spray nozzle located

at the front of the machine.

13. Radiator/Filler Cap –Holds coolant or water necessary

to keep engine at a safe operating temperature. Remove

this cap to add water or antifreeze.

14. Kill Switch - Shuts down engine when operator is not

sitting in seat.

15. Lights – Low voltage halogen light.

16. Hydraulic Oil Filler Cap – Remove this cap to add

hydraulic oil.

17. Hydraulic Oil Sight Glass - Indicates the level of the

hydraulic oil in the reservoir.

18. Right Foot Pedal – Controls blade speed. Slow blade

speed is accomplished by slightly depressing the foot

pedal. Maximum blade speed is accomplished by fully

depressing the foot pedal.

19. Spray Nozzle – Spray nozzle for retardant.

20. Left Foot Riser – Operator foot rest pedal.

21. Fuel Gauge/Filler Cap - Indicates the amount of fuel in

the fuel tank. Remove this cap to add fuel.

22. Hydraulic Reservoir – Part of frame. Holds hydraulic oil

necessary for pump operation.

PAGE 14 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 15

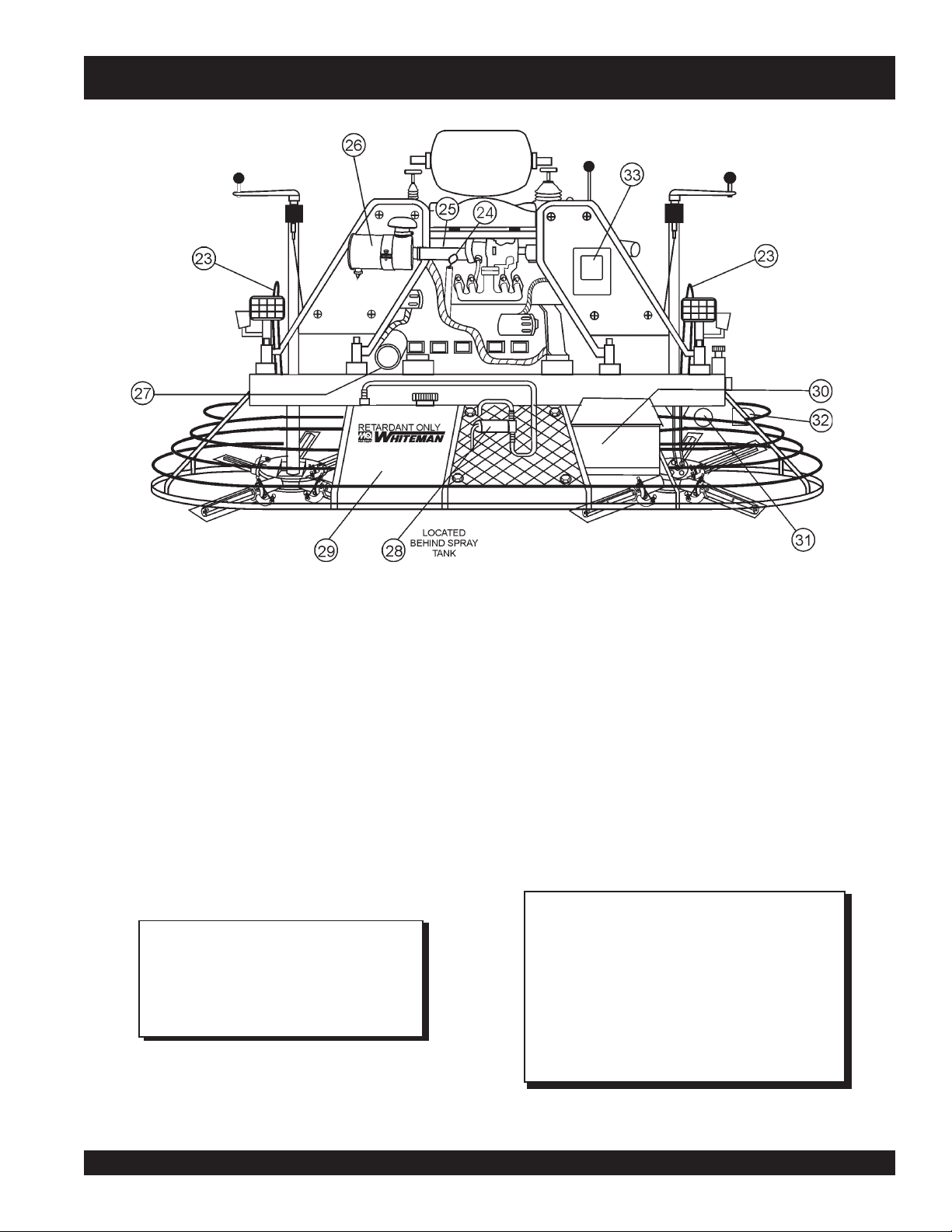

HTH44T— CONTROLS AND INDICATORS

Figure 3. HTH44T Controls and Indicators (Rear)

23. Lift Loops –Located on both the left and right sides of

the main frame. Used when the trowel must be lifted onto

a concrete slab.

24. Engine Oil Dipstick – Indicates engine oil level.

25. Engine Oil Filler Cap - Remove this cap to add engine

oil.

26. Air Filter – Prevents dirt and other debris from entering

the fuel system.

27. Oil Filter – Provides oil filtering for the engine.

28. Retardant Spray Motor – Used with the spray control

button.

NOTE

Read this entire instruction manual

Specification and part number

completely before attempting to operate this

are subject to change without

machine.

notice.

29. Retardant Spray Tank - Holds 5 gallons of retardant or

30. Battery - Provides +12V DC power to the electrical

31. Hydraulic Suction Filter - Filters hydraulic fluid prior to

32. Hydraulic Return Filter - Filters hydraulic returning to

33. Documentation Box - Contains information regarding

water.

system.

entering the system.

reservoir.

the trowel.

NOTE

The following section is intended as a basic guide

to the Ride-On Power Trowel operation, and is

not to be considered a complete guide to concrete

finishing. It is strongly suggested that all operators

(experienced and novice) read “

published by the American Concrete Institute,

Detroit Michigan.

Slabs on Grade

”

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 15

— PAGE RM

Page 16

HTH44T— INITIAL START-UP

This section is intended to assist the operator with the initial

start-up of the HTH44T series Ride-On Power Trowel. It is

extremely important that this section be read carefully before

attempting to use the trowel in the field.

DO NOT use your Ride-On Power Trowel until this section is

thoroughly understood

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Failure to understand the operation of the

HTH44T series Ride-On Power Trowel could

result in severe damage to the trowel or

personal injury.

See Figures 2 and 3 (Pages 12 and 13) for the location of any

control or indicator referenced in this manual.

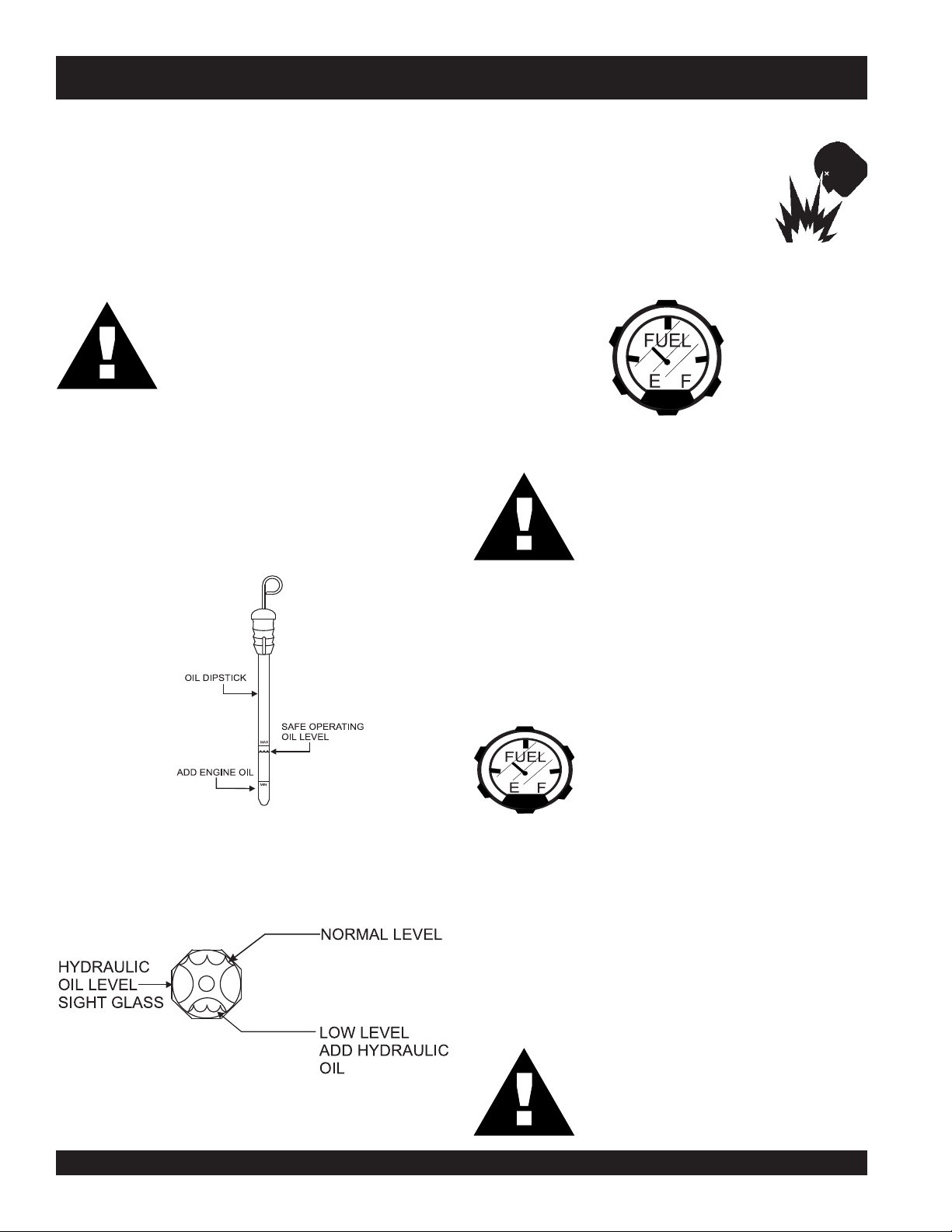

Engine Oil

1. Pull the engine oil dipstick from its holder.

2. Determine if engine oil is low (Figure 4), add correct

amount of engine oil to bring oil level to a normal safe

level.

Fuel

1. Determine if the engine fuel is low (Figure

6). If fuel level is low, remove the fuel filler

cap and fill with diesel fuel. Handle fuel

safely. Motor fuels are highly flammable

and can be dangerous if mishandled. DO

NOT smoke while refueling. DO NOT attempt to refuel

the ride-on trowel if the engine is hot or running.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Starting the Engine

Figure 6. Fuel Gauge

NEVER store the Ride-On Power Trowel

with fuel in the tank for any extended period

of time. ALWAYS clean up spilled fuel

immediately.

1. With one foot on the ground and the other foot placed on

the trowel’s platform, grab hold of any part of the frame

and lift yourself onto the trowel. Then sit down in the

operator’s seat

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Figure 4. Engine Oil Dipstick

Hydraulic Oil

1. Determine if the hydraulic oil is low by observing the level

of oil in the hydraulic Oil Sight Glass (Figure 5).

Figure 5. Hydraulic Oil Sight Glass

2. The Whiteman Ride-On Power Trowel is equipped with

a safety

seat assembly. Remember the engine will not start unless

an operator is sitting in the operator’s seat. The weight

of an operator depresses an electrical switch, which will

allow the engine to start.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

DO NOT grab hold of the joysticks or pitch

tower assemblies to lift yourself onto the

trowel. Pulling on the joysticks or pitch

towers assemblies repeatedly will weaken

the units. Use any part of the frame to lift

yourself on the trowel.

kill switch

. This switch is located beneath the

NEVER disable or disconnect the kill switch.

It is provided for the operators’ safety and

injury may result if it is disabled,

disconnected or improperly maintained.

PAGE 16 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 17

HTH44T— INITIAL START-UP

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

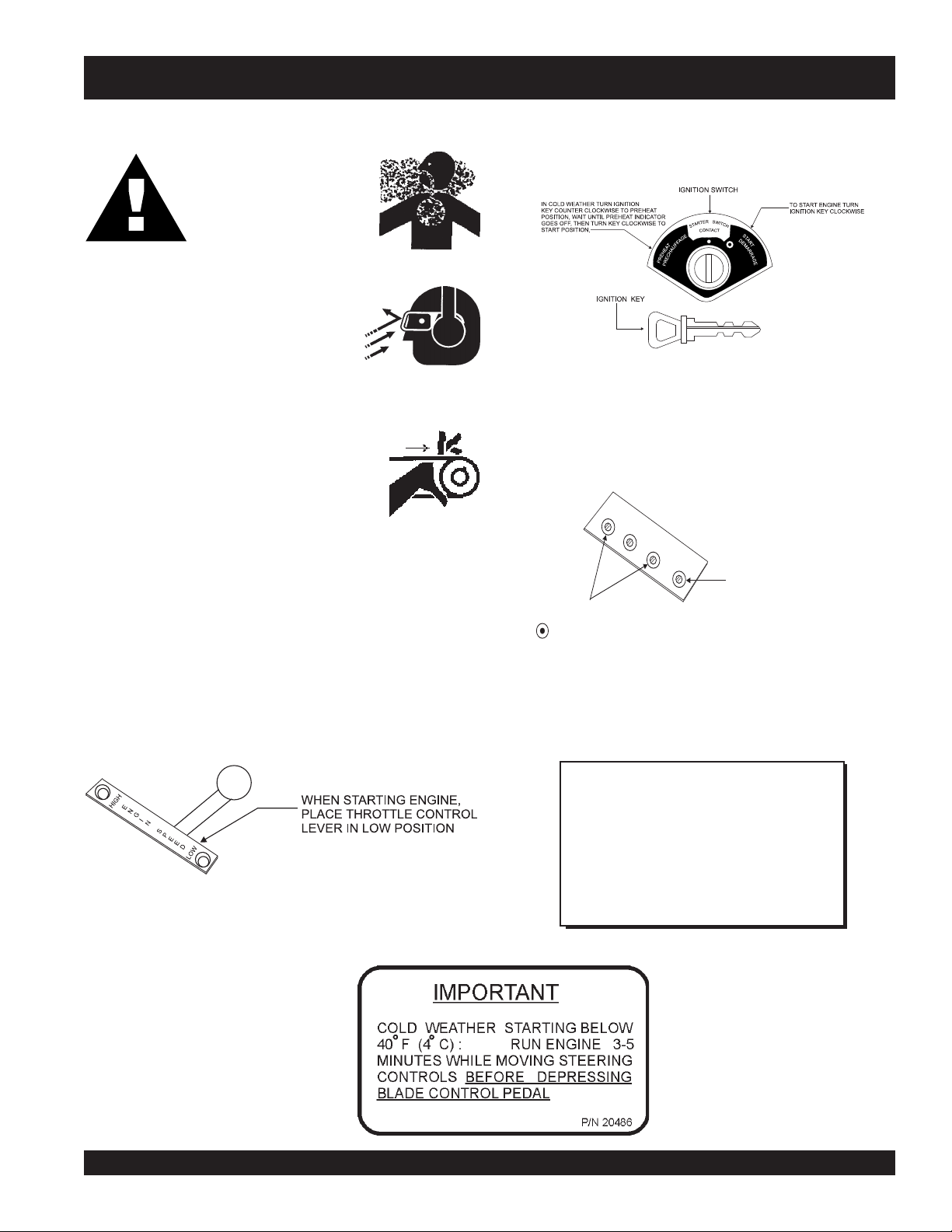

5. Insert the

NEVER operate the

trowel in a confined area

or enclosed area structure

that does not provide

ample free flow of air.

ALWAYS wear approved eye and hearing

protection before operating the ride-on

power trowel.

6. Turn the ignition key clockwise to the (start) position. The

NEVER place hands or feet inside the guard

oil

rings while the engine is running. ALWAYS

shut the engine down before performing any

kind of maintenance service on the trowel.

3. It is recommended that the kill switch be used to stop the

engine after every use. Doing this will verify that the switch

is working properly and presents no danger to the

OIL AND CHARGE INDICATOR LIGHTS

COME ON WHEN IGNITION SWITCH IS

IN THE POSITION.

operator. Remember to turn the key to the “OFF” position

after stopping the machine. Not doing so may drain your

units’ battery

ignition key

into the ignition switch (Figure 8).

Figure 8. Ignition Switch and Key

and charge indicator lights (Figure 9) should be on.

OIL

WATER

CHARGE

P

R

E

H

E

A

T

ON FOR APPROXIMATELY 5-10 SECONDS

WHEN IGNITION SWITCH IS IN THE

PRE HEAT POSITION.

Figure 9. Oil and Charge Indicator Lights

4. Place the

engine throttle lever (

Figure 7) in the

LOW

position.

NOTE

In

cold

weather turn the ignition key

counter clockwise to the preheat position,

wait until the BLUE preheat indicator goes

off before turning the ignition key clockwise

to the start position. Two or three preheat

Figure 7. Engine Throttle Control Lever (Low)

cycles may be necessary in very cold

weather.

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 17

— PAGE RM

Page 18

7. Turn ignition key fully clockwise and listen for engine to

start. Once engine has started release ignition key. Let

engine warm for a few minutes.

HTH44T— INITIAL START-UP

8. Place the

engine throttle lever

(Figure 10) in the

HIGH

position.

Figure 10. Engine Throttle Control Lever (High)

9. The engine should be running at full RPM.

10. Repeat this section a few times to get fully acquainted

with the engine starting procedure.

NOTE

All directional references with respect to

the joysticks are from the

operator’s

seat

position.

Steering

Two joysticks (Figures 11 and 12) located to the left and right of

the operator’s seat provide directional control for the HTH44T

Ride-On Power Trowel. Table 3 illustrates the various directional

positions of the joysticks and their effect on the ride-on trowel.

1. The foot pedal (Figure 13) solely controls blade speed.

The position of the foot pedal determines the blade speed.

Slow blade speed is obtained by slightly depressing the

pedal. Maximum blade speed is obtained by fully

depressing the pedal.

Figure 12. Right Joystick

KCITSYOJ NOITCERID STLUSER

tfeL drawroFkcitsyoJevoM

tfeL drawkcaBkcitsyoJevoM

thgiR drawroFkcitsyoJevoM

thgiR drawkcaBkcitsyoJevoM

thgiRdnatfeL

thgiRdnatfeL

thgiR thgiRkcitsyoJevoM

thgiR tfeLkcitsyoJevoM

htoBevoM

drawroFskcitsyoJ

htoBevoM

drawkcaBskcitsyoJ

gninoitisoPlanoitceriDkcitsyoJ.3elbaT

edistfelehtylnosesuaC

otlewortno-edirehtfo

.drawrofevom

edistfelehtylnosesuaC

otlewortno-edirehtfo

.drawkcabevom

edisthgirehtylnosesuaC

otlewortno-edirehtfo

.drawrofevom

edisthgirehtylnosesuaC

otlewortno-edirehtfo

.drawkcabevom

lewortno-edirehtsesuaC

nidrawrofevomot

.enilthgiartsa

lewortno-edirehtsesuaC

drawkcabevomot

.enilthgiartsani

lewortno-edirehtsesuaC

.thgirehtotevomot

lewortno-edirehtsesuaC

tfelehtotevomot

Figure 11. Left Joystick Control

Figure 13. Blade Speed Control Foot Pedal

PAGE 18 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 19

HTH44T— INITIAL START-UP

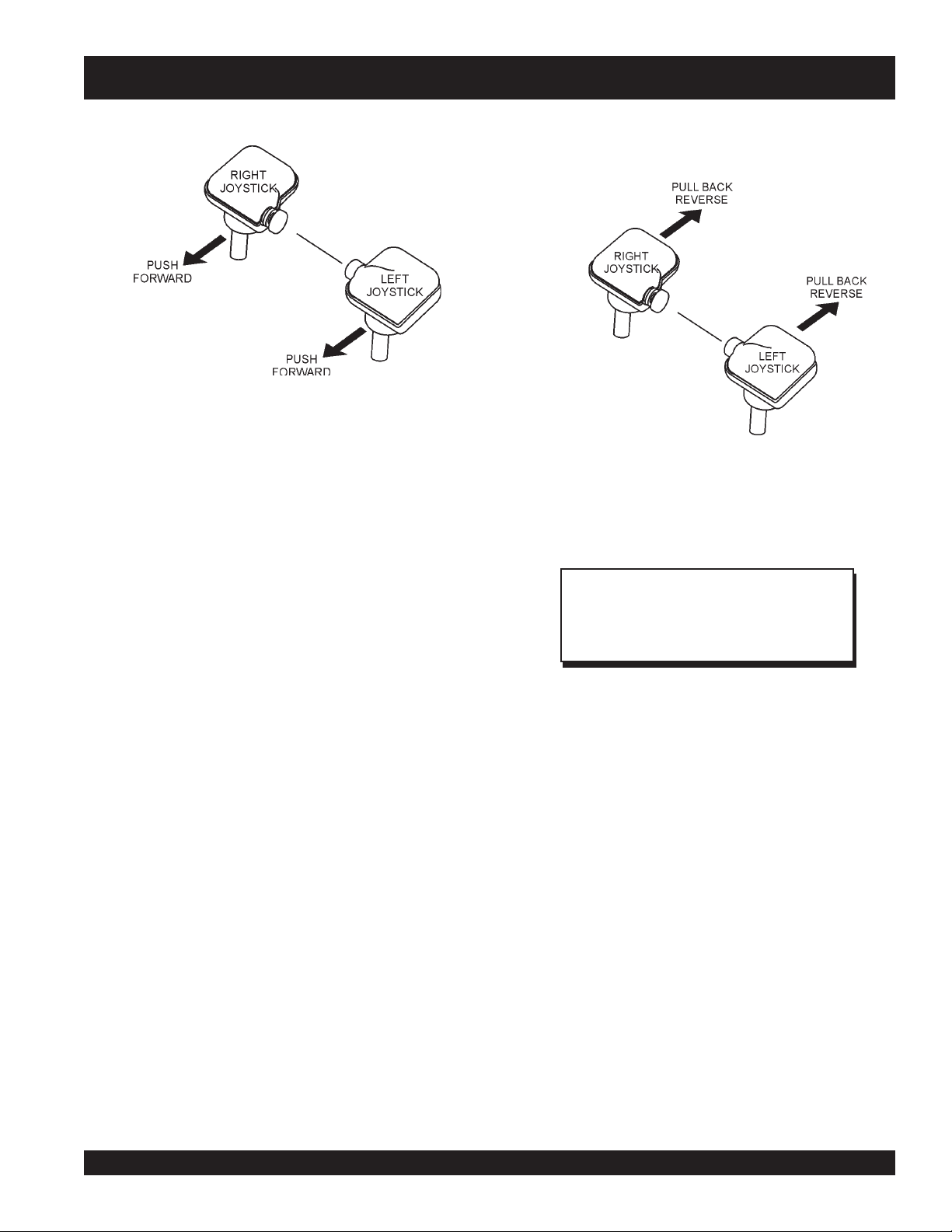

2. Push both the left and right joysticks forward (Figure 14).

Figure 14. Joystick Control Forward Direction

3. With your right foot slowly depress the right foot pedal

halfway. Notice that the ride-on power trowel begins to

move in a forward direction. Release both joystick controls

to stop forward movement then remove your right foot

from the right foot pedal.

4. Practice holding the machine in one place as you increase

blade speed. When about 75% of maximum blade speed

has been reached, the blade will be moving at proper

finishing speed. The machine may be difficult to keep in

one place. Trying to keep the ride-on trowel stationary is

a good practice for operation.

5. Practice maneuvering the Ride-on Power Trowel using

the information listed in Table 3. Try to practice controlled

motions as if you were finishing a slab of concrete.

Practice edging and covering a large area

6. Try adjusting the pitch of the blades. This can be done

with the ride-on trowel stopped or while the trowel is

moving, whatever feels comfortable. Test the operation

of optional equipment like retardant spray and lights if

equipped.

7. Push both the left and right joysticks backward (Figure

15) and repeat steps 3 through 6 while substituting the

word reverse for forward.

Figure 15. Joystick Control Reverse Direction

Engine Shut-Down

1. Return the speed control lever (Figure 7) to low idle, and

allow the engine to idle for 5 minutes .

2. Turn the ignition key counter-clockwise to the "

switch contact

3. Clean and remove any foreign debris from the trowel.

NOTE

Failure to allow the engine to idle for 5

minutes before shutting engine

OFF

may

lead to turbocharger damage.

starter

" position, then remove the key.

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 19

— PAGE RM

Page 20

HTH44T— MAINTENANCE

NOTE

See the engine manual supplied with your

machine for appropriate engine maintenance

schedule and troubleshooting guide for

problems.

At the front of the book (Page 7) there is a “Daily Pre-Operation

Checklist”. Make copies of this checklist and use it on a daily

basis.

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

MAINTENANCE SCHEDULE

Change

of use, then change every 250 hours.

the

Disconnect spark plug

wires and battery cables

before attempting any

service or maintenance on

the Ride-on Power Trowel.

ALWAYS allow the engine to cool before

servicing. NEVER attempt any maintenance

work on a hot! (muffler, radiator, etc.) trowel.

hydraulic oil

and

filter

after the first 100 hours

MAINTENANCE PROCEDURES

Checking/Adjusting Blade Speed

Because the two hydraulic drive motors operate independent

of each other, the blade speed between them may vary. If the

unit’s steering is difficult to control, the blade speeds may need

to be checked, or if the spider is spinning noticeably faster or

slower than the other side, the blade speed may need to be

checked. It is also recommended that the blade speed be

checked at least once a year.

Blade speed adjustment is a two-step process. First, the left

spider’s speed should be checked and/or adjusted. Second,

the right spider’s speed should be adjusted to match the left.

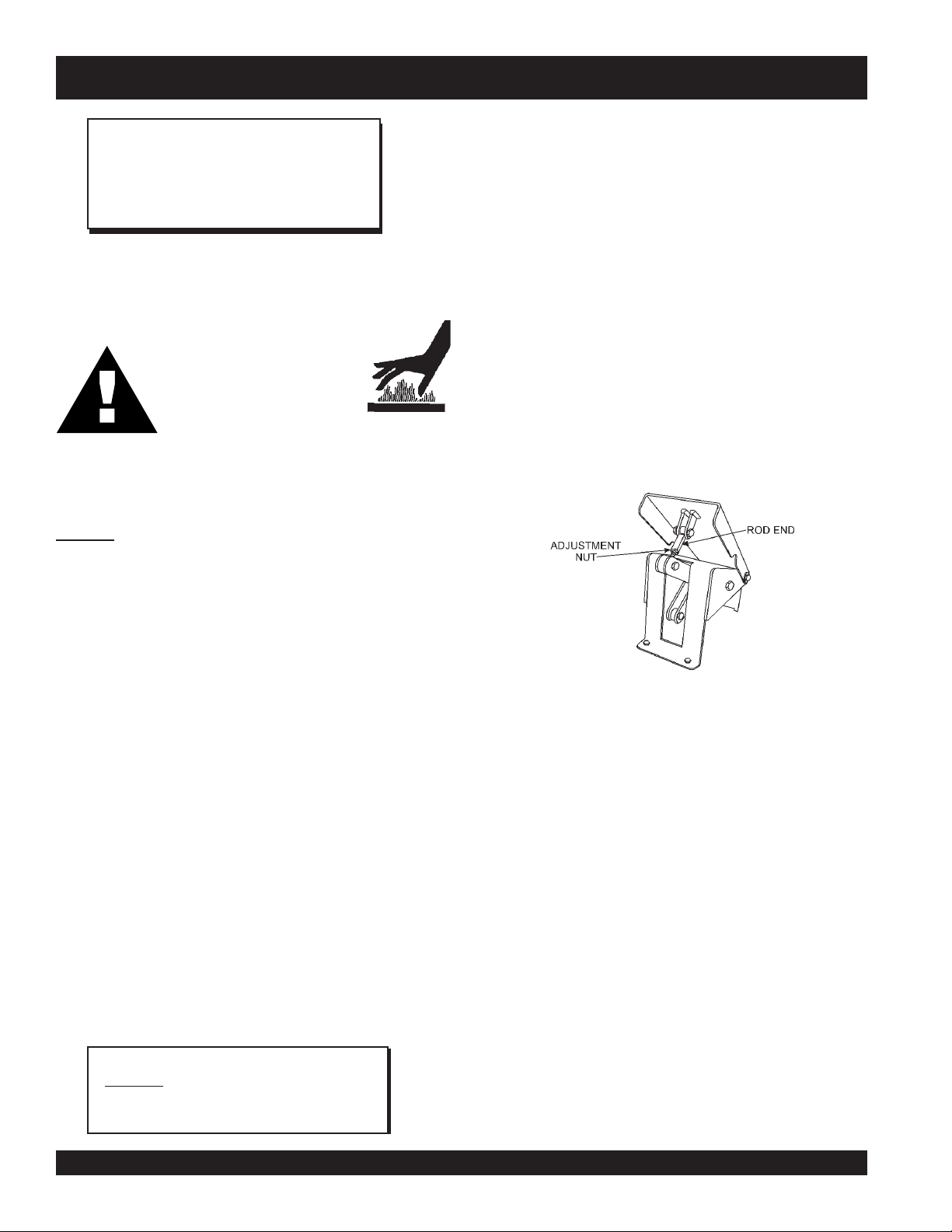

Left Spider Speed Adjustment

The left spider’s speed is adjusted by changing the length of

the rod end spacing (Figure 16) at the front of the foot pedal.

Lengthening the spacing increases the blade speed;

shortening the spacing decreases the blade speed.

Daily (8-10 Hours)

1. Check the fluid levels in the engine and reservoir, fill as

necessary.

Weekly (30-40 Hours)

1. Relube arms, thrust collar and clutch

2. Replace blades if necessary.

3. Check and clean or replace the engine air filter as

necessary.

4. Replace engine oil and filter as necessary, see engine

manual.

Monthly (100-125 Hours)

1. Remove, clean, reinstall and relube the arms and thrust

collar. Adjust the blade arms.

Yearly (500-600 Hours)

1. Check and replace if necessary the arm bushings, and

thrust collar bushings.

2. Check pitch control cables for wear.

3. Adjust blade speed.

4. Replace hydraulic fluid and both hydraulic filters.

NOTE

Change

the first 100 hours of use, then change

every 250 hours.

the

hydraulic oil

and

filter

after

Figure 16. Blade Speed Control Foot Pedal

Right Spider Speed Adjustment

The right spider’s speed is adjusted by changing the length of

the connecting rod on the pump actuation levers (Figure 17,

Page 21). This rod is basically a turnbuckle. Rotating it in one

direction increases the length and corresponding spider speed.

Rotating it the opposite direction decreases the length and

spider speed. The right spider’s speed should be within 3 rpm

of the left.

A good starting point in the adjustment process is to adjust

the rod such that both spiders begin to rotate at the same time

when the foot pedal is slowly depressed. This will, generally,

get the speeds fairly close. Close enough for use if

instrumentation is unavailable (i.e. on the job site). From this

point on, some form of instrumentation is required to verify

that the right spider speed is within the tolerance specified

above. A strobe or magnetic pickup type speed indicator is

recommended to verify the speeds.

The speeds should be adjusted on a dry concrete floor with

the blades pitched flat. Units with a Kubota turbocharged

engine should be set at 155-160 rpm with the engine at full

speed.

PAGE 20 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 21

HTH44T— MAINTENANCE

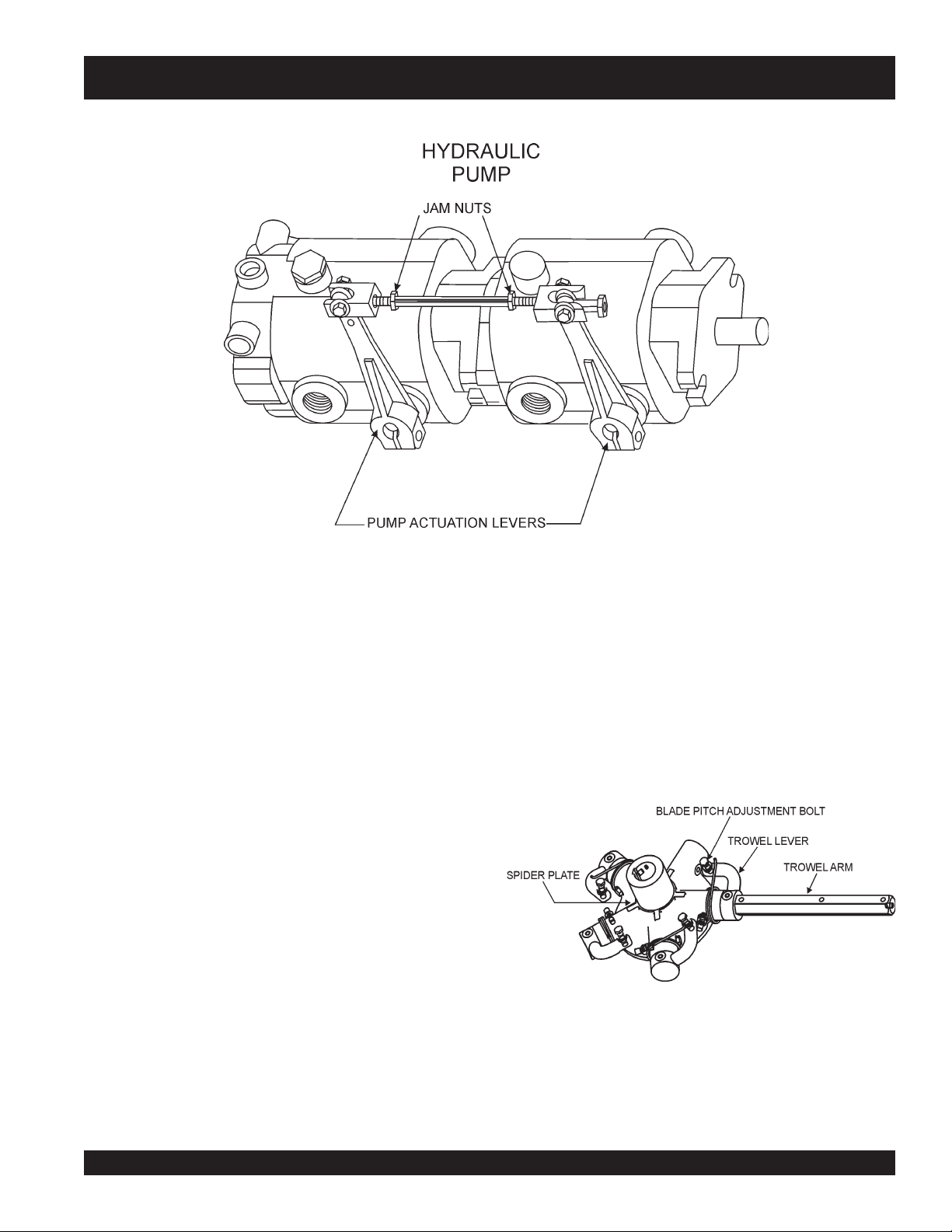

Figure 17. Pump Actuation Levers/Speed Control Rod

Matching Blade Pitch for Both Sets of Blades

Sometimes it may be necessary to match blade pitch between

the two sets of blades. There are some signs that this may be

necessary. For example, the differences in pitch could cause

a noticeable difference in finish quality between the two sets

of blades. Or, the difference in blade pitch could make the

machine difficult to control. This is due to the surface area in

contact with the concrete (the blade set with the greater contact

area tends to stick to the concrete more).

To fix this problem, each spider assembly can be pitched

individually. With a Single Pitch machine, the operator is forced

to constantly make adjustments on each pitch tower. On a

Twin Pitch machine, the operator must lift up on one of the

pitch control handles, disengaging the linkage between the

towers. Once this is done, a pitch control crank can be turned

to adjust the difference. Make sure to lock the linkage back in

place when finished with adjustments.

Blade Pitch Adjustment Procedure

The maintenance adjustment of blade pitch is an adjustment

that is made by a bolt (Figure 18) on the arm of the trowel

blade finger. This bolt is the contact point of the trowel arm to

the lower wear plate on the thrust collar. The goal of adjustment

is to promote consistent blade pitch and finishing quality.

There are some things to look for when checking to see if

adjustment is necessary. Is the machine wearing out blades

unevenly (i.e. one blade is completely worn out while the others

look new)? Does the machine have a perceptible rolling or

bouncing motion when in use? Look at the machine while it is

running, do the guard rings “rock up and down” relative to the

ground? Do the pitch control towers rock back and forth? These

are some of the indications that the blade pitch may need to

be adjusted using the adjustment bolts on the trowel blade

finger.

Figure 18. Blade Pitch Adjustment Bolt

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 21

— PAGE RM

Page 22

HTH44T— MAINTENANCE

The easiest and most consistent way to make this adjustment

is to use the Trowel Arm Adjustment Fixture (P.N. 9177) that is

manufactured by Whiteman. This fixture will allow consistent

adjustment of the trowel arm fingers. It comes with all the

hardware necessary to properly accomplish this maintenance

and instructions on how to properly utilize this tool. Adjusting

the trowel arm fingers without a fixture requires a special talent.

If a trowel arm adjustment fixture is not available and immediate

adjustment is necessary; we suggest the following procedure.

If you can see or feel which blade is pulling harder, adjust the

bolt that corresponds to that blade. Another way to determine

which blades need adjustment is to place the machine on a

flat surface and pitch the blades as flat as possible. Now, look

at the adjustment bolts. They should all barely make contact

with the lower wear plate on the spider. If you can see that

one of them is not making contact; some adjustment will be

necessary.

It will be possible to adjust the “high” bolts down to the level of

the one that is not touching, or adjust the “low” bolt up to the

level of the higher ones. If possible, adjust the low bolt up to

the level of the rest of the bolts. This is the fastest way, but

may not always work. Verify that after adjustment, the blades

pitch correctly. Often times, if the blades are incorrectly

adjusted, they will not be able to pitch flat. This occurs when

the adjusting bolts have been raised too high. Conversely,

sometimes the adjusting bolts are too low and the blades

cannot be pitched high enough for finishing operations.

Changing A Blade

Whiteman recommends that all the blades on the entire

machine be changed at the same time. If only one or some of

the blades are changed at one time, the machine will not finish

concrete consistently and the machine may wobble or bounce.

1. Place the machine on a flat, level surface. Adjust the blade

pitch control to make the blades as flat as possible. Note

the blade orientation on the trowel arm. This is important

for ride-on trowels as the two sets of blades counterrotate. Lift the machine up, placing blocks under the main

guard ring to support it.

2. Remove the bolts and lock washers on the trowel arm,

and then remove the blade.

3. Scrape all concrete and debris from the trowel arm. This

is important to properly seat the new blade.

4. Install the new blade, maintaining the proper orientation

for direction of rotation.

5. Affix the bolts and lock washers.

6. Repeat steps 2-5 for all remaining blades.

PAGE 22 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 23

HTH44T— MAINTENANCE

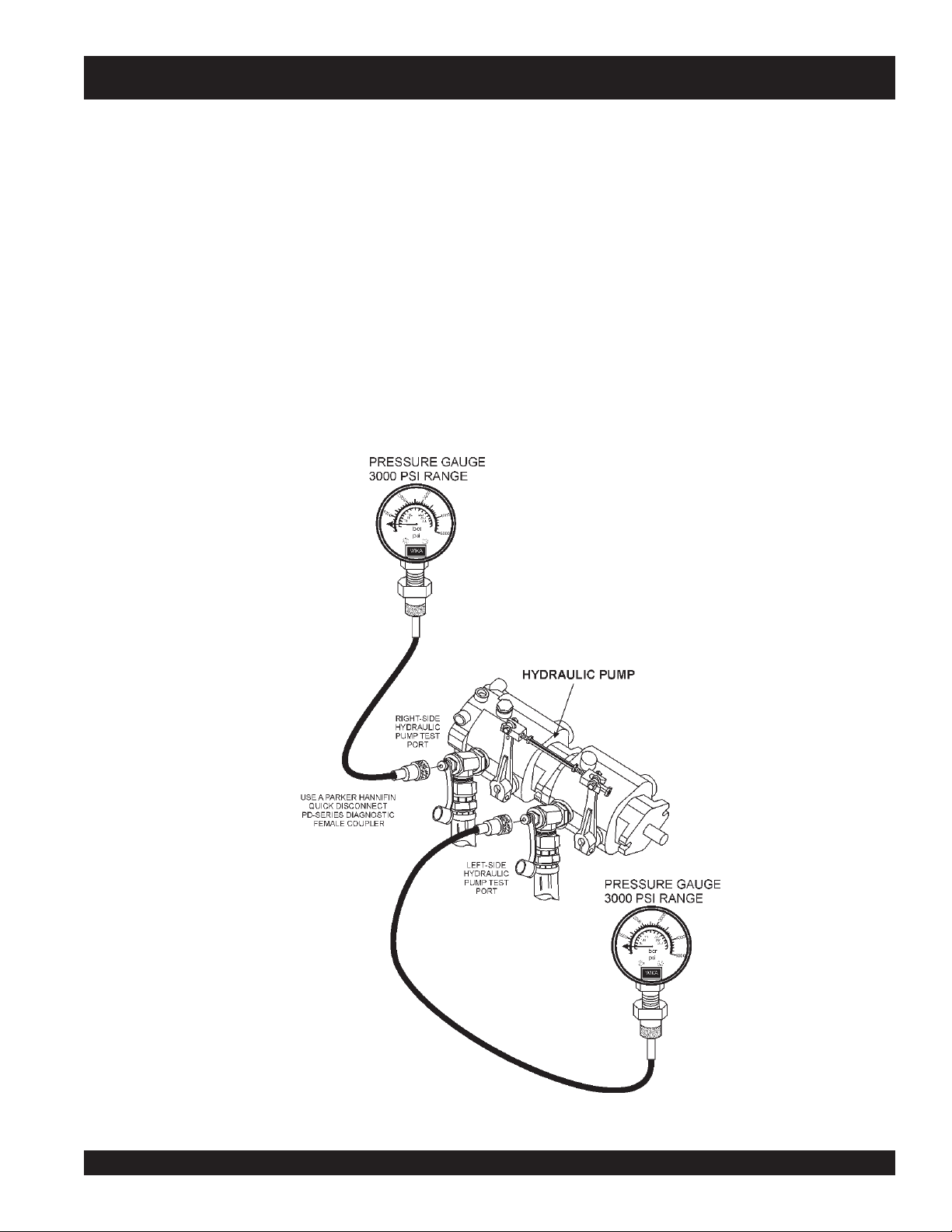

Checking Hydraulic Pressure

It should be mentioned that most hydraulic problems are a

result of low fluid levels. Before checking any other possibilities,

make sure the hydraulic fluid level is half way up the sight

glass which is located at the right end of the frame.

Hydraulic pressure can be checked using a pressure gauge

(Figure 19) with a range of at least 5,000 psi. Two male

diagnostic quick couplers (one for each pump) are located in

the elbow fittings (Figure 19) at the front of the pump. It is best

to use two gauges simultaneously, but it is possible to use

only one gauge and repeat the procedure for each side.

To fully test the hydraulic system, the spiders will need to be

locked so that they cannot rotate. This can easily be done by

wrapping a chain around an arm on each spider, thus chaining

them together in the back of the trowel.

Once the pressure gauges are installed and the spiders chained

together, the system can be checked.

With the foot pedal in the idle position and the engine at full

speed, the pressure should be 200 to 300 psi. If the pressure

is less than 200 psi, the charge system may need to be

inspected and/ or serviced. In particular, the suction filter and

charge pump relief valve should be checked. The suction filter

may be plugged, or the relief valve may be stuck. Either

condition may cause low charge pressure.

With the engine at 50% to 70% of full speed, and spiders

chained together, slowly depress the foot pedal and read the

gauges. The pressure should get to at least 3,100 psi. If the

pressure will not attain 3,100 psi, the pump should be inspected

and/or serviced by an authorized service representative.

Figure 19. Pressure Gauge (Hydraulic Pump)

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 23

— PAGE RM

Page 24

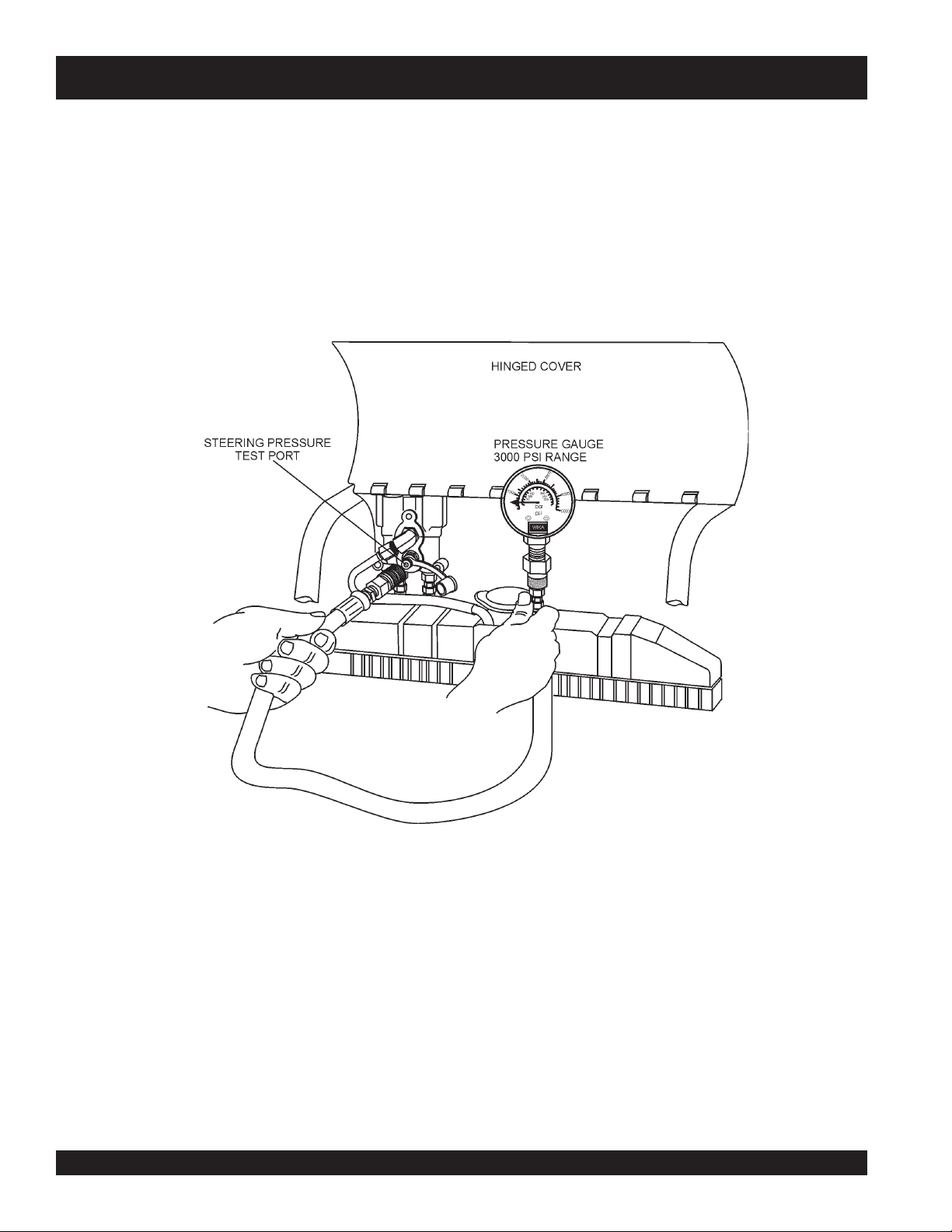

Checking Steering Pressure

Lift the hinged radiator access cover and insert the test

pressure gauge (300 to 600 PSI) as shown in Figure 20 into

the left steering valve's diagnostic quick coupler.

Run the engine at full RPM. The left steering valve's factory

setting is 145 PSI, however some operators may prefer a more

responsive steering (higher pressure required) and some

operators may prefer a "softer feel" (lower pressure required).

HTH44T— MAINTENANCE

Figure 20. Pressure Gauge (Left Steering Valve)

PAGE 24 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 25

HTH44T— MAINTENANCE

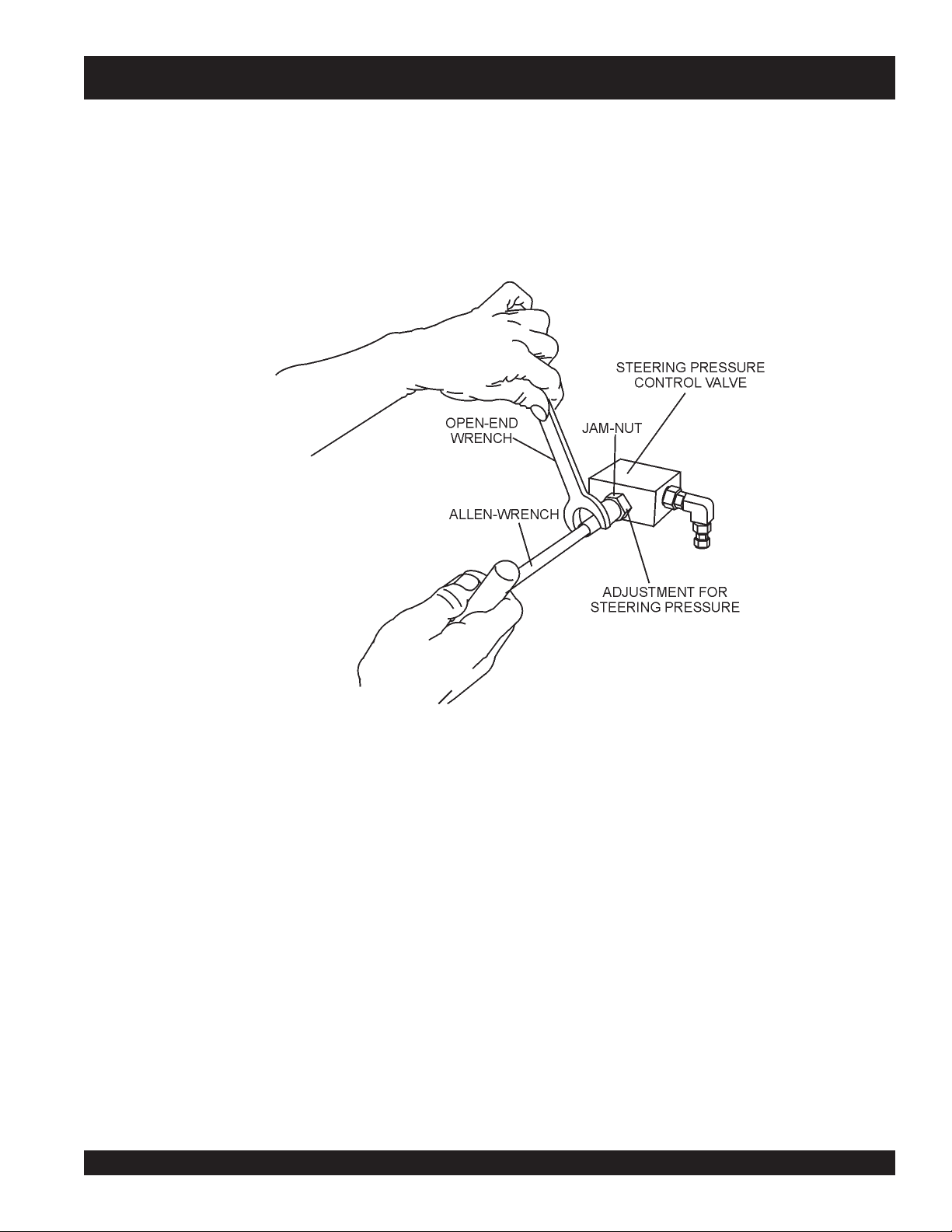

Steering Pressure Adjustment

On the steering pressure relief valve use an open-end wrench

to loosen the jam nut and an allen-wrench to adjust the

steering pressure to the desired setting somewhere between

115 and 180 PSI. Retighten the jam nut.

The steering pressure should be checked with the engine at

full RPM. It is not necessary to move either steering control

during the pressure test.

Figure 21. Steering Pressure Adjustment

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 25

— PAGE RM

Page 26

HTH44T— TROUBLESHOOTING

GNITOOHSELBUORT.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?noitcnuflamhctiwslliK

.lla

tatonrohguorgninnurenignE

?leuF

?noitingI

?smelborprehtO .launams’rerutcafunamenignetlusnoC

.gninoitcnuftonhctiwsllikytefaS

?stcatnocdaB .hctiwsecalpeR

?sedalB

?redipS

?snoitcennoceriwesooL .yrassecensaecalpeR.gniriwkcehC

?smraleworttneB

.yltcerrocgninoitcnuf

.yrassecenfihctiwsecalper;detaes

.rabedalbehtotlellarapdna

.yletaidemmitiecalper,tnebylthgilsnevesismra

sirotarepoehtnehwgninoitcnufsihctiwsllikehttahterusekaM

otdeilppusgniebleufsierehterusekaM.metsysleufehttakooL

.deggolctonsiretlifleufehttahterusneotkcehC.enigneeht

sidnarewopsahhctiwsnoitingiehttahterusneotkcehC

.nrowylevissecxeton,noitidnocdoognierasedalbniatrecekaM

ehtmorf)mm05("2nahtsselonerusaemdluohssedalbhsiniF

onerusaemdluohssedalbobmoc,egdegniliartehtotrabedalb

thgiartsebdluohsedalbfoegdegniliarT.)mm98("5.3tahtssel

saelgnahctipemasehttateserasedalbllatahtkcehC

rofelbaliavasiloottnemtsujdadleifA.redipsehttaderusaem

.)

tnempiuqElanoitpOees(smralewortehtfotnemtsujdathgieh

ehtfoenofI.smraleworttnebrofylbmessaredipsehtkcehC

sllor,secnuob“lewortfI

nevenusekamro,etercnoc

.”etercnocnislriws

?ralloctsurhT

?hctipedalB

?tfahsniaM

elbitpecrepasahenihcaM

.gninnurelihwnoitomgnillor

?ekoY

?sgnihsubmraleworT

er

?gnihsubralloctsurhT

?nrowgniraebtsurhT

.yrassecenfiecalpeR

.yrassecenfisnoitcurtsni

.tnioptnemhcatta

.ralloctsurhtehtnignihsubehtecalper

.eerfgninnipssititahteesotgniraebtsurhtehtkcehC

ebdluohsylbmessaxobraegehtfotfahstuptuoniamehT

.yrassecensaekoyecalpeR.pacraeweht

ybenodebnacsihT.ssenthgitrofsgnihsubmralewortehtkcehC

"8/1nahteromsierehtfI.nwoddnapusmralewortehtgnivom

ebdluohssgnihsubeht,mraehtfopitehttalevartfo)mm2.3(

.emitemasehttadecalperebdluohssgnihsubllA.decalp

.redipsehtnotignitatorybralloctsurhtehtfossentalfehtkcehC

.ralloctsurhtehtecalper)mm5.0("20.0nahteromybseiravtifI

tlitnactifI.redipsehtnotignikcorybralloctsurhtehtkcehC

,].D.Oralloctsurhtehttaderusaemsa[)mm6.1("61/1nahterom

noitcesecnanetniaMreptsujdA.hctiptnetsisnocrofsedalbkcehC

dnathgiartsnurtsumtfahsniamehT.ssenthgiartsrofdekcehc

re

dipsehttadnuorfotuo)mm80.0("300.0nahteromebtonnac

noylnevesserpekoyehtfosregnifhtobtahterusekamotkcehC

PAGE 26 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 27

HTH44T— TROUBLESHOOTING

)DEUNITNOC(GNITOOHSELBUORT.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?gniriW

.gnikrowton)lanoitpo(sthgiL

?sthgiL .nekorbfiecalpeR.doogllitserasblubthgilfieesotkcehC

otkcehcdna

.yrassecensaecalpeR

hctiwsffo/noretsamehtgnidulcni,snoitcennoclacirtcelellakcehC

.strohsonhtiwnoitidnocdoognisigniriwfiees

?tnadrateR

?gniriW

ton)lanoitpo(yarpstnadrateR

.gnikrow

?hctiwsdaB

?pmupyarpsdaB

?tnemtsujdafotuodeepsedalB

?stnenopmocnroW

.evisnopsernusignireetS

?stoviP

?erusserpciluardyH

.yrassecen

.pmupehtecalper,doog

.tnemtsujdadeepsedalbnonoitceseeS

.yrassecenfiecalper

.erusserpciluardyhgnikcehcno

saknatlliF.tneserpsitnadratererusekamotknatehtkcehC

hctiwsffo/noretsamgnidulcni,snoitcennoclacirtcelellakcehC

.yrassecensagniriwdnastnenopmocecalpeR.snoitcennoc

.nekorbfiecalpeR.hctiwsffo/noretsamfoytiunitnocehtkcehC

tub,nodenrutsihctiwsehtnehwtneserpegatlovasahpmupfI

erapmupehtotsnoitcennoclacirtcelednaetarepotonseod

stnenopmocegaknildnasgniraebgnireetsforaewrofkcehC

.srotomevirdciluardyhfotnemevomeerferusneotkcehC

noitceseeS.etauqedasierusserpciluardyhtahterusneotkcehC

sinoitisopgnitarepO

.elbatrofmocnu

?seldnahknarC

)lanoitpo(hctiPniwTnoegakniL

.gnikrowton

?trapnekorB

?rotareporoftsujdataeS

.yletaidemmistrapnekorbllaecalpeR

.taesehtfotnorfehtnodetacolrevelhtiwtaestsujdA

sarafsanwoddehsuperaseldnahknarchtobtahterusekaM

.degagnesiegaknilehttahtserusnesihtgnioD.elbissop

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 27

— PAGE RM

Page 28

HTH44T— EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarified in the “Remarks” Column.

QTY. Column

Numbers Used — Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other

parts that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

same unique symbol will be included when this item is

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break — Used to list an effective serial

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use — Indicates that the part

is used only with the specific model number or model

number variant listed. It can also be used to show a

part is NOT used on a specific model or model number

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

available items. Examples include battery cables, shims,

and certain washers and nuts.

“Not Sold Separately” — Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

for sale through Multiquip.

PAGE 28 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 29

HTH44T— SUGGESTED SPARE PARTS & SERVICE ITEMS

HTH44T SERIES - KUBOTA 44 HP TURBO ENGINE

1 Unit

Qty. P/N Description

5 ............ 2829 ................ ARMS

2 ............ 9005 ................ LEVER TROWEL ARM (L.S.)

20 .......... 0166A .............. WASHER

20 .......... 1876 ................ JAM NUT

20 .......... 0164B .............. SCREW

5 ............ 11039 ............... BUSHING

2 ............ 9111 ................. SPRING (L.S.)

20 .......... 1875 ................ WASHER

20 .......... 1322 ................ SCREW ASM, ARM RETAINING

2 ............ 11419 ............... SPIDER PLATE (WEAR)

20 .......... 1162A .............. CAP GREASE FITTING

20 .......... 16602............... SCREW (HHC 3/8 -16 X 3/8)

2 ............ 2143 ................ SPRING (R.S.)

2 ............ 1986 ................ LEVER TROWEL ARM (R.S.)

2 ............ 12005............... SAFETY-OFF ("KILL" SWITCH)

20 .......... 0181B .............. WASHER 1/4 IN

1 ............ 11418 ............... FUEL CAP/GAUGE (ENG)

1 ............ 12010............... FUEL SCREEN

2 ............ 19633............... BUSHING, RUBBER FUEL

1 ............ 12332............... CAP, HYDRAULIC RESEVOIR

1 ............ 11402 ............... FILTER, HYDRAULIC RETURN

1 ............ 20567............... FILTER, HYDRAULIC SUCTION

1 ............ EATON 70142-938 SEAL KIT (EATON HYD PUMP)

1 ............ 12238 ............... KEY, SHAFT

1 ............ EATON 61295.. SEAL KIT, REAR (PORT END)

1 ............ 12313............... SEAL, INPUT SHAFT

1 ............ EATON 61338-000 SEAL KIT, (HYD MOTOR)

1 ............ 11874 ............... GROMMET, (HYD PUMP LEVER)

1 ............ 20003............... ROD END, FEM (HYD PUMP LEVER)

4 ............ 11577 ............... PLATE, VIBRATION MOUNT (ENG)

1 ............ 11491 ............... CABLE, THROTTLE (FOOT PEDAL)

1 ............ 11611 ............... ROD END, FEM RH (HYD THROTTLE)

1 ............ 2153 ................ ROD END, FEM RH(THROTTLE CABLE)

1 ............ 11643 ............... ROD END, MALE (RH)

1 ............ 12548............... SPRAY PUMP

1 ............ 392292............. SPRAY NOZZEL

1 ............ 19633............... BUSHING, RUBBER FUEL

1 ............ 2108 ................ CAP, SPRAY TANK

1 ............ 12009............... SCREEN FILTER

10 .......... 10031............... WASHER, 1/4"

Qty. P/N Description

1 ............ 19638 .................... BRACKET BATTERY

2 ............ 11693 .................... BOLT BATTERY BRACKET

1 ............ 10314 .................... CABLE, BATTERY+ (RED)

1 ............ 10313 .................... CABLE, BATTERY-(BLACK)

1 ............ 1597 ..................... CABLE, (NEG 16.5")

6 ............ 2509 ..................... WING NUT

1 ............ 20511 .................... SWITCH, IGNITION

1 SET .... 12627 .................... KEYSET, IGNITION

2 ............ 12307 .................... BULB, INDICATOR LIGHT

1 ............

1 ............ 11382 .................... INDICATOR PLUG (RED)

1 ............ 11098 .................... CIRCUIT BREAKER 40 AMP, 12V

1 ............ 4682 ..................... TOGGLE SWITCH

1 ............ 8381 ..................... BOOT, TOGGLE SWITCH

1 ............ 11792 .................... ACCESSORY SOLENOID

1 ............ 11694 .................... HOUR METER

11585 .................... INDICATOR PLUG (BLUE)

PARTS FOR KUBOTA 44 HP TURBO ENGINE

Qty. P/N Description

1 ............ KUBOTA P/N 16271-32090 OIL FILTER

1 ............ KUBOTA P/N 17351-11083 AIR FILTER ELEMENT

1 ............ 70000-43081 ... FUEL FILTER

1 ............ 16282-97010 ... FAN BELT

2 ............ 16241-72870 ... RADIATOR HOSE

4 ............ 36200-82720 ... HOSE CLAMP

1 ............ 20295 ............... MUFFLER HTH44

1 ............ 20122 ............... MUFFLER BLANKET

1 ............ 20318 ............... MUFFLER KIT, KUBOTA VI505-TE

1 ............ 10434 ............... CLAMP, HOSE 2"

1 ............ 20112 ............... BRACKET, ENGINE THROTTLE CABLE

1 ............ 10568 ............... THROTTLE CABLE (ENGINE)

1 ............ 11531 ............... BELLHOUSING, KUBOTA VH 1305/150

1 ............ 11605 ............... FLANGE, ENG KTR NYLON

1 ............ 20316 ............... FAN, PUSHER, KUBOTA

1 ............ 20320 ............... RADIATOR KIT, KUBOTA VI505-TE

1 ............ 11983 ............... TANK, RADIATOR OVERFLOW

1 ............ 20327 ............... AIR CLEANER KIT, KUBOTA VI505-TE

1 ............ 20566 ............... HARNESS, WIRE 44HP ENGINE(HTH)

1 ............ 20322 ............... HARNESS, WIRE KUBOTA 44T

1 ............ 20321 ............... MANUAL, KUBOTA OWNERS, VI505-TE

NOTE

Part numbers on this Suggested

Spare Parts List may supercede/

replace the P/N shown in the text

pages of this book.

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 29

— PAGE RM

Page 30

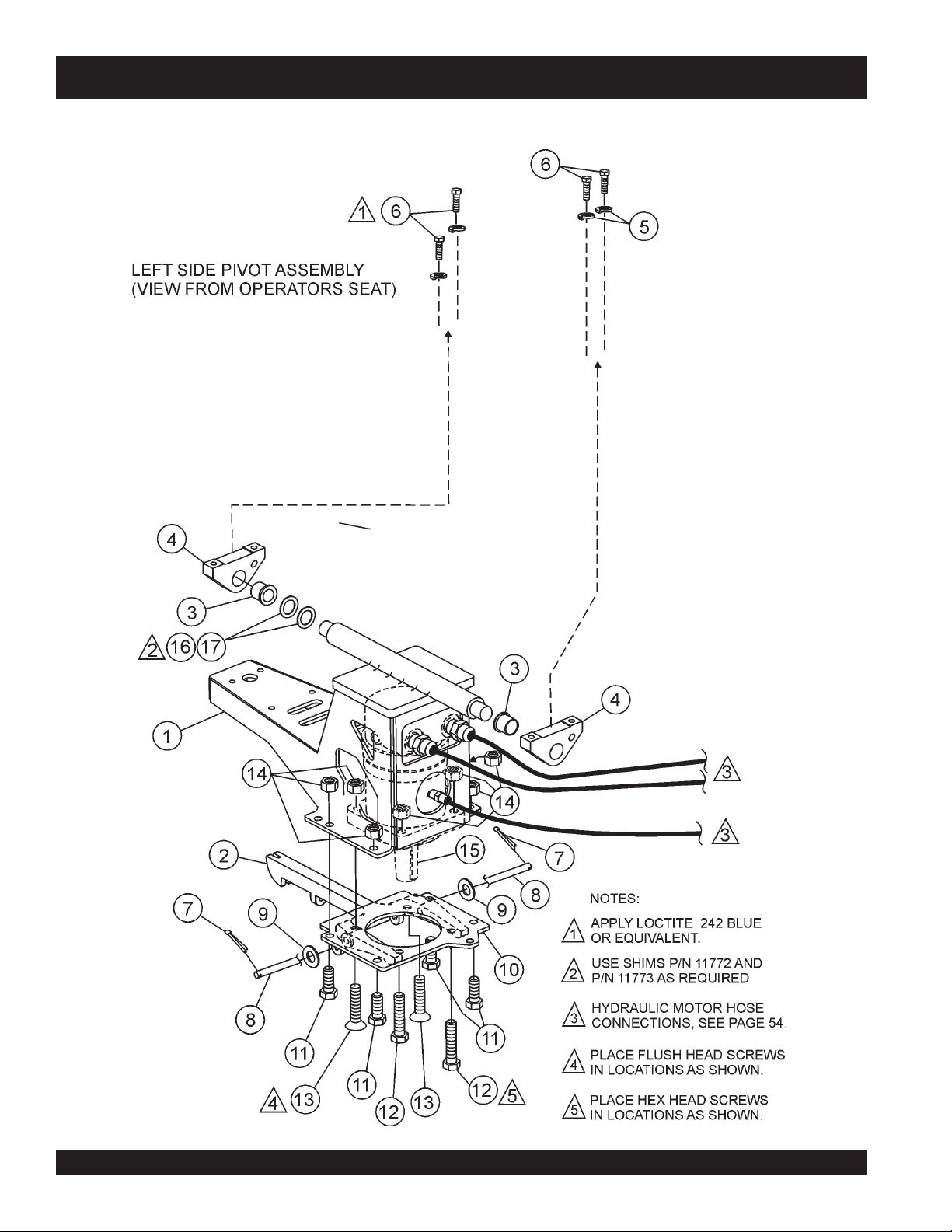

PIVOT ASSY. (LEFT)

HTH44T— PIVOT ASSY. (LEFT)

PAGE 30 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 31

HTH44T— PIVOT ASSY. (LEFT)

PIVOT ASSY. (LEFT)

NO. PART NO. PART NAME QTY. REMARKS

1 12968 MOUNT, HYD. MOTOR LEFT 1

2 11499 YOKE 1

3 10221 BUSHING 2

4 11555 ROCKER BLOCK 2

5 0166A WASHER, LOCK 3/8 MED. 4

6 1023 SCREW, HHC 3/8- 16 X 1- 1/4 4

7 0183 PIN,COTTER 1/8 1- 1/4 2

8 11648 PIN, PIVOT 1

9 0448 WASHER, FLAT 7/16 SAE 2

10 12983 MOUNT, HYD. MOTOR BOTTOM ........................ 1 ............... DOES NOT INCL ITEM 2, YOKE

11 3214 SCREW, HHC 1/2- 13 X 1- 1/4 4

12 13178 SCREW, HHC 1/2- 13 X 2 1/4 2

13 11882 SCREW, FHSC 1/2- 13 X 2 1/4 2

14 10176 NUT, NYLOC 1/2- 13 8

15 20002 MOTOR, EATON VIS30 24CID 1

16 11772 SHIM .................................................................. AR

17 11773 SHIM .................................................................. AR

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 31

— PAGE RM

Page 32

PIVOT ASSY. (RIGHT)

HTH44T— PIVOT ASSY. (RIGHT)

PAGE 32 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 33

HTH44T— PIVOT ASSY. (RIGHT)

PIVOT ASSY. (RIGHT)

NO. PART NO. PART NAME QTY. REMARKS

1 12967 MOUNT, HYD. MOTOR RIGHT 1

2 11450 TRUNNION 1

3 10221 BUSHING 4

4 11555 ROCKER BLOCK 2

5 0166A WASHER, LOCK 3/8 MED. 6

6 1023 SCREW, HHC 3/8- 16 X 1- 1/4 6

7 0183 PIN, COTTER 1/8 1- 1/4 2

8 11648 PIN, PIVOT 1

9 0448 WASHER, FLAT 7/16 SAE 2

10 12983 MOUNT, HYD. MOTOR BOTTOM ........................ 1 ............... DOES NOT INCLUDE ITEM 14

11 3214 SCREW, HHC 1/2- 13 X 1- 1/4 4

12 13178 SCREW, HHC 1/2- 13 X 2 1/4 2

13 11882 SCREW, FHSC 1/2- 13 X 2 1/4 2

14 11499 YOKE 1

15 10176 NUT, NYLOC 1/2- 13 8

16 11154 RETAINER, CLUTCH 2

17 10138 SCREW, SHS 1/4- 20 X 1/2, N.P. 1

18 11420 SHAFT, PIVOT 1

19 20002 MOTOR, EATON VIS30 24CID 1

20 11772 SHIM .................................................................. AR

21 11773 SHIM .................................................................. AR

20 11772 SHIM (USE AS REQUIRED)

21 11773 SHIM (USE AS REQUIRED)

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 33

— PAGE RM

Page 34

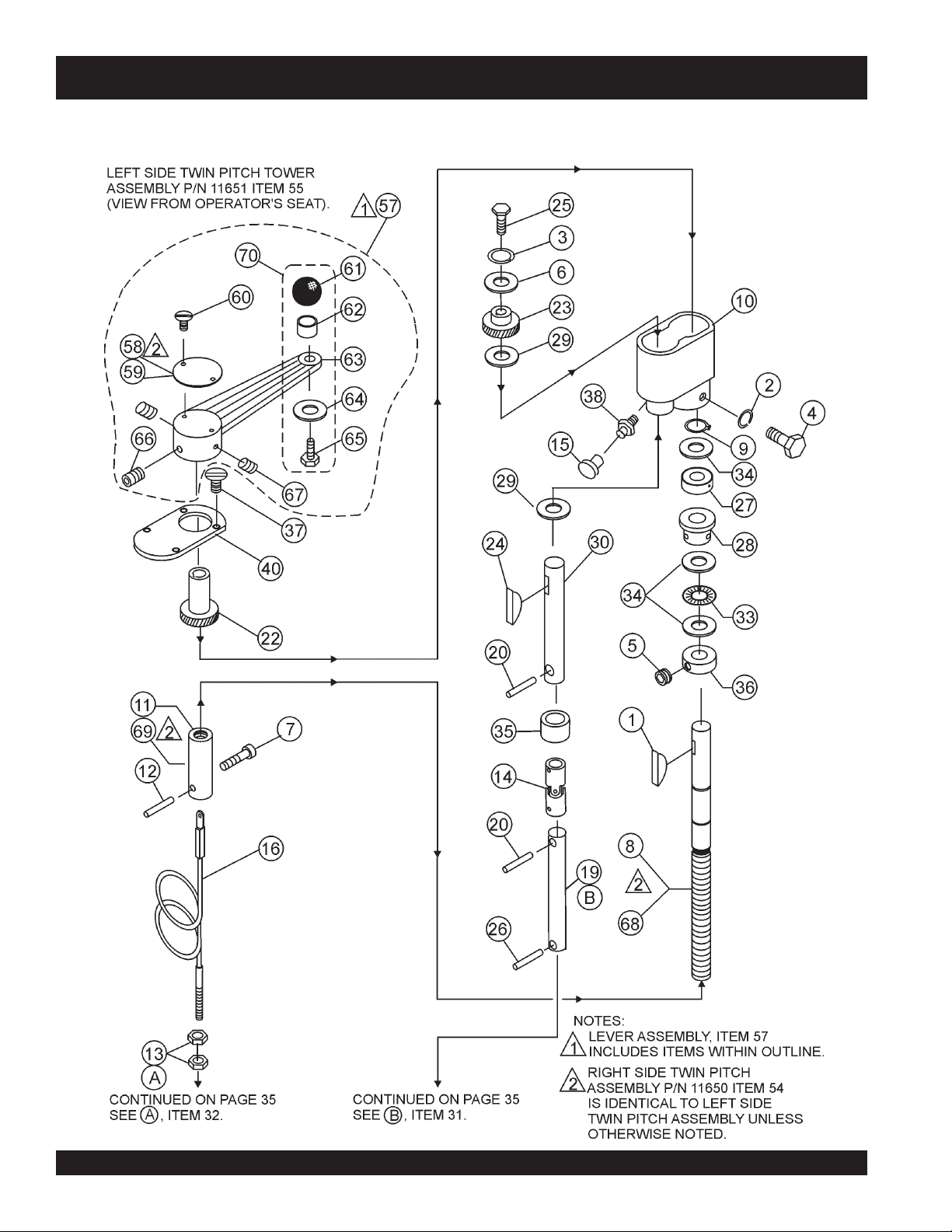

LEFT/RIGHT TWIN PITCH ASSY.

HTH44T— TWIN PITCH ASSY. (LEFT/RIGHT)

PAGE 34 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 35

LEFT/RIGHT TWIN PITCH ASSY.

HTH44T— TWIN PITCH ASSY. (LEFT/RIGHT)

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 35

— PAGE RM

Page 36

HTH44T— TWIN PITCH ASSY. (LEFT/RIGHT)

LEFT/RIGHT TWIN PITCH ASSY.

NO PART NO PART NAME QTY. REMARKS

1+% 0126 B KEY, WOODRUFF #9 1

2+% 0161C WASHER, LOCK 5/16 MED 3

3*+% 0181 B WASHER, LOCK, 1/4 MED 1

4+% 0655 SCREW, HHC 5/16 – 18 X 3/4 3

5+% 0685 SCREW, SHS 5/16 – 18 X 5/16 1

6+% 0948 WASHER, FLAT, 1/4 SAE 1

7+% 10382 BOLT, SHOULDER, 3/8 X 3/8 LONG 1

8+ 10511 SHAFT, PITCH CONTROL, LH TPC 1

9+% 10512 RING, SNAP, TRUARC 5160 – 75 1

10+% 10546 HOUSING, PITCH CONTROL, 1-3/4 1

11+ 10722 SLIDE BLOCK, LH PITCH CON 1

12+% 10723 PIN, SPIROL 3/16 X 1 3/8 HD 1

13+% 1116 NUT, BRASS JAM 5/16 – 18 2

14*+% 11583 U-JOINT, PITCH CONTROL 1

15*+% 1162 A CAP, GREASE ZERK, #2 YELLOW 1

16+% 11623 CABLE, PITCH ASM 1

17 11630 TUBE, PITCH CONTROL 1

18 11649 SPACER, PITCH SPRING 1

19+% 11652 SHAFT, TWIN PITCH 1

20*+% 11654 PIN, ROLL 1/8 Z 1 PLATED 2

22+% 1529 GEAR, MASTER, TPC 1

23+% 1530 GEAR, SLAVE, TPC 1

24*+% 1578 KEY, WOODRUFF, #3 1

25+% 1579 SCREW, HHC 1/4 – 20 X 1/2 1

26+% 1586 PIN, ROLL 1/8 X 3/4 1

27+% 1604 BEARING, BALL 1

28+% 1612 BEARING, ALUM – PITCH CONTR 1

29*+% 1733 WASHER, 1/32 X 1/2 HARDENED 6

30+% 2007 SHAFT 1

31 2012 SLEEVE, ADJ – LONG, RIDER 1

32 2156 SPRING, COIL 1

33+% 2169 BEARING, THRUST, TORR #NTA 1220 1

34+% 2170 BEARING, RACE, TORR #TRA 1220 3

35+% 2311 SPACER, 3/4 X 1/2 X 8L 1

36+% 2367 SET COLLAR 1

37+% 2620 SCREW, BHC 10 – 24 X 5/8 4

38*+% 2621 ZERK, GREASE STR 1/4 – 28 1

40+% 2649 COVER, PITCH CONT HOUSING 1

PAGE 36 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 37

HTH44T— TWIN PITCH ASSY. (LEFT/RIGHT)

LEFT/RIGHT TWIN PITCH ASSY.

NO PART NO PART NAME QTY. REMARKS

41 0202 SCREW, HHC 5/16 – 18 X 1 8

42 0300 B WASHER, FLAT, 5/16 SAE 8

43

44

45

46

47

48

49

50

51

52

53 5283 NUT, NYLOC 5/16 – 18 8

54 11650 RIGHT SIDE TWIN PITCH CONT ASSY ............ 1 .......... INCLS ITEM W/%

55

56 11655 MITER BOX ASSY ............................................. 1 .......... INCLS ITEM W/

57 1617 LEVER ASSY, TROWEL ADJUSTMENT ............ 2 .......... INCLS ITEM W/#

58# 2300 DECAL, AL PITCH, RH 1

59# 2332 DECAL, AL PITCH, LH 1

60# 4014 SCREW, 2-3/16 P-K TYPE U DRIVE 4

61# 4403 CRANK KNOB 1

62# 3231 SPACER 1

63# 1615 CRANK LEVER 1

64# 1733 HARDEN WASHER 1

65# 1616 SHOULDER BOLT 1

66# 0185 SCREW, SHSS 3/8 – 16 X 3/8" 1

67# 1528 SCREW, SHSS 1/4 – 20 X 5/16" 1

68% 10510 SHAFT, PITCH CONTROL, RH TPC 1

69% 10721 SLIDE BLOCK, RH PITCH CONTROL 1

70 2737 KNOB KIT 1

0730 SCREW, HHC 1/4 – 20 X 1 16

*

11653 SLEEVE, W/U-JOINT 1

*

1577 SET COLLAR, 1/2 4

*

1987 MITER BOX, PITCH CONTROL 2

*

1988 MIT BOX, BEARING CAP RIDERS 4

*

2021 SHAFT, MITER VERT JRT 2

*

2022 SHAFT, MITER VERTICAL 3

*

2062 GEAR, MITER, TPC 4

*

2845 SHAFT, MITER BOX HORIZ 1

*

4514 SCREW, HHC 1/4 – 20 X 5/8 4

*

11651 LEFT SIDE TWIN PITCH TOWER ASSY ........... 1 .......... INCLS ITEM W/+

*

*

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 37

— PAGE RM

Page 38

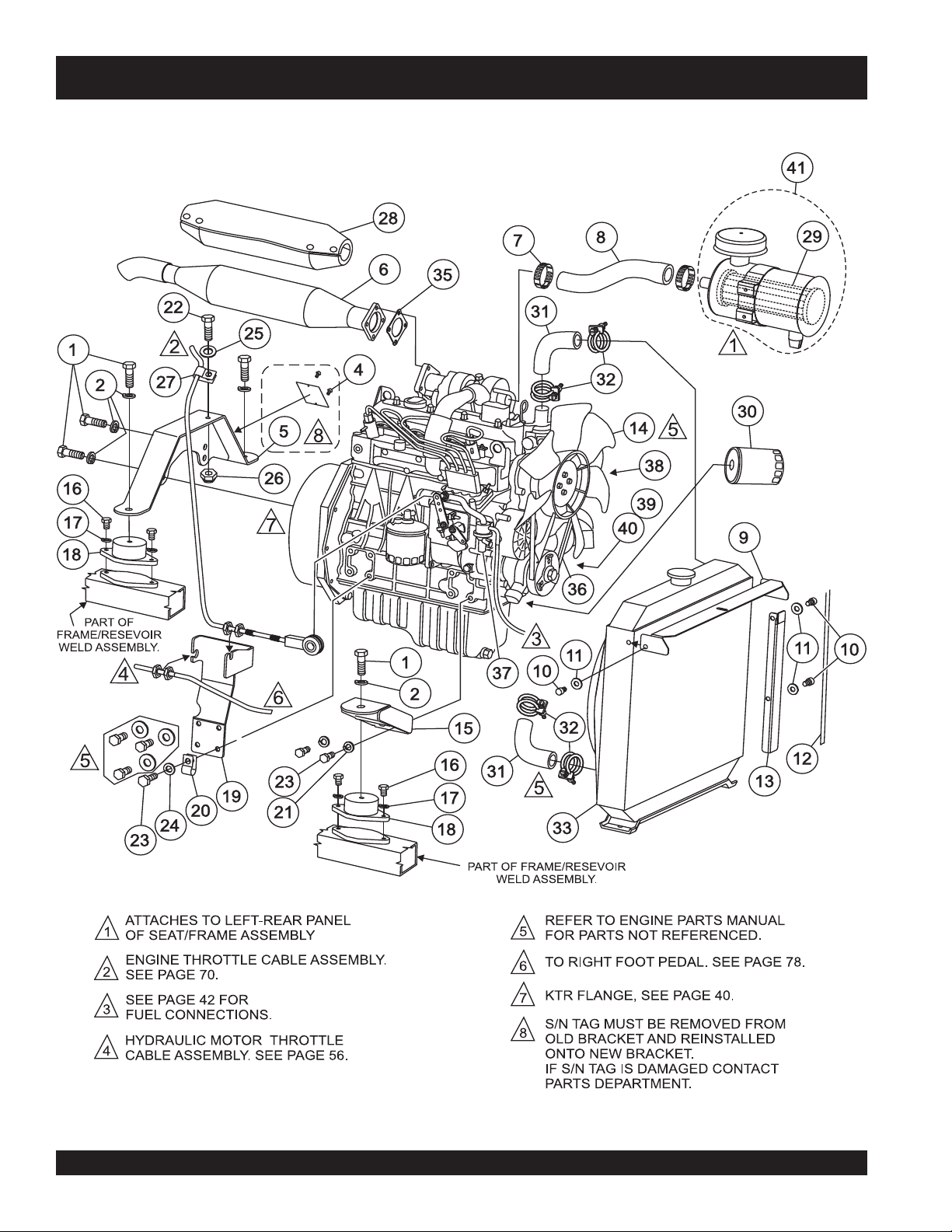

ENGINE (KUBOTA

HTH44T— ENGINE (KUBOTA)

PAGE 38 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 39

HTH44T— ENGINE (KUBOTA)

ENGINE (KUBOTA)

NO. PART NO. PART NAME QTY. REMARKS

1 5218 SCREW, HHC 1/2- 13 X 1- 1/2 6

2 5054A WASHER, LOCK, 1/2 MED 6

4 4014 SCREW, DRIVE #2- 3/16 U- DRIVE 2

5 11517 MOUNT, RIGHT MOTOR ...................................... 1 ...............(REPLACE S/N TAG ONTO

................................................................................................. NEW MOUNT)

6 20295 MUFFLER, HTH44 1

7 10434 CLAMP, HOSE 2 INCH ID 2

8 20123 HOSE, AIR CLEANER 1

9 20091 PLATE, AIR DAM TOP 1

10 2198 SCREW, SHC M6- 1.0 X 10MM 3

11 0948 WASHER, FLAT 1/4 SAE 3

12 60049 TRIM EDGE, 1/32 (62B3- 1/32) ............................ 1 ............... SOLD IN FOOT-LENGTHS

13 20093 PLATE, AIR DAM REAR 1

14 20108 ENGINE PACKAGE KUBOTA 44HP TURBO 1

15 12958 MOUNT, ENGINE LEFT W/ A 2

16 6869 SCREW, HHC 3/8- 24 X 1/2 8

17 0166A WASHER, LOCK 3/8 MED. 8

18 11577 PLATE, VIBRATION MOUNT 4

19 20112 BRACKET, THROTTLE 1

20 8125 CLAMP, HOSE SUPPORT, 5/8 1

21 2955 WASHER,LOCK, 7/16 MED 4

22 0202 SCREW, HHC 5/16- 18 X 1 1

23 11662 SCREW, HHC M10- 1.25 X 25MM 5

24 10136 WASHER, FLAT 3/8 SAE 1

25 0300B WASHER, FLAT 5/16 SAE 1

26 5283 NUT, NYLOC 5/16-18 1

27 8128 CLAMP, HOSE SUPPORT 5/16 1

28 20122 BLANKET, MUFFLER 1

29% 17351-11083 ELEMENT, AIR CLEANER 1

30 16271-32090 OIL FILTER, ENGINE 1

31 16241-72870 HOSE, RADIATOR 2

32 36200-82720 CLAMP, RADIATOR 4

33 20320 RADIATOR KIT 1

35 15263-12370 GASKET, MUFFLER 1

36 16282-97010 FAN BELT 1

37 16285-52032 FUEL PUMP, KUBOTA 1

38 16241-64010 ALTERNATOR 1

39 37560-63010 STARTER 1

40 01123-50830 BOLT, STARTER 2

41 1629611013 AIR CLEANER ASSY ........................................... 1 ...............INCLUDES ITEMS W/%

HTH44T • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #8 (03/27/12) — PAGE 39

— PAGE RM

Page 40

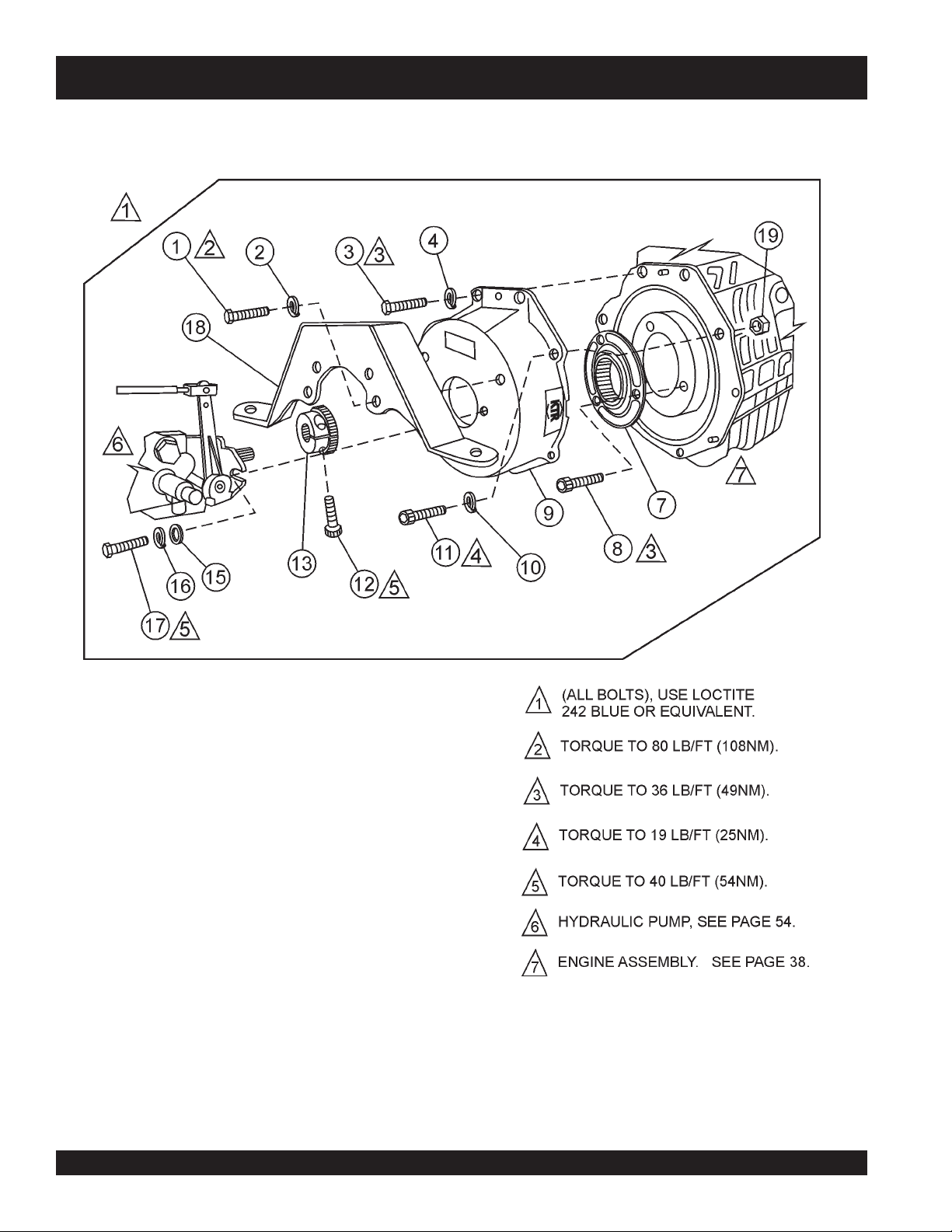

ENGINE (KUBOTA)

HTH44T— ENGINE FLANGE (KUBOTA)

PAGE 40 — HTH44T • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #8 (03/27/12)

)

Page 41

HTH44T— ENGINE FLANGE (KUBOTA)

ENGINE (KUBOTA)

NO. PART NO. PART NAME QTY. REMARKS

1 5218 SCREW, HHC 1/2- 13 X 1- 1/2 2

2 5054A WASHER, LOCK, 1/2 MED 2